A Biodegradable Ramie Fiber-Based Nonwoven Film Used for Increasing Oxygen Supply to Cultivated Soil

Abstract

:Featured Application

Abstract

1. Introduction

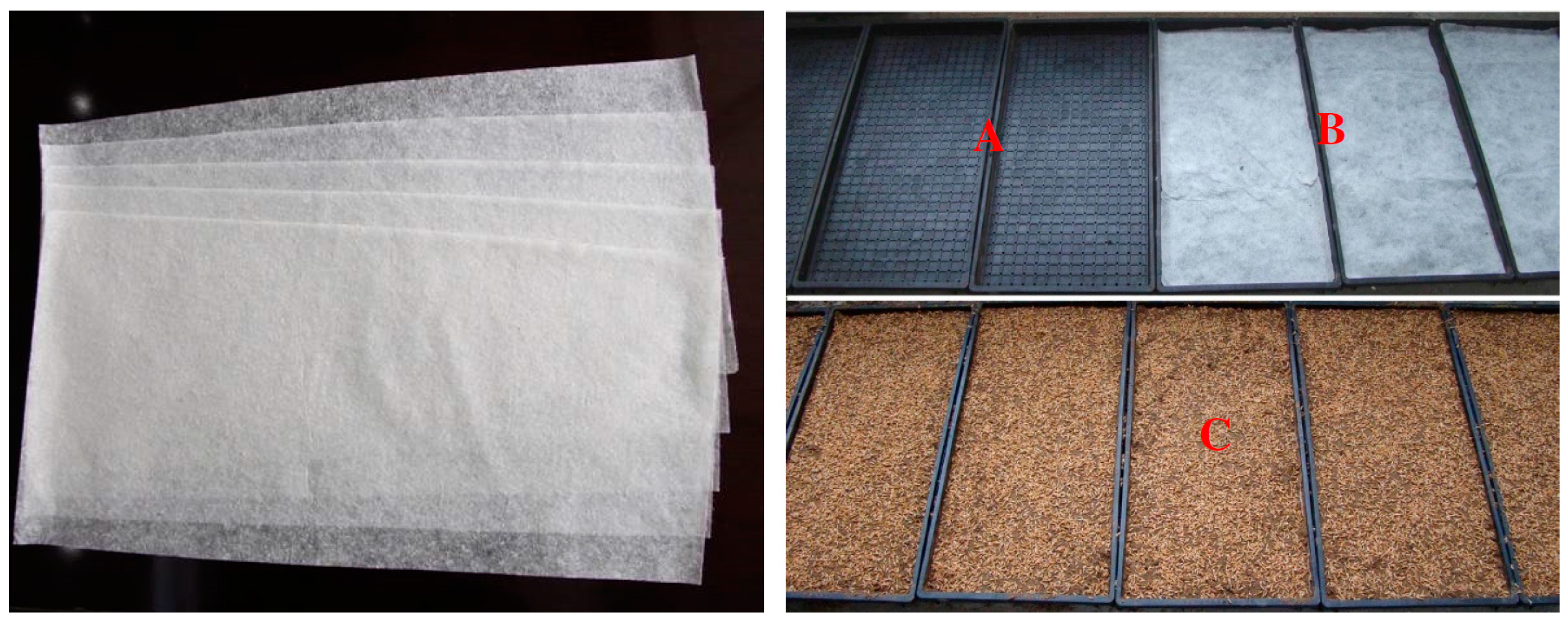

2. Materials and Methods

2.1. Materials and Reagents

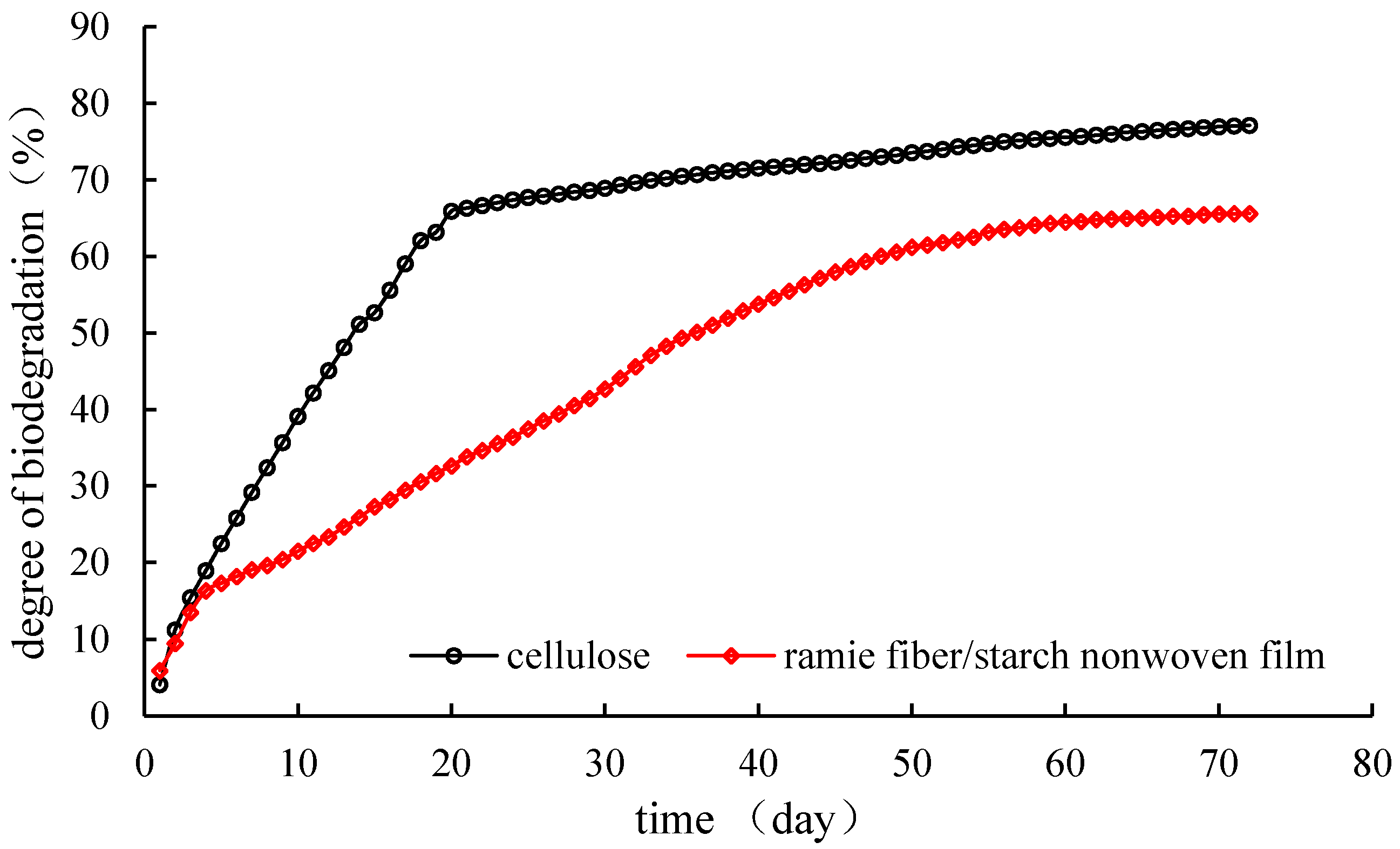

2.2. Evaluation of Biodegradability

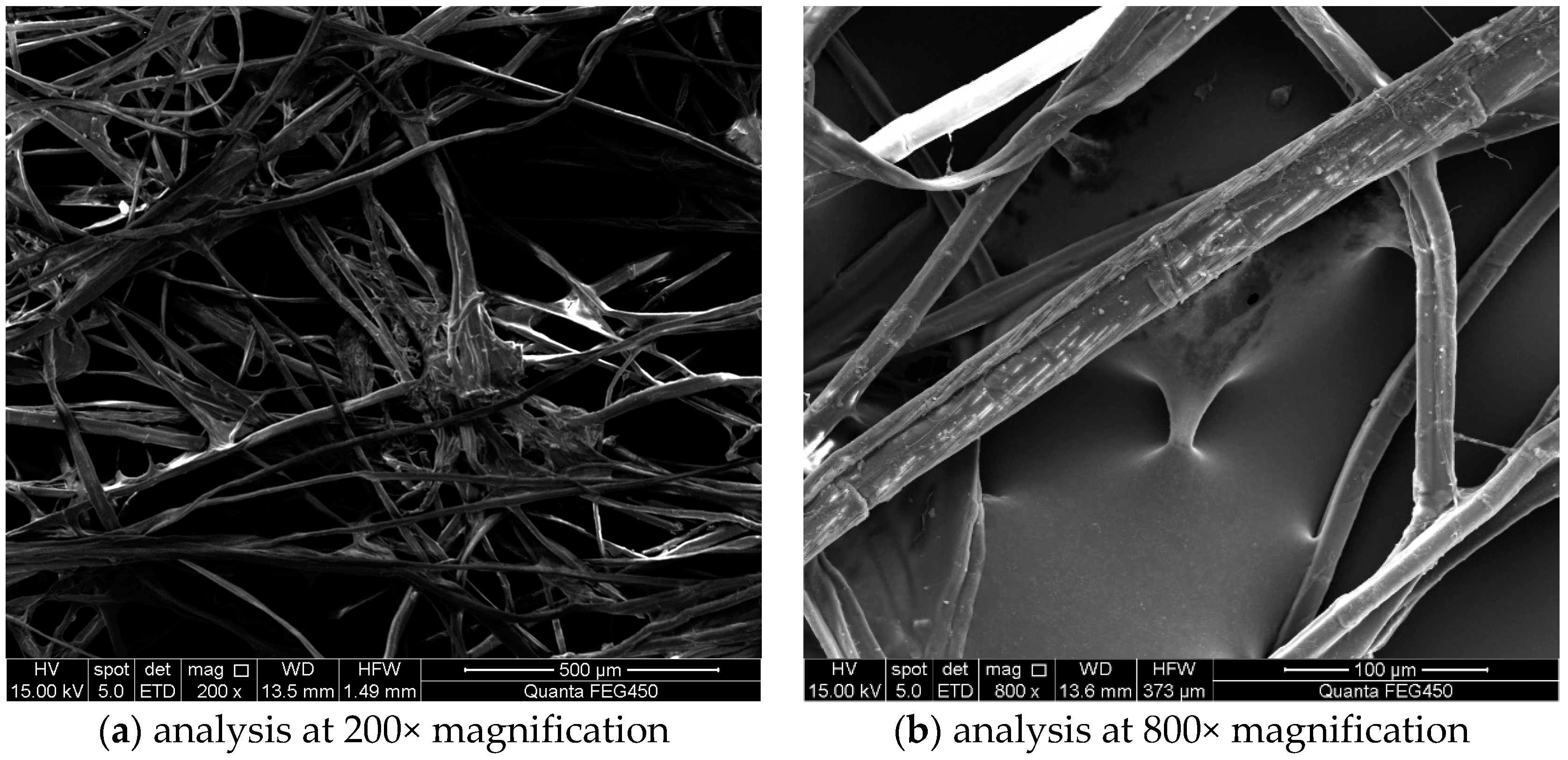

2.3. Analysis Related to Porosity Characteristics

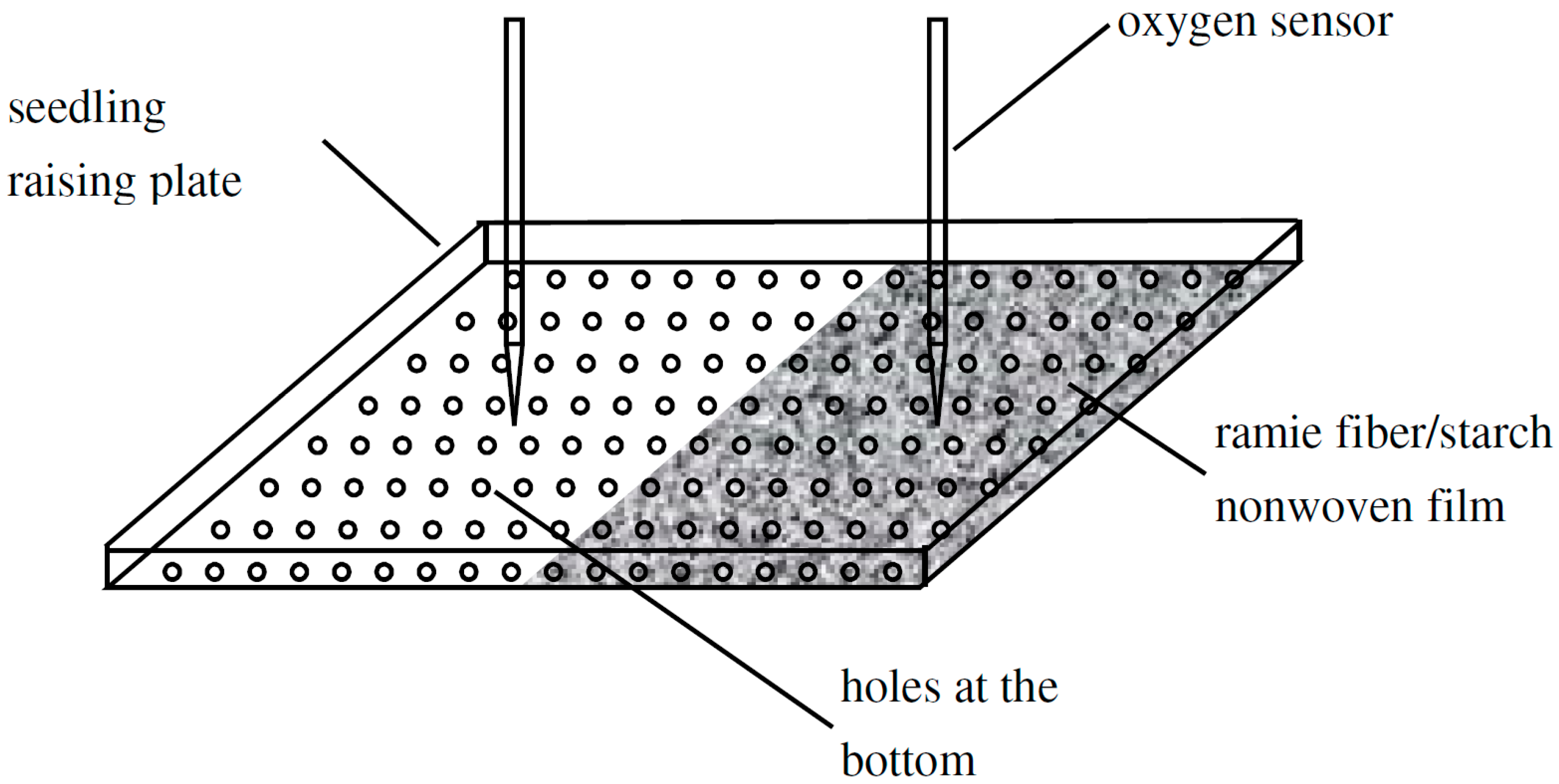

2.4. Actual Detection of the Effect on Oxygen Supply to Soil

2.5. Simulation Demonstration of the Effect on Oxygen Supply

3. Results and Discussion

3.1. Biodegradability

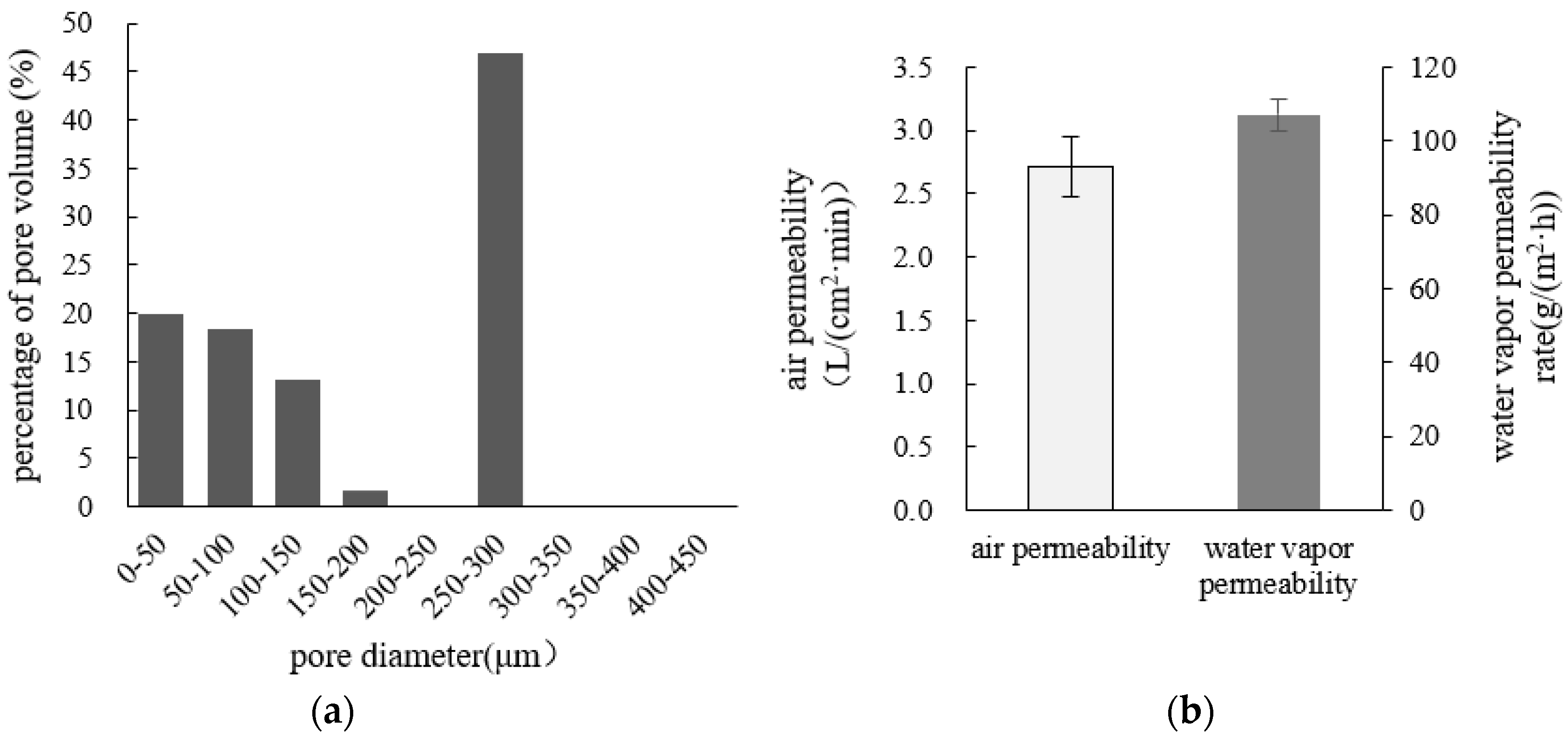

3.2. Porosity Characteristics

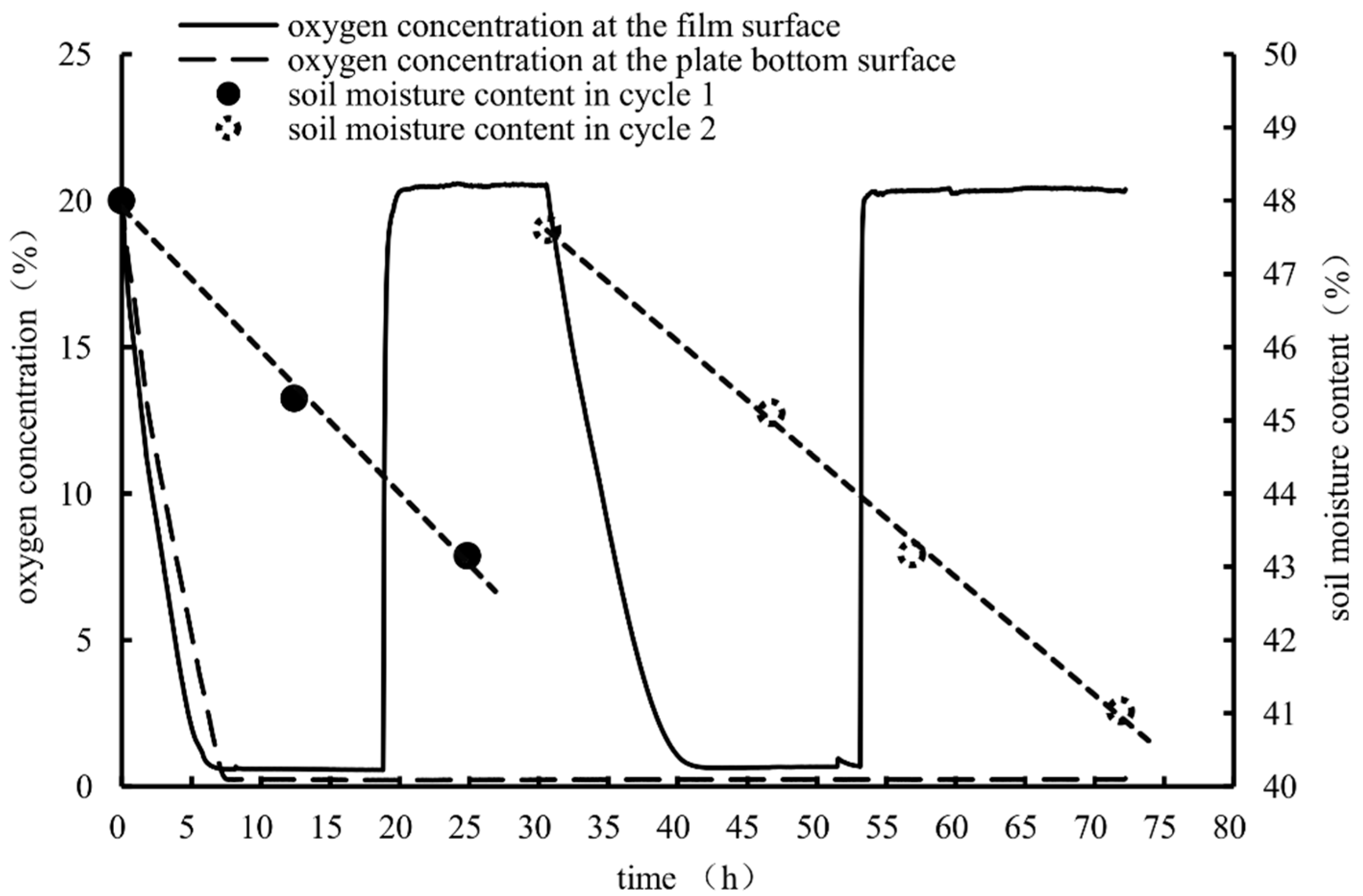

3.3. Effect on Oxygen Supply to Soil

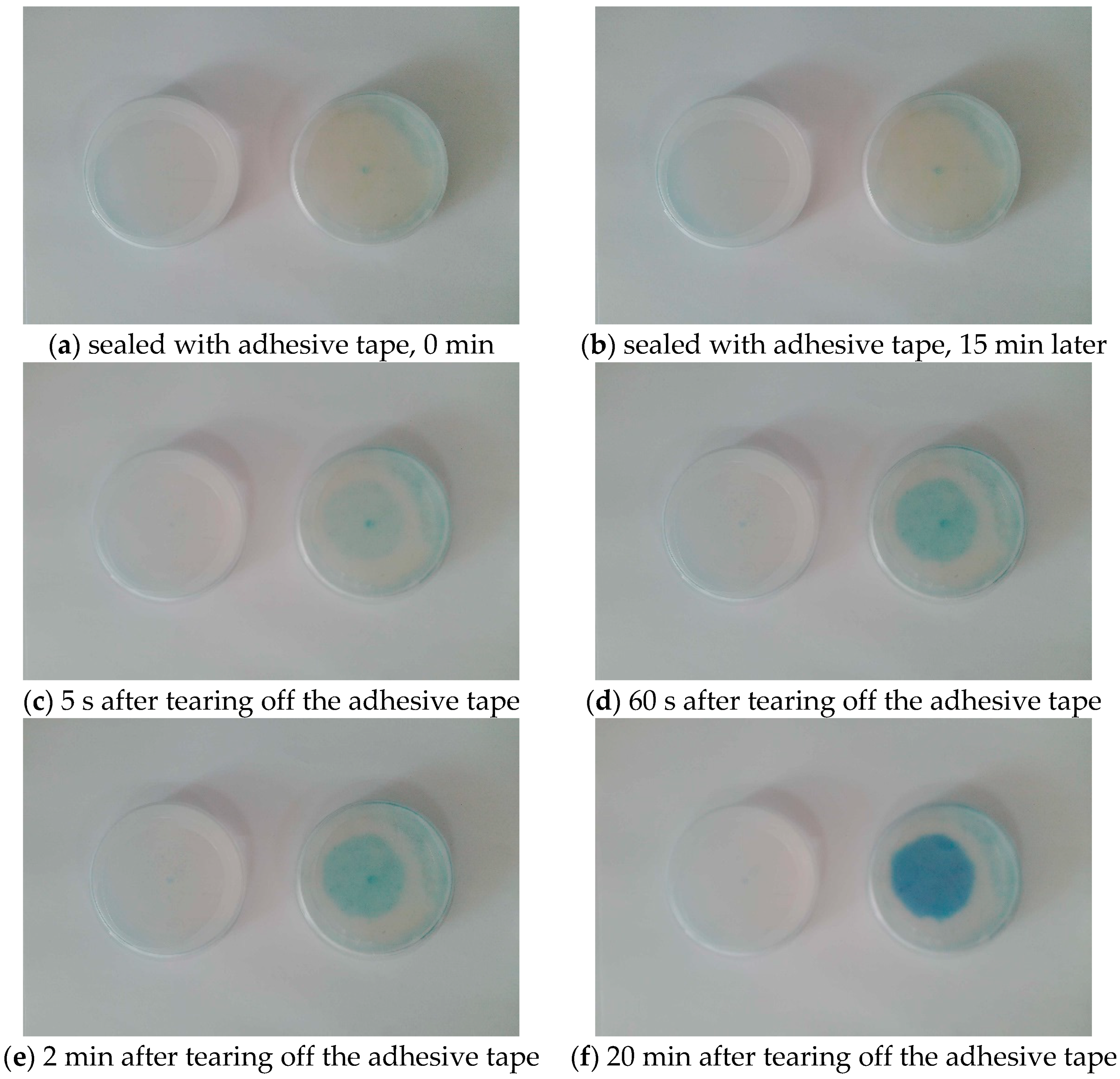

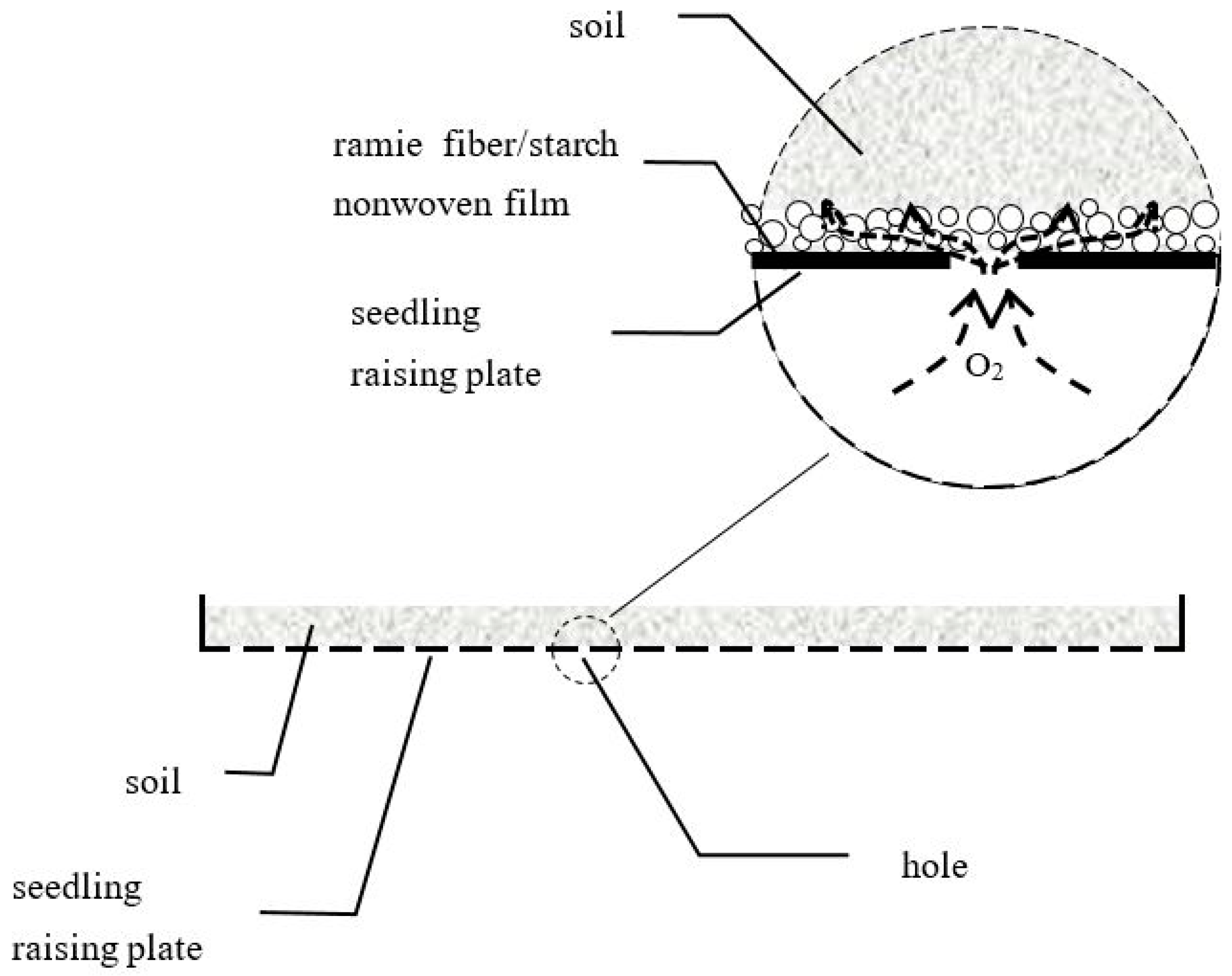

3.4. Process of Oxygen Into the Soil

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lament, W.J., Jr. Plastic mulches for the production of vegetable crops. HortTechnology 1993, 3, 35–39. [Google Scholar]

- Tarara, J.M. Microclimate modification with plastic mulch. HortScience 2000, 35, 169–180. [Google Scholar]

- Espí, E.; Salmerón, A.; Fontecha, A.; García, Y.; Real, A.I. Plastic films for agricultural applications. J. Plast. Film Sheeting 2006, 22, 85–102. [Google Scholar] [CrossRef]

- Scarascia-Mugnozza, G.; Sica, C.; Russo, G. Plastic materials in European agriculture: Actual use and perspectives. J. Agric. Eng. 2011, 42, 15–28. [Google Scholar] [CrossRef]

- Shu, Y.J.; Zhou, Y.L.; Zhang, Z.X.; Zhu, H.X.; Wang, Z. Effect of bast-fiber film mulching and fertilization interaction on soil nutrient, soil enzyme activity and pepper growth. Chin. J. Eco-Agric. 2012, 20, 175–180. [Google Scholar] [CrossRef]

- Wortman, S.E.; Kadoma, I.; Crandall, M.D. Assessing the potential for spunbond, nonwoven biodegradable fabric as mulches for tomato and bell pepper crops. Sci. Hortic. 2015, 193, 209–217. [Google Scholar] [CrossRef]

- An, H.Y.; Liu, W.; Zhang, J.K.; Sheng, S.; Xie, J.; Sun, G.Q.; Wang, R.X.; Miao, Q.S. Effects of seedbed mulched non-textile on the temperature of seedbed and growth of seedlings. Vegetables 2018, 4, 13–17. [Google Scholar]

- Jiao, X.N.; Li, B.B.; Zhou, X.J.; Li, J. The functions and application of agricultural nonwovens. Tech. Text. 2002, 145, 30–34. [Google Scholar]

- Jin, G.R.; Fu, F.D.; Wang, Y.H.; Wang, H.Y.; Ge, Y.Y. Applicational study of bast fiber mulch and non-woven equipment horticultural production. Plant Fiber Sci. China 2006, 28, 322–326. [Google Scholar]

- Du, Z.F.; Zhang, Q. Study on the performance between the nonwovens membrane and plastic membrane used in agriculture. Tech. Text. 2007, 25, 33–36. [Google Scholar]

- Ajmeri, J.R.; Ajmeri, C.J. Developments in nonwovens as agrotextiles. In Advances in Technical Nonwovens, 1st ed.; Kellie, G., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 365–384. ISBN 9780081005750. [Google Scholar]

- Yan, C.R.; Mei, X.R.; He, W.Q.; Zheng, S.H. Present situation of residue pollution of mulching plastic film and controlling measures. Trans. CSAE 2006, 22, 269–272. [Google Scholar]

- Liu, E.K.; He, W.Q.; Yan, C.R. ‘White revolution’ to ‘white pollution’—Agricultural plastic film mulch in China. Environ. Res. Lett. 2014, 9, 091001. [Google Scholar] [CrossRef]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Tröger, J.; Muñoz, K.; Frör, O.; Schaumann, G.E. Plastic mulching in agriculture: Trading short-term agronomic benefits for long-term soil degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef] [PubMed]

- Blanco, I.; Loisi, R.V.; Sica, C.; Schettini, E.; Vox, G. Agricultural plastic waste mapping using GIS: A case study in Italy. Resour. Conserv. Recyc. 2018, 137, 229–242. [Google Scholar] [CrossRef]

- Dharmalingam, S.; Hayes, D.G.; Wadsworth, L.C.; Dunlap, R.N.; Debruyn, J.M.; Lee, J.; Wszelaki, A.L. Soil degradation of polylactic acid/polyhydroxyalkanoate-based nonwoven mulches. J. Polym. Environ. 2015, 23, 302–315. [Google Scholar] [CrossRef]

- Domagała-Świątkiewicz, I.; Siwek, P. The effect of direct covering with biodegradable nonwoven film on the physical and chemical properties of soil. Pol. J. Environ. Stud. 2013, 22, 667–674. [Google Scholar]

- Wadsworth, L.C.; Hayes, D.G.; Wszelaki, A.L.; Washington, T.L.; Martin, J.; Lee, J.; Raley, R.; Pannell, C.T.; Dharmalingam, S.; Miles, C.; et al. Evaluation of degradable spun-melt 100% polylactic acid nonwoven mulch materials in a greenhouse environment. J. Eng. Fibers Fabr. 2013, 8, 50–59. [Google Scholar]

- Hablot, E.; Dharmalingam, S.; Hayes, D.G.; Wadsworth, L.C.; Blazy, C.; Narayan, R. Effect of simulated weathering on physicochemical properties and inherent biodegradation of PLA/PHA nonwoven mulches. J. Polym. Environ. 2014, 22, 417–429. [Google Scholar] [CrossRef]

- Xu, H.; Jia, S.S.; Pei, Y.G.; Luo, J.; Ye, W.; Hu, W.J.; Zhang, Y.J. Performances and preparation of cotton nonwoven film strengthened by chitosan. Shanghai Text. Sci. Technol. 2012, 40, 55–57. [Google Scholar]

- Liu, T.; Huang, C.; Han, X.J.; Xu, Y.H.; Wang, H. Preparation and performance of mulching film of nonwoven flax and silk fabric. J. Text. Res. 2010, 31, 71–75. [Google Scholar]

- Yan, T.T.; Liu, Y.H.; Yin, J.F. Research on the preparation of agricultural nonwoven film based on jute fiber. J. Yancheng Inst. Technol. 2013, 26, 11–15. [Google Scholar]

- Debnath, S. Jute-based sustainable agrotextiles, their properties and case studies. In Roadmap to Sustainable Textiles and Clothing, 1st ed.; Muthu, S.S., Ed.; Springer Science Business Media: Singapore, 2014; pp. 277–325. ISBN 978-981-287-064-3. [Google Scholar]

- Li, S.J.; Lin, L.J. Performance of farm nonwoven fabric and its application to vegetable production in spring and winter. Tech. Text. 2002, 20, 30–34. [Google Scholar]

- Wang, C.H.; Guo, B.C. Application and development of nonwovens in agriculture. Nonwovens 2004, 12, 30–32. [Google Scholar]

- Wang, C.Y.; Yi, Y.J.; Zhou, W.L.; Li, M.; Wang, H.Y. Preliminary study of raising rice seedling padded with bast fiber film for machine-transplanting. Plant Fiber Sci. China 2013, 35, 19–21. [Google Scholar]

- Jin, G.R.; Xu, S.C.; Mao, G.F.; Wang, J.W.; Chen, C.L.; Luo, X.H.; Zhu, G.L.; Zhang, J.Q. Application effects of bast fiber film in hard disk seedling of mechanical-transplanting early rice. Acta Agric. Zhejiangensis 2013, 25, 431–434. [Google Scholar]

- Xiong, C.C.; Li, J.Z.; Wang, H.W.; Yu, A.A.; Li, X.; Tang, D.L. Test and demonstration of degradable bast fiber mulching film breeding and machine transplanting technology of early rice seedling. Hubei Agric. Sci. 2013, 52, 2994–2996. [Google Scholar]

- Wang, C.Y.; Yi, Y.J.; Zhou, W.L.; Cheng, J.P.; Zhao, F.; Li, M.; Wang, H.Y. Effects of bast fiber film mat on seedling root growth and yield of machine-transplanted rice. J. Chin. Agric. Mech. 2013, 34, 84–88. [Google Scholar]

- Zhou, W.L.; Wang, C.Y.; Yi, Y.J.; Liu, Q.; Wang, H.Y.; Tan, Z.J. Effect of bast fiber film and seedling fertilizer application methods on quality of machine-transplanted rice seedling. ACTA Agric. Boreali Sin. 2016, 31, 191–197. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China. Determination of the Ultimate Aerobic Biodegradability of Plastic Materials under Controlled Composting Conditions—Method by Analysis of Evolved Carbon Dioxide; GB/T 19277.1-2011; Standards Press of China: Beijing, China, 2011.

- Shiono, K.; Ogawa, S.; Yamazaki, S.; Isoda, H.; Fujimura, T.; Nakazono, M.; Colmer, T.D. Contrasting dynamics of radial O2-loss barrier induction and aerenchyma formation in rice roots of two lengths. Ann. Bot. 2011, 107, 89–99. [Google Scholar] [CrossRef] [PubMed]

- Ponnamperuma, F.N. The chemistry of submerged soils. Adv. Agron. 1972, 24, 29–96. [Google Scholar]

- Guan, L.Z. General Soil Science, 2nd ed.; China Agricultural University Press: Beijing, China, 2016; Volume 73, ISBN 9787811171310. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Niu, Y.; Wang, C.; Yang, Y.; Tan, Z.; Yi, Y.; Yu, W.; Wang, H. A Biodegradable Ramie Fiber-Based Nonwoven Film Used for Increasing Oxygen Supply to Cultivated Soil. Appl. Sci. 2018, 8, 1813. https://doi.org/10.3390/app8101813

Zhou W, Niu Y, Wang C, Yang Y, Tan Z, Yi Y, Yu W, Wang H. A Biodegradable Ramie Fiber-Based Nonwoven Film Used for Increasing Oxygen Supply to Cultivated Soil. Applied Sciences. 2018; 8(10):1813. https://doi.org/10.3390/app8101813

Chicago/Turabian StyleZhou, Wanlai, Yanbin Niu, Chaoyun Wang, Yuanru Yang, Zhijian Tan, Yongjian Yi, Wang Yu, and Hongying Wang. 2018. "A Biodegradable Ramie Fiber-Based Nonwoven Film Used for Increasing Oxygen Supply to Cultivated Soil" Applied Sciences 8, no. 10: 1813. https://doi.org/10.3390/app8101813

APA StyleZhou, W., Niu, Y., Wang, C., Yang, Y., Tan, Z., Yi, Y., Yu, W., & Wang, H. (2018). A Biodegradable Ramie Fiber-Based Nonwoven Film Used for Increasing Oxygen Supply to Cultivated Soil. Applied Sciences, 8(10), 1813. https://doi.org/10.3390/app8101813