Thermoelectric Cooling-Aided Bead Geometry Regulation in Wire and Arc-Based Additive Manufacturing of Thin-Walled Structures

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

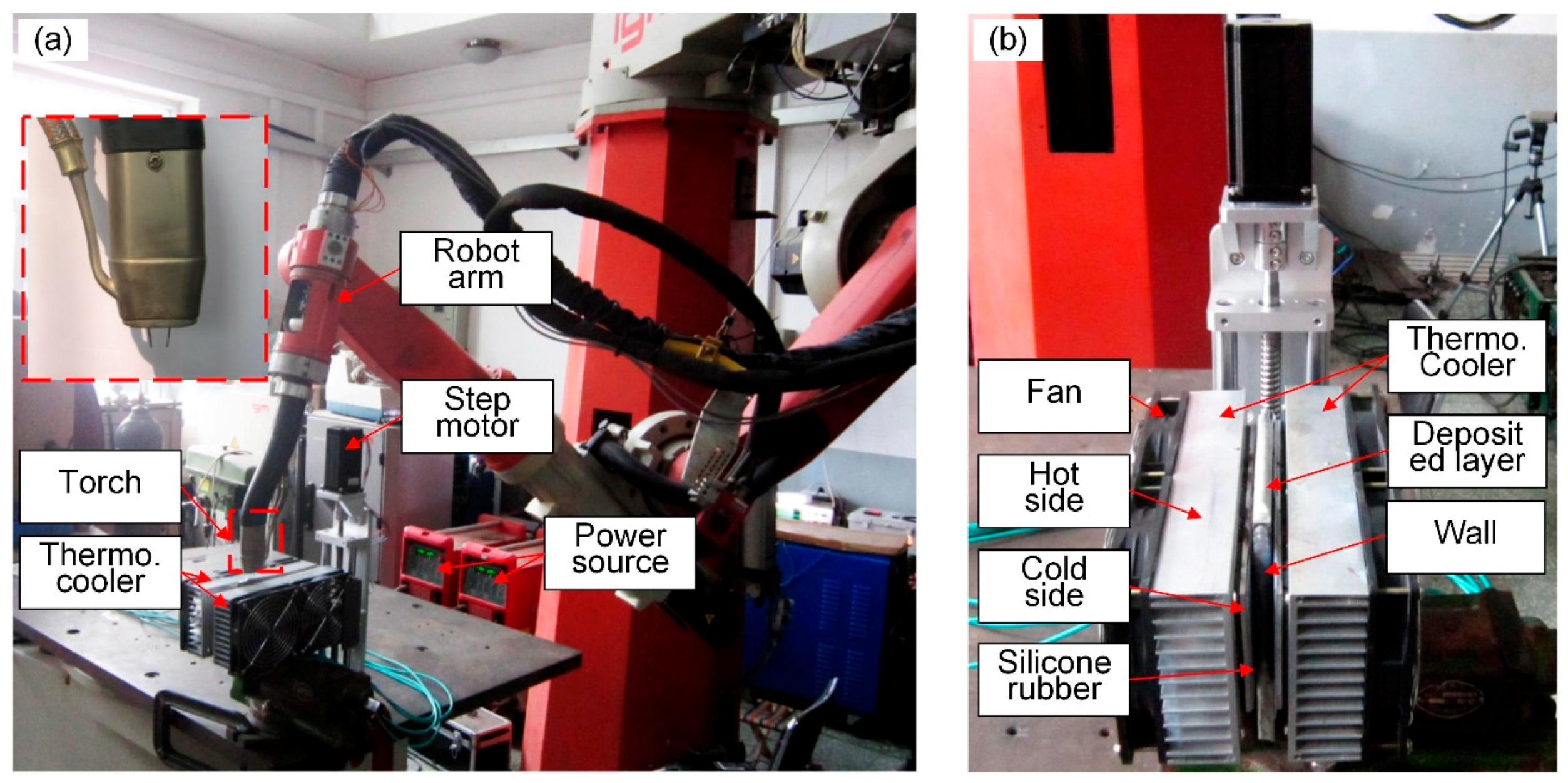

2.1. Experimental Setup

2.2. In-Process Active Cooling System

2.3. Experimental Design

3. Results and Discussion

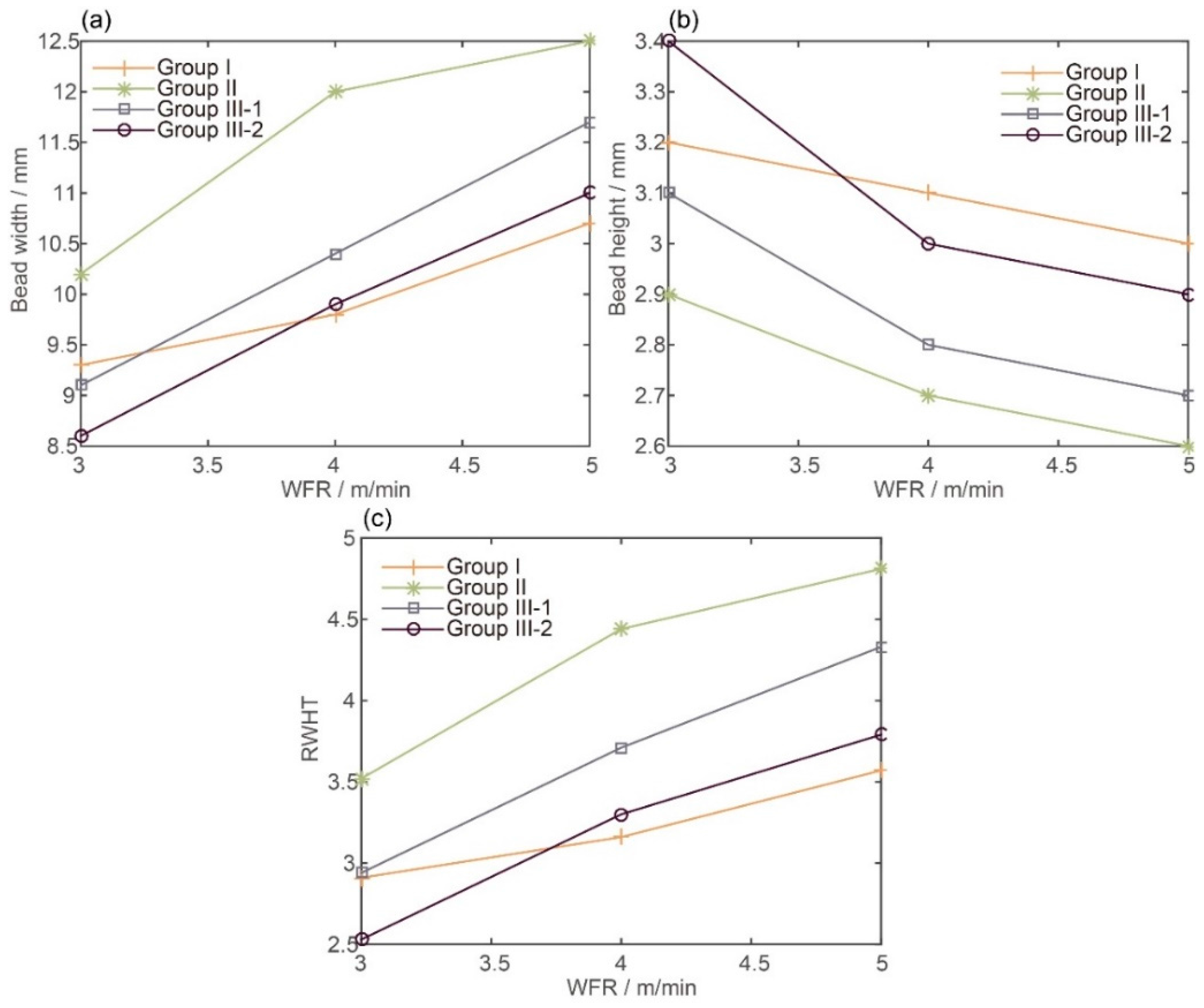

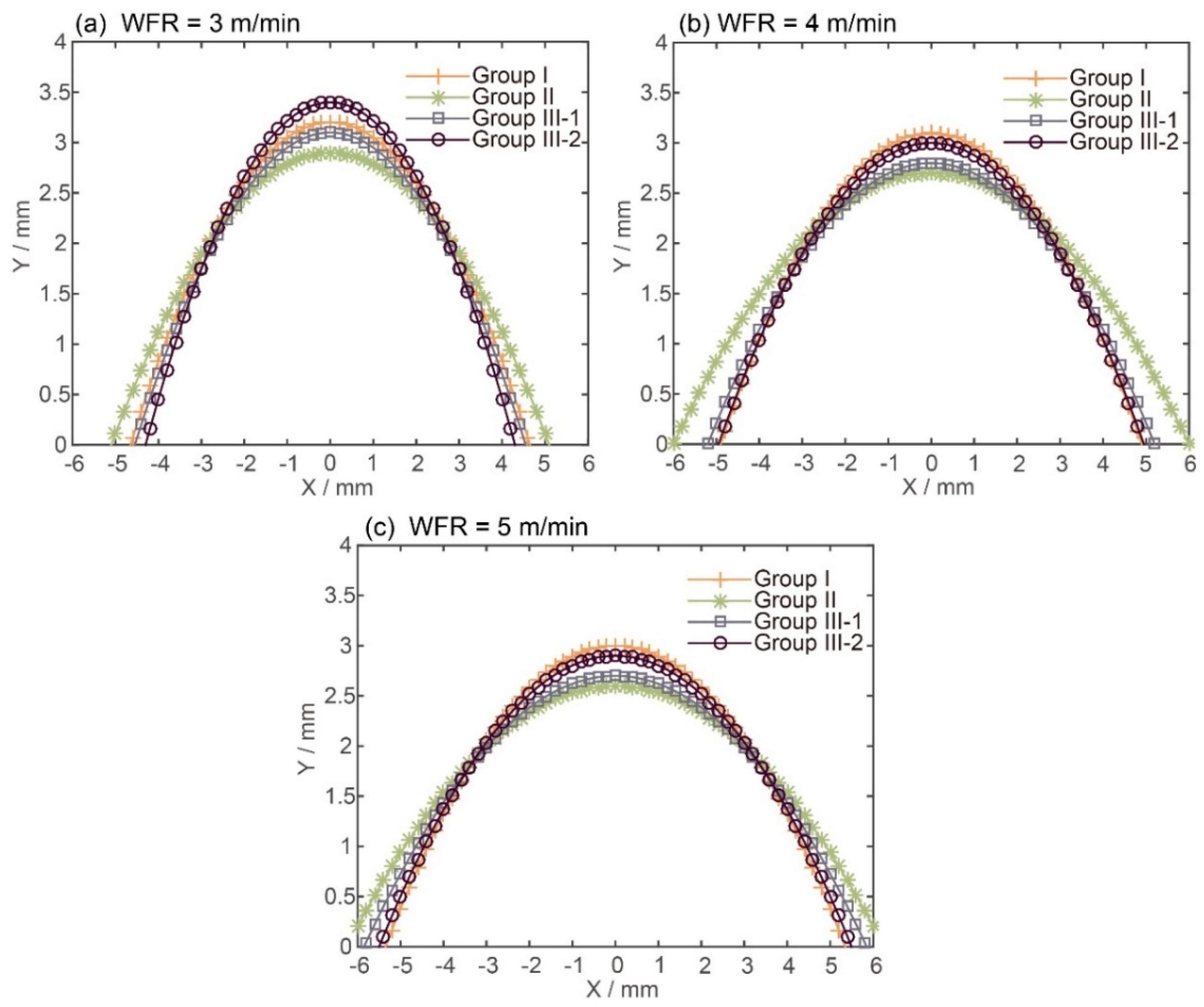

3.1. Effect of Heat Input on the Bead Geometry

3.2. Effect of Wall Height on the Bead Geometry

3.3. Effect of Heat Dissipation on the Bead Geometry

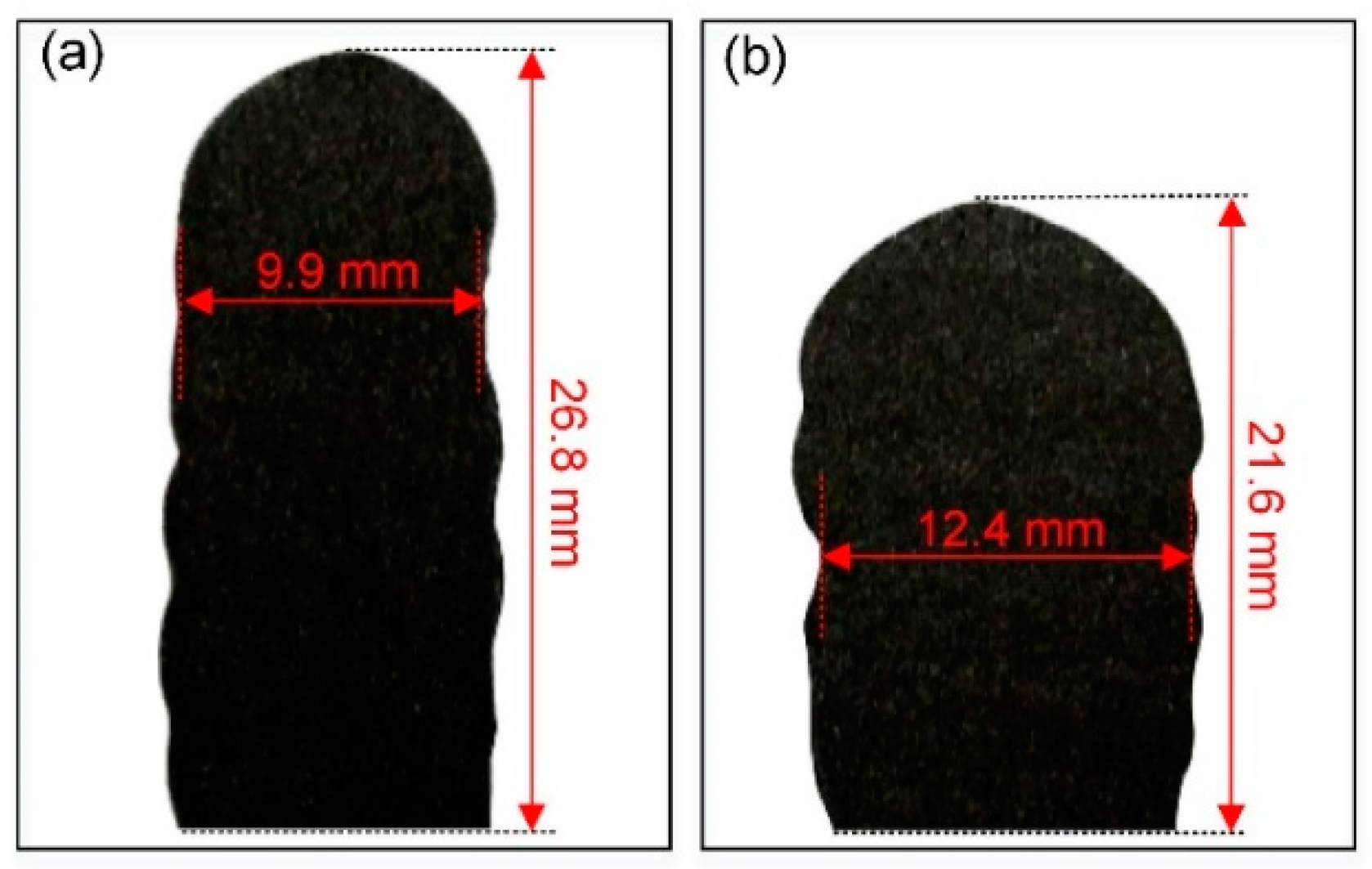

3.4. Case Study

4. Conclusions

- (1)

- The upper and the lower layers could experience a similar heat dissipation condition with the aid of thermoelectric cooling, therefore resulting in similar thermal cycling, molten pool shape, and, ultimately, bead geometry with no need to adjust the process parameters. The case study shows a decrease of 56.8% in bead width error and an increase of 16.3% in material utilization.

- (2)

- The productivity of the WAAM process can be significantly improved with thermoelectric cooling, due to not only the increased ratio of bead height to bead width, but also the reduced interlayer dwell time. The case study shows a decrease of 60.9% in total fabrication time.

- (3)

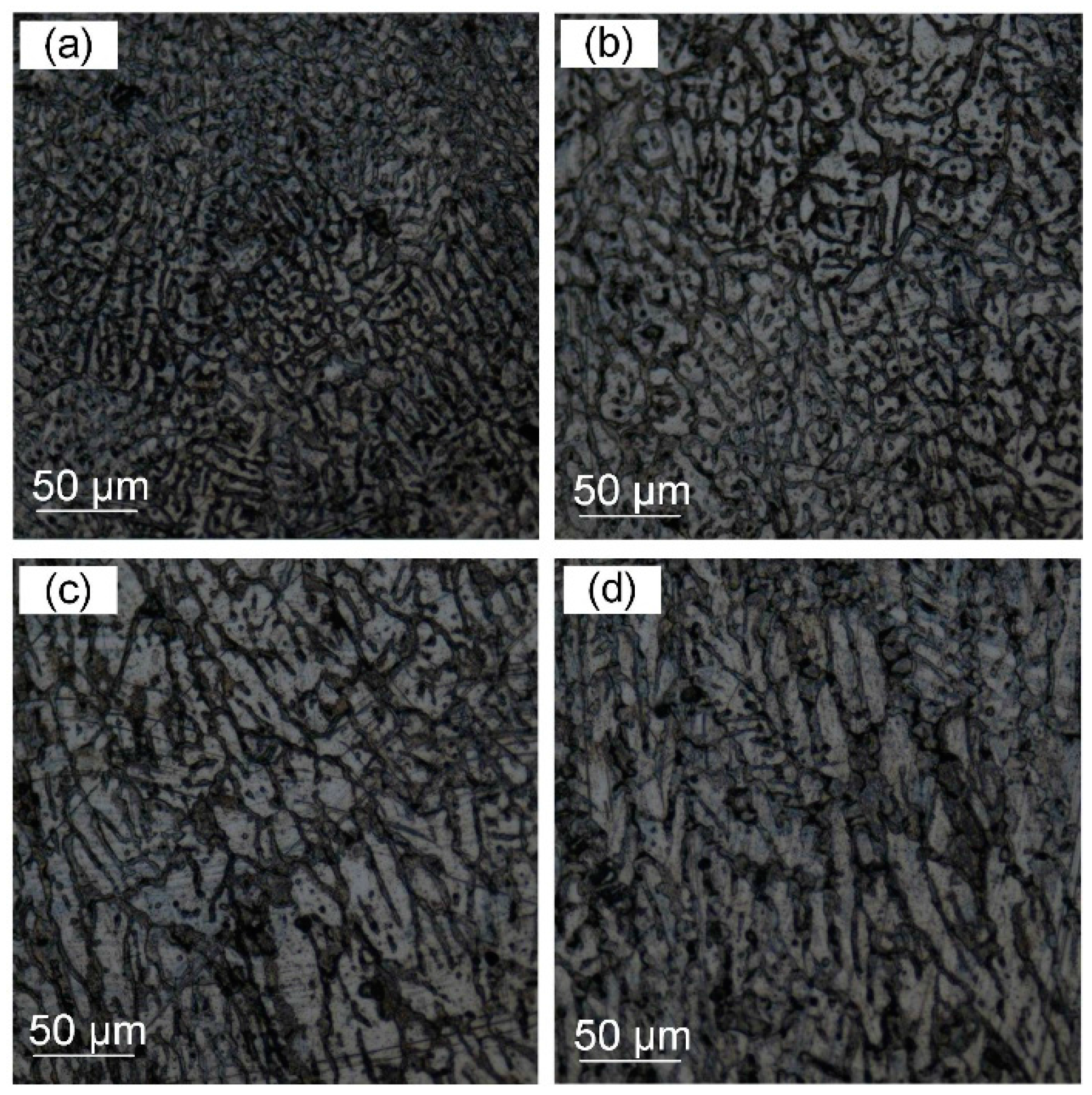

- Much finer microstructures can be obtained in the middle parts of the deposited walls, and are attributed to the increased cooling rate. The average grain size is reduced from 7.96 μm to 5.97 μm.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for additive manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An overview of additive manufacturing of titanium components by directed energy deposition: Microstructure and mechanical properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Zhong, Y.; Rännar, L.E.; Wikman, S.; Koptyug, A.; Liu, L.; Cui, D.; Shen, Z. Additive manufacturing of ITER first wall panel parts by two approaches: Selective laser melting and electron beam melting. Fusion Eng. Des. 2017, 116, 24–33. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Pan, Z.; Ding, D.; Wu, B.; Cuiuri, D.; Li, H.; Norrish, J. Arc Welding Processes for Additive Manufacturing: A Review. In Transactions on Intelligent Welding Manufacturing; Chen, S., Zhang, Y., Feng, Z., Eds.; Springer: Singapore, 2017; Volume 1, pp. 3–24. ISBN 978-981-10-5355-9. [Google Scholar]

- Xu, X.; Ding, J.; Ganguly, S.; Diao, C.; Williams, S. Oxide accumulation effects on wire + arc layer-by-layer additive manufacture process. J. Mater. Process. Technol. 2017, 252, 739–750. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A tool-path generation strategy for wire and arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2014, 73, 173–183. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2016, 7, 641–647. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot. Comput. Integr. Manuf. 2015, 34, 8–19. [Google Scholar] [CrossRef]

- Li, F.; Chen, S.; Shi, J.; Tian, H.; Zhao, Y. Evaluation and optimization of a hybrid manufacturing process combining wire arc additive manufacturing with milling for the fabrication of stiffened panels. Appl. Sci. 2017, 7, 1233. [Google Scholar] [CrossRef]

- Michaleris, P. Modeling metal deposition in heat transfer analyses of additive manufacturing processes. Finite Elem. Anal. Des. 2014, 86, 51–60. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, G.; Yin, Z.; Wu, L. A 3D dynamic analysis of thermal behavior during single-pass multi-layer weld-based rapid prototyping. J. Mater. Process. Technol. 2011, 211, 488–495. [Google Scholar] [CrossRef]

- Wu, B.; Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; Han, J.; Fei, Z. Effects of heat accumulation on the arc characteristics and metal transfer behavior in wire arc additive manufacturing of Ti6Al4V. J. Mater. Process. Technol. 2017, 250, 304–312. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Hu, J.; Wu, L. Bead geometry prediction for robotic GMAW-based rapid manufacturing through a neural network and a second-order regression analysis. J. Intell. Manuf. 2014, 25, 157–163. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, W.; Ouyang, J.; Kovacevic, R. Rapid prototyping of 4043 al-alloy parts by VP-GTAW. J. Mater. Process. Technol. 2004, 148, 93–102. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X. Optimisation of interpass temperature and heat input for wire and arc additive manufacturing 5A06 aluminium alloy. Sci. Technol. Weld. Join. 2017, 22, 472–483. [Google Scholar] [CrossRef]

- Xiong, J.; Yin, Z.; Zhang, W. Closed-loop control of variable layer width for thin-walled parts in wire and arc additive manufacturing. J. Mater. Process. Technol. 2016, 233, 100–106. [Google Scholar] [CrossRef]

- Sproesser, G.; Chang, Y.J.; Pittner, A.; Finkbeiner, M.; Rethmeier, M. Environmental energy efficiency of single wire and tandem gas metal arc welding. Weld. World 2017, 61, 733–743. [Google Scholar] [CrossRef]

- Zhao, D.; Tan, G. A review of thermoelectric cooling: Materials, modeling and applications. Appl. Therm. Eng. 2014, 66, 15–24. [Google Scholar] [CrossRef]

- Meng, J.H.; Wang, X.D.; Zhang, X.X. Transient modeling and dynamic characteristics of thermoelectric cooler. Appl. Energy 2013, 108, 340–348. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; Duin, S.V.; Larkin, N. Bead modelling and implementation of adaptive MAT path in wire and arc additive manufacturing. Robot. Comput. Integr. Manuf. 2016, 39, 32–42. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Gao, H.; Wu, L. Modeling of bead section profile and overlapping beads with experimental validation for robotic GMAW-based rapid manufacturing. Robot. Comput. Integr. Manuf. 2013, 29, 417–423. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Zhang, W. Forming appearance analysis in multi-layer single-pass GMAW-based additive manufacturing. Int. J. Adv. Manuf. Technol. 2015, 80, 1767–1776. [Google Scholar] [CrossRef]

- Nikam, S.H.; Jain, N.K.; Jhavar, S. Thermal modeling of geometry of single-track deposition in micro-plasma transferred arc deposition process. J. Mater. Process. Technol. 2016, 230, 121–130. [Google Scholar] [CrossRef]

- Easton, M.A.; Stjohn, D.H. Improved prediction of the grain size of aluminum alloys that includes the effect of cooling rate. Mater. Sci. Eng. A 2008, 486, 8–13. [Google Scholar] [CrossRef]

- Cong, B.; Qi, Z.; Qi, B.; Sun, H.; Zhao, G.; Ding, J. A comparative study of additively manufactured thin wall and block structure with Al-6.3%Cu alloy using cold metal transfer process. Appl. Sci. 2017, 7, 275. [Google Scholar] [CrossRef]

| Run No. | Group No. | Heat Dissipation Conditions | Process Parameters | ||||

|---|---|---|---|---|---|---|---|

| WFR (m/min) | TS (m/min) | U (V) | I (A) | Cooling Power | |||

| 1 | I | Flat substrate + conduction | 3 | 0.3 | 130 | 17.9 | - |

| 2 | 4 | 0.4 | 176 | 18.6 | - | ||

| 3 | 5 | 0.5 | 222 | 19.5 | - | ||

| 4 | II | Wall + convection & radiation | 3 | 0.3 | 130 | 17.9 | - |

| 5 | 4 | 0.4 | 176 | 18.6 | - | ||

| 6 | 5 | 0.5 | 222 | 19.5 | - | ||

| 7 | III-1 | Wall + thermoelectric cooling | 3 | 0.3 | 130 | 17.9 | 240 W |

| 8 | 4 | 0.4 | 176 | 18.6 | 240 W | ||

| 9 | 5 | 0.5 | 222 | 19.5 | 240 W | ||

| 10 | III-2 | 3 | 0.3 | 130 | 17.9 | 360 W | |

| 11 | 4 | 0.4 | 176 | 18.6 | 360 W | ||

| 12 | 5 | 0.5 | 222 | 19.5 | 360 W | ||

| Run No. | Sample 1 | Sample 2 | Sample 3 | Maximum Error | ||||

|---|---|---|---|---|---|---|---|---|

| Width (mm) | Height (mm) | Width (mm) | Height (mm) | Width (mm) | Height (mm) | Width (mm) | Height (mm) | |

| 1 | 9.27 | 3.27 | 9.34 | 3.23 | 9.48 | 3.16 | 0.21 | 0.11 |

| 2 | 9.66 | 3.18 | 9.83 | 3.11 | 10.01 | 3.03 | 0.35 | 0.15 |

| 3 | 10.55 | 3.09 | 10.71 | 3.02 | 10.95 | 2.91 | 0.40 | 0.18 |

| 4 | 10.11 | 2.97 | 10.22 | 2.94 | 10.36 | 2.89 | 0.25 | 0.08 |

| 5 | 11.85 | 2.79 | 12.04 | 2.74 | 12.33 | 2.59 | 0.48 | 0.20 |

| 6 | 12.44 | 2.66 | 12.52 | 2.63 | 12.66 | 2.57 | 0.22 | 0.09 |

| 7 | 9.01 | 3.17 | 9.15 | 3.13 | 9.54 | 3.03 | 0.53 | 0.14 |

| 8 | 10.32 | 2.88 | 10.43 | 2.85 | 10.67 | 2.71 | 0.35 | 0.17 |

| 9 | 11.57 | 2.77 | 11.74 | 2.74 | 12.21 | 2.66 | 0.64 | 0.11 |

| 10 | 8.49 | 3.45 | 8.63 | 3.42 | 8.96 | 3.31 | 0.47 | 0.14 |

| 11 | 9.86 | 3.05 | 9.96 | 3.01 | 10.35 | 2.90 | 0.49 | 0.15 |

| 12 | 10.80 | 2.96 | 11.02 | 2.91 | 11.54 | 2.73 | 0.74 | 0.23 |

| Indicator | Convection + Radiation | Thermoelectric Cooling | Relative Error |

|---|---|---|---|

| Bead width error | 4.4 mm | 1.9 mm | −56.8% |

| Material utilization | 64.5% | 80.8% | +16.3% |

| Number of layers | 46 | 37 | −19.6% |

| Deposition time | 690 s | 555 s | −19.6% |

| Cooling time | 8100 s | 2880 s | −64.4% |

| Total time | 8790 s | 3435 s | −60.9% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Chen, S.; Shi, J.; Zhao, Y.; Tian, H. Thermoelectric Cooling-Aided Bead Geometry Regulation in Wire and Arc-Based Additive Manufacturing of Thin-Walled Structures. Appl. Sci. 2018, 8, 207. https://doi.org/10.3390/app8020207

Li F, Chen S, Shi J, Zhao Y, Tian H. Thermoelectric Cooling-Aided Bead Geometry Regulation in Wire and Arc-Based Additive Manufacturing of Thin-Walled Structures. Applied Sciences. 2018; 8(2):207. https://doi.org/10.3390/app8020207

Chicago/Turabian StyleLi, Fang, Shujun Chen, Junbiao Shi, Yun Zhao, and Hongyu Tian. 2018. "Thermoelectric Cooling-Aided Bead Geometry Regulation in Wire and Arc-Based Additive Manufacturing of Thin-Walled Structures" Applied Sciences 8, no. 2: 207. https://doi.org/10.3390/app8020207

APA StyleLi, F., Chen, S., Shi, J., Zhao, Y., & Tian, H. (2018). Thermoelectric Cooling-Aided Bead Geometry Regulation in Wire and Arc-Based Additive Manufacturing of Thin-Walled Structures. Applied Sciences, 8(2), 207. https://doi.org/10.3390/app8020207