Linking the Effect of Aggregate Interaction to the Compaction Theory for Asphalt Mixtures Using Image Processing

Abstract

:1. Introduction

2. Compaction Theories and Compactability in Asphalt Mixtures

3. Image Processing Technique Used

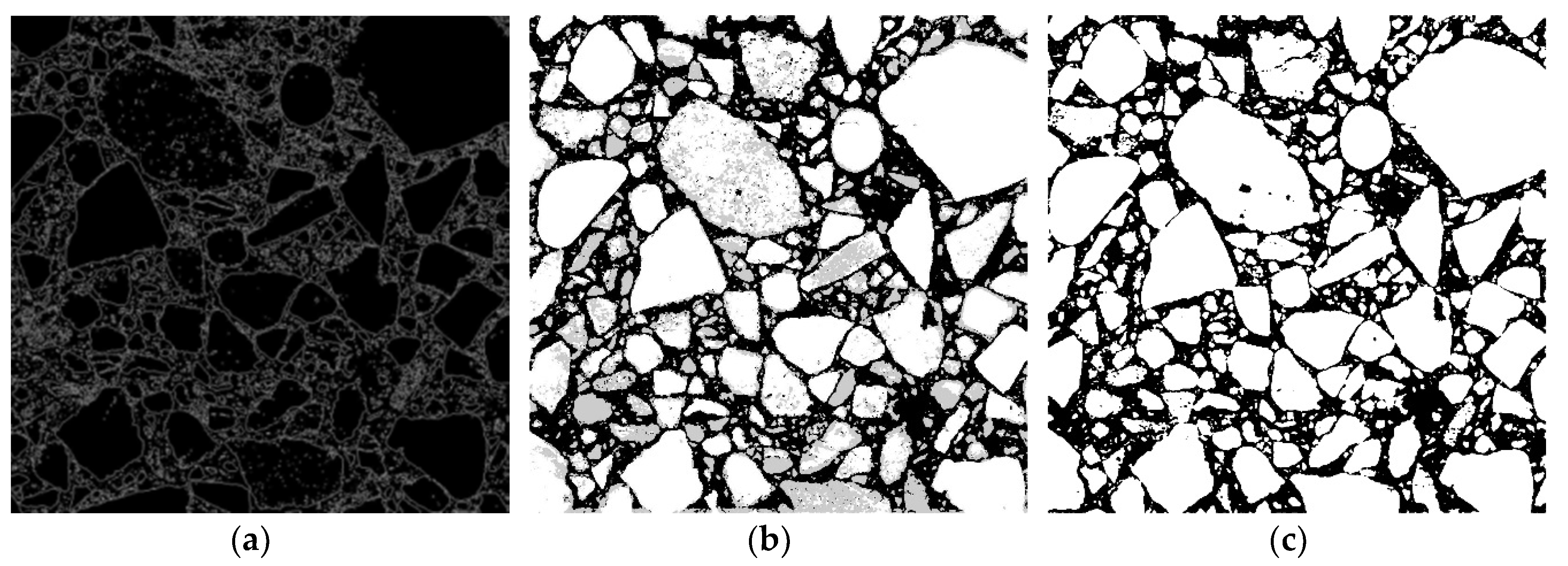

3.1. Image Enhancements

3.2. Threshold with the Edge Detection

3.3. Morphological Operations

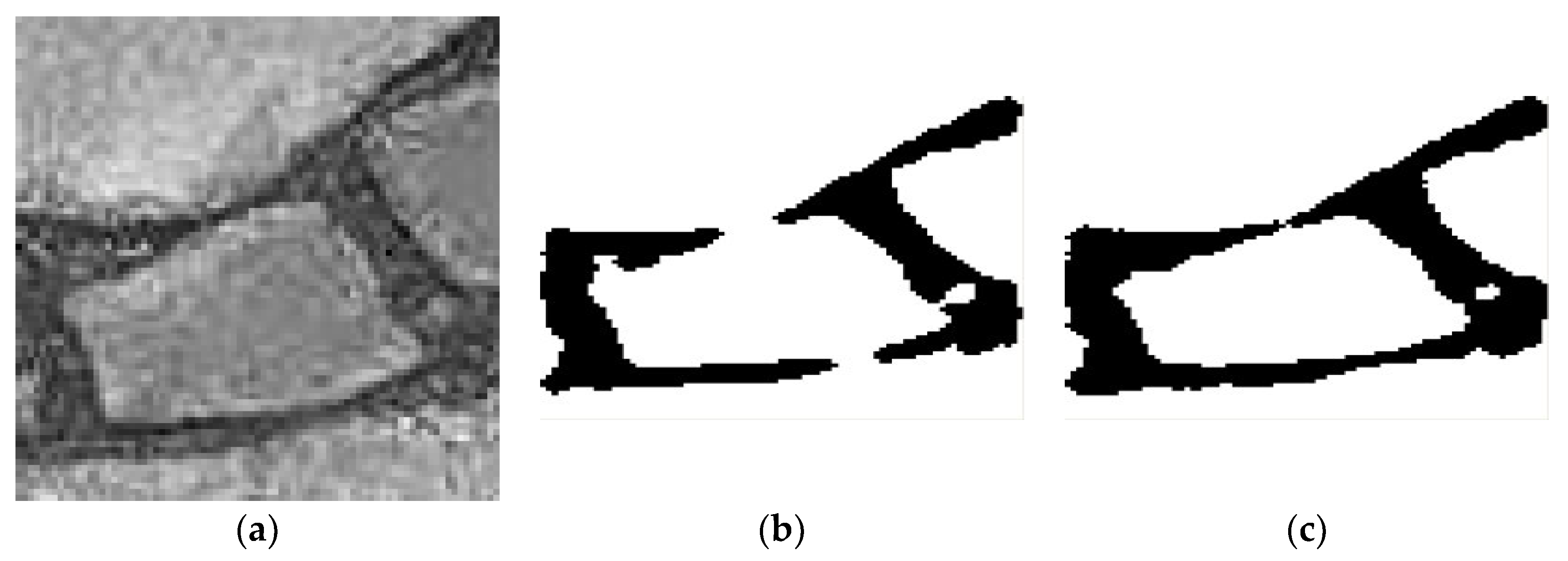

3.4. Objects Splitting

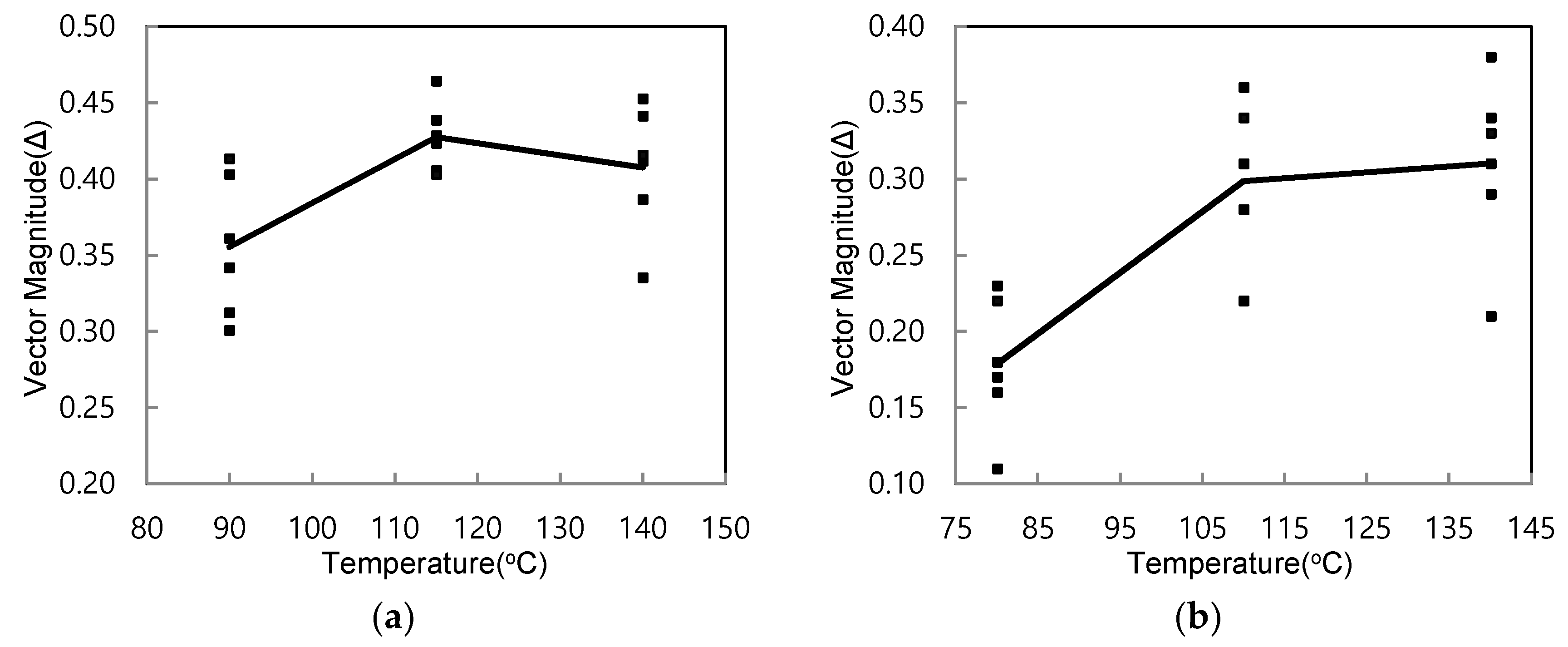

3.5. Aggregate Orientation

4. Materials and Methods

5. Results and Discussion

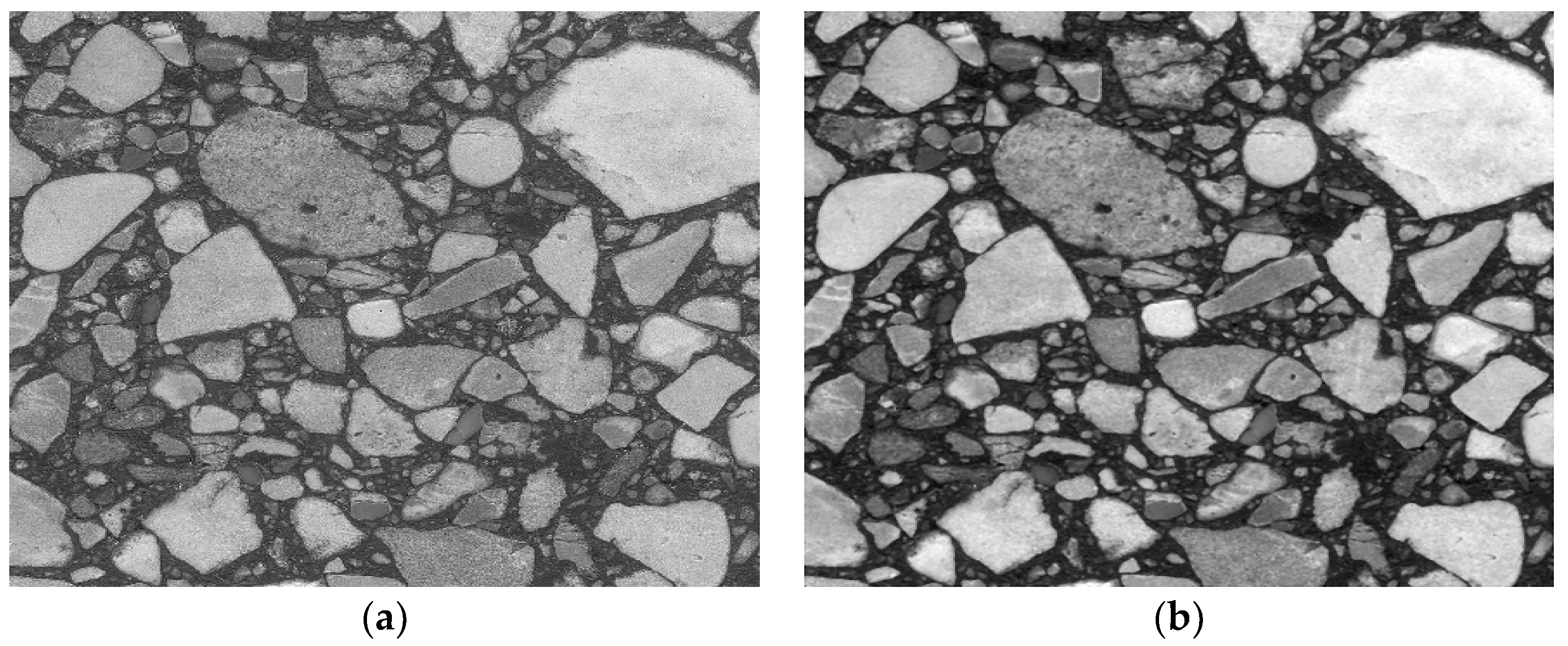

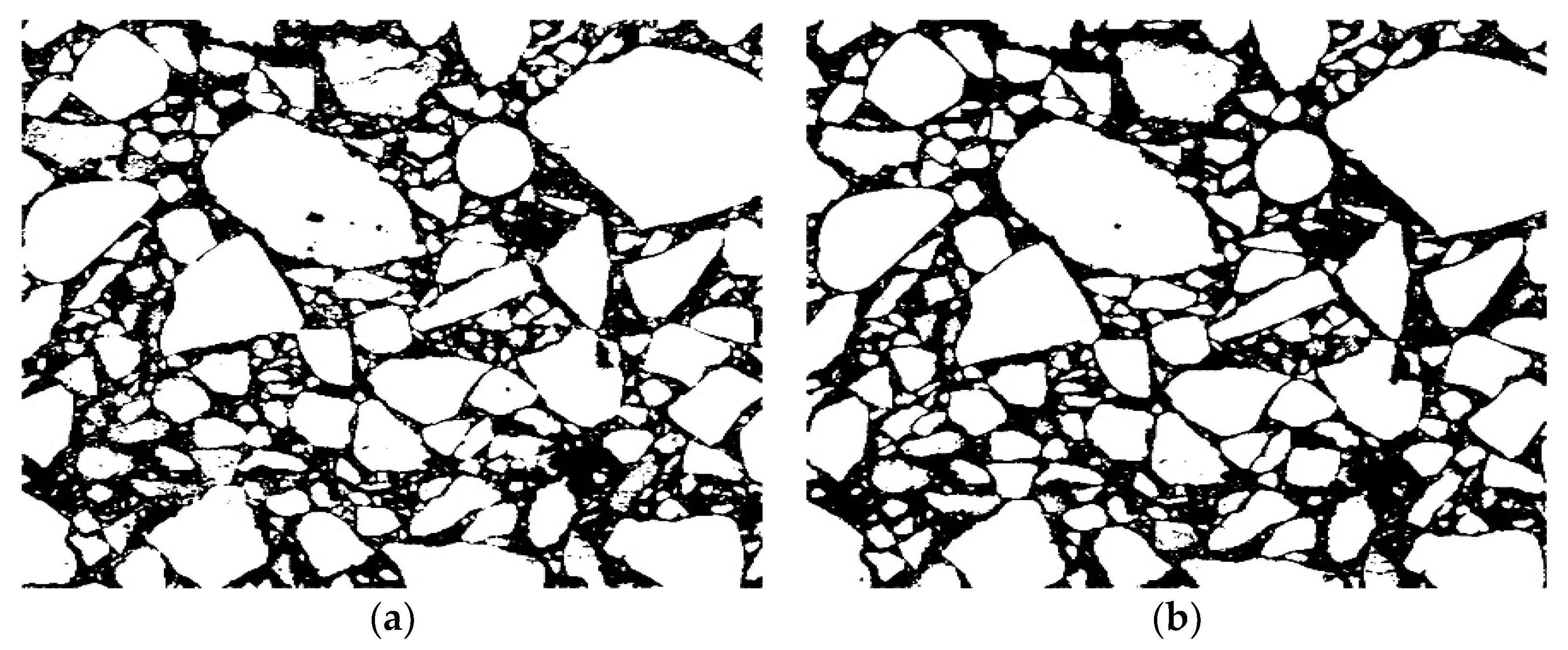

5.1. Results of Image Analysis

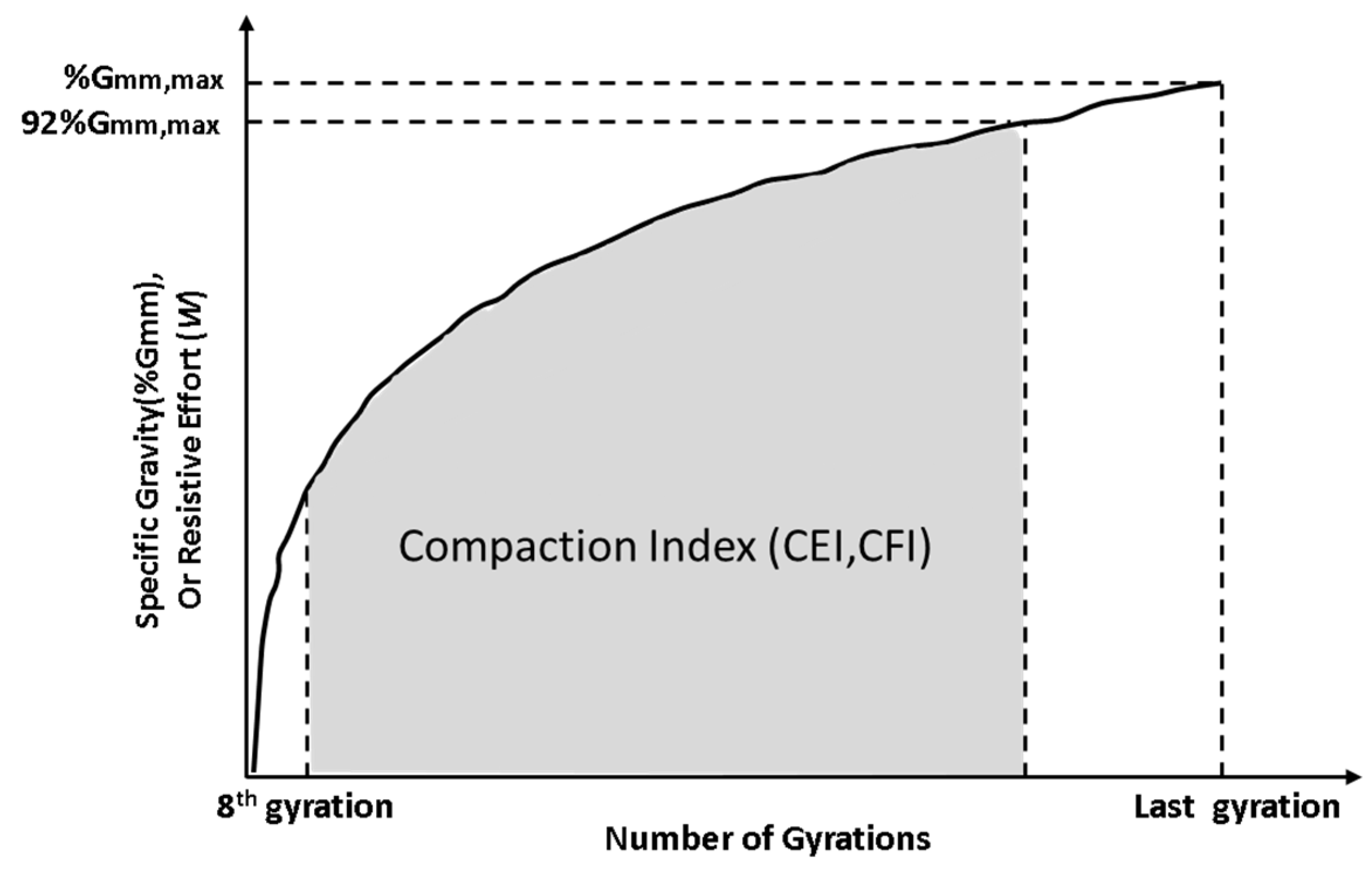

5.2. Compaction Energy Efforts

5.3. Effects of Mixtures Volumetric Change on the Rearrangement of Aggregates

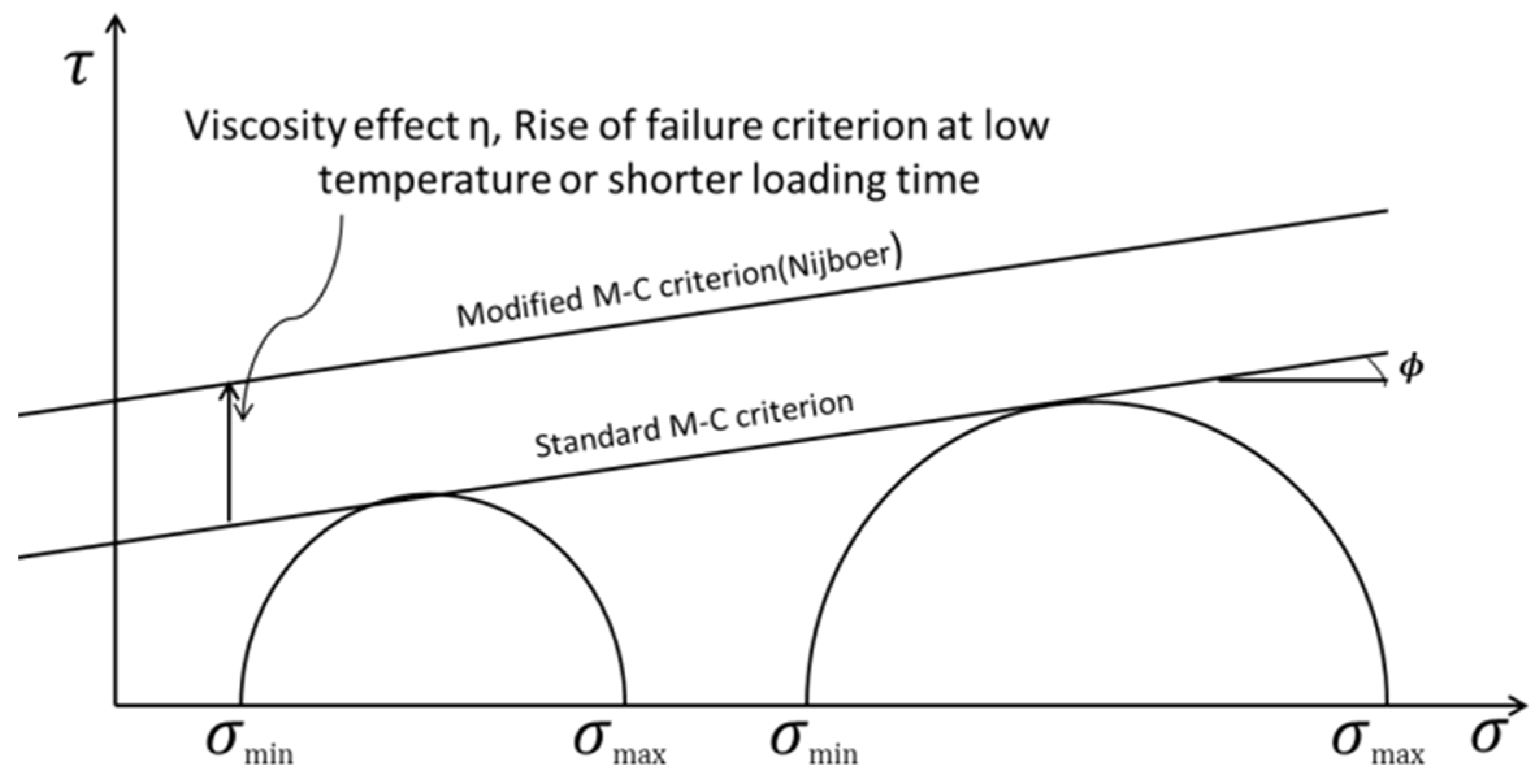

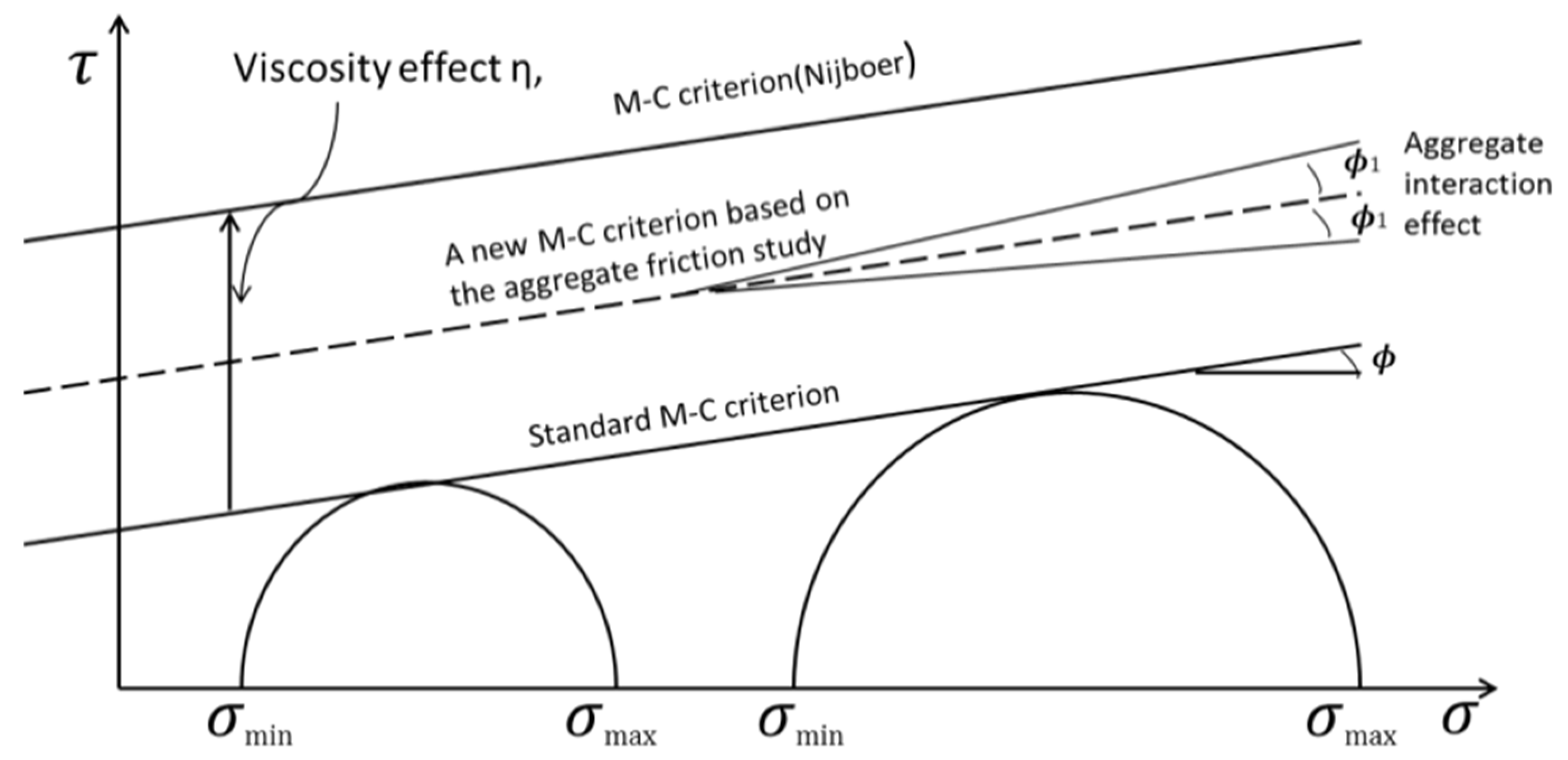

5.4. Modifying Mohr–Coulomb Compaction Concept from the Study

6. Conclusions

- Image processing was developed to conduct a better analysis of the internal structure of the asphalt mixture, including detailed image processing techniques that solved the difficulty regarding the separation of objects by equalizing, filtering for denosing, and thresholding. The results of the t-test show that it is reliable and confident to evaluate the internal structure interpretation of the mixture with good repeatability.

- The aggregate orientation and the energy index were highly dependent on the compaction temperature. At high viscosity, the aggregates were not sufficiently able to slide and be moved for rearrangement; thus, the mixture needs more energy for compaction. There is an optimum compaction temperature at which a preferred orientation exists to provide a low-energy index. Excessive compaction temperature is unnecessary to obtain a better rearrangement of aggregates. Conversely, an excessive compaction temperature was found to be responsible for increasing the interaction of aggregates and causing a reduction in the amount of asphalt for lubrication.

- The results of the aggregate orientation and energy index studies show that the compaction temperature changes the asphalt mixture volume and causes internal friction changes due to aggregate interactions. The effect of the mixture volume change on the aggregate friction behavior was evaluated by the Veac and the Pba. Mixture acquires more Veac, at which an optimum compaction temperature produces low CEI and CFI values. Despite being higher than the optimum temperature for the PG62-28 mixture, the Veac decreased by 0.4% and 0.35% of the Pba, which flowed into the aggregates. This volumetric change in the Veac and Pba can produce a large frictional interaction between aggregates and eliminate the viscosity effect to increase a better rearrangement of aggregates.

- The aggregate interaction effect was introduced to modify the More–Coulomb compaction concept, and it explains the additional friction that is produced due to the change in the volumetrics of mixture. The additional friction parameter is sensitive to the compaction temperature.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, C.; Wang, H.; You, Z.; Yang, X. Compaction characteristics of asphalt mixture with different gradation type through superpave gyratory compaction and X-ray CT scanning. Constr. Build. Mater. 2006, 129, 243–255. [Google Scholar] [CrossRef]

- Chen, J.; Wang, H.; Li, L. Virtual testing of asphalt mixture with two-dimensional and three-dimensional random aggregate structures. Int. J. Pavement Eng. 2015, 1–13. [Google Scholar] [CrossRef]

- Delage, K.P. The Effect of Fine Aggregate Angularity on Hot Mix Asphalt Performance. Master’s Thesis, University of Wisconsin-Madison, Madison, WI, USA, 2001. [Google Scholar]

- Tashman, L.; Masad, E.; Peterson, B.; Saleh, H. Internal structure analysis of asphalt mixes to improve the simulation of superpave gyratory compaction to field conditions. J. Assoc. Asph. Paving Technol. 2001, 70, 605–645. [Google Scholar]

- Chen, M.J.; Wong, Y.D. Evaluation of the development of aggregate packing in porous asphalt mixture using discrete element method simulation. Road Mater. Pavement Des. 2017, 18, 64–85. [Google Scholar] [CrossRef]

- Maerz, N.H. Technical and computational aspects of the measurement of aggregate shape by digital image analysis. J. Comput. Civ. Eng. 2004, 18, 10–18. [Google Scholar] [CrossRef]

- Sefidmazgi, N.R.; Teymourpour, P.; Bahia, H. Effect of particle mobility on aggregate structure formation in asphalt mixtures. Road Mater. Pavement Des. 2013, 14 (Suppl. 2), 16–34. [Google Scholar] [CrossRef]

- Sefidmazgi, N.R. Defining Effective Aggregate Skeleton in Asphalt Mixture Using Digital Imaging. Master’s Thesis, University of Wisconsin-Madison, Madison, WI, USA, 2011. [Google Scholar]

- Bessa, S.; Branco, V.T.C.; Soares, J.B.; Neto, J.A.N. Aggregate shape properties and their influence on the behavior of hot-mix asphalt. J. Mater. Civ. Eng. 2015, 27, D04014212. [Google Scholar] [CrossRef]

- Caro, S.; Castillo, D.; Darabi, M.; Masad, E. Influence of different sources of microstructural heterogeneity on the degradation of asphalt mixtures. Int. J. Pavement Eng. 2018, 19, 9–23. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Experimental evaluation of high performance base course and road base asphalt concrete with electric arc furnace steel slags. J. Hazard. Mater. 2010, 181, 938–948. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Masad, E.; Muhunthan, B.; Shashidar, N.; Harman, T. Quantifying laboratory compaction effects on the internal structure of asphalt concrete. Trans. Res. Rec. 1999, 1681, 179–185. [Google Scholar] [CrossRef]

- Perez-Jimenez, F.; Martinez, A.H.; Miro, R.; Hernandez-Barrera, D.; Araya-Zamorano, L. Effect of compaction temperature and procedure on the design of asphalt mixtures using marshall and gyratory compactor. Constr. Build. Mater. 2014, 65, 264–269. [Google Scholar] [CrossRef]

- Sefidmazgi, N.R.; Tashman, L.; Bahia, H. Internal Structure characterization of asphalt mixtures for rutting performance using imaging analysis. Road Mater. Pavement Des. 2012, 13 (Suppl. 1), 21–37. [Google Scholar] [CrossRef]

- Georgiou, P.; Sideris, L.; Loizos, A. Evaluation of the effects of gyratory and field compaction on asphalt mix internal structure. Mater. Struct. 2016, 49, 665–676. [Google Scholar] [CrossRef]

- Delgadillo, R.; Bahia, H. Effect of temperature and pressure on hot mixed asphalt compaction: Field and laboratory study. J. Mater. Civ. Eng. 2008, 20, 440–448. [Google Scholar] [CrossRef]

- Yin, A.; Yang, X.; Zhang, C.; Zeng, G.; Yang, Z. Three-dimensional heterogeneous fracture simulation of asphalt mixture under uniaxial tension with cohesive crack model. Constr. Build. Mater. 2015, 76, 103–117. [Google Scholar] [CrossRef]

- Airey, G.D.; Collop, A.C. Mechanical and structural assessment of laboratory and field compacted asphalt mixtures. Int. J. Pavement Eng. 2015, 17, 50–63. [Google Scholar] [CrossRef]

- Jiang, J.; Ni, F.; Gao, L.; Yao, L. Effect of the contact structure characteristics on rutting performance in asphalt mixtures using 2d imaging analysis. Constr. Build. Mater. 2017, 136, 426–435. [Google Scholar] [CrossRef]

- Cong, L.; Peng, J.; Guo, Z.; Wang, Q. Evaluation of fatigue cracking in asphalt mixtures based on surface energy. J. Mater. Civ. Eng. 2017, 29, D4015003. [Google Scholar] [CrossRef]

- Hassan, N.A.; Airey, G.D.; Hainin, M.R. Characterization of micro-structural damage in asphalt mixtures using image analysis. Constr. Build. Mater. 2014, 54, 27–38. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Influence of the aggregate skeleton design method on the permanent deformation resistance of stone mastic asphalt. J. Mater. Res. Innov. 2014, 18, 96–101. [Google Scholar] [CrossRef]

- Kehagia, F. Skid resistance performance of asphalt wearing courses with electric arc furnace slag aggregates. Waste Manag. Res. 2009, 27, 288–294. [Google Scholar] [CrossRef] [PubMed]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef] [PubMed]

- Bahia, H.; Friemel, T.; Peterson, P.; Russel, J. Optimization of constructability and resistance to traffic: A new design approach for HMA using the superpave compactor. J. Assoc. Asph. Paving Technol. 1998, 67, 189–232. [Google Scholar]

- Guler, M.; Bahia, H.; Bosscher, P.; Plesha, M. Device for measuring shear resistance of hot-mix asphalt in gyratory compactor. Trans. Res. Rec. 2000, 1723, 116–124. [Google Scholar] [CrossRef]

- Azari, H.; McCuen, R.H.; Stuart, K.D. Optimum compaction temperature for modified binder. J. Trans. Eng. 2003, 129, 531–537. [Google Scholar] [CrossRef]

- Sombre, R.; Newcomb, D.; Chadbourn, B.; Voller, V. Parameter to define the laboratory compaction temperature range of hot-mix asphalt. J. Assoc. Asph. Paving Technol. 1998, 67, 125–152. [Google Scholar]

- Fallaha, F.; Khabaz, F.; Kim, Y.R.; Reddy Kommidi, S.; Haghshenas, H.F. Molecular dynamics modeling and simulation of bituminous binder chemical aging due to variation of oxidation level and saturate-aromatic-resin-asphaltene fraction. Fuel 2019, 237, 71–80. [Google Scholar] [CrossRef]

- Khabaz, F.; Khare, R. Molecular simulations of asphalt rheology: Application of time–temperature superposition principle. J. Rheol. 2018, 62, 941–954. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- Masad, E.; Scarpas, A.; Alipour, A.; Rajagopal, K.R.; Kasbergen, C. Finite element modelling of field compaction of hot mix asphalt. Part I: Theory. Int. J. Pavement Eng. 2016, 17, 13–23. [Google Scholar] [CrossRef]

- Masad, E.; Scarpas, A.; Rajagopal, K.R.; Kassem, E.; Koneru, S.; Kasbergen, C. Finite element modelling of field compaction of hot mix asphalt. Part II: Applications. Int. J. Pavement Eng. 2016, 17, 24–38. [Google Scholar] [CrossRef]

- Dai, Q.; Sadd, M.H.; Parameswaran, V.; Shukla, A. Prediction of damage behaviors in asphalt materials using a micromechanical finite-element model and image analysis. J. Eng. Mech. 2005, 131, 668–677. [Google Scholar] [CrossRef]

- Alvarez, A.E.; Martin, A.E.; Estakhri, C. Internal structure of compacted permeable friction course mixtures. Constr. Build. Mater. 2010, 24, 1027–1035. [Google Scholar] [CrossRef]

- Stakston, A.D.; Bahia, H.; Bushek, J.J. Effect of fine aggregate angularity on compaction and shearing resistance of asphalt mixtures. Trans. Res. Rec. 2001, 1761, 26–31. [Google Scholar] [CrossRef]

- Masad, E.; Jandhyala, V.K.; Dasgupta, N.; Somadevan, N.; Shashidhar, N. Characterization of air void distribution in asphalt mixes using X-ray computed tomography. J. Mater. Civ. Eng. 2002, 14, 122–129. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Chen, J. Micromechanical analysis of asphalt mixture fracture with adhesive and cohesive failure. Eng. Fra. Mech. 2014, 132, 104–119. [Google Scholar] [CrossRef]

- Onifade, I.; Jelagin, D.; Guarin, A.; Kringos, N. Asphalt Internal structure characterization with X-ray computed tomography and digital image processing. In Multi-Scale Modeling and Characterization of Infrastructure Materials; Kringos, N., Birgisson, B., Frost, D., Wang, L., Eds.; Springer: Dordrecht, The Netherlands, 2013; Chapter 11; pp. 139–158. [Google Scholar]

- Bessa, I.S.; Castelo Branco, V.T.F.; Soares, J.B. Evaluation of different digital image processing software for aggregates and hot mix asphalt characterizations. Constr. Build. Mater. 2012, 37, 370–378. [Google Scholar] [CrossRef]

- Bruno, L.; Parla, G.; Celauro, C. Image analysis for detecting aggregate gradation in asphalt mixture from planar images. Constr. Build. Mater. 2012, 28, 21–30. [Google Scholar] [CrossRef]

- Khattak, M.J.; Khattab, A.; Rizvi, H.R. Imaged-based discrete element modeling of hot mix asphalt mixtures. Mater. Struct. 2015, 48, 2417–2430. [Google Scholar] [CrossRef]

- Guo, Q.; Bian, Y.; Li, L.; Jiao, Y.; Tao, J.; Xiang, C. Stereological estimation of aggregate gradation using digital image of asphalt mixture. Constr. Build. Mater. 2015, 94, 458–466. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, X.; Li, Z.; Chen, Z. Research on the homogeneity of asphalt pavement quality using X-ray computed tomography (ct) and fractal theory. Constr. Build. Mater. 2014, 68, 587–598. [Google Scholar] [CrossRef]

- Renken, P. Compaction in the Laboratory and in Practice. In Mechanical Tests for Bituminous Mixes. Characterization, Design and Quality Control; Fritz, H.W., Eustacchio, E., Eds.; Chapman and Hall: London, UK, 1990; pp. 32–36. [Google Scholar]

- Soille, P. Morphological Image Analysis: Principles and Applications, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-540-42988-3. [Google Scholar]

- Hartig, S.M. Basic image analysis and manipulation in ImageJ. Curr. Protoc. Mol. Biol. 2013, 102, 1–12. [Google Scholar] [CrossRef]

- Matlab. 2017. Available online: http://mathworks.com (accessed on 24 October 2018).

| Aggregate Source | Gradation & NMAS | Asphalt Binder Grade | Compaction Temperature (°C) | Number of Specimens |

|---|---|---|---|---|

| Crushed Gravel | Fine (19 mm) | PG64-28 | 90 | 2 |

| 115 | 2 | |||

| 140 | 2 | |||

| PG58-28 | 80 | 2 | ||

| 110 | 2 | |||

| 140 | 2 |

| Mixture Identification | 1 Gsb | Asphalt Contents (%) | Compaction Temperature (°C) | %Gmm at Ndesign | Air Void (%) | Gmm | VMA (%) | VFA (%) | 1 Veac (%) | 2 Pba (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| PG 58-28 | 2.722 | 5.0 | 140 | 96.0 | 4.0 | 2.541 | 15.1 | 70.8 | 11.1 | 0.54 |

| 96.1 | 3.9 | 2.547 | 15.3 | 69.9 | 11.1 | 0.44 | ||||

| 110 | 96.0 | 4.0 | 2.538 | 15.3 | 72.3 | 11.2 | 0.39 | |||

| 95.9 | 4.1 | 2.532 | 15.4 | 71.4 | 11.3 | 0.28 | ||||

| 80 | 94.3 | 5.7 | 2.541 | 15.7 | 68.7 | 10.7 | 0.41 | |||

| 95.2 | 4.8 | 2.540 | 15.8 | 68.1 | 10.6 | 0.41 | ||||

| PG 64-28 | 2.722 | 5.1 | 140 | 96.0 | 4.0 | 2.546 | 14.7 | 72.3 | 10.7 | 0.58 |

| 95.9 | 4.1 | 2.555 | 14.8 | 71.9 | 10.6 | 0.74 | ||||

| 115 | 95.9 | 4.1 | 2.532 | 15.4 | 73.1 | 11.3 | 0.35 | |||

| 95.9 | 4.1 | 2.529 | 15.5 | 72.9 | 11.3 | 0.30 | ||||

| 90 | 95.0 | 5.0 | 2.541 | 16.1 | 67.6 | 10.7 | 0.50 | |||

| 94.8 | 5.2 | 2.538 | 15.9 | 68.4 | 10.6 | 0.45 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Kang, M. Linking the Effect of Aggregate Interaction to the Compaction Theory for Asphalt Mixtures Using Image Processing. Appl. Sci. 2018, 8, 2045. https://doi.org/10.3390/app8112045

Kim K, Kang M. Linking the Effect of Aggregate Interaction to the Compaction Theory for Asphalt Mixtures Using Image Processing. Applied Sciences. 2018; 8(11):2045. https://doi.org/10.3390/app8112045

Chicago/Turabian StyleKim, Kyoungchul, and Myungook Kang. 2018. "Linking the Effect of Aggregate Interaction to the Compaction Theory for Asphalt Mixtures Using Image Processing" Applied Sciences 8, no. 11: 2045. https://doi.org/10.3390/app8112045

APA StyleKim, K., & Kang, M. (2018). Linking the Effect of Aggregate Interaction to the Compaction Theory for Asphalt Mixtures Using Image Processing. Applied Sciences, 8(11), 2045. https://doi.org/10.3390/app8112045