Analytical Point-Cloud Based Geometric Modeling for Additive Manufacturing and Its Application to Cultural Heritage Preservation

Abstract

Featured Application

Abstract

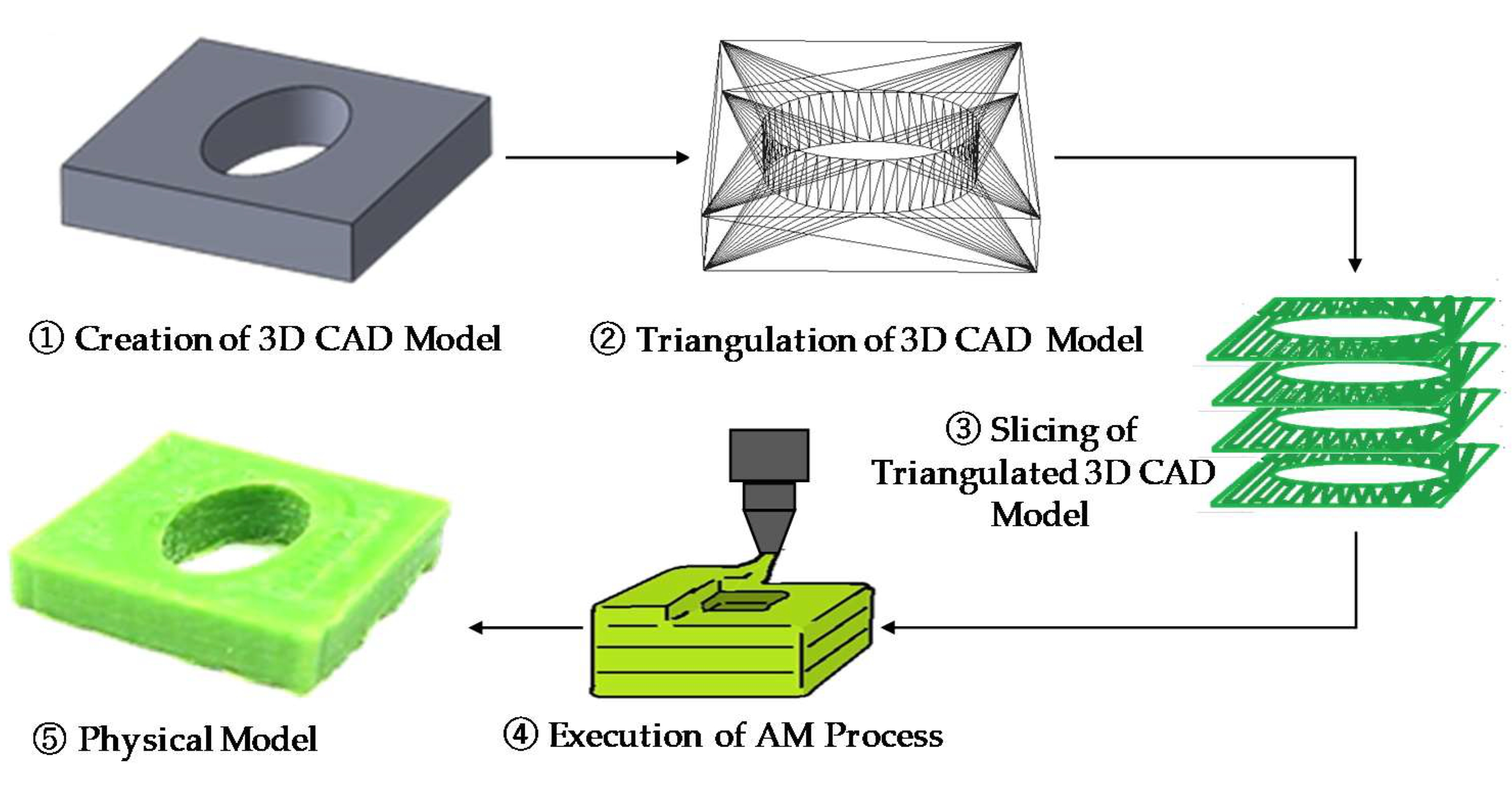

1. Introduction

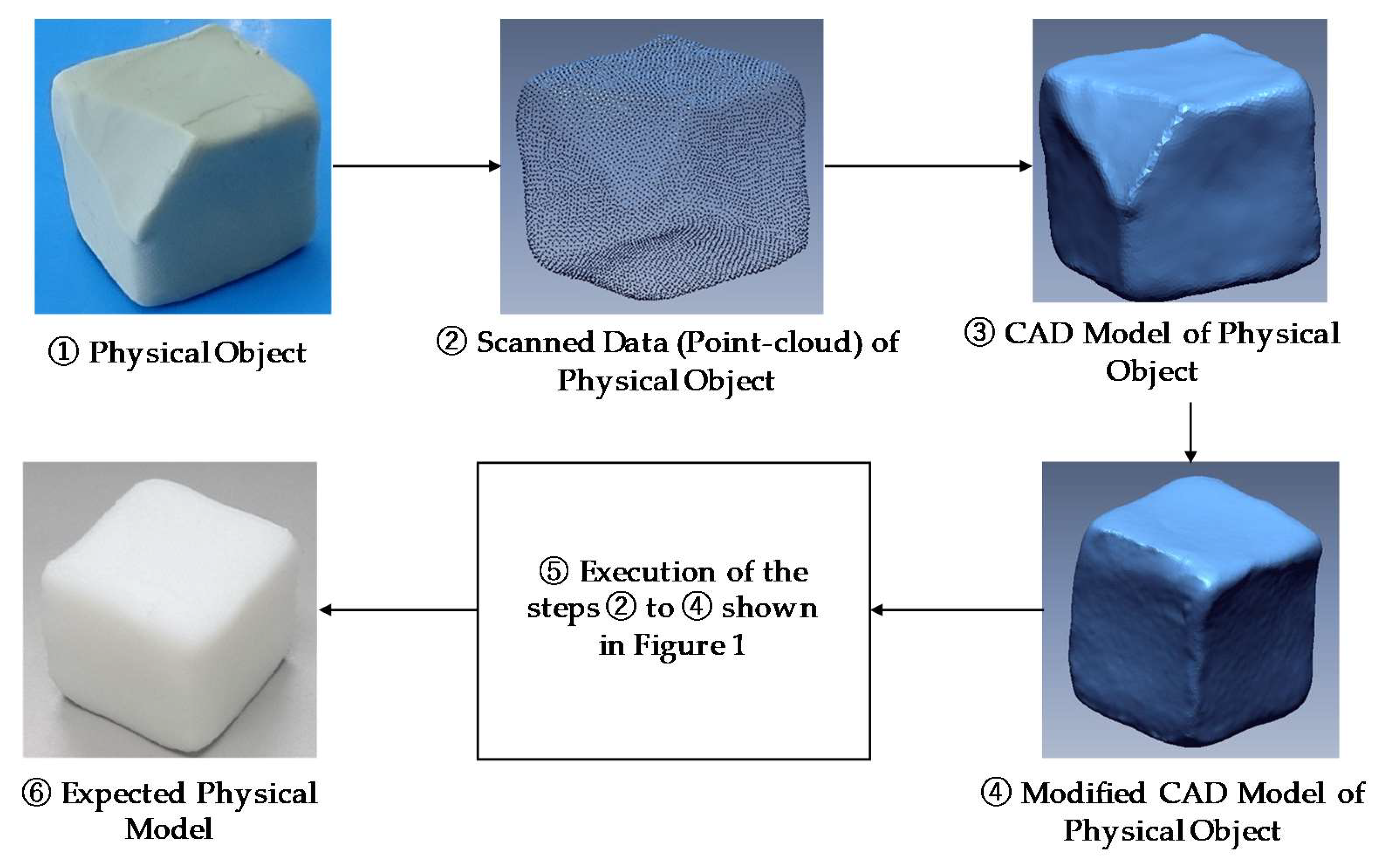

2. Literature Review

2.1. Data Acquisition Process for PCAM

2.2. Surface Model Creation Techniques for PCAM

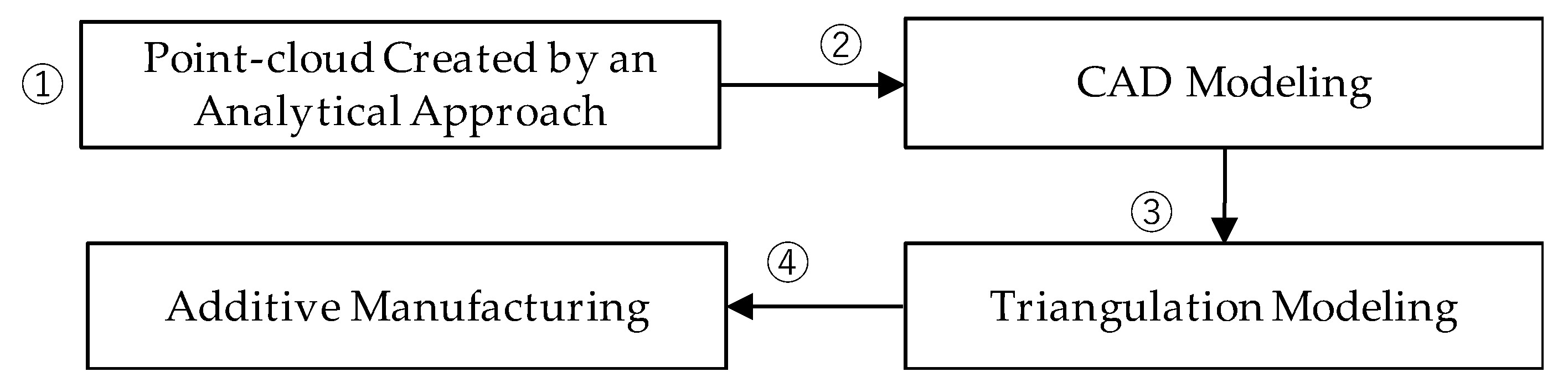

3. Method

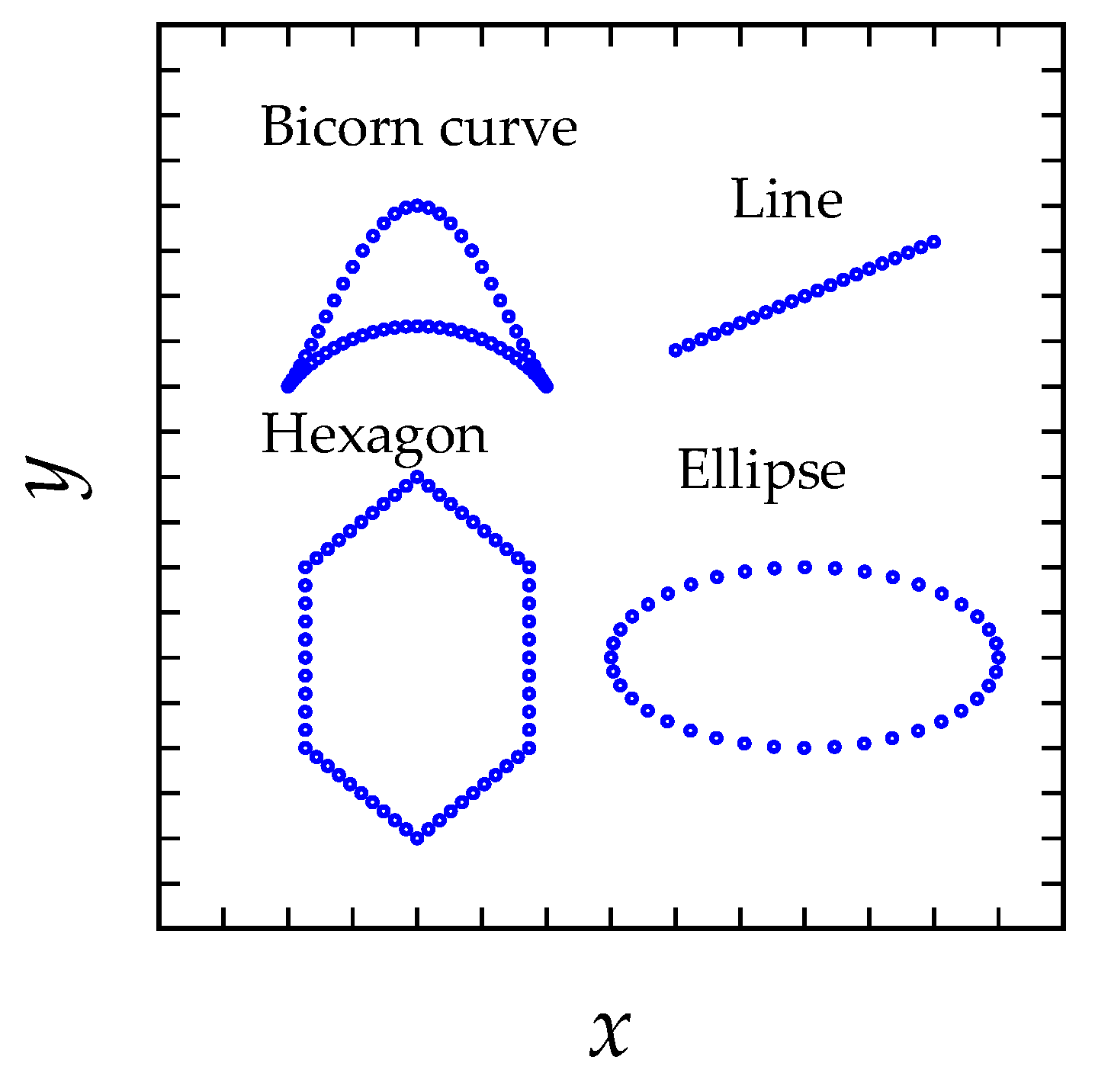

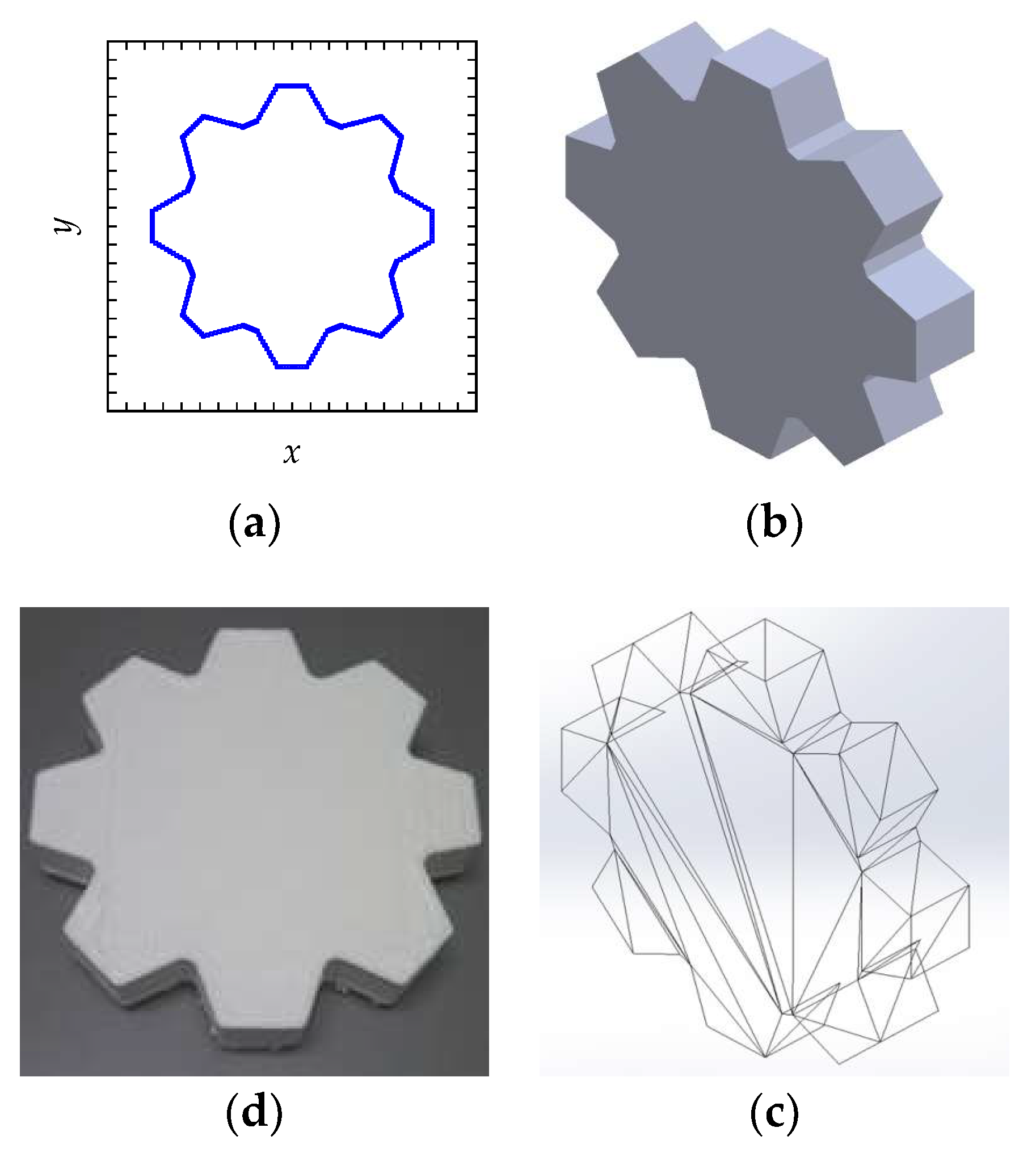

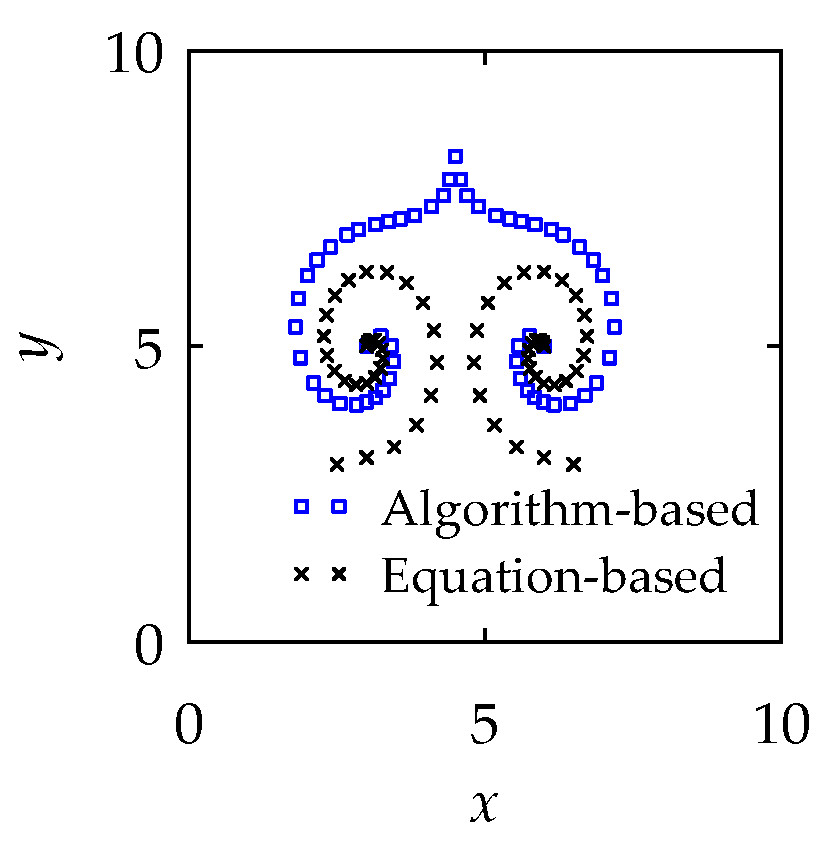

3.1. Parametric-Equation-Based Approach

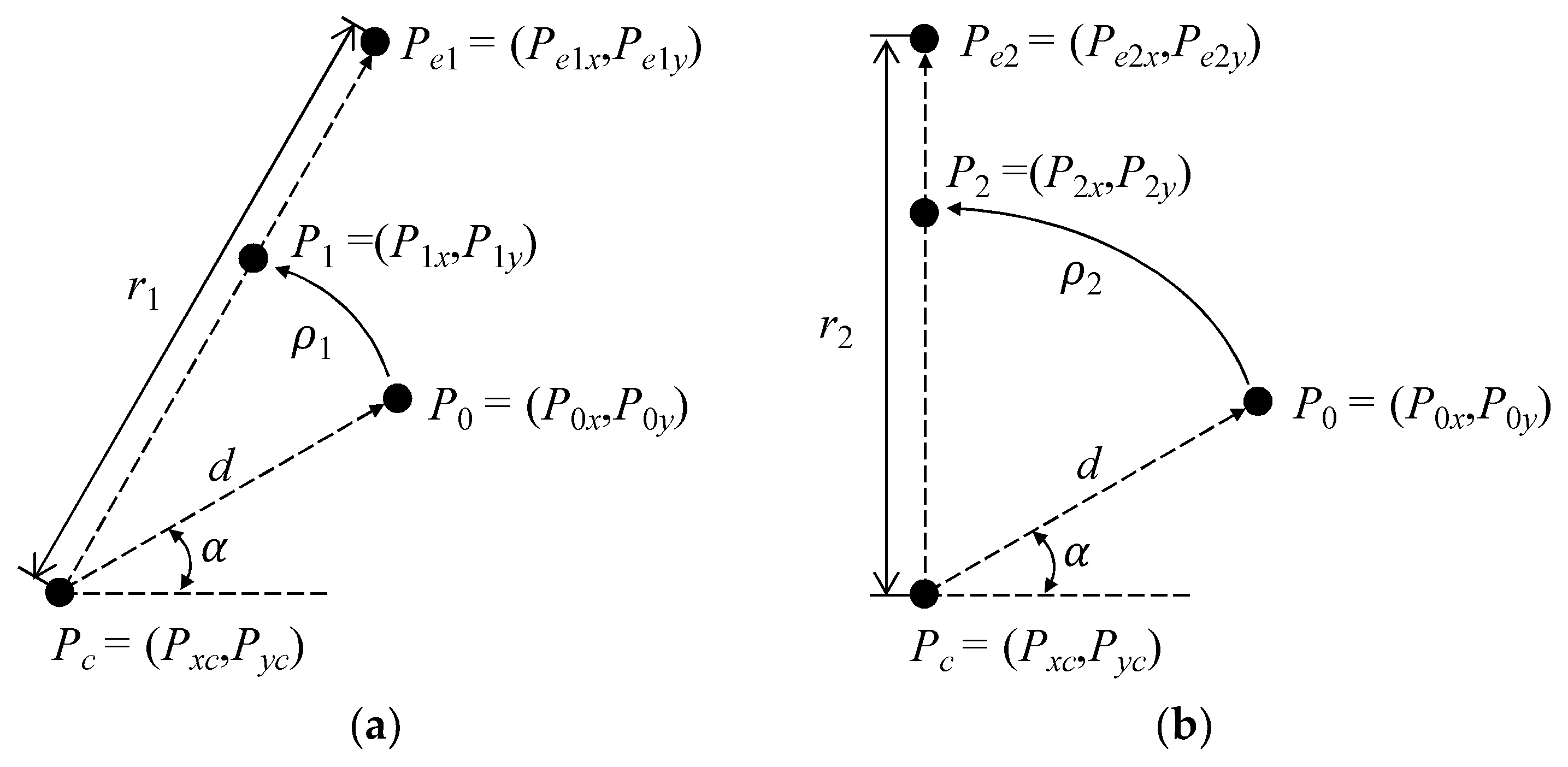

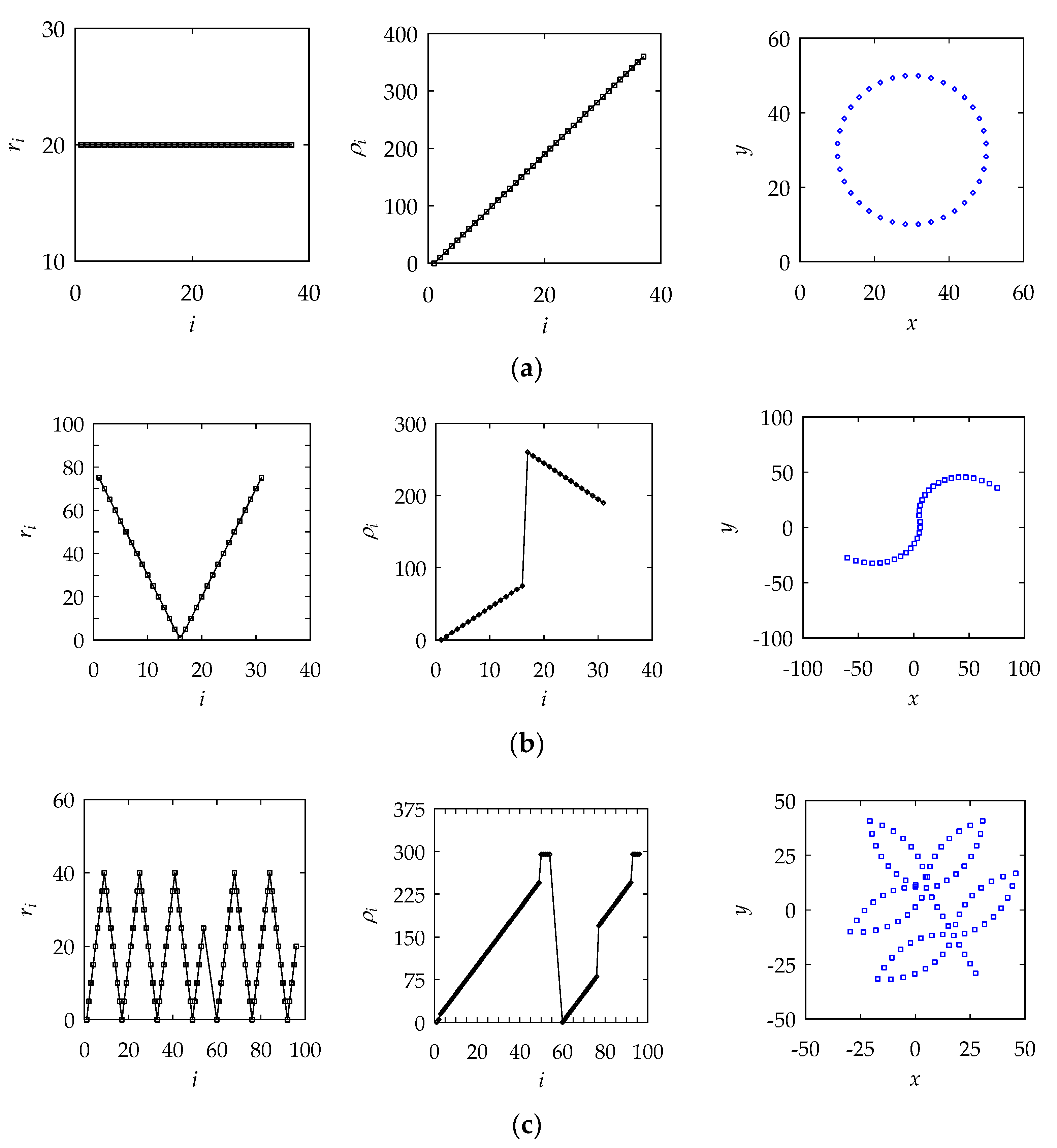

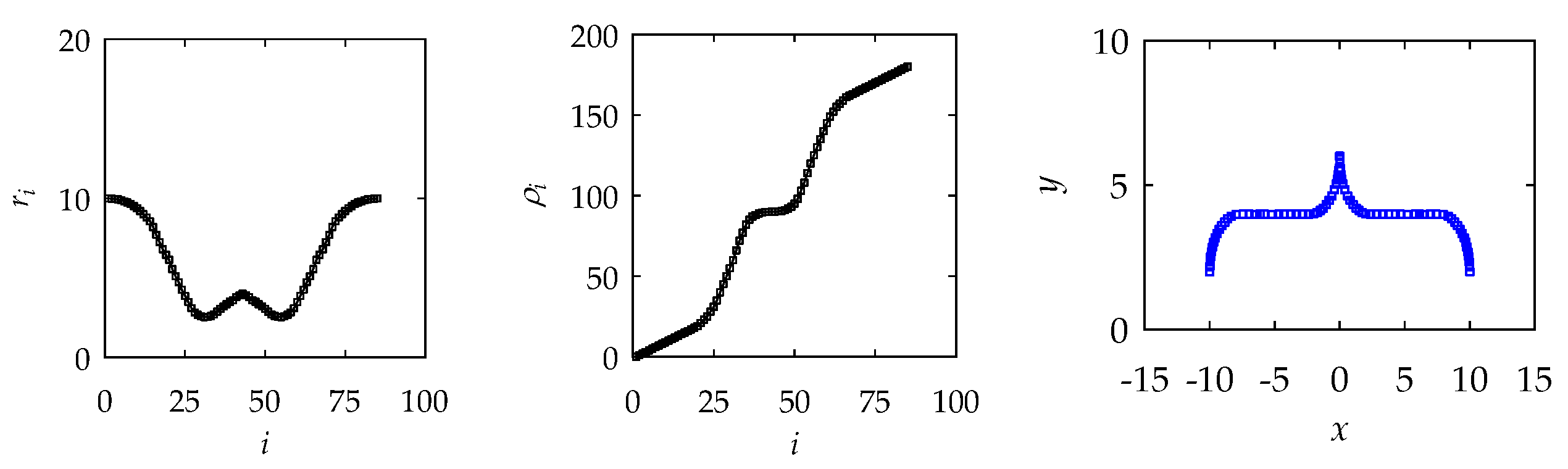

3.2. Algorithmic Approach

| Algorithm 1 Point-cloud Creation Algorithm | ||

| 1 | Define: Center Point Pc = (Pcx, Pcy) ∈ ℜ2, Length d > 0, Initial Angle α ∈ ℜ | |

| 2 | Define: Instantaneous Distances (ri ∈ ℜ | i = 1, ..., n) | |

| 3 | Define: Rotational Angles (ρi ∈ ℜ| i = 1, ..., n) | |

| 4 | Calculate: P0 = (P0x, P0y) so that and | |

| 5 | Iterate: | For i = 1, ..., n |

| Rotate P0 by an angle ρi around Pc in the counter-clockwise direction to create Pi = (Pix, Piy) so that and Extend Pi to Pei that is point on the line PcPi at a distance ri from Pc and | ||

| End For | ||

| 6 | Output: Point-Cloud, PC = {Pei | i = 1, ..., n} | |

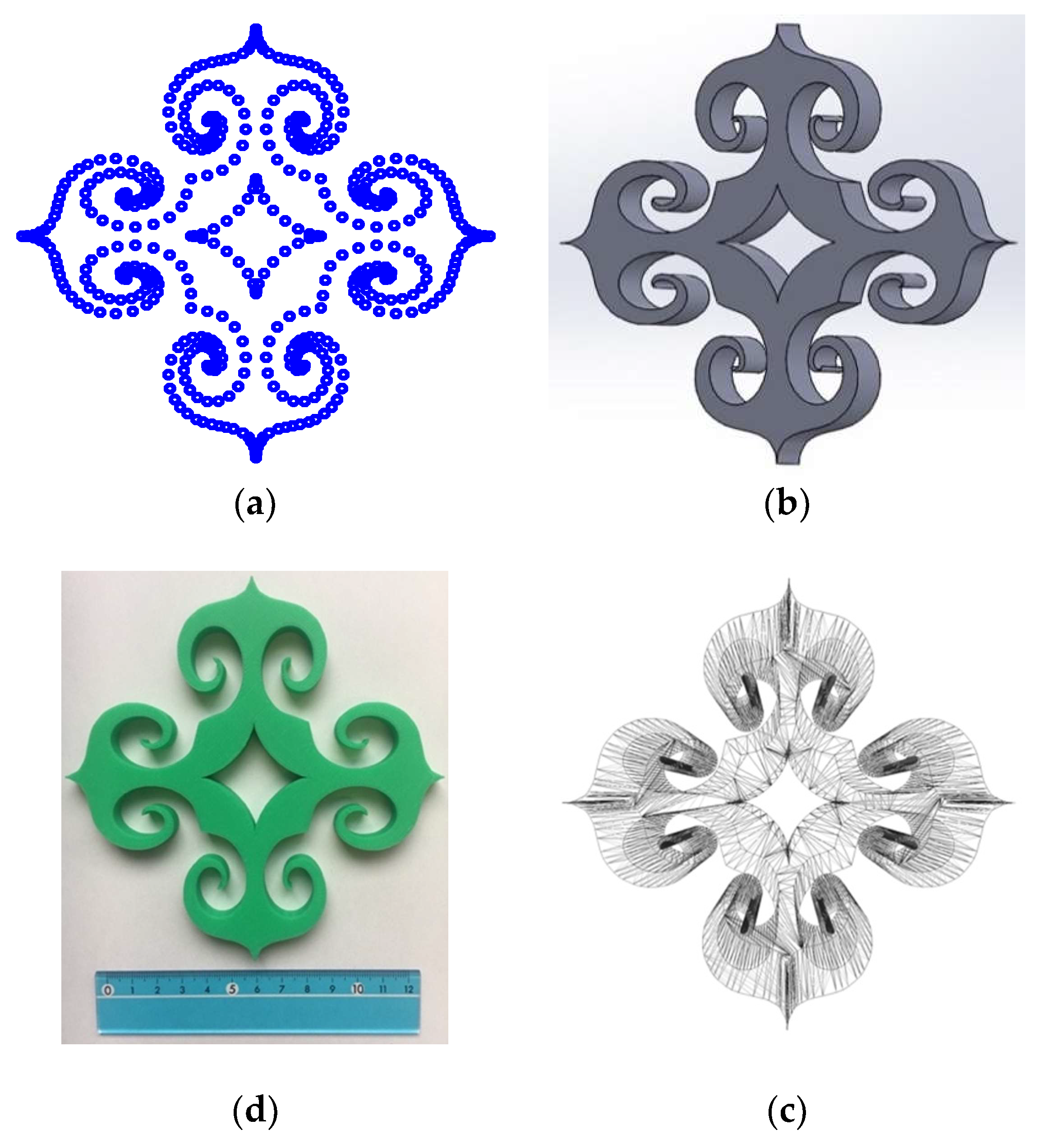

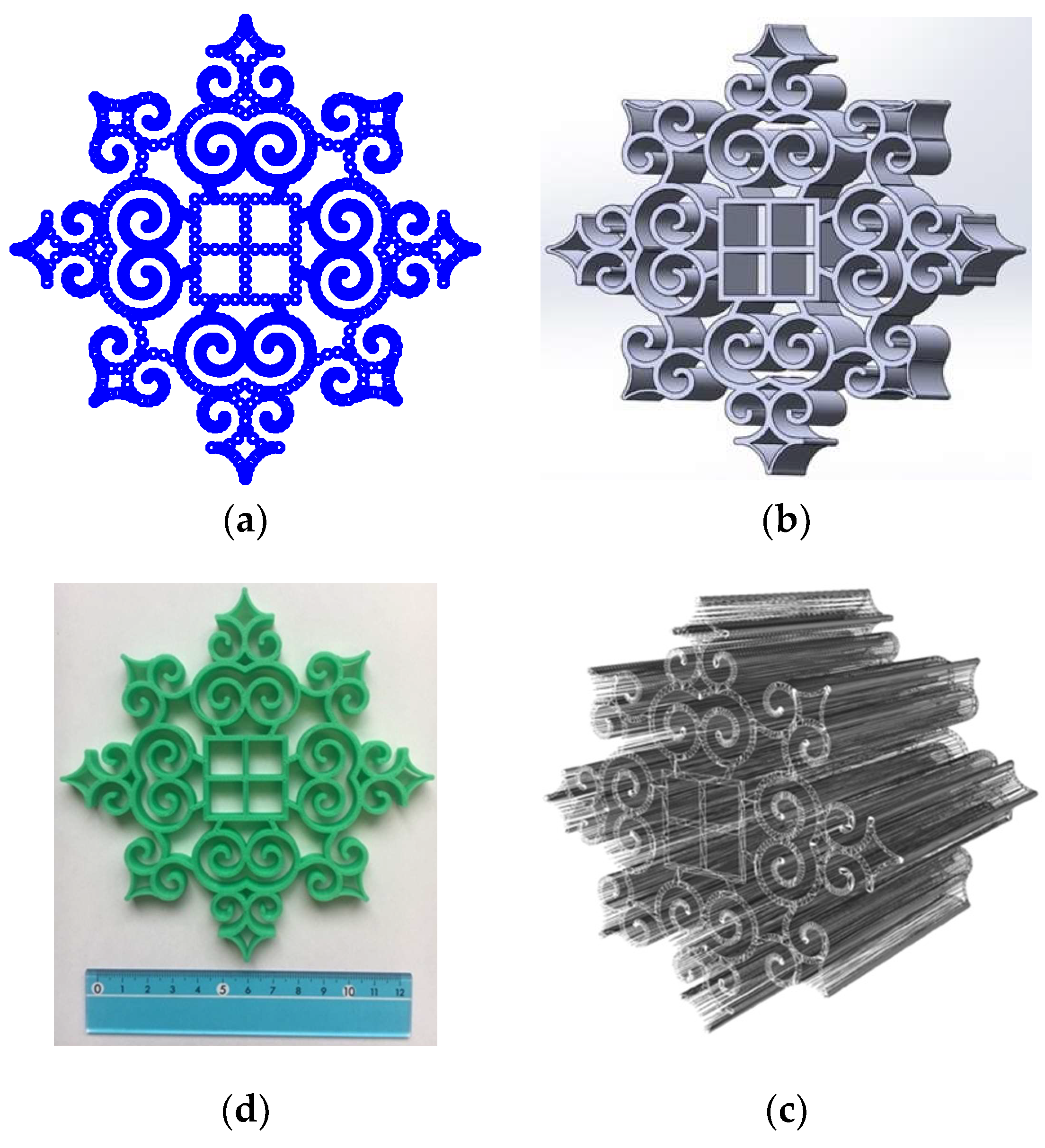

4. Cultural Heritage Preservation

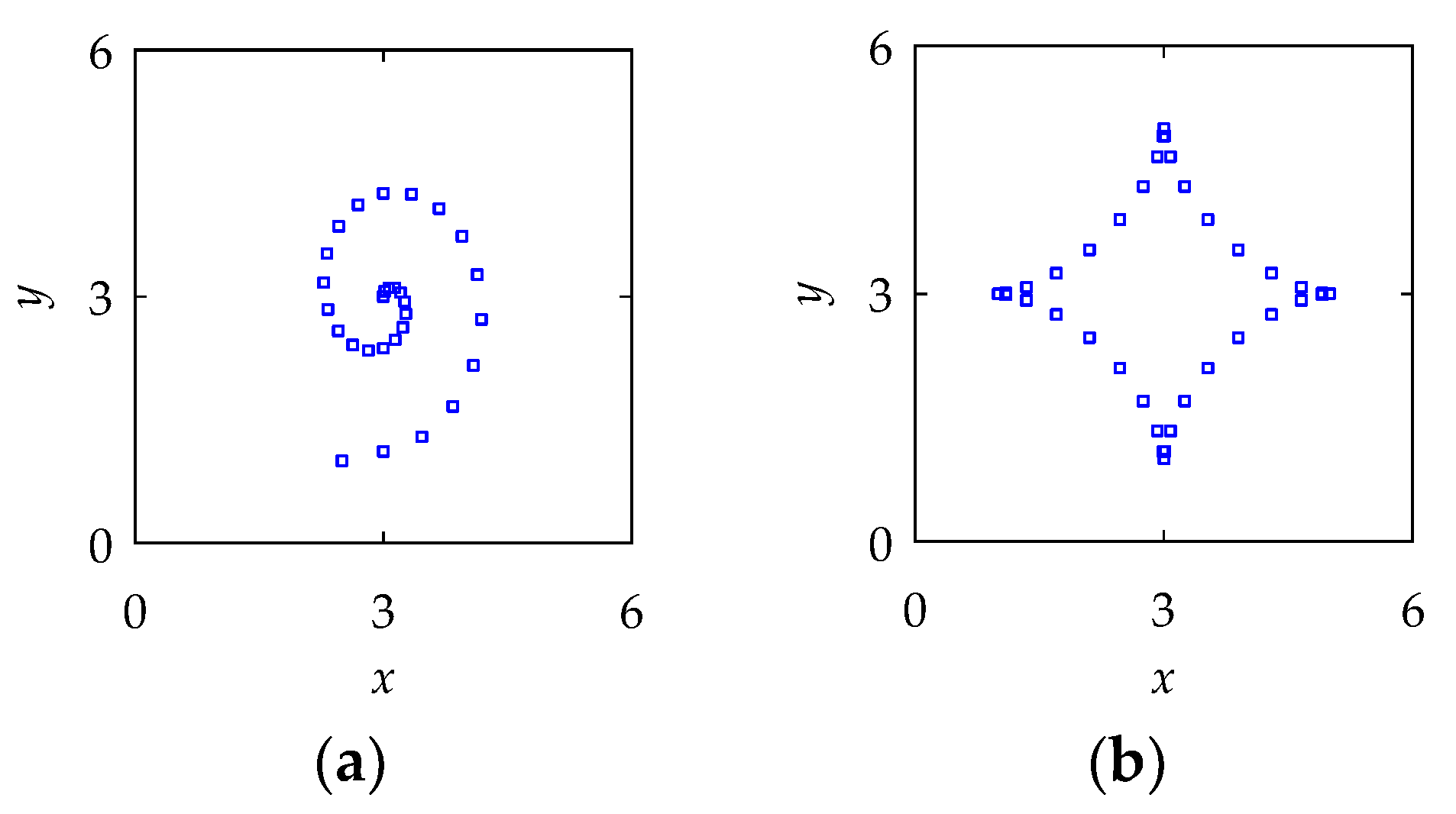

4.1. Classification of Ainu Motifs

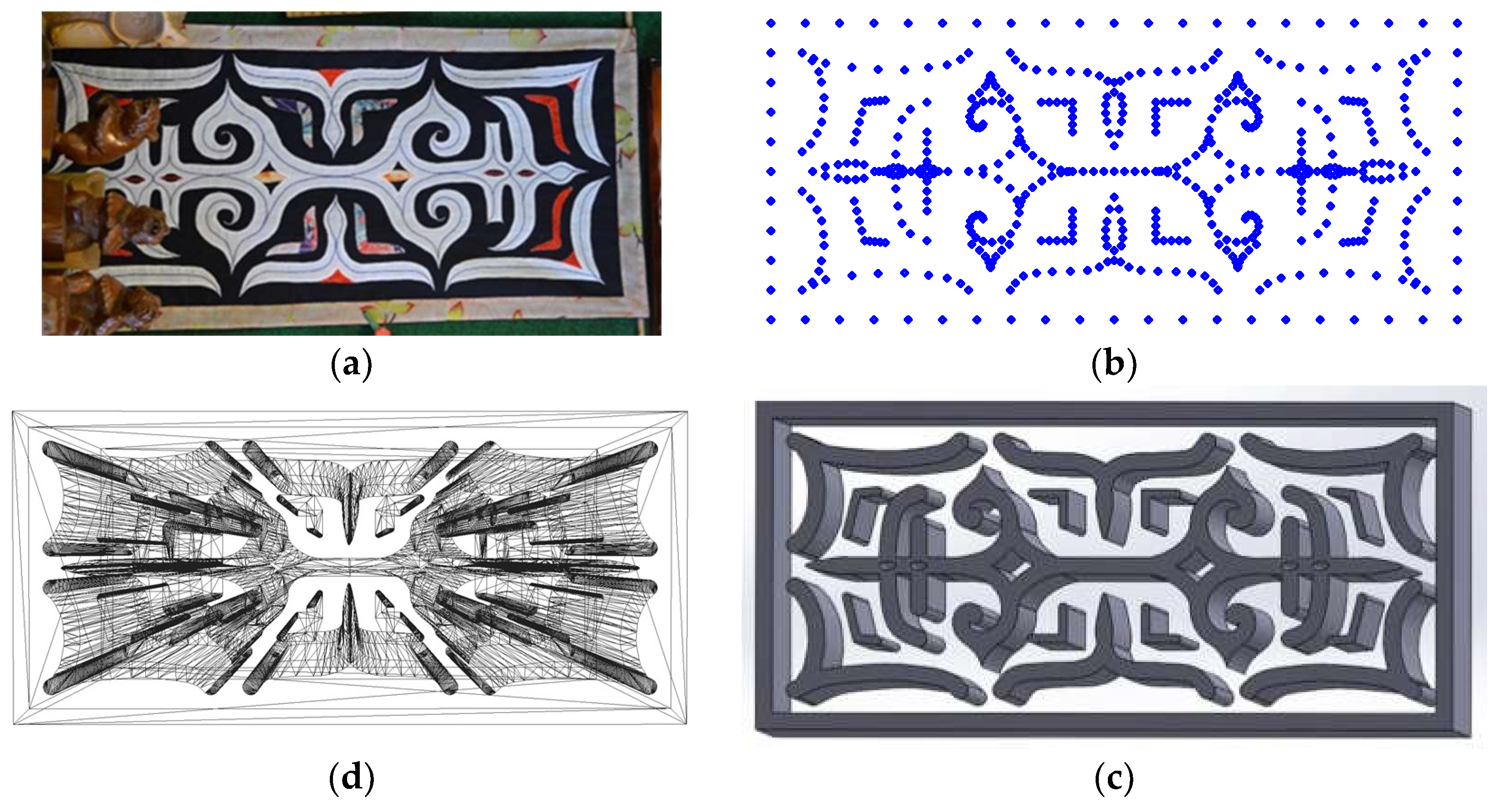

4.2. Point-Cloud Creation

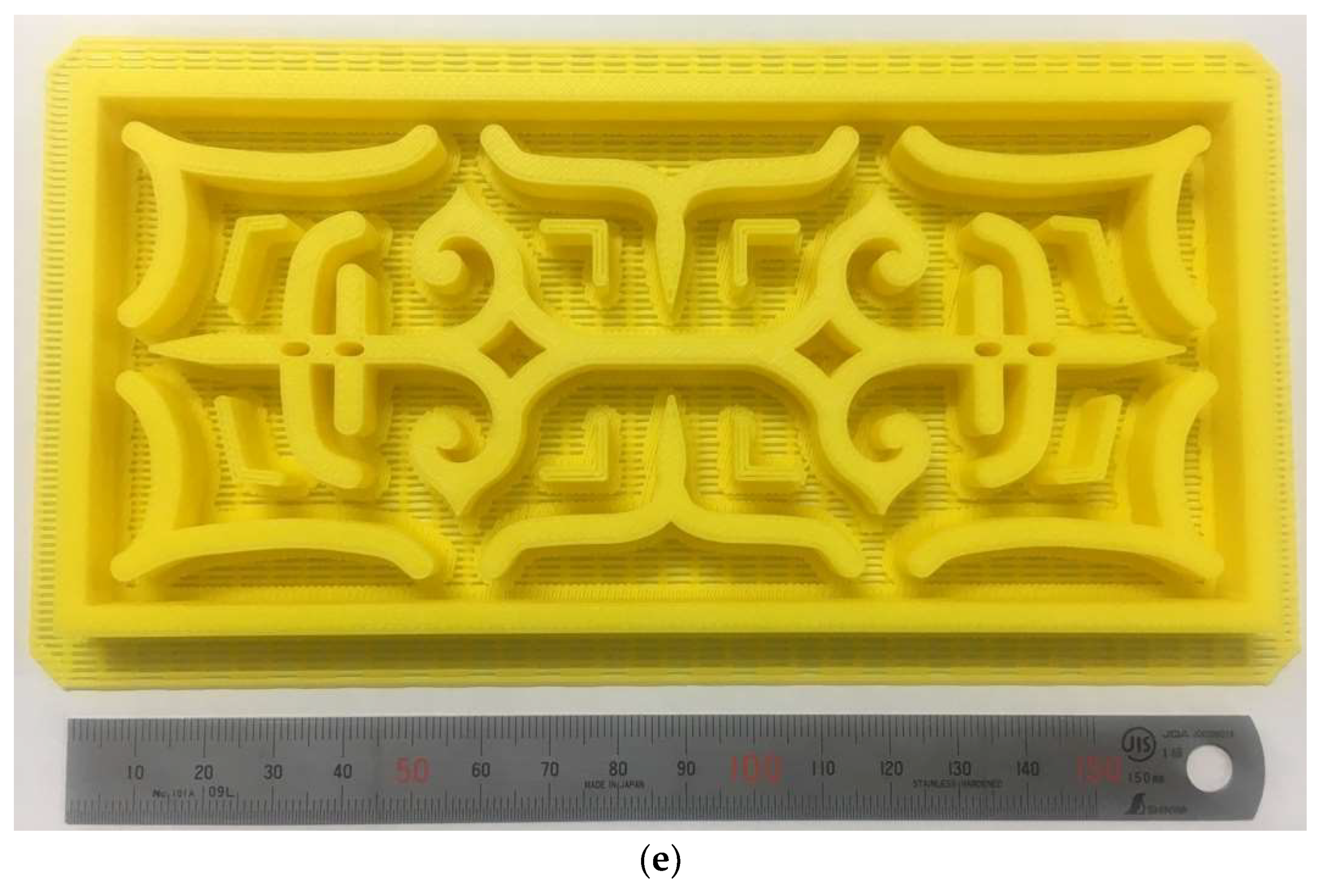

4.3. CAD Modeling, Triangulation Modeling and AM

5. Concluding Remarks

Author Contributions

Conflicts of Interest

Appendix A. Details of Equation-Based Point-Clouds

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015. [Google Scholar]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Bourell, D.L.; Rosen, D.W.; Leu, M.C. The Roadmap for Additive Manufacturing and Its Impact. 3D Print. Addit. Manuf. 2014, 1, 6–9. [Google Scholar] [CrossRef]

- Hirz, M.; Rossbacher, P.; Gulanová, J. Future trends in CAD—From the perspective of automotive industry. Comput.-Aided Des. Appl. 2017, 14, 734–741. [Google Scholar] [CrossRef]

- Yap, Y.L.; Tan, Y.S.; Tan, H.K.; Peh, Z.K.; Low, X.Y.; Yeong, W.Y.; Tan, C.S.; Laude, A. 3D printed bio-models for medical applications. Rapid Prototyp. J. 2017, 23, 227–235. [Google Scholar] [CrossRef]

- Hieu, L.C.; Zlatov, N.; Vander Sloten, J.; Bohez, E.; Khanh, L.; Binh, P.H.; Oris, P.; Toshev, Y. Medical rapid prototyping applications and methods. Assem. Autom. 2005, 25, 284–292. [Google Scholar] [CrossRef]

- Sun, W.; Starly, B.; Nam, J.; Darling, A. Bio-CAD modeling and its applications in computer-aided tissue engineering. Comput.-Aided Des. 2005, 37, 1097–1114. [Google Scholar] [CrossRef]

- Mannoor, M.S.; Jiang, Z.; James, T.; Kong, Y.L.; Malatesta, K.A.; Soboyejo, W.O.; Verma, N.; Gracias, D.H.; McAlpine, M.C. 3D Printed Bionic Ears. Nano Lett. 2013, 13, 2634–2639. [Google Scholar] [CrossRef] [PubMed]

- Steffan, D.; Dominic, E. A CAD and AM process for maxillofacial prostheses bar-clip retention. Rapid Prototyp. J. 2016, 22, 170–177. [Google Scholar] [CrossRef]

- Luximon, Y.; Ball, R.M.; Chow, E.H.C. A design and evaluation tool using 3D head templates. Comput.-Aided Des. Appl. 2016, 13, 153–161. [Google Scholar] [CrossRef]

- Jung, W.; Park, S.; Shin, H. Combining volumetric dental CT and optical scan data for teeth modeling. Comput.-Aided Des. 2015, 67–68, 24–37. [Google Scholar] [CrossRef]

- Urbanic, R.J. From thought to thing: Using the fused deposition modeling and 3D printing processes for undergraduate design projects. Comput.-Aided Des. Appl. 2016, 13, 768–785. [Google Scholar] [CrossRef][Green Version]

- Galina, L.; Na, X. Academic library innovation through 3D printing services. Libr. Manag. 2017, 38, 208–218. [Google Scholar] [CrossRef]

- Heather, M.M.-L. Makers in the library: Case studies of 3D printers and maker spaces in library settings. Libr. Hi Tech 2014, 32, 583–593. [Google Scholar] [CrossRef]

- Wannarumon, S.; Bohez, E.L.J. A New Aesthetic Evolutionary Approach for Jewelry Design. Comput.-Aided Des. Appl. 2006, 3, 385–394. [Google Scholar] [CrossRef][Green Version]

- 3DR Holdings, LLC. 3D Printed Clothing. October 2017. Available online: https://3dprint.com/tag/3d-printed-clothing/ (accessed on 15 November 2017).

- Balance, N. The Future of Running Is Here. April 2016. Available online: https://www.newbalance.com/article?id=4041 (accessed on 16 November 2017).

- i.materialize. 3D Printed Fashion: 10 Amazing 3D Printed Dresses. 2017. Available online: https://i.materialise.com/blog/3d-printed-fashion-dresses/ (accessed on 15 November 2017).

- Nike. Nike Debuts First-Ever Football Cleat Built Using 3D Printing Technology. February 2013. Available online: https://news.nike.com/news/nike-debuts-first-ever-football-cleat-built-using-3d-printing-technology (accessed on 16 November 2017).

- Sun, J.; Zhou, W.; Yan, L.; Huang, D.; Lin, L.Y. Extrusion-based food printing for digitalized food design and nutrition control. J. Food Eng. 2018, 220 (Suppl. C), 1–11. [Google Scholar] [CrossRef]

- Lin, C. 3D Food Printing: A Taste of the Future. J. Food Sci. Educ. 2015, 14, 86–87. [Google Scholar] [CrossRef]

- Ferreira, I.A.; Alves, J.L. Low-cost 3D food printing. Ciênc. Tecnol. Mater. 2017, 29, e265–e269. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134 (Suppl. C), 702–711. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151 (Suppl. C), 292–299. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21 (Suppl. C), 262–268. [Google Scholar] [CrossRef]

- Scopigno, R.; Cignoni, P.; Pietroni, N.; Callieri, M.; Dellepiane, M. Digital Fabrication Techniques for Cultural Heritage: A Survey. In Computer Graphics Forum; Wiley: Hoboken, NJ, USA, 2017; Volume 36, pp. 6–21. [Google Scholar] [CrossRef]

- Conner, B.P.; Manogharan, G.P.; Meyers, K.L. An assessment of implementation of entry-level 3D printers from the perspective of small businesses. Rapid Prototyp. J. 2015, 21, 582–597. [Google Scholar] [CrossRef]

- Holzmann, P.; Breitenecker, R.J.; Soomro, A.A.; Schwarz, E.J. User entrepreneur business models in 3D printing. J. Manuf. Technol. Manag. 2017, 28, 75–94. [Google Scholar] [CrossRef]

- Camille, B. What are you printing? Ambivalent emancipation by 3D printing. Rapid Prototyp. J. 2015, 21, 572–581. [Google Scholar] [CrossRef]

- James, D.W.; Belblidia, F.; Eckermann, J.E.; Sienz, J. An innovative photogrammetry color segmentation based technique as an alternative approach to 3D scanning for reverse engineering design. Comput.-Aided Des. Appl. 2017, 14, 1–16. [Google Scholar] [CrossRef]

- Masuda, H.; Niwa, T.; Tanaka, I.; Matsuoka, R. Reconstruction of Polygonal Faces from Large-Scale Point-Clouds of Engineering Plants. Comput.-Aided Des. Appl. 2015, 12, 555–563. [Google Scholar] [CrossRef]

- Krznar, N.; Pilipović, A.; Šercer, M. Additive Manufacturing of Fixture for Automated 3D Scanning—Case Study. Procedia Eng. 2016, 149 (Suppl. C), 197–202. [Google Scholar] [CrossRef]

- Várady, T.; Martin, R.R.; Cox, J. Reverse engineering of geometric models—An introduction. Comput.-Aided Des. 1997, 29, 255–268. [Google Scholar] [CrossRef]

- Paulic, M.; Irgolic, T.; Balic, J.; Cus, F.; Cupar, A.; Brajlih, T.; Drstvensek, I. Reverse Engineering of Parts with Optical Scanning and Additive Manufacturing. Procedia Eng. 2014, 69 (Suppl. C), 795–803. [Google Scholar] [CrossRef]

- Nooran, R. 3D Printing: Technology, Applications, and Selection, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Yang, J.; Cao, Z.; Zhang, Q. A fast and robust local descriptor for 3D point cloud registration. Inf. Sci. 2016, 346–347 (Suppl. C), 163–179. [Google Scholar] [CrossRef]

- Li, W.; Song, P. A modified ICP algorithm based on dynamic adjustment factor for registration of point cloud and CAD model. Pattern Recognit. Lett. 2015, 65 (Suppl. C), 88–94. [Google Scholar] [CrossRef]

- Zhao, X.; Ilieş, H.T. Learned 3D shape descriptors for classifying 3D point cloud models. Comput.-Aided Des. Appl. 2017, 14, 507–515. [Google Scholar] [CrossRef]

- Watanabe, T.; Niwa, T.; Masuda, H. Registration of Point-Clouds from Terrestrial and Portable Laser Scanners (Special Issue on Digital Engineering for Complex Shapes). Int. J. Autom. Technol. 2016, 10, 163–171. [Google Scholar] [CrossRef]

- Syed, H.M.; Mohammed, A.M.; Abdulrahman, M.A.-A. The influence of surface topology on the quality of the point cloud data acquired with laser line scanning probe. Sens. Rev. 2014, 34, 255–265. [Google Scholar] [CrossRef]

- Lee, K.H.; Woo, H. Direct integration of reverse engineering and rapid prototyping. Comput. Ind. Eng. 2000, 38, 21–38. [Google Scholar] [CrossRef]

- Fayolle, P.-A.; Pasko, A. An evolutionary approach to the extraction of object construction trees from 3D point clouds. Comput.-Aided Des. 2016, 74 (Suppl. C), 1–17. [Google Scholar] [CrossRef]

- Schwartz, A.; Schneor, R.; Molcho, G.; Weiss Cohen, M. Surface detection and modeling of an arbitrary point cloud from 3D sketching. Comput.-Aided Des. Appl. 2017, 1–11. [Google Scholar] [CrossRef]

- Xu, J.; Hou, W.; Zhang, H. An improved virtual edge approach to slicing of point cloud for additive manufacturing. Comput.-Aided Des. Appl. 2017, 1–7. [Google Scholar] [CrossRef]

- Huang, H.; Mok, P.Y.; Kwok, Y.L.; Au, J.S. Automatic Block Pattern Generation from a 3D Unstructured Point Cloud. Res. J. Text. Appar. 2010, 14, 26–37. [Google Scholar] [CrossRef]

- Peternell, M.; Steiner, T. Reconstruction of piecewise planar objects from point clouds. Comput.-Aided Des. 2004, 36, 333–342. [Google Scholar] [CrossRef]

- Pralay, P. An easy rapid prototyping technique with point cloud data. Rapid Prototyp. J. 2001, 7, 82–90. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A.; Rosen, P.; Rajab, K. Generating point clouds for slicing free-form objects for 3-D printing. Comput.-Aided Des. Appl. 2017, 14, 242–249. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A.; Rosen, P.; Rajab, K. Point cloud slicing for 3-D printing. Comput.-Aided Des. Appl. 2018, 15, 90–97. [Google Scholar] [CrossRef]

- Ma, J.; Chen, J.S.; Feng, H.Y.; Wang, L. Automatic construction of watertight manifold triangle meshes from scanned point clouds using matched umbrella facets. Comput.-Aided Des. Appl. 2017, 14, 742–750. [Google Scholar] [CrossRef]

- Zhong, S.; Yang, Y.; Huang, Y. Data Slicing Processing Method for RE/RP System Based on Spatial Point Cloud Data. Comput.-Aided Des. Appl. 2014, 11, 20–31. [Google Scholar] [CrossRef]

- Yang, P.; Schmidt, T.; Qian, X. Direct Digital Design and Manufacturing from Massive Point-Cloud Data. Comput.-Aided Des. Appl. 2009, 6, 685–699. [Google Scholar] [CrossRef]

- Percoco, G.; Galantucci, L.M. Local-genetic slicing of point clouds for rapid prototyping. Rapid Prototyp. J. 2008, 14, 161–166. [Google Scholar] [CrossRef]

- Chang, M.-C.; Leymarie, F.F.; Kimia, B.B. Surface reconstruction from point clouds by transforming the medial scaffold. Comput. Vis. Image Underst. 2009, 113, 1130–1146. [Google Scholar] [CrossRef]

- Sharif Ullah, A.M.M.; Sato, Y.; Kubo, A.; Tamaki, J.I. Design for Manufacturing of IFS Fractals from the Perspective of Barnsley’s Fern-leaf. Comput.-Aided Des. Appl. 2015, 12, 241–255. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S.; D’Addona, D.M.; Harib, K.H.; Lin, T. Fractals and Additive Manufacturing. Int. J. Autom. Technol. 2016, 10, 222–230. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S.; Omori, R.; Nagara, Y.; Kubo, A.; Tamaki, J. Toward Error-free Manufacturing of Fractals. Procedia CIRP 2013, 12 (Suppl. C), 43–48. [Google Scholar] [CrossRef]

- Sharif Ullah, A.M.M. Design for additive manufacturing of porous structures using stochastic point-cloud: A pragmatic approach. Comput.-Aided Des. Appl. 2018, 15, 138–146. [Google Scholar] [CrossRef]

- Neumüller, M.; Reichinger, A.; Rist, F.; Kern, C. 3D Printing for Cultural Heritage: Preservation, Accessibility, Research and Education. In 3D Research Challenges in Cultural Heritage; Ioannides, M., Quak, E., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2014; Volume 8355, pp. 119–134. [Google Scholar]

- Hess, M.; Robson, S. Re-engineering Watt: A case study and best practice recommendations for 3D colour laser scans and 3D printing in museum artefact documentation. In Lacona IX—Lasers in Conservation; Archetype Publications: London, UK, 2013; pp. 154–162. [Google Scholar]

- Furferi, R.; Governi, L.; Volpe, Y.; Puggelli, L.; Vanni, N.; Carfagni, M. From 2D to 2.5D i.e. from painting to tactile model. Graph. Models 2014, 76, 706–723. [Google Scholar] [CrossRef]

- Cheung, S.C.H. Ainu culture in transition. Futures 2003, 35, 951–959. [Google Scholar] [CrossRef]

- Introduction of Traditional Crafts: Ainushiriki. 2016. Available online: http://www.city.sapporo.jp/shimin/pirka-kotan/jp/kogei/ainu-siriki/ (accessed on 15 January 2018).

| Number | Motif | Ainu Name | Description |

|---|---|---|---|

| 1 |  | Ayusi | A shape marked with thorn |

| 2 |  | Moreu | A spiral shape |

| 3 |  | Arus-moreu | A spiral shape with small thorns |

| 4 |  | Sikike-nu-moreu | A spiral shape with corners |

| 5 |  | Sik | An eye shape |

| 6 |  | Utasa | A shape that intersects each other |

| 7 |  | Uren-moreu | Two spiral shapes |

| 8 |  | Ski-uren-moreu | Two spiral shapes with an eye shape |

| 9 |  | Moreu-etok | A shape like a spirally plant |

| 10 |  | Punkar | A shape like vine |

| 11 |  | Apapo-piras (u) ke | A shape like flower |

| 12 |  | Apapo-epuy | A shape like flower bud |

| 13 |  | - | A shape like heart type |

| 14 |  | - | A shape like fishing bell |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tashi; Ullah, A.S.; Watanabe, M.; Kubo, A. Analytical Point-Cloud Based Geometric Modeling for Additive Manufacturing and Its Application to Cultural Heritage Preservation. Appl. Sci. 2018, 8, 656. https://doi.org/10.3390/app8050656

Tashi, Ullah AS, Watanabe M, Kubo A. Analytical Point-Cloud Based Geometric Modeling for Additive Manufacturing and Its Application to Cultural Heritage Preservation. Applied Sciences. 2018; 8(5):656. https://doi.org/10.3390/app8050656

Chicago/Turabian StyleTashi, AMM Sharif Ullah, Michiko Watanabe, and Akihiko Kubo. 2018. "Analytical Point-Cloud Based Geometric Modeling for Additive Manufacturing and Its Application to Cultural Heritage Preservation" Applied Sciences 8, no. 5: 656. https://doi.org/10.3390/app8050656

APA StyleTashi, Ullah, A. S., Watanabe, M., & Kubo, A. (2018). Analytical Point-Cloud Based Geometric Modeling for Additive Manufacturing and Its Application to Cultural Heritage Preservation. Applied Sciences, 8(5), 656. https://doi.org/10.3390/app8050656