A Novel Design of Through-Hole Depth On-Machine Optical Measuring Equipment for Automatic Drilling and Riveting

Abstract

Featured Application

Abstract

1. Introduction

2. Approach Description

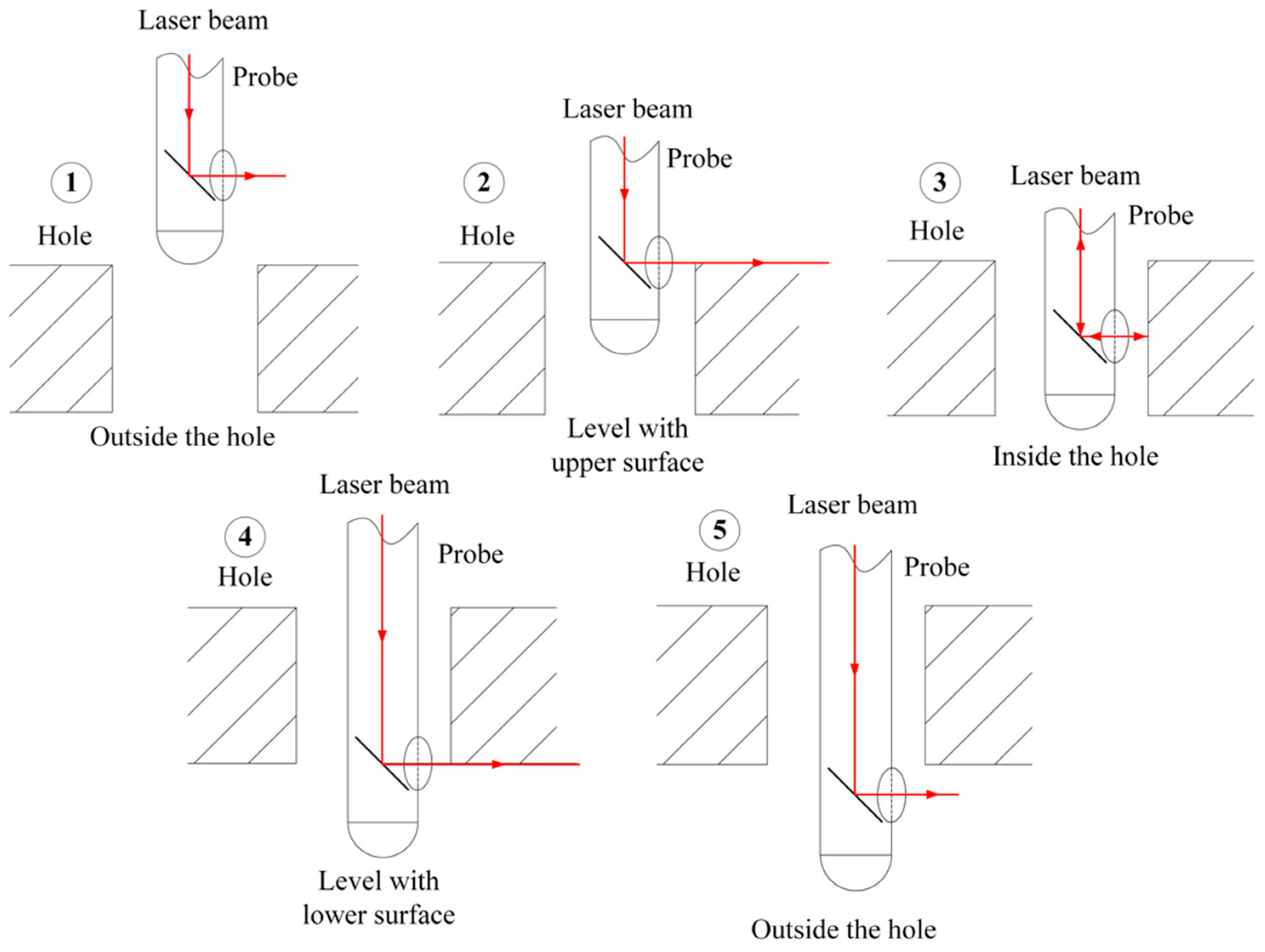

2.1. Measurement Scheme

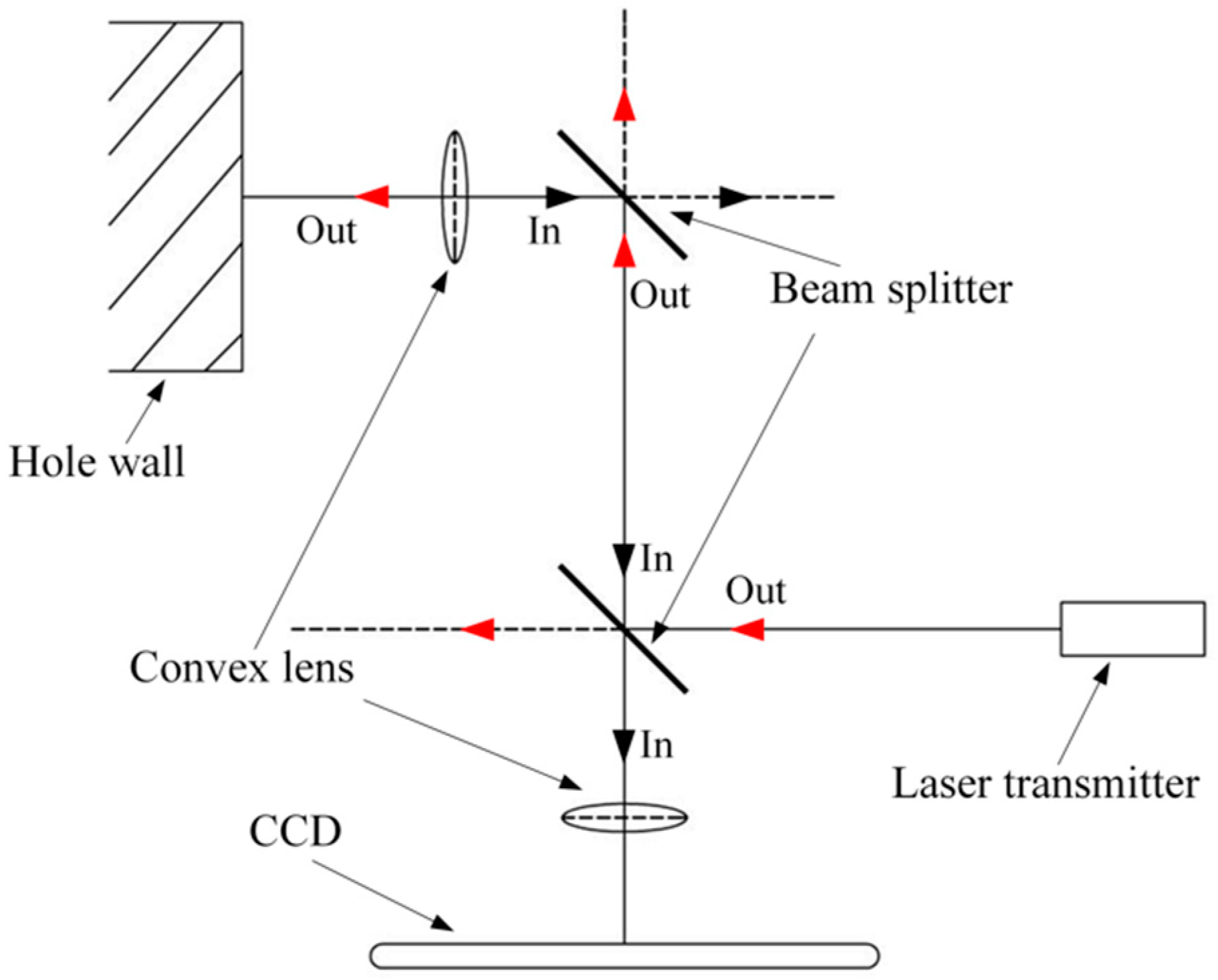

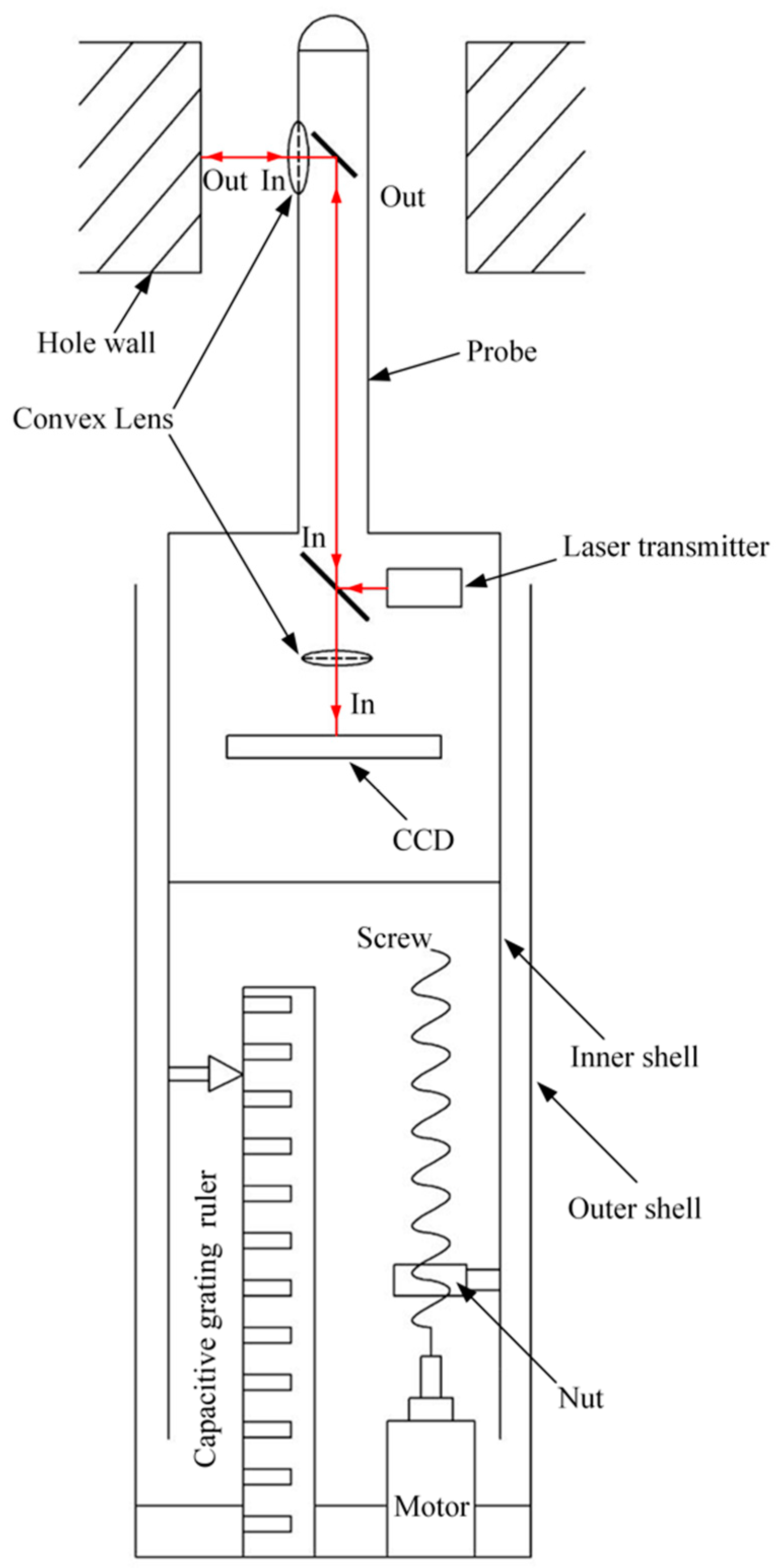

2.2. Optical Path Design

2.3. Image Processing

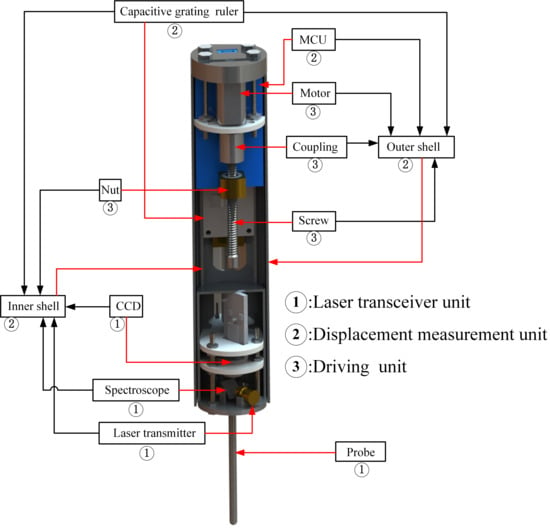

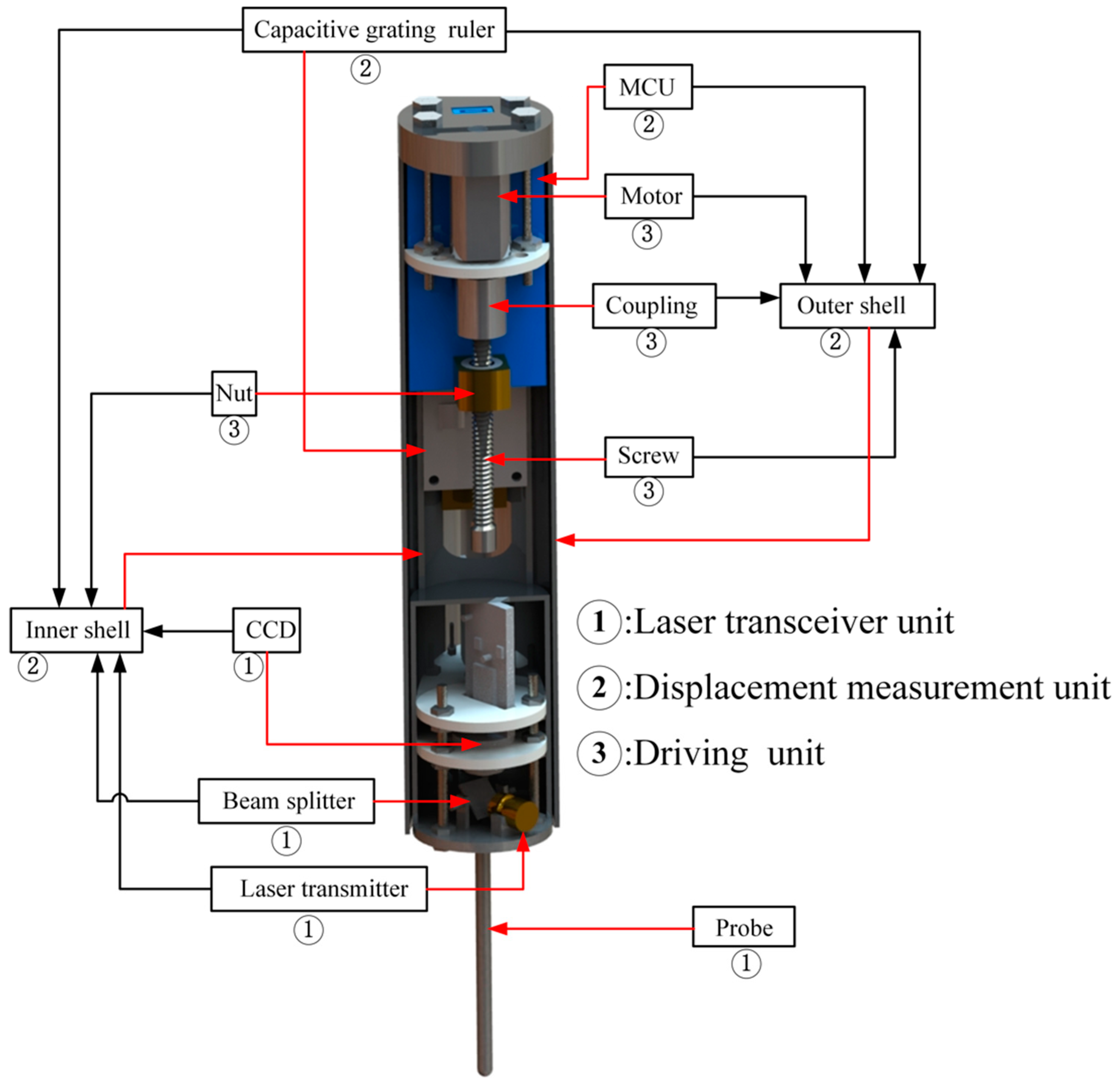

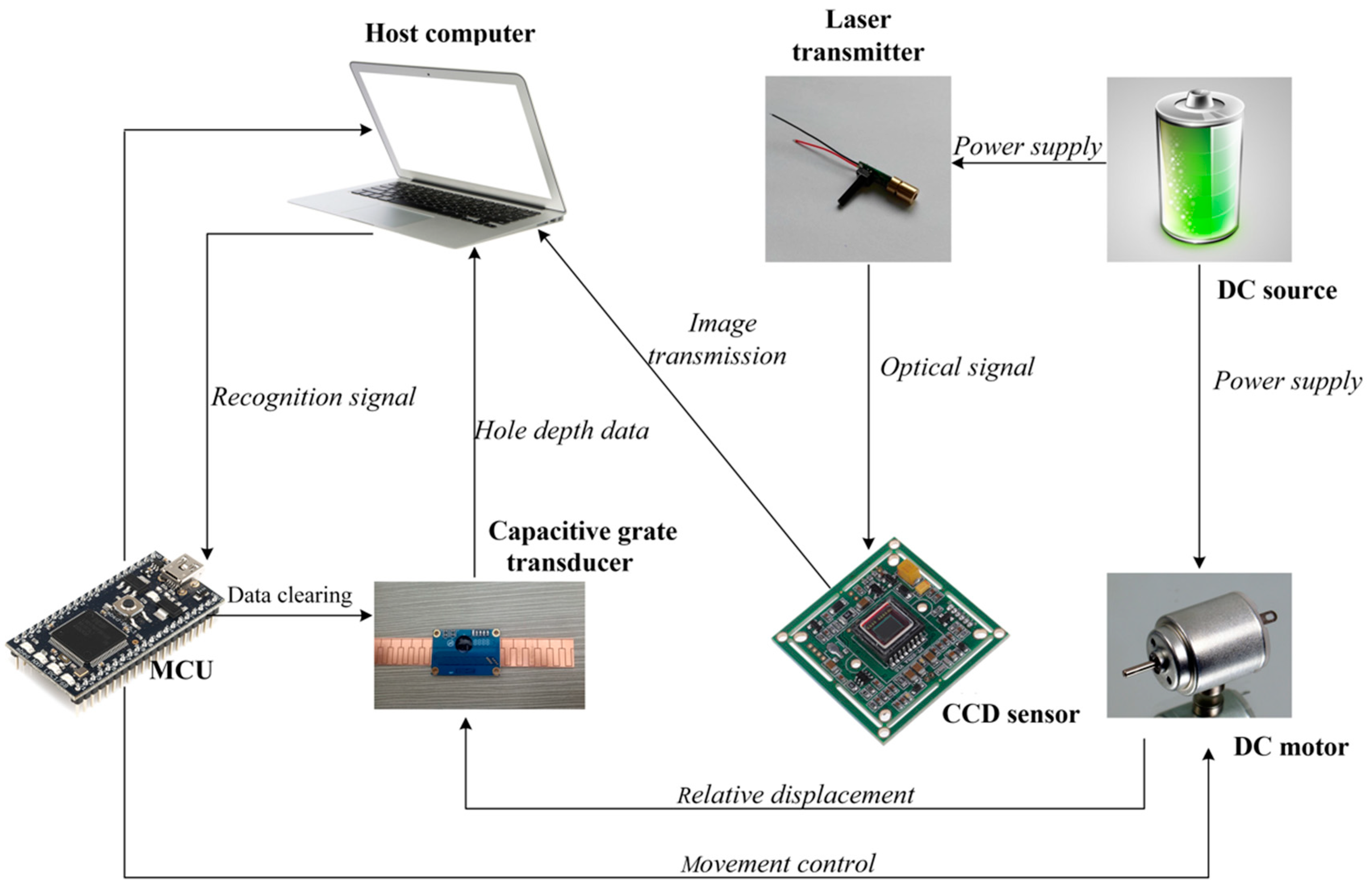

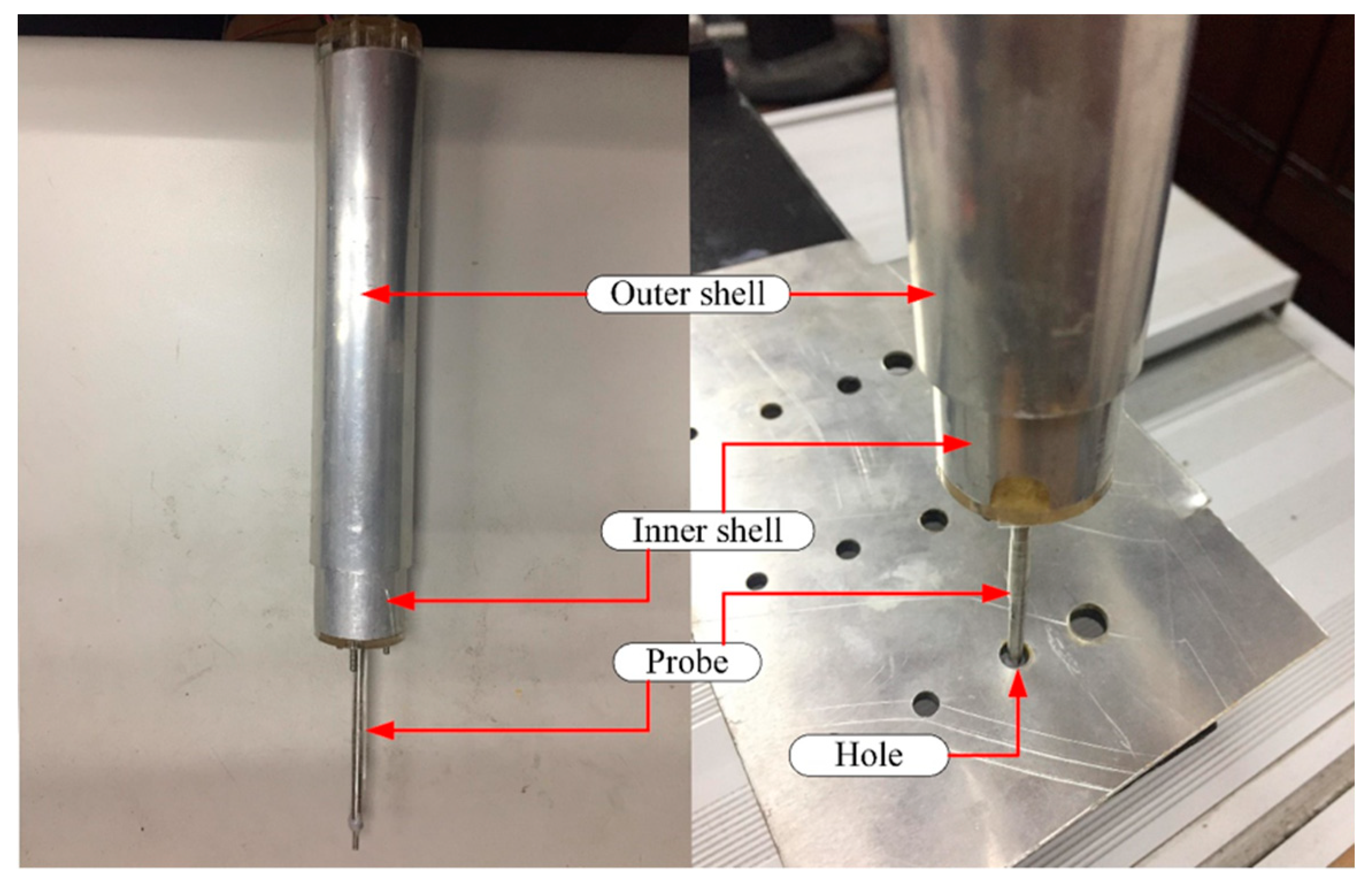

2.4. Hardware Design

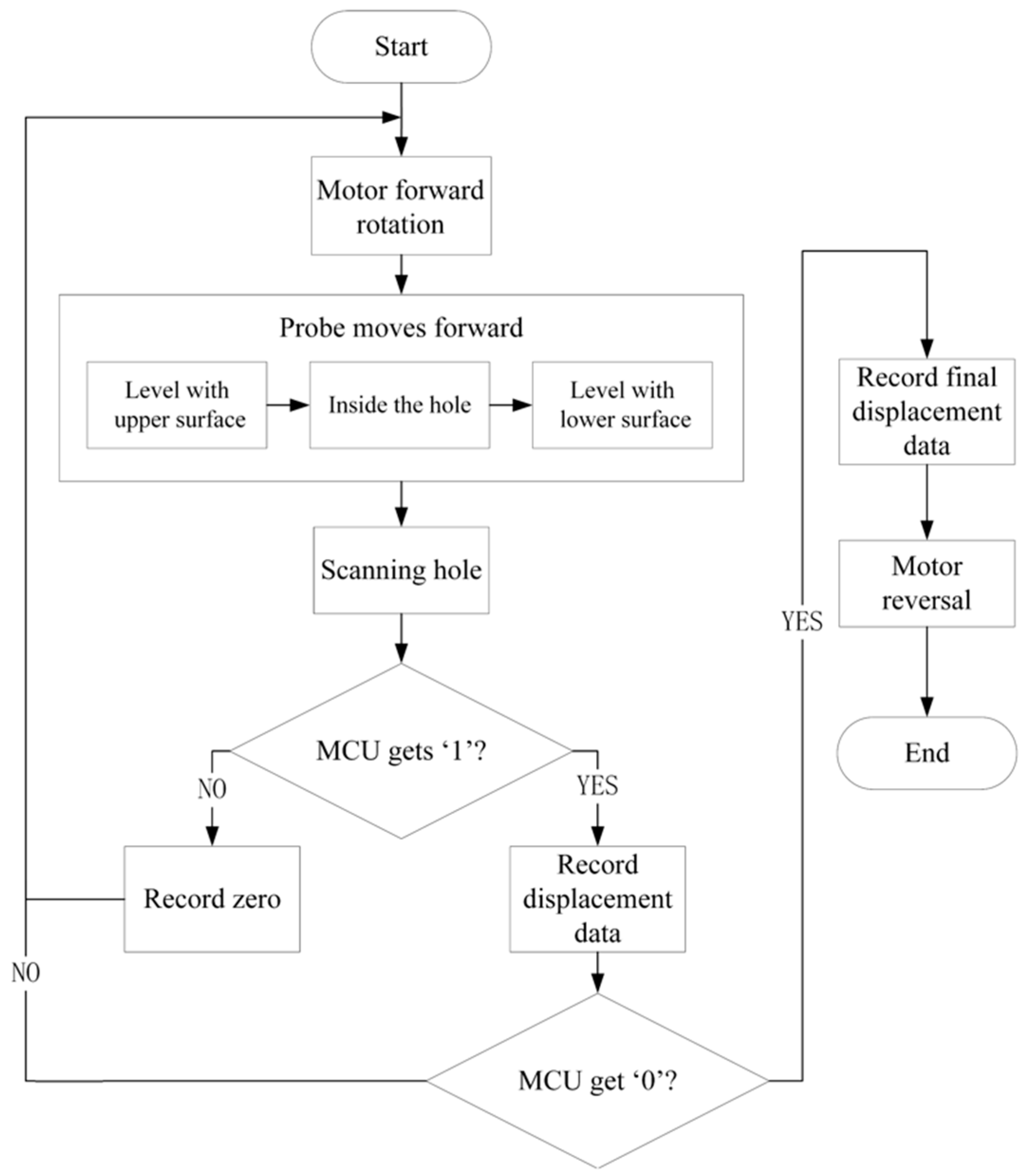

2.5. Software Design

3. Experiment Results

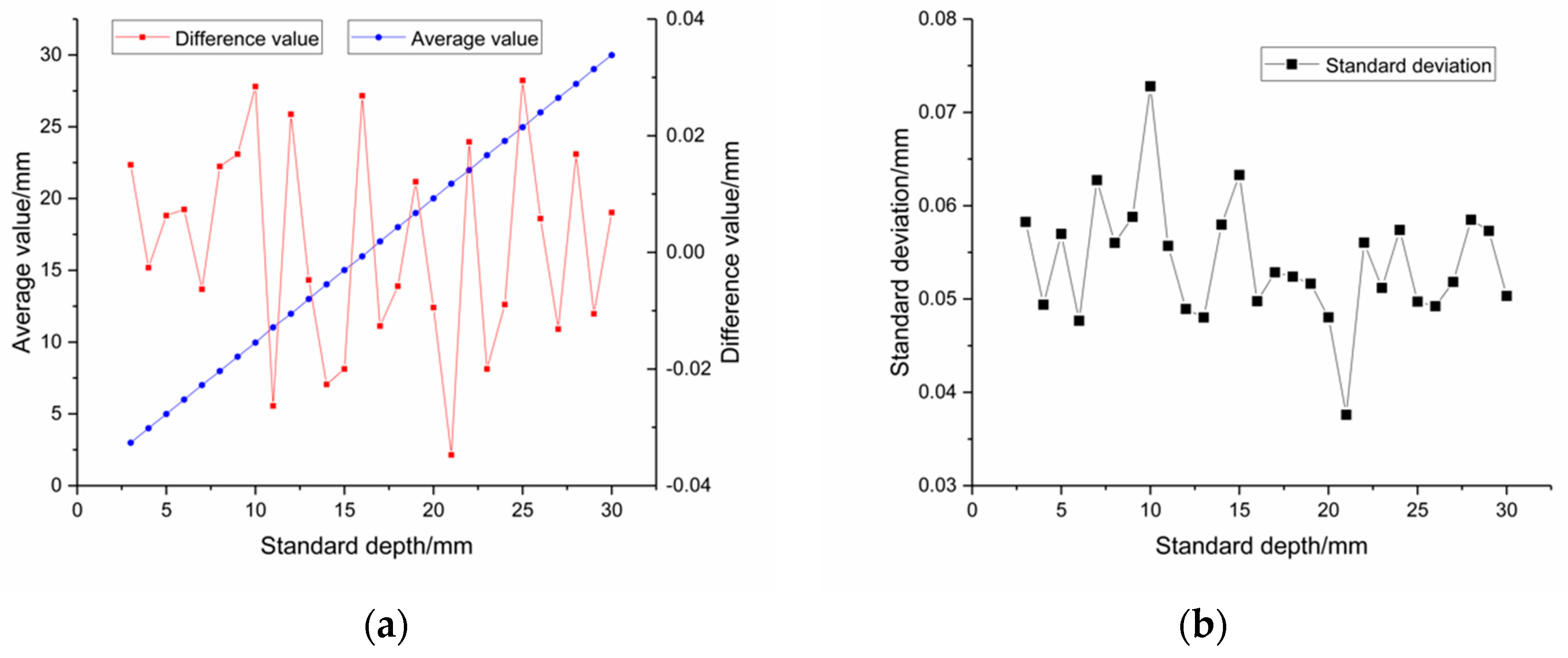

3.1. Measurement Accuracy and Repeatability Verification

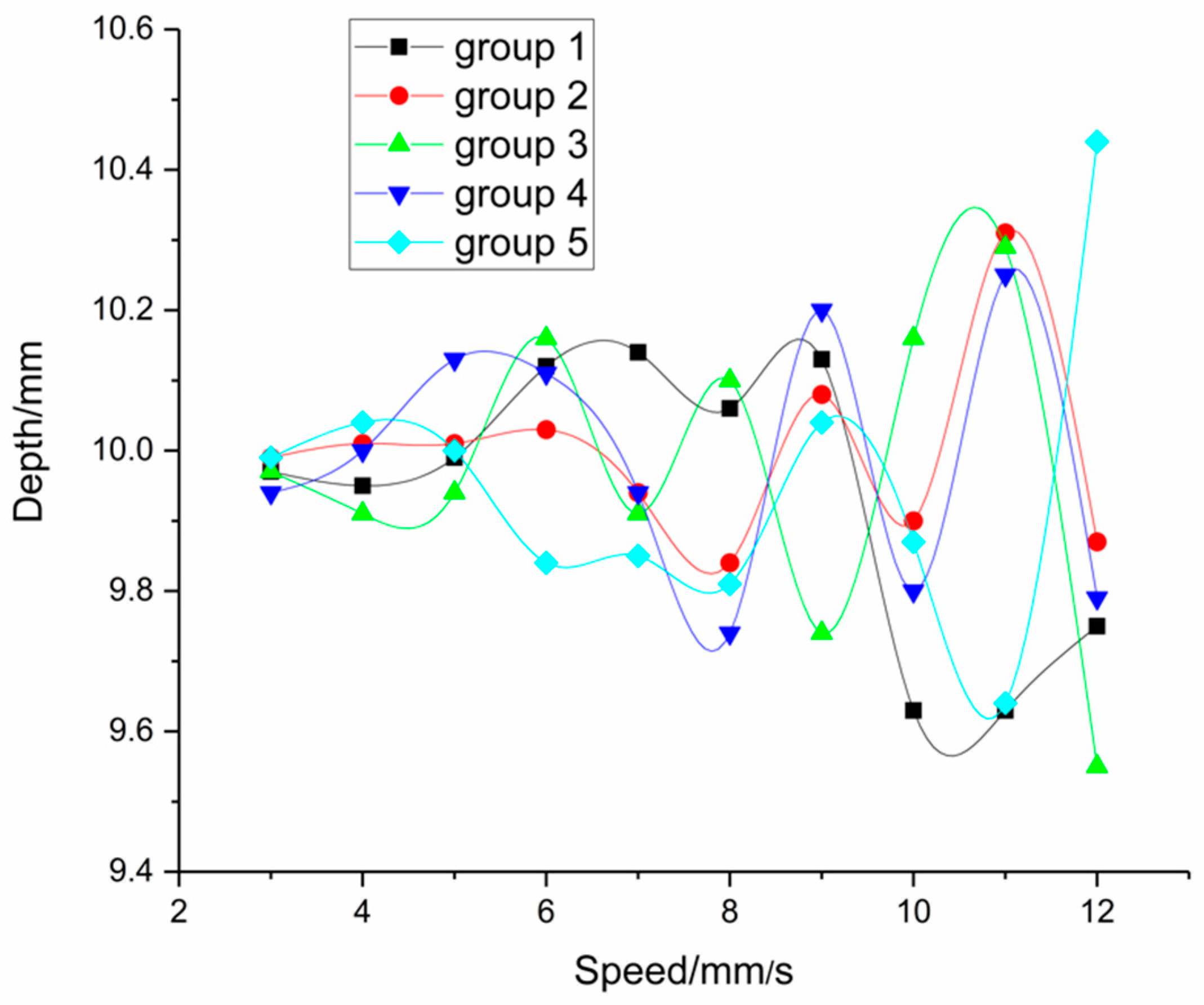

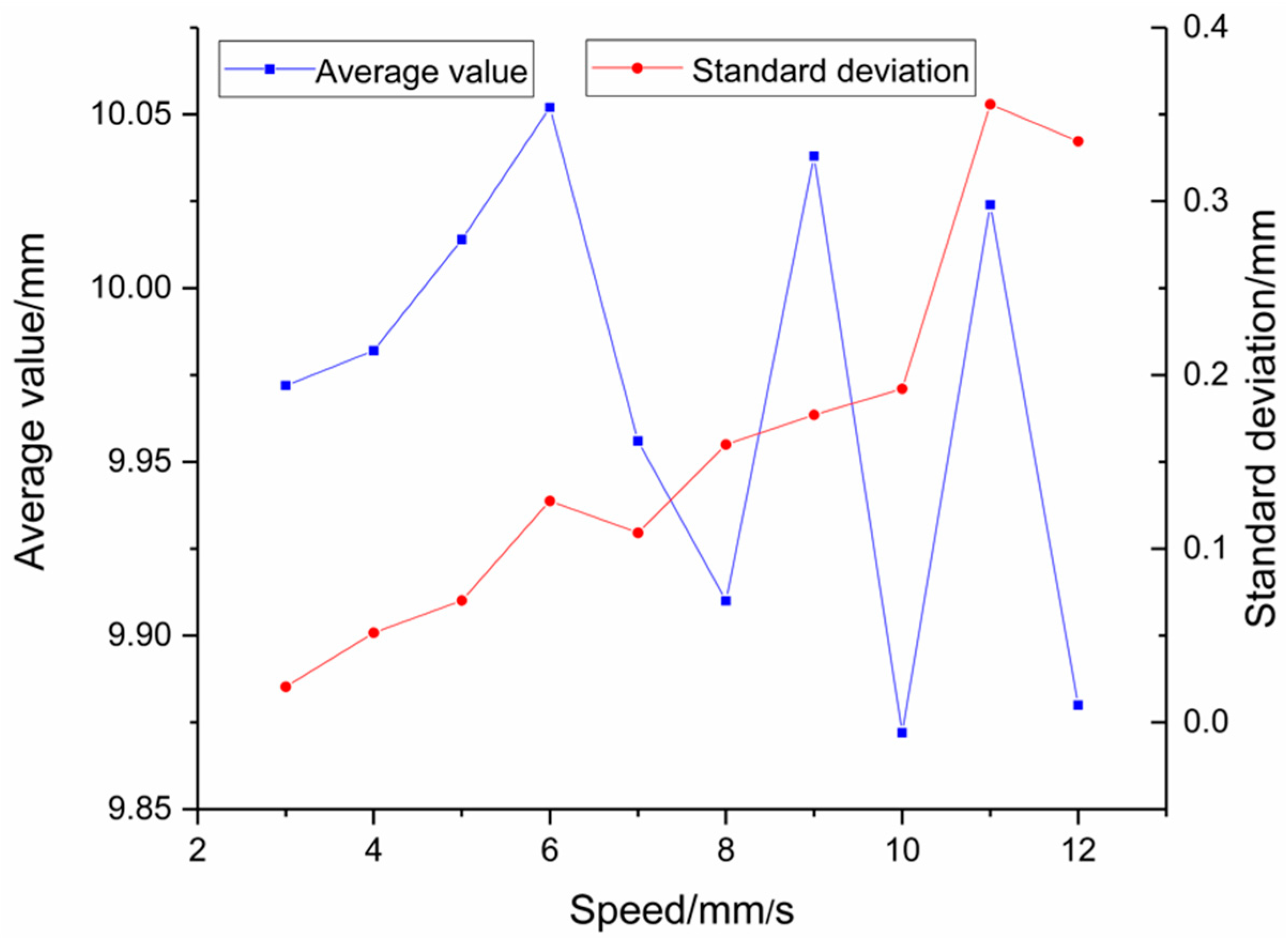

3.2. The Effect of Feed Speed on Measurement Accuracy and Stability

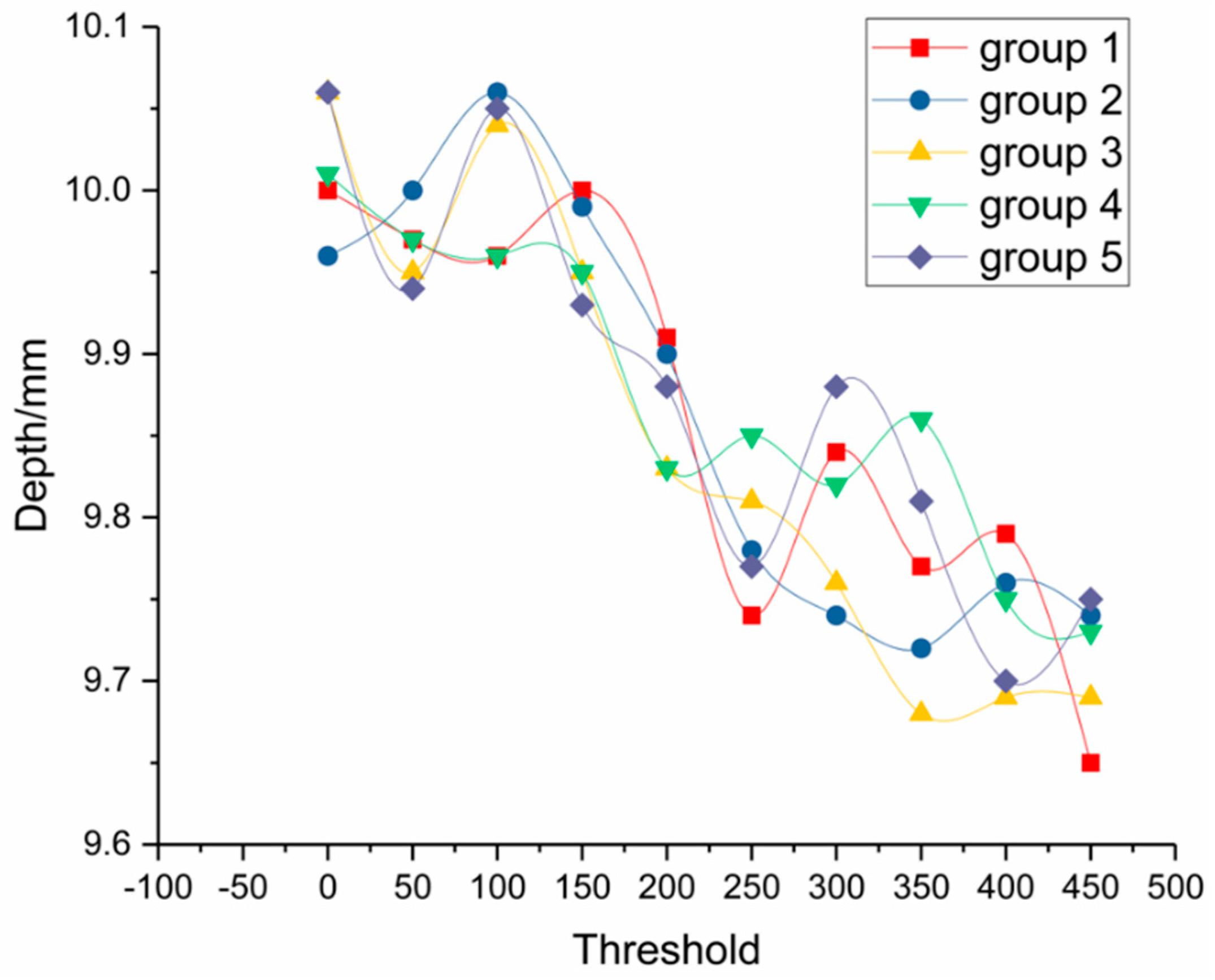

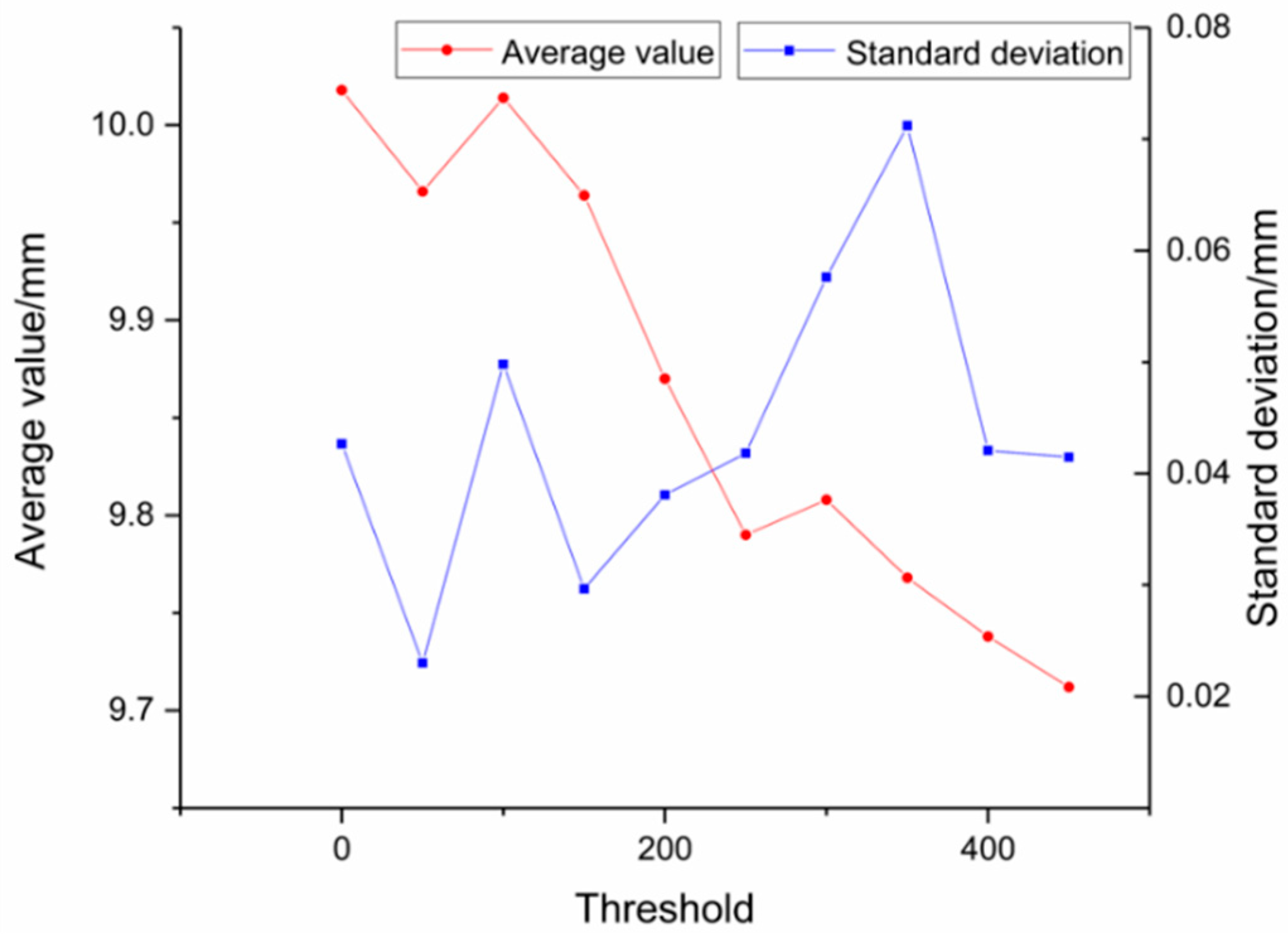

3.3. The Effect of Pixel Threshold on Measurement Accuracy and Stability

4. Analysis and Discussion

- According to the repetitive measurement experiment in Section 3.1, it can be seen that in the absence of error compensation algorithm and under measuring speed of 4 mm/s and white pixel threshold of 100, the measurement error of each time is about 0.05 mm and does not exceed 0.1 mm; the fluctuation range of standard deviation is between 0.038 mm and 0.073 mm. Above accuracy and stability of the designed measuring device are sufficient to meet the hole depth measuring requirements for automatic drilling and riveting of large-scale composite board parts.

- Through the experiment on the effect of feed speed on measurement accuracy in Section 3.2, it can be seen that with the increase of probe feed speed, the measurement stability of the device decreases gradually. Considering the factors of measurement efficiency, the optimal probe feed speed is 5 mm/s, while ensuring its measurement stability.

- Based on the effect of pixel threshold on measurement values in Section 3.3, it can be seen that with the increase of the pixel threshold, the measured hole depth gradually decreases, which is in line with expectations. Moreover, with the increase of pixel threshold, the stability of measurement fluctuates. Therefore, in order to bring the measuring result closer to the true value, the optimal pixel threshold in this experiment should be 100. In practical applications, the optimal pixel threshold needs to be adjusted according to the measurement object due to effects such as flash, burrs, iron filings, etc.

- In follow-up studies, we can further design and optimize an error compensation algorithm and automatic calibration method, study the corresponding relationship between feed speed and measurement error and find an effective compensation method, study the mapping relationship between pixel threshold and measurement error and offer a compensation method, study the specific relationship between the diameter of the laser spot and the measurement accuracy, etc., so as to further improve the measurement accuracy and efficiency of the device.

- This paper only focuses on the design of measuring methods and measuring devices, and preliminarily proves the feasibility of the proposed method. Follow-up research can integrate the prototype device into the automatic riveting manipulator arm and measure the actual engineering sample, and further explore the feasibility and stability of its engineering application.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dehoff, R.; Duty, C.; Peter, W. Case study: Additive manufacturing of aerospace brackets. Adv. Mater. Process. 2013, 171, 22–25. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, Y.; Bi, Q.; Wang, Y. Research on surface normal measurement and adjustment in aircraft assembly. Precis. Eng. 2017, 50, 482–493. [Google Scholar] [CrossRef]

- Patterson, J.B.; Grenestedt, J.L. Manufacturing of a composite wing with internal structure in one cure cycle. Compos. Struct. 2018, 206, 601–609. [Google Scholar] [CrossRef]

- Ahmed, E.; Wan Badaruzzaman, W.H.; Wright, H.D. Two-way bending behavior of profiled steel sheet dry board composite panel system. Thin-Walled Struct. 2002, 40, 971–990. [Google Scholar] [CrossRef]

- Tian, W.; Zhou, Z.; Liao, W. Analysis and investigation of a rivet feeding tube in an aircraft automatic drilling and riveting system. Int. J. Adv. Manuf. Technol. 2016, 82, 973–983. [Google Scholar] [CrossRef]

- Bernard, T.; Bergmann, H.W.; Haberling, C.; Haldenwanger, H. Joining Technologies for Al-Foam—Al-Sheet Compound Structures. Adv. Eng. Mater. 2002, 4, 798–802. [Google Scholar] [CrossRef]

- Li, Y.; Li, N.; Gao, J. Tooling design and microwave curing technologies for the manufacturing of fiber-reinforced polymer composites in aerospace applications. Int. J. Adv. Manuf. Technol. 2014, 70, 591–606. [Google Scholar] [CrossRef]

- Hassan, A.; Maskin, M.; Tom, P.P.; Brayon, F.; Hlavac, P.; Mohamed, F. Operator response modeling and human error probability in TRIGA Mark II research reactor probabilistic safety assessment. Ann. Nucl. Energy 2017, 102, 179–189. [Google Scholar] [CrossRef]

- Shetty, D.; Eppes, T.; Campana, C.; Filburn, T.; Nazaryan, N. New Approach to the Inspection of Cooling Holes in Aero-Engines. Opt. Lasers Eng. 2009, 47, 686–694. [Google Scholar] [CrossRef]

- Baeg, M.H.; Baeg, S.H.; Moon, C.; Jeong, G.M.; Ahn, H.S.; Kim, D.H. A New Robotic 3D Inspection System of Automotive Screw Hole. Int. J. Control Autom. Syst. 2008, 6, 740–745. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Lopez, I. Non-destructive inspection of drilled holes in reinforced honeycomb sandwich panels using active thermography. Infrared Phys. Technol. 2012, 55, 491–498. [Google Scholar] [CrossRef]

- Gong, X.; Su, H.; Zhang, Z.T.; Xu, C. Vision-based quality inspection for components with small diameter and deep hole. In Proceedings of the IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 6–9 August 2017; IEEE: New York, NY, USA, 2017; pp. 2016–2021. [Google Scholar]

- Bernard, F.; Flaherty, T.; O’Connor, G.M. Novel fiber-based technique for inspection of holes in narrow-bore tubes. In Proceedings of the Optical Measurement Systems for Industrial Inspection VI, Munich, Germany, 15–18 June 2009; SPIE-The International Society for Optical Engineering: Bellingham, WA, USA, 2009; p. 7389. [Google Scholar]

- Zavyalov, P. 3D Hole Inspection Using Lens with High Field Curvature. Meas. Sci. Rev. 2015, 15, 52–57. [Google Scholar] [CrossRef]

- Quest, D.; Gayer, C.; Hering, P. Depth measurements of drilled holes in bone by laser triangulation for the field of oral implantology. J. Appl. Phys. 2012, 111, 013106. [Google Scholar] [CrossRef]

- Takeda, M.; Aokl, T.; Miyamoto, Y.; Tanaka, H.; Gu, R.; Zhang, Z. Absolute three-dimensional shape measurements using coaxial and coimage plane optical systems and Fourier fringe analysis for focus detection. Opt. Eng. 2000, 39, 61–68. [Google Scholar] [CrossRef]

- Heredia-Ortiz, M.; Patterson, E.A. On the industrial applications of moire and fringe projection techniques. Strain 2003, 39, 95–100. [Google Scholar] [CrossRef]

- Casavola, C.; Pappalettera, G.; Pappalettere, C. Design of a fiber optics fringe projector for 3D reconstruction of dental elements. In Proceedings of the 3rd Mediterranean Photonics Conference, Trani, Italy, 7–9 May 2014. [Google Scholar] [CrossRef]

- Lin, C.H.; Powell, R.A.; Jiang, L.; Xiao, H.; Chen, S.J.; Tsai, H.L. Real-time depth measurement for micro-holes drilled by lasers. Meas. Sci. Technol. 2010, 21, 025307. [Google Scholar] [CrossRef]

- Ho, C.C.; Chiu, C.M.; Chang, Y.J.; Hsu, J.C.; Kuo, C.L. On-line depth measurement for laser-drilled holes based on the intensity of plasma emission. Meas. Sci. Technol. 2014, 25, 094007. [Google Scholar] [CrossRef]

- Hung, Y.H.; Chien, H.L.; Lee, Y.C. Excimer Laser Three-Dimensional Micromachining Based on Image Projection and the Optical Diffraction Effect. Appl. Sci. 2018, 8, 1690. [Google Scholar] [CrossRef]

- Agnesi, A.; Degiorgio, V. Beam splitter phase shifts: Wave optics approach. Opt. Laser Technol. 2017, 95, 72–73. [Google Scholar] [CrossRef]

- Kumar, U.P.; Haifeng, W.; Mohan, N.K.; Kothiyal, M.P. White light interferometry for surface profiling with a colour CCD. Opt. Lasers Eng. 2012, 50, 1084–1088. [Google Scholar] [CrossRef]

- Jahedsaravani, A.; Massinaei, M.; Marhaban, M.H. Development of a machine vision system for real-time monitoring and control of batch flotation process. Int. J. Miner. Process. 2017, 167, 16–26. [Google Scholar] [CrossRef]

- Carney, M.N.; Johnston, W.M. A novel regression model from RGB image data to spectroradiometric correlates optimized for tooth colored shades. J. Dent. 2016, 51, 45–48. [Google Scholar] [CrossRef]

- Chaves-Gonzalez, J.M.; Vega-Rodriguez, M.A.; Gomez-Pulido, J.A.; Sanchez-Perez, J.M. Detecting skin in face recognition systems: A colour spaces study. Digit. Signal Prog. 2010, 20, 806–823. [Google Scholar] [CrossRef]

- Seo, D.K.; Kim, Y.H.; Eo, Y.D.; Park, W.Y. Learning-Based Colorization of Grayscale Aerial Images Using Random Forest Regression. Appl. Sci. 2018, 8, 1269. [Google Scholar] [CrossRef]

- Pai, K.J.; Qin, L.D.; Lin, C.H.; Tang, S.Y. Start-Up Current Spike Mitigation of High-Power Laser Diode Driving Controller for Vehicle Headlamp Applications. Appl. Sci. 2018, 8, 1532. [Google Scholar] [CrossRef]

- Chen, Q.; Sun, Q.S.; Heng, P.A.; Xia, D.S. A double-threshold image binarization method based on edge detector. Pattern Recognit. 2008, 41, 1254–1267. [Google Scholar] [CrossRef]

- Nouira, H.; Vissiere, A.; Damak, M.; David, J.M. Investigation of the influence of the main error sources on the capacitive displacement measurements with cylindrical artefacts. Precis. Eng. 2013, 37, 721–737. [Google Scholar] [CrossRef]

- Lee, D.; Cho, J.; Kim, C.H.; Lee, S.H. Application of laser spot cutting on spring contact probe for semiconductor package inspection. Opt. Laser Technol. 2017, 97, 90–96. [Google Scholar] [CrossRef]

| Standard Depth (mm) | Five sets of Actual Measured Value (mm) | ||||

|---|---|---|---|---|---|

| First | Second | Third | Fourth | Fifth | |

| 3 | 3.03 | 3.08 | 2.98 | 2.93 | 2.90 |

| 4 | 4.00 | 4.01 | 3.98 | 4.07 | 4.10 |

| 5 | 5.01 | 5.10 | 5.06 | 5.03 | 5.07 |

| 6 | 5.99 | 6.09 | 6.03 | 5.99 | 5.96 |

| 7 | 7.03 | 7.00 | 7.09 | 7.10 | 6.90 |

| 8 | 7.94 | 7.93 | 8.02 | 8.01 | 8.05 |

| 9 | 8.93 | 9.05 | 8.97 | 8.90 | 8.91 |

| 10 | 9.93 | 10.04 | 9.90 | 9.93 | 10.00 |

| 11 | 10.94 | 11.03 | 11.08 | 11.1 | 11.02 |

| 12 | 11.95 | 11.97 | 12.06 | 11.91 | 11.95 |

| 13 | 13.05 | 13.08 | 13.03 | 13.07 | 12.96 |

| 14 | 14.04 | 14.07 | 14.05 | 13.92 | 14.01 |

| 15 | 15.06 | 15.05 | 15.05 | 15.09 | 15.04 |

| 16 | 15.98 | 15.92 | 15.92 | 16.01 | 15.93 |

| 17 | 17.07 | 17.00 | 16.94 | 17.02 | 17.07 |

| 18 | 18.04 | 18.06 | 18.01 | 17.98 | 18.00 |

| 19 | 18.95 | 18.99 | 18.95 | 19.02 | 19.02 |

| 20 | 19.99 | 20.07 | 20.05 | 20.06 | 20.03 |

| 21 | 20.97 | 21.08 | 20.97 | 21.01 | 21.03 |

| 22 | 22.08 | 21.98 | 21.95 | 22.04 | 21.95 |

| 23 | 23.02 | 22.93 | 22.99 | 23.06 | 22.98 |

| 24 | 24.03 | 24.03 | 23.94 | 23.94 | 23.98 |

| 25 | 24.98 | 25.00 | 25.07 | 24.98 | 24.96 |

| 26 | 25.94 | 25.97 | 26.03 | 25.95 | 25.94 |

| 27 | 27.08 | 26.98 | 27.07 | 26.99 | 26.94 |

| 28 | 27.92 | 28.02 | 28.05 | 28.07 | 27.96 |

| 29 | 29.00 | 28.92 | 29.07 | 29.05 | 28.98 |

| 30 | 29.97 | 30.06 | 30.05 | 29.99 | 29.97 |

| Feed Speed (mm/s) | Five Groups of Actual Measured Value (mm) | ||||

|---|---|---|---|---|---|

| First | Second | Third | Fourth | Fifth | |

| 3 | 9.97 | 9.99 | 9.97 | 9.94 | 9.99 |

| 4 | 9.95 | 10.01 | 9.91 | 10.00 | 10.04 |

| 5 | 9.99 | 10.01 | 9.94 | 10.13 | 10.00 |

| 6 | 10.12 | 10.03 | 10.16 | 10.11 | 9.84 |

| 7 | 10.14 | 9.94 | 9.91 | 9.94 | 9.85 |

| 8 | 10.06 | 9.84 | 10.10 | 9.74 | 9.81 |

| 9 | 10.13 | 10.08 | 9.74 | 10.20 | 10.04 |

| 10 | 9.63 | 9.9 | 10.16 | 9.80 | 9.87 |

| 11 | 9.63 | 10.31 | 10.29 | 10.25 | 9.64 |

| 12 | 9.75 | 9.87 | 9.55 | 9.79 | 10.44 |

| Pixel Threshold | Five Groups of Actual Measured value (mm) | ||||

|---|---|---|---|---|---|

| First | Second | Third | Fourth | Fifth | |

| 0 | 10 | 9.96 | 10.06 | 10.01 | 10.06 |

| 50 | 9.97 | 10 | 9.95 | 9.97 | 9.94 |

| 100 | 9.96 | 10.06 | 10.04 | 9.96 | 10.05 |

| 150 | 10 | 9.99 | 9.95 | 9.95 | 9.93 |

| 200 | 9.91 | 9.9 | 9.83 | 9.83 | 9.88 |

| 250 | 9.74 | 9.78 | 9.81 | 9.85 | 9.77 |

| 300 | 9.84 | 9.74 | 9.76 | 9.82 | 9.88 |

| 350 | 9.77 | 9.72 | 9.68 | 9.86 | 9.81 |

| 400 | 9.79 | 9.76 | 9.69 | 9.75 | 9.7 |

| 450 | 9.65 | 9.74 | 9.69 | 9.73 | 9.75 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, N.; Zhao, W.; Wang, X.; Tao, Y.; Hou, Z. A Novel Design of Through-Hole Depth On-Machine Optical Measuring Equipment for Automatic Drilling and Riveting. Appl. Sci. 2018, 8, 2671. https://doi.org/10.3390/app8122671

Wu N, Zhao W, Wang X, Tao Y, Hou Z. A Novel Design of Through-Hole Depth On-Machine Optical Measuring Equipment for Automatic Drilling and Riveting. Applied Sciences. 2018; 8(12):2671. https://doi.org/10.3390/app8122671

Chicago/Turabian StyleWu, Nianhan, Wu Zhao, Xin Wang, Ye Tao, and Zhengmeng Hou. 2018. "A Novel Design of Through-Hole Depth On-Machine Optical Measuring Equipment for Automatic Drilling and Riveting" Applied Sciences 8, no. 12: 2671. https://doi.org/10.3390/app8122671

APA StyleWu, N., Zhao, W., Wang, X., Tao, Y., & Hou, Z. (2018). A Novel Design of Through-Hole Depth On-Machine Optical Measuring Equipment for Automatic Drilling and Riveting. Applied Sciences, 8(12), 2671. https://doi.org/10.3390/app8122671