Intrinsic Magnetic Properties of Ce2Fe14B Modified by Al, Ni, or Si

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

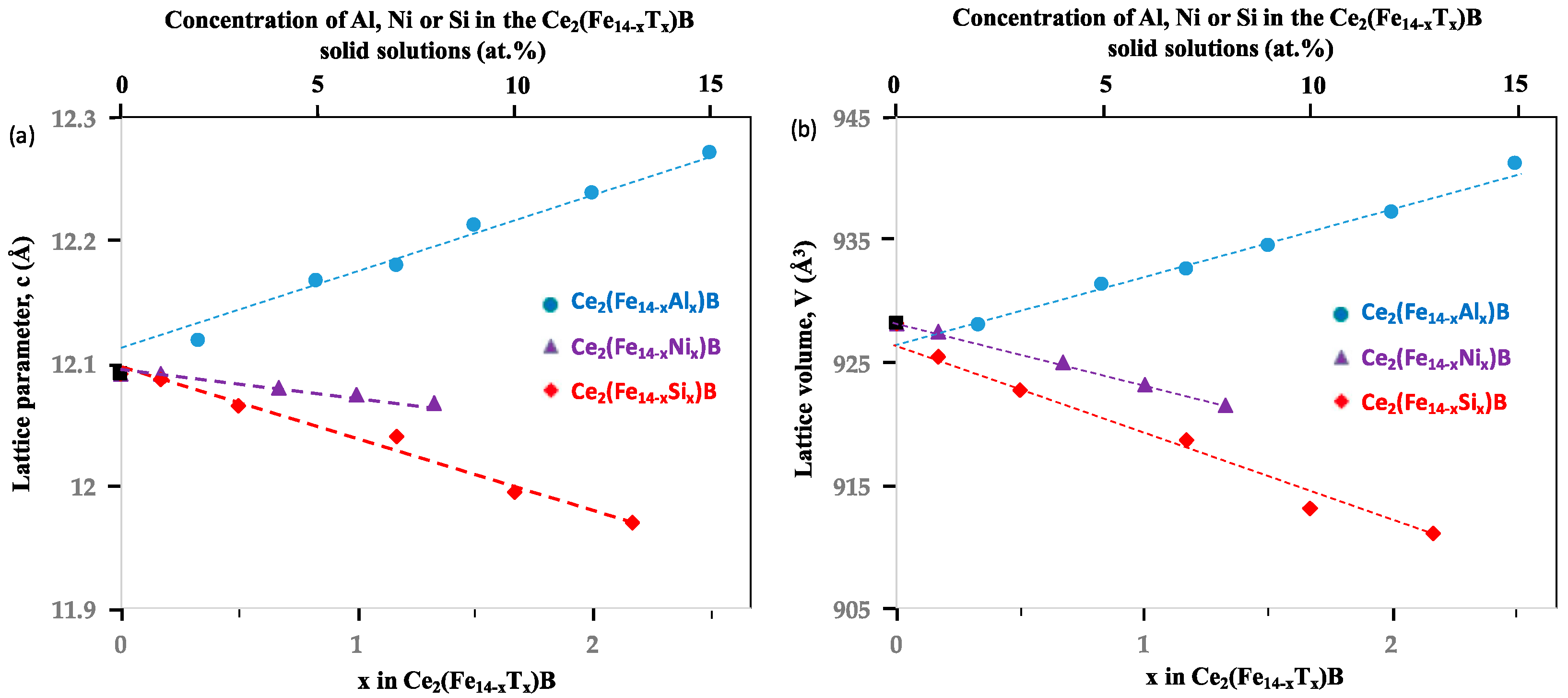

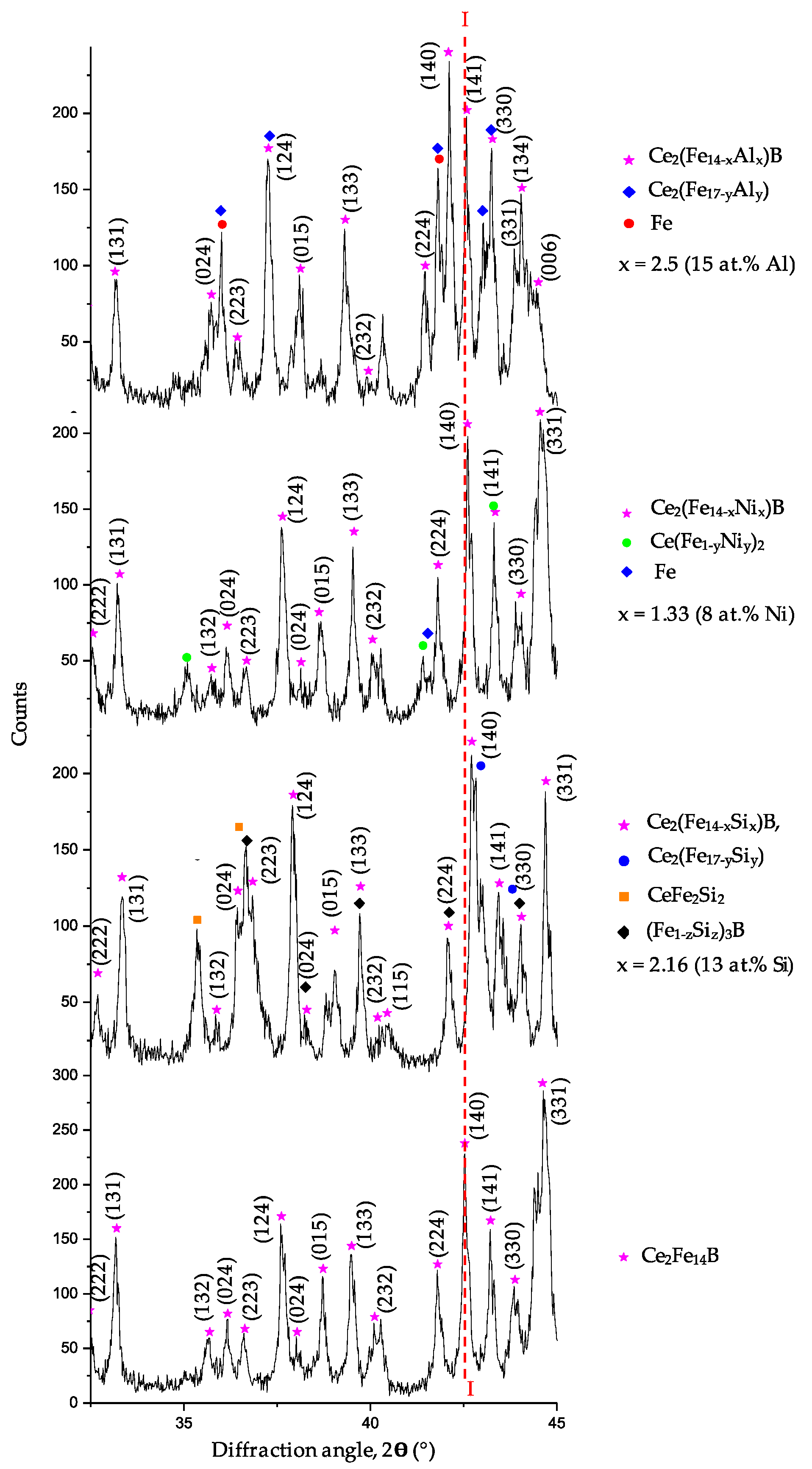

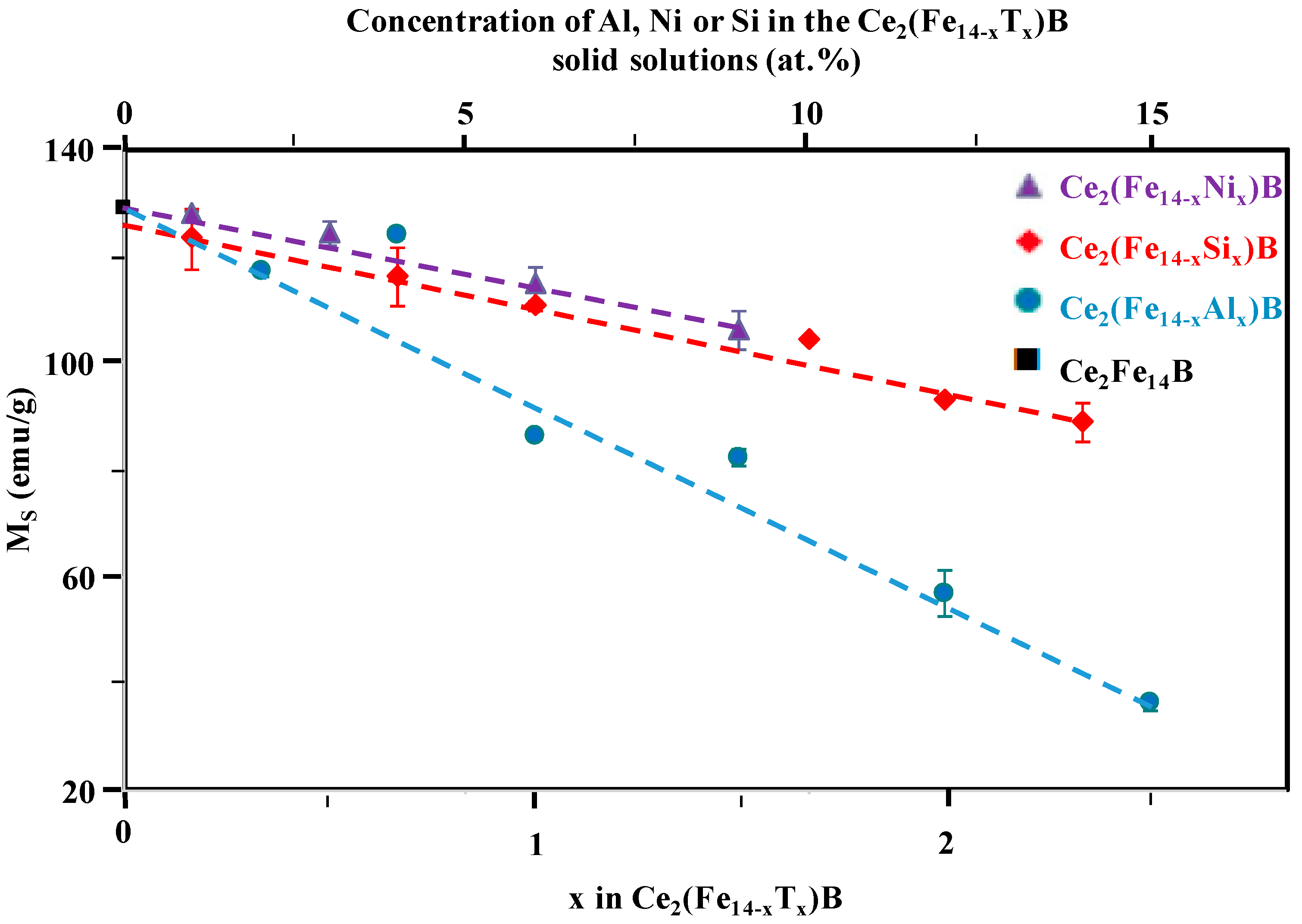

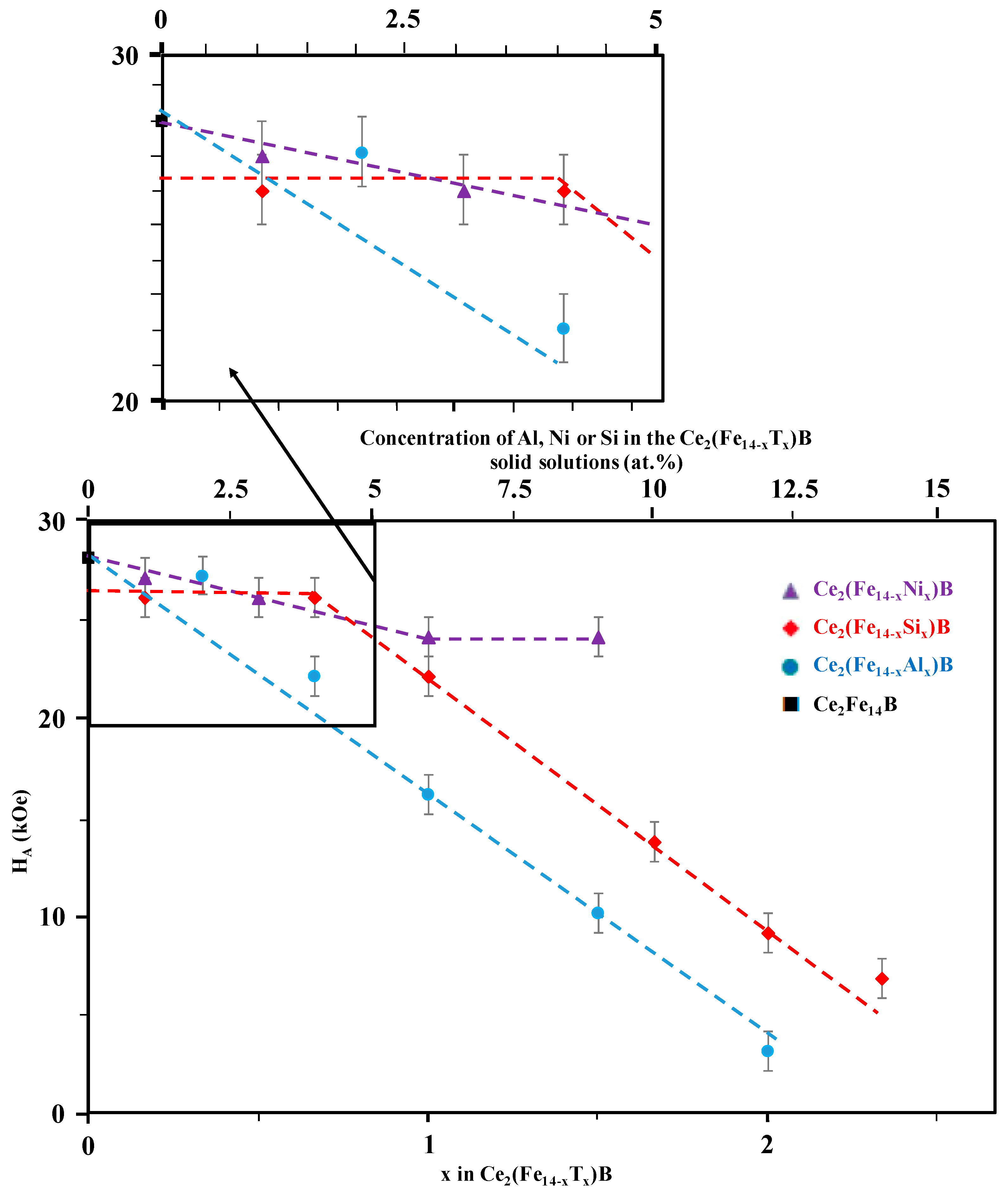

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hisyam, A.; Ismail, N.A.; Taib, M.K.A.M.; Shariff, S. Leaching study of precious metal recovery from ferric permanent magnet waste. ARPN J. Eng. Appl. Sci. 2016, 11, 9981–9984. [Google Scholar]

- Dupont, D.; Binnemans, K. Recycling of rare earths from NdFeB magnets using a combined leaching/extraction system based on the acidity and thermomorphism of the ionic liquid [Hbet][Tf2N]. Green Chem. 2015, 17, 2150–2163. [Google Scholar] [CrossRef]

- Herbst, J.F.; Meyer, M.S.; Pinkerton, F.E. Magnetic hardening of Ce2Fe14B. J. Appl. Phys. 2012, 111, 07A718. [Google Scholar] [CrossRef]

- Herbst, J. R2Fe14B materials: Intrinsic properties and technological aspects. Rev. Mod. Phys. 1991, 63, 819–898. [Google Scholar] [CrossRef]

- Grössinger, R.; Sun, X.K.; Eibler, R.; Buschow, K.H.J.; Kirchmayr, H.R. The temperature dependence of the anisotropy field in R2Fe14B compounds (R = Y, La, Ce, Pr, Nd, Gd, Ho, Lu). Le J. Phys. Colloq. 1985, 46, C6-221–C6-224. [Google Scholar] [CrossRef]

- Herbst, J.F.; Croat, J.J. Neodymium-iron-boron permanent magnets. J. Magn. Magn. Mater. 1991, 100, 57–78. [Google Scholar] [CrossRef]

- Sinnema, S.; Radwanski, R.J.; Franse, J.J.M.; de Mooij, D.B.; Buschow, K.H.J. Magnetic properties of ternary rare-earth compounds of the type R2Fe14B. J. Magn. Magn. Mater. 1984, 44, 333–341. [Google Scholar] [CrossRef]

- Alam, A.; Johnson, D.D. Mixed valency and site-preference chemistry for cerium and its compounds: A predictive density-functional theory study. Phys. Rev. B 2014, 89, 235126. [Google Scholar] [CrossRef]

- Pathak, A.K.; Khan, M.; Gschneidner, K.A., Jr.; Mccallum, R.W.; Zhou, L.; Sun, K.; Dennis, K.W.; Zhou, C.; Pinkerton, F.E.; Kramer, M.J.; et al. Cerium: An unlikely replacement of Dysprosium in high performance Nd–Fe–B permanent magnets. Adv. Mater. 2015, 27, 2663–2667. [Google Scholar] [CrossRef] [PubMed]

- Alam, A.; Khan, M.; Mccallum, R.W.; Johnson, D.D. Site-preference and valency for rare-earth sites in (R-Ce)2Fe14B magnets. Appl. Phys. Lett. 2013, 102, 42402. [Google Scholar] [CrossRef]

- Pathak, A.K.; Khan, M.; Gschneidner, K.A., Jr.; Mccallum, R.W.; Zhou, L.; Sun, K.; Kramer, M.J.; Pecharsky, V.K. Magnetic properties of bulk, and rapidly solidified nanostructured (Nd1−xCex)2Fe14−yCoyB ribbons. Acta Mater. 2016, 103, 211–216. [Google Scholar] [CrossRef]

- Pathak, A.K.; Gschneidner, K.A., Jr.; Khan, M.; Mccallum, R.W.; Pecharsky, V.K. High performance Nd–Fe–B permanent magnets without critical elements. J. Alloys Compd. 2016, 668, 80–86. [Google Scholar] [CrossRef]

- Li, Z.B.; Shen, B.G.; Zhang, M.; Hu, F.X.; Sun, J.R. Substitution of Ce for Nd in preparing R2Fe14B nanocrystalline magnets. J. Alloys Compd. 2015, 628, 325–328. [Google Scholar] [CrossRef]

- Yan, C.; Guo, S.; Chen, R.; Lee, D.; Yan, A. Effect of Ce on the magnetic properties and microstructure of sintered Didymium–Fe–B magnets. IEEE Trans. Magn. 2014, 50, 2102605. [Google Scholar] [CrossRef]

- Zhou, C.; Haddad, D.; Kukreja, R.S.; Pinkerton, F.E.; Sun, K.; Kramer, M.J. Magnetic hardening of CeFe11Ti and the effect of TiC addition. IEEE Trans. Magn. 2015, 51, 2100104. [Google Scholar] [CrossRef]

- Zhou, C.; Pinkerton, F.E.; Herbst, J.F. Magnetic properties of CeFe11−xCoxTi with ThMn12 structure. J. Appl. Phys. 2014, 115, 17C716. [Google Scholar] [CrossRef]

- Zhou, C.; Pinkerton, F.E.; Herbst, J.F. High Curie temperature of Ce–Fe–Si compounds with ThMn12 structure. Scr. Mater. 2015, 95, 66–69. [Google Scholar] [CrossRef]

- Zhou, C.; Tessema, M.; Meyer, M.S.; Pinkerton, F.E. Synthesis of CeFe10.5Mo1.5 with ThMn12-type structure by melt spinning. J. Magn. Magn. Mater. 2013, 336, 26–28. [Google Scholar] [CrossRef]

- Zhou, C.; Pinkerton, F.E. Magnetic hardening of CeFe12−xMox and the effect of nitrogenation. J. Alloys Compd. 2014, 583, 345–350. [Google Scholar] [CrossRef]

- Wang, R.; Shen, X.; Liu, Y.; Li, J. Effects of Ga addition on the formability of main phase and microstructure of hot-deformed Ce–Fe–B Magnets. IEEE Trans. Magn. 2016, 52, 2101806. [Google Scholar] [CrossRef]

- Chang-Jiang, Y.; Shuai, G.; Ren-Jie, C.; Dong, L.; A-Ru, Y. Phase constitution and microstructure of Ce–Fe–B strip-casting alloy. Chin. Phys. B 2014, 23, 107501. [Google Scholar]

- Hirosawa, S.; Matsuura, Y.; Yamamoto, H.; Fujimura, S.; Sagawa, M.; Yamauchi, H. Magnetization and magnetic anisotropy of R2Fe14B measured on single crystals. J. Appl. Phys. 1986, 59, 873–879. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, M.; Li, W.; Zheng, L.; Zhao, D.; Du, X.; Du, A. The microstructure and magnetic properties of melt-spun CeFeB ribbons with varying Ce content. Electron. Mater. Lett. 2015, 11, 109–112. [Google Scholar] [CrossRef]

- Skoug, E.J.; Meyer, M.S.; Pinkerton, F.E.; Tessema, M.M.; Haddad, D.; Herbst, J.F. Crystal structure and magnetic properties of Ce2Fe14−xCoxB alloys. J. Alloys Compd. 2013, 574, 552–555. [Google Scholar] [CrossRef]

- Xing, M.; Han, J.; Lin, Z.; Wan, F.; Li, C.; Liu, S.; Wang, C.; Yang, J.; Yang, Y. Anisotropic ternary Ce13Fe80B7 powders prepared by hydrogenation–disproportionation–desorption–recombination process and the diffusion of Ce–Cu eutectic alloys. J. Magn. Magn. Mater. 2013, 331, 140–143. [Google Scholar] [CrossRef]

- Zhang, M.; Shen, B.; Hu, F.; Sun, J. The effect of Si substitution on structure and magnetic properties in Mischmetal–Fe–B ribbons. In Proceedings of the 2015 IEEE International Magnetics Conference (INTERMAG), Beijing, China, 11–15 May 2015. [Google Scholar]

- Hirosawa, S.; Yamaguchi, Y.; Tokuhara, K.; Yamamoto, H.; Fujimura, S.; Sagawa, M. Magnetic properties of Nd2(Fe1−xMx)14B measured on single crystals (M = Al, Cr, Mn and Co). IEEE Trans. Magn. 1987, 23, 2120–2122. [Google Scholar] [CrossRef]

- Kowalczyk, A.; Stefanski, P.; Wrzeciono, A.; Szlaferek, A. Structure and magnetic properties of R2Fe14−xNixB compounds (R = Nd and Gd). Phys. Status Solidi 1989, 114, 355–358. [Google Scholar] [CrossRef]

- Kou, X.C.; Sun, X.K.; Chuang, Y.C.; Zhao, T.S.; Grossinger, R.; Kirchmayr, H.R. Exchange interaction and magnetic anisotropy in Nd2(Fe13M)B compounds (M = Ga, Si, Al). J. Magn. Magn. Mater. 1989, 82, 327–334. [Google Scholar] [CrossRef]

- Jurczyk, M.; Kowalczyk, A.; Wrzeciono, A. Magnetic properties of Nd2Fe14−xSixB compounds. Phys. Status Solidi 1987, 101, K65. [Google Scholar] [CrossRef]

- Jurczyk, M.; Kowalczyk, A. Effect of silicon additions on the magnetic properties of Nd2Fe12Co2B alloy. J. Magn. Magn. Mater. 1987, 68, 331–334. [Google Scholar] [CrossRef]

- Orimoloye, K.; Kevorkov, D.; Medraj, M. Phase equilibria and magnetic phases in the Fe-rich regions of the Fe-Ce-{Ni, Si, Al}-B quaternary systems. J. Alloys Compd. 2017. submitted. [Google Scholar]

- Putz, H.; Brandenburg, K. Pearson’s Crystal Data. Crystal Structure Database for Inorganic Compounds; CD-ROM Software Version 1.3; ASM International: Materials Park, OH, USA, 2007. [Google Scholar]

- Asti, G.; Rinaldi, S. Nonaliticity of the magnetization curve: Application to the measurement of anisotropy in polycrystalline samples. Phys. Rev. Lett. 1972, 28, 1584–1586. [Google Scholar] [CrossRef]

- Asti, G.; Rinaldi, S. Singular points in the magnetization curve of a polycrystalline ferromagnet. J. Appl. Phys. 1974, 45, 3600–3610. [Google Scholar] [CrossRef]

- Liu, X.; Ryan, D.H.; Wang, M.; Lu, Q.; Zhang, H. Experimental and first-principles determination of the magnetocrystalline anisotropy in MnxGa. AIP Adv. 2017, 7, 56216. [Google Scholar] [CrossRef]

- Grossinger, R.; Sun, X.K.; Eibler, R.; Buschow, K.H.J.; Kirchmayr, H.R. Temperature dependence of anisotropy fields and initial susceptibilities in R2Fe14B compounds. J. Magn. Magn. Mater. 1986, 58, 55–60. [Google Scholar] [CrossRef]

- Denton, A.R.; Ashcroft, N.W. Vegard’s law. Phys. Rev. A 1991, 43, 3161–3164. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.H.; Basu, S.; Zhang, Y.; Parvizi-Majidi, A.; Xiao, J.Q. Pinning effect of the grain boundaries on magnetic domain wall in FeCo-based magnetic alloys. J. Appl. Phys. 1999, 85, 6655–6659. [Google Scholar] [CrossRef]

- Landgraf, J.F.G.; Filipini da Silvera, J.R.; Rodrigues, D., Jr. Determining the effect of grain size and maximum induction upon coercive field of electrical steels. J. Magn. Magn. Mater. 2011, 323, 2335–2339. [Google Scholar] [CrossRef]

- Tong, H.Y.; Shi, F.G. Magnetic properties of polycrystalline FeBSi alloys with ultrafine grains. Scr. Mater. 1996, 34, 1887–1892. [Google Scholar] [CrossRef]

- Burzo, E.; Plugaru, N.; Pop, V.; Stanciu, L.; Wallace, W.E. Bulk magnetic properties of the Y2TxFe14−xB compounds, where T = Al, Ni, or Co. Solid State Commun. 1986, 58, 803–805. [Google Scholar] [CrossRef]

- Jurczyk, M. On the magnetic behaviour of Nd2Fe12−xTxCo2B compounds (T = Al, V, Cr). IEEE Trans. Magn. 1988, 24, 1942–1944. [Google Scholar] [CrossRef]

- Bolzoni, F.; Leccabue, F.; Moze, O.; Pareti, L.; Solzi, M. Magnetocrystalline anisotropy of Ni and Mn substituted Nd2Fe14B compounds. J. Magn. Magn. Mater. 1987, 67, 373–377. [Google Scholar] [CrossRef]

- Ku, H.C.; Yen, L.S. Magnetic properties of the new permanent magnet compounds Nd2(Fe0.9M0.1)14B (M = Sc, Ti, V, Cr, Mn, Co, Ni). J. Less Common Met. 1987, 127, 43–48. [Google Scholar] [CrossRef]

- Burzo, E.; Stanciu, L.; Wallace, W.E. On the magnetic behaviour of Y2Fe14−xNixB and Y2Fe14−xCoxB. J. Less Common Met. 1985, 111, 83–86. [Google Scholar] [CrossRef]

- Pedziwiatr, A.T.; Wallace, W.E.; Burzo, E.; Pop, V. Magnetic properties of Y2Fe14−xMxB compounds where M = Si or Cu. Solid State Commun. 1987, 61, 61–64. [Google Scholar] [CrossRef]

- Dai, S.; Morrish, A.H.; Zhou, X.Z.; Hu, B.P.; Zhang, S.G. Mossbauer study of the permanent magnet material Nd2(Fe1−xNix)14B. J. Appl. Phys. 1988, 63, 3722–3724. [Google Scholar] [CrossRef]

- Marasinghe, G.K.; Pringle, O.A.; Long, G.J.; Yelon, W.B.; Grandjean, F. A neutron diffraction and Mössbauer spectral study of the structure and magnetic properties of the Y2Fe14−xSixB solid solutions. J. Appl. Phys. 1994, 76, 2960–2968. [Google Scholar] [CrossRef]

- Marasinghe, G.K.; Pringle, O.A.; Long, G.J.; James, W.J.; Xie, D.; Li, J.; Yelon, W.B.; Grandjean, F. Neutron diffraction and Mössbauer effect study of the preferential silicon site occupation and magnetic structure of Nd2Fe14−xSixB. J. Appl. Phys. 1993, 74, 6798–6809. [Google Scholar] [CrossRef]

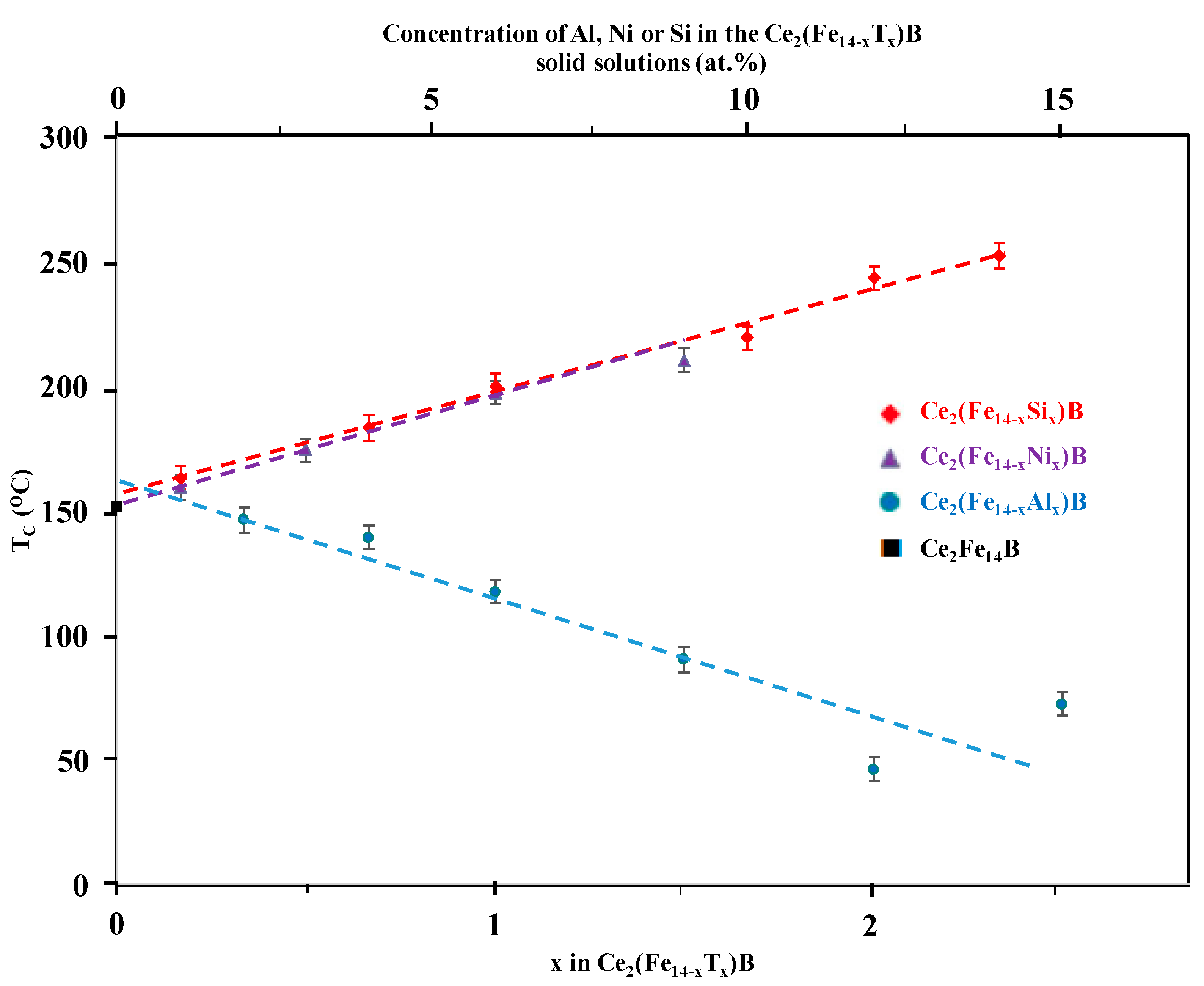

| Key Alloy Number | Dopant Concentration in Ce2(Fe14−xTx)B | Relative Amount of Ce2(Fe14−xTx)B (vol %) | MS (emu/g) at 25 °C | HA (kOe) at 25 °C | TC (°C) | |

|---|---|---|---|---|---|---|

| (Atom %) | x | |||||

| Ce–Fe–B system | ||||||

| 0 | 0 | 0 | 81.1 | 130 | 28.1 | 151 |

| Ce–Fe–Al–B system | ||||||

| 1 | 1.91 | 0.32 | 82.1 | 117.1 | 27.2 | 146 |

| 2 | 3.85 | 0.64 | 74.6 | 123.6 | 22.1 | 139 |

| 3 | 6.09 | 1.02 | 95.0 | 86.0 | 16.1 | 117 |

| 4 | 9.33 | 1.56 | 88.0 | 82.3 | 10.1 | 90 |

| 5 | 12.22 | 2.04 | 93.7 | 56.8 | 3.1 | 46 |

| 6 | 14.62 | 2.44 | 64.0 | 36.1 | -* | 72 |

| Ce–Fe–Ni–B system | ||||||

| 1 | 1.05 | 0.18 | 73.6 | 127.9 | 27.1 | 159 |

| 2 | 2.94 | 0.49 | 94.2 | 124.3 | 26.1 | 174 |

| 3 | 6.17 | 1.03 | 73.6 | 114.8 | 24.1 | 197 |

| 4 | 8.71 | 1.45 | 88.4 | 106.3 | 24.1 | 210 |

| Ce–Fe–Si–B system | ||||||

| 1 | 1.30 | 0.22 | 91.8 | 123.1 | 26.1 | 163 |

| 2 | 3.75 | 0.63 | 84.2 | 116.1 | 26.1 | 183 |

| 3 | 6.62 | 1.1 | 83.9 | 110.4 | 22.1 | 200 |

| 4 | 10.04 | 1.67 | 86.5 | 104.2 | 13.7 | 219 |

| 5 | 12.62 | 2.1 | 96.8 | 93.0 | 9.1 | 243 |

| 6 | 13.60 | 2.26 | 78.6 | 88.8 | 6.8 | 252 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orimoloye, K.; Ryan, D.H.; Pinkerton, F.E.; Medraj, M. Intrinsic Magnetic Properties of Ce2Fe14B Modified by Al, Ni, or Si. Appl. Sci. 2018, 8, 205. https://doi.org/10.3390/app8020205

Orimoloye K, Ryan DH, Pinkerton FE, Medraj M. Intrinsic Magnetic Properties of Ce2Fe14B Modified by Al, Ni, or Si. Applied Sciences. 2018; 8(2):205. https://doi.org/10.3390/app8020205

Chicago/Turabian StyleOrimoloye, Kayode, Dominic H. Ryan, Frederick E. Pinkerton, and Mamoun Medraj. 2018. "Intrinsic Magnetic Properties of Ce2Fe14B Modified by Al, Ni, or Si" Applied Sciences 8, no. 2: 205. https://doi.org/10.3390/app8020205

APA StyleOrimoloye, K., Ryan, D. H., Pinkerton, F. E., & Medraj, M. (2018). Intrinsic Magnetic Properties of Ce2Fe14B Modified by Al, Ni, or Si. Applied Sciences, 8(2), 205. https://doi.org/10.3390/app8020205