Design and Experiment of a Novel Façade Cleaning Robot with a Biped Mechanism

Abstract

:1. Introduction

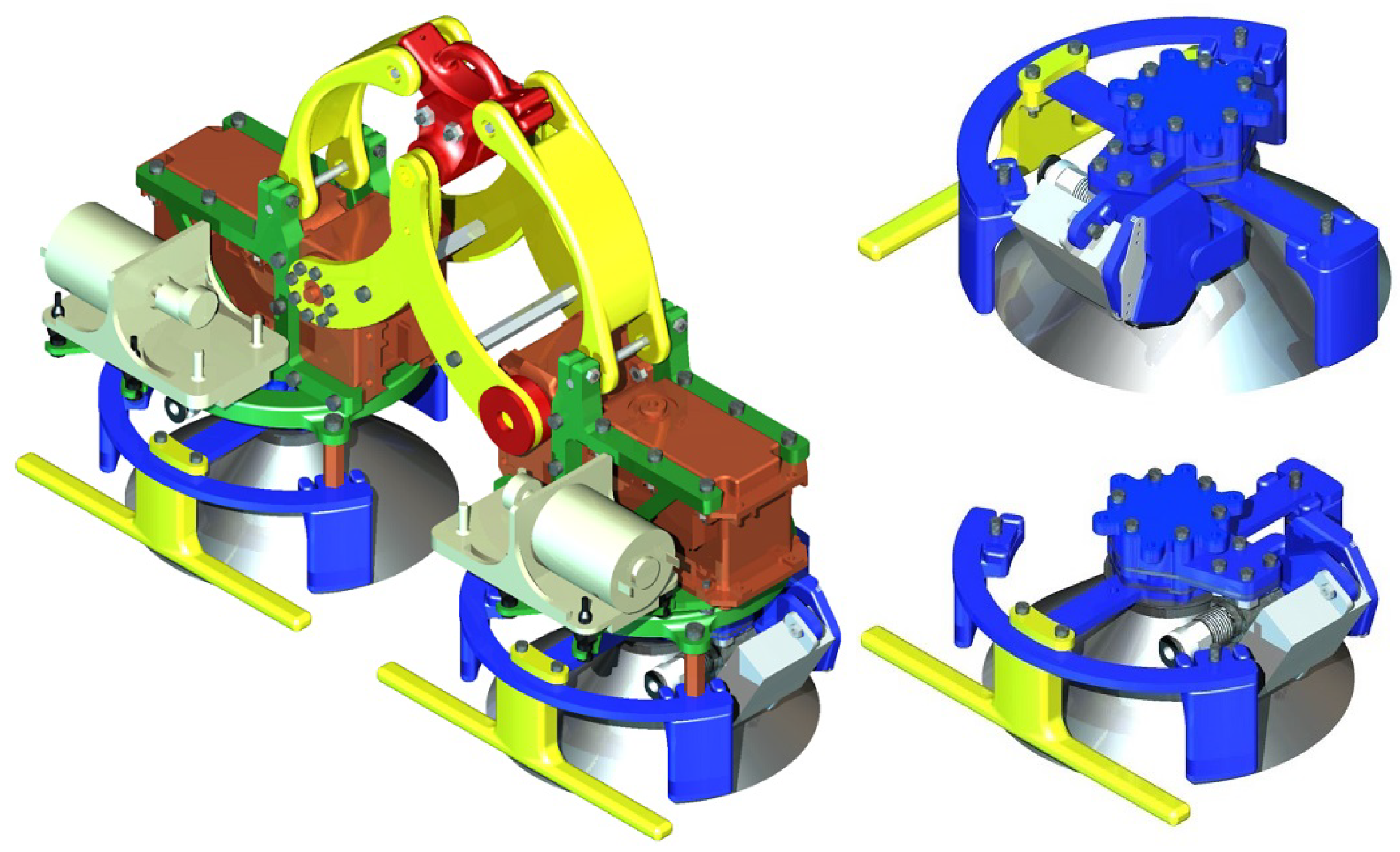

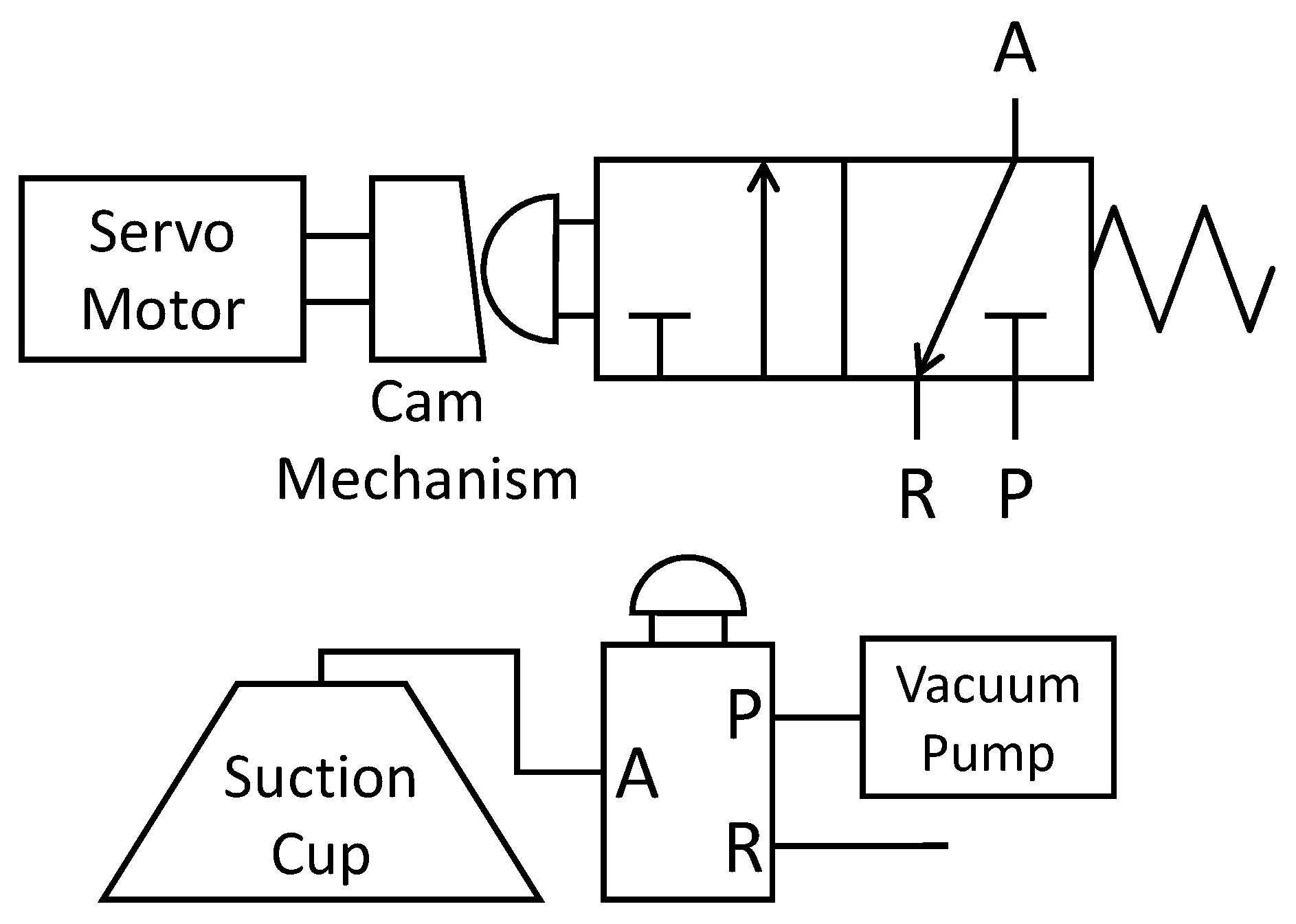

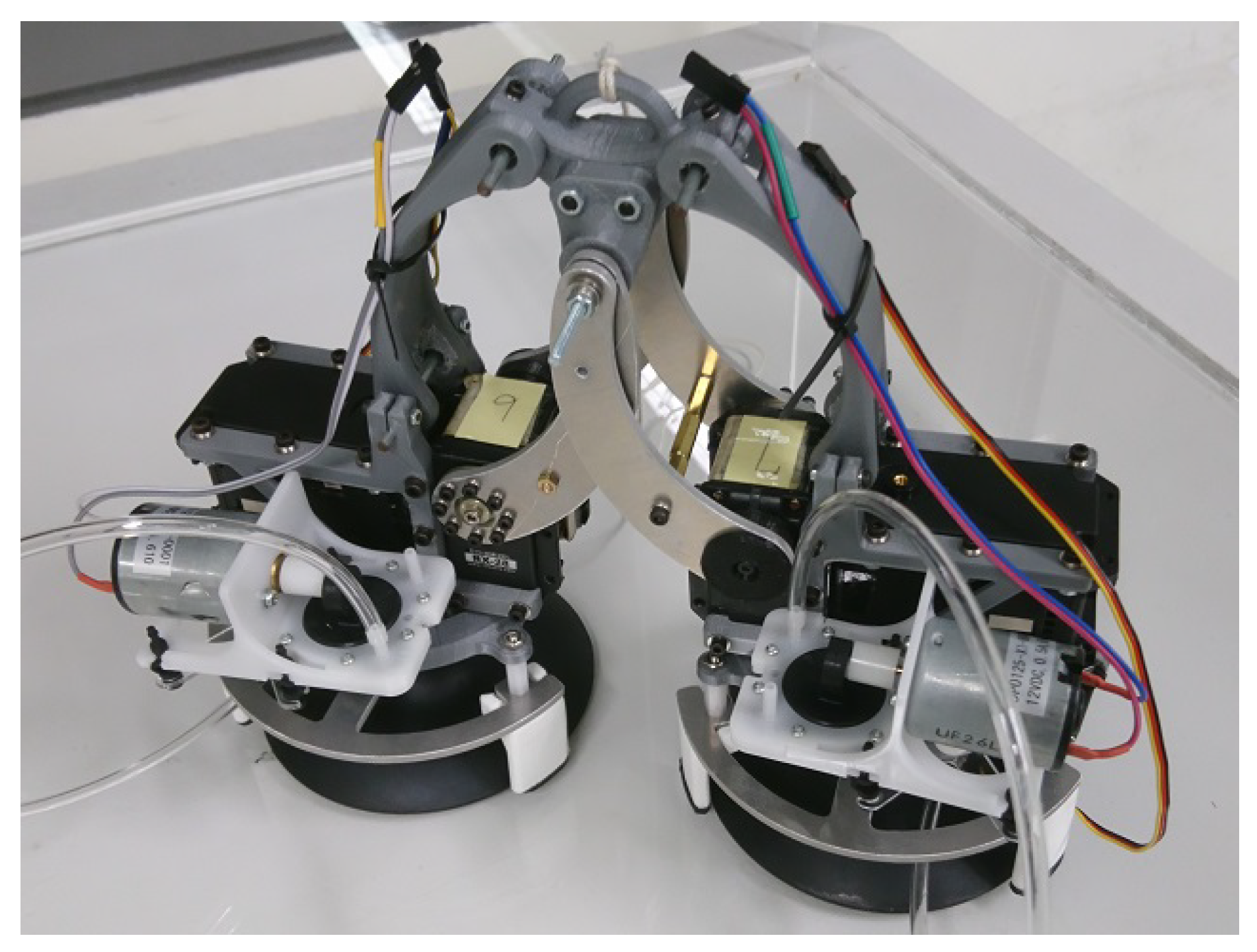

2. Development of Biped Robot

2.1. Design Challenges

- Development of the biped robot

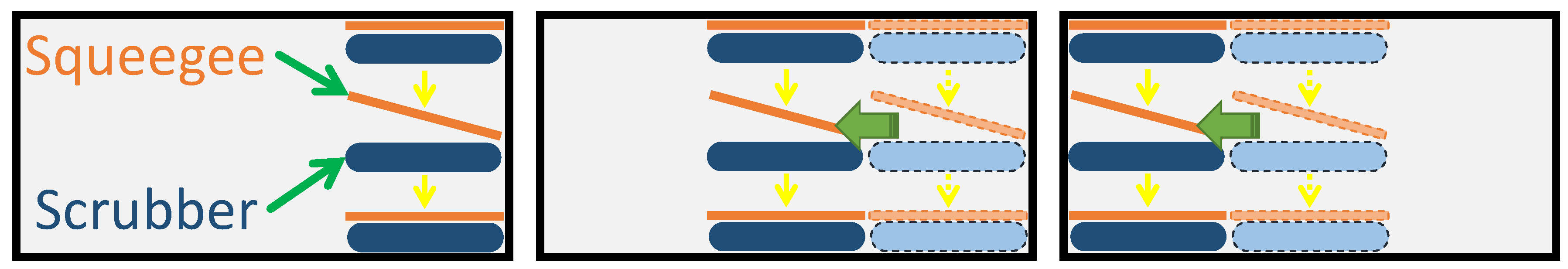

- Development of a cleaning unit with the squeegee installed next to the scrubber

- Design of a control system capable of keeping both the scrubber and the squeegee in contact with the glass surface.

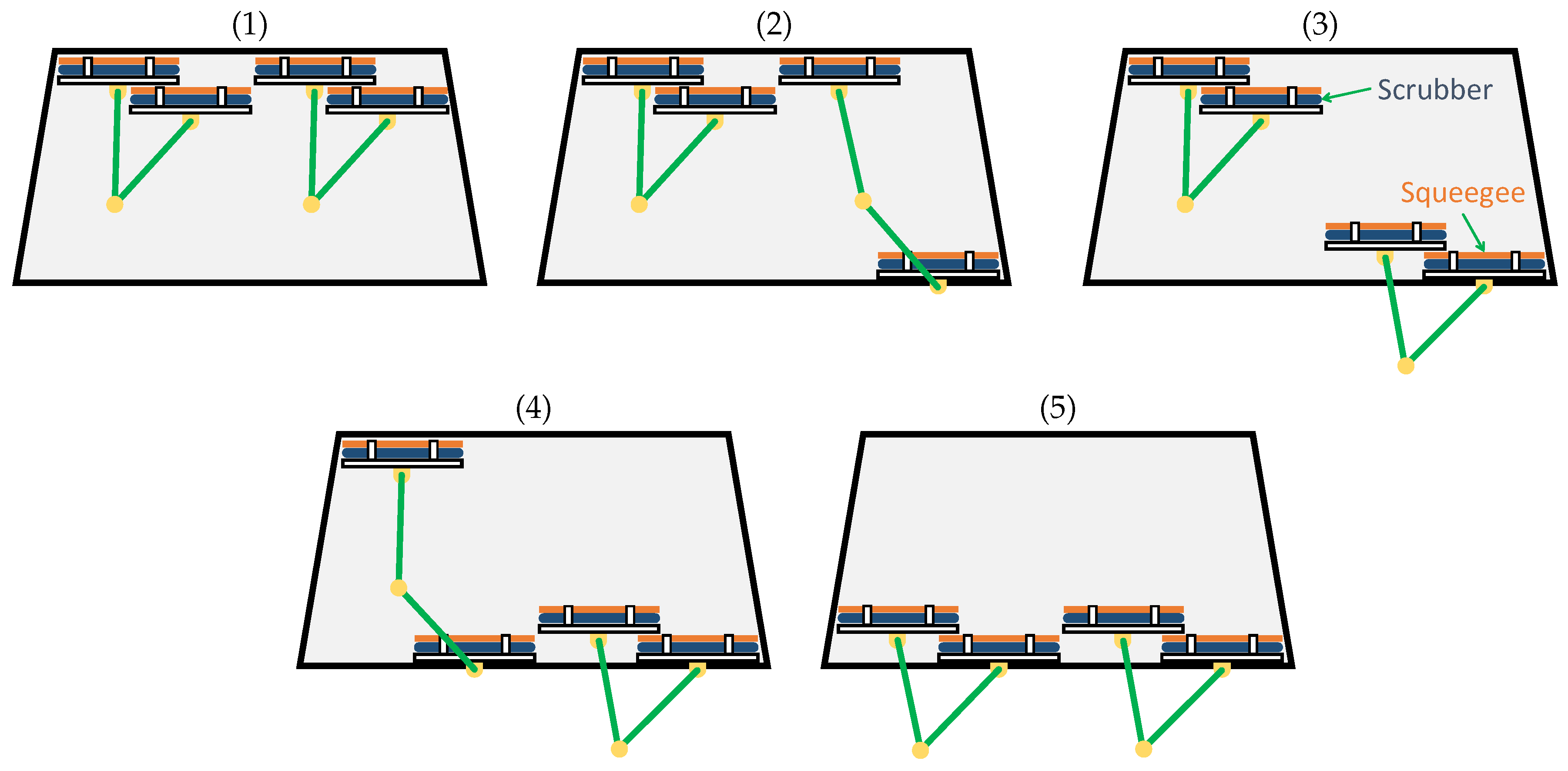

- Design of a transition planner in order to clean in one direction

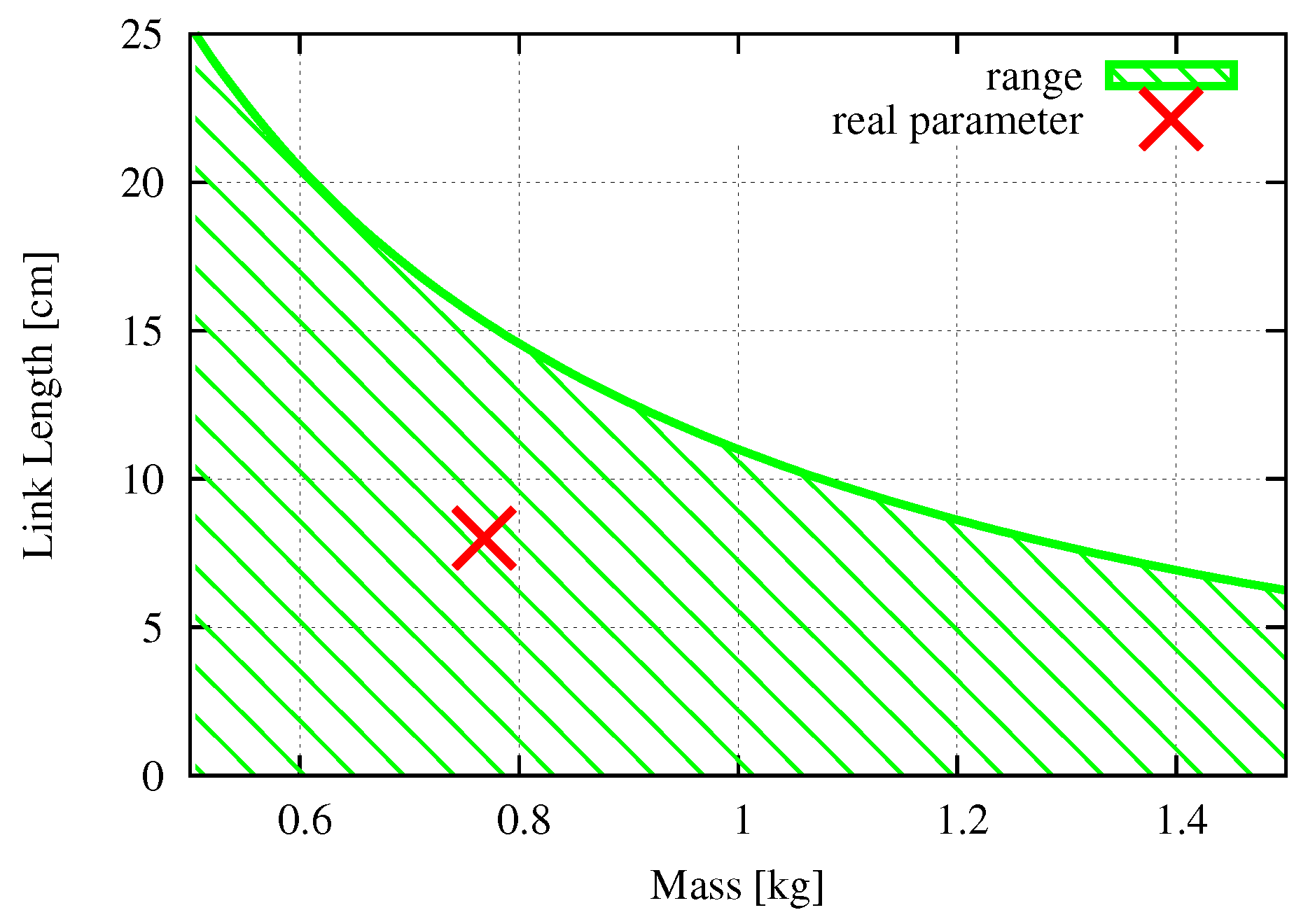

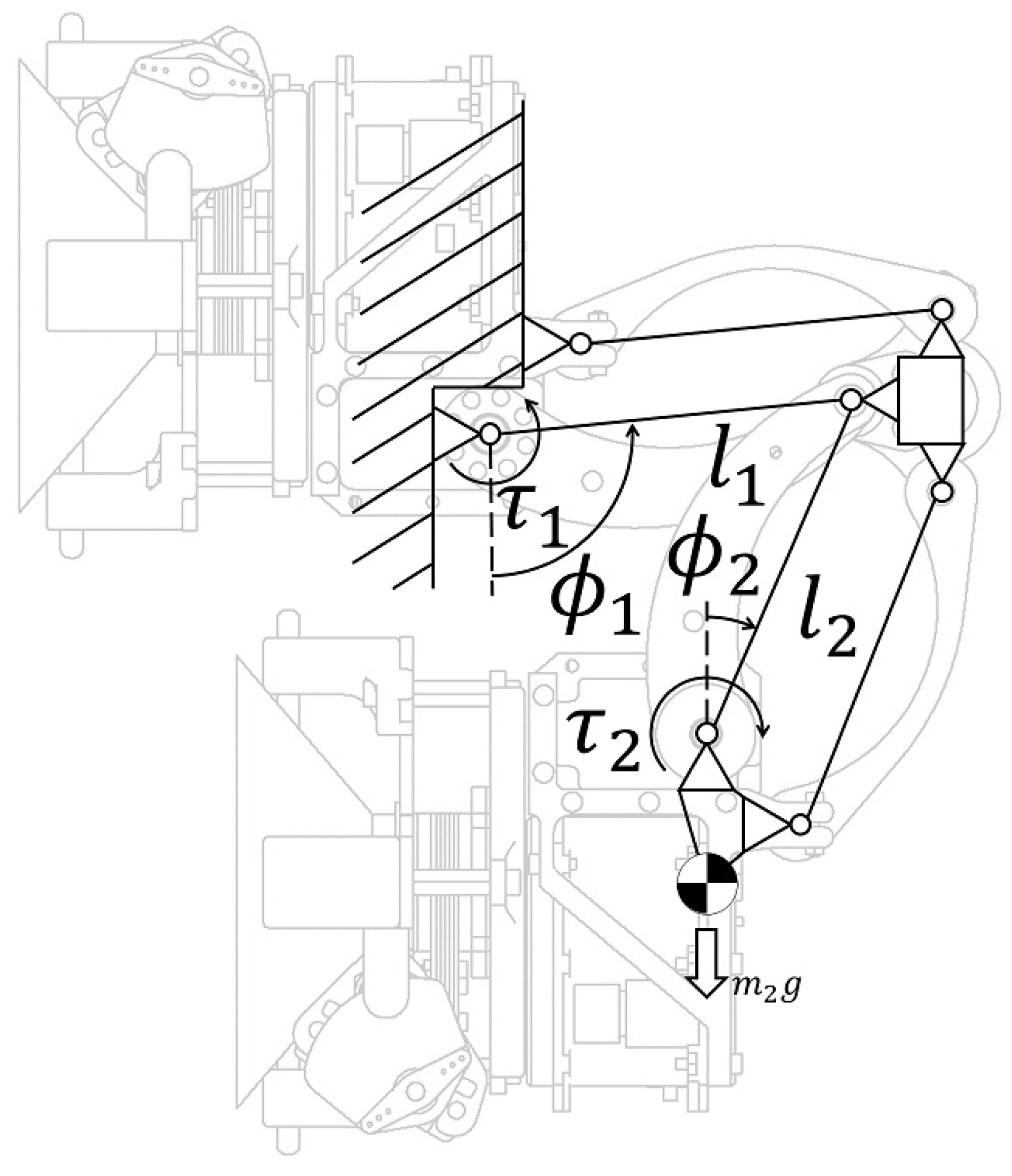

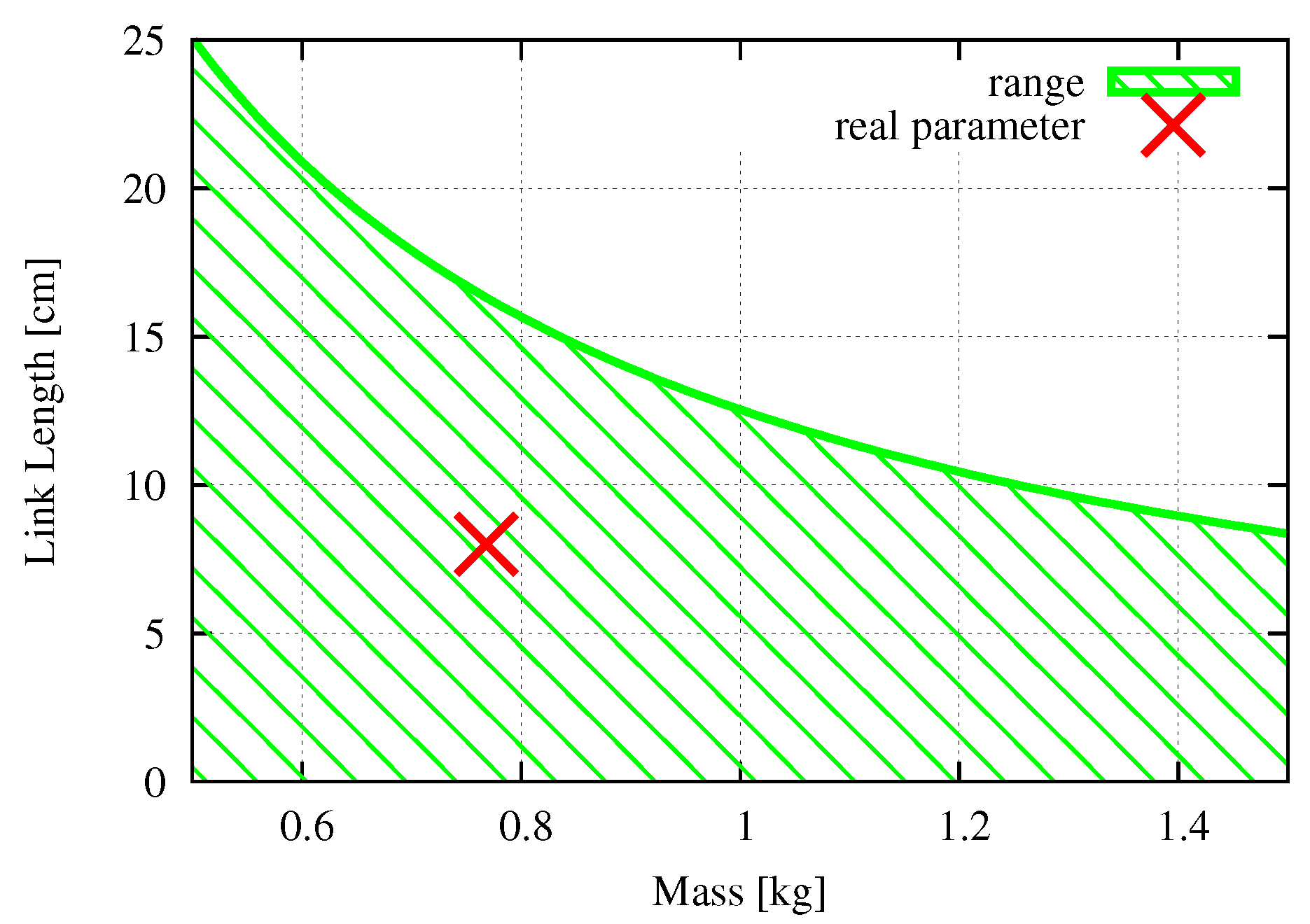

2.2. Biped Robot Design

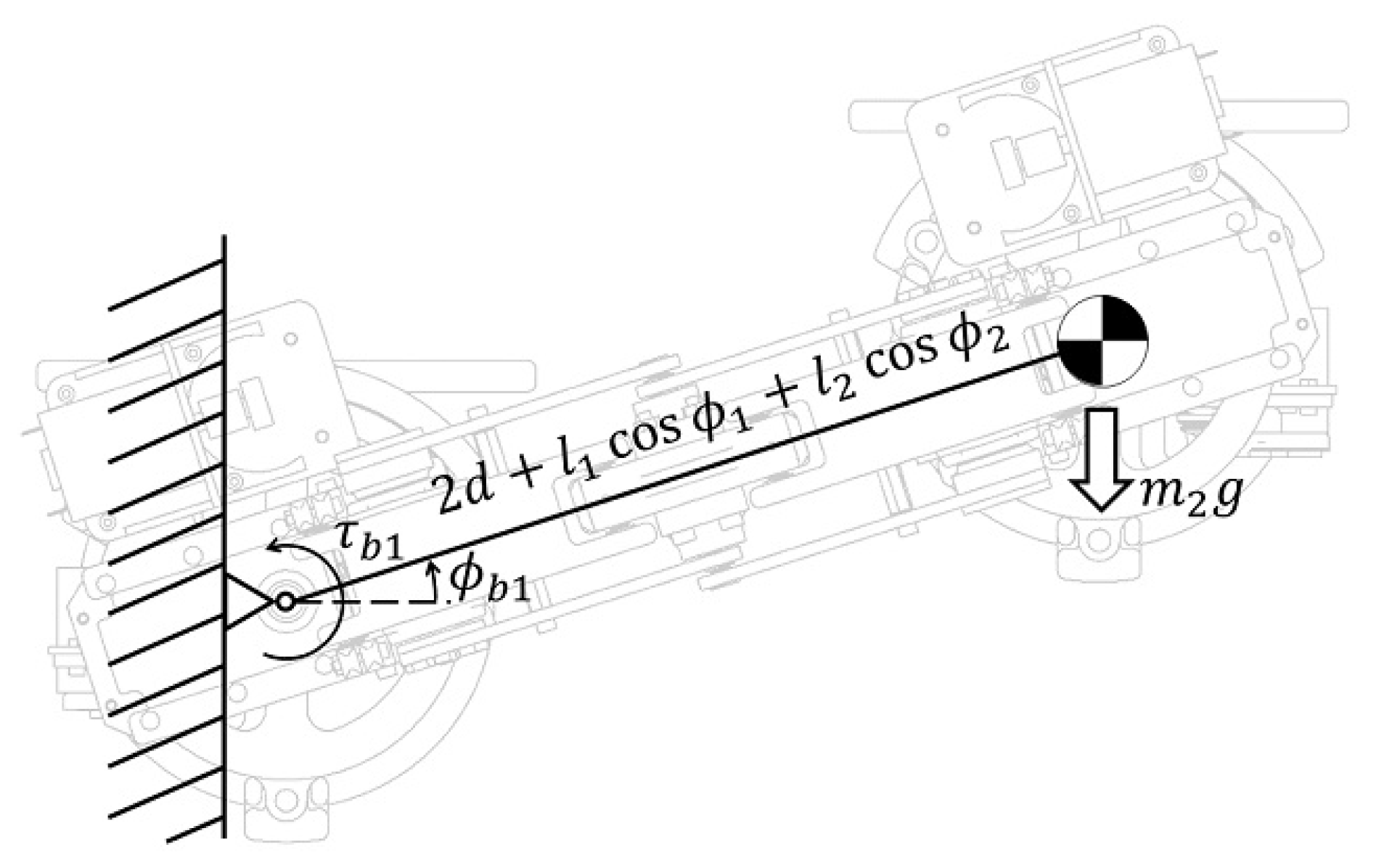

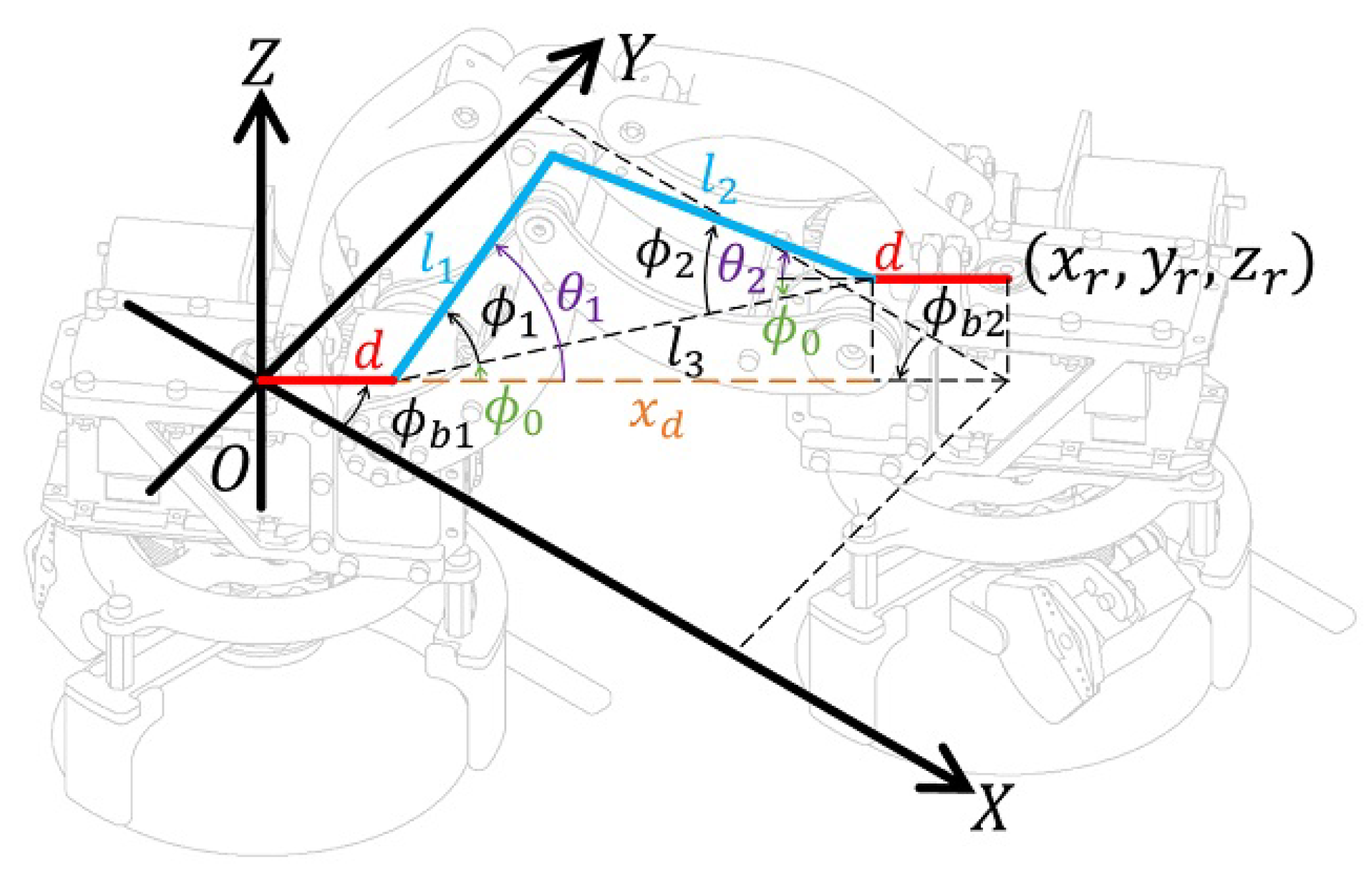

3. Trajectory Generation

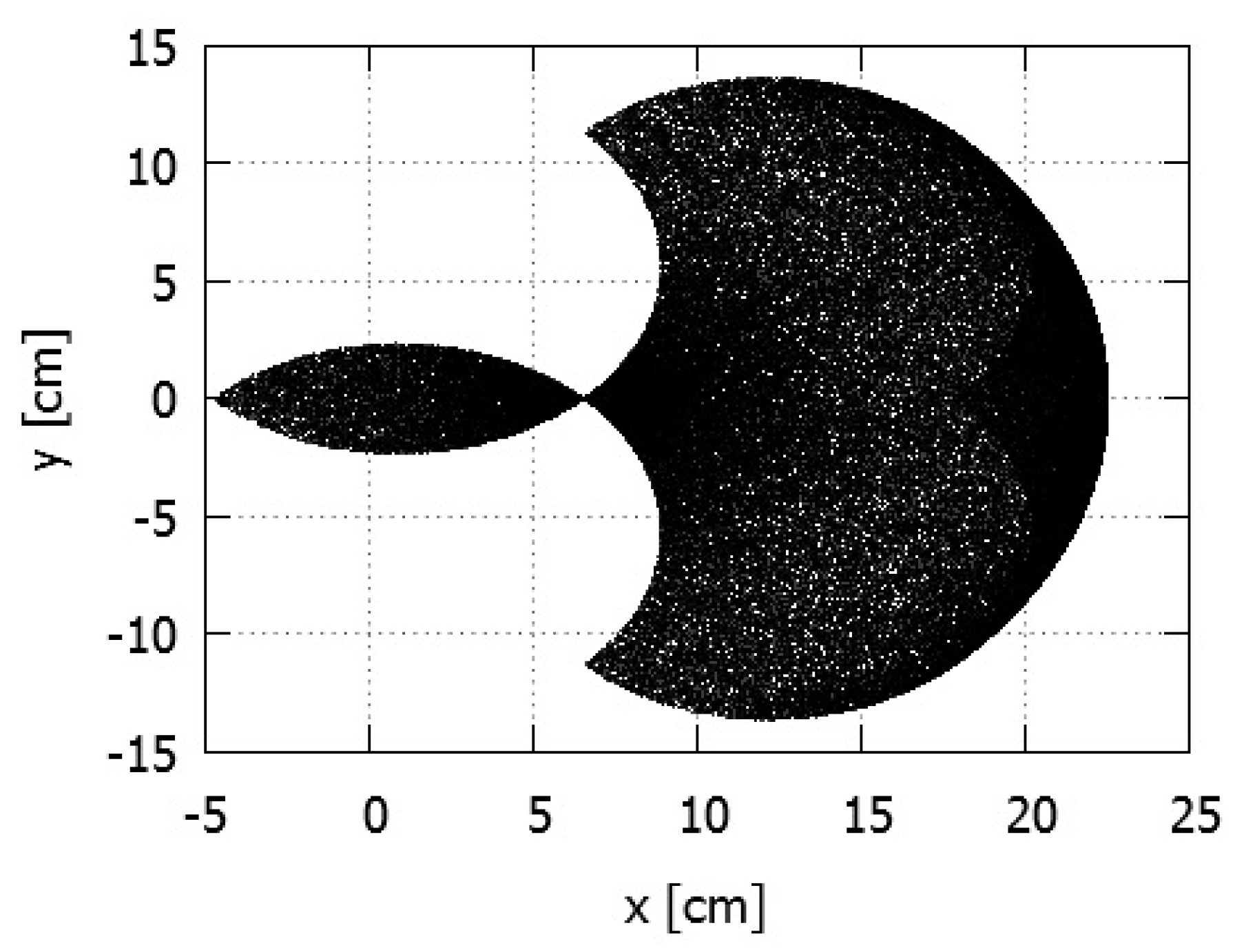

3.1. Inverse Kinematics

3.2. Fifth-Degree Polynomial Interpolation

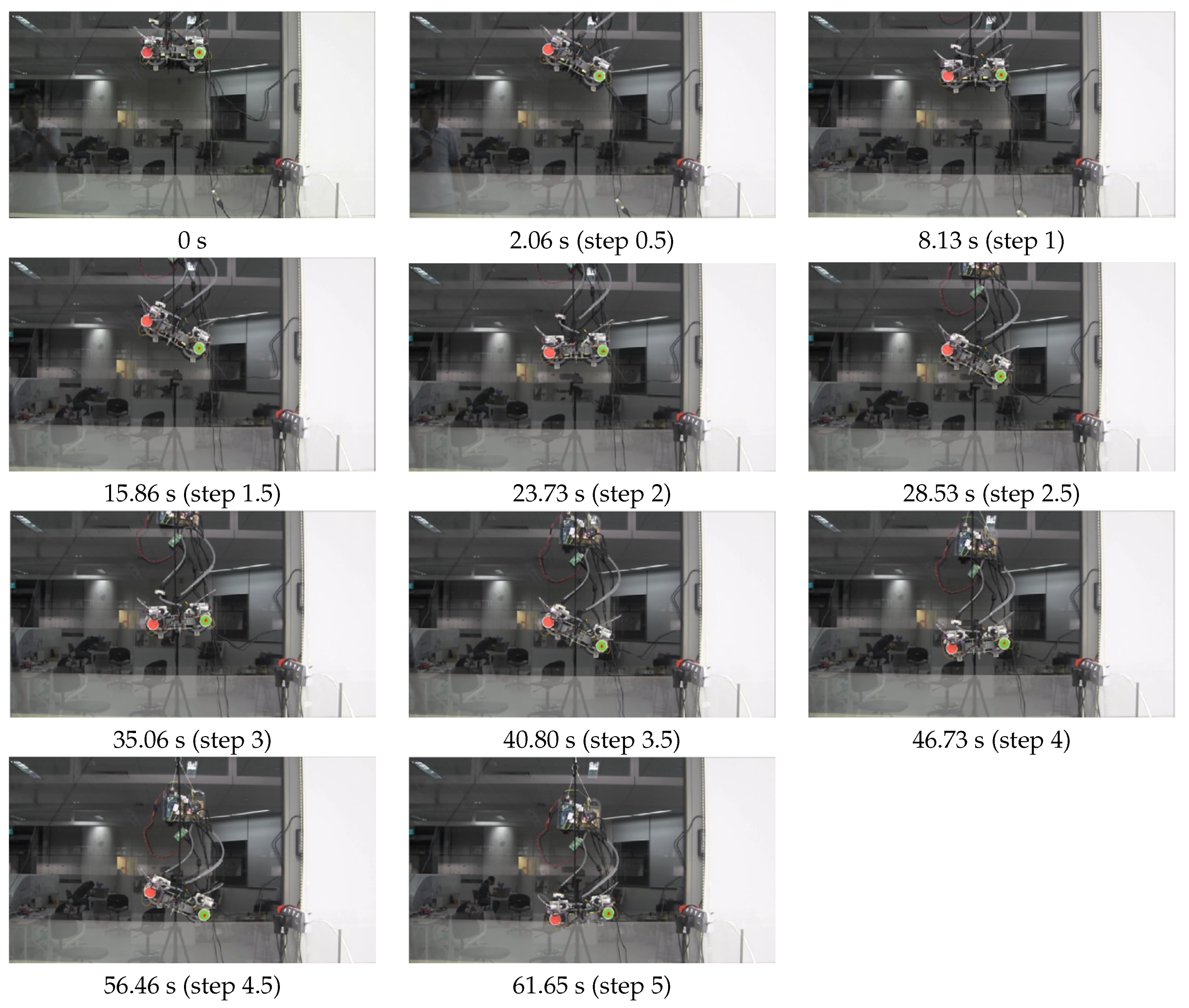

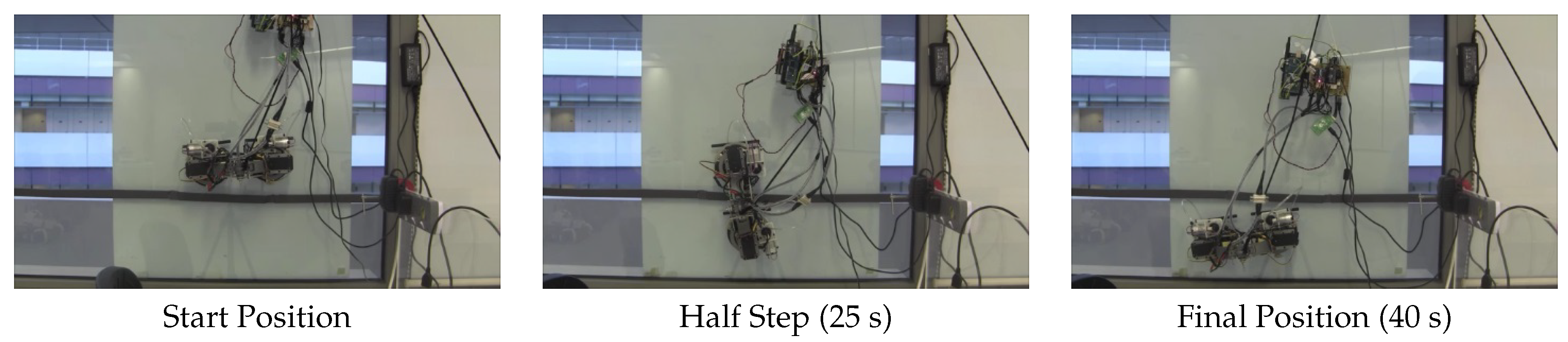

3.3. Gait Generation Based on Sequential Control

- Lift up the idling leg vertically

- Move the idling leg to the target step position horizontally against the glass surface

- Bring down the idling leg to the glass surface

- Switch the idling leg and the supporting leg, and repeat 1∼3

4. Experiments

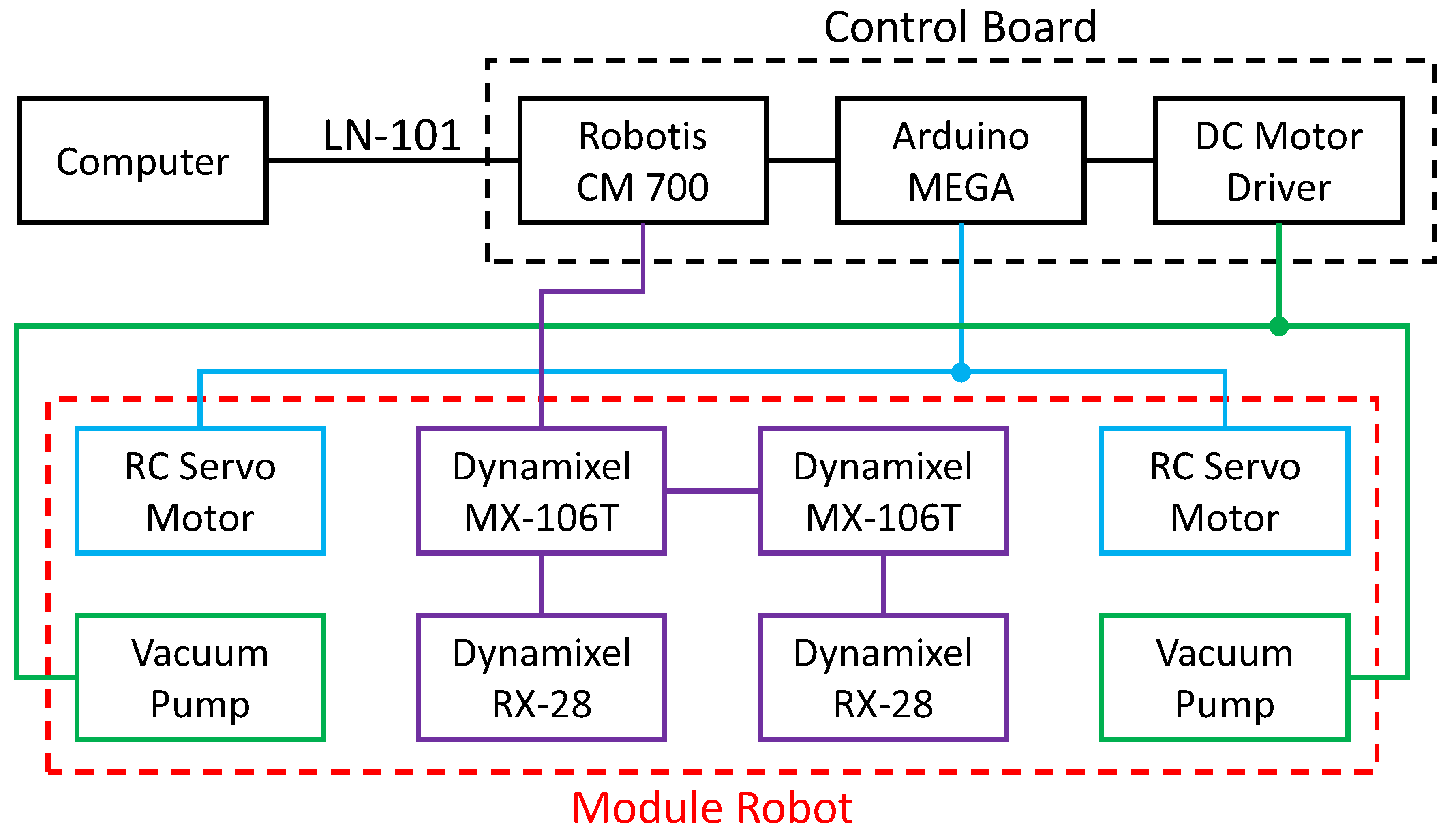

4.1. System Architecture and Experiments

4.2. Discussions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Frey, C.B.; Osborne, M.A. The future of employment: How susceptible are jobs to computerisation. Technol. Forecast. Soc. Chang. 2013, 7. [Google Scholar] [CrossRef]

- International Fedration of Robotics. Service Robot Statistics. Available online: http://www.ifr.org/service-robots/statistics/ (accessed on 21 November 2018).

- Aldred, J. Burj Khalifa—A new high for high-performance concrete. In Proceedings of the Institution of Civil Engineers-Civil Engineering; Thomas Telford Ltd.: London, UK, 2010; Volume 163, pp. 66–73. [Google Scholar]

- Baker, W.F. The World’s tallest building. STRUCTURE, June 2011. [Google Scholar]

- Baker, W.F.; Korista, D.S.; Novak, L.C. Burj Dubai: engineering the world’s tallest building. Struct. Des. Tall Spec. Build. 2007, 16, 361–375. [Google Scholar] [CrossRef]

- Weismantle, P.A.; Smith, G.L.; Sheriff, M. Burj Dubai: an architectural technical design case study. Struct. Des. Tall Spec. Build. 2007, 16, 335–360. [Google Scholar] [CrossRef]

- Zeljic, A.S. Shanghai Tower Façade Design Process. In Proceedings of the International Conference of Building Envelope Systems, Vancouver, BC, Canada, 27–30 June 2010; Available online: http://www.gensler.com/uploads/documents/Shanghai_Tower_Facade_Design_Process_11_10_2011.pdf (accessed on 21 November 2018).

- Xia, J.; Poon, D.; Mass, D. Case study: Shanghai Tower. CTBUH J. 2010, 2010, 12–18. [Google Scholar]

- Zhaoa, X.; Ding, J.; Suna, H. Structural design of shanghai tower for wind loads. Procedia Eng. 2011, 14, 1759–1767. [Google Scholar] [CrossRef]

- BBC. Shanghai Window Cleaning Cradle Swings out of Control. Available online: http://www.bbc.com/news/world-asia-china-32176401 (accessed on 21 November 2018).

- BBC. Window Washers Rescued from High up World Trade Center. Available online: http://www.bbc.com/news/world-us-canada-30028969 (accessed on 21 November 2018).

- Zhang, H.; Zhang, J.; Zong, G.; Wang, W.; Liu, R. Sky cleaner 3: A real pneumatic climbing robot for glass-wall cleaning. IEEE Robot. Autom. Mag. 2006, 13, 32–41. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, J.; Zong, G. Effective nonlinear control algorithms for a series of pneumatic climbing robots. In Proceedings of the 2006 IEEE International Conference on Robotics and Biomimetics, Kunming, China, 17–20 December 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 994–999. [Google Scholar]

- Zhang, H.; Zhang, J.; Zong, G. Requirements of glass cleaning and development of climbing robot systems. In Proceedings of the 2004 International Conference on Intelligent Mechatronics and Automation, Chengdu, China, 26–31 August 2004; IEEE: Piscataway, NJ, USA, 2004; pp. 101–106. [Google Scholar]

- Sun, D.; Zhu, J.; Lai, C.; Tso, S. A visual sensing application to a climbing cleaning robot on the glass surface. Mechatronics 2004, 14, 1089–1104. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, J.; Tso, S.K. A Climbing Robot for Cleaning Glass Surface with Motion Planning and Visual Sensing; INTECH Open Access Publisher: London, UK, 2007. [Google Scholar]

- Serbot-AG. Available online: http://www.serbot.ch/en/ (accessed on 21 November 2018).

- Seo, K.; Cho, S.; Kim, T.; Kim, H.S.; Kim, J. Design and stability analysis of a novel wall-climbing robotic platform (ROPE RIDE). Mech. Mach. Theory 2013, 70, 189–208. [Google Scholar] [CrossRef]

- Kim, T.Y.; Kim, J.H.; Seo, K.C.; Kim, H.M.; Lee, G.U.; Kim, J.W.; Kim, H.S. Design and Control of a Cleaning Unit for a Novel Wall-Climbing Robot. Appl. Mech. Mater. 2014, 541–542, 1092–1096. [Google Scholar] [CrossRef]

- Kim, T.; Seo, K.; Kim, J.H.; Kim, H.S. Adaptive impedance control of a cleaning unit for a novel wall-climbing mobile robotic platform (ROPE RIDE). In Proceedings of the 2014 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Besacon, France, 8–11 July 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 994–999. [Google Scholar]

- Fraunhofer-IFF. Available online: http://www.iff.fraunhofer.de/en.html (accessed on 21 November 2018).

- Böhme, T.; Schmucker, U.; Elkmann, N.; Sack, M. Service robots for facade cleaning. In Proceedings of the 24th Annual Conference of the IEEE Industrial Electronics Society, Aachen, Germany, 31 August–4 September 1998; IEEE: Piscataway, NJ, USA, 1998; Volume 2, pp. 1204–1207. [Google Scholar]

- Elkmann, N.; Schmucker, U.; Scharfe, H.; Schoop, C.; Kubbe, I. Drive Device for Moving a Robot or Vehicle on Flat, Inclined or Curved Surfaces, Particularly of a Glass Construction and Robot with Drive Device. U.S. Patent 5,959,424, 28 September 1999. [Google Scholar]

- Elkmann, N.; Hortig, J.; Fritzsche, M. Cleaning automation. In Springer Handbook of Automation; Springer: Berlin, Germany, 2009; pp. 1253–1264. [Google Scholar]

- Elkmann, N.; Felsch, T.; Sack, M.; Saenz, J.; Hortig, J. Innovative service robot systems for facade cleaning of difficult-to-access areas. In Proceedings of the 2002 IEEE/RSJ International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–4 October 2002; IEEE: Piscataway, NJ, USA, 2002; Volume 1, pp. 756–762. [Google Scholar]

- Elkmann, N.; Kunst, D.; Krueger, T.; Lucke, M.; Böhme, T.; Felsch, T.; Stürze, T. SIRIUSc–Façade cleaning robot for a high-rise building in munich, germany. In Climbing and Walking Robots; Springer: Berlin, Germnay, 2005; pp. 1033–1040. [Google Scholar]

- Bridge, B.; Elkmann, N.; Lucke, M.; Krüger, T.; Kunst, D.; Stürze, T.; Hortig, J. Kinematics, sensors and control of the fully automated façade-cleaning robot SIRIUSc for the Fraunhofer headquarters building, Munich. Ind. Robot Int. J. 2008, 35, 224–227. [Google Scholar]

- Cepolina, F.E.; Muscolo, G.G. Design of a robot for hygienization of walls in hospital environments. In Proceedings of the ISR/Robotik 2014; 41st International Symposium on Robotics, Munich, Germany, 2–3 June 2014; pp. 1–7. [Google Scholar]

- Akinfiev, T.; Armada, M.; Nabulsi, S. Climbing cleaning robot for vertical surfaces. Ind. Robot Int. J. 2009, 36, 352–357. [Google Scholar] [CrossRef]

- Ott, C.; Baumgärtner, C.; Mayr, J.; Fuchs, M.; Burger, R.; Lee, D.; Eiberger, O.; Albu-Schäffer, A.; Grebenstein, M.; Hirzinger, G. Development of a biped robot with torque controlled joints. In Proceedings of the 2010 10th IEEE-RAS International Conference on Humanoid Robots (Humanoids), Nashville, TN, USA, 6–8 December 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 167–173. [Google Scholar]

- Al-Busaidi, A.M. Development of an educational environment for online control of a biped robot using MATLAB and Arduino. In Proceedings of the Mechatronics (MECATRONICS), 2012 9th France-Japan & 7th Europe-Asia Congress on and 2012 13th Int’l Workshop on Research and Education in Mechatronics (REM), Paris, France, 21–23 November 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 337–344. [Google Scholar]

- Liu, C.Y.; Wang, J.C. Forecasting the development of the biped robot walking technique in Japan through S-curve model analysis. Scientometrics 2009, 82, 21–36. [Google Scholar] [CrossRef]

- Guan, Y.; Jiang, L.; Zhu, H.; Zhou, X.; Cai, C.; Wu, W.; Li, Z.; Zhang, H.; Zhang, X. Climbot: A modular bio-inspired biped climbing robot. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), San Francisco, CA, USA, 25–30 September 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1473–1478. [Google Scholar]

- Minor, M.; Dulimarta, H.; Danghi, G.; Mukherjee, R.; Tummala, R.L.; Aslam, D. Design, implementation, and evaluation of an under-actuated miniature biped climbing robot. In Proceedings of the 2000 IEEE/RSJ International Conference on Intelligent Robots and Systems, Takamatsu, Japan, 31 October–5 November 2000; IEEE: Piscataway, NJ, USA, 2000; Volume 3, pp. 1999–2005. [Google Scholar]

- AbuKhalil, T.; Sobh, T.; Patil, M. Survey on decentralized modular robots and control platforms. In Innovations and Advances in Computing, Informatics, Systems Sciences, Networking and Engineering; Springer: Berlin, Germany, 2015; pp. 165–175. [Google Scholar]

- Patil, M.; Abukhalil, T.; Patel, S.; Sobh, T. UB robot swarm—Design, implementation, and power management. In Proceedings of the 2016 12th IEEE International Conference on Control and Automation (ICCA), Kathmandu, Nepal, 1–3 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 577–582. [Google Scholar]

- Okazaki, Y.; Yamamoto, M.; Komatsu, M.; Tsusaka, Y.; Adachi, Y. Development of a Human Safe, Multi-Degree-of-Feedom Robot Arm Technology using Pneumatic Muscles (in Japanese). J. Robot. Soc. Jpn. 2010, 28, 62–70. [Google Scholar] [CrossRef]

- Noguchi, Y.; Iwase, M.; Hatakeyama, S.; Izutsu, M. A Yoyo Trick Realized by Parallel-Link Manipulator. In Proceedings of the 39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 4049–4054. [Google Scholar]

- Takeda, Y.; Okada, M. Development of a Jumping Robot with a Non-Circular Gear. In Proceedings of the 2012 JSME Conference on Robotics and Mechatronics, Hamamatsu, Japan, 27–29 May 2012; Volume 3, pp. 2A2–V04. [Google Scholar]

| Model Number | MX-106T | RX-28 | HS-5085MG |

|---|---|---|---|

| Maker | ROBOTIS | ROBOTIS | HITEC |

| Stall Torque | 8.4 Nm | 3.7 Nm | 4.3 kg·cm |

| No Load Speed | 45 rpm | 85 rpm | 0.13 rec/60deg |

| Weight | 153 g | 72 g | 21.9 g |

| Voltage | 12 V | 12 V | 6 V |

| Model Number | DP0125 |

| Maker | Nitto Kohki |

| Attainable Vacuum | −33.3 kPa |

| Free Air Displacement | 2.5 L/min |

| Voltage | 12 V |

| Weight | 80 g |

| Notation | Parameters |

|---|---|

| Link length | |

| Mass | |

| d | Length from center of the foot unit to the joint |

| Length between the joint of each foot unit | |

| Length of on the X–Y plane |

| Sequence | x [cm] | y [cm] | z [cm] |

|---|---|---|---|

| 1 | |||

| 2 | |||

| 3 | |||

| 4 | |||

| 5 | |||

| 6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nansai, S.; Onodera, K.; Veerajagadheswar, P.; Rajesh Elara, M.; Iwase, M. Design and Experiment of a Novel Façade Cleaning Robot with a Biped Mechanism. Appl. Sci. 2018, 8, 2398. https://doi.org/10.3390/app8122398

Nansai S, Onodera K, Veerajagadheswar P, Rajesh Elara M, Iwase M. Design and Experiment of a Novel Façade Cleaning Robot with a Biped Mechanism. Applied Sciences. 2018; 8(12):2398. https://doi.org/10.3390/app8122398

Chicago/Turabian StyleNansai, Shunsuke, Keichi Onodera, Prabakaran Veerajagadheswar, Mohan Rajesh Elara, and Masami Iwase. 2018. "Design and Experiment of a Novel Façade Cleaning Robot with a Biped Mechanism" Applied Sciences 8, no. 12: 2398. https://doi.org/10.3390/app8122398

APA StyleNansai, S., Onodera, K., Veerajagadheswar, P., Rajesh Elara, M., & Iwase, M. (2018). Design and Experiment of a Novel Façade Cleaning Robot with a Biped Mechanism. Applied Sciences, 8(12), 2398. https://doi.org/10.3390/app8122398