Monitoring Damage Using Acoustic Emission Source Location and Computational Geometry in Reinforced Concrete Beams

Abstract

:1. Introduction

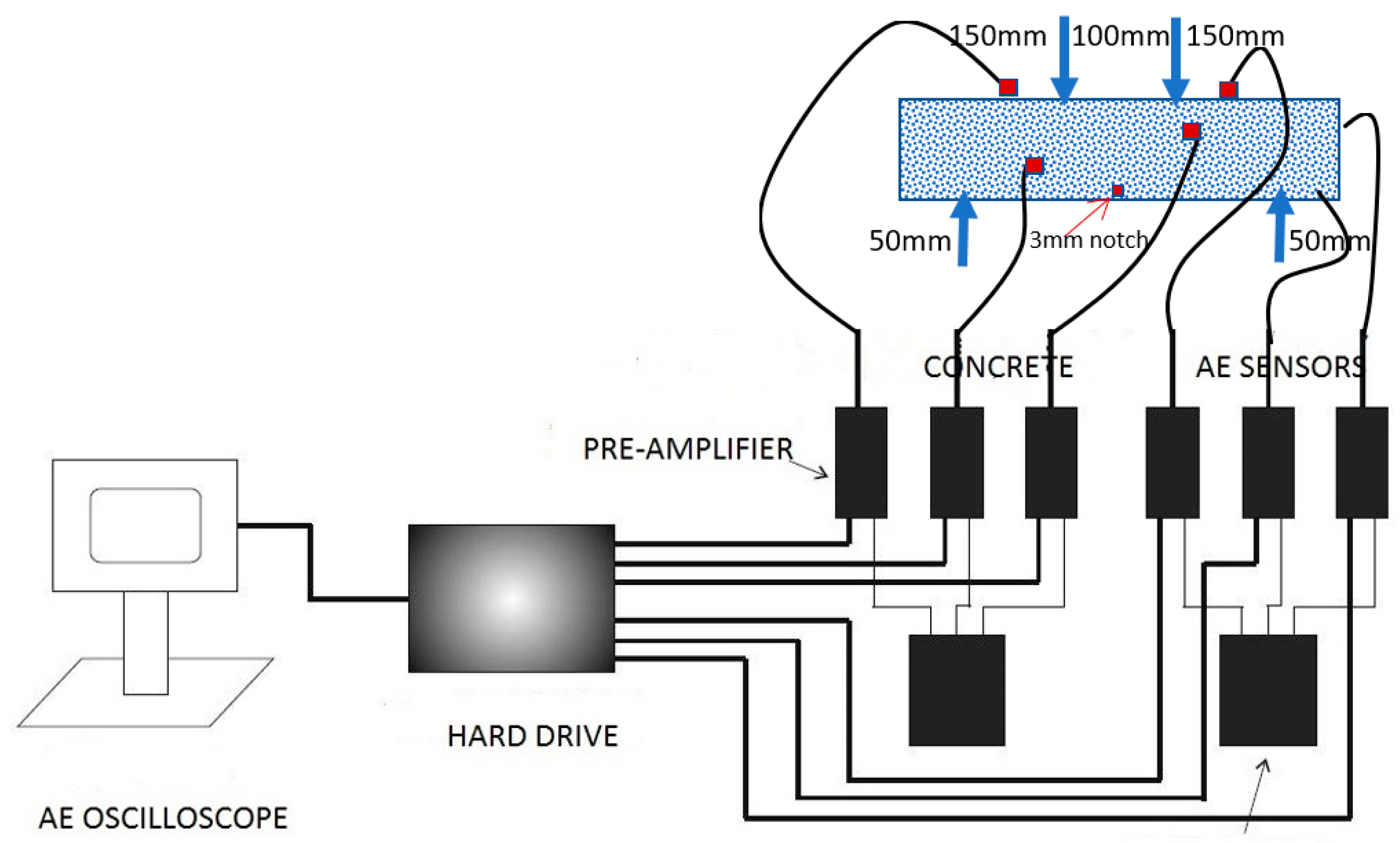

2. Acoustic Emission Test on RC Beams

2.1. Factors Affecting Acoustic Emission Tests

- (a)

- Localization of damage—Determining the localization of cracks inside RC beams is an important concern that researchers need to explore. As an example, time reverse modeling using the AE test is applied in RC specimens and confirmed to be capable of localizing AE activity caused by concrete cracking [23]. In addition, the combination of AE signals and digital imaging can reveal and possibly characterize damage in concrete [24].

- (b)

- Size of specimens—Reinforced beam specimens of three sizes of scales are made to investigate the size effect of concrete beams when the bending test is introduced using digital image correlation (DIC) and AE. In large beams, tensile micro-cracking is observed in the initial and intermediate level of loadings, while shear cracking is evident at the final stages [25]. In another study, zoning is used to explore the behavior of mode of failure near the support and at the midspan of a long beam. Zones near the support tested under the four-point bending test showed that the initial load from 20 to 50% dominantly result in the tensile mode of failure, followed by shear failure over 50 to 100% ultimate load. On the other hand, the middle zone of the beam exhibits a different behavior. It undergoes the dominant tensile mode of failure from 0 to 100% of ultimate load and few shear modes are observed at the final stage of the ultimate load [26].

- (c)

- Mode of failure—Fracture modes are investigated in beams tested in the three-point bending test. Tensile cracks occurred first followed by shear cracks. In addition, elementary finite element models are used to investigate the stress field of tensile stress and shear stress in the beam to redesign the experiment setup to have more dominant shear cracks [27]. Another study considered composite slabs with layers of casted wire mesh, and tested failure modes of punching and flexure. A damage index using AE energy is used when a high AE energy class is found to be associated with activities in the FPZ [28].

2.2. Relationship of Fracture Mechanics and Acoustic Emission Test Results

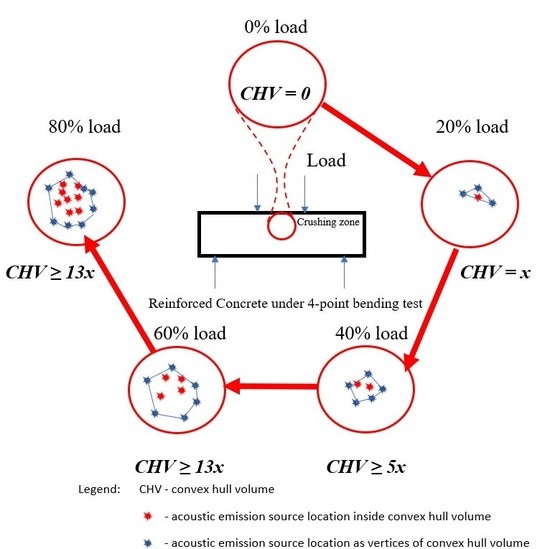

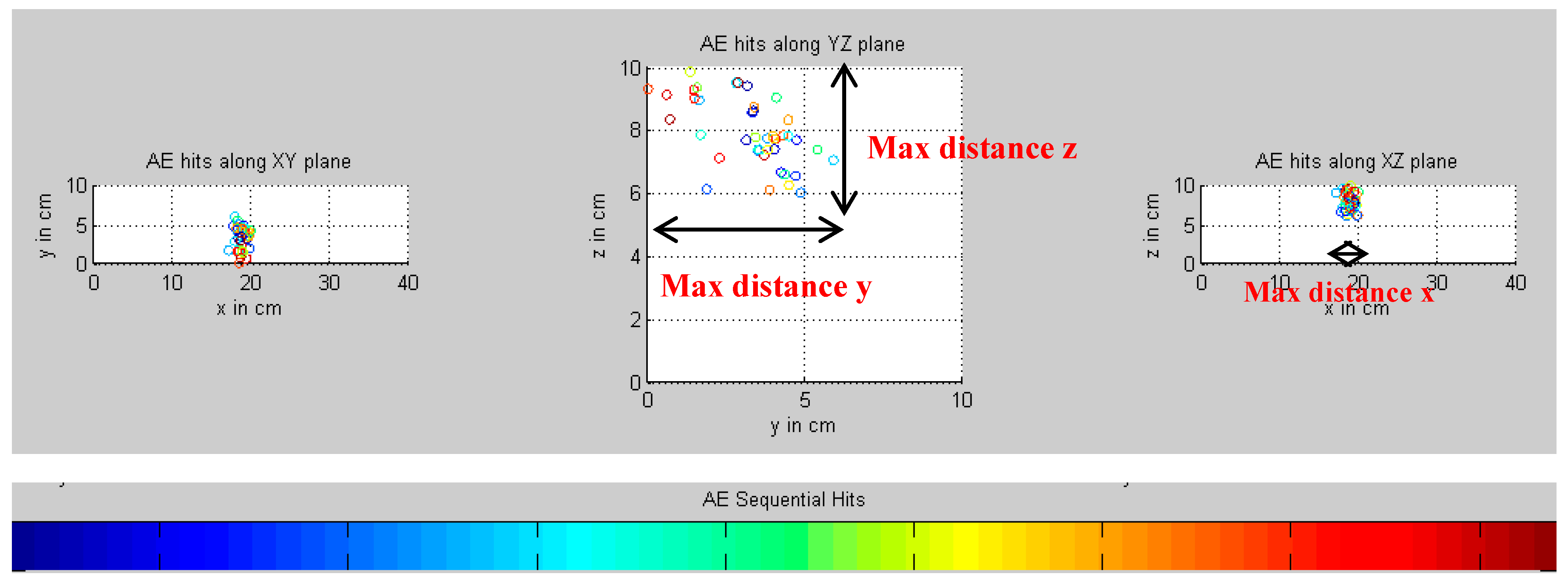

2.3. Using Computational Geometry and Acoustic Emission Source Location (AESL)

3. Experimental Methodology

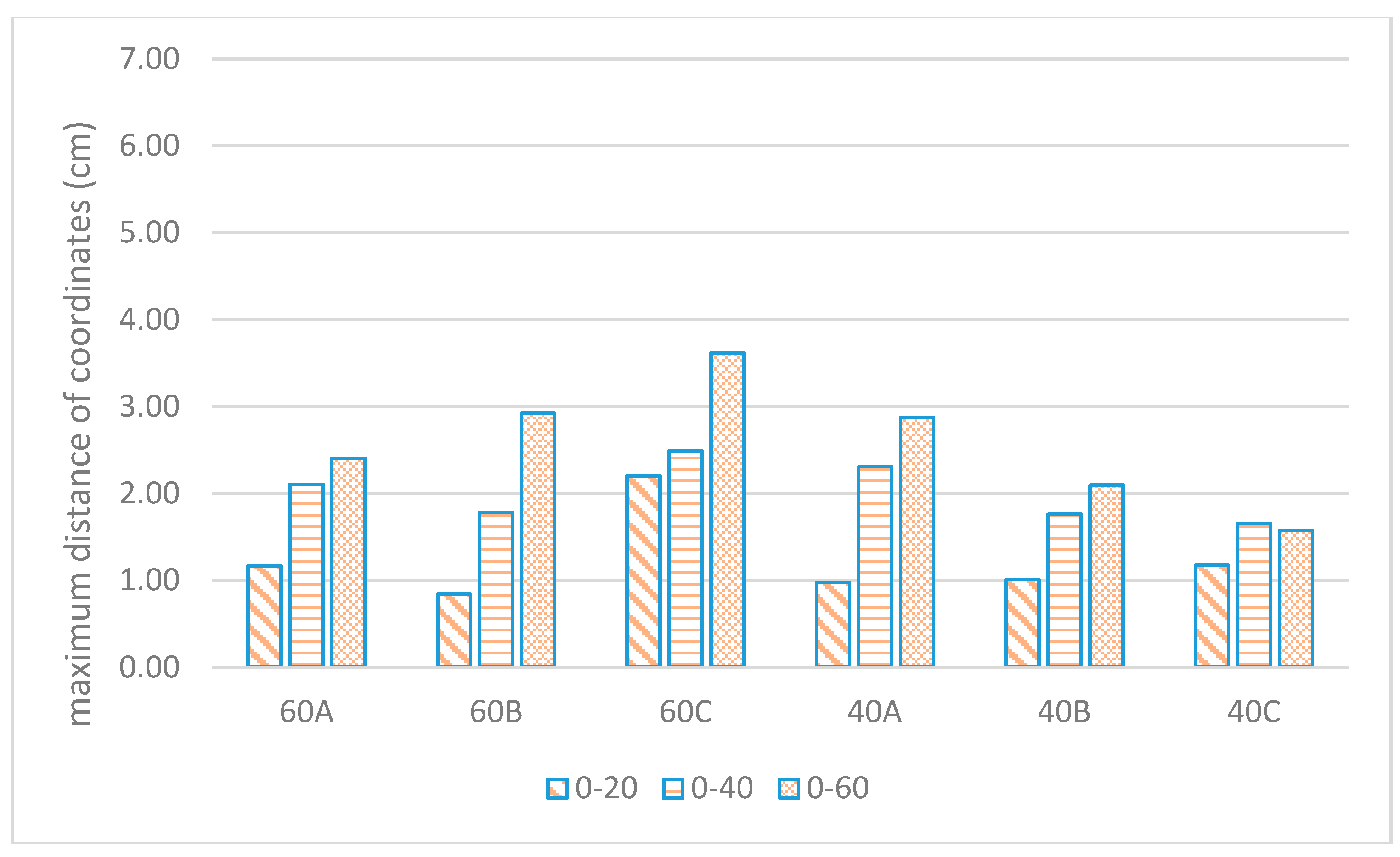

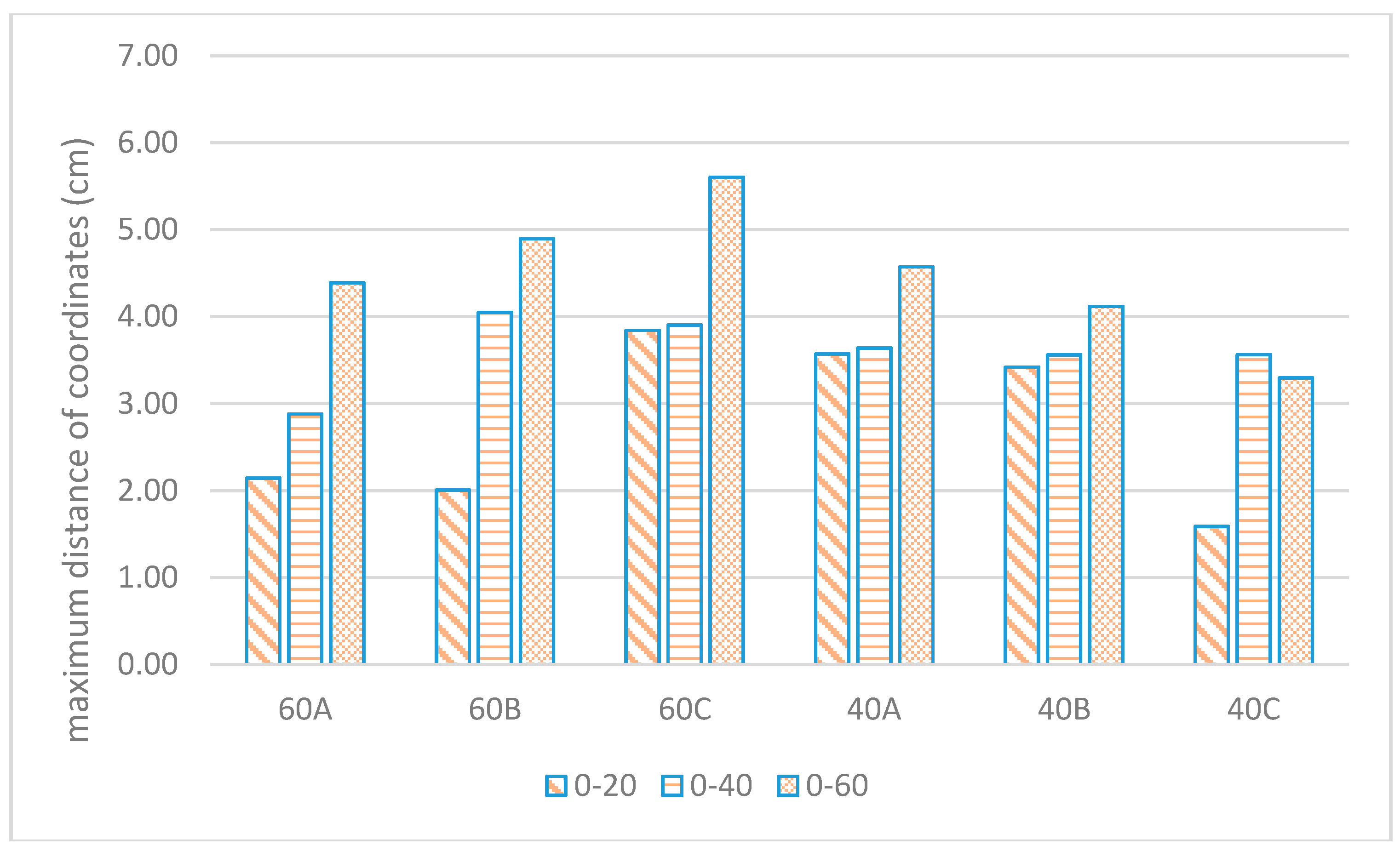

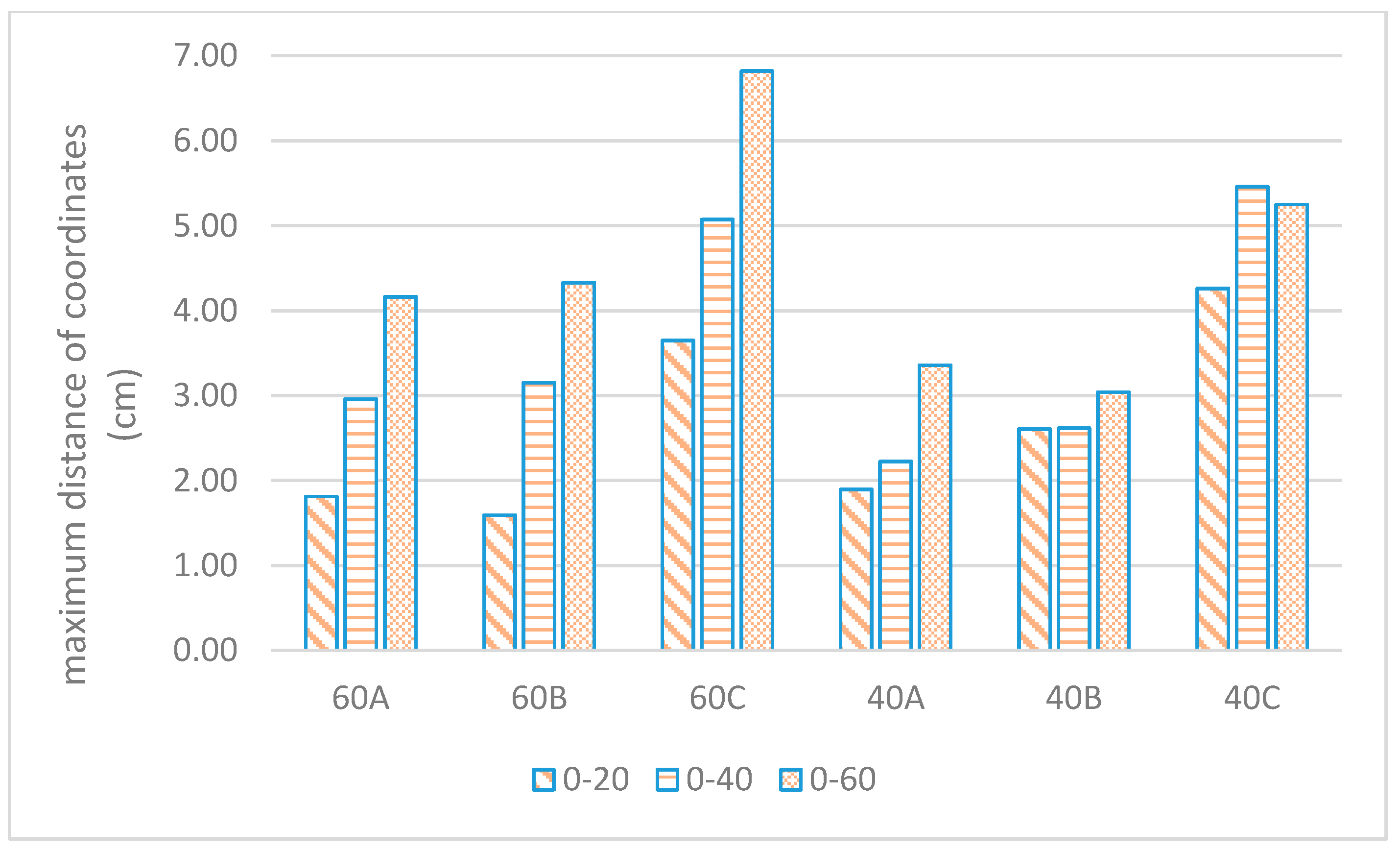

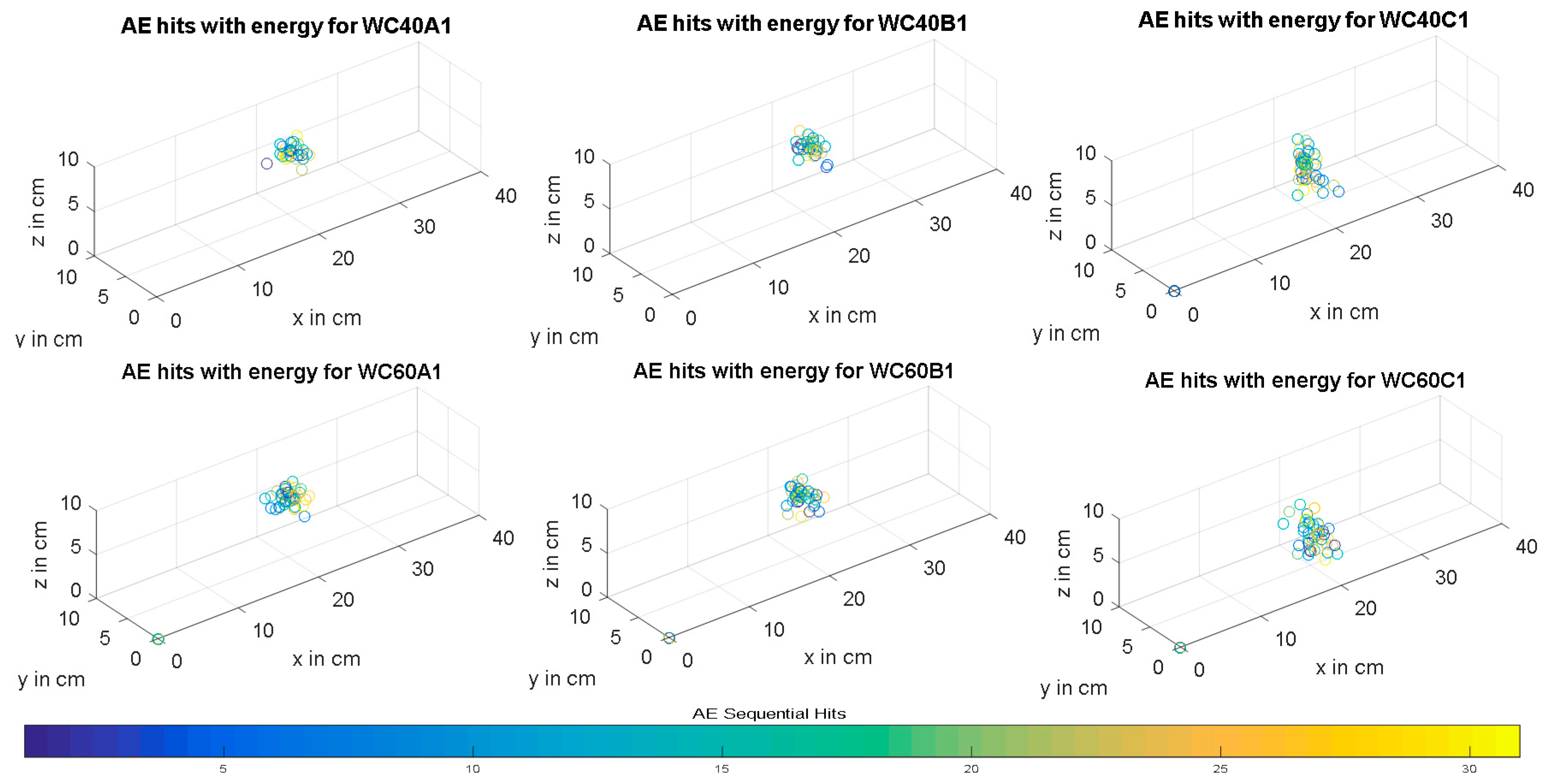

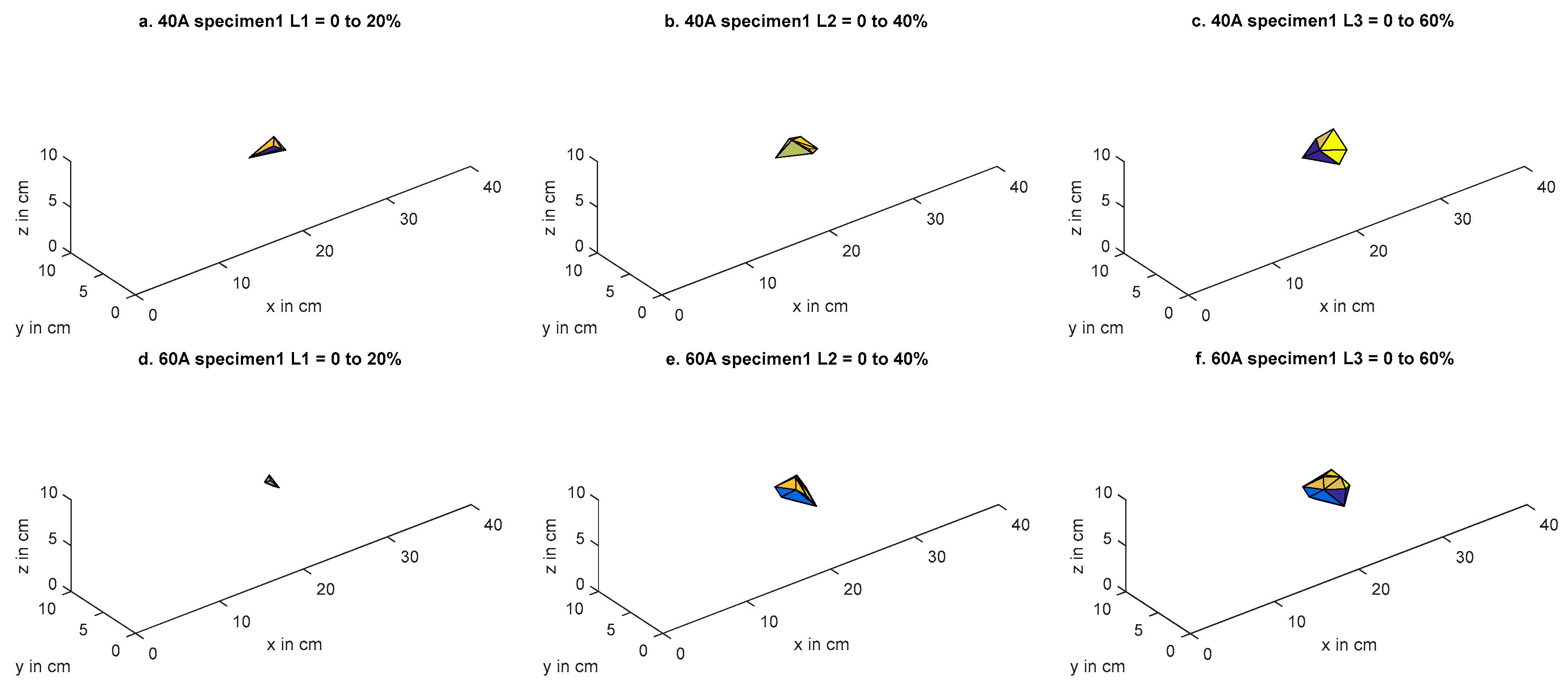

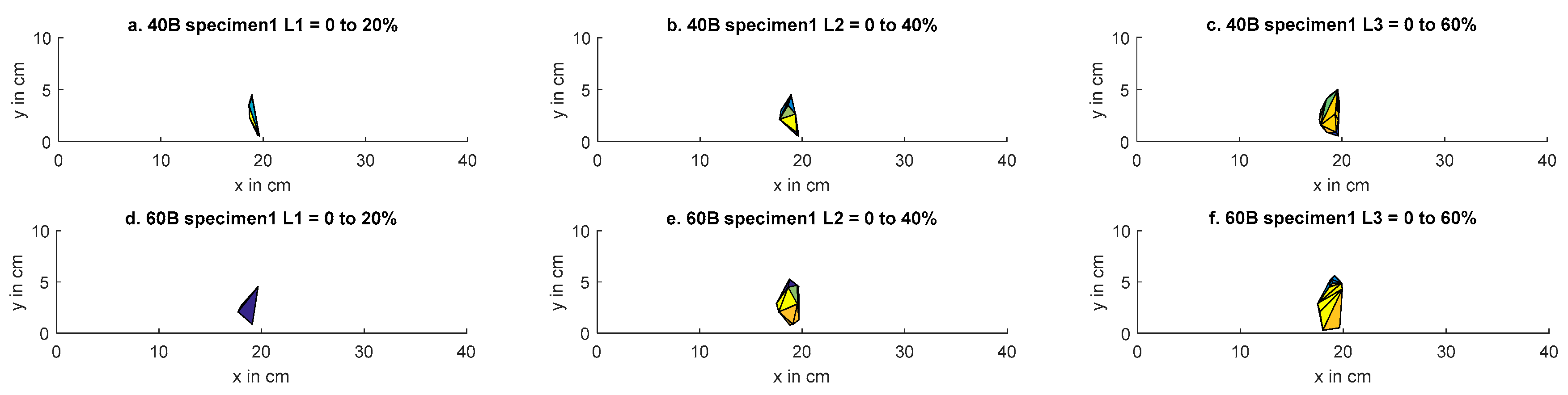

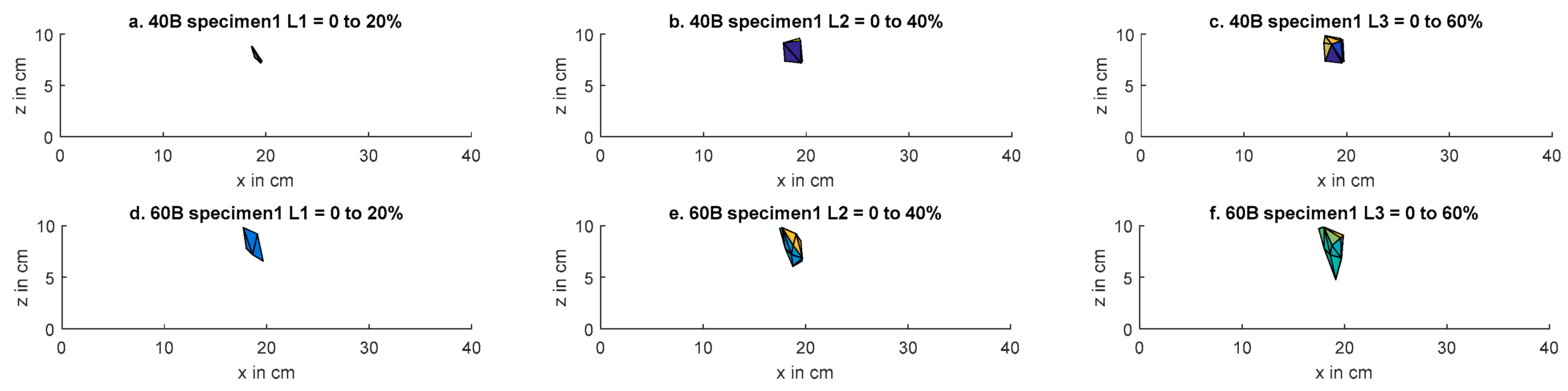

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Acronyms and Symbols

| Acronym/Symbol | Description |

| AE | Acoustic Emission |

| AESL | Acoustic Emission Source Location |

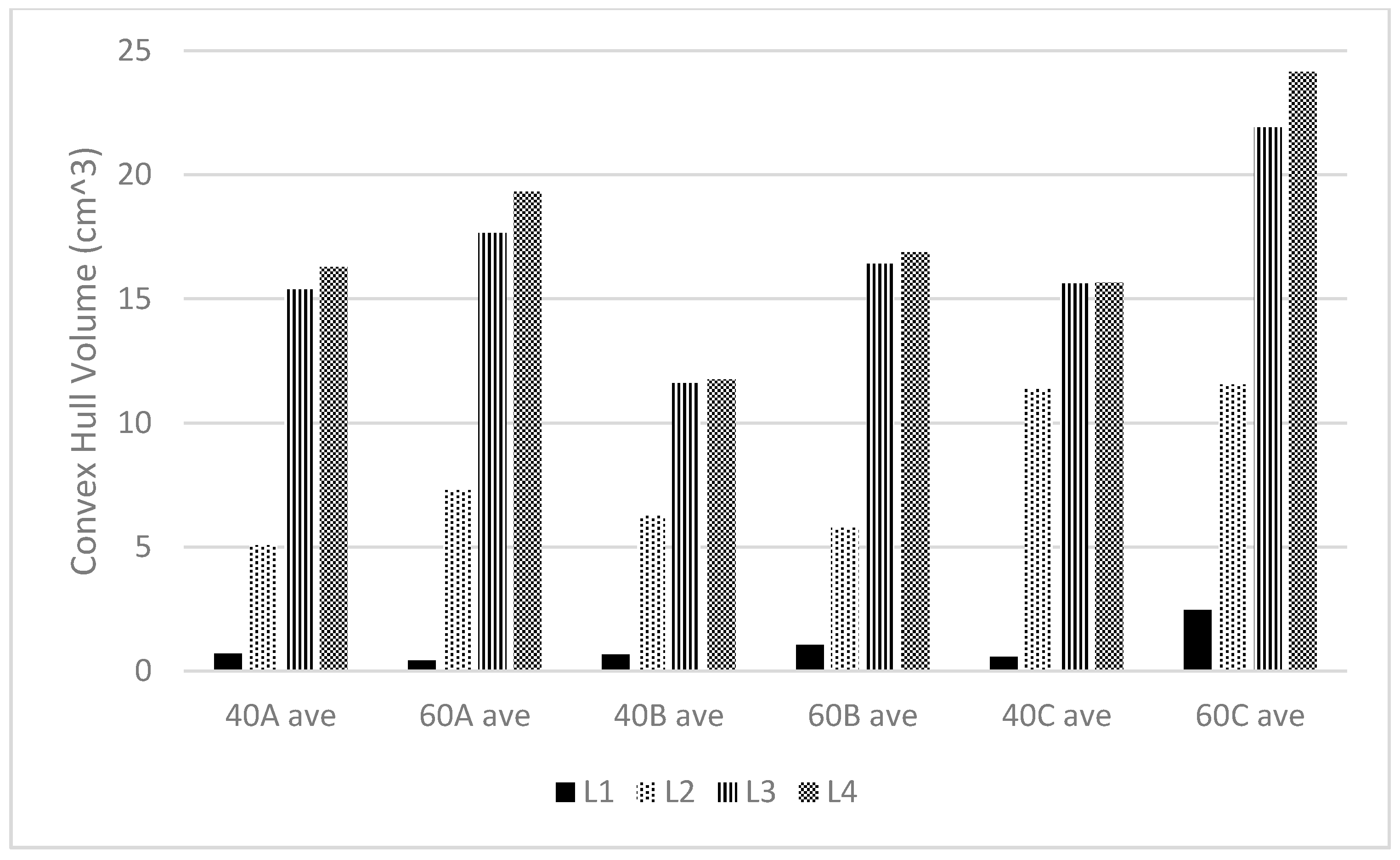

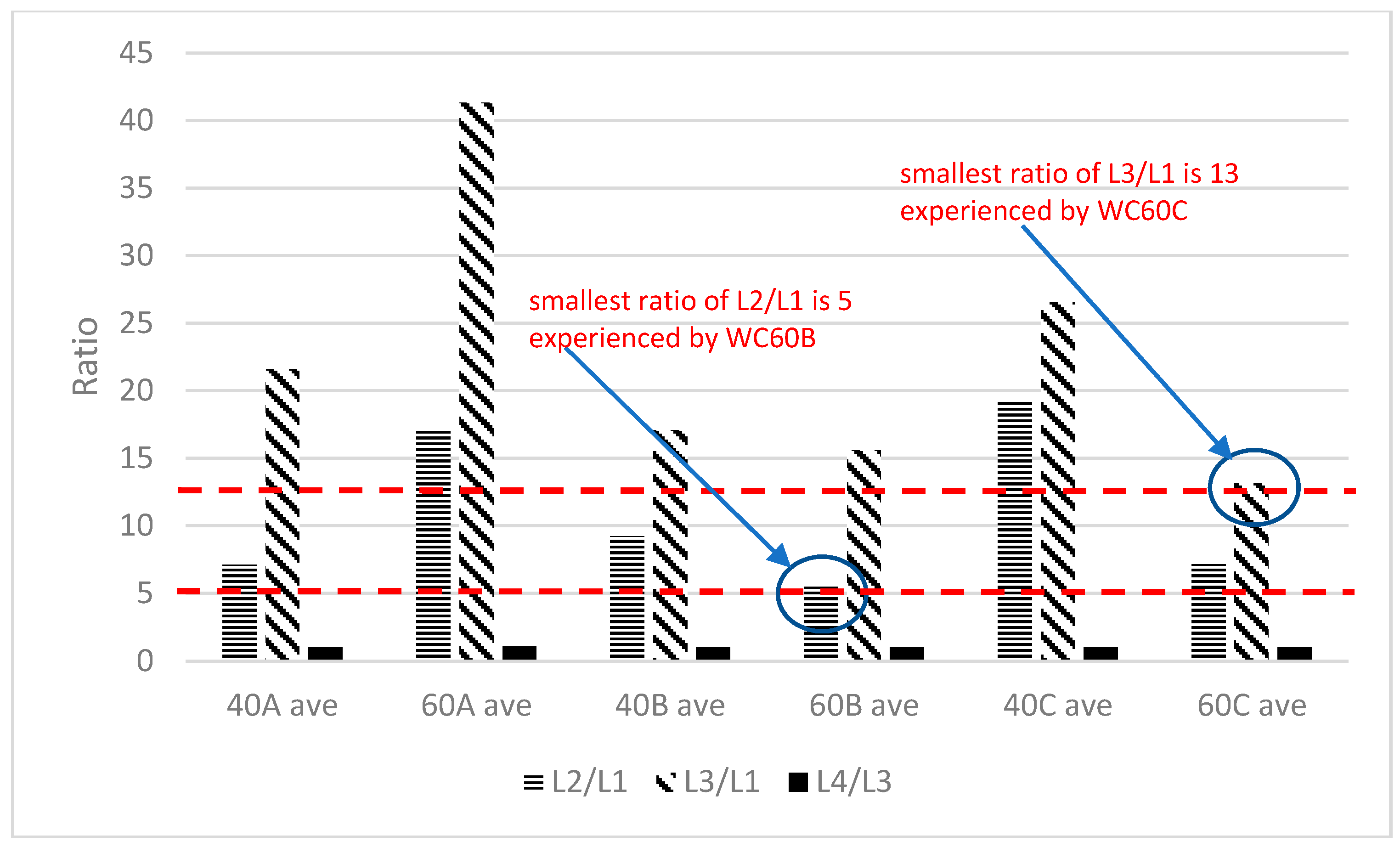

| CHV | Convex Hull Volume |

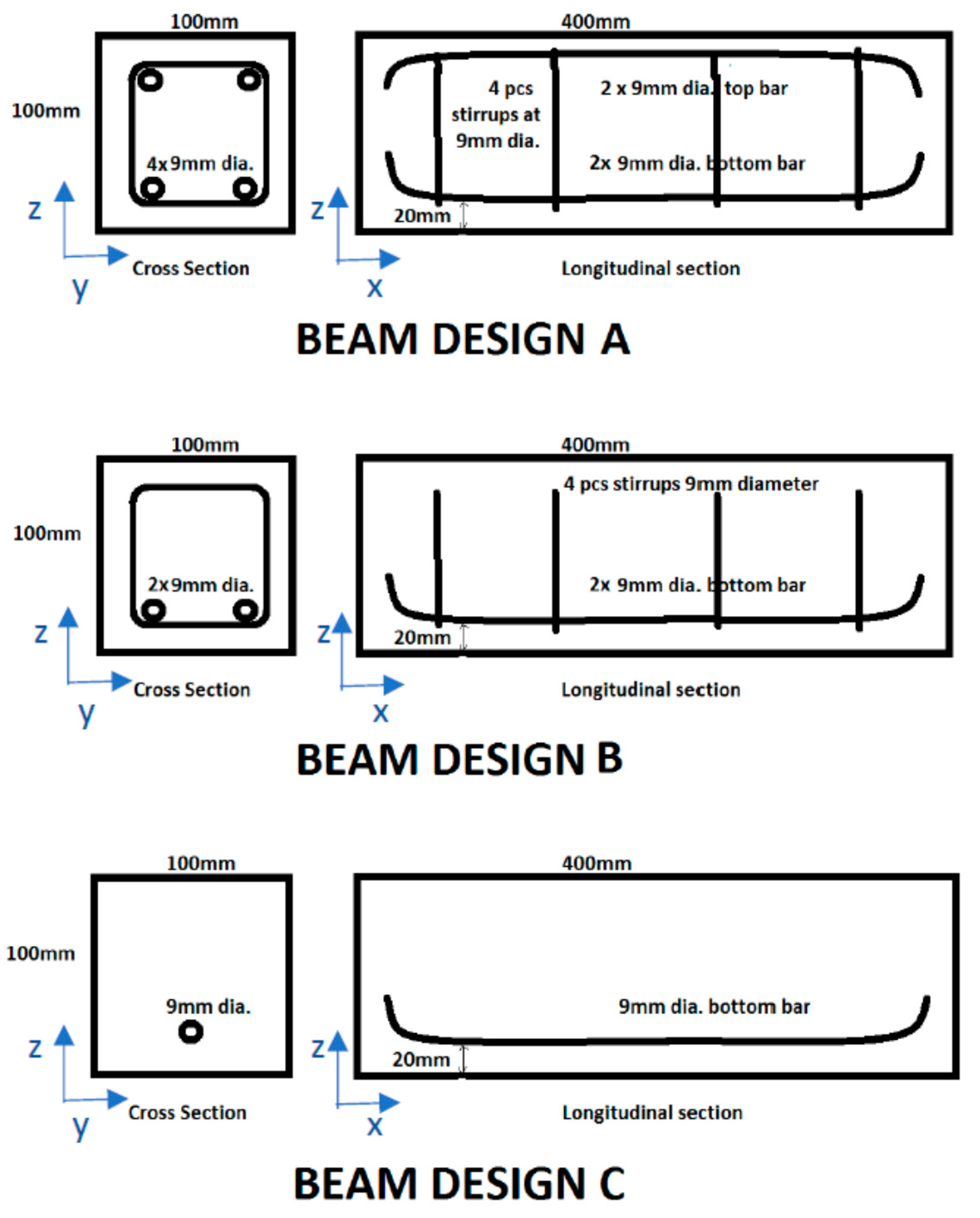

| Design A | Two longitudinal top bars and two longitudinal bottom bars |

| Design B | Two longitudinal bottom bars |

| Design C | One longitudinal bottom bar |

| DIC | Digital Image Correlation |

| FPZ | Fracture Process Zone |

| ITZ | Interfacial Transition Zone |

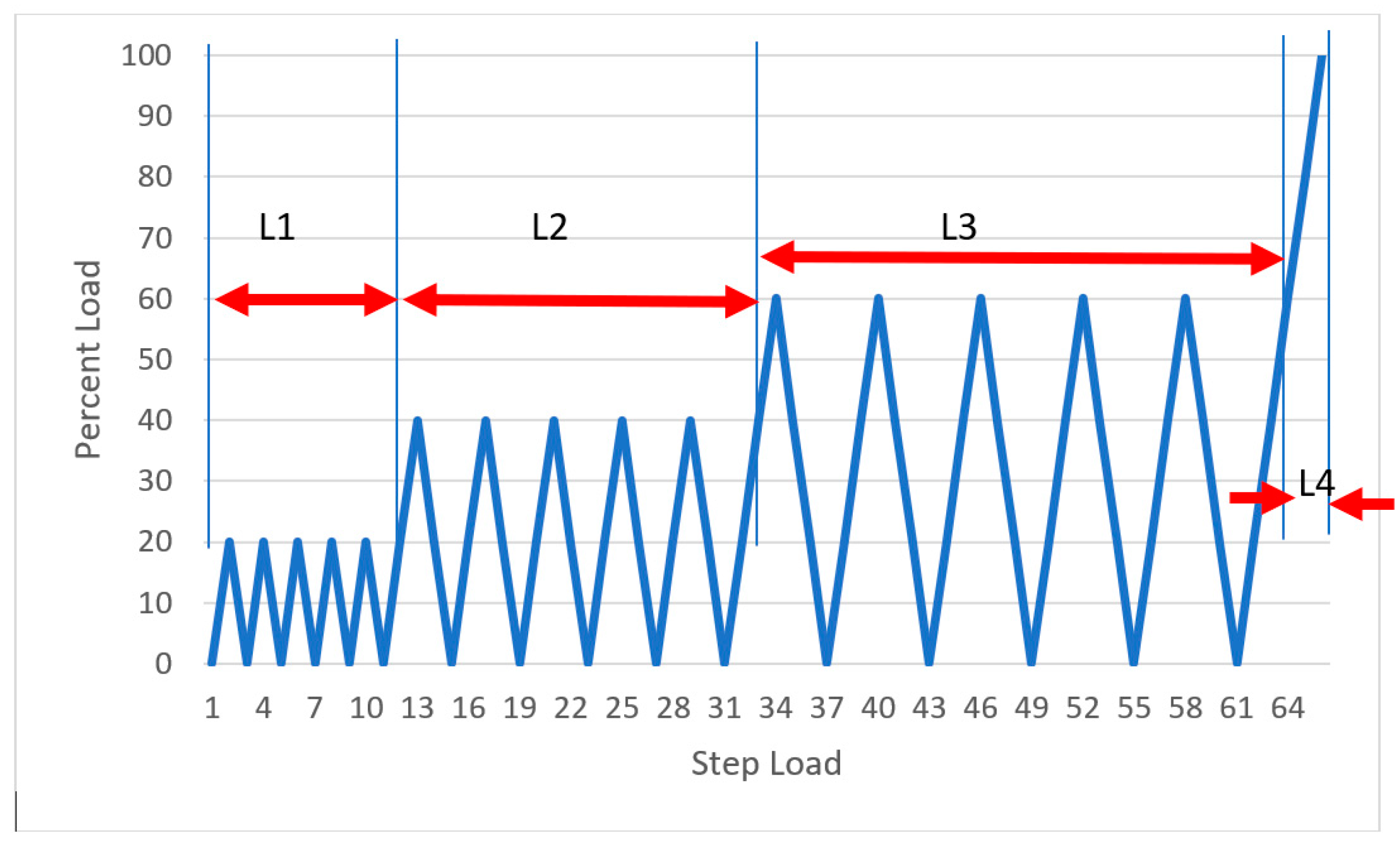

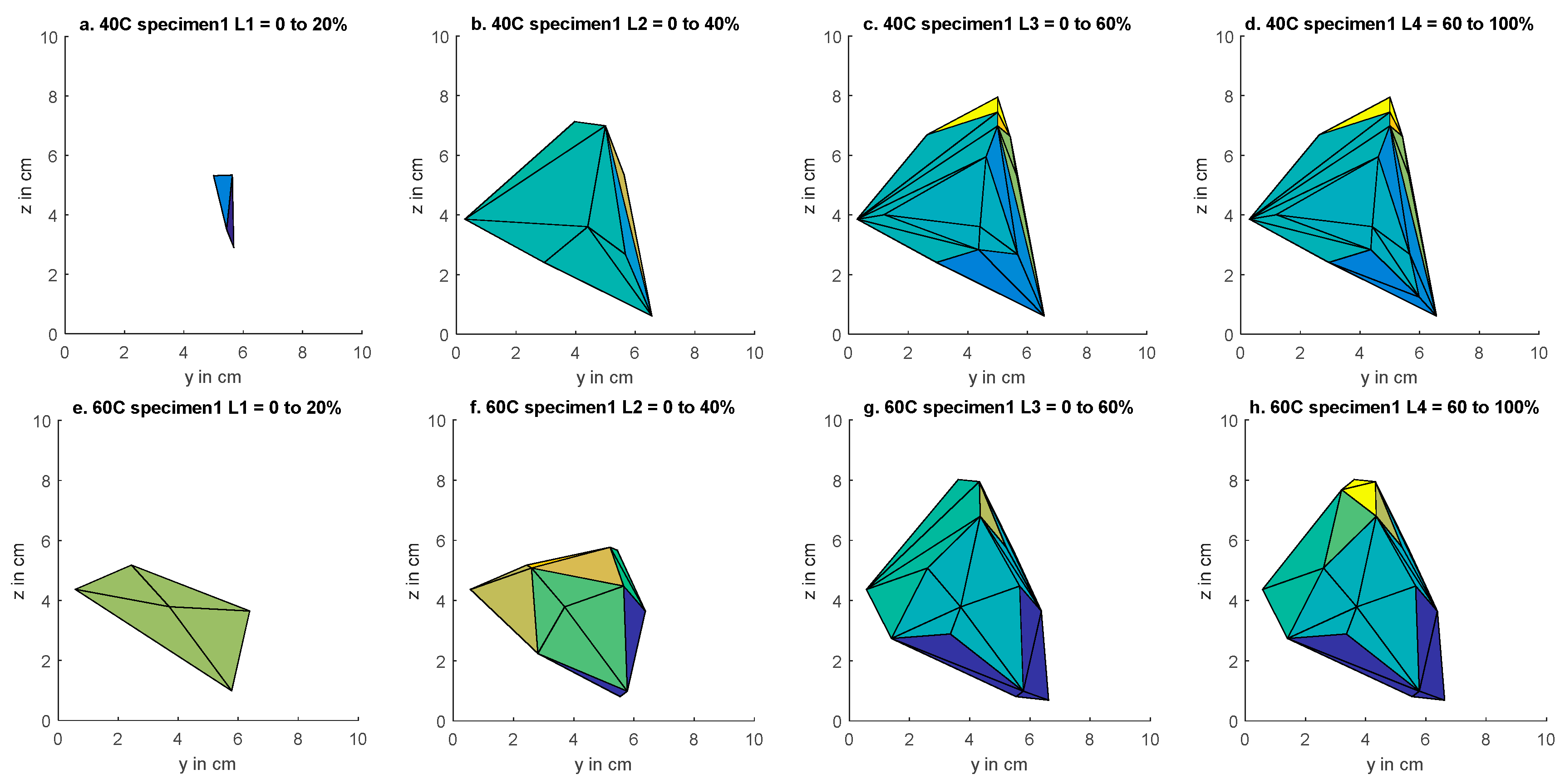

| L1 | Cyclic load from 0 to 20% of ultimate load |

| L2 | Cyclic load from 0 to 40% of ultimate load |

| L3 | Cyclic load from 0 to 60% of ultimate load |

| L4 | Load from 60 to 100% of ultimate load |

| NDT | Non-Destructive Test |

| RC | Reinforced Concrete |

| WC40 | Water-Cement Ratio of 0.40 |

| WC40 | Water-Cement Ratio of 0.60 |

References

- Ongpeng, J.M.C.; Oreta, A.W.C.; Hirose, S. Effect of Load Pattern in the Generation of Higher Harmonic Amplitude in Concrete Using Nonlinear Ultrasonic Test. J. Adv. Concrete Technol. 2016, 14, 205–214. [Google Scholar] [CrossRef]

- Ongpeng, J.M.C.; Oreta, A.W.C.; Hirose, S.; Nakahata, K. Nonlinear Ultrasonic Investigation of Concrete with Varying Aggregate Size under Uniaxial Compression Loading and Unloading. J. Mater. Civ. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Ongpeng, J.M.C.; Soberano, M.; Oreta, A.W.C.; Hirose, S. Artificial Neural Network Model using Ultrasonic Test Results to Predict Compressive Stress in Concrete. Comput. Concrete 2017, 19, 59–68. [Google Scholar] [CrossRef]

- Ongpeng, J.M.C.; Oreta, A.W.C.; Hirose, S. Damage progression in concrete using acoustic emission test through convex hull visualization. ACI Mater. 2016, 113, 737–744. [Google Scholar] [CrossRef]

- Li, Z.; Shah, S.P. Localization of microcracking in concrete under uniaxial tension. ACI Mater. 1994, 91, 372–381. [Google Scholar]

- Lim, H.J.; Song, B.; Park, B.; Sohn, H. Noncontact fatigue crack visualization using nonlinear ultrasonic modulation. NDT E Int. 2015, 73, 8–14. [Google Scholar] [CrossRef]

- Carpenteri, A.; Lacidogna, G. Damage monitoring of an historical masonry building by the acoustic emission technique. Mater. Struct. 2006, 39, 161–167. [Google Scholar]

- Li, Z.; Li, F.; Li, X. P-wave arrival determination and AE characterization of concrete. J. Eng. Mech. 2000, 126, 194. [Google Scholar] [CrossRef]

- Li, Z.; Li, F.; Shah, S.P. Application of Acoustic Emission Technique to detection of reinforcing steel corrosion in concrete. ACI Mater. 1998, 95, 68–81. [Google Scholar]

- Ohtsu, M. The history and development of acoustic emission in concrete engineering. Mag. Concrete Res. 1996, 48, 321–330. [Google Scholar] [CrossRef]

- Suzuki, T.; Ohtsu, M.; Shigeishi, M. Relative damage evaluation of concrete in a road bridge by AE rate-process analysis. Mater. Struct. 2007, 40, 221–227. [Google Scholar] [CrossRef]

- Ettouney, M.M.; Alampalli, S. Infrastructure Health in Civil Engineering: Theory and Components; CRC Press: Boca Raton, FL, USA, 2012; pp. 363–426. [Google Scholar]

- Xiangqian, F.; Shaowei, H.; Jun, L.; Congjie, W. Acoustic emission properties of concrete on dynamic tensile test. Constr. Build. Mater. 2016, 114, 66–75. [Google Scholar] [CrossRef]

- Noorsuhada, M.N. An overview on fatigue damage assessment of reinforced concrete structures with the aid of acoustic emission technique. Constr. Build. Mater. 2016, 112, 424–439. [Google Scholar] [CrossRef]

- Ohtsu, M. AE and Related NDT for Damage Evaluation of Civil Structures: Prospective Applications of AE measurements to infra-dock of concrete structures. Constr. Build. Mater. 2018, 158, 1134–1142. [Google Scholar] [CrossRef]

- Ohtsu, M. Elastic wave methods for NDE in concrete based generalized theory of acoustic emission. Constr. Build. Mater. 2016, 122, 845–854. [Google Scholar] [CrossRef]

- Farnam, Y.; Geiker, M.R.; Bentz, D.; Weiss, J. Acoustic emission waveform characterization of crack origin and mode in fractured and ASR damaged concrete. Cem. Concrete Compos. 2015, 60, 135–145. [Google Scholar] [CrossRef]

- Paul, S.C.; Pirskawetz, S.; Van Zijl, G.P.A.G.; Schmidt, W. Acoustic emission for characterising the crack propagation in strain-hardening cement-based composites (SHCC). Cem. Concrete Res. 2015, 69, 19–24. [Google Scholar] [CrossRef]

- Saliba, J.; Matallah, M.; Loukili, A.; Regoin, J.P.; Gregorie, D.; Verdon, L.; Pijaudier-Cabot, G. Experimental and numerical analysis of crack evolution in concrete through acoustic emission technique and mesoscale modelling. Eng. Fract. Mech. 2016, 167, 123–137. [Google Scholar] [CrossRef]

- Ongpeng, J.M.C.; Oreta, A.W.C.; Hirose, S. Monitoring Damage in Reinforced Concrete Structure using Seesaw Effect through Acoustic Emission test. In Proceedings of the 32nd European Conference on Acoustic Emission Testing (EWGAE 2016), Prague, Czech Republic, 7–9 September 2016; pp. 383–392. [Google Scholar]

- Bosia, F.; Pugno, N.; Lacidogna, G.; Carpinteri, A. Mesoscopic modeling of Acoustic Emission through an energetic approach. Int. J. Solids Struct. 2008, 45, 5856–5866. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Accornero, F.; Mpalaskas, A.C.; Matikas, T.E.; Aggelis, D.G. Influence of damage in the acoustic emission parameters. Cem. Concrete Compos. 2013, 44, 9–16. [Google Scholar] [CrossRef]

- Kocur, G.K.; Saenger, E.H.; Grosse, C.U.; Vogel, T. Time reverse modeling of acoustic emissions in a reinforced concrete beam. Ultrasonics 2016, 65, 96–104. [Google Scholar] [CrossRef] [PubMed]

- Lacigdona, G.; Piana, G.; Carpinteri, A. Acoustic Emission and Modal Frequency Variation in Concrete Specimens under Four-point Bending. Appl. Sci. 2017, 7, 339. [Google Scholar] [CrossRef]

- Alam, S.Y.; Loukili, A.; Grondin, F.; Roziere, E. Use of digital image correlation and acoustic emission technique to study the effect of structural size on cracking of reinforced concrete. Eng. Fract. Mech. 2015, 143, 17–31. [Google Scholar] [CrossRef]

- Shahidan, S.; Pullin, R.; Bunnori, N.M.; Holford, K.M. Damage Classification in Reinforced Concrete beam by Acoustic Emission. Constr. Build. Mater. 2013, 45, 78–86. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Mpalaskas, A.C.; Matikas, T.E. Investigation of different fracture modes in cement-based materials by acoustic emission. Cem. Concrete Res. 2013, 48, 1–8. [Google Scholar] [CrossRef]

- Behnia, A.; Ranjbar, N.; Chai, H.K.; Masaeli, M. Failure prediction and reliability analysis of ferrocement composite structures by incorporating machine learning into acoustic emission monitoring technique. Constr. Build. Mater. 2016, 122, 823–832. [Google Scholar] [CrossRef]

- Ongpeng, J.M.C. Acoustic Emission Test in Visualizing Crack Progression for Concrete Beams. Asian J. Civ. Eng. 2016, 17, 479–486. [Google Scholar]

- Vidya Sagar, R. A parallel between earthquake sequences and acoustic emissions released during the fracture process in reinforced concrete structures under flexural loading. Constr. Build. Mater. 2016, 114, 772–793. [Google Scholar] [CrossRef]

- Selman, E.; Ghiami, A.; Alver, N. Study of fracture evolution in FRP-strengthened reinforced concrete beam under cyclic load by acoustic emission technique: An integrated mechanical-acoustical energy approach. Constr. Build. Mater. 2015, 95, 832–841. [Google Scholar] [CrossRef]

- Antonaci, P.; Bocca, P.; Masera, D. Fatigue crack propagation monitoring by Acoustic Emission signal analysis. Eng. Fract. Mech. 2012, 81, 26–32. [Google Scholar] [CrossRef]

- Alam, S.Y.; Saliba, J.; Loukili, A. Fracture examination in concrete through combined digital image correlation and acoustic emission techniques. Constr. Build. Mater. 2014, 69, 232–242. [Google Scholar] [CrossRef]

- Tschegg, E.K.; Schneemayer, A.; Merta, I.; Rieder, K.A. Energy dissipation capacity of fibre reinforced concrete under biaxial tension-compression load. Part II: Determination of the fracture process zone with the acoustic emission technique. Cem. Concrete Compos. 2015, 62, 187–194. [Google Scholar] [CrossRef]

- Shah, S.G.; Chandra Kishen, J.M. Use of acoustic emissions in flexural fatigue crack growth studies on concrete. Eng. Fract. Mech. 2012, 87, 36–47. [Google Scholar] [CrossRef]

- Shah, D.G.; Chandra Kishen, J.M. Fracture behavior of concrete-concrete interface using acoustic emission technique. Eng. Fract. Mech. 2010, 77, 908–924. [Google Scholar] [CrossRef]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- De Berg, M.; Kreveld, M.V.; Overmars, M.; Schwarzkopf, O. Computational Geometry Algorithms and Applications, 2nd ed.; Springer: Berlin, Germany, 1998. [Google Scholar]

- Suresh Kumar, C.; Arumugam, V.; Sengottuvelusamy, R.; Srinivasan, S.; Dhakal, H.N. Failure strength prediction of glass/epoxy composite laminates from acoustic emission parameters using artificial neural network. Appl. Acoust. 2017, 115, 32–41. [Google Scholar] [CrossRef]

- Li, S.; Song, Y.; Zhou, G. Leak detection of water distribution pipeline subject to failure of socket joint based on acoustic emission and pattern recognition. Measurement 2018, 115, 39–44. [Google Scholar] [CrossRef]

- Morizet, N.; Godin, N.; Tang, J.; Maillet, E.; Fregonese, M.; Normand, B. Classification of acoustic emission signals using wavelets and Random Forests: Application to localized corrosion. Mech. Syst. Signal Process. 2016, 70, 1026–1037. [Google Scholar] [CrossRef]

- Cormen, T.; Leiserson, C.; Rivest, R.; Stein, C. Introduction to Algorithms, 3rd ed.; MIT Press: Cambridge, MA, USA, 2009. [Google Scholar]

- Barber, C.B.; Dobkin, D.P.; Huhdanpaa, H.T. The quickhull algorithm for convex hulls. ACM Trans. Math. Softw. 1996, 22, 469–483. [Google Scholar] [CrossRef]

- Petyrniak, R. Application of convex hull algorithm for defect detection in selected biological materials. Solid State Phenom. 2013, 197, 41–46. [Google Scholar] [CrossRef]

- Just-Agosto, F.; Shafiq, B.; Serrano, D. Development of a damage detection scheme applicable to sandwich composites. J. Sandw. Struct. Mater. 2007, 9, 343–363. [Google Scholar] [CrossRef]

| Maximum Aggregate Size (mm) | Unit Quantity (kg/m3) | ||||

|---|---|---|---|---|---|

| W/C (%) | Cement | Sand | Gravel | Water-Reducing Agent | |

| 20 mm | 40 and 60 | 344 | 761 | 1038 | 0.69 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ongpeng, J.M.C.; Oreta, A.W.C.; Hirose, S. Monitoring Damage Using Acoustic Emission Source Location and Computational Geometry in Reinforced Concrete Beams. Appl. Sci. 2018, 8, 189. https://doi.org/10.3390/app8020189

Ongpeng JMC, Oreta AWC, Hirose S. Monitoring Damage Using Acoustic Emission Source Location and Computational Geometry in Reinforced Concrete Beams. Applied Sciences. 2018; 8(2):189. https://doi.org/10.3390/app8020189

Chicago/Turabian StyleOngpeng, Jason Maximino C., Andres Winston C. Oreta, and Sohichi Hirose. 2018. "Monitoring Damage Using Acoustic Emission Source Location and Computational Geometry in Reinforced Concrete Beams" Applied Sciences 8, no. 2: 189. https://doi.org/10.3390/app8020189

APA StyleOngpeng, J. M. C., Oreta, A. W. C., & Hirose, S. (2018). Monitoring Damage Using Acoustic Emission Source Location and Computational Geometry in Reinforced Concrete Beams. Applied Sciences, 8(2), 189. https://doi.org/10.3390/app8020189