A Tunable Mid-Infrared Solid-State Laser with a Compact Thermal Control System

Abstract

:1. Introduction

2. Module Design

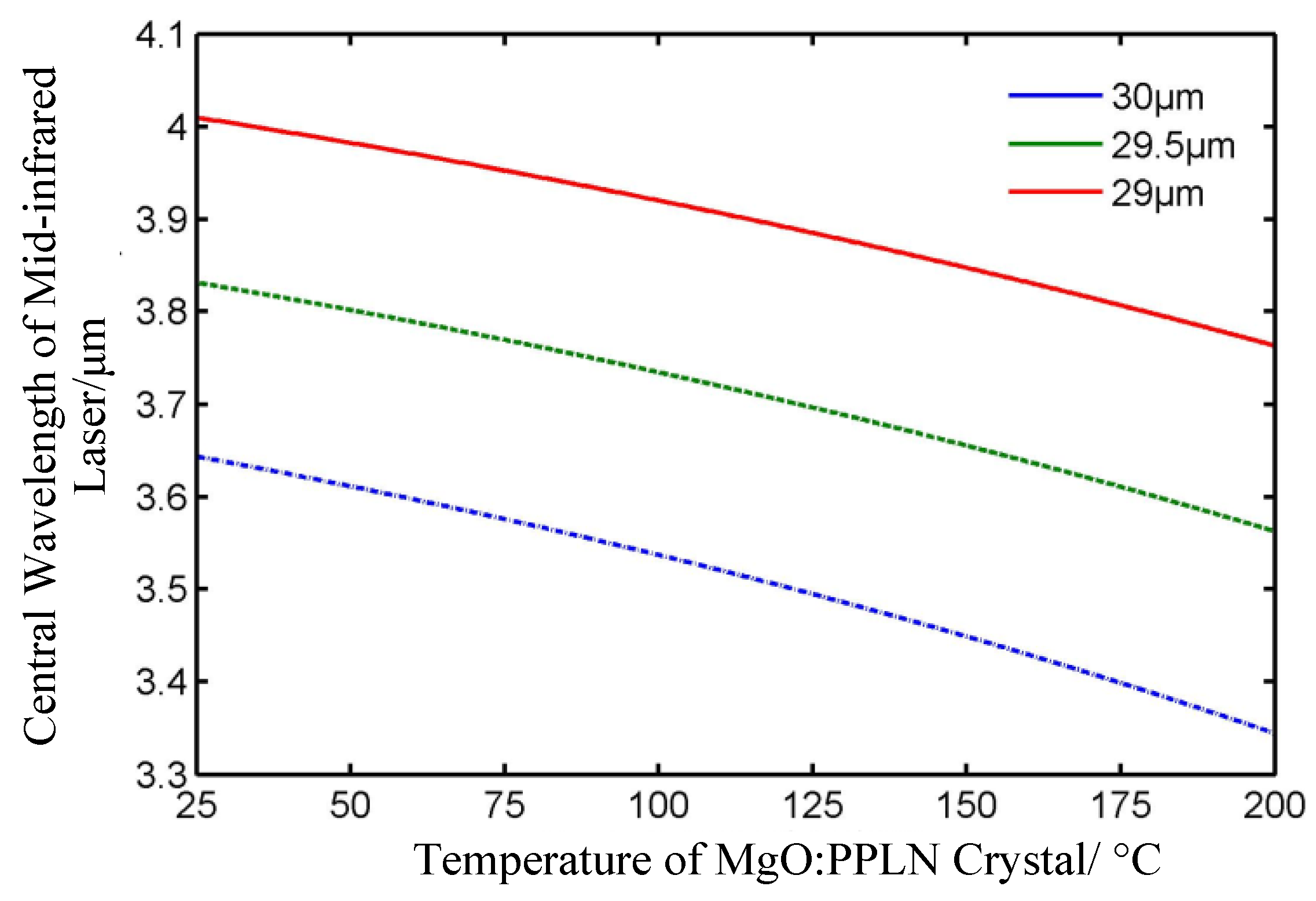

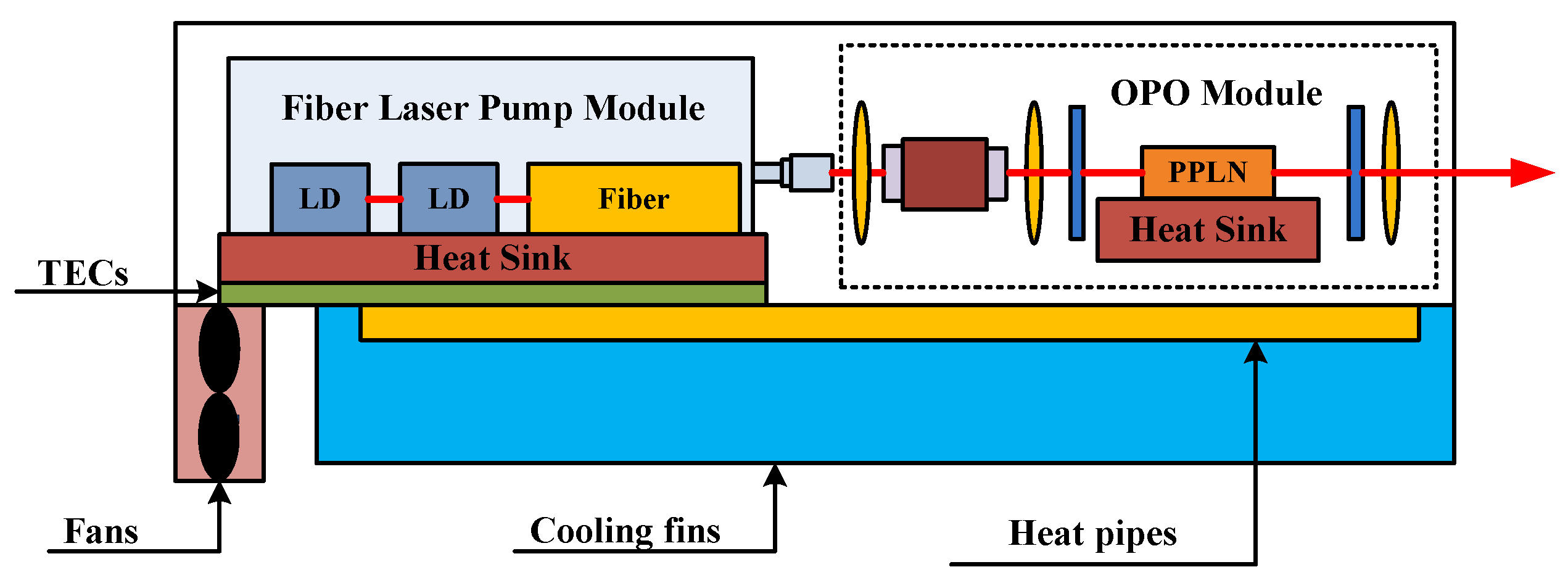

2.1. Design of a Tunable Mid-Infrared Solid-State Laser

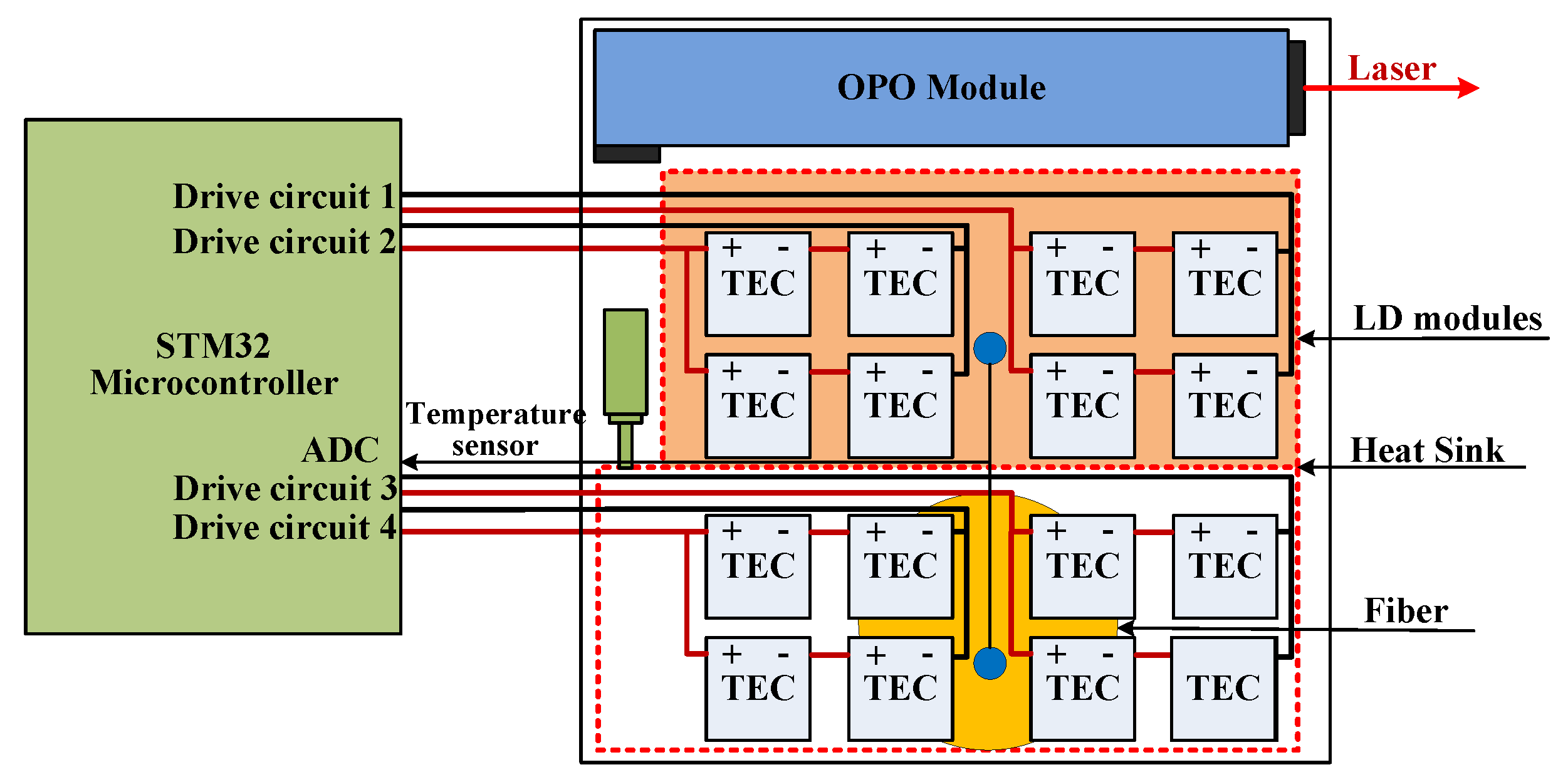

2.2. Design of the Thermal Control System

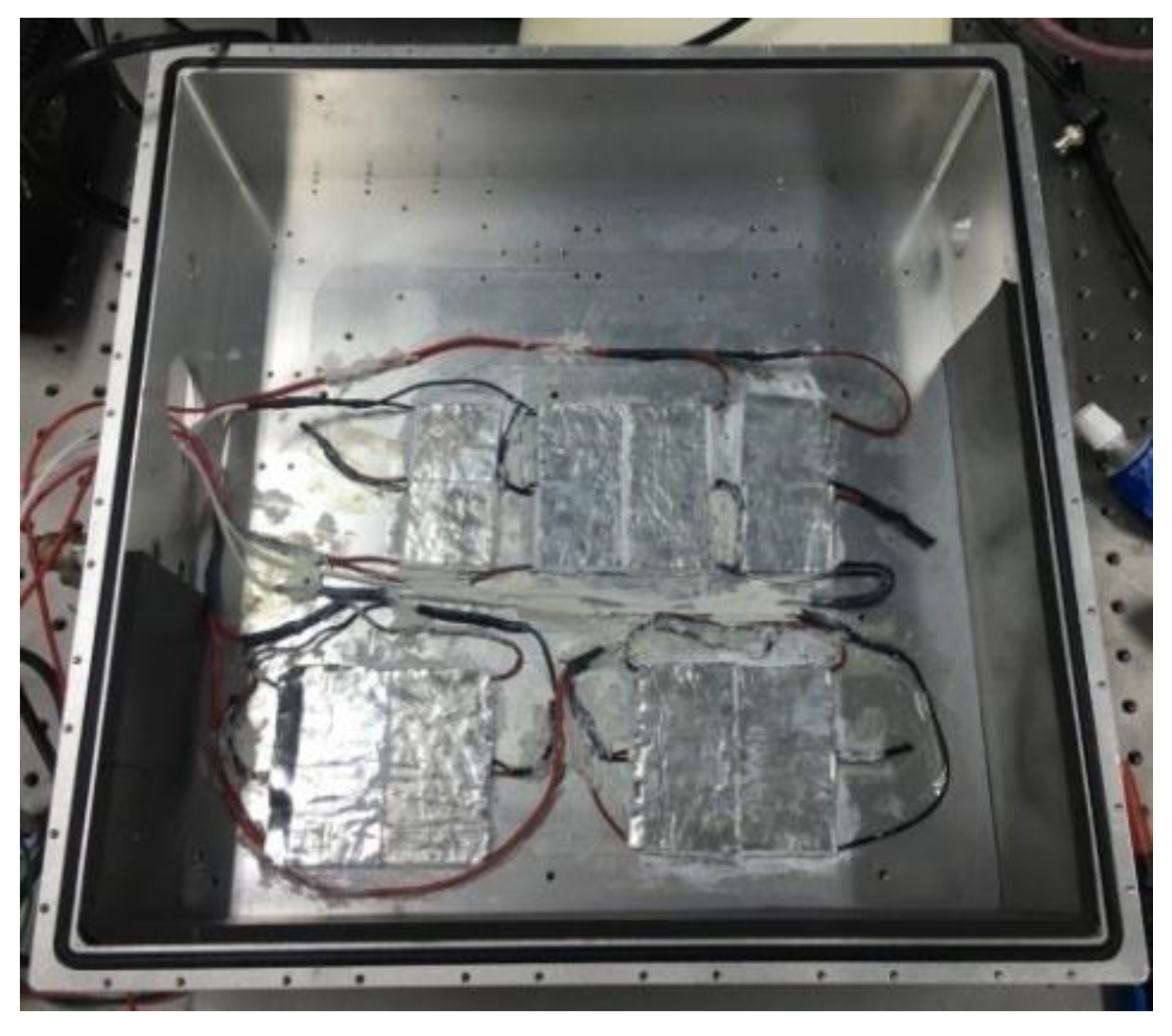

2.2.1. Constitution of the Thermal Control System

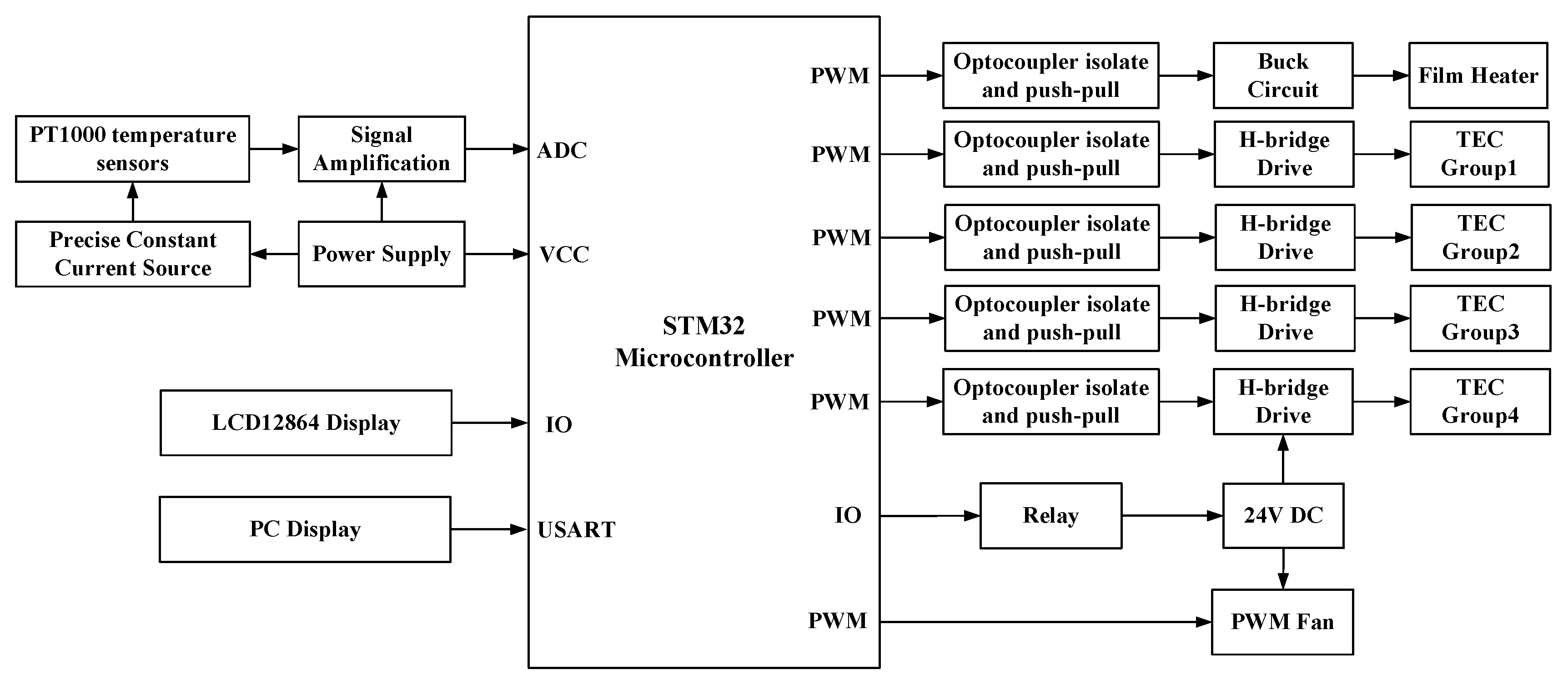

2.2.2. Hardware Circuit Design of the Thermal Control System

2.2.3. Software Design of the Thermal Control System

- (1)

- (2)

- (3)

3. Mathematical Model and Numerical Simulation

3.1. Thermal Analysis of TEM

3.2. Mathematical Model of the Thermal Control System

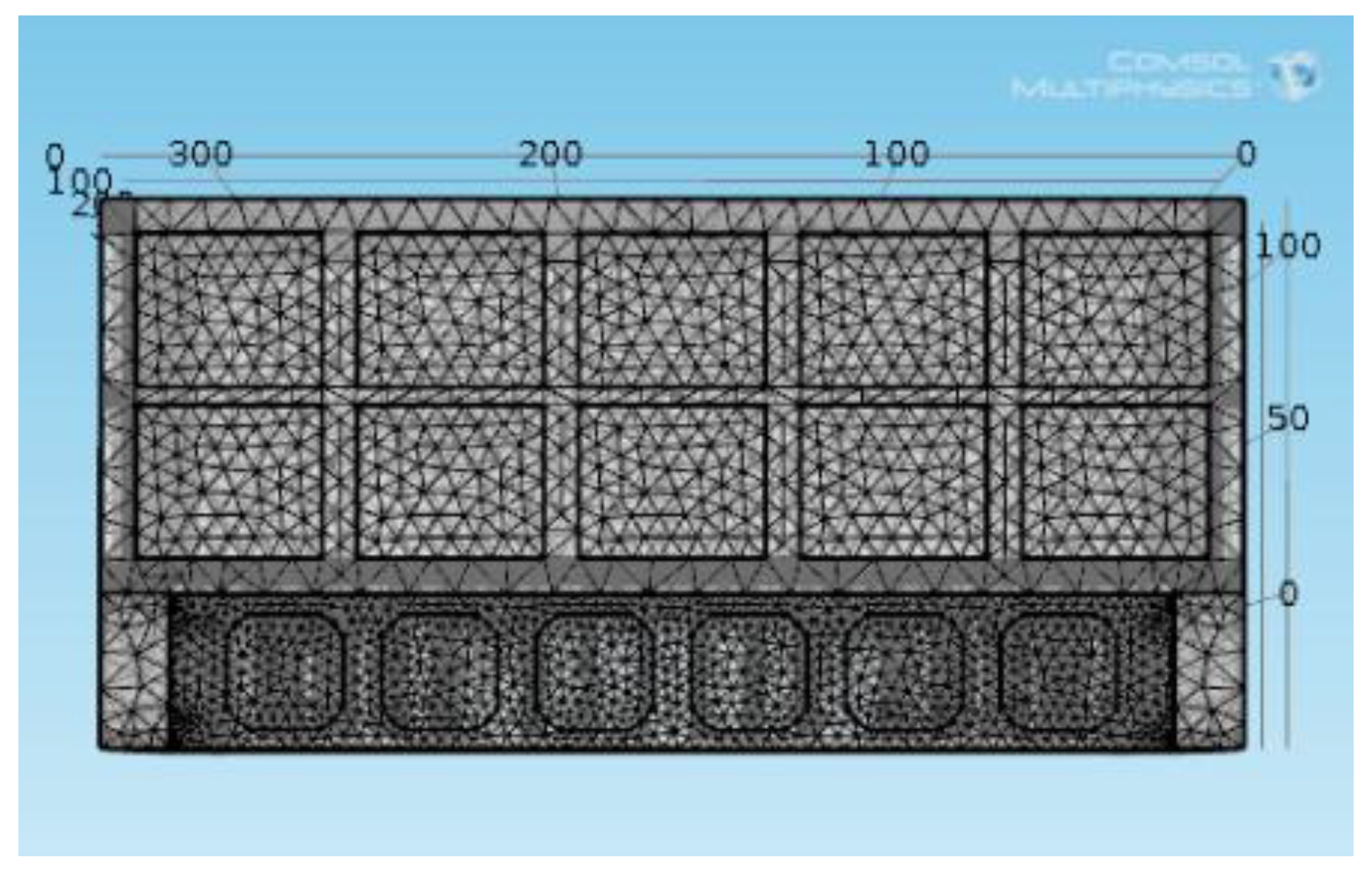

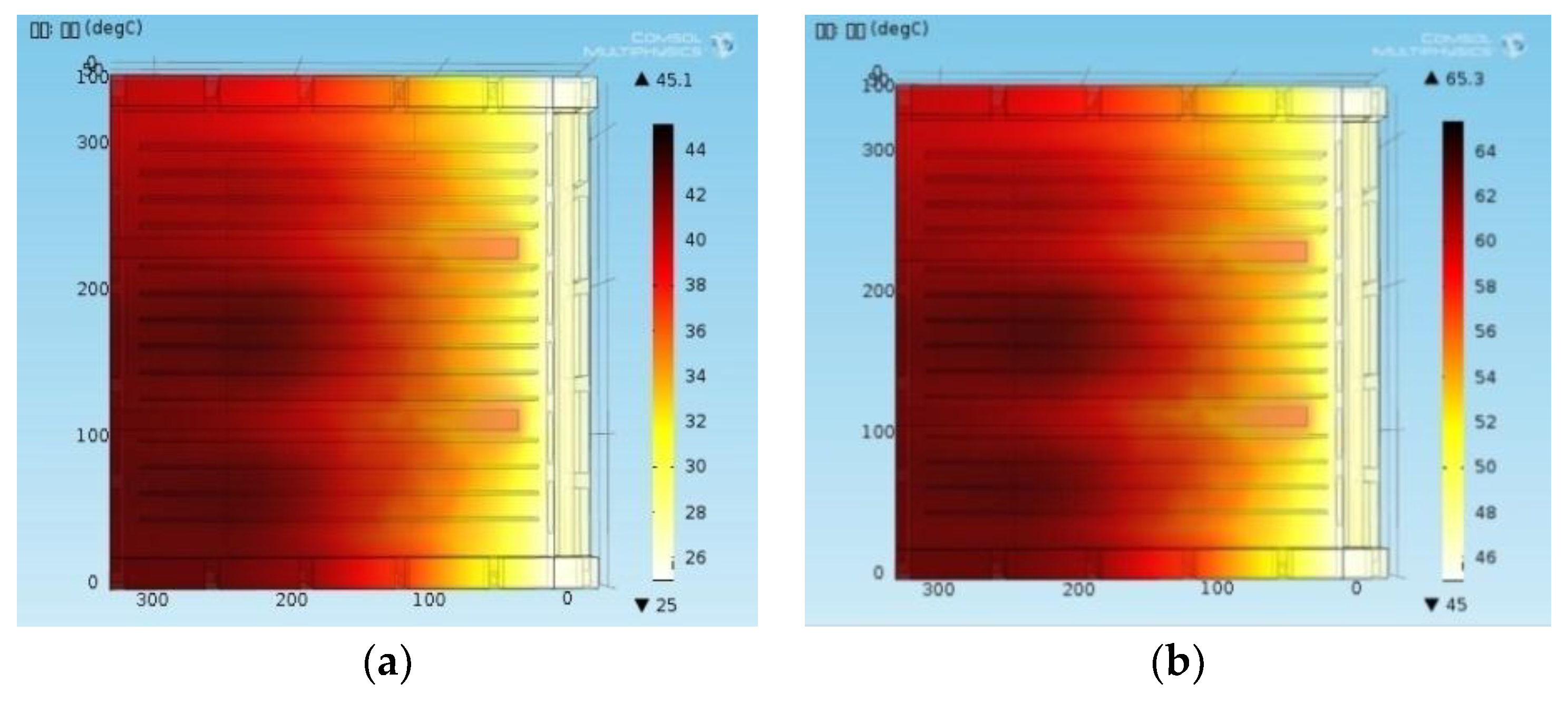

3.3. Numerical Simulation

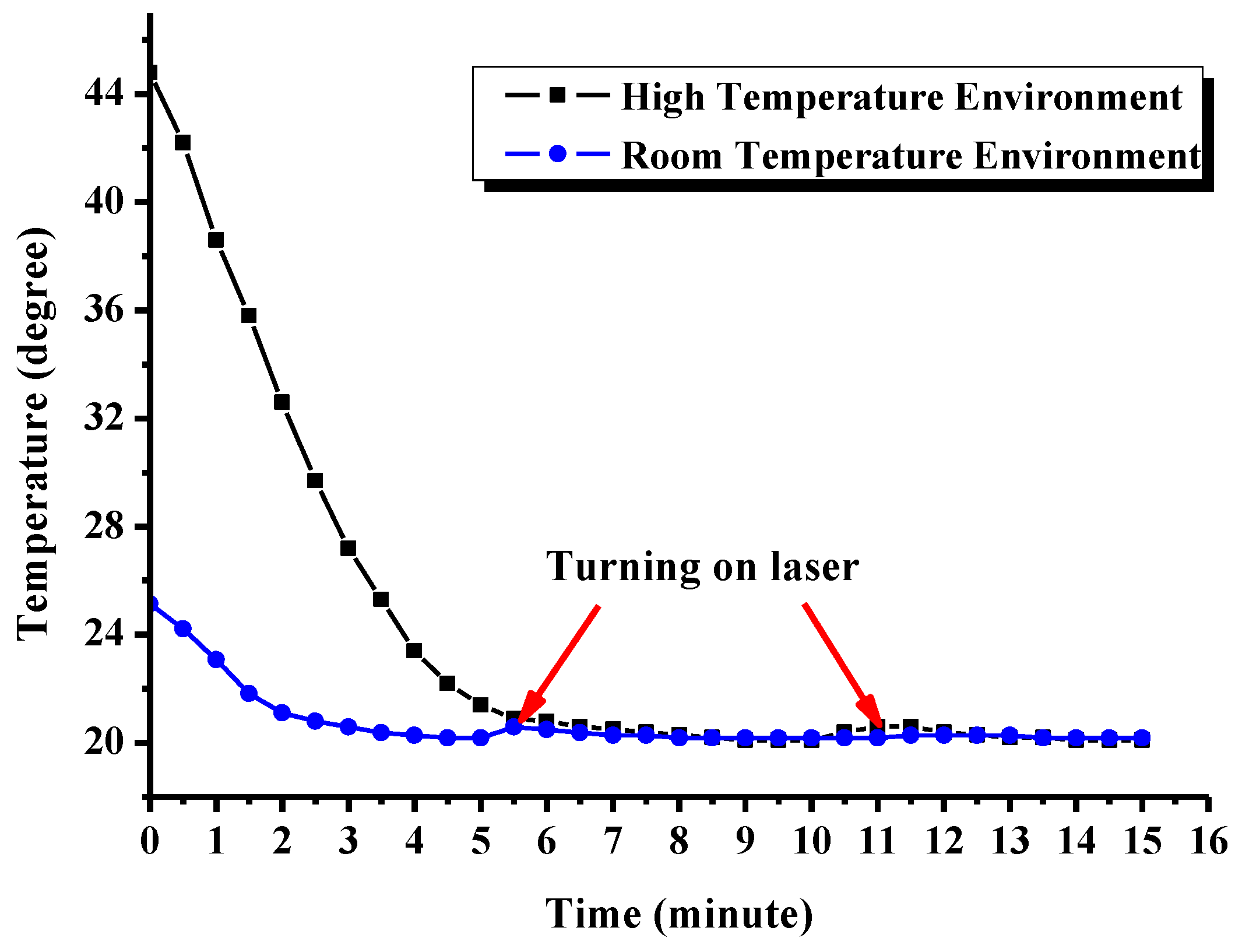

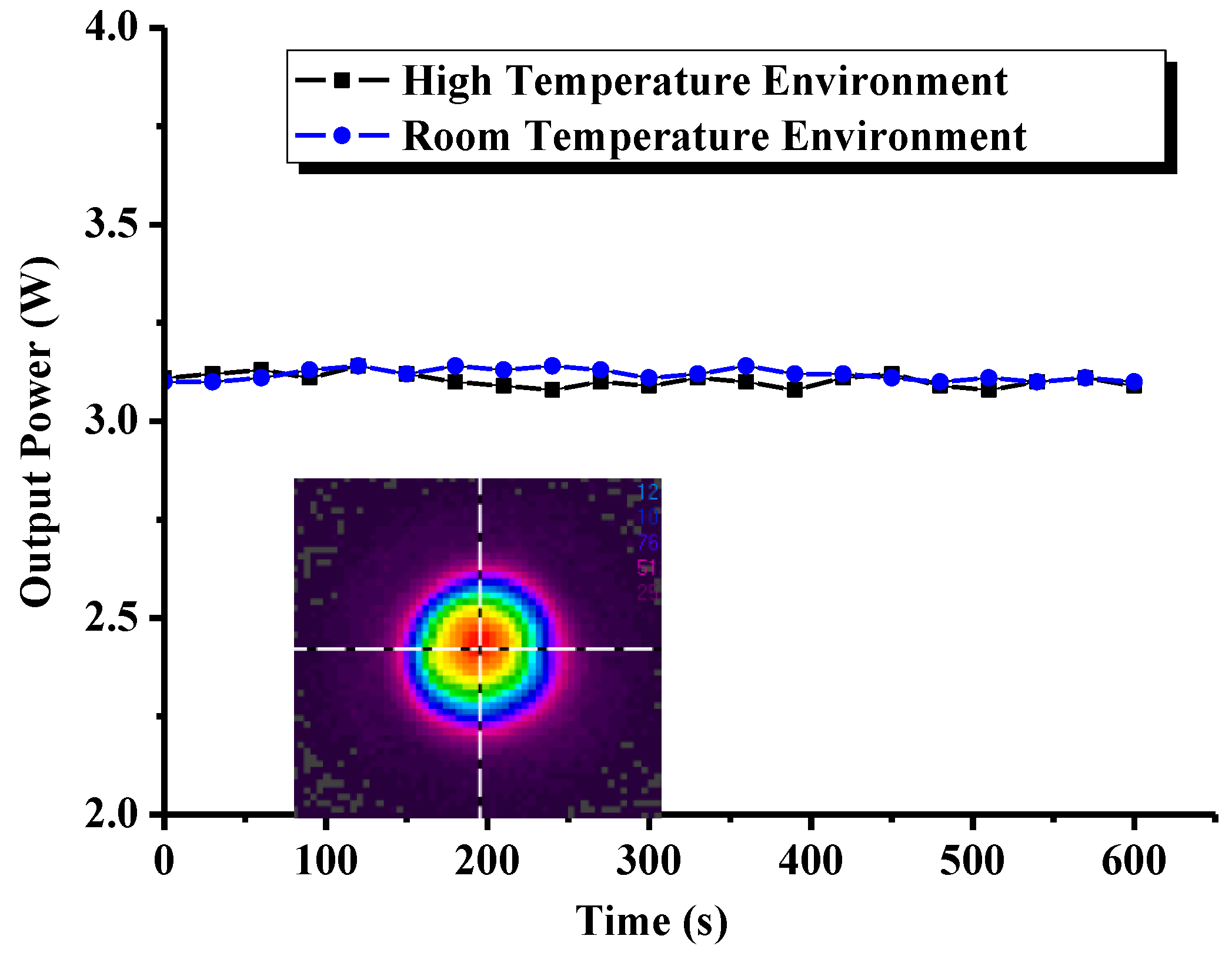

4. Experiment Results and Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jin, Y.W.; Cristescu, S.M.; Harren, F.J.; Mandon, J. Two-crystal mid-infrared optical parametric oscillator for absorption and dispersion dual-comb spectroscopy. Opt. Lett. 2014, 39, 3270–3273. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Tang, P.H.; Chen, Y.; Zhao, C.J.; Shen, D.Y.; Wen, S.C.; Fan, D.Y. Highly efficient tunable mid-infrared optical parametric oscillator pumped by a wavelength locked, Q-switched Er:YAG laser. Opt. Express. 2015, 23, 20812–20819. [Google Scholar] [CrossRef] [PubMed]

- Steinle, T.; Kumar, V.; Floess, M.; Steinmann, A.; Marangoni, M.; Koch, C.; Wege, C.; Gerullo, G.; Giessen, H. Synchronization-free all-solid-state laser system for stimulated Raman scattering microscopy. Light Sci. Appl. 2016, 5, e16149. [Google Scholar] [CrossRef]

- Yan, M.; Luo, P.L.; Iwakuni, K.; Millot, G.; Hansch, T.W.; Picque, N. Mid-infrared dual-comb spectroscopy with electro-optic modulators. Light Sci. Appl. 2017, 6, e17076. [Google Scholar] [CrossRef]

- Darvish, G.; Moravvej-Farshi, M.K.; Zarifkar, A.; Saghafi, K. Pre-compensation techniques to suppress the thermally induced wavelength drift in tunable DBR lasers. IEEE J. Quantum Electron. 2008, 44, 958–965. [Google Scholar] [CrossRef]

- Andreoni, E.; Xu, J.H.; Cartaleva, S.; Celli, R.M.; Mango, F.; Gozzini, S. A simple system of thermal control and frequency stabilization of solitary diode lasers. Rev. Sci. Instrum. 2000, 71, 3648–3652. [Google Scholar] [CrossRef]

- Datta, M.; Choi, H.W. Microheat exchanger for cooling high power laser diodes. Appl. Therm. Eng. 2015, 90, 266–273. [Google Scholar] [CrossRef]

- Shu, S.L.; Hou, G.Y.; Wang, L.J.; Tian, S.C.; Vassiliev, L.L.; Tong, C.Z. Heat dissipation in high-power semiconductor lasers with heat pipe cooling system. J. Mech. Sci. Technol. 2017, 31, 2607–2612. [Google Scholar] [CrossRef]

- Jia, G.N.; Qiu, Y.T.; Yan, A.R.; Yao, S.; Wang, Z.Y. Laser three-dimensional printing microchannel heat sink for high-power diode laser array. Opt. Eng. 2016, 55, 096105. [Google Scholar] [CrossRef]

- Mu, J.; Feng, G.J.; Yang, H.M.; Zhang, H.; Zhou, S.H. Research on multiannular channel liquid cooling method for thin disk laser. Opt. Eng. 2014, 53, 056110. [Google Scholar] [CrossRef]

- Zhang, W.; Shen, L.M.; Yang, Y.X.; Chen, H.X. Thermal management for a micro semiconductor laser based on thermoelectric cooling. Appl. Therm. Eng. 2015, 90, 664–673. [Google Scholar] [CrossRef]

- Zhao, D.L.; Tan, G. A review of thermoelectric cooling: Materials, modeling and applications. Appl. Therm. Eng. 2014, 66, 15–24. [Google Scholar] [CrossRef]

- Li, C.; Jiao, D.; Jia, J.Z.; Guo, F.; Wang, J. Thermoelectric cooling for power electronics circuits: Modeling and active temperature control. IEEE Trans. Ind. Appl. 2014, 50, 3995–4005. [Google Scholar] [CrossRef]

- Li, J.H.; Zhang, X.R.; Zhou, C.; Zheng, J.G.; Ge, D.S.; Zhu, W.H. New application of an automated system for high-power LEDs. IEEE/ASME Trans. Mechatron. 2016, 21, 1035–1042. [Google Scholar] [CrossRef]

- Noguchi, N.; Okuchi, T. A peltiercooling diamond anvil cell for low-temperature Raman spectroscopic measurements. Rev. Sci. Instrum. 2016, 87, 125107. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Liu, X.S.; Peng, C.; Liu, Y.Q.; Wang, Z.Y. High Power Diode-Side-Pumped Q-Switch Nd:YAG Solid-State Laser with a Thermoelectric Cooler. Appl. Sci. 2015, 5, 1837–1845. [Google Scholar] [CrossRef]

- Wang, H.; Yu, Y.L. Dynamic modeling of PID temperature controller in a tunable laser module and wavelength transients of the controlled laser. IEEE J. Quantum Electron. 2012, 48, 1424–1431. [Google Scholar] [CrossRef]

- Shen, L.M.; Chen, H.X.; Xiao, F.; Yang, Y.X.; Wang, S.W. The step-change cooling performance of miniature thermoelectric module for pulse laser. Energy Convers. Manag. 2014, 80, 39–45. [Google Scholar] [CrossRef]

- Lineykin, S.; Ben-Yaakov, S. Analysis of thermoelectric coolers by a spice-compatible equivalent-circuit model. IEEE Power Electron. Lett. 2005, 3, 63–66. [Google Scholar] [CrossRef]

- Lineykin, S.; Ben-Yaakov, S. Modeling and analysis of thermoelectric modules. IEEE Trans. Ind. Appl. 2007, 43, 505–512. [Google Scholar] [CrossRef]

| Parameters | ||

|---|---|---|

| Internal resistance | 1 Ω ±10% | |

| Imax | 12 A | |

| Vmax | 15.4 V | |

| - | Th = 27 °C | Th = 50 °C |

| Qmax | 110 W | 134 W |

| ΔTmax | 68 °C | 75 °C |

| Solder melting point | 138 °C | |

| Material | Thermal Conductivity (W/m·K) | Size | Number | Flow Rate (m3/s) | |

|---|---|---|---|---|---|

| Cabinet | Aluminum 6063-T83 | 201 | 330 × 330 × 115 mm3 (L × W × H) Wall thickness: 10mm | / | / |

| Fin | Aluminum 6063-T83 | 201 | 300 × 50 mm2 (L × W) Fin thickness: 2mm Fin spacing: 20mm | 14 | / |

| Heat pipe | / | Evaporation section:2 × 104 Condensation section: 500 | 280 × 12 × 5 mm3 (L × W × H) | 2 | / |

| Fan | / | / | 40 × 40 × 10 mm3 | 6 | 0.011 |

| Ambient Environment Temperature (Ta) | T1 | TEC Driving Current | Position of TEMs | R3 | TEM Cooling Output (Qc1) | System Cooling Capacity (Qc) |

|---|---|---|---|---|---|---|

| 298.15 K (25 °C) | 293.15 K (20 °C) | 5 A | TEMs near the edge | 0.04 K/W | 39.5 W | 636 W |

| TEMs in the middle | 0.03 K/W | 40 W | ||||

| 318.15 K (45 °C) | 293.15 K (20 °C) | 5 A | TEMs near the edge | 0.04 K/W | 24 K/W | 387.2 W |

| TEMs in the middle | 0.03 K/W | 24.4 W |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, D.; He, Y.; Zhang, K.; Pan, Q.; Chen, F.; Guo, L. A Tunable Mid-Infrared Solid-State Laser with a Compact Thermal Control System. Appl. Sci. 2018, 8, 878. https://doi.org/10.3390/app8060878

Yu D, He Y, Zhang K, Pan Q, Chen F, Guo L. A Tunable Mid-Infrared Solid-State Laser with a Compact Thermal Control System. Applied Sciences. 2018; 8(6):878. https://doi.org/10.3390/app8060878

Chicago/Turabian StyleYu, Deyang, Yang He, Kuo Zhang, Qikun Pan, Fei Chen, and Lihong Guo. 2018. "A Tunable Mid-Infrared Solid-State Laser with a Compact Thermal Control System" Applied Sciences 8, no. 6: 878. https://doi.org/10.3390/app8060878

APA StyleYu, D., He, Y., Zhang, K., Pan, Q., Chen, F., & Guo, L. (2018). A Tunable Mid-Infrared Solid-State Laser with a Compact Thermal Control System. Applied Sciences, 8(6), 878. https://doi.org/10.3390/app8060878