On the Effect of Filling Rate on Positive Macrosegregation Patterns in Large Size Cast Steel Ingots

Abstract

1. Introduction

2. Materials and Experimental Process

3. Results and Discussions

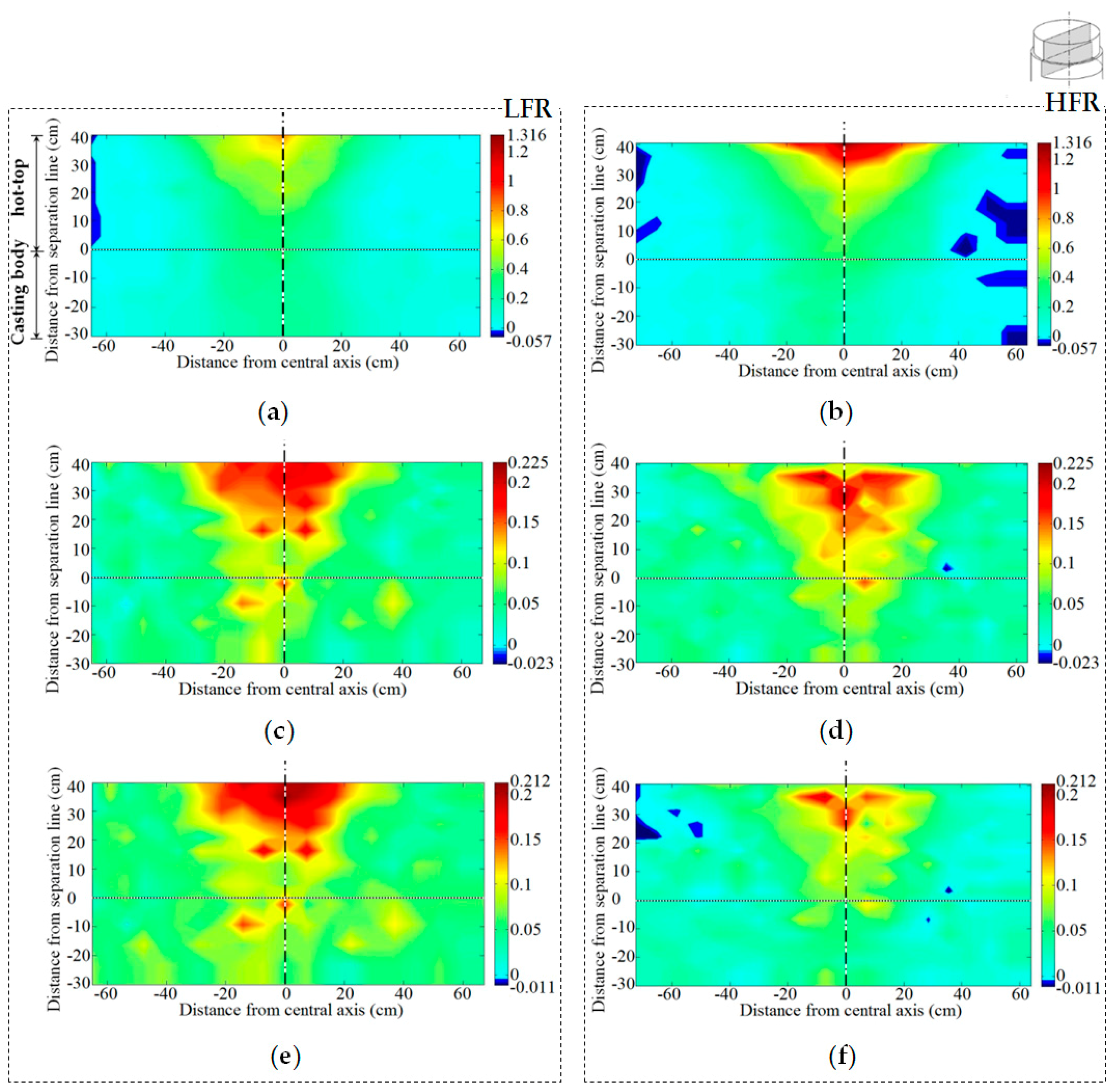

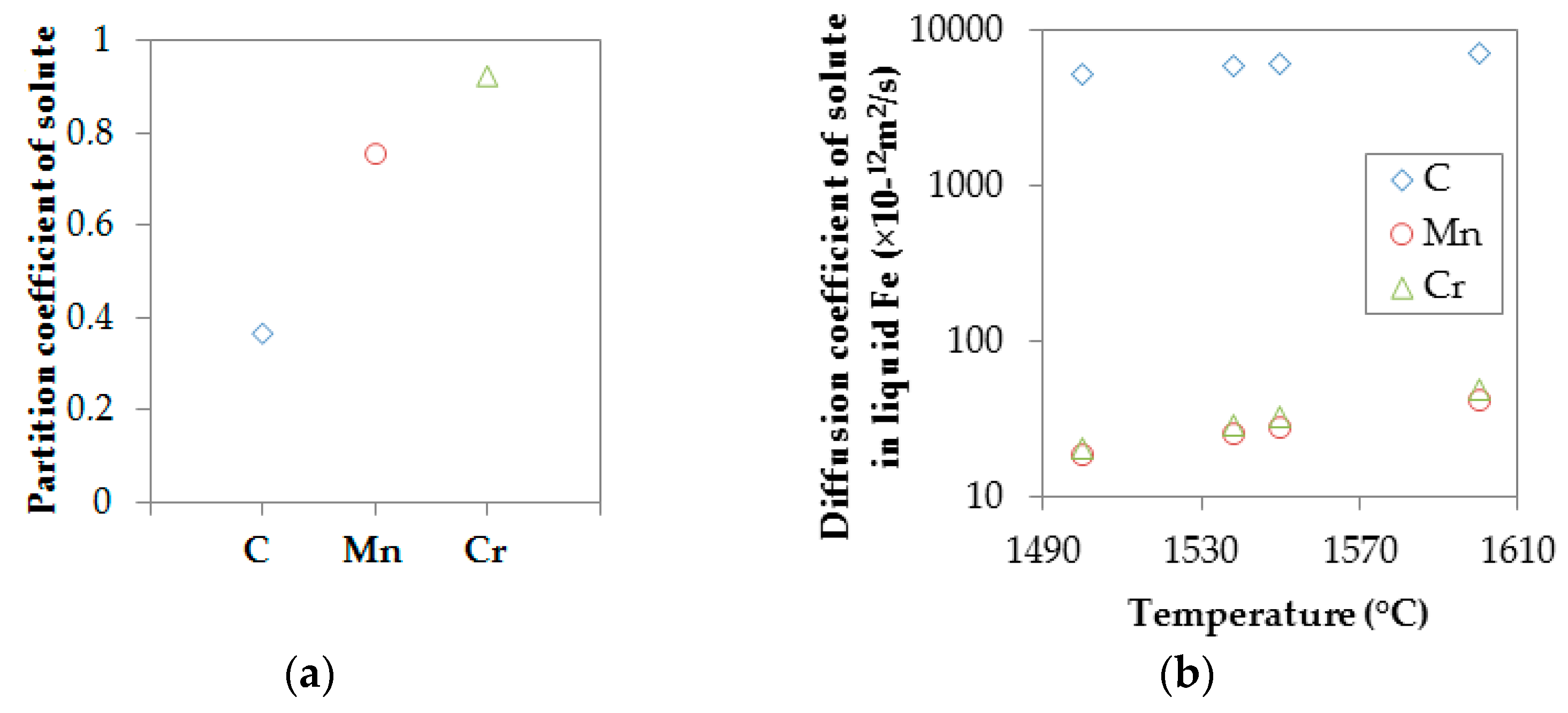

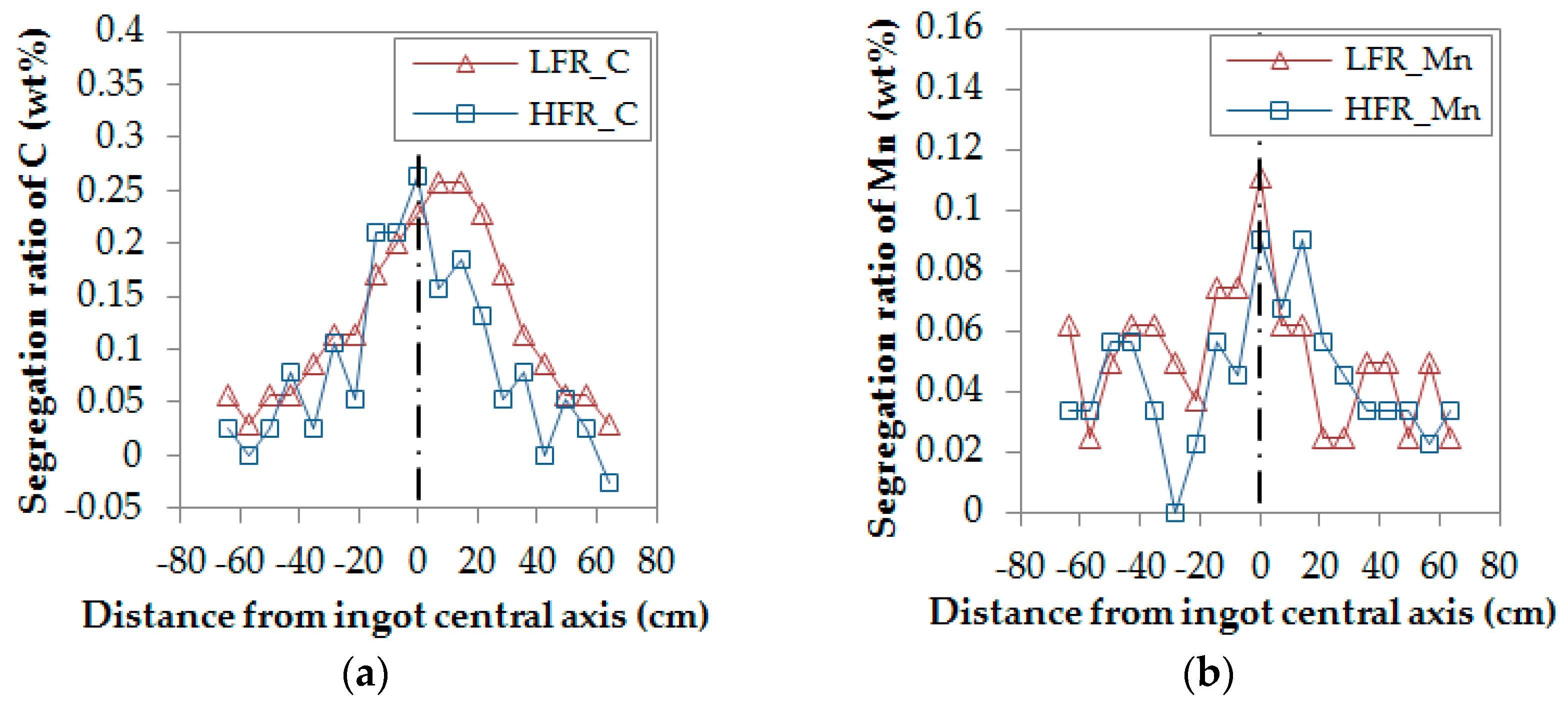

3.1. General Macrosegregation Patterns

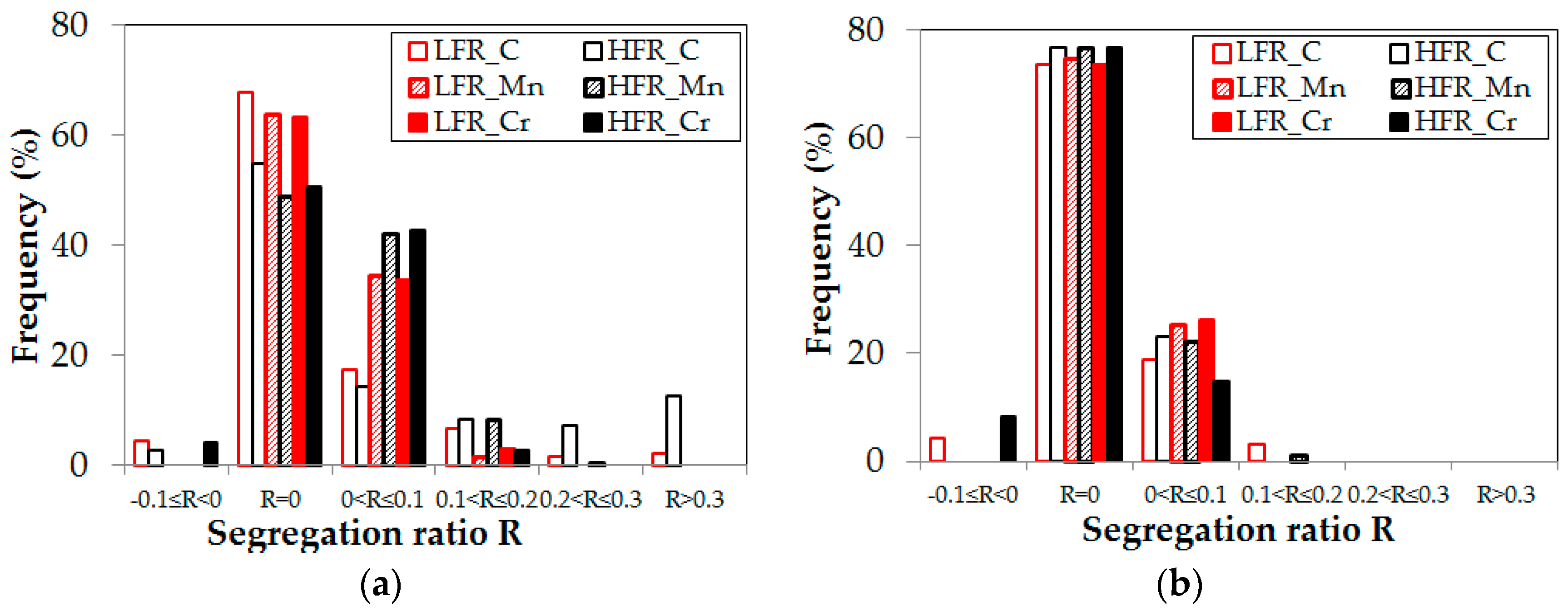

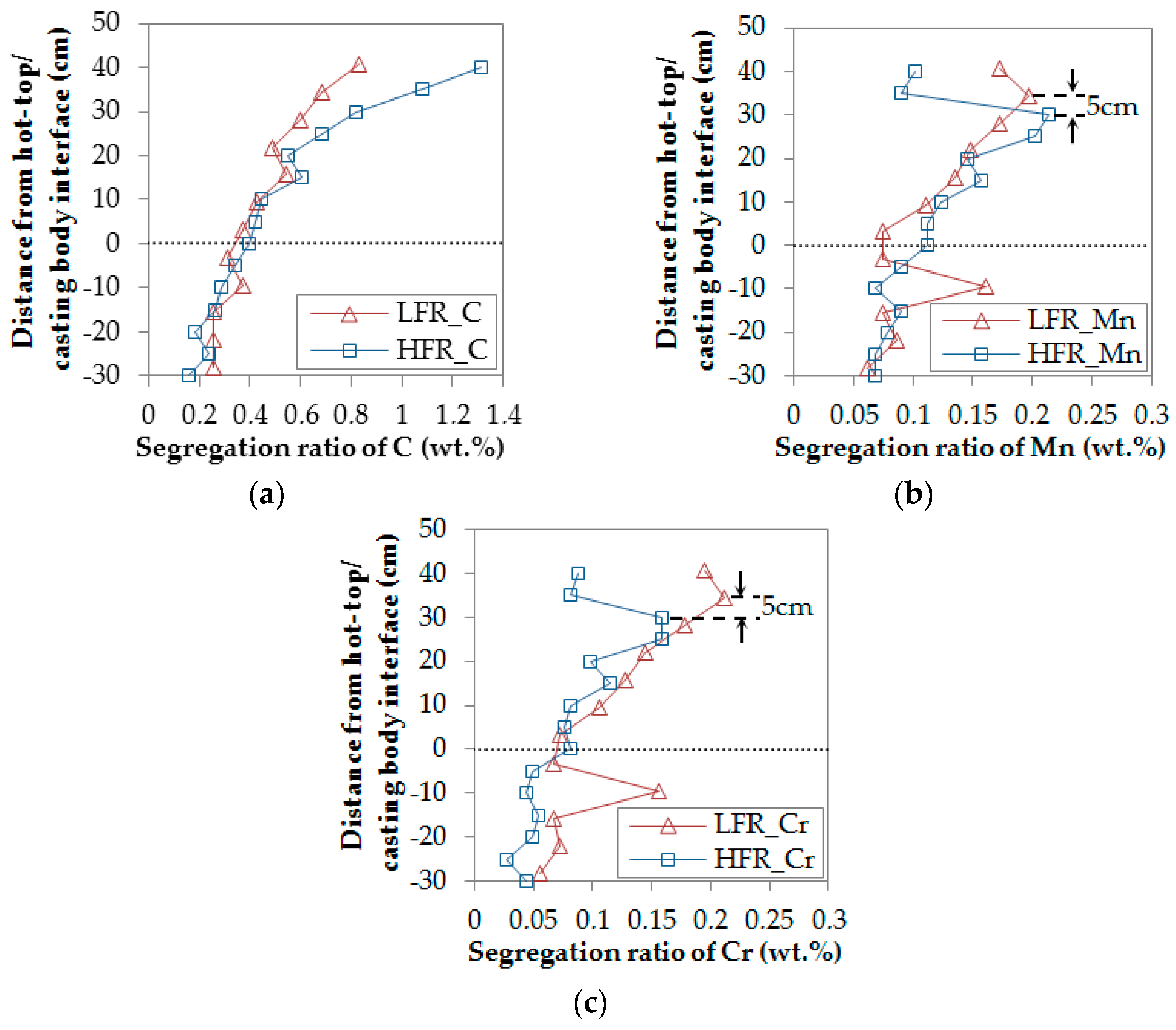

3.2. Effect of Filling Rate on Segregation Severity

3.3. Effect of Filling Rate on Fluid Flow and Solidification Time

4. Conclusions

- General macrosegregation patterns presented the solute dependence of segregation features, which was related to the difference in the solid-liquid partition coefficient and diffusion capability of each element in the liquid iron.

- Frequency distribution of segregation ratios, as well as the axial and horizontal concentration evolutions, presented less severe segregation in the casting body of the ingot with the higher filling rate.

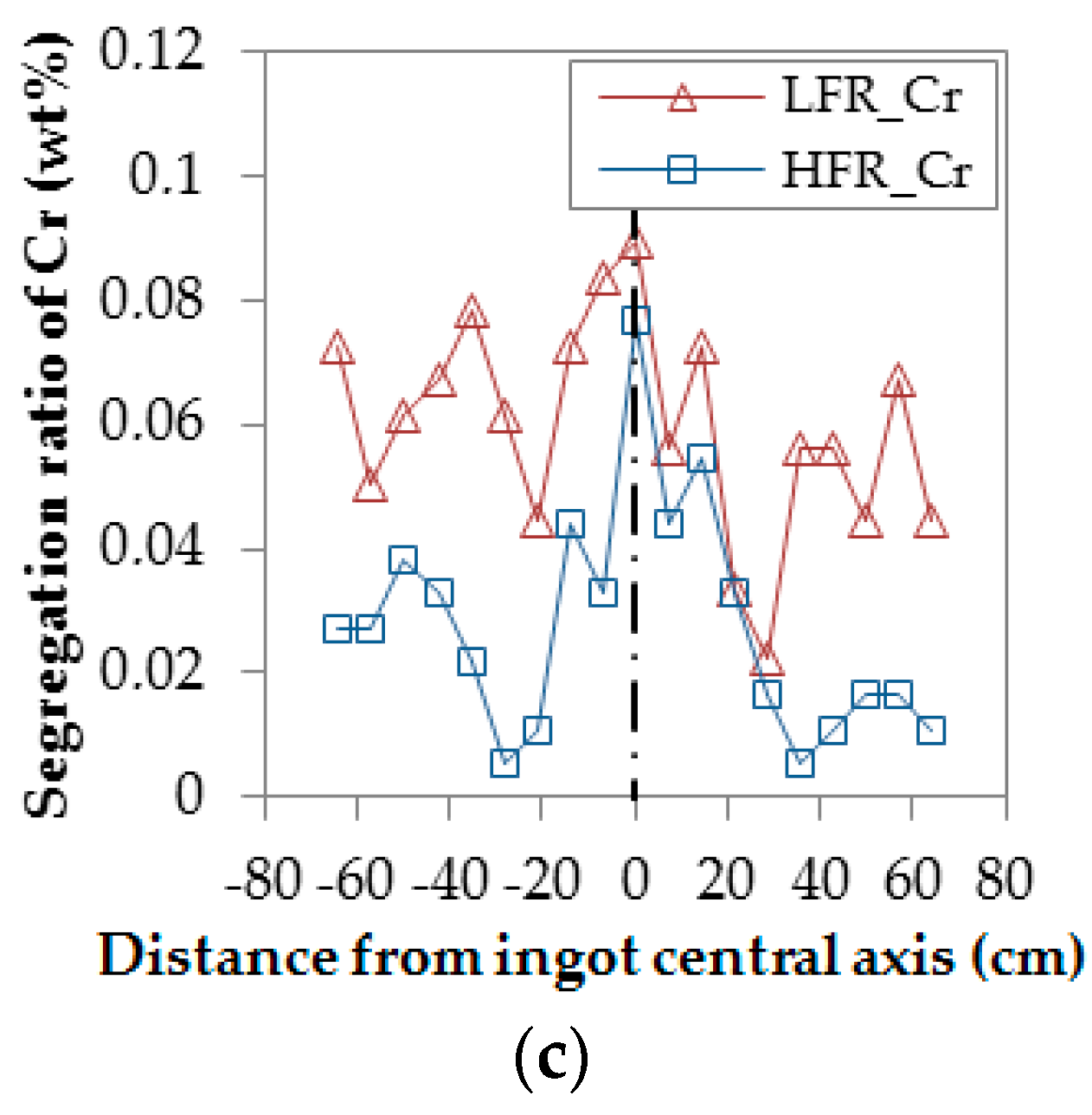

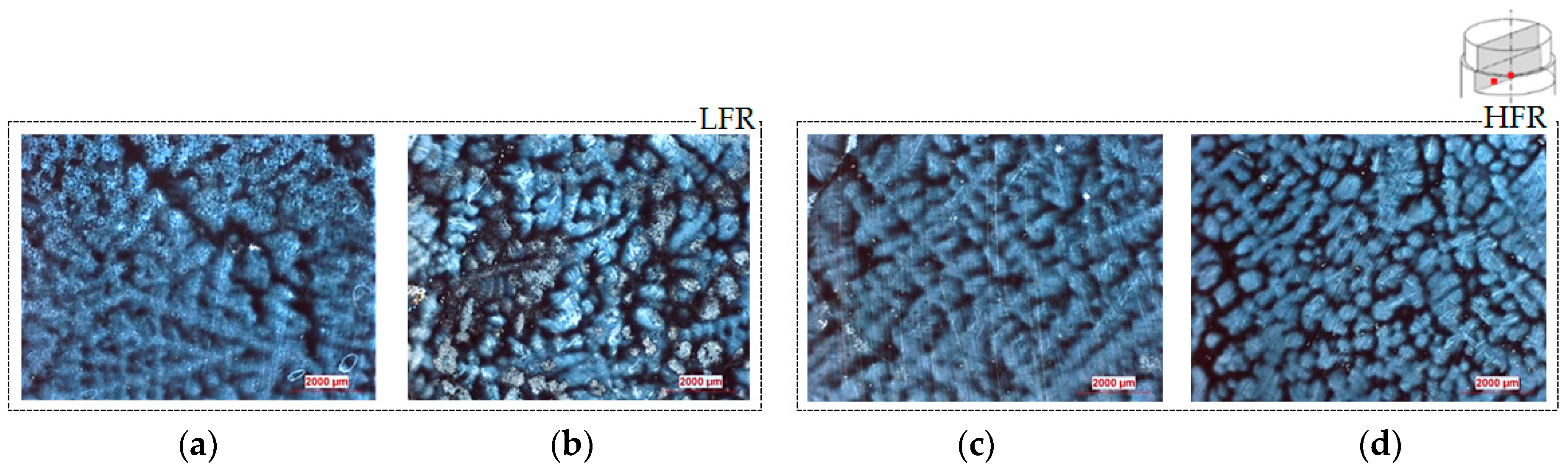

- One source of the reduced solute segregation in the casting body in the higher filling rate case is the presence of higher liquid instabilities at the start of solidification, which was predicted by the Reynolds number calculations during the filling process, and confirmed by macroetch grain morphology observations in the first solidified zones.

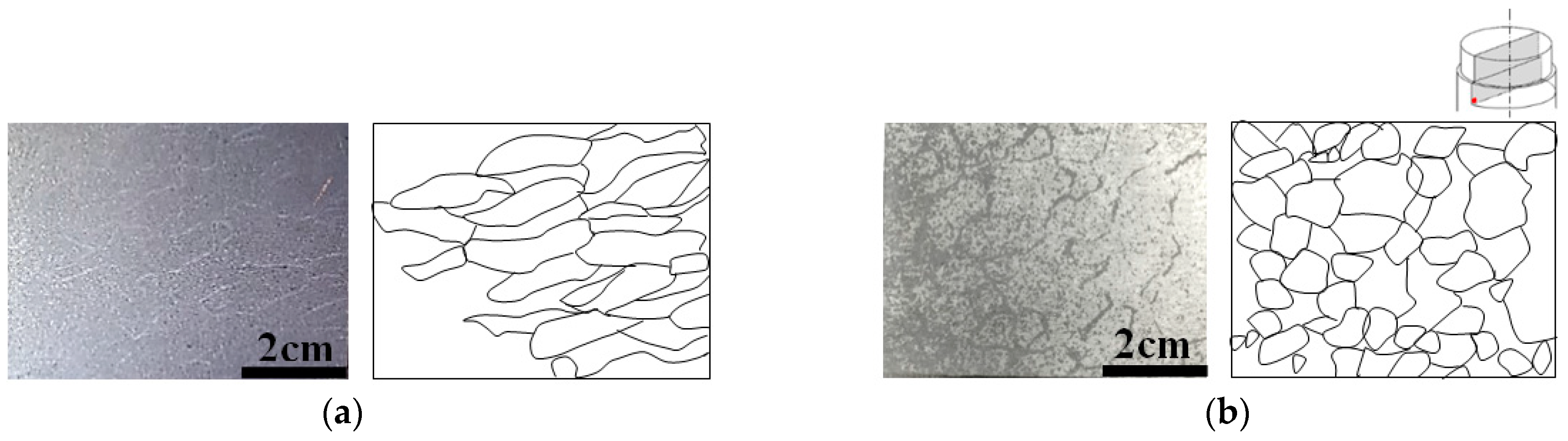

- Another source for the lower segregation intensity in the casting body of higher filling rate case is the shorter solidification time, resulting in less time available for solutes to transport, which was revealed by the SDAS measurements along the cutting section of the ingot in the regions solidified in the intermediate and final stages of the solidification process.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Majka, T.F.; Matlock, D.K.; Krauss, G. Development of microstructural banding in low-alloy steel with simulated Mn segregation. Metall. Mater. Trans. A 2002, 33A, 1627–1637. [Google Scholar] [CrossRef]

- Loucif, A.; Fredj, E.B.; Harris, N.; Shahriari, D.; Jahazi, M.; Lapierre-Boire, L.P. Evolution of A-type macrosegregation in large size steel ingot after multistep forging and heat Treatment. Metall. Mater. Trans. B 2018, 49B, 1046–1055. [Google Scholar] [CrossRef]

- Pickering, E.J.; Chesman, C.; Al-Bermani, S.; Holland, M.; Davies, P.; Talamantes-Silva, J. A comprehensive case study of macrosegregation in a steel ingot. Metall. Mater. Trans. B 2015, 46B, 1860–1874. [Google Scholar] [CrossRef]

- Flemings, M.C. Our understanding of macrosegregation: Past and present. ISIJ Int. 2000, 40, 833–841. [Google Scholar] [CrossRef]

- Beckermann, C. Modeling of macrosegregation: Applications and future needs. Int. Mater. Rev. 2002, 47, 243–261. [Google Scholar] [CrossRef]

- Combeau, H.; Založnik, M.; Hans, S.; Richy, P.E. Prediction of macrosegregation in steel ingots: Influence of the motion and the morphology of equiaxed grains. Metall. Mater. Trans. B 2009, 40B, 289–304. [Google Scholar] [CrossRef]

- Pikkarainen, T.; Vuorenmaa, V.; Rentola, I.; Leinonen, M.; Porter, D. Effect of superheat on macrostructure and macrosegregation in continuous cast low-alloy steel slabs. IOP Conf. Ser. Mater. Sci. Eng. 2016, 117, 1–7. [Google Scholar] [CrossRef]

- Galkin, A.N.; Zyuban, N.A.; Rutskii, D.V.; Gamanyuk, S.B.; Puzikov, A.Y.; Firsenko, V.V. Effect of chilling of the top part of a steel ingot on the conditions of its crystallization and the quality of forgings obtained from it. Metallurgist 2013, 57, 199–206. [Google Scholar] [CrossRef]

- Dub, V.S.; Romashkin, A.N.; Mal’ginov, A.N.; Ivanov, I.A.; Tolstykh, D.S. Effect of the geometry of an ingot on its chemical heterogeneity. Part I. Metallurgist 2014, 57, 987–995. [Google Scholar] [CrossRef]

- Lee, J.; Mok, J.; Hong, C.P. Straightforward numerical analysis of casting process rectangular mold: From filling to solidification. ISIJ Int. 1999, 39, 1252–1261. [Google Scholar] [CrossRef]

- Im, I.T.; Kim, W.S.; Lee, K.S. A unified analysis of filling and solidification in casting with natural convection. Int. J. Heat Mass Transf. 2001, 44, 1507–1515. [Google Scholar] [CrossRef]

- Ravindran, K.; Lewis, R.W. Finite element modelling of solidification effects in mould filling. Finite Elem. Anal. Des. 1998, 31, 99–116. [Google Scholar] [CrossRef]

- Yadav, A.; Pathak, N.; Kumar, A.; Dutta, P.; Sarkar, S. Effects of the filling process on the evolution of the mushy zone and macrosegregation in alloy casting. Model. Simul. Mater. Sci. 2009, 17, 1–19. [Google Scholar] [CrossRef]

- Kermanpur, A.; Eskandari, M.; Purmohamad, H.; Soltani, M.A.; Shateri, R. Influence of mould design on the solidification of heavy forging ingots of low alloy steels by numerical simulation. Mater. Des. 2010, 31, 1096–1104. [Google Scholar] [CrossRef]

- Pickering, E.J. Macrosegregation in steel ingots: The applicability of modelling and characterisation techniques. ISIJ Int. 2013, 53, 935–949. [Google Scholar] [CrossRef]

- Andersson, J.O.; Helander, T.; Höglund, L.; Shi, P.F.; Sundman, B. THERMO-CALC & DICTRA, computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Qian, S.; Hu, X.; Cao, Y.; Kang, X.; Li, D. Hot top design and its influence on feeder channel segregates in 100-ton steel ingots. Mater. Des. 2015, 87, 205–214. [Google Scholar] [CrossRef]

- Duan, Z.; Tu, W.; Shen, B.; Shen, H.; Liu, B. Experimental measurements for numerical simulation of macrosegregation in a 36-ton steel ingots. Metall. Mater. Trans. A 2016, 47A, 3597–3605. [Google Scholar] [CrossRef]

- MATLAB and Statistics Toolbox Release 2012b; The MathWorks, Inc.: Natick, MA, USA, 2012.

- Schneider, M.C.; Beckermann, C. Formation of macrosegregation by multicomponent thermosolutal convection during the solidification of steel. Metall. Mater. Trans. A 1995, 26A, 2373–2388. [Google Scholar] [CrossRef]

- Miettinen, J. Calculation of solidification-related thermophysical properties for steels. Metall. Mater. Trans. B 1997, 28B, 281–297. [Google Scholar] [CrossRef]

- Marx, K.; Rödl, S.; Schramhauser, S.; Seemann, M. Optimization of the filling and solidification of large ingots. In Proceedings of the 2nd International Conference Ingot Casting Rolling & Forging ICRF, Milan, Italy, 7–9 May 2014; Volume 11–12, pp. 11–19. [Google Scholar]

- Reikher, A.; Barkhudarov, M.R. Casting: An Analytical Approach—Engineering Materials and Processes; Verlag London Ltd.: London, UK, 2007; pp. 23–25. ISBN 978-1-84628-850-0. [Google Scholar]

- Wu, M.; Vakhrushev, A.; Nummer, G.; Pfeiler, C.; Kharicha, A.; Ludwig, A. Importance of melt flow in solidifying mushy zone. Open Transp. Phenom. J. 2010, 2, 16–23. [Google Scholar] [CrossRef]

- JMatPro User’s Guide; Sente Software Ltd.: 2005. Available online: https://manualzz.com/doc/4150587/jmatpro-user-s-guide (accessed on 8 October 2018).

- Campbell, J. Complete Casting Handbook—Metal Casting Processes, Metallurgy, Techniques and Design, 1st ed.; Butterworth-Heinemann: Waltham, MA, USA, 2011; pp. 119–269. ISBN 9781856178099. [Google Scholar]

- Willers, B.; Eckert, S.; Michel, U.; Haase, I.; Zouhar, G. The columnar-to-equiaxed transition in Pb–Sn alloys affected by electromagnetically driven convection. Mat. Sci. Eng. A 2005, 402, 55–65. [Google Scholar] [CrossRef]

- Zhao, Z.; Cui, J.; Dong, J.; Zhang, B. Effect of low-frequency magnetic field on microstructures and macrosegregation of horizontal direct chill casting 7075 aluminum alloy. J. Mater. Process. Technol. 2007, 182, 185–190. [Google Scholar] [CrossRef]

- Zhu, Q.F.; Zhao, Z.H.; Cui, J.Z.; Zuo, Y.B.; Wang, X.J. Effect of combined application of electromagnetic fields on horizontal direct chill casting of 7050 aluminium alloy. Mater. Sci. Technol. 2008, 24, 560–566. [Google Scholar] [CrossRef]

- Wang, X.; Ma, N.; Bliss, D.F.; Isele, G.W.; Becla, P. Combining static and rotating magnetic fields during modified vertical bridgman crystal growth. J. Thermophys. Heat Transf. 2007, 21, 736–743. [Google Scholar] [CrossRef]

- Wang, B.; Yang, Y.; Tang, W. Microstructure refinement of AZ91D alloy solidified with pulsed magnetic field. Trans. Nonferrous Met. Soc. China 2008, 18, 536–540. [Google Scholar] [CrossRef]

- Aboutalebi, M.R. Modelling of Turbulent Transport Phenomena and Solidification in Continuous Casting Systems. Ph.D. Thesis, Department of Mining and MetaIlurgical Engineering, McGill University, Montreal, QC, Canada, February 1994. [Google Scholar]

- Liu, D.R.; Kang, X.H.; Fu, P.X.; Li, D.Z. Modeling of macrosegregation in steel ingot: Influence of mold shape and melt superheat. Kovove Mater. 2011, 49, 143–153. [Google Scholar] [CrossRef]

- Zhang, C.; Bao, Y.; Wang, M. Influence of casting parameters on shrinkage porosity of a 19 ton steel ingot. Metall. Ital. 2016, 1, 37–44. [Google Scholar]

- Vives, C.; Perry, C. Effects of electromagnetic stirring during the controlled solidification of tin. Intl. J. Heat Mass Transf. 1986, 29, 21–33. [Google Scholar] [CrossRef]

- Hachani, L.; Saadi, B.; Wang, X.D.; Nouri, A.; Zaidat, K. Experimental analysis of the solidification of Sn–3 wt. % Pb alloy under natural convection. Intl. J. Heat Mass Transf. 2012, 55, 1986–1996. [Google Scholar] [CrossRef]

- Liu, S.F.; Liu, L.Y.; Kang, L.G. Refinement role of electromagnetic stirring and strontium in AZ91 magnesium alloy. J. Alloys Compd. 2008, 450, 546–550. [Google Scholar] [CrossRef]

| C | Mn | Cr | P | S | Si | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.36 | 0.85 | 1.82 | 0.01 | 0.0023 | 0.4 | 0.16 | 0.45 | balance |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Loucif, A.; Jahazi, M.; Tremblay, R.; Lapierre, L.-P. On the Effect of Filling Rate on Positive Macrosegregation Patterns in Large Size Cast Steel Ingots. Appl. Sci. 2018, 8, 1878. https://doi.org/10.3390/app8101878

Zhang C, Loucif A, Jahazi M, Tremblay R, Lapierre L-P. On the Effect of Filling Rate on Positive Macrosegregation Patterns in Large Size Cast Steel Ingots. Applied Sciences. 2018; 8(10):1878. https://doi.org/10.3390/app8101878

Chicago/Turabian StyleZhang, Chunping, Abdelhalim Loucif, Mohammad Jahazi, Rami Tremblay, and Louis-Philippe Lapierre. 2018. "On the Effect of Filling Rate on Positive Macrosegregation Patterns in Large Size Cast Steel Ingots" Applied Sciences 8, no. 10: 1878. https://doi.org/10.3390/app8101878

APA StyleZhang, C., Loucif, A., Jahazi, M., Tremblay, R., & Lapierre, L.-P. (2018). On the Effect of Filling Rate on Positive Macrosegregation Patterns in Large Size Cast Steel Ingots. Applied Sciences, 8(10), 1878. https://doi.org/10.3390/app8101878