Abstract

Sprinkler irrigation systems are widely used in medium and large scale farms in different forms. However less types are available to apply in small farms due to their high costs. The current study was done according to a novel cost effective design for a semi-permanent sprinkler irrigation system for small farm owners. The new layout known as Corner Pivot Lateral (CPL) was examined in irrigation test center at Lijian Scientific and Technological Demonstration Park, at Nanning city, China. CPL was implemented without a main/sub mainline pipe, by applying a single pivoting lateral at the corner of the plot that directly connected to the resource to convey water from the pump. The lateral moves around the corner using a rotating elbow in a quadrant pattern manually to cover the entire farm. A conventional semi-permanent system was applied for the same farm as reference. A cost analysis on the required components as well as annual operational costs was carried out for comparison and control. Results showed that a lower system component would be needed for the CPL method. Overall, more than a 15% capital cost reduction with 7% annual cost decrement was achieved for CPL in this experiment comparatively. The Catch can technique was applied to examine the CPL system’s efficiency and 79% water distribution uniformity around the sprinkler was obtained. This new method can encourage small estate holders to switch from traditional to pressurized systems which optimizes water application costs.

1. Introduction

Considering the importance of sustainable development, the growing population [1], the need for food [2], scant water resources [3] and low water application efficiency of traditional irrigation methods, the rapid growth of new irrigation systems is increasingly required. Almost 70% of our finite water resources are being used in the agriculture sector, mainly in not so efficacious traditional irrigation methods [4]. Moreover, as per statistics more than 11.5% of the earth planet lands are cultivated, out of which only 2.2% are irrigated and the rest are rain fed [2]. Meanwhile, these irrigated farms are providing 40% of overall required food [5]. Therefore, research on this area must be done to promote and intensify new irrigation methods implementation, taking into account water application optimization as a global imperative, costs, as well as economic benefits from a farmer’s point of view. In general, due to relatively high capital expenses, sprinkler irrigation systems are not so justifiable for smaller farms. On the other hand, in some parts of the world including regions in China, India, Africa and South American countries, whether for traditional or political reasons, the private land ownership system is more highly oriented towards smallholding. Therefore, a cheaper system can address this problem. In this work, by probing the current methods, a new layout has been introduced to more cost-effectively and innovatively enhance the mechanism, which suits small scale plots [6,7].

Sprinkler systems are more flexible and applicable in different conditions to some extent rather than traditional flood irrigation strategies [8,9], or trickle [10,11]. They work with medium (i.e., solid set) to high (i.e., gun) pressure and up to 85% efficiency [12,13,14]. Nevertheless, due to high cost requirements, wherever enough supply water is available, they are not the first choice and farmers are not willing to switch from traditional systems to new systems. Indeed, without government funds, in most regions small plot owners would not be able to afford pressurized irrigation. According to different economic studies on sprinkler irrigation systems [15,16,17], main/sub mainline length and dimension have a great influence on the system capital and annual costs requirements. Therefore, semi-permanent or portable systems have reduced the pipes and other components to offer a cost-effective option [18,19]. Mobility of laterals with buried main/sub mainline in a semi-permanent system makes it a desirable alternative with lower capital cost requirement compared to a solid set layout, while portable system offers a totally mobile component (including the mainline) layout to reduce the expenses further [20]. However, this mobility will impose a higher labor requirement as well. As per a recent work [21] a clock hand layout (CHL) technique was applied to reduce the pipe length, diameter and other required components of an ordinary semi-permanent system. It could lower the capital costs by up to 37% and annual costs by up to 11% comparatively.

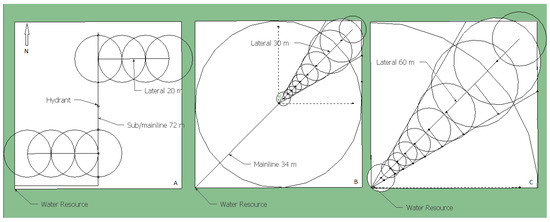

Hence, the current system layout has been developed by focusing on the costs and taking into account expediency and feasibility assurance. Investment in an irrigation project must be profitable for farmers with a reasonable break-even point to compensate for initial and operational expenses. This is more important for small state owners to return the investment costs in the shortest possible time when farms are the only income resource for a family. Therefore, it can help yeoman and small farms, especially when external subsidies are not accessible, so low cost systems are preferred. For the present work, a corner pivot lateral layout sprinkler irrigation system (CPL), is designed based on a quadrant movement of a center-pivot system, but it moves manually. In this layout a considerable length of required pipe will be diminished (compared to traditional semi-permanent system) which will lower the capital and consequently operational and annual expenses. The theory was put forward according to a small plot requirement as an integration of both semi-permanent and center-pivot techniques. In this novel design, the lateral is directly connected to the water resource at the corner of the farm and it will rotate around the pivot point 90 degrees in square shape plots (and less or more according to the plot shape) manually. It also needs a smaller number of fittings, outlet valves, and coupling joints if properly designed, which will consequently reduce the grand total costs. In a conventional semi-permanent system which is normally designed as split-lateral (Figure 1A), the two removable laterals are on the both ends of the sub mainline in a homolographic pattern and are transferred lengthwise regularly to cover the entire farm. Hydrants will be placed isochronally to supply the laterals along the main or sub main pipe. In a CHL semi-permanent design [21], the mainline is shortened to the plot center to feed the lateral (Figure 1B), however unlike for CHL, in a CPL system (Figure 1C) the main or sub mainline is converted to a lateral with sprinklers installed on it and indeed retrofitted to a semi-portable system. In fact, for a CPL layout, there will only be one hydrant required which uses a rotation elbow at the corner where the lateral is connected to the water supply. The below diagrams (Figure 1) shows all 3 concepts comparatively.

Figure 1.

Schematic comparison of (A) semi-permanent split lateral (B) CHL and (C) CPL layout.

To evaluate and measure the system feasibility, CPL layout implementation was done in a 2300 m2 farm. System was operated during one month (from 1st to 30th May 2018) after installation in an irrigation test center. A split lateral semi-permanent layout was designed and evaluated for the same plot. DU coefficient or water distribution uniformity examination of the lower quarter, via catch can test method, was monitored and measured [22,23]. A cost comparison for the 2 systems was carried out on the components as well as annual costs to identify the influencing factors [24,25].

2. Materials and Methods

2.1. Systems Designing

The CPL system was set up in a 48 m × 48 m farm in Guangxi province, China. Two irrigation system plans, one as traditional semi-permanent using 2 laterals and another as CPL applying a single lateral, were designed. PVC pipes were used to simplify the installation and implementation process since CPL has different sprinkler distances and aluminum tubing have fixed length and fittings for sprinklers. The farm water supply was from the distribution network at the test center (provided from the nearest river) and had 5 L per second maximum discharge rate located at the southwest corner of the farm. The field was plain and had zero slope as shown in the below figure (Figure 2).

Figure 2.

Corner pivot lateral testing at irrigation test center.

In order to specify the soil infiltration rate (I), soil texture evaluation was carried out on the site. Based on the outcomes and soil texture triangle diagram, the farm soil type was identified as loam and the infiltration rate was accounted for 13 mm per hour. The Soil water holding capacity or SWHC [26] and other basic information used to design an irrigation system according to the site long term measured data are provided and calculated in Table 1 [27,28]. “I” was considered as the limiting margin in sprinklers or sprayer selection process in which they were elected to work at lower than the infiltration rate to prevent runoff. In contrast with ordinary semi-permanent layouts in which sprinkler distances are equal, in a CPL system the lateral irrigates a slice of the watering area at each cycle, therefore the sprinklers’ distance of throw will increase toward the lateral to the outmost side. Since the farm corner is a smaller area, sprayers with minor throw distance were applied, however bigger radius sprinklers were used at the end of the line, the same as in the center-pivot technique [29].

Table 1.

Farm basic indicators for irrigation systems designing.

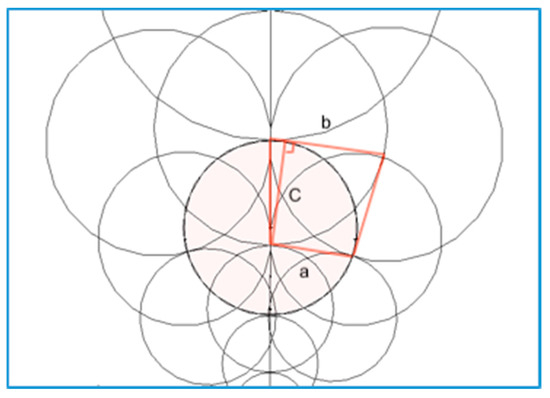

The maximum allowable discharge rate for each sprinkler was calculated individually according to a modified formula (Equation (1)) [28]. Definitively for sprinklers the discharge rate is expressed as the volume of water per time i.e., liter per second dispersed on the farm. In an ordinary rectangular shape area among 4 sprinklers for semi-permanent, to calculate the maximum discharge rate, the infiltration rate is multiplied by area (sprinklers distance or Si multiply by lateral distance or Sm). While in CPL, due to radial lateral moves, the area is more like trapezoid than rectangle shape. The conceptualized imbalanced overlapping has been illustrated below (Figure 3). Hence, the discharge rate for sprinklers in CPL is adjusted accordingly in which the lateral distance (Sm) would be the average distances of lateral in 2 continuous sprinklers that is additive along the lateral towards its end. Also the sprinkler distance would be the trapezium height (right angled c in Figure 3) between the 2 sides (a & b sides in Figure 3). With this we have replaced the rectangle area with trapezium in the below formula:

in this equation:

Figure 3.

CPL sprinklers trapezium overlapping pattern.

- I is the soil infiltration rate in millimeter per hour

- q is the sprinkler allowable discharge rate in liter per second

- Sl is the upright sprinklers distance or c in meter

- Sm is the average laterals distance in meter (a + b)/2

An ordinary head to head sprinkler/sprayer design was customized to be implemented for CPL [21,30]. In semi-permanent or solid set systems, the sprinklers interval is constant. This will consequently provide a uniform coverage pattern for these layouts. However, since the sprinklers radiuses are unequal in CPL, therefore the coverage pattern of an individual sprinkler/sprayer by the previous and next watering circle is imbalanced, as a function of sprinklers throw distance. The new pattern causes the matching point of the prior and next watering circles to fall not exactly in the center but close to it according to their radius, like asymmetrical intersecting circles. Each additive radius along a CPL pipeline, on average had a minor overlap of 40–45% and a larger overlap of 55–60% accordingly. Hence, the trapezoid shape area between every 4 nozzles completely overlaps. Indeed, the lateral movement (or distance) is based on the last sprinkler distance of throw. When the outmost sprinkler radius is identified, then the remaining sprinklers/sprayers radiuses determination will be done accordingly. The two tangential lines, from the farm corner surrounding the outmost sprinkler wet diameter, would be the irrigation slice boundaries to place the rest of sprinklers in an imbalanced head to head pattern during the designing process (Figure 1C).

Taking into account the most influencing factors such as availability, economical criteria, maximum allowable discharge rates and working pressure, the selected brand was China drip and the model was RS5022 for the endmost sprinkler. The radius was 12.5 m, two nozzles, a discharge rate of 1200 L/h and working pressure of 3 atmospheres. In total 6 different types (10 pieces) of sprayers/sprinklers were installed on the lateral, including 2 for the corner catcher. CPL lateral distance (on the perimeter of the circle) based on the distance of throw was selected as 12.5 m. Total of 7 set moves were planned to cover the entire plot. Sprinklers/sprayers interval on the lateral varied from 2.7 up to 11.6 m depending on their radiuses. Sprinklers were working with 0.02 to 0.33 L per second discharge rate. Via using bigger radius sprinklers at the end of lateral we can reduce the amount of manual work and if the soil permeability of the site is high, applying greater sprinklers discharge rate will decrease the total required time to operate the system. For this new layout, due to the need to apply several sprayer/sprinkler types on the lateral and taking into account the fact that the pressure changes along the lateral might affect the sprayers, therefore a constant discharge rate sprinkler/sprayers was availed to avoid discrepancies if pressure exceeds a threshold value. Otherwise applying pressure regulators is necessary as it was used in one of the 2 bar sprayers for this study, due to limited available brands in the market.

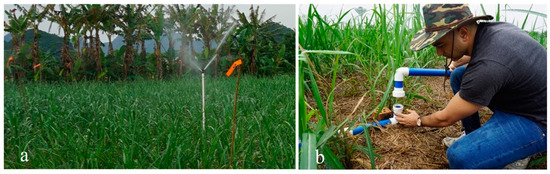

The corner arm pipe (applying two sprinklers) was split to two sections, one 9 m and another one 9.2 m. It can be split, folds out and back when the lateral approaches the corner or reaches the near side. Both pieces were equipped with rotating elbows to provide recurving ability. The sprinklers had shutoff valves to close them as and when the corner watering is not required. Fixed routes were identified to lay the lateral in specific directions for each set move. The quadratic curve was measured and colorful flags were placed to mark the next lateral position. The flags and rotating elbow are shown in the below picture (Figure 4a,b respectively).

Figure 4.

Flags used to specify the directions (a) and CPL corner arm with rotating ability (b).

The reference system (semi-permanent split lateral layout) as control was designed for the farm using a butterfly nozzle (SP3302) with 7 m radius, 6.8 m lateral as well as sprinkler distance. The split laterals (two laterals) being transferred lengthwise and had 3 to 4 sprinklers on each to operate concurrently. Sprinklers were working at 3 bar pressure and 0.167 L/S flow. The primary planning parameters for CPL and split lateral are assessed and listed in the below table (Table 2).

Table 2.

CPL and split lateral layouts designing criteria.

Spraying intensity and hydro-module were calculated according to the lateral discharge rate divide to the slice area. As calculating it for each sprinkler will give different answers, hence the average spraying intensity was used. To choose the right pump and power unit, the amount of the TDH and friction loss were computed using the Hazen William formula. The velocity control margin of 0.6 to 1.6 m/s was applied to examine if the selected pipes diameter is suitable [31,32]. The demonstration park (where the examination was done in) was not in a windy area, therefore the wind drift impacts were not considered. Table 3 shows CPL system components versus split lateral system in detail. The similar required components for both layouts include gauge pressure, air vacuum/release valve, pump, and water filter are not listed in this table but are accounted for in table number 4 where the systems total costs are calculated. Energy requirements in kilowatt hours are metered as a function of system flow rate, total dynamic head, working hours, and pump efficiency. Pump power consumption in kilowatt was measured according to the below equation [33]:

in this formula (Equation (2)), P: is the pump power requirement per kw, Q: the total system flow rate in liter per second, H: The total required head in meter, EP: the pump efficiency (here was 70 percent).

Table 3.

Split lateral and CPL layouts requirements.

The designed telescopic lateral length for CPL in this study was 60.2 m out of which 18.2 m was the corner arm. A total of 30.5 m was laid as 2 inches and the rest as 1-inch diameter pipe. The lateral was extended straight across the farm toward the end since no accompanying outlet valve was needed. As for the split lateral layout, 2” PVC tubing was designed for main pipe buried from the water resource along the side to the mid and then crossing the middle of the plot to supply the 2 connected laterals. The tubing size for the 44.4 m of the main pipe was 2” and remaining 27.2 m as 1” pipe was applied.

2.2. Catch Can Examination

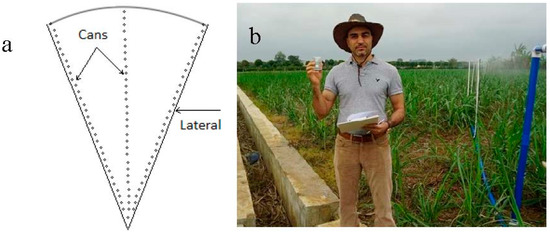

In order to make sure the irrigation rate and sprinklers were overlapping, distribution uniformity tests were examined via the catch can method in the farm [34]. 4 runs were carried out to meter the volume of water spread in each spot of the plot in the irrigated slices between the 2 set move. Plastic cups were applied to harvest the samples and since it was light, a stone was placed inside each cup to avoid them being dropped. The amount of collected water after 3 quarters of watering time was measured via beakers and the tests were redone in identical slices after the following set-move. Tables based on the method were provided to record the evaluated values. Therefore, overlaps were monitored horizontally as well as vertically. In total 178 plastic cans posited in 3 different straight-line. Parallel with the lateral, cups were located in every 1 m in a rectilinear pattern to cover the entire radius for each sprinkler. The distances between the cans were different horizontally across the 2 straight-lines (as demonstrated in Figure 5), since there were various throw distances along the lateral.

Figure 5.

The 3 straight-line layout (a) and the DULQ measurements via beakers (b).

To measure the can volume, its diameter, height and bottom area were scaled to obtain the water application depth. The average of the harvested samples was measured according to the plastic can area and the required time to harvest those quantities. The lowermost 25% of the values, were averaged to divide by the average of the entire values as DULQ of the low quarter distribution uniformity [35].

3. Results

3.1. CPL and Split Lateral Irrigation Systems Cost Comparison

The economical comparison was conducted taking into account the both layouts’ component costs requirements as well as annual cash outflows. The below table (Table 4) presents summarized required expenses for CPL as well as split lateral in the plot for comparison and control. According to the outcomes CPL layout needed 15% less initial investment and a 7% lower estimated annual cost than traditional split lateral. As a result, these lower capital costs will lead to a minor yearly maintenance and repair costs as well as cheaper replacement and depreciation fee for components. It will also cause a lower insurance fee, tax as well as interest (opportunity expenses) that accounted for 2.5–3.3 percent of the total capital cost. CPL has the same water consumption but a 2.5% lower electricity requirement. TDH was calculated at negligible amount of only 1.6% lesser for CPL.

Table 4.

CPL and split lateral layouts cost comparison for a half-acre farm in USD.

Outcomes revealed that the 15% decline of capital cost for corner pivot design is due to its shorter pipe length and smaller size requirement, however the other components include outlet valves, fitting and burring fee have lower financial impacts. In total ten sprinklers and sprayers were needed to be installed on CPL but seven on split lateral layout (which could be less but would have negligible impacts financially). Yet, since the size and radiuses of sprinklers were decreased toward the corner in CPL, the overall sprinkler costs in CPL were only slightly higher compared to the split lateral. Moreover, the 2 inches of reduced pipe require a minor 2 inch fitting for CPL layout that is less expensive. Annual working hours for CPL were 9.5% higher because longer irrigation time per revolution in 7 set moves wa needed for sufficient watering compared to 8 set moves in split lateral.

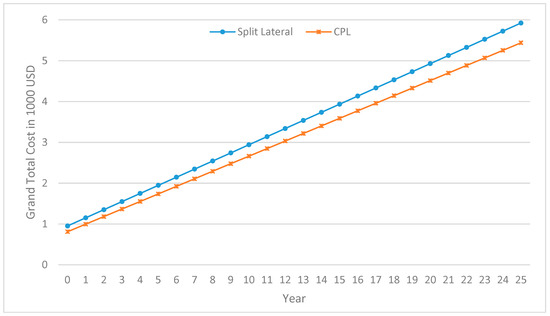

As a point of comparison, for CPL and split lateral layouts the grand total cost discrepancy in % during 25 years is shown in the below graph (Figure 6).

Figure 6.

Accumulative total cost in 25 years for split lateral & CPL layouts in 1000$.

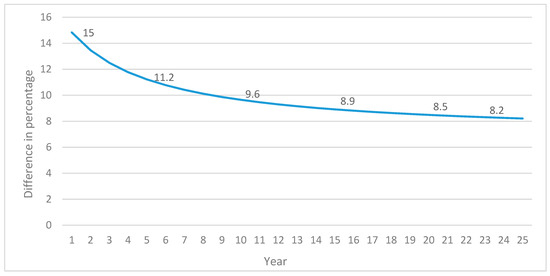

As the diagram presents at the project start date, there will be a relatively high difference between CPL and the ordinary split lateral at 15%. The gap will gradually increase as the time passes and the total amount increases due to the additive annual costs. Hence, the capital cost will be lighter proportionally. Below diagram (Figure 7) however, shows the profitability difference between the two systems over the 25 years’ time. The difference is lower in terms of ratio but increases for the monetary and quantity factors. It shows a small difference to some extent during the following decades at 9.6% after the next 10 and finally an 8.2% smaller grand total cost than split lateral in 25 years. Based on the quantitative calculations, the diagram would not reach 0% even within a century, that is remarkably larger than a regular project time horizon.

Figure 7.

Grand total cost difference in % between CPL and split lateral in 25 years.

3.2. Distribution Uniformity Results via Catch Can Method

To control the irrigation rate and check the distribution uniformity at 3.8 bar (≅55 psi) operating pressure, the applied plastic cups different dimensions were measured. The can bottom radius of 2.5 cm and 19.6 square centimeter bottom area were sized with capacity of two hundred milliliters. During 4 runs of sample collection (45 min for each run), in average 15.1 milliliters of water was dispersed in each can while the low quarter average was 11.9 milliliters. In order to calculate the irrigation rate during the measurement time, these volumes of water were divided by the can bottom area at 10.3 mm per hour. Low or high amounts of water around anyone of the sprinklers (which sometimes can be confirmed via observations too) means that the area is under or over irrigated and hence it must be exchanged. In order to compute the DU, the low quarter’s mean of the recorded data for 45 out of 178 samples were calculated at 6.08 mm and then divided by the entire 178 samples average for 7.72 mm.

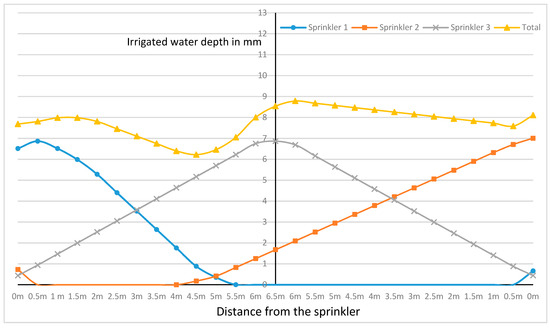

Some relative research have achieved a distribution uniformity of 74% for a linear system and 90% for center-pivot sprinkler irrigation systems [36]. Li and Rao achieved 62% up to 84% uniformity for sprinkler irrigation [37,38], while others obtained 57% for a semi-permanent system [39]. In this work average of 79% DULQ was attained as a relatively high uniformity coefficient. This clearly shows that the new layout can efficiently fulfil the required water depth in every spot in the farm. The following graph (Figure 8) presents the water distribution pattern of CPL sprinkler coverage for one of the sprinklers. As can be seen, the graph is slightly imbalanced for the irrigated circle in which the amount of received water (in average) was 12 percent higher in one side.

Figure 8.

Depth of irrigated water in mm & its uniformity around a sprinkler in CPL (6.5 m radius).

The results revealed a triangular shape (or bell form) of distributed water around the sprinklers, which means the pressure was satisfactory. In case of having under or over pressured sprinkler/sprayers, an imbalance distribution pattern will form that is donut shape with larger droplets (for low pressure) or having over irrigation close to the sprinkler (for high pressure) respectively [19]. Outcomes indicates that the area between the two radial legs was efficiently irrigated with an acceptable sprinklers coverage. Taking into consideration this novel layout coverage pattern, any irrigated circle in it had an overlap of 55 percent from the front side and 45 percent from the back sprinkler.

4. Discussions

The new layout demonstrated less investment and costs requirement compared to the split lateral layout. The omission of the mainline caused a more than 40% reduction in the length of the pipes and minimized the number of hydrants, while less fittings were required. Although the items prices differ in various regions, nonetheless since the evaluation is based on ratio, the hypothesis clarification is valid. Analyzing the results showed that the cost-effectiveness on the capital cost for CPL will lead to a shorter break-even point. It means the investments will be returned to the investor within a shorter time. This is critical due to the importance of the first years for yeoman financially. Hence, a cheaper pressured system can reduce the smallholding financial stresses to implement such projects. Moreover, since there was a 7% decrease of yearly expenses for CPL, therefore during a longer time period this layout is more efficient than a conventional split lateral design.

While actual soil moist distribution uniformity might be higher than the can’s results [40], distribution uniformity demonstrated the feasibility of the system with an acceptable level of performance. The impacts of the wind were negligible in this experiment but for areas affected by wind, to minimize the evaporation loss and wind drift, the start point of the CPL lateral at the farm corner needs to be shifted, which avoids the wind affecting uniformity of irrigation. The move must be opposite to the wind direction in accordance with its velocity [41]. This is an influencing factor in smaller plots since the wind will severely affect smallholding areas [42], especially on the sprayers. In case of any deficiency, re-nozzling might be the solution as the system performance was found to be highly sensitive to the sprinkler/sprayer type. The sprinklers selection accuracy can also balance the irrigated water over the land surface, which causes yield variation avoidance.

With regards to the labor requirements, CPL needs equal manpower, although the number of system working hours is about 9.5% higher. Operating the system during the current experiment showed that the required manual work in CPL is the same in terms of labor traveling distance for transferring pipes, the number of pipes that need to be picked up and transferred and number of uncoupling during one revolution. For CPL in each irrigation cycle, the labor needs to transfer 7 pieces of pipes for 7 times (49), however in split lateral the farmer carries 6 pieces for 8 times (48) while both need to travel for almost 900 m. The labor fee is not considered in the total cost as chiefly employing labor for small farms is not justifiable.

Altogether, based on the outcomes the beneficial advantages of CPL design highlighted are:

- A reduction in total required tubing (up to 40%) in square form lands.

- Reducing the quantity and size of needed fittings.

- Reducing the hydrants to 1 only.

- Set-move simplicity that going from one side of the farm to another is not needed.

- Ease of operation with elimination of jointing the lateral to several hydrants.

- Minor need of maintenance.

- The layout matches smallholding requirements.

- No farm leveling is needed since the transfer is manual.

- Lower capital and annual expenses.

This new layout has some limitations and disadvantages as well listed and are discussed here:

- A Quadrat circular irrigation pattern that causes 79% of the farm to be irrigated is good enough. Nevertheless, using the foldable corner catcher pipe will rather cover the entire corner area. In particular, the manual process of the system offers an easy use of the corner arm, as and when it is required, enhances the irrigable field without complexity. Applying big guns (part-circle sprinklers) on the lateral endpoint which can cover an extensive area same as in center pivot is an alternative too. Overall around 5% of the farm will not be well irrigated and will almost have rain fed like yield.

- The CPL layout needs hand-move same as other semi-permanent or portable systems.

- A more complicated irrigation system design is required compared to split lateral as it has more details in the required components.

5. Conclusions

More than two third of limited freshwater supplies around the word are being utilized in agriculture to produce food and other products. Insufficient farm products for a growing population can be increased by encouraging small estate holders to use pressured irrigation methods which balance and optimize water application efficiency. This is critical, particularly in areas situated at water stressed zones [43], considering water and food insufficiency which leads to poverty. Applying a sprinkler system is expensive where sufficient water is available for farmers, knowing governmental subsidy limitations as well as reimbursement time. Profitable pressured techniques can provide more desirable options which small farm owners can afford to invest in.

The current study aimed to introduce a cost saving sprinkler system with 15% lower capital as well as 7% less annual costs (mainly due to the capital cost related fees such as insurance, etc.). There will be no main /sub mainline in this layout as the lateral will lay from the corner of the plot radially and will manually move on a circumference circle’s quarter. Corner pivot lateral (CPL) is a cost-effective integration of the 2 traditional irrigation methods such as center pivot and semi-permanent split lateral. As presented the new layout cuts the amount and size of required pipes, fittings, and hydrant valves, besides yearly costs which consequently offer a light, adaptable, feasible and economical sprinkler irrigation system for small scale plots.

CPL demonstrated an acceptable level of water distribution uniformity and irrigation rate at 79%. Since corner pivot is not an automated system, manpower reliability is necessary for manual operation assurance. Small holders would be the target group for this new technology. Taking into account the land ownership models in the majority of countries within Asia, South America and Africa, CPL can be a localized competitor for other pressured sprinkler layouts. Hence, such a technique, owing to its financial benefits, incentivizes the farmers towards irrigation system implementation, which leads to achieving maximized irrigation efficiency and saves water supplies in developing countries need to produce adequate agricultural products while developing sustainably.

Author Contributions

S.R.—Conceptualization, investigation and writing the original draft, L.G.—writing, review and editing, X.C. and L.H.—supervision, S.Y.—funding and acquisition, S.S.—resources, and M.R.T.—validation.

Funding

This research was funded by Natural Science Foundation of China (Code: 41761048; Code: 41701248; Code: 41501230) and the Guangxi Natural Science Foundation (Code: 2017GXNSFBA198102; Code: 2016GXNSFAA380197).

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Technical details of applied Sprinklers & Sprayers.

Table A1.

Technical details of applied Sprinklers & Sprayers.

| Sprinklers & Sprayers Model | Diameter (m) | Discharge Rate (L/h) | Working Pressure (bar) |

|---|---|---|---|

| MS3008 Model Green | 7.6 | 277.0 | 3.0 |

| MS8070 Model Blue | 5 | 77.2 | 3.0 |

| MS8070 Model Blue | 5 | 77.2 | 3.0 |

| MS3006 Model Red | 6.6 | 145.0 | 2.0 |

| MS3008 Model Green | 7.6 | 278.0 | 3.0 |

| Butterfly Nozzle Model | 13.5 | 446.0 | 3.0 |

| SP3303 Model | 16 | 625.0 | 3.0 |

| RS5022-7 Double-nozzle | 25 | 1200.0 | 3.0 |

| RS5022-7 Double-nozzle | 25 | 1200.0 | 3.0 |

| SP3302 Model | 15 | 510.0 | 3.0 |

References

- United Nations, Department of Economic and Social Affairs, Population Division. 2017. Available online: https://esa.un.org/unpd/wpp/ (accessed on 17 June 2018).

- The State of the World’s Land and Water Resources for Food and Agriculture. In Managing Systems at Risk; Summary Report; FAO: Rome, Italy, 2011; p. 9.

- Gleick, P.H. Water in Crisis: A Guide to the Worlds Fresh Water Resources; Chapter 2; Oxford University: Oxford, UK, 1993; p. 13. [Google Scholar]

- Shiklomanov, I.A. Appraisal and Assessment of World Water Resources. Water Int. 2000, 25, 11–32. [Google Scholar] [CrossRef]

- Siebert, S.; Döll, P.; Feick, S.; Hoogeveen, J.; Frenken, K. Global Map of Irrigation Areas; Version 4.0.1.; Johann Wolfgang Goethe University, Frankfurt am Main, Germany/Food and Agriculture Organization of the United Nations: Rome, Italy, 2007. [Google Scholar]

- Oster, J.D.; Wichelns, D. Economic and agronomic strategies to achieve sustainable irrigation. Irrig. Sci. 2003, 22, 107–120. [Google Scholar] [CrossRef]

- Ganjegunte, G.; Clark, J. Improved irrigation scheduling for freshwater conservation in the desert southwest U.S. Irrig. Sci. 2017, 35, 315–326. [Google Scholar] [CrossRef]

- Battikhi, A.M.; Abu-Hammad, A.H. Comparison between the efficiencies of surface and pressurized irrigation systems in Jordan. Irrig. Drain. Syst. 1994, 8, 109–121. [Google Scholar] [CrossRef]

- Krutz, L.J.; Irby, T.; Golden, B.; Pringle, L.; Falconer, L. Improving Furrow Irrigation Efficiency, Mississippi Soybean Promotion Board Project No. 54-2013 Annual Report. 2014. Available online: www.mssoy.org (accessed on 25 June 2018).

- Smajstrla, A.G.; Boman, B.J.; Clark, G.A.; Haman, D.Z.; Harrison, D.S.; Izuno, F.T.; Pitts, D.J.; Zazueta, F.S. Efficiencies of Florida Agricultural Irrigation Systems, Agricultural and Biological Engineering Department, Florida Cooperative Extension Service; Institute of Food and Agricultural Sciences, University of Florida: Gainesville, FL, USA, 1991. [Google Scholar]

- Daoud, R.; Peter, M.; George, A.; Dani, F. Efficiency of Drip Irrigation System For «Paulownia» Trees in the Aakkar Coastal Plain of Lebanon. Int. J. Plant Anim. Environ. Sci. 2017, 7. [Google Scholar] [CrossRef]

- Laycock, A. Irrigation Systems, Design, Planning and Construction; CABI: Hong Kong, China, 2007; pp. 170–185. [Google Scholar]

- Al-Jamal, M.S.; Ball, S.; Sammis, T.W. Comparison of sprinkler, trickle and furrow irrigation efficiencies for onion production. Agric. Water Manag. 2001, 46, 253–266. [Google Scholar] [CrossRef]

- Hamdy, A. Water use efficiency in irrigated agriculture: An analytical review. In Water Use Efficiency and Water Productivity; Wasamed Project; CIHEAM: Italy, 2007; pp. 9–19. [Google Scholar]

- Martínez, J.M.; Martinez, R.S.; Martín-Benito, J.T. Analysis of water application cost with permanent set sprinkler irrigation systems. Irrig. Sci. 2004, 23, 103–110. [Google Scholar] [CrossRef]

- Ortiz Romero, J.N.; Montero Martínez, J.; Martínez, R.S.; Tarjuelo Martín-Benito, J.M. Set Sprinkler Irrigation and Its Cost. J. Irrig. Drain. Eng. 2006, 132, 445–452. [Google Scholar] [CrossRef]

- Montero, J.; Martínez, A.; Valiente, M.; Moreno, M.A.; Tarjuelo, J.M. Analysis of water application costs with a center pivot system for irrigation of crops in Spain. Irrig. Sci. 2013, 31, 507–521. [Google Scholar] [CrossRef]

- Rolland, L. Mechanized Sprinkler Irrigation; Chapter 15; FAO Irrigation and Drainage Paper: Rome, Italy, 1982; p. 367. [Google Scholar]

- Gilley, J.R. Sprinkler Irrigation Systems; Agricultural Engineering Department, Texas A & M University: College Station, TX, USA; pp. 195–234.

- Waller, P.; Yitayew, M. Irrigation Lateral Design—Irrigation and Drainage Engineering; Springer: Cham, Switzerland, 2016; pp. 105–121. [Google Scholar]

- Gan, L.; Rad, S.; Chen, X.; Fang, R.; Yan, L.; Su, S. Clock Hand Lateral, A New Layout for Semi-Permanent Sprinkler Irrigation System. Water 2018, 10, 767. [Google Scholar] [CrossRef]

- ASAE. Procedure for Sprinkler Testing and Performance Reporting; ASAE American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 1985. [Google Scholar]

- Saidi, A.; Hammami, M.; Daghari, H.; Boughdiri, A.; Ben Ali, H. Irrigation Uniformity Impacts on Water Use Efficiency and Soil Salinity: Case Study of Tomato Crop under Trickle Irrigation System in the North-East of Tunisia. J. Hydrogeol. Hydrol. Eng. 2016, 6, 2. [Google Scholar] [CrossRef]

- Wang, X. A Study of the Irrigation Water Pricing System in China; Master of Environmental Studies Capstone Projects; Department of Earth and Environmental Science, University of Pennsylvania: Philadelphia, PA, USA, 2010; p. 13. [Google Scholar]

- Zhou, N. Key China Energy Statistics; China Energy group, Lawrence Berkeley National Laboratory; University of California: Oakland, CA, USA, 2016; p. 26. [Google Scholar]

- Ferrant, S.; Bustillo, V.; Burel, E.; Salmon-Monviola, J.; Claverie, M.; Jarosz, N.; Yin, T.; Rivalland, V.; Dedieu, G.; Demarez, V.; et al. Extracting Soil Water Holding Capacity Parameters of a Distributed Agro-Hydrological Model from High Resolution Optical Satellite Observations Series. Remote Sens. Precis. Agric. 2016, 8, 154. [Google Scholar] [CrossRef]

- FAO. 2016. Available online: http://www.fao.org/nr/water/aquastat/irrigationmap/index.stm (accessed on 3 July 2018).

- Alizadeh, A. Irrigation Systems Design, Pressured Irrigation Systems Design; Agricultural Department, University of Fredousi: Mashhad, Iran, 2006; Volume 2. [Google Scholar]

- Marjang, N.; Merkley, G.P.; Shaban, M. Center-pivot uniformity analysis with variable container spacing. Irrig. Sci. 2012, 30, 149–156. [Google Scholar] [CrossRef]

- Louie, M.J.; Selker, J.S. Sprinkler head maintenance effects on water application uniformity. J. Irrig. Drain. Eng. 2000, 126, 142–148. [Google Scholar] [CrossRef]

- Cuenca, R.H. Irrigation system design. An engineering approach; Department of Agricultural Engineering, Oregon State University: Corvallis, OR, USA, 1989; p. 552. [Google Scholar]

- Lansey, K.; El-Shorbagy, W. Design of Pumps and Pump Facilities. In Storm Water Collection Systems Design Handbook; McGraw-Hill Professional: New York, NY, USA, 2001; p. 12. [Google Scholar]

- Jackson, T.M.; Khan, S.; Hafeez, M. A comparative analysis of water application and energy consumption at the irrigated field level. Agric. Water Manag. 2010, 97, 1477–1485. [Google Scholar] [CrossRef]

- Bortolini, L.; Martello, M. Effects of Water Distribution Uniformity on Waxy Corn (Zea mays L.) Yield: Preliminary Results. J. Water Resour. Prot. 2014, 6, 1037. [Google Scholar] [CrossRef]

- Merriam, J.L.; Keller, J. Farm Irrigation System Evaluation: A Guide to Management; Utah State University: Logan, UT, USA, 1978. [Google Scholar]

- Dukes, M.D.; Perry, C. Uniformity testing of variable-rate center pivot irrigation control systems. Precis. Agric. 2006, 7, 205. [Google Scholar] [CrossRef]

- Li, J.; Rao, M. Field evaluation of crop yield as affected by non-uniformity of sprinkler-applied water and fertilizers. Agric. Water. Manag. 2003, 59, 1–13. [Google Scholar] [CrossRef]

- Li, J.; Li, B.; Rao, M. Spatial and temporal distributions of nitrogen and crop yield as affected by non-uniformity of sprinkler irrigation. Agric. Water Manag. 2005, 76, 160–180. [Google Scholar] [CrossRef]

- Ascough, G.W.; Kiker, G.A. The effect of irrigation uniformity on irrigation water requirements. Water Sa 2002, 28, 235–242. [Google Scholar] [CrossRef]

- Dukes, M.D.; Haley, M.B.; Hanks, S.A. Sprinkler irrigation and soil moisture uniformity. In Proceedings of the 27th Annual International Irrigation Show, San Antonio, TX, USA, 5–7 November 2006; pp. 446–460. [Google Scholar]

- Yazar, A. Evaporation and drift losses from sprinkler irrigation systems under various operating conditions. Agric. Water Manag. 1984, 8, 439–449. [Google Scholar] [CrossRef]

- Dechmi, F.; Playán, E.; Cavero, J.; Faci, J.M.; Martínez-Cob, A. Wind effects on solid set sprinkler irrigation depth and yield of maize (Zea mays). Irrig. Sci. 2003, 22, 67–77. [Google Scholar] [CrossRef]

- Taye, M.; Dyer, E.; Hirpa, F.; Charles, K. Climate Change Impact on Water Resources in the Awash Basin, Ethiopia. Water 2018, 10, 1560. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).