High-Speed Welding of Stainless Steel with Additional Compensatory Gas Jet Blow Molten Pool

Abstract

1. Introduction

2. Principles and Methods

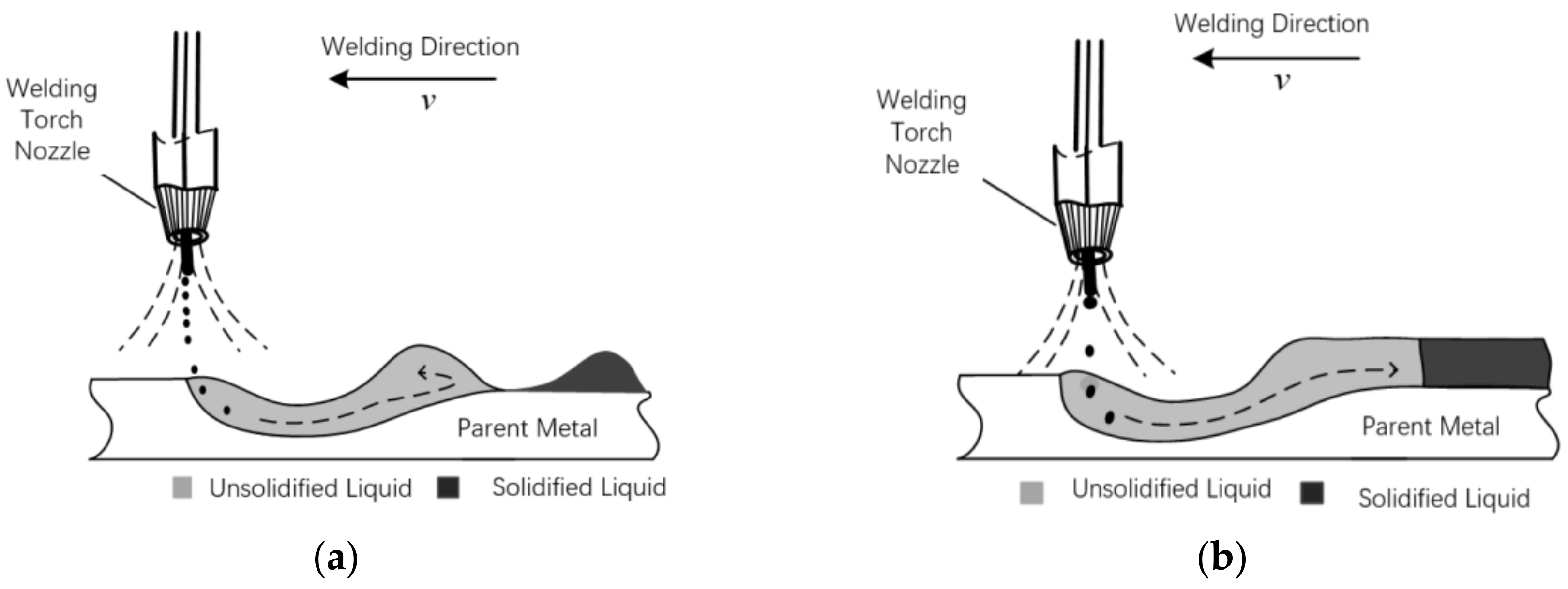

2.1. Analysis of Humping Bead Formation Mechanism with Relative Speed

- (1)

- The introduction of the additional gas jet at the rear position near the arc welding zone can affect the high temperature molten pool that has not yet solidified;

- (2)

- The impact force generated by the compensatory gas jet can significantly change the natural solidification mode of the welding molten pool, thereby apparently improving the weld formation and stirring the molten pool;

- (3)

- The gas cover formed during the process of compensatory gas jet impact on the molten pool can effectively extend the protection time on the surface of the molten pool;

- (4)

- The impact force effect formed by the compensatory gas jet and the thermal directional feedback effect caused by the gas cover can increase the molten pool width and weld depth.

2.2. Mechanism Analysis of High-Speed Welding Molten Pool Blowed by Additional and Compensatory Gas Jet

3. Experimental Materials and Equipment

4. Results and Discussion

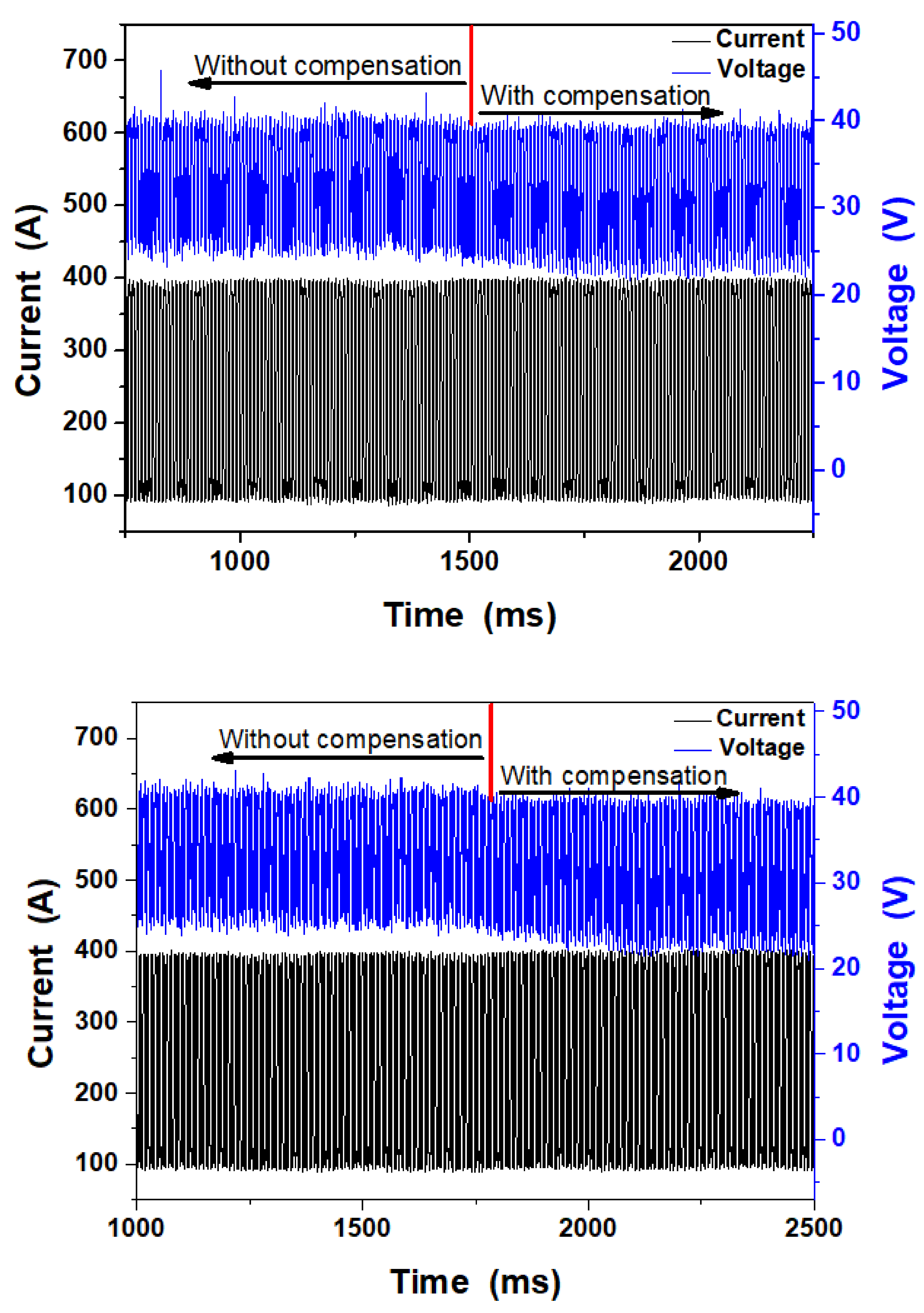

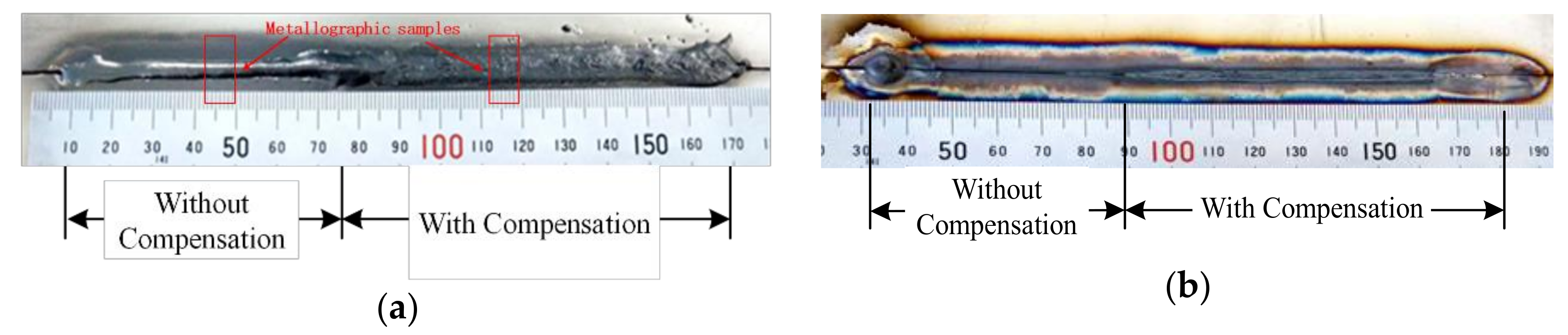

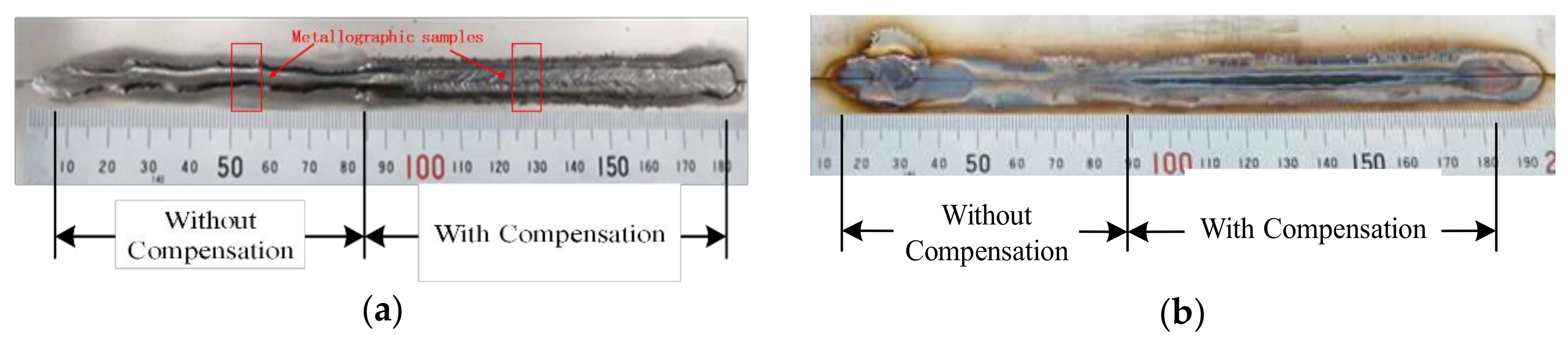

4.1. Butt Welding Using Compensatory Gas Jet Impinging on Molten Pool

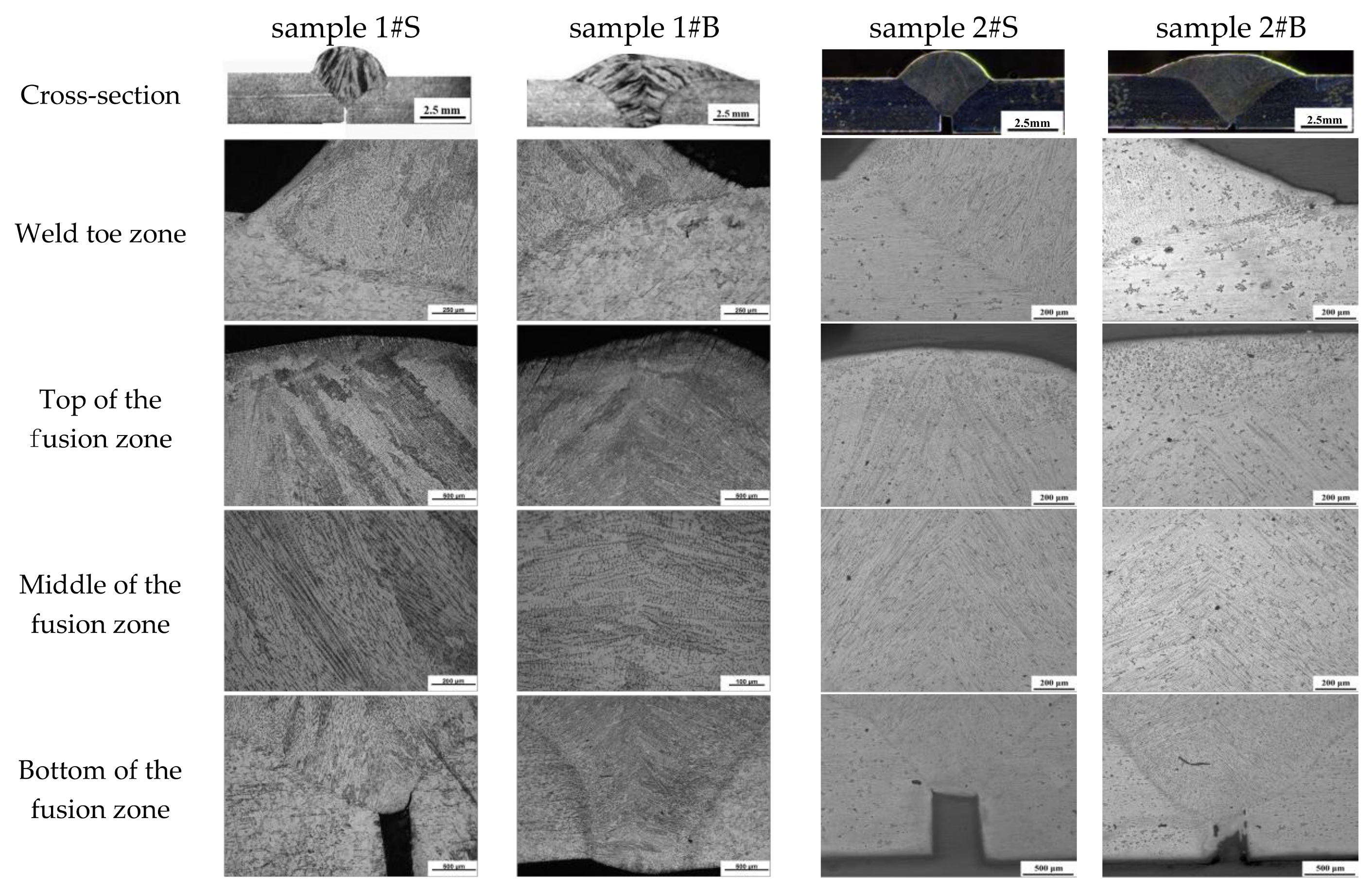

4.2. Analysis of Microstructure

4.3. Rockwell Hardness Test and Analysis

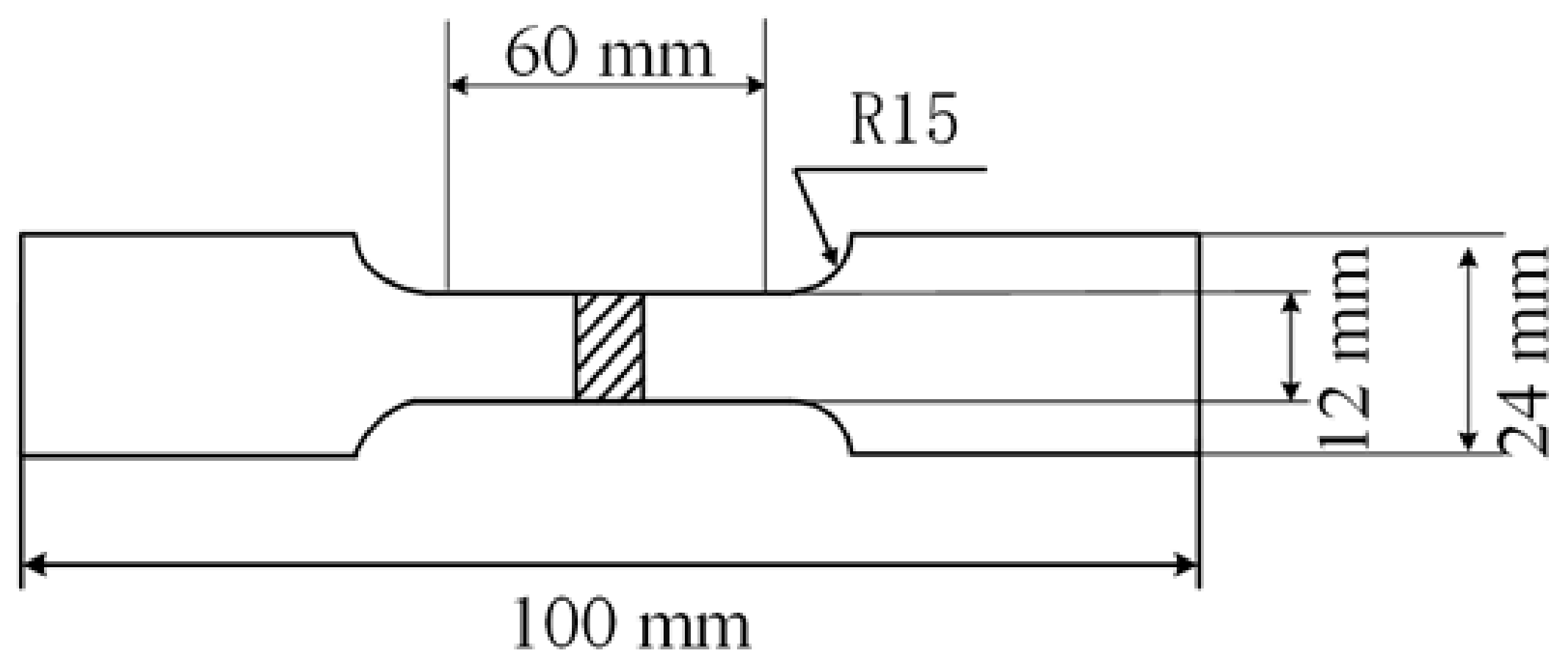

4.4. Tensile Strength Test and Analysis

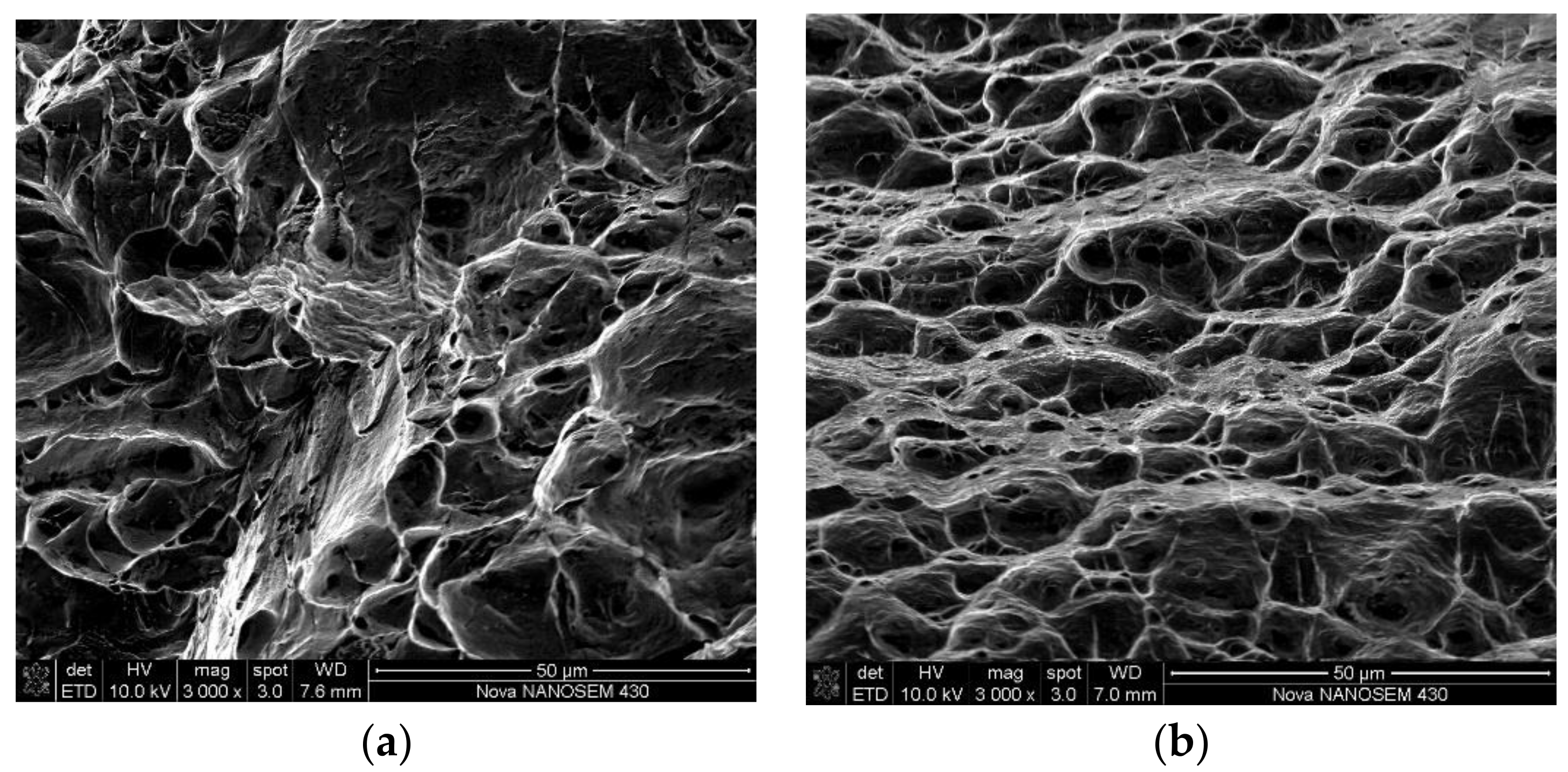

4.5. Fracture Surface Analysis

5. Conclusions

- (1)

- The method of welding with a compensatory gas jet impinging on the molten pool has an obvious positive effect on the solidification of high-speed welds. The appearance of the weld with jet blow is flat, uniform and high-quality, without obvious defects such as humping beads and undercuts.

- (2)

- The effect of impinging and stirring of the molten pool by the compensatory gas jet significantly refines the grains of the weld, accompanying an increase of the molten pool width and a slight increase in molten pool depth. The macroscopic morphology of the weld cross-section, as well as the microstructures in the weld-toe zone, the near-surface region, the middle, and the bottom of the weld all showed the stirring effect of the gas jet on the molten pool, as well as improved grain refinement.

- (3)

- By adopting compensatory gas jet impinging on the molten pool, the hardness values of the weld center and that of the heat-affected zone were enhanced. The capacities of the welds to withstand fractures were increased by 24.9% and 10.4% at the welding speeds of 154 cm/min and 167 cm/min, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Meng, X.; Qin, G.; Zou, Z. Investigation of humping defect in high speed gas tungsten arc welding by numerical modelling. Mater. Des. 2016, 94, 69–78. [Google Scholar] [CrossRef]

- Ueyama, T.; Ohnawa, T.; Tanaka, M.; Nakata, K. Effects of torch configuration and welding current on weld bead formation in high speed tandem pulsed gas metal arc welding of steel sheets. Sci. Technol. Weld. Join. 2013, 10, 750–759. [Google Scholar] [CrossRef]

- Wu, C.S.; Hu, Z.H.; Zhong, L.M. Prevention of humping bead associated with high welding speed by double-electrode gas metal arc welding. Int. J. Adv. Manuf. Technol. 2012, 63, 573–581. [Google Scholar] [CrossRef]

- Sundaram, M.; Jose, J.P.; Jaffino, G. Welding defects extraction for radiographic images using C-means segmentation method. In Proceedings of the International Conference on Communication and Networking Technologirs, Sivakasi, India, 18–19 December 2014; pp. 79–83. [Google Scholar]

- Cui, L.; Yang, X.; Wang, D.; Cao, J.; Xu, W. Experimental study of friction taper plug welding for low alloy structure steel: Welding process, defects, microstructures and mechanical properties. Mater. Des. 2014, 62, 271–281. [Google Scholar] [CrossRef]

- Katayama, S.; Kawahito, Y.; Mizutani, M. Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys. Procedia 2010, 5, 9–17. [Google Scholar] [CrossRef]

- Olsson, R.; Stemvers, M.; Stares, I. High speed welding gives a competitive edge. Weld. Rev. Int. 1995, 14, 129–131. [Google Scholar]

- Alfaro, S.C.A.; Franco, F.D. Exploring Infrared Sensoring for Real Time Welding Defects Monitoring in GTAW. Sensors 2010, 10, 5962–5974. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.L.; Elmer, J.W.; Debroy, T. Crystal growth during keyhole mode laser welding. Acta Mater. 2017, 133, 10–20. [Google Scholar] [CrossRef]

- Li, D.J.; Lu, S.P.; Li, D.Z.; Li, Y.Y. Weld Pool Shape Variations and Electrode Protection in Double Shielded TIG Welding. Adv. Mater. Res. 2010, 97–101, 3978–3981. [Google Scholar] [CrossRef]

- Shanping, L.U.; Dongjie, L.I.; Dianzhong, L.I.; Yiyi, L.I. Double shielded TIG welding method. Trans. China Weld. Inst. 2010, 31, 21–24. [Google Scholar]

- Siewert, E.; Hussary, N.; Schnick, M.; Dreher, M.; Schuster, H.; Wagner, R.; Eichler, S. New GTAW variant for high-throughput aluminum welding. Weld World. 2018, 62, 1–7. [Google Scholar] [CrossRef]

- Howse, D.S.; Lucas, W. Investigation into arc constriction by active fluxes for tungsten inert gas welding. Sci. Technol. Weld. Join. 2000, 5, 189–193. [Google Scholar] [CrossRef]

- Zacharia, T.; David, S.A.; Vitek, J.M.; Debroy, T. Weld pool development during GTA and laser beam welding of Type 304 stainless steel; Part I—Theoretical analysis. Weld. J. 1989, 68, 499–509. [Google Scholar]

- Lu, S.P.; Fujii, H.; Nogi, K. Weld shape variation and electrode protection under Ar-(Ar-O2) double shielded GTA welding. Sci. Technol. Weld. Join. 2009, 14, 726–733. [Google Scholar] [CrossRef]

- Li, G.H.; Yang, Z.K.; Wang, Y.Q. Research on Process of Gdouble Gas Sheielded TIG Welding Applied on Sheet Armour Steel. New Technol. New Process. 2013, 11, 112–115. [Google Scholar]

- Zhang, L.J.; Zhang, J.X.; Gong, S.L. Recent advance in research for keyhole behavior during laser deep penetration welding process. Laser J. 2009, 5, 3–5. [Google Scholar]

- Pei, Y.L.; Shan, J.G.; Ren, J.L. Effect of Welding Speed on Melt Flow Behavior in High Speed Laser Welding Process. Chin. J. Lasers 2013, 5, 61–66. [Google Scholar]

- Zhou, Y.; Cai, Y.; Heng, H.K.; Sheng, J.; Li, F. Influence of side assist gas on microstructure and corrosion resistance of welds of austenitic stainless steel in laser welding. Chin. J. Lasers 2017, 5, 113–120. [Google Scholar]

- Oliveira, J.P.; Miranda, R.M.; Fernandes, F.M.B. Welding and Joining of NiTi Shape Memory Alloys: A Review. Prog. Mater. Sci. 2017, 88, 412–466. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Zeng, Z.; Andrei, C.; Fernandes, F.M.B.; Miranda, R.M.; Ramirez, A.J.; Omori, T.; Zhou, N. Dissimilar laser welding of superelastic NiTi and CuAlMn shape memory alloys. Mater. Des. 2017, 128, 166–175. [Google Scholar] [CrossRef]

- Da, C.T.; Bohórquez, C.E. Ultrasound in arc welding: A review. Ultrasonics 2015, 56, 201–209. [Google Scholar]

- Gery, D.; Long, H.; Maropoulos, P. Effects of welding speed, energy input and heat source distribution on temperature variations in butt joint welding. J. Mater. Process. Technol. 2005, 167, 393–401. [Google Scholar] [CrossRef]

- Armentani, E.; Esposito, R.; Sepe, R. The influence of thermal properties and preheating on residual stresses in welding. Int. J. Comput. Mater. Sci. Surf. Eng. 2007, 1, 146–162. [Google Scholar] [CrossRef]

- Hazvinloo, H.; Honarbakhsh, A. Effect of gas-shielded flux cored arc welding parameters on weld width and tensile properties of weld metal in a low carbon steel. J. Appl. Sci. 2010, 10, 658–663. [Google Scholar]

- Armentani, E.; Pozzi, A.; Sepe, R. Finite-element simulation of temperature fields and residual stresses in butt welded joints and comparison with experimental measurements. In Proceedings of the ASME 2014 12th Biennial Conference on Engineering Systems Design and Analysis, Copenhagen, Denmark, 25–27 June 2014; pp. 25–27. [Google Scholar]

- Somashekara, M.; Naveenkumar, M.; Kumar, A.; Viswanath, C.; Simhambhatla, S. Investigations into effect of weld-deposition pattern on residual stress evolution for metallic additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 90, 2009–2025. [Google Scholar] [CrossRef]

- Cai, X.; Fan, C.; Lin, S.; Yang, C.; Hu, L.; Ji, X. Effects of shielding gas composition on arc behaviors and weld formation in narrow gap tandem GMAW. Int. J. Adv. Manuf. Technol. 2017, 91, 3449–3456. [Google Scholar] [CrossRef]

- Dong, C.W.; Xue, J.X.; Min, X.; Qiang, Z. Effects of additional compensation shielding gas on high speed pulsed MIG welding seams. Trans. China Weld. Inst. 2015, 36, 85–88. [Google Scholar]

- Dong, C.W.; Xue, J.X.; Jiang, X.M. In Effects of additional compensation shielding gas on stainless steel pulse MIG welding. In Proceedings of the 2016 IEEE Workshop on Advanced Robotics and its Social Impacts (ARSO), Shanghai, China, 8–10 July 2016; pp. 128–133. [Google Scholar]

- Yao, P.; Xue, J.X.; Zhou, K.; Wang, X.; Zhu, Q. Symmetrical transition waveform control on double-wire MIG welding. J. Mater. Process. Technol. 2016, 229, 111–120. [Google Scholar] [CrossRef]

| Component | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | Ti | Nb |

| Test Value | 0.027 | 1.81 | 0.55 | 19.71 | 9.84 | 0.02 | 0.014 | 0.006 | 0.03 | – | – |

| Number | Welding Speed v (cm/min) | Compensatory Status | Average Current I (A) |

|---|---|---|---|

| 1#S | 154 | without compensation | 268 |

| 1#B | 154 | with compensation | 268 |

| 2#S | 167 | without compensation | 268 |

| 2#B | 167 | with compensation | 268 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, C.; Xue, J.; Zhang, Z.; Jin, L.; Hu, Y.; Wu, W. High-Speed Welding of Stainless Steel with Additional Compensatory Gas Jet Blow Molten Pool. Appl. Sci. 2018, 8, 2170. https://doi.org/10.3390/app8112170

Dong C, Xue J, Zhang Z, Jin L, Hu Y, Wu W. High-Speed Welding of Stainless Steel with Additional Compensatory Gas Jet Blow Molten Pool. Applied Sciences. 2018; 8(11):2170. https://doi.org/10.3390/app8112170

Chicago/Turabian StyleDong, Changwen, Jiaxiang Xue, Zhanhui Zhang, Li Jin, Yu Hu, and Wei Wu. 2018. "High-Speed Welding of Stainless Steel with Additional Compensatory Gas Jet Blow Molten Pool" Applied Sciences 8, no. 11: 2170. https://doi.org/10.3390/app8112170

APA StyleDong, C., Xue, J., Zhang, Z., Jin, L., Hu, Y., & Wu, W. (2018). High-Speed Welding of Stainless Steel with Additional Compensatory Gas Jet Blow Molten Pool. Applied Sciences, 8(11), 2170. https://doi.org/10.3390/app8112170