Abstract

Laser welding has been widely used in various industry fields. In order to further alter and broaden its applicability, a novel technology of laser welding under vacuum is introduced. The combination of high power laser and low ambient pressure provides an excellent welding performance and quality. In this paper, an overview on laser welding under vacuum is presented. It begins with a short introduction about the research status of laser welding under vacuum. Next, the equipment of laser welding under vacuum is introduced. Then, the fundamental phenomena of laser welding under vacuum, including penetration depth, weld geometry, plasma plume, molten pool and keyhole behaviors, are summarized in detail. Finally, the applications and prospects of laser welding under vacuum are proposed.

1. Introduction

Welding, a joining method by heat or pressure to make the materials reach the connection between atoms, is the most versatile and realistic joining technology in every industrial field [,]. Like the arc, plasma and electron beams, a laser beam can also be used as heat source in the welding. Laser beam has been applied to welding since the first ruby laser was invented by Doctor Maiman [,,]. In the last 20 years, laser welding has experienced rapid development. Because of the advantages of high quality, high precision, high efficiently, high performance, high flexibility, high speed, low distortion and low deformation, laser welding has been the most advanced and the best developing foreground welding method [,,,]. In the field of laser beam welding, constant attempts to alter and broaden the application possibilities have been made for years. New laser beam welding methods are appearing constantly, for example, laser welding with filler wire, remote laser welding, laser scanning welding, and so on [,,,,,,,,]. Among these new laser welding methods, laser welding under vacuum or under reduced pressure is one of the most promising methods. Although there are some different opinions about laser welding under vacuum, the exceeding expected laser welding phenomena and excellent weld quality under vacuum or reduced pressure both attract the interests of researchers.

This paper makes a short overview of laser welding under vacuum. It begins with a short introduction about the research status of laser welding under vacuum. Next, the equipment of laser welding under vacuum are introduced. Then, the fundamental phenomena of laser welding under vacuum, including penetration depth, weld geometry, plasma plume, molten pool and keyhole behaviors, are presented in details. Finally, the applications and prospects of laser welding under vacuum are proposed.

2. The Research Status of Laser Welding under Vacuum

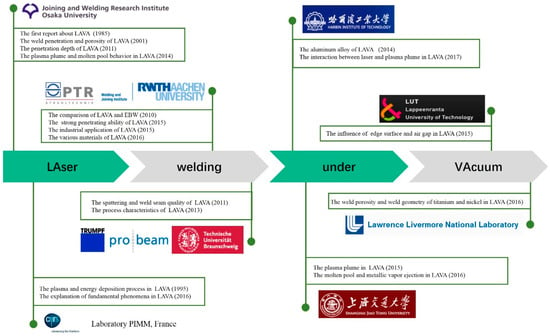

Laser welding under vacuum or reduced pressure has a history of more than 30 years. As shown in Figure 1, the first report about laser welding under vacuum or under reduced pressure dates back to the 1980s. Arata et al. [] (Joining and Welding Research Institute, JWRI for short, at Osaka University) made the first effort to carry out the experiment of laser welding under vacuum conditions. The original intent of this research was to suppress the plasma and achieve a deep penetration in CO2 laser welding. The problem of laser induced plasma, which is the most severe problem in laser welding at atmospheric, was completely solved by laser welding under vacuum. In addition, the exceeding expected penetration depth, which was approximate 2 times the depth of laser welding at atmospheric pressure, was achieved by laser welding under vacuum. However, this new laser welding method did not attract much attention due to the inadequate development of laser welding in industrial fields at that time. JWRI at Osaka University insisted on the research about laser welding under vacuum and paid their attention to fundamental phenomena in laser welding under vacuum. In 2001, the effect of vacuum on weld penetration and porosity formation was investigated in high-power CO2 and YAG laser welding []. The reason for no porosity in vacuum was explained by keyhole and molten pool behaviors. In 2011, Katayama et al. [] performed a high power disc laser welding experiment on 304 stainless steel and A5052 aluminum using a new chamber for laser welding under vacuum achieved by using rotary pumps. Sound deep single pass weld of 73 mm in penetration depth on type 304 stainless steel was obtained at a laser power of 26 kW, a welding speed of 0.3 m/min, a defocused distance of −40 mm and an ambient pressure of 0.1 kPa. The research of Katayama et al. [] showed the penetrability of laser welding under vacuum which was similar to that of electron beam welding and the application feasibility of laser welding under vacuum on thick plate welding.

Figure 1.

The research status of laser welding under vacuum.

Fabbro et al. (PIMM Laboratoire, Paris, France) have also been studying laser welding under vacuum or reduced pressure for many years. The research of Fabbro et al. mainly focused on the explanation of weld geometry changes and penetration improvement under vacuum conditions. In 1995, Fabbro et al. [] observed the plasma suppression at low pressure by measuring plasma size, electron temperature and electron density. The energy deposition process inside the keyhole was compared to explain the different weld seam profiles between vacuum and atmosphere. Recently, Fabbro et al. [] made a detailed explanation of fundamental phenomena in laser welding under vacuum by theoretical analysis and numerical simulation.

Since 2000, lasers have experienced an extremely rapid development. Especially during the last 10 years, the high-power (>10 kW, up to 100 kW) and high-brightness (<15 mm mrad) solid state lasers (fiber lasers or disk lasers) emerged into market [,]. Due to the availability of a new generation of high brightness multi-kilowatt solid state lasers, high-power laser beam welding became a new stimulus. However, some new problems, for example, the weld defects of sagging and spatter, the intense plasma plume and turbulent molten pool flow, are accompanied during high-power laser beam welding [,,]. That means that the application of high power single pass laser welding encounters a bottleneck. Under such a background, the method of laser welding under vacuum or reduced pressure has been enjoying a renaissance.

In 2010, the Welding and Joining Institute (ISF) of RWTH Aachen University started research work of laser welding under vacuum using a 600 W single-mode fiber laser and a 12 kW multimode fiber laser []. The weld formations of both thick plate and thin plate were compared between laser welding under vacuum and electron beam welding. Based on the impressive results of the preliminary study, ISF of RWTH Aachen University built up a welding equipment for laser welding under vacuum on cooperation with PTR Strahltechnik GmbH A large number of process exploration tests of laser welding under vacuum were carried out on this new laser welding equipment [,,]. The results of process tests showed that laser welding had a strong penetrating ability and a good adaptability for materials. Various materials, for example unalloyed steel, high alloyed steel, nickel-base alloy, titanium alloy and even copper alloy, were welded and achieved a deep and sound weld. In terms of the research results of laser welding under vacuum, ISF of RWTH Aachen University actively promoted this technology in the industrial field.

In 2011, Institute of Joining and Welding (ifs) at TU Braunschweig started studying laser welding under vacuum on a corporation with Trumpf Laser- und Systemtechnik GmbH and Pro-beam AG & Co. [,]. Instead of the beam generator, a laser beam was coupled into a vacuum chamber of a former electron beam welding machine to carry out laser welding under vacuum. The influence of ambient pressure on spattering and weld quality in laser beam welding was presented. The process characteristics of laser welding at reduced ambient pressure was studied in detail.

In recent years, more and more researchers have shown their interest in laser welding under vacuum. In 2014, the State Key Laboratory of Advanced Welding and Joining (AWJ) at Harbin institute of technology investigated the laser bead on plate welding of aluminum alloy under reduced pressure []. In 2017, the effect of ambient pressure on weld formations and the interaction between laser radiation and plasma plume were further investigated []. In 2015, Laboratory of Laser Processing at Lappeenranta University of Technology studied the influence of joint edge surface edge roughness and pre-set air gap on the weld quality and penetration depth in partial vacuum conditions laser beam welding []. In 2014, Shanghai Jiao Tong University investigated the plasma plume in fiber laser welding under subatmospheric pressure []. In 2016, the dynamic coupling between molten pool and metallic vapor ejection in fiber laser welding under subatmospheric pressure was further studied []. In 2015, Daimler AG in Germany carried out the welding experiments of 16MnCr5 steel and ALMg3 aluminum using X-ray analysis to investigate the keyhole behavior at the reduced ambient pressure []. In 2016, Lawrence Livermore National Laboratory, USA, performed the study about the effect of reduced pressure on laser keyhole weld porosity and weld geometry in pure titanium and nickel [].

Significant advantages of laser welding under vacuum or reduced pressure are attracting the attention of researchers and show great value of research and practical application. In the further 5–10 years, laser welding under vacuum will become a key issue in laser beam welding.

3. The Equipment of Laser Welding under Vacuum

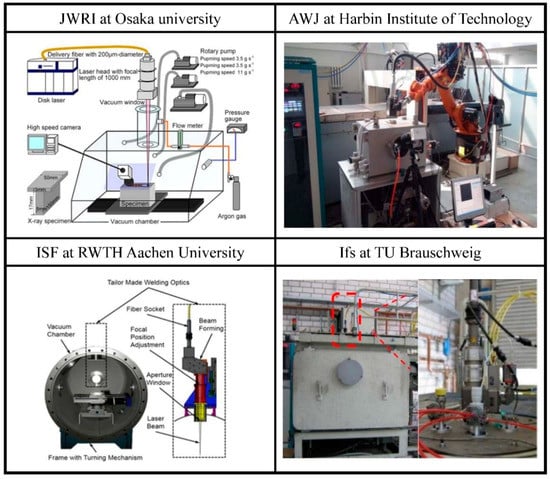

In order to carry out laser welding under vacuum, the first issue is to build up a vacuum chamber for laser welding. The simplest way is to refer to the basic design of electron beam welding. Instead of an electron beam generator, a laser processing head is installed in vacuum chamber. The design of a built-in laser head has the advantage of a more flexible laser welding under vacuum machine. However, a special seal should be designed to couple optical fiber and water-cooled pipelines into vacuum chamber. With the cooperation of ISF at RWTH Aachen University and II-VI HIGHYAG, a fiber-fiber-coupler was design to develop an easy and affordable method to transfer laser power into the vacuum. The fiber-fiber-coupler open the possibility of high power laser processing with built-in laser head under vacuum []. Unlike electron beams, laser radiation is a matter of light. Laser beams can pass through the glass into a vacuum. Therefore, there is another structural design for laser welding under vacuum. Laser processing head is fixed outside the vacuum chamber. Only the laser beam is coupled into the vacuum chamber through glass. As shown in Figure 2, most of the research institutions used the second design according to the current reports. JWRI at Osaka University created a transparent vacuum chamber using acrylic [,]. The rotary pump was used to achieve vacuum conditions. The design of transparent vacuum chamber was beneficial to take photos with high speed camera and other optical tests. AWJ of Harbin Institute of Technology set up a 680 × 400 × 400 mm vacuum chamber. The theoretical limit vacuum level was 6.6 × 10−4 Pa by using a rotary pump and a molecular pump simultaneously. The ifs at TU Braunschweig reformed a 1.5 m3 vacuum chamber of former electron beam welding plant []. A blank flange was manufactured in which a quartz glass was located as a coupling-in window to couple laser into chamber. ISF at RWTH Aachen University established a cylinder vacuum chamber of 0.6 m3 []. The vacuum chamber was equipped with two rotary vacuum pumps. This vacuum chamber had a minimum vacuum pressure of 10−3 hPa and the ability to reach 0.1 hPa in 5 min. Besides, the vacuum chamber could realize different welding positions by turning around the longitudinal axis.

Figure 2.

The equipment of laser welding under vacuum. Reproduced with permission from [], Springer, 2016; Reproduced with permission from [], Laser Institute of America, 2011; Reproduced with permission from [], Taylor & Francis, 2014.

According to the above designs of vacuum chamber, the equipment of laser welding under vacuum basically consists of three parts: laser processing head, vacuum chamber and coupling-in window. The laser processing head should be set above the vacuum chamber. A conventional system for laser welding at atmosphere can easily fulfill the requirement. Compared with electron beam welding, laser welding under vacuum has a relatively low requirement of vacuum level. Therefore, the vacuum chamber structure of laser welding is relatively simple. Hence, the key part of the vacuum chamber is the coupling-in window for coupling the laser beam into the vacuum. A ZnSn glass were used as coupling-in window in CO2 laser welding under vacuum. A quartz glass was used for solid laser welding under vacuum. In laser welding under vacuum, intense metal vapor ejected from keyhole and deposited on the surface of glass. That means that the stability of laser propagation and the lifetime of glass could be seriously affected. A laser head with long focusing length [,,] (JWRI at Osaka University and ISF at RWTH Aachen University) or a special coupling-in window [,] (ISF at RWTH Aachen University and ifs at TU Braunschweig) with a rather small gas flow under the glass are used to protect the coupling-in window from process emissions. Furthermore, the coupling-in glass is coated with an antireflection film and equipped with a water-cooling device for long-time welding with high power.

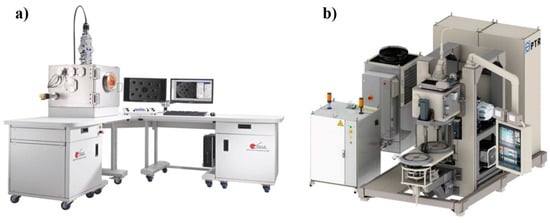

In the last 2–3 years, the systematic equipment of laser welding under vacuum entered the market. As shown in Figure 3, LAVA-L95 and LASVAC PL 01 are two typical systematic equipment of laser welding under vacuum [,,]. With the support of ISF at RWTH Aachen University, the machines were developed separately by FOCUS Gmbh and PTR Company. In order to meet the demand for different processes or products, a unit assembly system is designed. That means the different laser sources and optics can be chosen in the equipment of laser welding under vacuum.

Figure 3.

The systematic equipment of laser welding under vacuum (a) LAVA-L95. Reproduced with permission from [], FOCUS electronics GmbH, 2017. (b) LASVAC PL 01. Reproduced with permission from [], PTR Strahltechnik GmbH, 2017.

4. Fundamental Phenomena during Laser Welding under Vacuum

4.1. The Influence of Ambient Pressure on Penetration Depth and Weld Geometry

The increase in penetration depth and change in weld geometry are the most obvious achievements brought by the reduction of ambient pressure. According to the present experiment results [,,,,], the penetration depth increases with the decrease of the ambient pressure. Based on the effect of ambient pressure on penetration depth, there exists a critical threshold of ambient pressure. That means the penetration no longer increases, and sometimes probably decreases when the ambient pressure is lower than the critical threshold. Because of the different machines and different experimental conditions, the critical pressures are not consistent. The previous results [,,,,] showed that the critical pressure was in the range of 0.1 kPa to 10 kPa. Abe et al. [] carried out the bead-on-plate welding of type 304 stainless steel plates and A5052 aluminum alloy with a 16 kW laser power at a welding speed of 1 m/min under reduced pressure. The results showed that the critical pressure was about 10 kPa and the penetration depth of both type 304 stainless steel plates and A5052 aluminum alloy at 10 kPa is nearly twice as deep as that at 101 kPa. The results of Abe et al. [] also revealed that the weld width decreased with the decreasing ambient pressure. The increase in penetration depth and the decrease in weld width led to a large difference in aspect ratio (penetration depth/weld width). That meant that the weld geometry between under vacuum and atmosphere were totally different. In comparison with conventional laser welding at atmospheric pressure, a deep and parallel weld, which is similar to electron beam welding, is achieved during laser welding under vacuum.

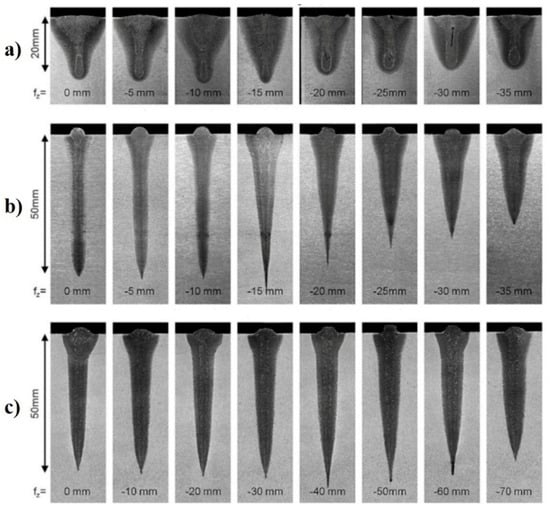

The results of ISF at RWTH Aachen university also proved the strong penetrating ability of laser welding under vacuum [,]. The cross section profiles of laser welding at atmosphere, laser welding under vacuum and electron beam welding are shown in Figure 4. With the same heat input, the penetration depth of both laser welding under vacuum and electron beam welding is about 50 mm. However, the pressure used in electron beam welding is two orders of magnitude lower than in laser welding under vacuum. The strong penetrating ability under low vacuum is the unique advantage of laser welding under vacuum.

Figure 4.

Comparison of cross section profiles using different welding processes (a) Laser welding (laser power is 16 kW, welding speed is 0.3 m/min, ambient pressure is 1000 mbar), (b) Laser welding under vacuum (laser power is 16 kW, welding speed is 0.3 m/min, ambient pressure is 10−1 mbar), (c) Electron beam welding (electron beam power is 16 kW, welding speed is 0.3 m/min, ambient pressure is 10−3 mbar). Reproduced with permission from [], John Willey and Sons, 2015.

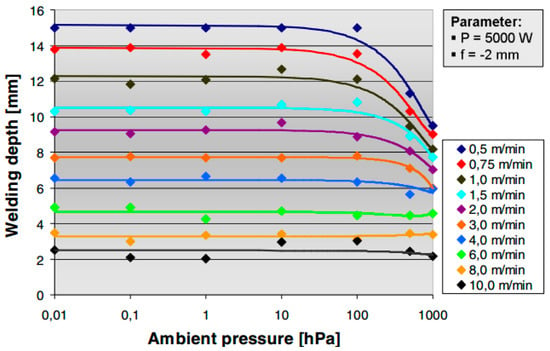

The ambient pressure, welding speed and defocused distance are the main parameters that control the weld appearance and penetration depth during laser welding under vacuum. It was found that, under vacuum condition, the increase of penetration depth was quite different at various welding speed [,]. As shown in Figure 5 (Figure 6 of “Influence of ambient pressure on spattering and weld seam quality in laser beam welding with the solid-state laser” reproduced with permission from Proceedings of the International Congress on Applications of Lasers and Electro-optics, October 2011), a remarkable increase of penetration depth occurs at low to medium speeds (up to approx. 3.0 m/min), it is true that there is a limit in the ambient pressure for improving penetration depth. Besides the lower the welding speed is, the more obvious the effect of ambient pressure on penetration depth is. When the welding speed is over 4 m/min, the ambient pressure has almost no impact on the penetration depth. The laser focus position carries with the most concentrated laser energy. The focus position (above the workpiece or below the workpiece) has an influence on the laser energy transfer along the keyhole. In the case of laser welding under vacuum, the laser energy disposition along the extreme deep keyhole has a distinct difference compared with the conventional laser welding. The keyhole depth under vacuum is much deeper than that at atmosphere. Therefore, the defocused distance is an important parameter to control the weld appearance and penetration depth under vacuum. In addition, the oscillating laser beam has been introduced into laser welding under vacuum. This has proved that the oscillation of laser beam affected the weld seam geometry, spattering behavior and weld meatal ajections [].

Figure 5.

Effect of ambient pressure on penetration depth at various welding speed ICALEO® 2011 Proceedings. Reproduced with permission from [], Laser Institute of America, 2011.

Figure 6.

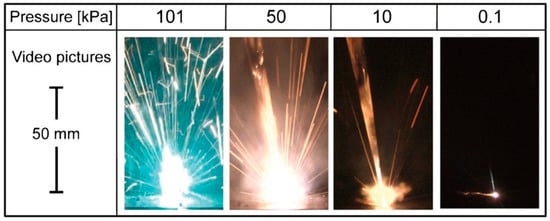

Typical video pictures of A5052 aluminum alloy laser induced plume observed under each reduced pressure (laser power is 16 kW, welding speed is 1 m/min, defocus distance is 0 mm). Reproduced with permission from [], Taylor & Francis, 2014.

4.2. The Influence of Ambient Pressure on Plasma Plume

It was known that the welding vapor plasma exerted a negative “shielding effect” in high-power CO2 laser welding. The strong inverse bremsstrahlung (I.B.) effect decreases the penetration depth and even stops the CO2 laser welding process due to the optical breakdown [,]. The vapor plasma exerts a different state between CO2 laser welding and solid laser welding. Due to the presence of a large number of non-ionized metal particles, the vapor plasma is called “metal vapor plume” in solid laser welding []. However, the plasma plume still causes some disturbances by Rayleigh or Mie scattering in solid laser welding [,,]. The previous studies [,,] showed that no matter whether CO2 laser welding or solid laser welding was used, the reduction of ambient pressure had a significant effect on plasma plume behavior. As shown in Figure 6 an extremely intensive and very bright plasma plume was exerted above the workpiece in high power laser welding at atmospheric pressure (101 kPa). The lower part plasma plume adjoined directly the keyhole has much higher brightness than the other part. Besides, a large number of spatters were observed around the plasma plume. The reduction of ambient caused an obvious change in plasma plume. When the ambient pressure reduced to 50 kPa, the change of plasma plume was already visible. Both the intensive luminescence and the volume of plasma plume decreased. At the reduced ambient pressure of 10 kPa, the intense illuminant plasma plume and obvious spattering disappeared. There was only a small brightness and volume of plasma plume above the keyhole. When the ambient pressure decreased at 0.1 kPa, the plasma plume was completely suppressed and invisible. The different materials and the welding parameters led the difference in critical ambient pressure of plasma plume disappearance.

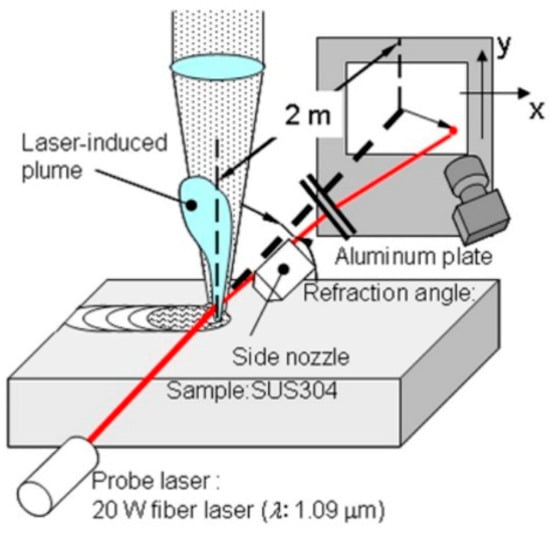

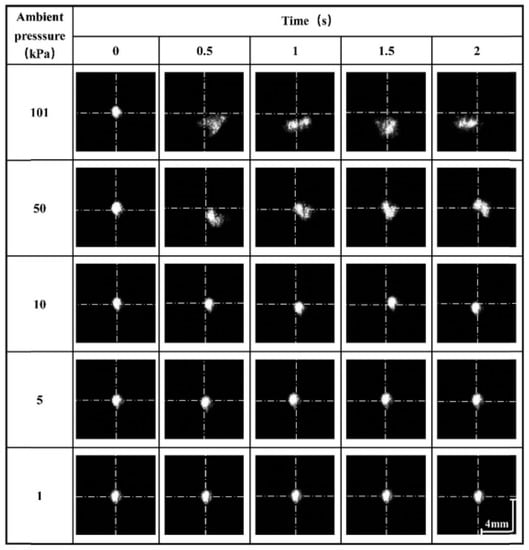

The enormous difference in the luminescence and the volume of plasma plume guide the research of the interaction between laser radiation and plasma plume under different ambient pressures. As shown in Figure 7, a probe laser, which horizontally passed through the plasma plume, was usually used to study the interaction between laser radiation and plasma plume [,]. As shown in Figure 8, the spot behaviors of a probe laser beam passing through the plasma plume under various ambient pressures are presented []. The results showed that the interaction between laser radiation and plasma plume was minimal at low ambient pressures. Therefore, the laser process was more stable under vacuum. In addition, the extinction of fiber laser radiation decreased with decreasing ambient pressure []. Although the interaction between laser radiation and plasma plume under different ambient pressures has been discussed, the essential influence of ambient pressure on plasma plume has not been presented in detail. On the one hand, the illuminant change of plasma plume means that the ambient pressure has a significant effect on the ionization state and formation condition of the plasma plume. On the other hand, the ambient pressure has a direct relation with the stress state of metal vapor behavior. This may lead to a different laser welding process.

Figure 7.

The schematic of studying the interaction between laser radiation and plasma plume using a probe laser. Reproduced with permission from [], Taylor & Francis, 2008.

Figure 8.

The spot behaviors of probe laser beam passing through the plasma plume under various ambient pressures (laser power is 5 kW, welding speed is 0.25 m/min, defocus distance is 0 mm). Reproduced with permission from [], Elsevier, 2017.

4.3. The Influence of Ambient Pressure on Molten Pool and Keyhole Behaviors

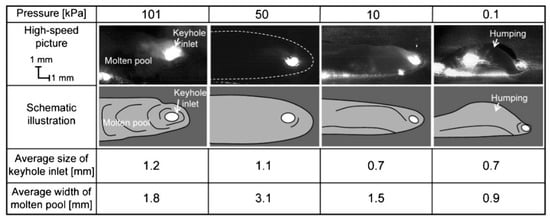

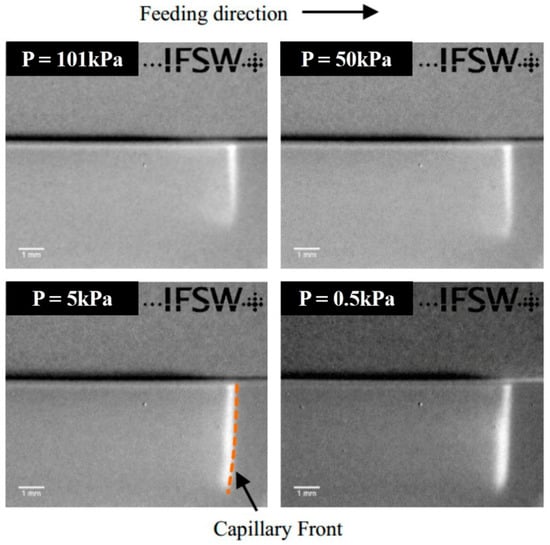

During laser welding, the molten pool and keyhole behaviors have a close relationship with weld quality and defect formation. Due to the specialty of molten pool and keyhole behaviors, it is difficult to understand and investigate the molten pool and keyhole behaviors. Therefore, the advanced imaging technology and numerical simulation are the main methods to study the molten pool and keyhole behaviors. Both methods are used to explore the effect of ambient pressure on the molten pool and keyhole behaviors. The surface molten pool and keyhole inlet of SUS 304 stainless steel under different ambient pressures were observed by Youhei et al. []. As shown in Figure 9, the surface molten pool and the keyhole inlet changed following the ambient pressure decreasing. The average diameter of keyholes decreased, the surface molten pool became narrower and more stable under vacuum conditions. Moreover, there were quite different liquid flows between atmospheric pressure and vacuum. Katayama et al. [] presented the liquid flow in the molten pool at various ambient pressures using the micro focused X-ray real-time observation. Based on the results of Katayama et al. [], there were two main differences in liquid flow between atmosphere and vacuum. On the one hand, the liquid flowed downward along the rear keyhole at atmospheric pressure. While the liquid flowed upwards along the rear keyhole wall under vacuum. That means the liquid flow along the rear keyhole is opposite. On the other hand, there was a molten flow along the bottom molten pool at atmospheric pressure, while there was no such strong flow near the bottom under vacuum. The differences in molten pool flow had a direct relationship with the porosity formation. In addition, the keyhole shapes at different pressures were observed directly by Engelhardt et al. []. Figure 10 (Figure 5 of “Time-resolved X-ray Analysis of the Keyhole Behavior during Laser Welding of Steel and Aluminum at Reduced Ambient Pressure” reproduced with permission from Proceedings of the International Congress on Applications of Lasers and Electro-optics, October 2015) shows the averaged keyhole shapes at ambient pressures from 0.5 kPa to 101 kPa. The keyhole depth increased with the decreasing of ambient pressure. This phenomenon corresponded to the increase in penetration depth under vacuum. In addition, the reduction of ambient pressure resulted in an increased inclination angle of the keyhole front and an increased bending of the keyhole tip.

Figure 9.

High speed video picture of keyhole inlet and molten pool in type 304 stainless steel weld observed under each reduced pressure(laser power is 16 kW, welding speed is 1 m/min, defocus distance is 0 mm). Reproduced with permission from [], Taylor & Francis, 2014.

Figure 10.

X-ray images of averaged keyhole shapes at ambient pressures from 0.5 kPa–101 kPa (laser power is 2 kW, welding speed is 1.2 m/min, defocus distance is 0 mm). ICALEO® 2015 Proceedings. Reproduced with permission from [], Laser Institute of America, 2015.

Pang et al. [,,] investigated the physical phenomenon of laser welding under vacuum by numerical simulation. Based on the 3D transient multiphase model of laser welding, an improved model of recoil pressure for laser welding under any ambient pressure was proposed. The comparison of the predicted keyhole wall temperature and the predicted velocity distribution of metallic vapor under atmosphere and vacuum are presented. The results show that the average keyhole wall temperature became lower and the predicted speed of metallic vapor increased under vacuum. Based on the previous results of numerical simulation, Fabbro et al. [] presented that the penetration depth improvement in laser welding under vacuum mainly resulted from the reduction of evaporation temperature. Less power per unit depth of keyhole is necessary due to the reduction of evaporation temperature, resulting in a deeper keyhole with the same incident laser power. The saturation of the penetration depth below some critical pressure is related to the recoil pressure. In addition, the recoil pressure and welding speed are positively related. At high welding speed, the recoil pressure is higher. Moreover, it is much higher than ambient pressure. Therefore, the reduction of ambient pressure cannot change the evaporation pressure inside the keyhole. This is the reason that at high welding speeds there is no improvement in penetration depths while at low welding speed, the reduction of ambient pressure will modify the evaporation pressure inside the keyhole due to relatively low recoil pressure. The low evaporation pressure results in the improvement in penetration depths under vacuum.

5. Applications of Laser Welding under Vacuum

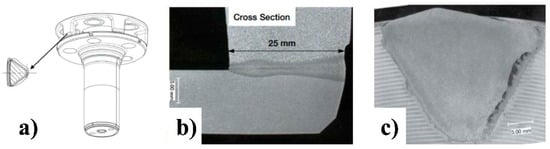

As an emerging welding technology, laser welding under vacuum has received much attention in recent years. The reports of laser welding under vacuum mainly focused on the effect of ambient pressure on laser welding phenomena. Laser welding under vacuum is still at the beginning stages of application. Based on the advantages of laser welding under vacuum, the applications of this competitive technology are expected. The main application attempt was on the mass production of drive section components with radial and/or axial weld seams [,,]. Within the framework of a cooperation of PTR Company and RWTH Aachen University, a cycle machine for welding with laser beam under vacuum was implemented. The planet wheel carrier and gear wheel were fabricated by the cycle machine for laser welding under vacuum. As shown in Figure 11, the plate wheel carriers consist of a planet wheel carrier with axle arm and a coronoid bole carrier. The welding zone is triangular and the maximally required penetration depth is 25 mm. A sound welded joint without oxides and spatters was fabricated using a laser power of 7.5 kW, a welding speed of 0.42 m/min, a focus position of −5 mm and an ambient pressure of 2 kPa. At the same time, Pro-beam, TRUMPF and the ifs at TU Braunschweig are also adapting the process for the low-pressure, spatter-free laser welding of powertrain components into industrial application [,]. The powertrain components requiring weld penetration depths of between three and six millimeters and a high feed rate were manufactured. Because of stable process without spatter, high weld quality and proper penetration depth, laser welding under vacuum is very suitable for the fabrication of powertrain components.

Figure 11.

The planet wheel carrier welded by laser welding under vacuum ((laser power is 7.5 kW, welding speed is 0.42 m/min, defocus distance is −5 mm, ambient pressure is 20 mbar-1). Reproduced with permission from [], John Willey and Sons, 2015. (a) The schematic of planet wheel carrier, (b) Cross-section in stud center, (c) Longitudinal section through the weld.

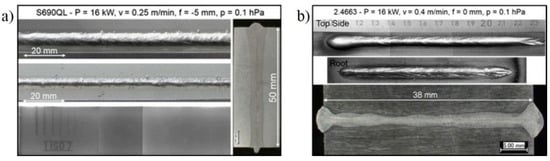

Laser welding has been widely used in various productions. However, laser welding is mainly used in the sheet structure with small thickness. With the advent of new high power solid lasers, the use of solid-state laser in deep penetration welding has been constantly explored. The exceeding expected phenomena of laser welding under vacuum make it very suitable for thick plate applications where low welding speeds can be applied to achieve very high penetration depth and for welding tasks with the highest demands on the weld quality. Some various materials, such us copper alloys, structural steels, duplex stainless steels, nickel-based alloys, titanium alloys and so on, have been welded by ISF at RWTH Aachen University [,,,]. As shown in Figure 12, the plate thickness of 50 mm for unalloyed steel S690QL was achieved by single pass laser welding under vacuum at a laser power of 16 kW, a welding speed of 0.5 m/min, a focus position of −5 mm and an ambient pressure of 10 Pa. The full penetration weld joint of 38 mm nickel-base alloy without was fabricated at a laser power of 16 kW, a welding speed of 0.4 m/min, a focus position of 0 mm and an ambient pressure of 10 Pa. As shown in Figure 12, both the weld joints presented a sound weld with super deep penetration depth. It is clear that laser welding under vacuum has the developing prospect of welding heavy section components under low vacuum. As we know, electron beam welding is thought to be suitable for single pass weld of thick plate [,]. In this regard, laser welding under vacuum is able to challenge the electron beam welding in terms of the weld quality and penetration depth. In addition, laser welding under vacuum has the following advantages: relatively low vacuum level, lack of X-ray radiation protection and possible arising of nonmetallic [,].

Figure 12.

The survey of weldable plate thicknesses/materials with laser welding under vacuum. Reproduced with permission from [], Springer, 2016. (a) Laser welding under vacuum of unalloyed steel S690QL, (b) Laser welding under vacuum of nickel-base alloy 617.

6. Prospects of Laser Welding under Vacuum

With the reference to the previous researches of laser welding under vacuum, the main advantages of laser welding under vacuum or reduced pressure are as follows [,,,]:

- Significant increase (More than two times) of the welding depth;

- Parallel-sided seams with reduced nail head;

- Increased process stability due to greatly reduced and stable plasma plume;

- Reduction of workpiece contamination by spatter and vaporization;

- Higher-quality, pore-free weld seams;

- Low operating costs due to efficient solid-state laser;

- Welding process without inert gas;

- Lower vacuum level and simpler device compared with electron beam welding.

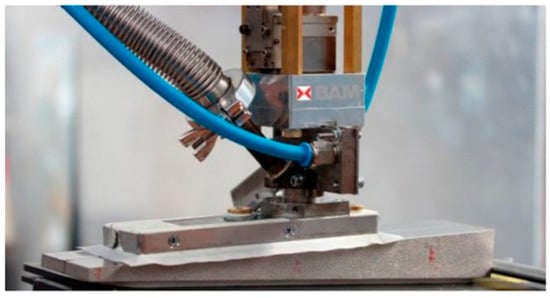

Despite the advantages of laser welding under vacuum above, the vacuum chamber causes laser welding loose the most important advantage: flexibility. In addition, the dimensions of the welded part were restricted by the dimensions of the vacuum chamber. A larger vacuum chamber means higher cost and associated pumping time []. A lot of trails were carried out to make the electron beam welding release the limitation of vacuum chamber. Rolls-Royce and TWI worked on a local vacuum, or “out of chamber” to expand the application of electron beam welding in thick section components []. However, the electron beam interaction with low pressure gases is the difficult point in the application of electron beam welding under local vacuum. However, the interaction of the laser with ambient gases is negligible. In addition, the relatively low vacuum can achieve an obvious increase in penetration depth. Therefore, laser welding under local vacuum or mobile vacuum has a more practical application value. ISF RWTH-Aachen and BAM, Germany has conducted some attempts in laser welding under mobile vacuum [,,]. As shown in Figure 13, a vacuum cap, which provides a local reduced ambient pressure of about 20 kPa above the welding area, was presented by BAM. The reduced pressure in the vacuum cap generate 50% higher penetration depth in comparison to welding under ambient pressure conditions. Due to the restriction of this movable seal, the vacuum level is very low and the penetration depth has no significant increase. The laser welding under vacuum can be combined with local vacuum electron beam welding to accumulate the disadvantages of those two processes. Hence, a local vacuum seal with a laser, instead of the electron beam generator may be a promising technique in the future.

Figure 13.

The mobile local vacuum chamber for high power laser beam welding of thick materials. Reproduced with permission from [], John Willey and Sons, 2015.

Laser welding under vacuum not only has promising application prospects, but also provides a special physical environment to achieve a fundamental understanding of the laser welding process. Laser keyhole welding is a complex physical process involving heat flow, melting, evaporation, solidification phase changes, melt flow, and vapor flow. Most physical phenomena in laser keyhole welding have not been fully understood due to the complexity of laser welding. The phenomena of laser welding are completely different at the same welding parameter except for ambient pressure. By comparing the differences between atmosphere and vacuum and analyzing the influences of ambient pressure, the essences of laser welding can be more deeply understood. For example, the interaction of laser radiation and plasma plume is a focused issue in high power laser welding. Under vacuum conditions, the plasma plume was suppressed completely. By studying the effect of ambient pressure on the plasma plume, we could get a better understanding of the interaction of laser radiation and plasma plume.

There is no such thing as a perfect technology. The laser welding under vacuum is no exception. There are also some challenges in laser welding under vacuum. As is stated above, the coupling-in window for coupling laser beam into vacuum is the key part of vacuum chamber for laser welding. The lifetime of coupling-in window determines the stability of the equipment of laser welding under vacuum. Besides, higher and higher laser power will be used in laser welding under vacuum in the future. The coupling-in window glasses should have a higher maximum limiting power. As we know, the laser processing head itself consists of optical glass. In the future, the integration of a laser processing head and coupling-in window on the vacuum chamber is probably a development trend of equipment of laser welding under vacuum. On the other hand, there are also many mechanisms yet to be explained in laser welding under vacuum. The research about the effect of ambient pressure on the plasma ionization and vapor ejection in plasma plume, the dynamic behavior of keyhole and molten pool, and the metallurgical behavior under vacuum will provide a good deal of insight into the fundamental processes of laser welding under vacuum.

7. Conclusions

A review of laser welding under vacuum including histories, equipment, fundamental phenomena, applications and prospects has been reported. The first test of laser welding under vacuum or under reduced pressure dates back to the 1980s. The development of high-power lasers means laser welding under vacuum is enjoying a renaissance. Compared with electron beam welding, the equipment of laser welding under vacuum is relatively simple. The coupling-in window for coupling the laser beam into a vacuum is the key part of vacuum system for laser welding. The ambient pressure has a significant influence on the phenomena of laser welding. The changes of plasma plume, keyhole and molten pool behaviors result in an excellent sound and deep welding performance. Based on the advantages of laser welding under vacuum, the application on drive section and powertrain components has been attempted in Germany. A local mobile vacuum for laser welding is expected to be a promising technology in the future. Besides, the vacuum environment is a benefit to further understanding the physical process of laser keyhole welding.

Acknowledgments

This work was supported by the National Key Research and Development Program of China (2016YFB1102100), “the Fundamental Research Funds for the Central Universities” (Grant NO.HIT.NSRIF.2017003) and the Nature Science Foundation of Heilongjiang Province (E2016027).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kou, S. Welding Metallurgy; Wiley: New York, NY, USA, 1987. [Google Scholar]

- Lancaster, J.F. Metallurgy of Welding; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Katayama, S. Handbook of Laser Welding Technologies; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Allmen, M.V.; Blatter, A. Laser-Beam Interactions with Materials: Physical Principles and Applications; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Duley, W.W. Laser Welding; Wiley: Hoboken, NJ, USA, 1999. [Google Scholar]

- Kacar, I.; Ozturk, F.; Yilbas, B.S. A review of and current state-of-the-art in laser beam welding in the automotive industry. Laser Eng. 2016, 33, 327–338. [Google Scholar]

- Cao, X.; Jahazi, M.; Immarigeon, J.P.; Wallace, W. A review of laser welding techniques for magnesium alloys. J. Mater. Process. Technol. 2006, 171, 188–204. [Google Scholar] [CrossRef]

- Martukanitz, R.P. A critical review of laser beam welding. In Lasers and Applications in Science and Engineering, Proceedings of the Society of Photo-Optical Instrumentation Engineers (SPIE), San Jose, CA, USA, 22–27 January 2005; Schriempf, J.T., Ed.; SPIE: Bellingham, WA, USA, 2005; Volume 5706, pp. 11–24. [Google Scholar]

- Cao, X.; Wallace, W.; Poon, C.; Immarigeon, J.P. Research and Progress in Laser Welding of Wrought Aluminum Alloys. I. Laser Welding Processes. Mater. Manuf. Process. 2003, 18, 1–22. [Google Scholar] [CrossRef]

- Dilthey, U.; Fuest, D.; Scheller, W. Laser welding with filler wire. Opt. Quantum Electron. 1995, 27, 1181–1191. [Google Scholar]

- Salminen, A.S.; Kujanpää, V.P. Effect of wire feed position on laser welding with filler wire. J. Laser Appl. 2003, 15, 2–10. [Google Scholar] [CrossRef]

- Salminen, A.S. Effects of filler wire feed on the efficiency of laser welding. In LAMP 2002: International Congress on Laser Advanced Materials Processing, Proceedings of SPIE—The International Society for Optical Engineering, Osaka, Japan, 27–31 May 2002; SPIE: Bellingham, WA, USA, 2003; pp. 263–268. [Google Scholar]

- Rasmussen, D.; Dubourg, L. Hybrid laser-GMAW welding of aluminum alloys: A review. In Proceedings of the 7th International Conference on Trends in Welding Research, Pine Mountain, Atlanta, GA, USA, 16–20 May 2005; pp. 133–142. [Google Scholar]

- Bagger, C.; Olsen, F.O. Review of laser hybrid welding. J. Laser Appl. 2005, 17, 2–14. [Google Scholar] [CrossRef]

- Lu, J.; Kujanpää, V. Review study on remote laser welding with fiber lasers. J. Laser Appl. 2013, 25, 052008. [Google Scholar] [CrossRef]

- Reinhart, G.; Munzert, U.; Vogl, W. A programming system for robot-based remote-laser-welding with conventional optics. CIRP Ann. Manuf. Technol. 2008, 57, 37–40. [Google Scholar] [CrossRef]

- Hatwig, J.; Minnerup, P.; Zaeh, M.F.; Reinhart, G. An automated path planning system for a robot with a laser scanner for remote laser cutting and welding. In Proceedings of the 2012 IEEE International Conference on Mechatronics and Automation (ICMA), Chengdu, China, 5–8 August 2012; pp. 1323–1328. [Google Scholar]

- Hao, K.; Li, G.; Gao, M.; Zeng, X. Weld formation mechanism of fiber laser oscillating welding of austenitic stainless steel. J. Mater. Process. Technol. 2015, 225, 77–83. [Google Scholar] [CrossRef]

- Arata, Y.; Abe, N.; Oda, T. Fundamental Phenomena in High Power CO_2 Laser (Report II): Vacuum Laser Welding (Welding Physics, Process & Instrument). Trans. JWRI 1985, 14, 217–222. [Google Scholar]

- Katayama, S.; Kobayashi, Y.; Mizutani, M.; Matsunawa, A. Effect of vacuum on penetration and defects in laser welding. J. Laser Appl. 2001, 13, 187–192. [Google Scholar] [CrossRef]

- Katayama, S.; Yohei, A.; Mizutani, M.; Kawahito, Y. Development of Deep Penetration Welding Technology with High Brightness Laser under Vacuum. Phys. Procedia 2011, 12, 75–80. [Google Scholar] [CrossRef]

- Verwaerde, A.; Fabbro, R.; Deshors, G. Experimental study of continuous CO2 laser welding at subatmospheric pressures. J. Appl. Phys. 1995, 78, 2981–2984. [Google Scholar] [CrossRef]

- Fabbro, R.; Hirano, K.; Pang, S. Analysis of the physical processes occurring during deep penetration laser welding under reduced pressure. J. Laser Appl. 2016, 28, 022427. [Google Scholar] [CrossRef]

- Bachmann, M.; Gumenyuk, A.; Rethmeier, M. Welding with High-power Lasers: Trends and Developments. Phys. Procedia 2016, 83, 15–25. [Google Scholar] [CrossRef]

- Nielsen, S.E. High Power Laser Hybrid Welding—Challenges and Perspectives. Phys. Procedia 2015, 78, 24–34. [Google Scholar] [CrossRef]

- Avilov, V.V.; Gumenyuk, A.; Lammers, M.; Rethmeier, M. PA position full penetration high power laser beam welding of up to 30 mm thick AlMg3 plates using electromagnetic weld pool support. Sci. Technol. Weld. Join. 2012, 17, 128–133. [Google Scholar] [CrossRef]

- Kawahito, Y.; Mizutani, M.; Katayama, S. High quality welding of stainless steel with 10 kW high power fibre laser. Sci. Technol. Weld. Join. 2009, 14, 288–294. [Google Scholar] [CrossRef]

- Zhang, X.; Ashida, E.; Katayama, S.; Mizutani, M. Deep penetration welding of thick section steels with 10 kW fiber laser. Q. J. Jpn. Weld. Soc. 2009, 27, 64–68. [Google Scholar] [CrossRef]

- Reisgen, U.; Olschok, S.; Longerich, S. Laser beam welding in vacuum—A comparison with electron beam welding. Weld. Cut. 2010, 9, 224–230. [Google Scholar]

- Reisgen, U.; Olschok, S.; Jakobs, S. Laser beam welding in vacuum of thick plate structural steel. In Proceedings of the 32th ICALEO, Orlando, FL, USA, 6–10 October 2013; pp. 341–360. [Google Scholar]

- Reisgen, U.; Olschok, S.; Jakobs, S.; Turner, C. Laser beam welding under vacuum of high grade materials. Weld. World 2016, 60, 1–11. [Google Scholar] [CrossRef]

- Reisgen, U.; Olschok, S.; Jakobs, S.; Turner, C. Sound Welding of Copper: Laser Beam Welding in Vacuum. Phys. Procedia 2016, 83, 447–454. [Google Scholar] [CrossRef]

- Börner, C.; Dilger, K.; Rominger, V.; Harrer, T.; Krüssel, T.; Löwer, T. Influence of ambient pressure on spattering and weld seam quality in laser beam welding with the solid-state laser. In Proceedings of the 30th ICALEO, Orlando, FL, USA, 23–27 October 2011; pp. 23–27. [Google Scholar]

- Börner, C.; Krussel, T.; Dilger, K. Process characteristics of laser beam welding at reduced ambient pressure. In Proceedings of the SPIE LASE, San Francisco, CA, USA, 2–7 February 2013; p. 86030M. [Google Scholar]

- Cai, C.; Peng, G.C.; Li, L.Q.; Chen, Y.B.; Qiao, L. Comparative study on laser welding characteristics of aluminium alloy under atmospheric and subatmospheric pressures. Sci. Technol. Weld. Join. 2014, 19, 547–553. [Google Scholar] [CrossRef]

- Jiang, M.; Tao, W.; Wang, S.; Li, L.; Chen, Y. Effect of ambient pressure on interaction between laser radiation and plasma plume in fiber laser welding. Vacuum 2017, 138, 70–79. [Google Scholar] [CrossRef]

- Sokolov, M.; Salminen, A.; Katayama, S.; Kawahito, Y. Reduced Pressure Laser Welding of Thick Section Structural Steel. J. Mater. Process. Technol. 2015, 219, 278–285. [Google Scholar] [CrossRef]

- Luo, Y.; Tang, X.; Lu, F.; Chen, Q. Effect of subatmospheric pressure on plasma plume in fiber laser welding. J. Mater. Process. Technol. 2015, 215, 219–224. [Google Scholar] [CrossRef]

- Luo, Y.; Tang, X.; Deng, S.; Lu, F.; Chen, Q.; Cui, H. Dynamic coupling between molten pool and metallic vapor ejection for fiber laser welding under subatmospheric pressure. J. Mater. Process. Technol. 2016, 229, 431–438. [Google Scholar] [CrossRef]

- Engelhardt, T.; Heider, A.; Weber, R.; Graf, T. Time-resolved X-ray analysis of the keyhole behavior during laser welding of steel and aluminum at reduced ambient pressure. In Proceedings of the 34th ICALEO, Atlanta, GA, USA, 18–22 October 2015; pp. 250–256. [Google Scholar]

- Elmer, J.W.; Vaja, J.; Carlton, H.D. The effect of reduced pressure on laser keyhole weld porosity and weld geometry in commercially pure titanium and nickel. Weld. J. 2016, 95, 419S–430S. [Google Scholar]

- Heinrici, A.; Bjelajac, G.; Jonkers, J.; Jakobs, S.; Olscho, S.; Reisgen, U. Vacuum fiber-fiber coupler. In Proceedings of the SPIE LASE, San Francisco, CA, USA, 28 January–2 February 2017; p. 100970F. [Google Scholar]

- Katayama, S.; Ido, R.; Nishimoto, K.; Mizutani, M.; Kawahito, Y. Full penetration welding of thick high tensile strength steel plate with high power disk laser in low vacuum. Q. J. Jpn. Weld. Soc. 2015, 33, 262–270. [Google Scholar] [CrossRef]

- Youhei, A.; Yousuke, K.; Hiroshi, N.; Koji, N.; Masami, M.; Seiji, K. Effect of reduced pressure atmosphere on weld geometry in partial penetration laser welding of stainless steel and aluminium alloy with high power and high brightness laser. Sci. Technol. Weld. Join. 2014, 19, 324–332. [Google Scholar] [CrossRef]

- Focus. Available online: http://www.focus-e-welding.de/Laser-Beam.html (accessed on 10 April 2017).

- Welding and Joining Institute. Available online: http://www.isf.rwth-aachen.de/cms/isf/Forschung/Forschungsbereiche/Strahlschweissen/~ldah/LaserstLaserstrahlsch-unter-Vakuum/lidx/1/ (accessed on 10 April 2017).

- Ptr-ebeam. Available online: http://www.ptr-ebeam.com/en/ptr-machines/2016-04-15-06-51-39/lasvac-pl-01.html (accessed on 10 April 2017).

- Jakobs, S.; Reisgen, U. Laser Beam Welding under reduced pressure—Range of possible applications for thick-plates. Stahlbau 2015, 84, 635–642. [Google Scholar] [CrossRef]

- Abe, Y.; Mizutani, M.; Kawahito, Y.; Katayama, S. Deep penetration welding with high power laser under vacuum. Trans. JWRI 2011, 103, 15–19. [Google Scholar]

- Reisgen, U.; Olschok, S.; Turner, C. Welding of thick plate copper with laser beam welding under vacuum. J. Laser Appl. 2017, 29, 022402. [Google Scholar] [CrossRef]

- Kim, K.R.; Farson, D.F. CO2 laser—Plume interaction in materials processing. J. Appl. Phys. 2001, 89, 681–688. [Google Scholar] [CrossRef]

- Beck, M.; Berger, P.; Hugel, H. The effect of plasma formation on beam focusing in deep penetration welding with CO2 lasers. J. Phys. D Appl. Phys. 1995, 28, 2430. [Google Scholar] [CrossRef]

- Shcheglov, P. Study of Vapour-Plasma Plume during High Power Fiber Laser Beam Influence on Metals; Bundesanstalt für Materialforschung und-Prüfung (BAM): Berlin, Germany, 2012.

- Kawahito, Y.; Kinoshita, K.; Matsumoto, N.; Mizutani, M.; Katayama, S. Effect of weakly ionised plasma on penetration of stainless steel weld produced with ultra high power density fibre laser. Sci. Technol. Weld. Join. 2008, 13, 749–753. [Google Scholar] [CrossRef]

- Kawahito, Y.; Kinoshita, K.; Matsumoto, N.; Katayama, S. Visualization of refraction and attenuation of near-infrared laser beam due to laser-induced plume. J. Laser Appl. 2009, 21, 96–101. [Google Scholar] [CrossRef]

- Shcheglov, P.Y.; Uspenskiy, S.A.; Gumenyuk, A.V.; Petrovskiy, V.N.; Rethmeier, M.; Yermachenko, V.M. Plume attenuation of laser radiation during high power fiber laser welding. Laser Phys. Lett. 2011, 8, 475–480. [Google Scholar] [CrossRef]

- Pang, S.; Hirano, K.; Fabbro, R.; Jiang, T. Explanation of penetration depth variation during laser welding under variable ambient pressure. J. Laser Appl. 2015, 27, 022007. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Zhou, J.; Shao, X.; Wang, C. 3D transient multiphase model for keyhole, vapor plume, and weld pool dynamics in laser welding including the ambient pressure effect. Opt. Laser Eng. 2015, 74, 47–58. [Google Scholar] [CrossRef]

- Reisgen, U.; Olschok, S.; Jakobs, S.; Mücke, M. Welding with the laser beam in vacuum. Laser Tech. J. 2015, 12, 42–46. [Google Scholar] [CrossRef]

- Welding and Joining Institute. Available online: http://www.isf.rwth-aachen.de/ (accessed on 10 April 2017).

- Pro-beam. Available online: http://www.pro-beam.com/en/capabilities/fabrication/laser-systems/?no_cache=1&sword_list%5B0%5D=vacuum (accessed on 10 April 2017).

- Laser Community. Available online: http://www.laser-community.com/en/low-pressure-solid-state-laser-welding-for-power-train-by-pro-beam-trumpf-ifs/ (accessed on 10 April 2017).

- Weglowski, M.S.; Blacha, S.; Phillips, A. Electron beam welding—Techniques and trends—Review. Vacuum 2016, 130, 72–92. [Google Scholar] [CrossRef]

- Letyagin, I.Y.; Trushnikov, D.N.; Belenkiy, V.Y. Benefits and Prospects of Laser Welding Application in Vacuum. KnE Mater. Sci. 2016, 1, 90–94. [Google Scholar] [CrossRef]

- Lawler, S.; Clark, D.; Punshon, C.; Bagshaw, N.; Disney, C.; Powers, J. Local vacuum electron beam welding for pressure vessel applications. Ironmak. Steelmak. 2015, 42, 722–726. [Google Scholar] [CrossRef]

- Schneider, A.; Gumenyuk, A.; Rethmeier, M. Mobile vacuum in pocket format. Laser Tech. J. 2015, 12, 43–46. [Google Scholar] [CrossRef]

- Schneider, A.; Gumenyuk, A.; Rethmeier, M. Mobile vacuum device for laser beam welding of thick materials. In Proceedings of the 3rd International Conference in Africa and Asia Welding and Failure Analysis of Engineering Materials, Luxor, Egypt, 2–5 November 2015. [Google Scholar]

- Reisgen, U.; Olschok, S.; Holtum, N.; Jakobs, S. Laser beam welding in mobile vacuum. In Proceedings of the Lasers in Manufacturing (LIM 2017), Munich, Germany, 26–29 January 2017. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).