1. Introduction

G*sin

δ was developed as a fatigue cracking parameter during the Strategic Highway Research Program (SHRP) for asphalt pavement. Complex shear modulus (

G*) is defined as the absolute value of peak shear stress divided by the absolute value of peak shear strain, whereas phase angel (

δ) is defined as the lag between strain and stress peak values due to the viscoelastic property of asphalt. The

G*sin

δ was proposed to limit the magnitude of

G* and

δ to select relative soft asphalt with a high elasticity, and thus to improve the fatigue resistance of asphalt binder. Based on unmodified binder, Anderson et al. [

1] found that the

G*sin

δ was able to differentiate various asphalt types and contents in resisting fatigue damage in a linear viscoelastic range.

With the increased usage of asphalt modifications (i.e., polymer, warm mix asphalt), researchers started to realize that

G*sin

δ cannot successfully be utilized in fatigue characterization, as

G*sin

δ has little relation to asphalt mixture fatigue testing results [

2,

3]. The possible reasons that caused such discrepancies include: (1) most responses of modified asphalt binder were non-linear, and it was not reasonable to use linear parameters to characterize a non-linear response; (2) one of the assumptions of

G*sin

δ was that all the asphalt binders share the same sensitivity to loading rate and testing temperature, whereas this assumption was not applicable to the modified binders [

3]; and (3)

G*sin

δ was tested at a low strain level with a fixed frequency and no damage was introduced during the test, whereas field traffic was much more complicated and with a higher level of damage severity. Higher stain in asphalt binder may induce significant amounts of viscous flow or yielding, as well as micro-cracking and macrocracking in areas of a high-stress concentration [

4].

Both fatigue test and fracture tests were developed to address the above issues. A repeated loading test was used to better simulate the field traffic load, which generates accumulated damage, including the time sweeping test [

3], linear amplitude sweep test [

5], and dynamic mechanical analyzer test [

6]. The fracture test can introduce damage with a high efficiency and is very time efficient. The major fracture tests consist of ductility, crack tip opening displacement, and the monotonic test.

Recently, the multiple stress creep recovery (MSCR) test was applied to quantify the fatigue since the MSCR recovery can be potentially used to evaluate the delayed elastic response of asphalt binder [

7]. The MSCR test does not impose the assumption that the material behavior is linear viscoelastic [

8]. The test is also sensitive to different binder types at elevated temperatures (i.e., 50 °C or higher). It was found that the MSCR test was able to distinguish modified binders from un-modified binders [

9]. The current study using the MSCR on fatigue resistance evaluation was majorly based on correlating MSCR results at a high performance grade (PG) temperature to asphalt fracture test results [

7].

In summary, multiple parameters were proposed to quantify the fatigue resistance of both modified and un-modified asphalt to address the limitations of the G*sin δ. The MSCR test, considering its wide application, is practical to investigate whether it is applicable to evaluate the fatigue performance of modified and unmodified asphalt binders. The current study using MSCR as part of a fatigue study was limited to high testing temperatures, and its correlation with mixture property was not well explored. The research objectives of this study were to (a) examine if the MSCR test was able to distinguish different binder types and additive contents at intermediate temperatures; and (b) evaluate if the MSCR test at intermediate temperatures could correlate well with the fatigue performance of the asphalt mixture. This paper will provide useful information for further implementation of the MSCR test on fatigue evaluations of asphalt pavement.

2. Methodology and Scope

Both modified and un-modified binders, including base binder, Styreneic Block Copolymers (SBS) modified binder, rubber modified binder, and warm mix binders (Sasobit, Evotherm M1 and Evotherm 3G), were included. The contents of Sasobit and rubber were 1%, 2%, and 3%, and 5%, 10%, and 15% by weight of asphalt binder, respectively. The ratios of SBS, Evotherm M1m and Evotherm 3G were 4.5%, 0.6%, and 0.6% by weight of asphalt binder, respectively. The aggregate consisting of three stockpiles with basalt was used as the major aggregate source. To better control aggregate gradation, three aggregate stockpiles were further sieved in a laboratory based on each individual sieve size. Mix design was validated in the laboratory to determine the optimum asphalt content using the Superpave method.

Several fatigue tests for both asphalt binders and asphalt mixtures were conducted, consisting of binder MSCR, a mixture semi-circular bending- Illinois flexibility index test (SCB-IFIT), and a mixture indirect tensile test (IDT). Other binder testing, including performance grading, viscosity, and binder monotonic fracture tests were also performed as the reference.

Table 1 shows a summary of the all the laboratory mixture and binder tests included in this paper.

The sensitivity of the MSCR test to the binder type and additive content was evaluated. The binder with the best fatigue resistance and the control base asphalt were further chosen to conduct the asphalt mixture fracture test. A ranking between the MSCR test and mixture fatigue test was further compared to evaluate if the MSCR test was well correlated with mixture performance. Short- and long-term aging were applied on both binders and mixtures to address the effect of aging. For all the asphalt binder and mixture tests, three repetitions were used, except for the bending beam rheometer (BBR) test, which includes two test replicates as specified in the AASHTO specification.

3. Data Collection

The asphalt binder and aggregate were collected from a local contractor in Nanjing, China. A PG 76-22 binder (without modification) was utilized as the base asphalt. The basalt used is the dominating aggregate type in Jiangsu, China. Basalt is grey to black in color, but rapidly weathers to brown or rust-red due to oxidation of its iron-rich minerals. It has very good characteristics in terms of soundness and abrasion resistance, whereas the major concern is the weak bonding between asphalt and aggregate due to the smooth surfaces of basalt aggregate. Anti-stripping was included to avoid the potential moisture damage.

Mix design was performed in the laboratory to determine the optimum asphalt content based on the Superpave method. A typical local mix with a nominal maximum aggregate size (NMAS) of 13.2 mm was used.

Table 2 shows the aggregate gradation and the mix design.

3.1. Binder and Mixture Aging Test

The asphalt binders were aged by a Thin-Film Oven Test (TFOT) to simulate short-term field aging according to AASHTO T179. The TFOT aged binders were further aged by Pressure Aging Vessel (PAV) to simulate long-term field aging based on AASHTO R28.

Regarding the asphalt mixtures, the short-term aging was conducted by placing loose mixtures in a stainless steel pan, which was then heated for 4 h at 135 °C in a traditional oven. Within the procedure, mixtures were stirred every 60 min to maintain uniform aging conditioning. In contrast, the long-term mixture aging was performed by utilizing specimens after gyratory compaction and shaping in an oven at 85 °C referring to AASHTO R30. The aging duration was set as two days (48 h), five days (120 h), and eight days (192 h), respectively. To avoid the large deformation or collapsing of specimens, all the specimens were wrapped in foil paper and tied with rubber bands, as seen in

Figure 1. The foil paper was stabbed to generate small vents to allow heated air to circulate around the specimens.

3.2. Binder MSCR Test

The MSCR test was used in this study to evaluate the asphalt binder’s resistance to fatigue cracking. The test was performed by a dynamic shear rheometer (DSR) under shear creep and recovery at two stress levels at a specified temperature. The creep portion of the test lasts for 1 s at a constant stress, followed by a 9 recovery. The test was run at a stress level of 0.1 kPa for 20 cycles followed by 10 cycles at a stress level of 3.2 kPa. The test temperatures were 20 °C, 25 °C, and 30 °C. A lower test temperature, such as 15 °C, was also tried, but no smooth time-strain curve can be achieved for rubber and SBS modified binders, and thus the results at 15 °C were not included in this paper.

The MSCR test procedure and results calculation at an intermediate temperature followed AASHTO TP70 and AASHTO M322 exactly. Two parameters, non-recoverable creep compliance (

Jnr), and percent recovery (

R), could be determined. Only percent recovery (

R) was analyzed since

Jnr and

R was well correlated [

10]. Furthermore, this paper focuses on percent recovery at a stress level of 3.2 kPa (

R3.2) since a high stress level is more critical for cracking performance.

3.3. Binder PG Test

A binder high temperature PG and intermediate temperature PG test was performed according to AASHTO MP 1 and AASHTO T315 using (DSR). The binder low temperature PG test was performed in accordance with AASHTO T313 using the BBR method.

3.4. Binder Viscosity Test

Viscosity is the ratio between the applied shear stress and the rate of shear and is usually used to measure the resistance of asphalt to flow. The test was conducted following AASHTO T316 using the Rotational Viscometer (RV) method at temperatures of 65 °C and 135 °C. The original asphalt binder (as supplied) and aged residue from the TFOT were both tested. Test results were used to determine laboratory mixing and compaction temperatures based on the binder temperature-viscosity curve. The determined mixing and compaction temperatures are 175 °C and 170 °C for SBS and rubber modified asphalt, and 160 °C and 145 °C for the rest of the binders.

3.5. Binder Fracture Energy Test

Fracture energy was identified to characterize the fracture properties of different asphalt binders at the intermediate temperature based on the stress-strain curve. Previous studies have shown that the fracture energy at intermediate temperatures has a good correlation with the field bottom-up fatigue cracking [

11,

12,

13]. Binder fracture energy is defined as the area underneath the shear stress-shear strain curve up to the peak stress. The samples were tested in monotonic shear mode by DSR using a constant shear rate to load the samples continuously until shear stress was significantly reduced and approaching zero. The test was performed at 20 °C, 25 °C, and 30 °C using a shear rate of 0.2 s

−1.

3.6. Mixture SCB-IFIT Test

An SCB-IFIT test was adopted to evaluate the fatigue resistance of the asphalt mixture at the intermediate temperature. Although the flexibility index (

FI) is newly proposed, it is simple and showed potential to match well with field cracking performance [

10]. It was reported that the FI value was sensitive enough to distinguish various asphalt mixtures and asphalt contents [

13]. The test specimen size was 150 mm in diameter and 50 mm in thickness, with a 15-mm notch in depth. The air voids for all the specimens were controlled within 7 ± 0.5%. The specimens were conditioned in a chamber at 25 °C for 2 h before testing. A loading rate of 50 mm/min was applied. Equation (1) shows the equation used to calculate the FI value:

where,

FI—is the flexibility index;

Gf—is the fracture energy;

m—is the absolute value of m-value after peak load in the load-displacement curve; and

A—is a unit conversion factor and scaling coefficient (taken as 0.01).

3.7. Mixture IDT Test

A mixture fracture test was conducted at room temperature to evaluate fatigue cracking resistance ability according to AASHTO T322 using an indirect (IDT) method. Two parameters were used for material characterization purposes, including IDT strength and fracture work density. Fracture work density is defined as the fracture work divided by the specimen volume; fracture work is defined as the area underneath the tensile stress versus tensile strain curve up to the peak stress. It was found in previous study that the fracture work density could be a good indicator for field fatigue cracking: a higher fracture work density value correlated with a lower field crack amount [

11,

14]. The test specimen size was 100 mm in diameter and 38 mm in thickness. The air void for all the specimens were controlled within 7 ± 0.5%. The test was conducted at 25 °C at a loading rate of 50 mm/min.

4. Asphalt Binder Test Results Analysis

4.1. Binder PG and Viscosity

Table 3 shows the test results of binder PG and viscosity at different aging conditions. As shown, the modification of base asphalt was affected more for the high temperature PG compared to the low temperature PG: most modified binders experienced a similarly low PG with base binder, whereas the high temperature PG either increased or decreased to various extents depending on the additive utilized. The Evotherm 3G was the only additive that decreased the high temperature PG of base asphalt and the reason for this needs further study. Additionally, it is interesting to note that the SBS modification increased both high- and low-temperature PGs, which could be attributed to the crosslinked elastomer network structure of the SBS [

15].

In addition,

ΔTc, which quantifies the difference in continuous low temperature PG for stiffness and relaxation (

m-value) properties, was also calculated. Results indicate that all the binders exhibited positive

ΔTc values (ranged from 0.2 °C to 2.2 °C), except for the modified rubber asphalts (ranged from −0.1 °C to −1.5 °C), indicating that most asphalts were stiffness controlled. It was pointed out that the absolute values of

ΔTc smaller than 2.5 °C indicated a low potential of thermal cracking, whereas the threshold value of 2.5 °C was proposed based on a comparison between

ΔTc results and field thermal crack amount [

16].

Compared to the base binder, the addition of Sasobit and Evotherm reduced viscosity, whereas the addition of SBS and rubber increased viscosity. It is also seen that the viscosity increased after TFOT aging.

4.2. Binder MSCR Test Results

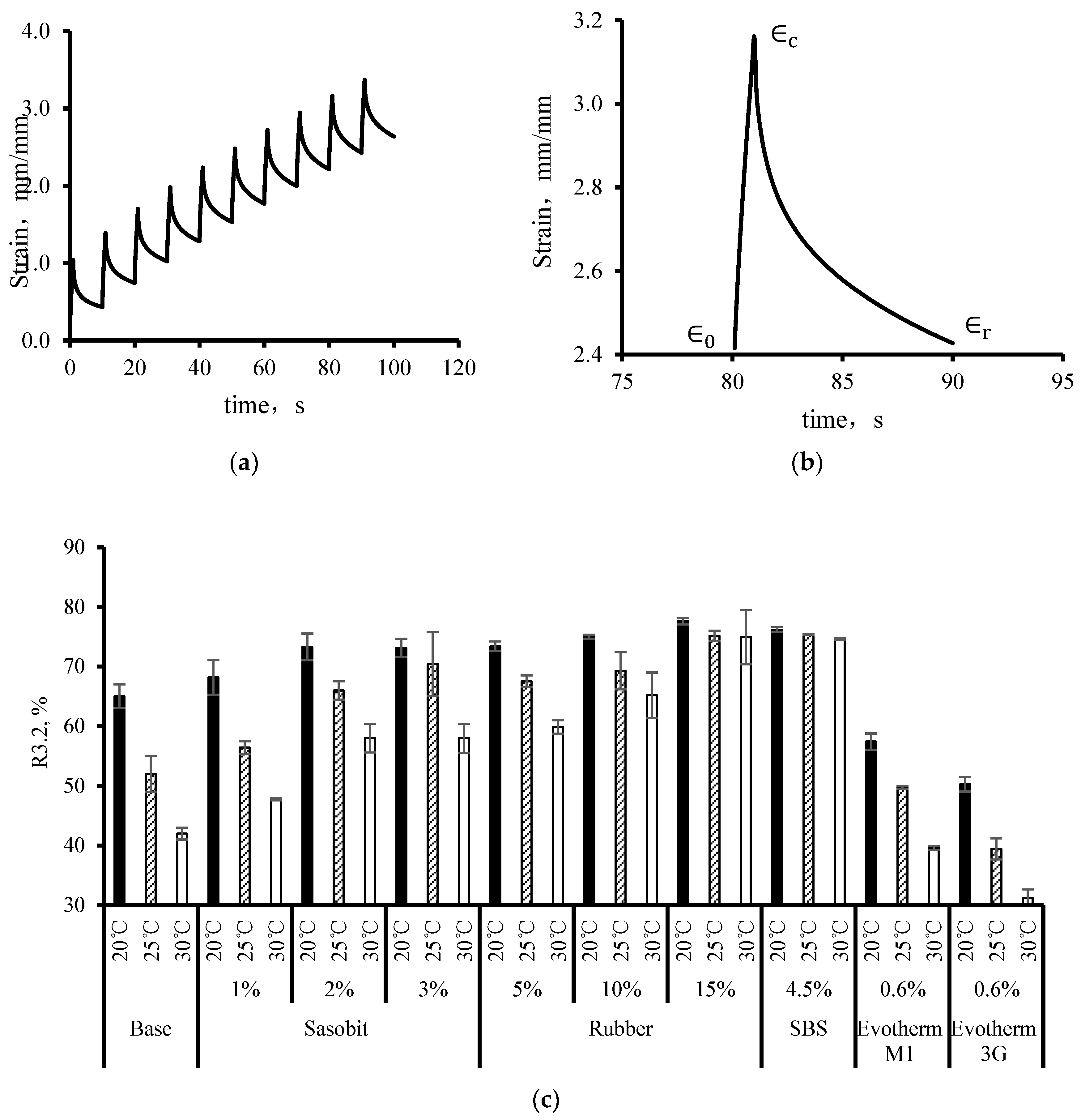

Figure 2a,b show the ten cycles of creep and data from recovery and test cycle number nine of MSCR testing at 25°C using TFOT/PAV aged base asphalt, respectively. As shown, the curves are fairly smooth with no jagged edges observed, indicating that the application of the MSCR test on fatigue resistance of asphalt binder is technically feasible without sacrificing data accuracy.

Figure 2c compares the MSCR

R3.2 among all the asphalt types based on the short-term TFOT aged binders. Error bars representing standard deviation of the results are also presented. It can be observed that the error bars are all in small values, representing good repetition of the test.

Additionally, the binders with 15% rubber and SBS hold high R3.2 values and were minorly affected by aging condition and temperature change. Although the asphalt property was very sensitive to the climatic condition, such sensitivity was diminished when SBS or a high content of rubber were applied to reform the base asphalt. In contrast, the Evotherm M1 and Evotherm 3G binders have the lowest R3.2 values and the results are greatly influenced by temperature alternation. The MSCR R3.2 values under TFOT/PAV aging showed exactly the same trend compared to TFOT aged binder with a slight increase of R3.2 values.

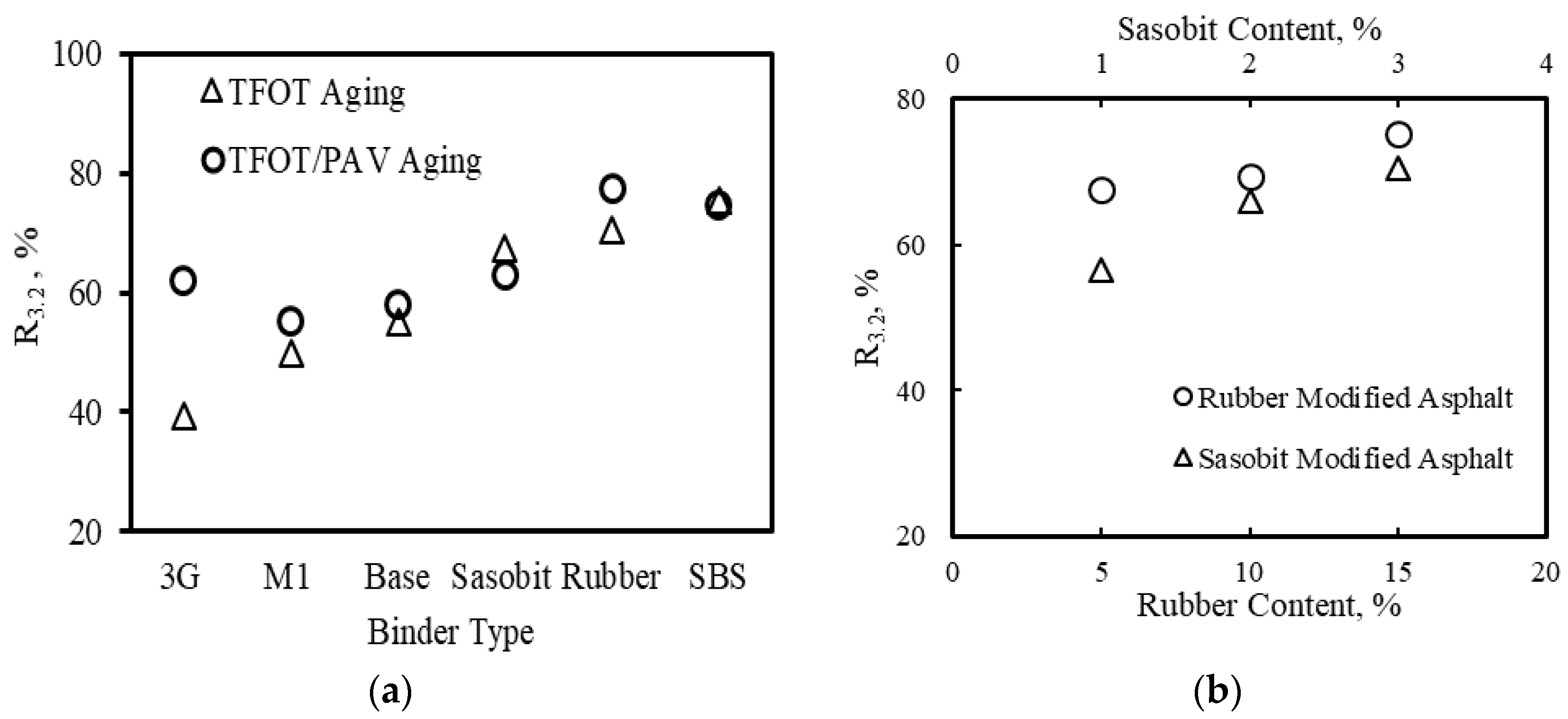

Figure 3a,b show the sensitivity of MSCR

R3.2 to asphalt binder type and additive content at a testing temperature of 25 °C. By visual observation, the MSCR

R3.2 was sensitive enough to distinguish different binder types and additive contents. A statistical t-test was conducted with a significance level of 0.05 between any two binder types in

Figure 3a, or between any two additive contents in

Figure 3b. Results indicate that except for the rubber-SBS pair (as shown in

Figure 3a) and 5% rubber −10% rubber pair (as shown in

Figure 3b), all the other pairs were statistically different.

Additionally,

Figure 3a shows that the MSCR

R3.2 values between TFOT aging and TFOT/PAV aging are almost overlapping except for the Evotherm 3G binder. Such a finding indicates the potential that the Evotherm 3G could experience a fast aging rate, as specified elsewhere [

17].

4.3. Binder Fracture Energy

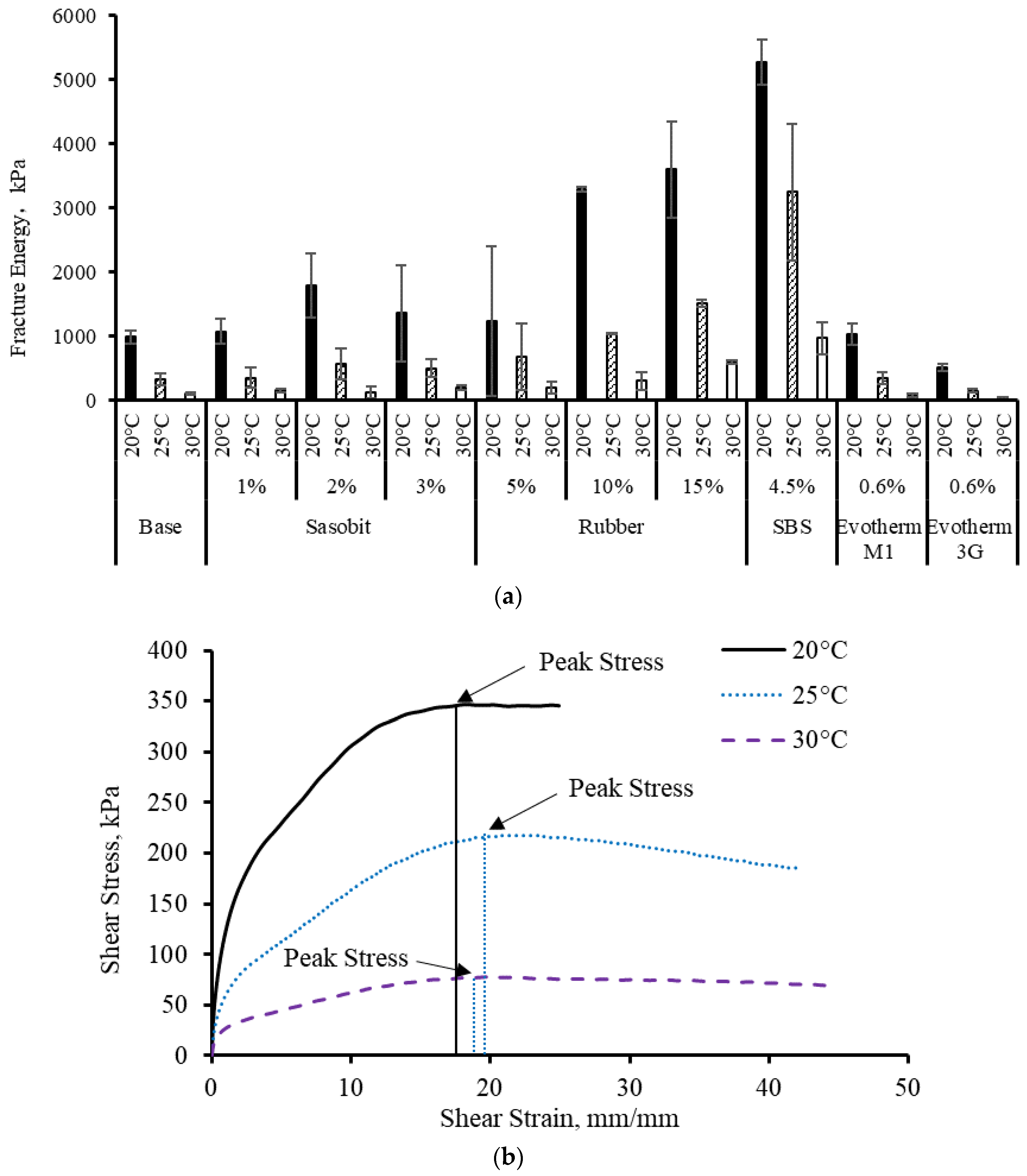

The binder fracture energy test results under TFOT aging are shown in

Figure 4a. It is seen that the trend between binder MSCR

R3.2 and fracture energy matched well. Specifically, the SBS modified binders showed the highest MSCR

R3.2 and fracture energy values, whereas the Evotherm M1 and 3G binders displayed the lowest magnitudes.

Additionally, the fracture energy value of the SBS modified binder was obviously altered per temperature change. The plot between shear strain and shear stress that was used to calculate fracture energy was checked, as shown in

Figure 4b. It is seen that the shear strains corresponding to the maximum shear stresses are close to each other, whereas the maximum shear stress values decreased with increased temperature. Thus, the reduced fracture energy for SBS modified binders at an elevated temperature was majorly caused by declined maximum shear stress.

The above analysis shows that the MSCR testing at intermediate temperatures is sensitive enough to differentiate various binder types and additive contents with good repetitions. Next, asphalt mixture SCB-IFIT and IDT testing were conducted to check if the asphalt MSCR test has a similar ranking with a mixture fatigue test. The SBS modified asphalt binder showed the best fracture resistance in the asphalt MSCR and fracture test, and was accordingly selected as the binder used in the mixture tests. Base binder was also selected as the control. Different aging durations of loose mix or compacted specimens were considered to evaluate if the relationship between asphalt MSCR and mixture fracture tests was stable under different oxidative conditions.

5. Asphalt Mixture Test Results Analysis

In the laboratory, the testing specimens using both base asphalt and SBS binder were fabricated using gyratory compaction, and were further cut into a proper size for testing. The volumetric information, such as air void and void in mineral aggregate (VMA), were checked. These specimens were aged under both short-term and long-term conditions, as discussed above.

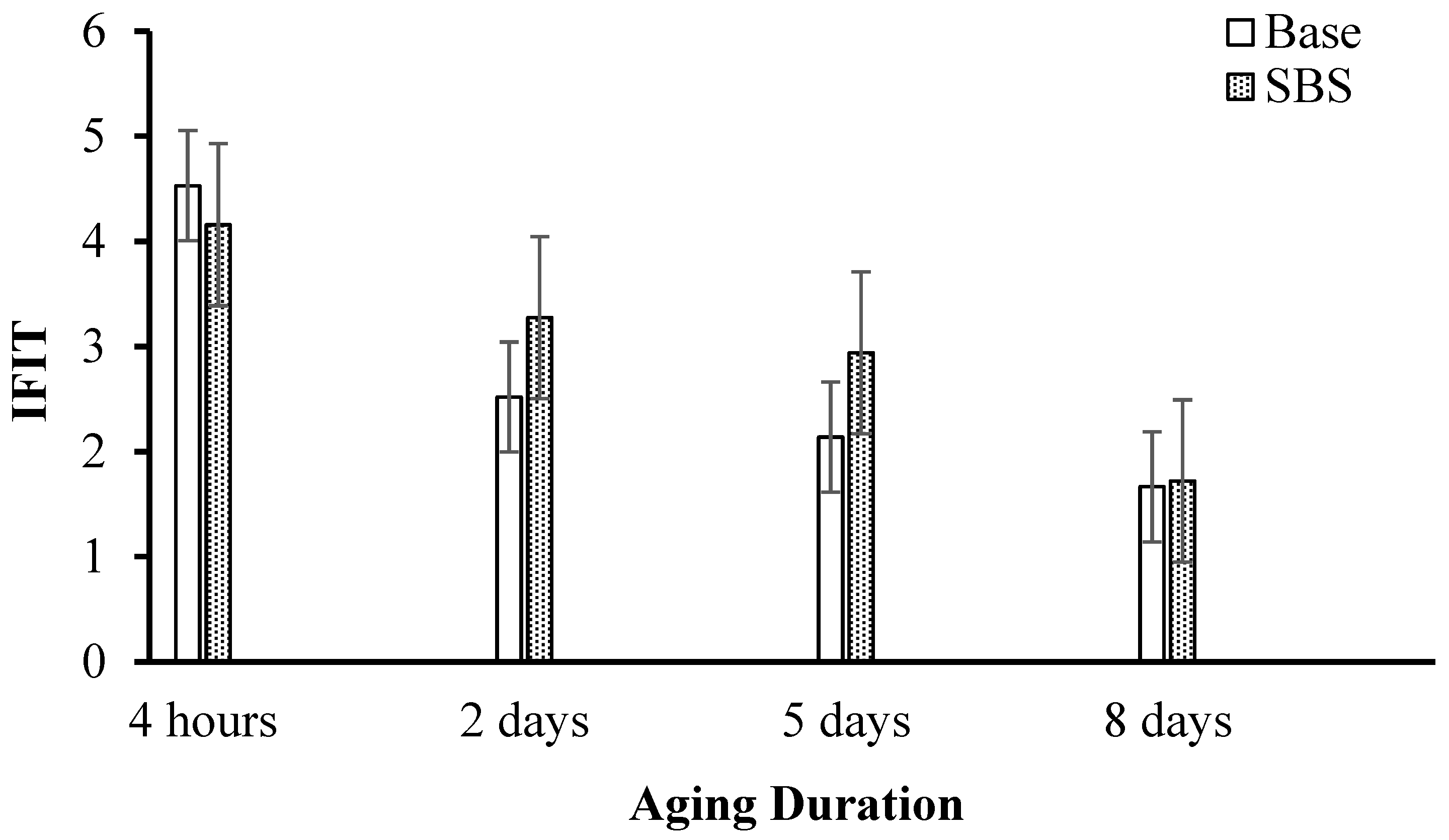

5.1. SCB-IFIT Test

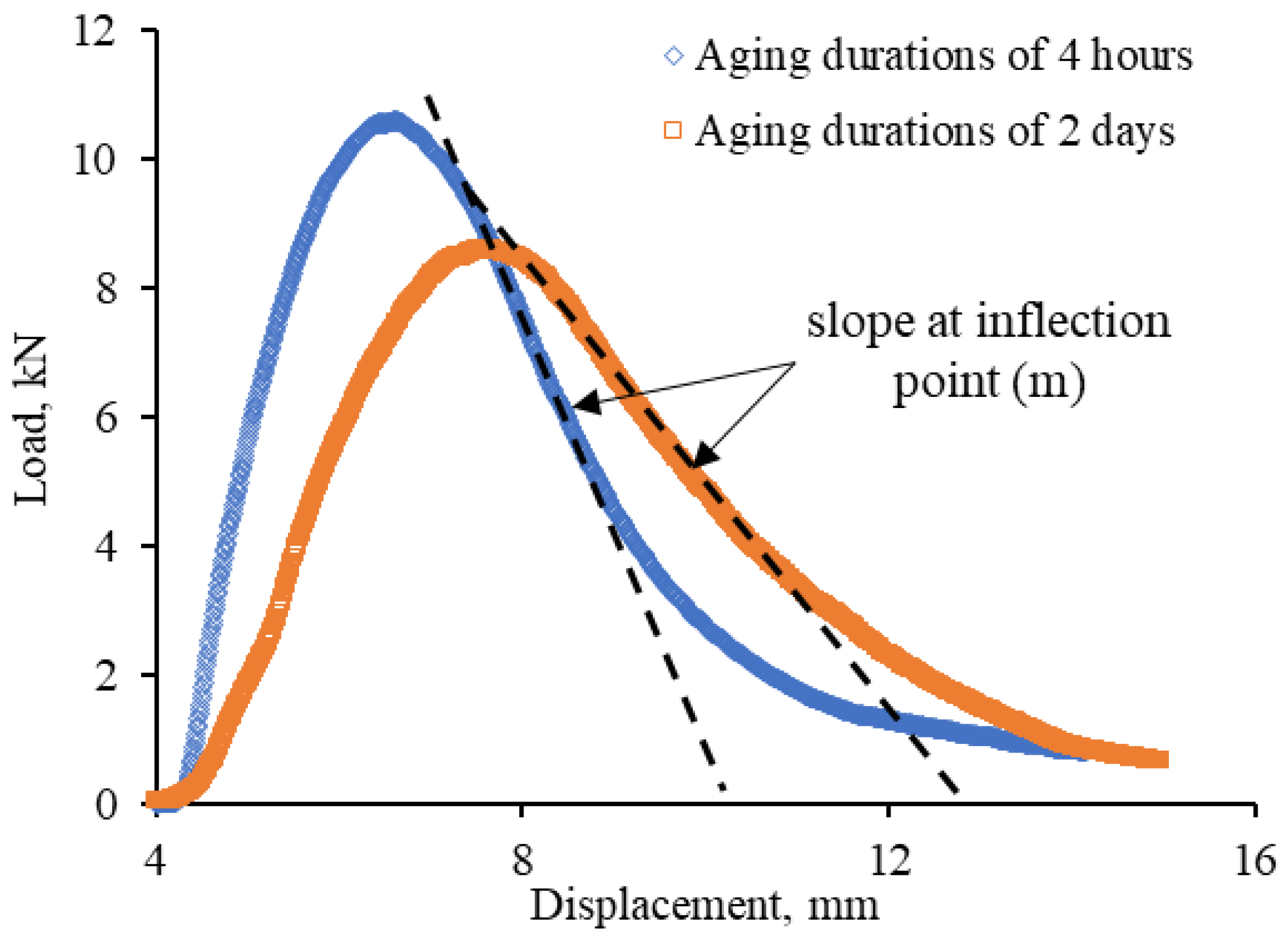

Figure 5 shows an example of the SCB-IFIT results using SBS modified binder based on the aging durations of 4 h and two days. As seen, the fracture energy (

Gf) in equation (1) is defined as the area underneath the entire curve, and the

m-value is the slope at the inflection point after peak load.

Figure 6 compares the testing results of SCB-IFIT for the asphalt mixtures using #70 and SBS modified binders at various aging durations. The figure shows a clear trend that the

FI values decreased for both binders with a longer aging duration, and thus cracking resistance is reduced. It is also observed that the asphalt mixture using #70 asphalt decreased faster in

FI in contrast to the specimen with SBS modified binders, especially between two aging durations. The fact that the SBS modified asphalt mixture aged less than base asphalt was also found by previous studies [

17,

18,

19].

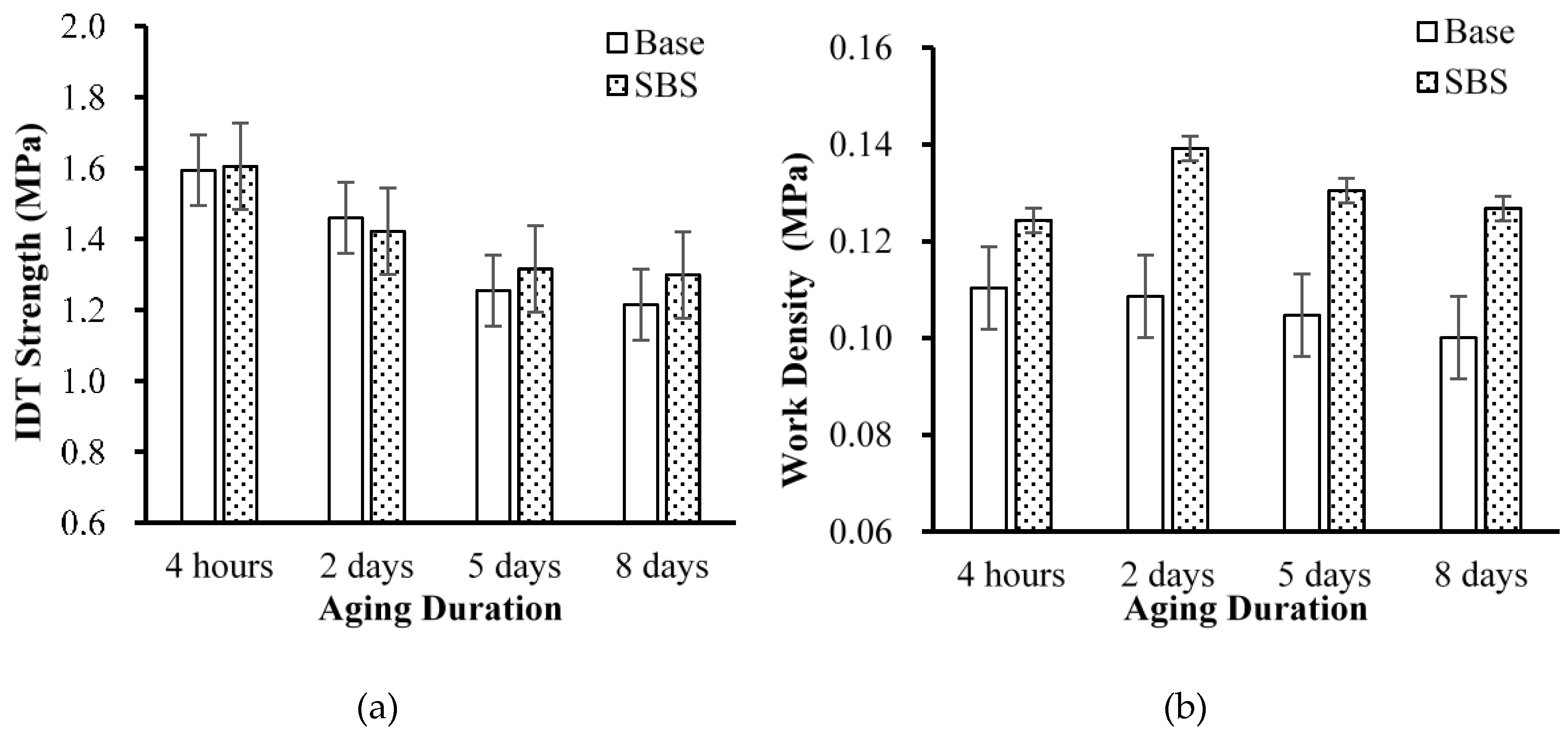

5.2. IDT Fracture Test

Test results of tensile strength and fracture work density under different aging conditions are shown in

Figure 7a,b, respectively. As seen, the IDT strength which only considers peak load was gradually decreased with aging, indicating the decreased cracking resistance.

Figure 7b shows that the fracture work density of asphalt mixture using #70 base asphalt decreased with aging time, indicating the reduced cracking resistance. In contrast, the fracture work density of the SBS modified asphalt mixture slightly increased at the end of eight days’ aging, which validates the field observation that SBS modified binder was less affected by aging compared to the control asphalt [

17]. Fracture work density combines the strength and ductility of a mixture, and since the IDT strength of both mixtures decreased over aging, it is reasonable to assume that the ductility of mixture using SBS modified binders could be higher than the mixture with base asphalt.

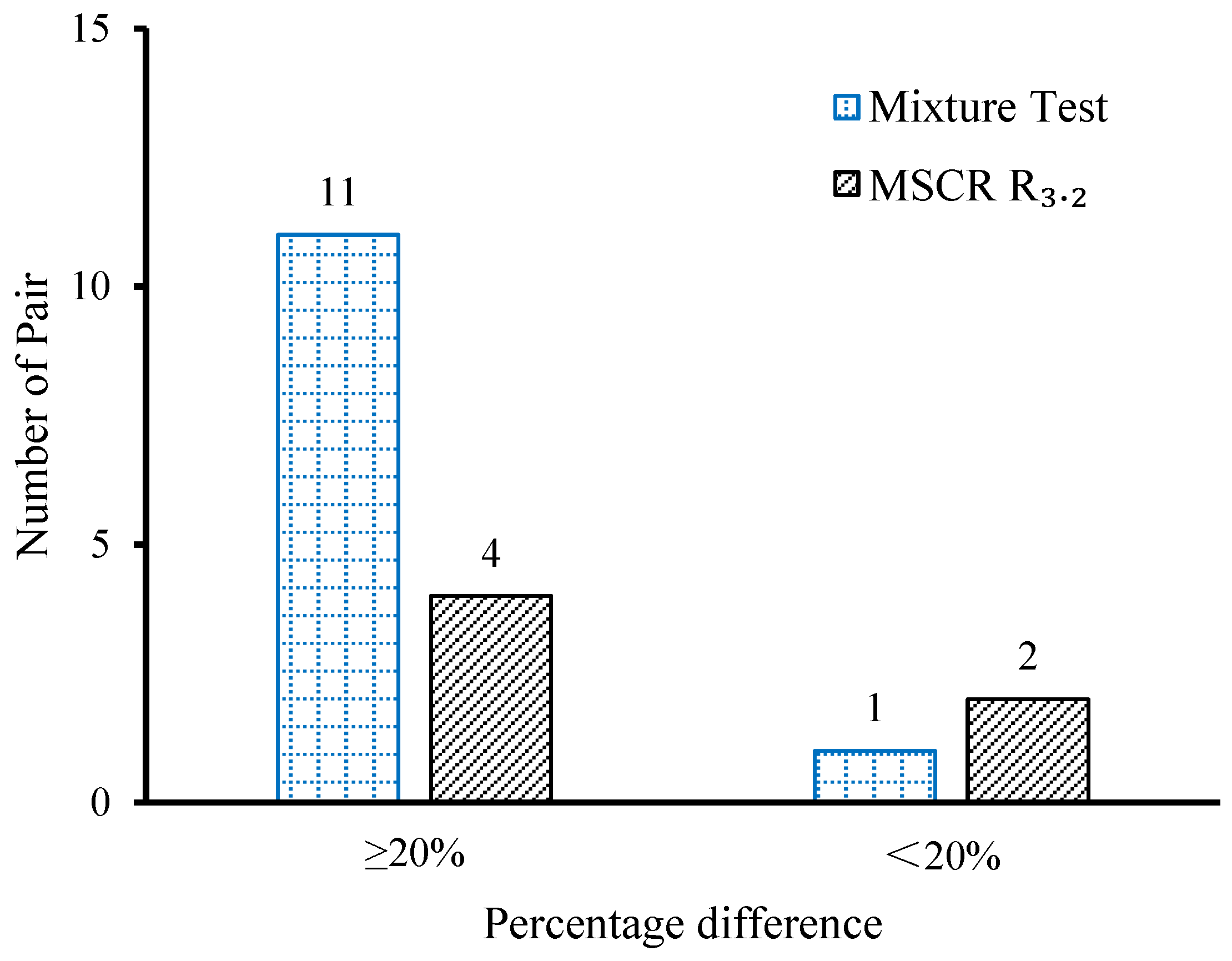

6. Ranking between Binder MSCR and Mixture Testing

A paired ranking method was used to determine if the binder MSCR test matched well with the mixture’s fatigue test. The method follows three steps: compare the MSCR results between base asphalt and SBS modified asphalt at different temperature and aging conditions and obtain a ranking (base asphalt ≥ SBS, or base asphalt < SBS, six comparisons in total); compare mixture testing between base asphalt and SBS modified asphalt at different aging conditions and obtain a ranking (base ≥ SBS, or base < mixture with SBS modified asphalt base asphalt < SBS, 12 comparisons in total). Then, the binder and mixture’s ranking results were compared.

The percent difference criterion was used for the ranking purpose. It is suggested based on engineering experience that if the percent difference was within 20%, then there was no significant difference between the pair [

20]. Otherwise, whichever mean value was higher indicated more/less crack resistance. Results are shown in

Figure 8. As seen, four out of six MSCR pairs showed a percentage difference over 20%, sharing the same trend with mixture ranking in which 11 out of 12 pairs showed a percentage difference over 20%. In contrast, one pair from the MSCR test and two pairs from mixtures’ test experienced a percentage difference less than 20%.

7. Summary of Findings

In this study, the applicability of the MSCR test on fatigue resistance of asphalt binder was evaluated. Six binder types with different modifications and additive contents were utilized. Mixture tests were also conducted to evaluate if the MSCR test could represent mixture fatigue performance. Based on the analysis, the following conclusions can be drawn:

The binder MSCR test can be conducted at intermediate temperatures (20 °C or higher) with a smooth data curve and good repetitions. However, testing temperatures at 15 °C or lower may result in a steep curve and needs to be performed with more caution.

The binder MSCR test at intermediate temperatures was sensitive enough to differentiate binder type and additive content at different aging durations.

The binder MSCR test at intermediate temperatures showed a similar ranking to the mixture’s fatigue test, indicating that the binder MSCR test could be potentially utilized to represent a mixture’s fatigue resistance where binder selection is a major concern.

The binder MSCR test, with binder fracture energy test and mixture’s tests, all proved that the SBS modified binder was less affected by aging and showed excellent performance in improving the mixture’s durability.

The above conclusions indicate that the MSCR test could be a promising method to evaluate the fracture properties of asphalt mixture. Further study on the correlation between MSCR and any field test roads could be necessary.

8. Clarification

This study focused on one specific aggregate gradation with six different binder types and varying aging conditions. The application of the MSCR test on quantifying the fatigue resistance of other materials such as recycled asphalt pavement (RAP) and porous pavements may need further investigation. This paper provides a framework which can be modified and implemented by local agencies for a variety of material types based on their needs and requirements.