Multi-Azimuth Failure Mechanisms in Phosphor-Coated White LEDs by Current Aging Stresses

Abstract

:1. Introduction

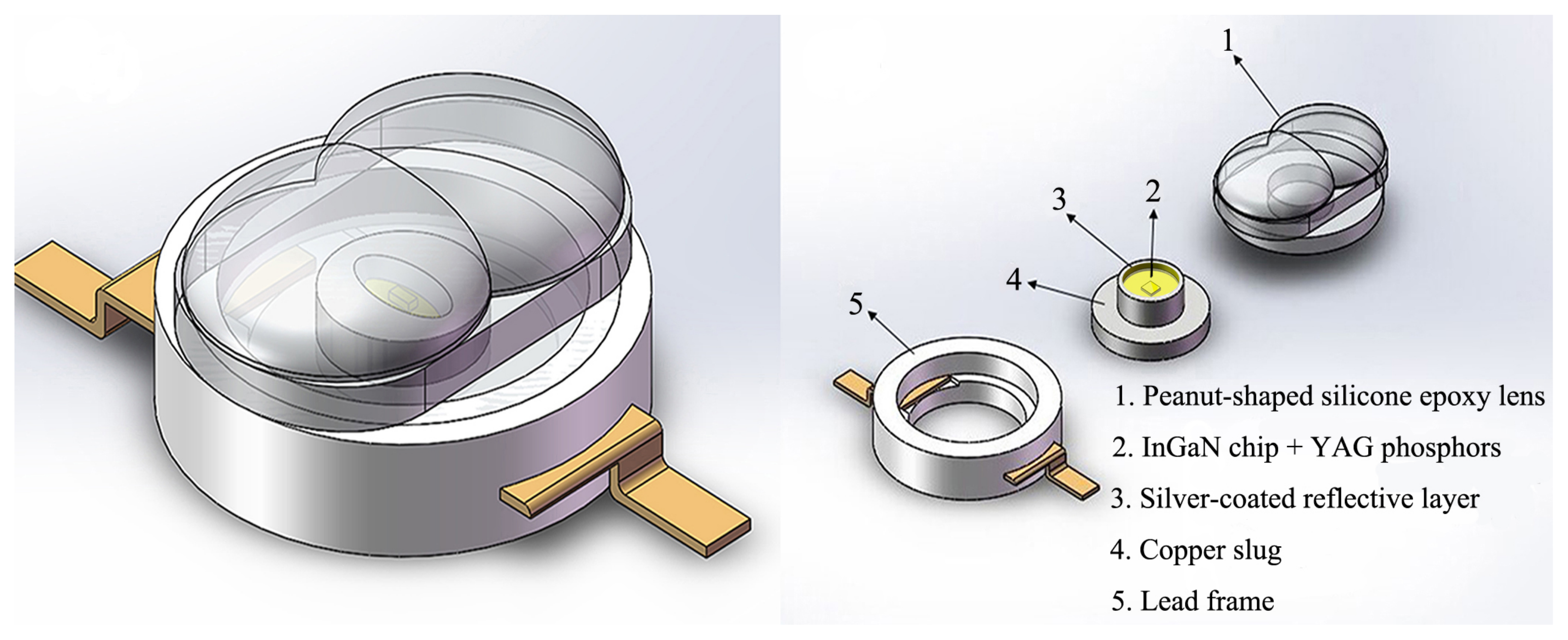

2. Experimental Methodology

3. Results and Discussions

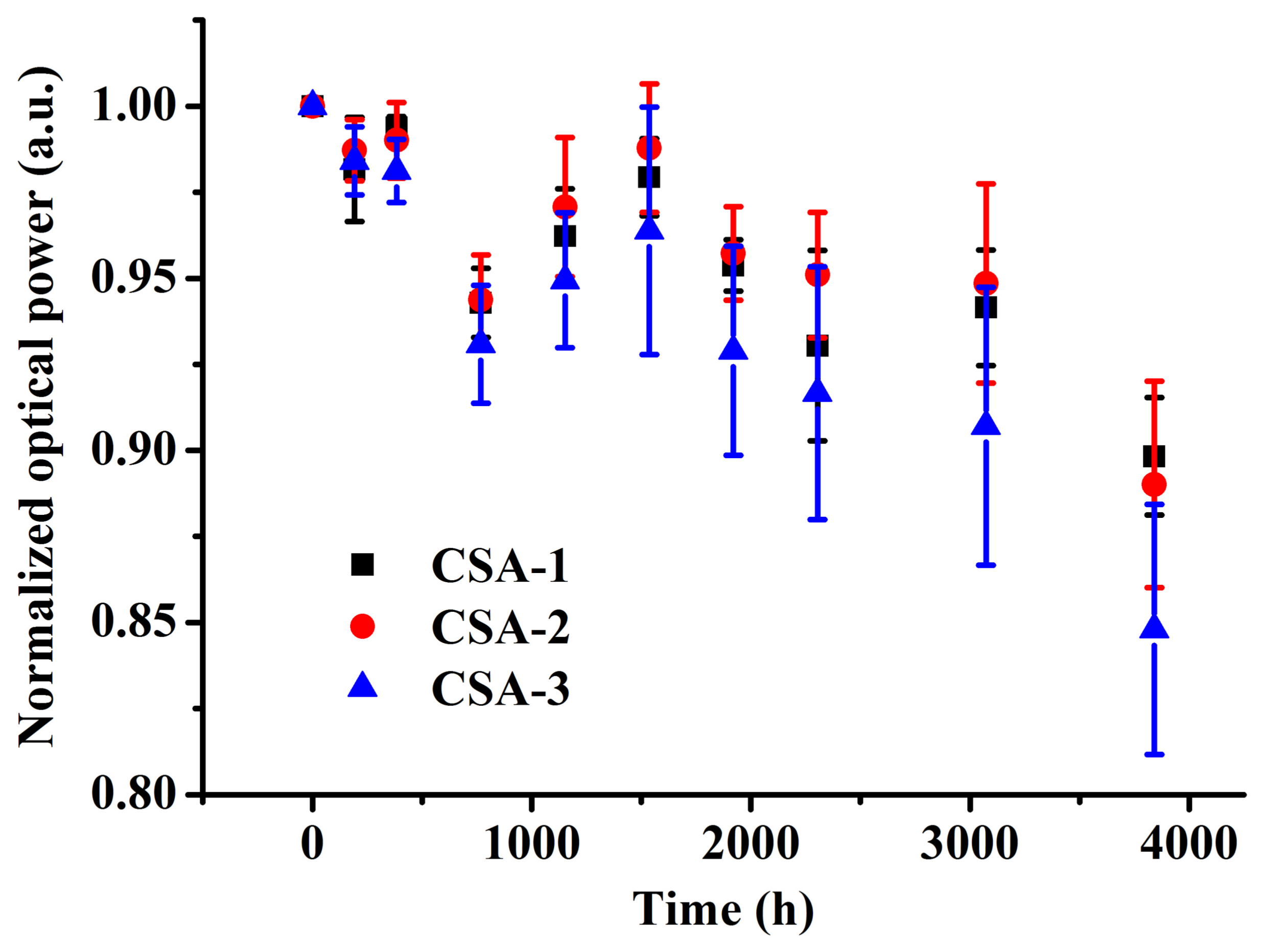

3.1. Photometric and Chromatic Analyses

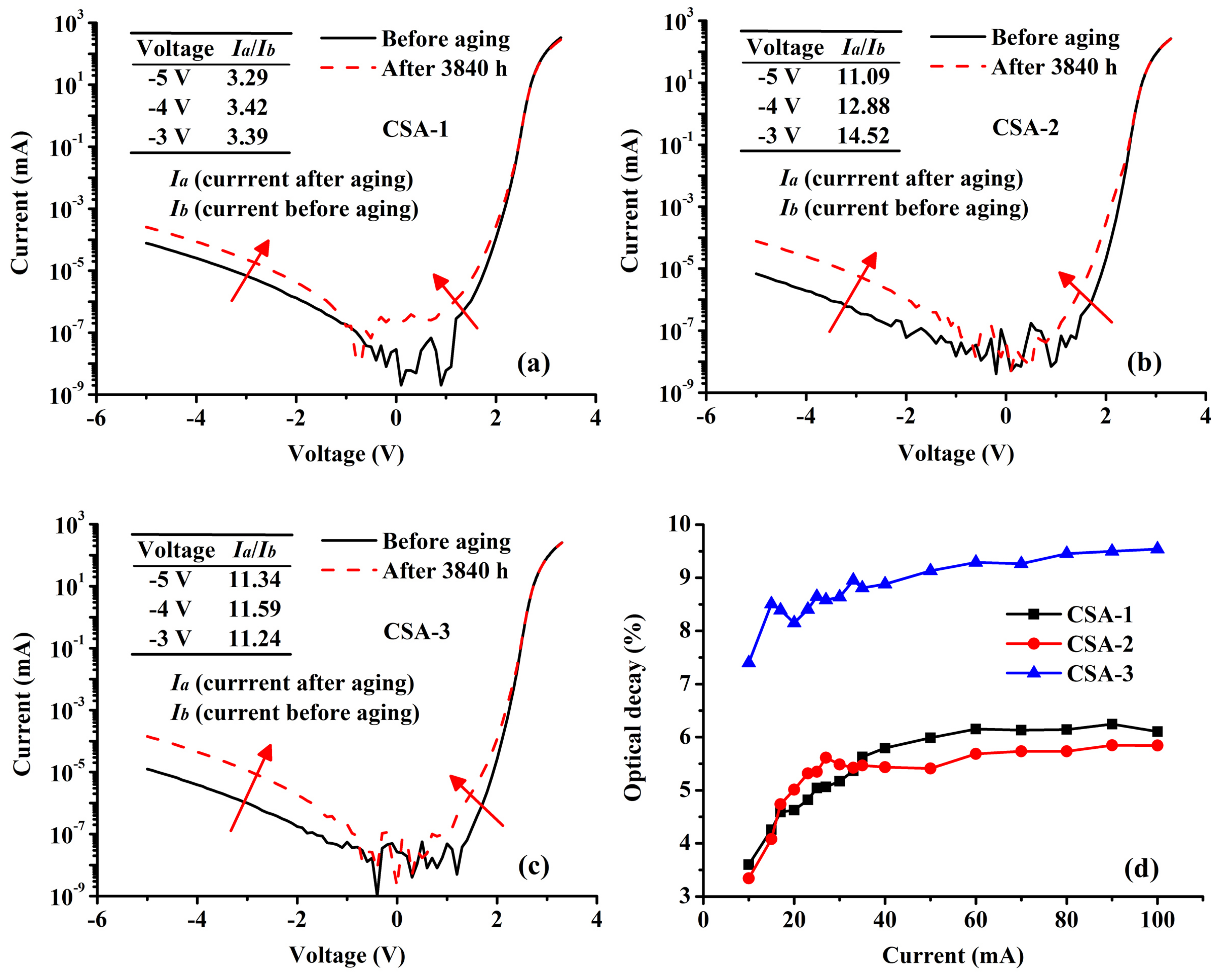

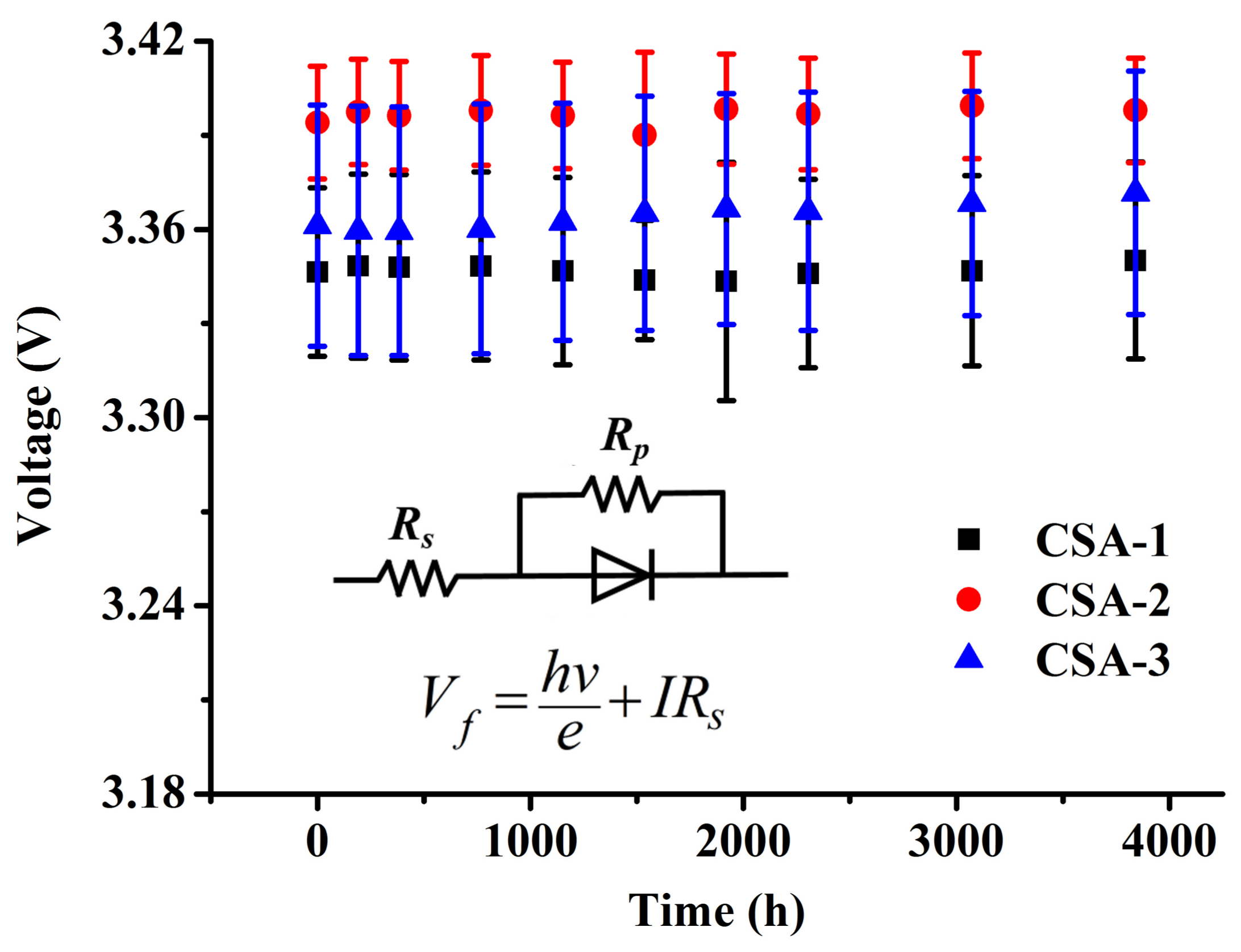

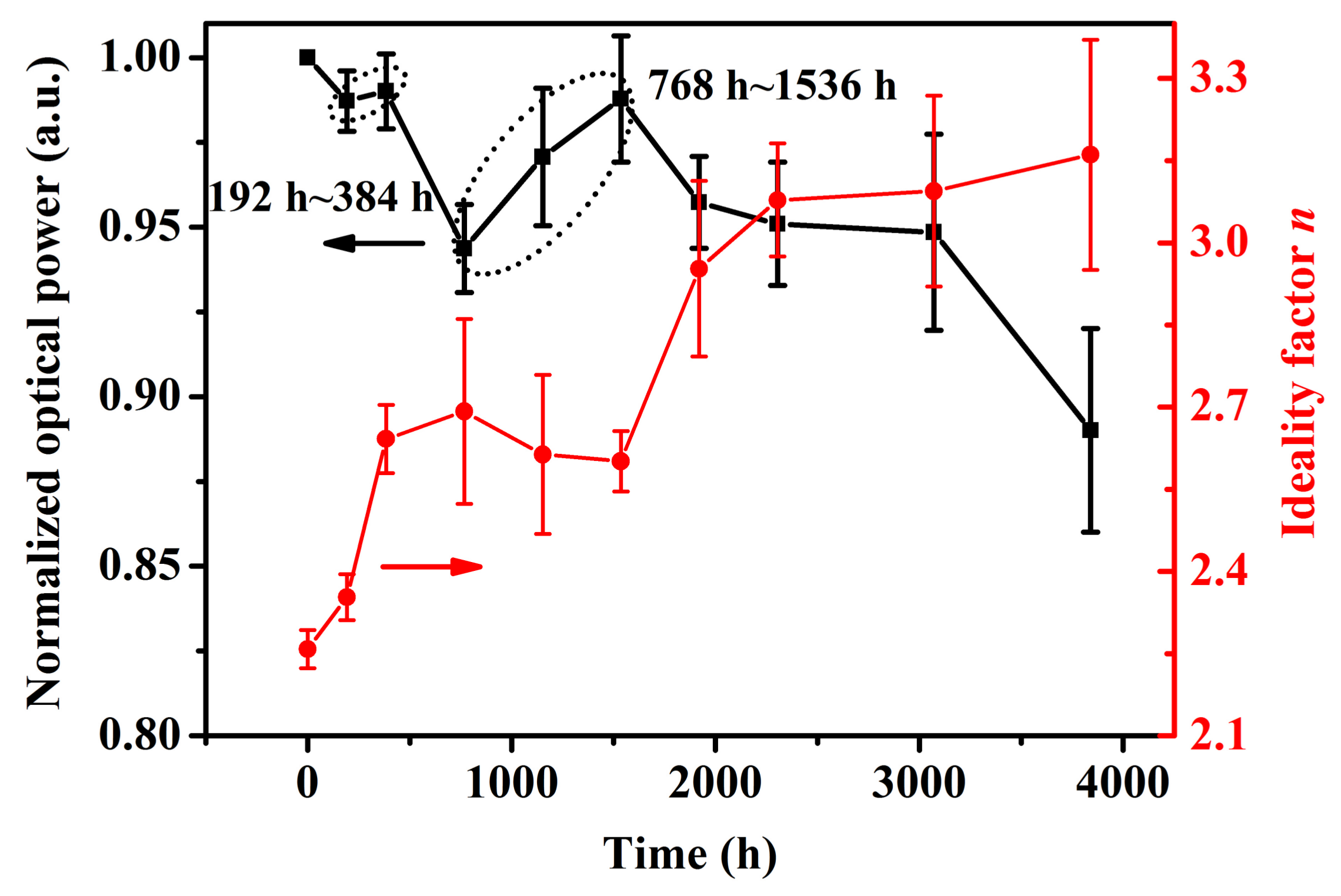

3.2. Electrical Analyses

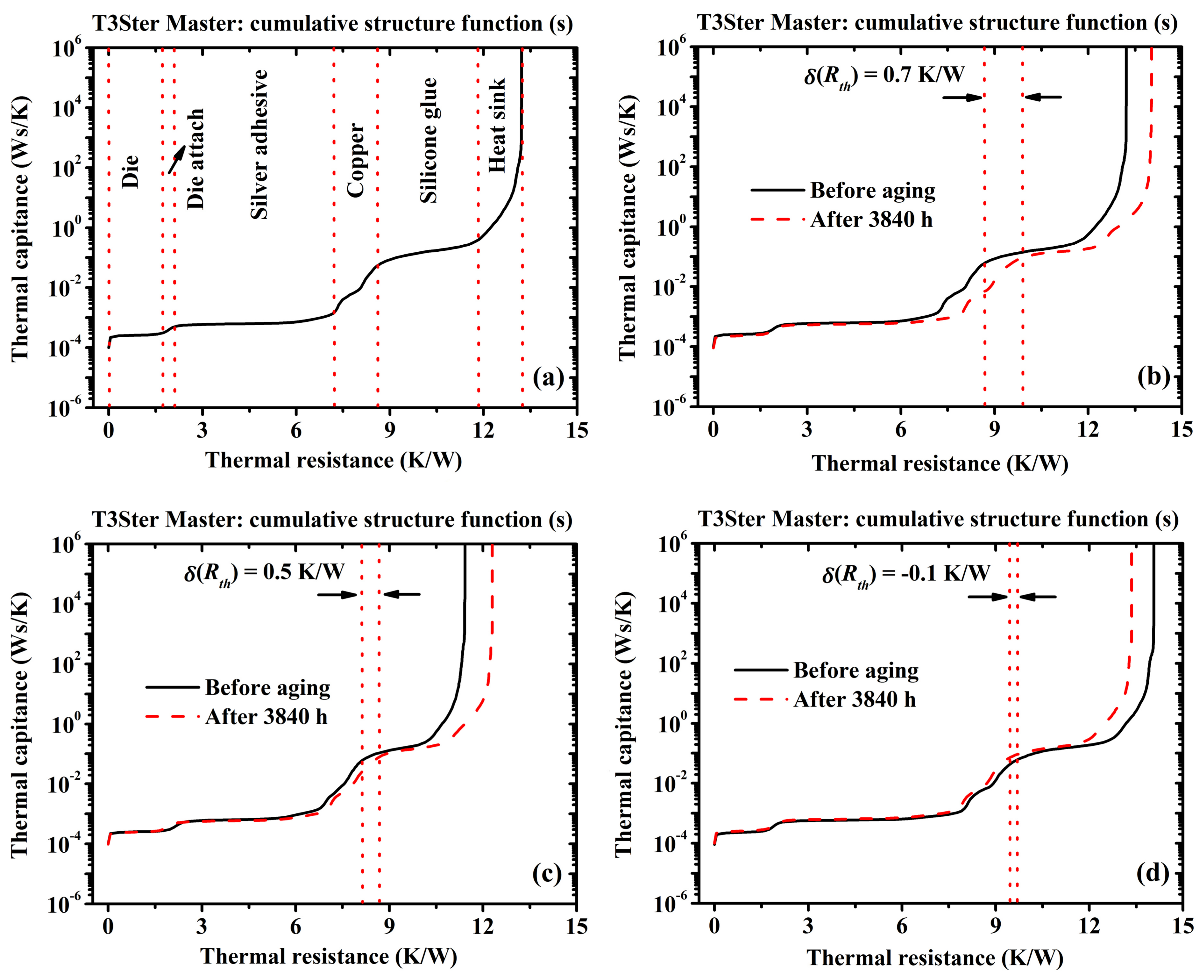

3.3. Thermal Analyses

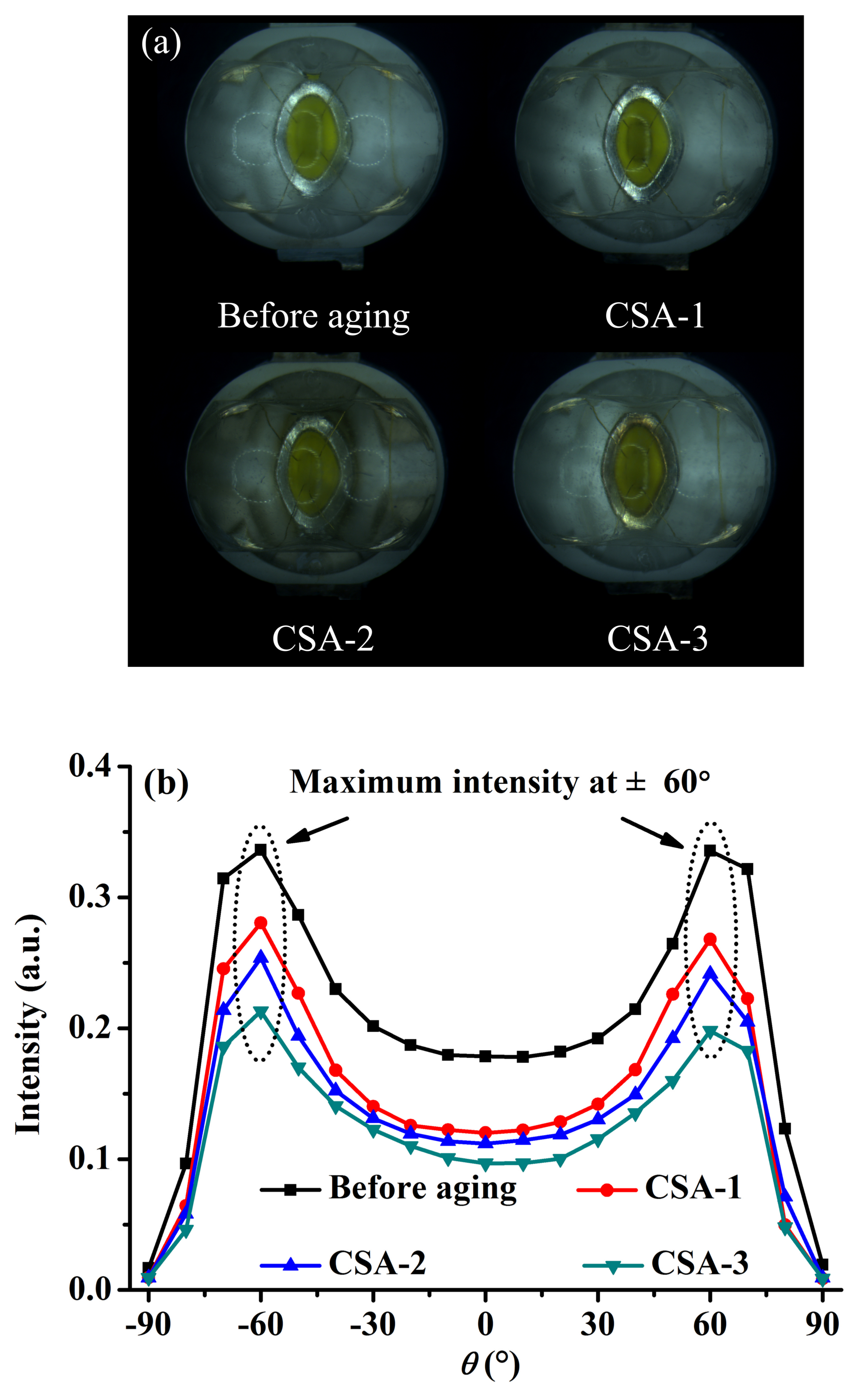

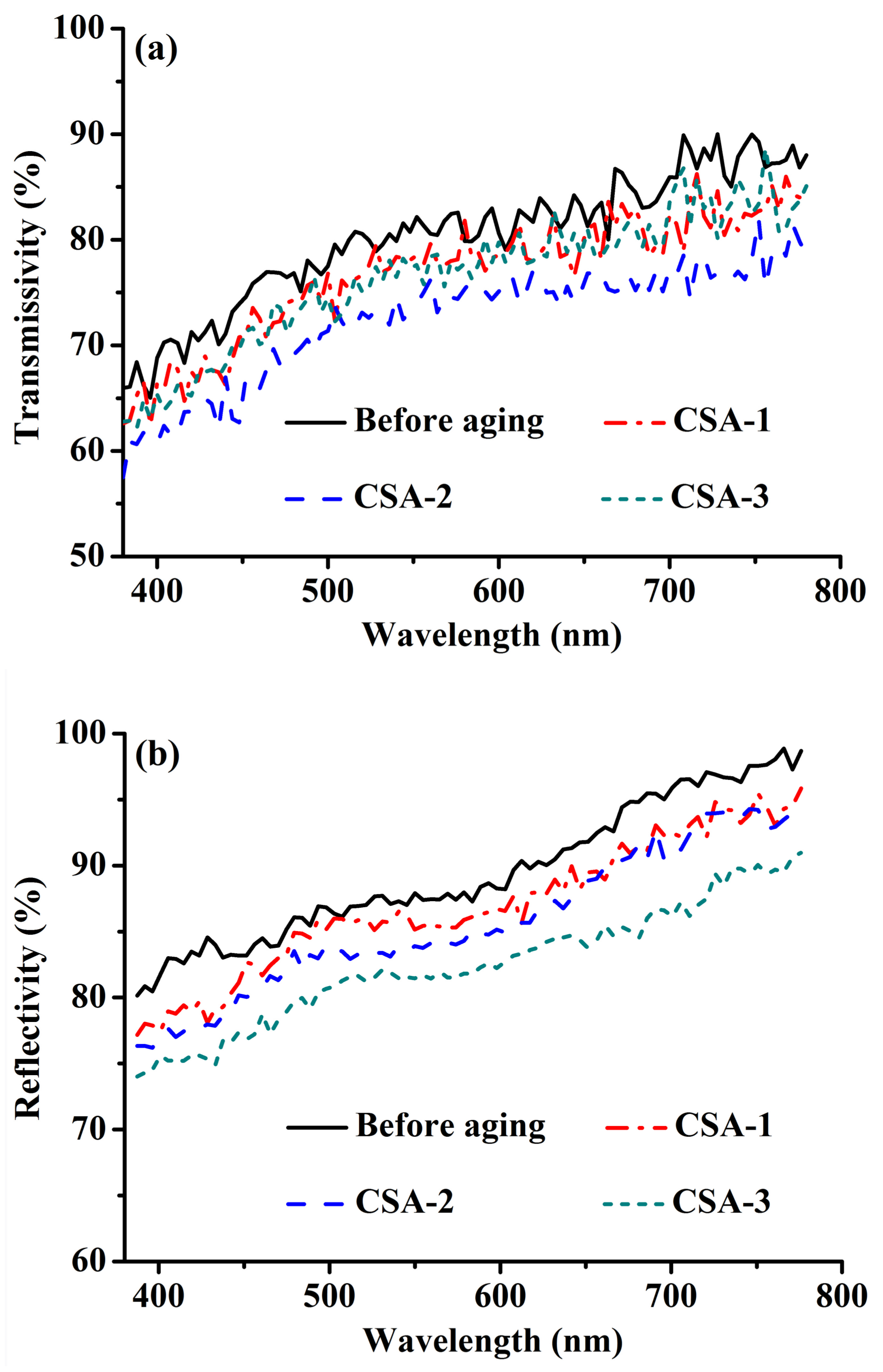

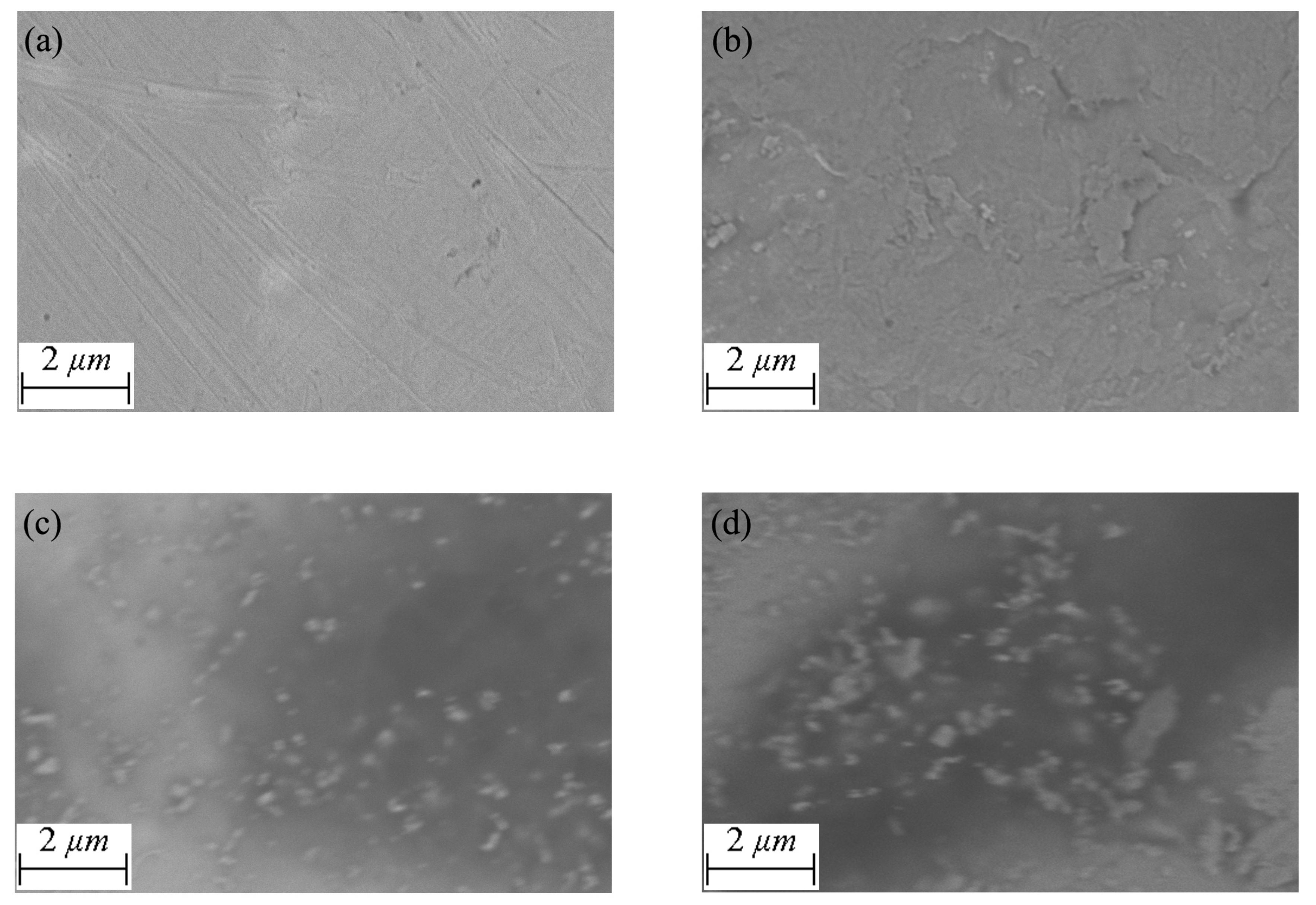

3.4. Packaging Analyses

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- May, B.J.; Selcu, C.M.; Sarwar, A.T.M.G.; Myers, R.C. Nanoscale current uniformity and injection efficiency of nanowire light emitting diodes. Appl. Phys. Lett. 2018, 112, 093107. [Google Scholar] [CrossRef]

- Tsai, H.; Nie, W.; Blancon, J.C.; Stoumpos, C.C.; Soe, C.M.M.; Yoo, J.; Crochet, J.; Tretiak, S.; Even, J.; Sadhanala, A.; et al. Stable light-emitting diodes using phase-pure ruddlesden-popper layered perovskites. Adv. Mater. 2018, 30, 1704217. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.Y.; Chen, K.J.; Wang, S.W.; Lin, C.C.; Wang, K.Y.; Li, J.R.; Lee, P.T.; Shih, M.H.; Li, X.L.; Chen, H.M.; et al. Improvement of light quality by DBR structure in white LED. Opt. Express 2015, 23, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.Q.; Shih, T.M.; Lu, Y.J.; Gao, Y.L.; Zhu, L.H.; Chen, G.L.; Zhang, J.H.; Lin, S.Q.; Chen, Z. Studies of scotopic/photopic ratios for color-tunable white light-emitting diodes. IEEE Photonics J. 2013, 5, 8200409. [Google Scholar] [CrossRef]

- Kim, G.; Sun, M.C.; Kim, J.H.; Park, E.; Park, B.G. GaN-based light emitting diodes using p-type trench structure for improving internal quantum efficiency. Appl. Phys. Lett. 2017, 110, 021115. [Google Scholar] [CrossRef]

- Tsai, Y.L.; Liu, C.Y.; Krishnan, C.; Lin, D.W.; Chu, Y.C.; Chen, T.P.; Shen, T.L.; Kao, T.S.; Charlton, M.D.B.; Yu, P.; et al. Bridging the “green gap” of LEDs: Giant light output enhancement and directional control of LEDs via embedded nano-void photonic crystals. Nanoscale 2016, 8, 1192–1199. [Google Scholar] [CrossRef] [PubMed]

- Fadil, A.; Ou, Y.Y.; Iida, D.; Kamiyama, S.; Petersen, P.M.; Ou, H.Y. Combining surface plasmonic and light extraction enhancement on InGaN quantum-well light-emitters. Nanoscale 2016, 8, 16340–16348. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.C.; Ou, S.L.; Horng, R.H.; Wuu, D.S. Improved performance of high-voltage vertical GaN LEDs via modification of micro-cell geometry. Appl. Sci. 2017, 7, 506. [Google Scholar] [CrossRef]

- Kim, T.; Seong, T.Y.; Kwon, O. Investigating the origin of efficiency droop by profiling the voltage across the multi-quantum well of an operating light-emitting diode. Appl. Phys. Lett. 2017, 108, 231101. [Google Scholar] [CrossRef]

- Guo, Z.Q.; Shih, T.M.; Gao, Y.L.; Lu, Y.J.; Zhu, L.H.; Chen, G.L.; Lin, Y.; Zhang, J.H.; Chen, Z. Optimization studies of two-phosphor-coated white light-emitting diodes. IEEE Photonics J. 2013, 5, 8200112. [Google Scholar] [CrossRef]

- Shen, W.Q.; Zhu, Y.W.; Wang, Z.L. Luminescent properties of Sr4Si3O8Cl4:Eu2+, Bi3+ phosphors for near UV InGaN-based light-emitting-diodes. Appl. Sci. 2015, 5, 1494–1502. [Google Scholar] [CrossRef]

- Meneghini, M.; Lago, M.D.; Trivellin, N.; Meneghesso, G.; Zanoni, E. Degradation mechanisms of high-power LEDs for lighting applications: An overview. IEEE Trans. Ind. Appl. 2014, 50, 78–85. [Google Scholar] [CrossRef]

- Renso, N.; Meneghini, M.; Buffolo, M.; Santi, C.D.; Meneghesso, G.; Zsnoni, E. Understanding the degradation processes of GaN based LEDs submitted to extremely high current density. Microelectron. Reliab. 2017, 76–77, 556–560. [Google Scholar] [CrossRef]

- Singh, P.; Tan, C.M. Degradation physics of high power LEDs in outdoor environment and the role of phosphor in the degradation process. Sci. Rep. 2016, 6, 24052. [Google Scholar] [CrossRef] [PubMed]

- Ruknudeen, F.; Asokan, S. Application of particle filter to on-board life estimation of LED lights. IEEE Photonics J. 2017, 9, 8201116. [Google Scholar] [CrossRef]

- Rahman, F.; George, A.F.; Drinkard, R. Short- and long-term reliability studies of broadband phosphor-converted red, green, and white light-emitting diodes. IEEE Trans. Device Mater. Rel. 2016, 16, 1–8. [Google Scholar] [CrossRef]

- Canale, L.; Dupuis, P.; Leng, S.; Zissis, G. Study of high-brightness LED samples aged under stress temperature conditions: Electrical characterizations and signature evolution analysis. IEEE Trans. Ind. Appl. 2016, 52, 502–510. [Google Scholar] [CrossRef]

- Fan, J.J.; Yu, C.H.; Qian, C.; Fan, X.J.; Zhang, G.Q. Thermal/luminescence characterization and degradation mechanism analysis on phosphor-converted white LED chip scale packages. Microelectron. Reliab. 2017, 74, 179–185. [Google Scholar] [CrossRef]

- Joglekar, S.; Azize, M.; Beeler, M.; Monroy, E.; Palacios, T. Impact of recess etching and surface treatments on ohmic contacts regrown by molecular-beam epitaxy for AlGaN/GaN high electron mobility transistors. Appl. Phys. Lett. 2016, 74, 041602. [Google Scholar] [CrossRef]

- Vaskuri, A.; Kärhä, P.; Baumgartner, H.; Kantamaa, O.; Pulli, T.; Poikonen, T.; Ikonen, E. Relationships between junction temperature, electroluminescence spectrum and ageing of light-emitting diodes. Metrologia 2018, 55, S86–S95. [Google Scholar] [CrossRef]

- Iqbal, F.; Kim, S.; Yie, H.Y.; Kim, Y.; Kim, H. Effect of alkali metal oxides on reliability and degradation of phosphor-in-glass encapsulants for white LEDs. Ceram. Int. 2016, 42, 10393–10398. [Google Scholar] [CrossRef]

- Neugebauer, S.; Hoffmann, M.P.; Witte, H.; Bläsing, J.; Dadgar, A.; Strittmatter, A.; Niermann, T.; Narodovitch, M.; Lehmann, M. All metalorganic chemical vapor phase epitaxy of p/n-GaN tunnel junction for blue light emitting diode applications. Appl. Phys. Lett. 2017, 110, 102104. [Google Scholar] [CrossRef]

- Lee, D.H.; Mitchell, B.; Fujiwara, Y.; Dierolf, V. Thermodynamics and kinetics of three Mg-H-VN complexes in Mg:GaN from combined first-principles calculation and experiment. Phys. Rev. Lett. 2014, 112, 205501. [Google Scholar] [CrossRef]

- Luo, X.B.; Hu, R.; Liu, S.; Wang, K. Heat and fluid flow in high-power LED packaging and applications. Prog. Energ. Combust. 2016, 56, 1–32. [Google Scholar] [CrossRef]

- Liu, L.L.; Yang, J.F.; Ling, M.J.; Zhong, J.W.; Teng, D.D.; Wang, G. Aggravated efficiency droop in vertical-structured gallium nitride light-emitting diodes induced by high temperature aging. J. Appl. Phys. 2013, 113, 083105. [Google Scholar] [CrossRef]

- Shimizu, K.T.; Böhmer, M.; Estrada, D.; Gangwal, S.; Grabowski, S.; Bechtel, H.; Kang, E.; Vampola, K.J.; Chamberlin, D.; Shchekin, O.B.; et al. Toward commercial realization of quantum dot based white light-emitting diodes for general illumination. Photonics Res. 2017, 5, A1–A6. [Google Scholar] [CrossRef]

- Yang, T.H.; Wu, S.M.; Sun, C.C.; Glorieux, B.; Chen, C.Y.; Chang, Y.Y.; Lee, X.H.; Yu, Y.W.; Chung, T.Y.; Lai, K.Y. Stabilizing CCT in pcW-LEDs by self-compensation between excitation efficiency and conversion efficiency of phosphors. Opt. Express 2017, 25, 29287–29295. [Google Scholar] [CrossRef]

- Cai, M.; Yang, D.G.; Huang, J.L.; Zhang, M.F.; Chen, X.P.; Liang, C.H.; Koh, S.; Zhang, G.Q. Color shift modeling of light-emitting diode lamps in step-loaded stress testing. IEEE Photonics J. 2017, 9, 8200114. [Google Scholar] [CrossRef]

- Borga, M.; Meneghini, M.; Rossetto, I.; Stoffels, S.; Posthuma, N.; Hove, M.V.; Marcon, D.; Decoutere, S.; Meneghesso, G.; Zanoni, E. Evidence of time-dependent vertical breakdown in GaN-on-Si HEMTs. IEEE Trans. Electron Dev. 2017, 64, 3616–3621. [Google Scholar] [CrossRef]

- Haller, C.; Carlin, J.F.; Jacopin, G.; Martin, D.; Butté, R.; Grandjean, N. Burying non-radiative defects in InGaN underlayer to increase InGaN/GaN quantum well efficiency. Appl. Phys. Lett. 2017, 111, 262101. [Google Scholar] [CrossRef]

- Ajia, I.A.; Edwards, P.R.; Pak, Y.; Belekov, E.; Roldan, M.A.; Wei, N.; Liu, Z.Q.; Martin, R.W.; Roqan, I.S. Generated carrier dynamics in V-pit-enhanced InGaN/GaN light-mitting diode. ACS Photonics 2018, 5, 820–826. [Google Scholar] [CrossRef]

- Bicanic, K.T.; Li, X.Y.; Sabatini, R.P.; Hossain, N.; Wang, C.F.; Fan, F.J.; Liang, H.Y.; Hoogland, S.; Sargent, E.H. Design of phosphor white light systems for high-power applications. ACS Photonics 2016, 3, 2243–2248. [Google Scholar] [CrossRef]

- Monti, D.; Meneghini, M.; Santi, C.D.; Meneghesso, G.; Zanoni, E. Degradation of UVA LEDs: Physical origin and dependence on stress conditions. IEEE Trans. Device Mater. Rel. 2016, 16, 213–218. [Google Scholar] [CrossRef]

- Spencer, P.; Clarke, E.; Murray, R. Carrier escape and the ideality factor in quantum dot p-n junctions. IEEE J. Quantum Elect. 2014, 50, 213–219. [Google Scholar] [CrossRef]

- Pfeiffer, L.N.; West, K.W. Quantum hall spin diode. Phys. Rev. Lett. 2017, 118, 186801. [Google Scholar] [CrossRef]

- Su, C.Y.; Tu, C.G.; Liu, W.H.; Lin, C.H.; Yao, Y.F.; Chen, H.T.; Wu, Y.R.; Kiang, Y.W.; Yang, C.C. Enhancing the hole-injection efficiency of a light-emitting diode by increasing Mg doping in the p-AlGaN electron-blocking layer. IEEE Trans. Electron Dev. 2017, 64, 3226–3233. [Google Scholar] [CrossRef]

- Chen, T.T.; Wang, C.P.; Fu, H.K.; Chou, P.T.; Ying, S.P. Electroluminescence enhancement in InGaN light-emitting diode during the electrical stressing process. Opt. Express 2014, 22, 1328–1333. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.D.; Li, Z.T.; Liang, G.W.; Tang, Y.; Yu, B.H.; Chen, K.H. Angular color uniformity enhancement of white light-emitting diodes by remote micro-patterned phosphor film. Opt. Lett. 2016, 4, 140–145. [Google Scholar] [CrossRef]

- Tsai, M.Y.; Tang, C.Y.; Wang, C.H.; Tsai, Y.Y.; Chen, C.H. Investigation on some parameters affecting optical degradation of LED packages during high-temperature aging. IEEE Trans. Device Mater. Rel. 2015, 15, 335–341. [Google Scholar] [CrossRef]

- Jung, E.J.; Kim, M.S.; Kim, H. Analysis of contributing factors for determining the reliability characteristics of GaN-based white light-emitting diodes with dual degradation kinetics. IEEE Trans. Electron Dev. 2013, 60, 186–191. [Google Scholar] [CrossRef]

- Lu, Y.J.; Guo, Z.Q.; Shih, T.M.; Gao, Y.L.; Huang, W.L.; Lu, H.L.; Lin, Y.; Chen, Z. Optical degradation mechanisms of indium gallium nitride-based white light emitting diodes by high-temperature aging tests. IEEE Trans. Rel. 2016, 65, 256–262. [Google Scholar] [CrossRef]

| Instrument | Model | Characteristic |

|---|---|---|

| Spectrometer | Spectro-320e | Wavelength: 170–1700 nm |

| Integrating Sphere | ISP-500, ISP-150 | Sizes: 500 mm, 150 mm |

| Angular Distribution Analyzer | LEDGON 100 | Angle range: 360; Angle accuracy: 1 |

| Transient Thermal Tester (T3Ster) | T3Ster 2000/100 | Testing currents: 0–500 mA; Resolution: 0.1 C |

| Electric Source Meter | Keithley 2611 | Maximum current: 1.5 A; Maximum voltage: 200 V |

| Temperature Controller | Keithley 2510 | Temperature range: 0–80 C; Resolution: 0.001 C |

| Field emission Scanning Electron Microscopy (FE-SEM) | Sigma-HD | Magnifications: 10–1,000,000×; Resolution: 1.0 nm |

| Energy Dispersive Spectrometer (EDS) | X-Max | SDD detector: 50 mm; Accuracy: 5 nm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Guo, Z.; Wu, T.; Zhuang, P.; Ye, Z.; Shi, Y.; Shih, T.-M.; Lu, Y.; Kuo, H.-C.; Chen, Z. Multi-Azimuth Failure Mechanisms in Phosphor-Coated White LEDs by Current Aging Stresses. Appl. Sci. 2018, 8, 610. https://doi.org/10.3390/app8040610

Peng Z, Guo Z, Wu T, Zhuang P, Ye Z, Shi Y, Shih T-M, Lu Y, Kuo H-C, Chen Z. Multi-Azimuth Failure Mechanisms in Phosphor-Coated White LEDs by Current Aging Stresses. Applied Sciences. 2018; 8(4):610. https://doi.org/10.3390/app8040610

Chicago/Turabian StylePeng, Zhangbao, Ziquan Guo, Tingzhu Wu, Peng Zhuang, Zhicheng Ye, Yuan Shi, Tien-Mo Shih, Yijun Lu, Hao-Chung Kuo, and Zhong Chen. 2018. "Multi-Azimuth Failure Mechanisms in Phosphor-Coated White LEDs by Current Aging Stresses" Applied Sciences 8, no. 4: 610. https://doi.org/10.3390/app8040610

APA StylePeng, Z., Guo, Z., Wu, T., Zhuang, P., Ye, Z., Shi, Y., Shih, T.-M., Lu, Y., Kuo, H.-C., & Chen, Z. (2018). Multi-Azimuth Failure Mechanisms in Phosphor-Coated White LEDs by Current Aging Stresses. Applied Sciences, 8(4), 610. https://doi.org/10.3390/app8040610