Experimental Evaluation of Thermal Performance and Durability of Thermally-Enhanced Concretes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Methods

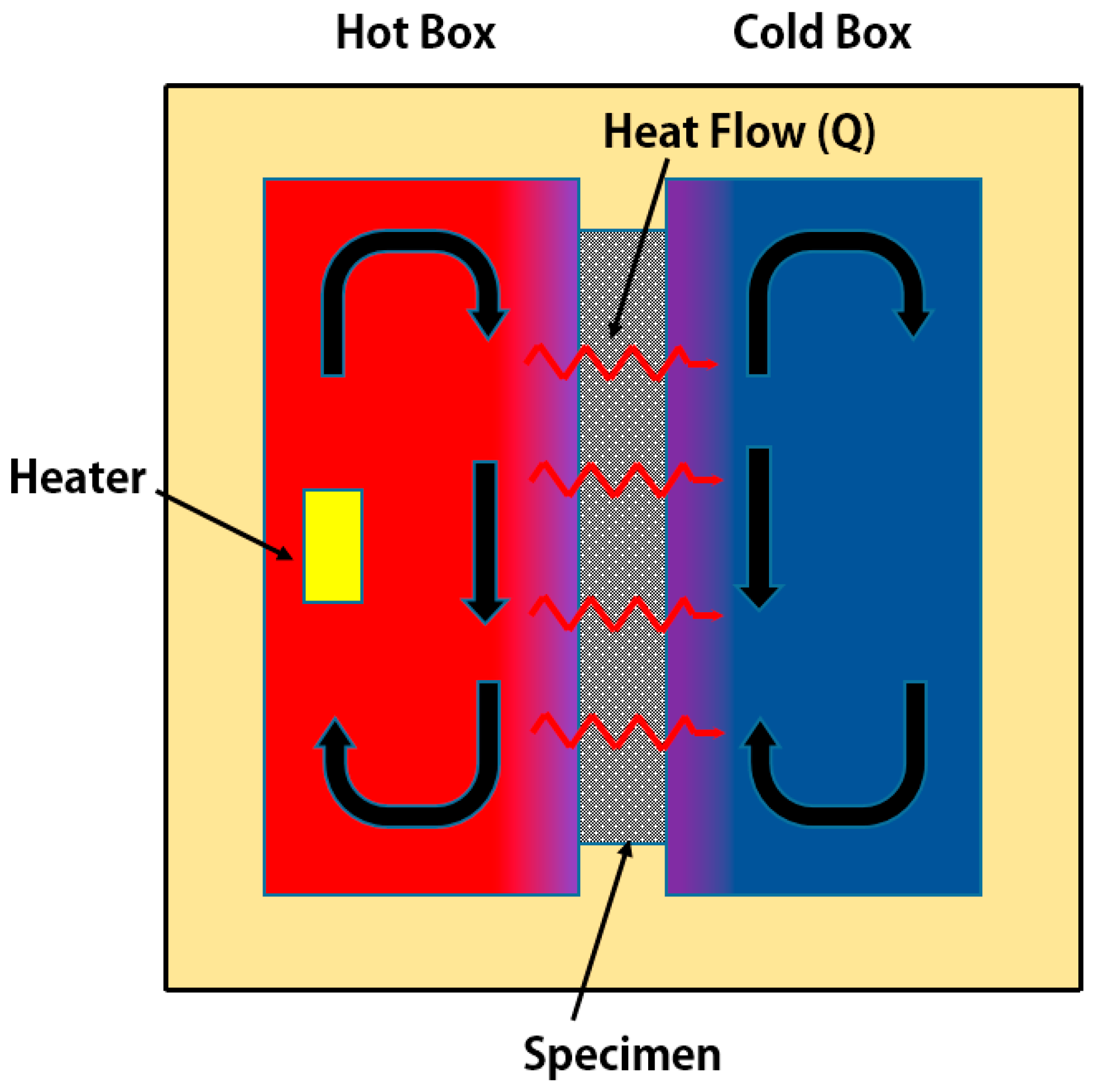

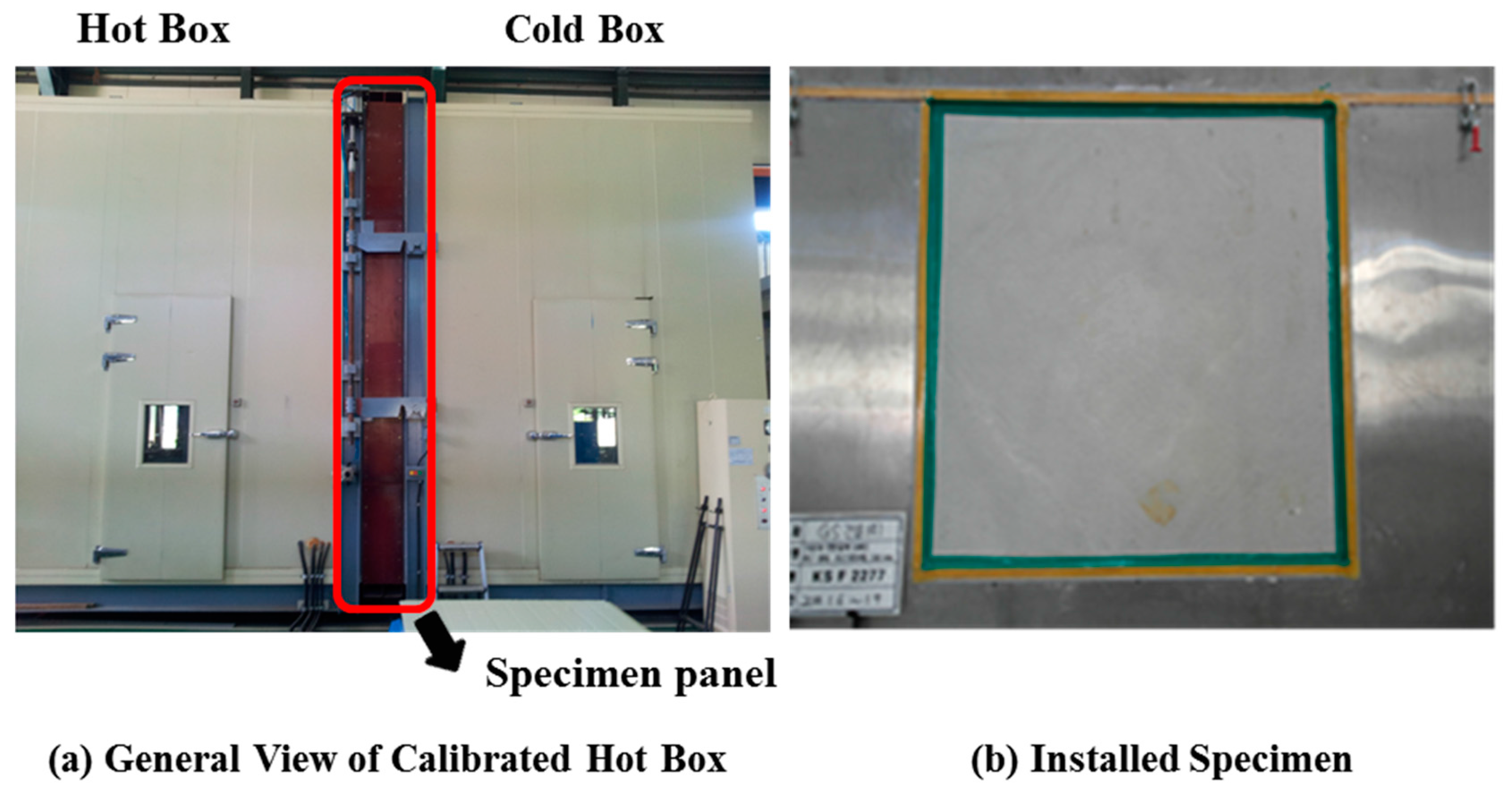

2.2.1. Thermal Properties

2.2.2. Durability Performance

3. Results and Discussion

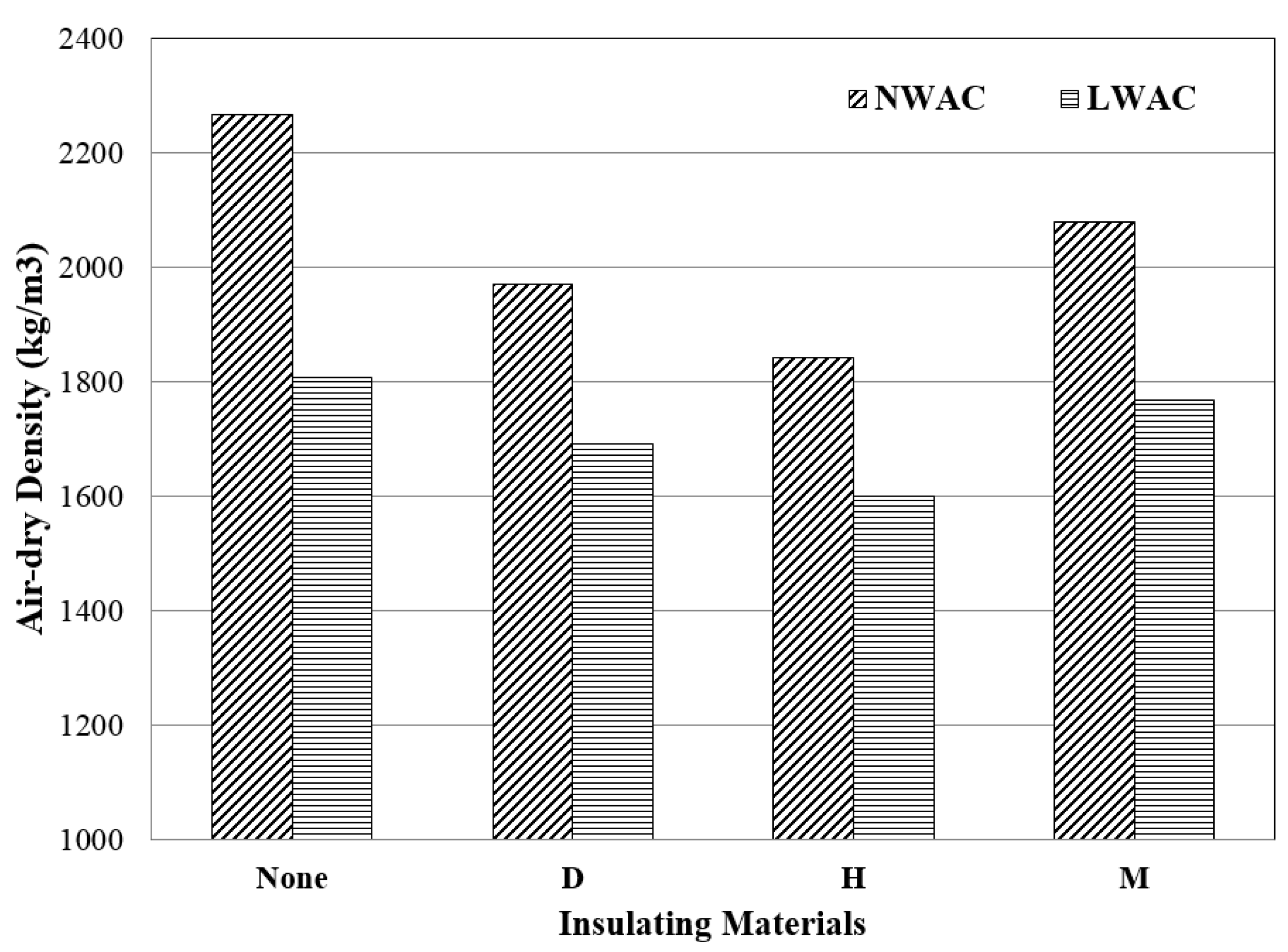

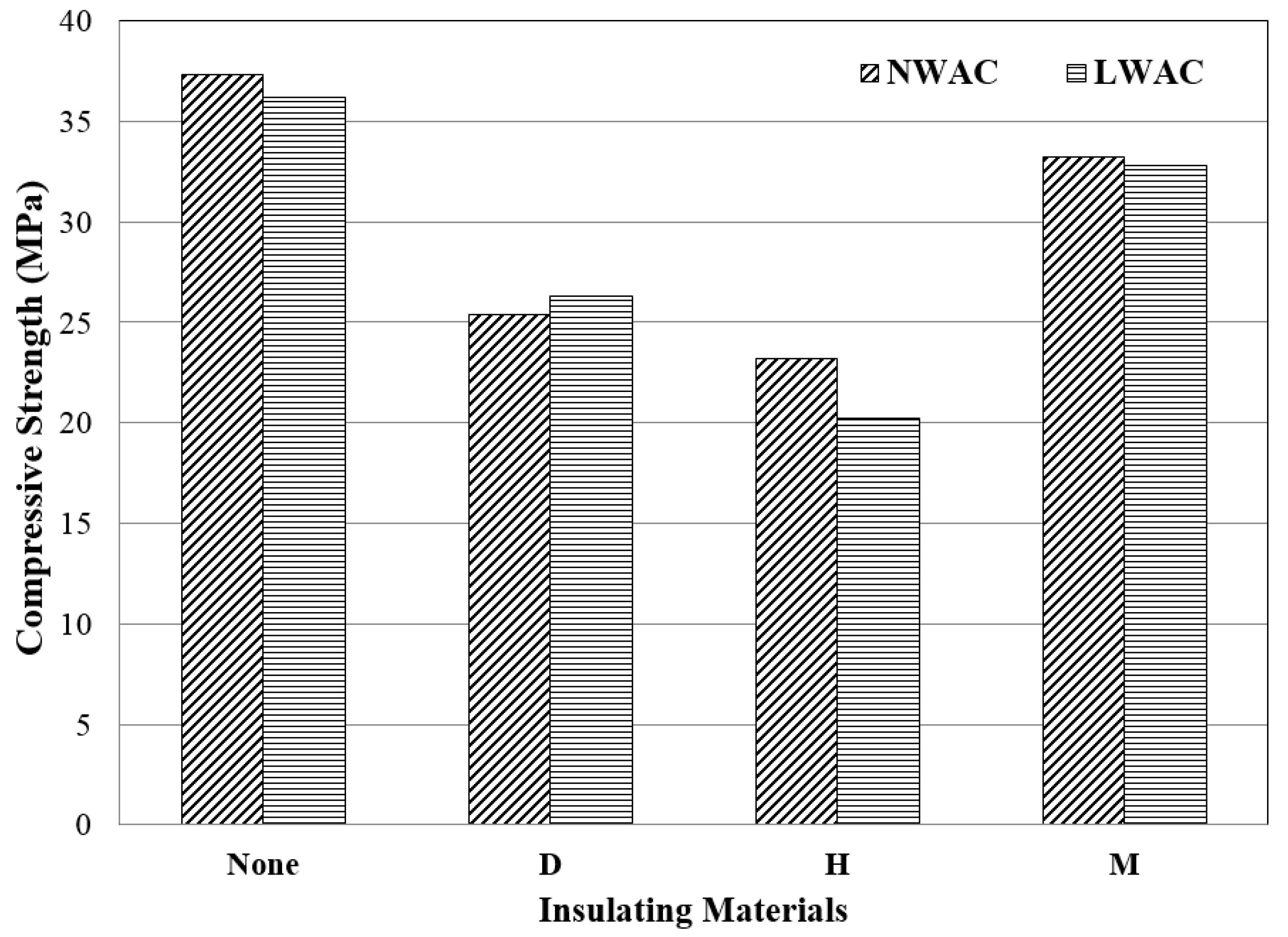

3.1. Physical Properties

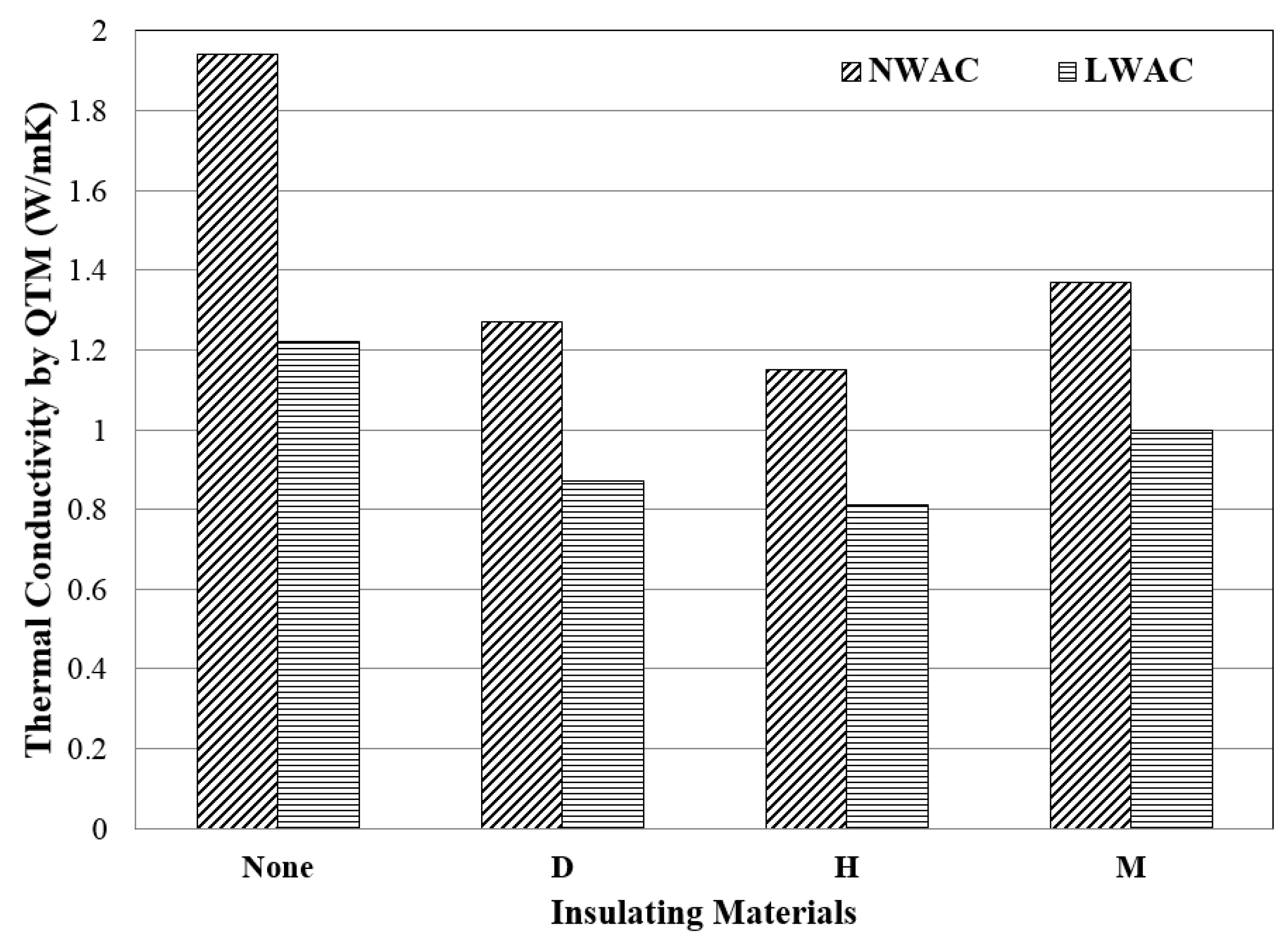

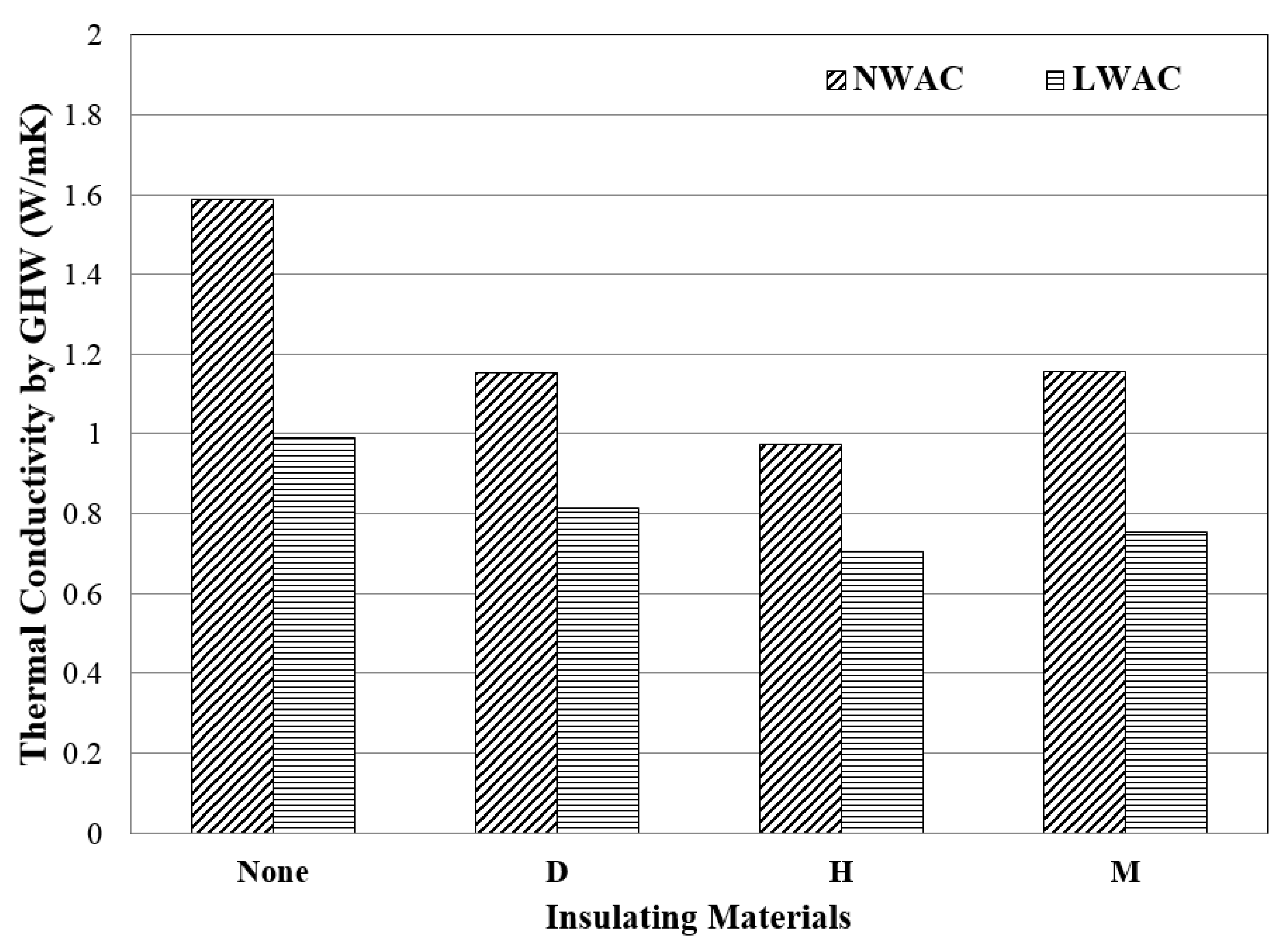

3.2. Thermal Conductivity

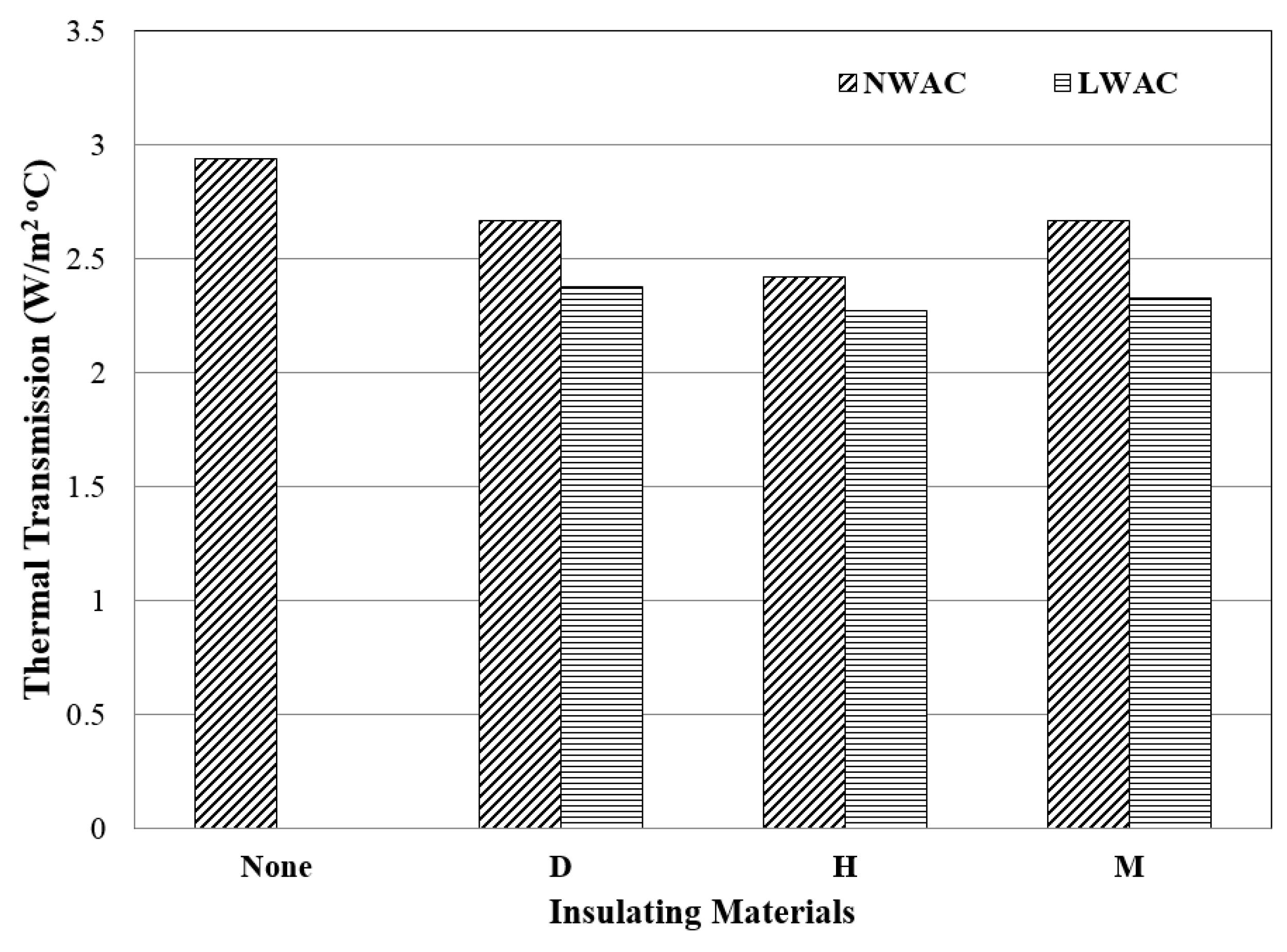

3.3. Thermal Transmission

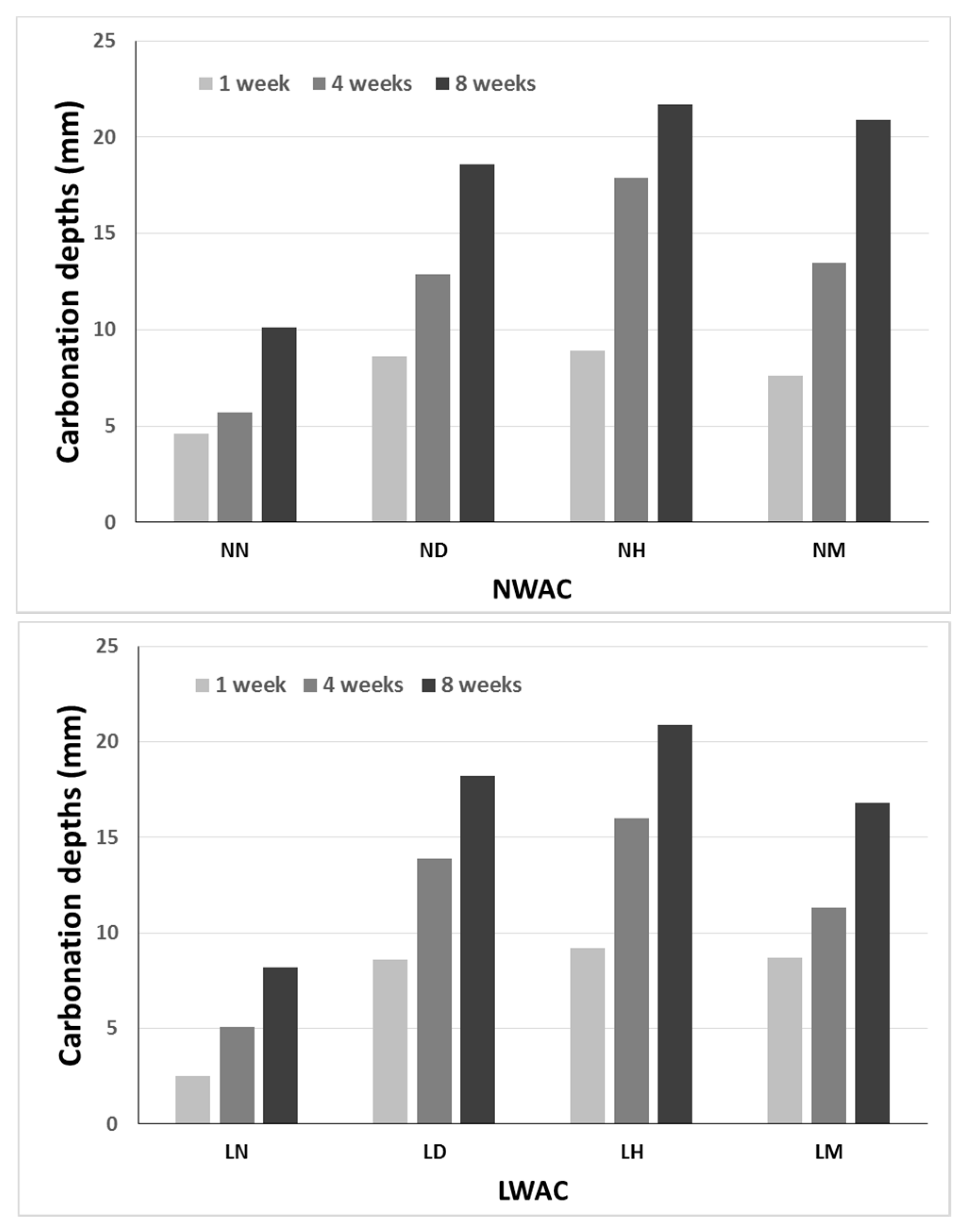

3.4. Resistance to Carbonation

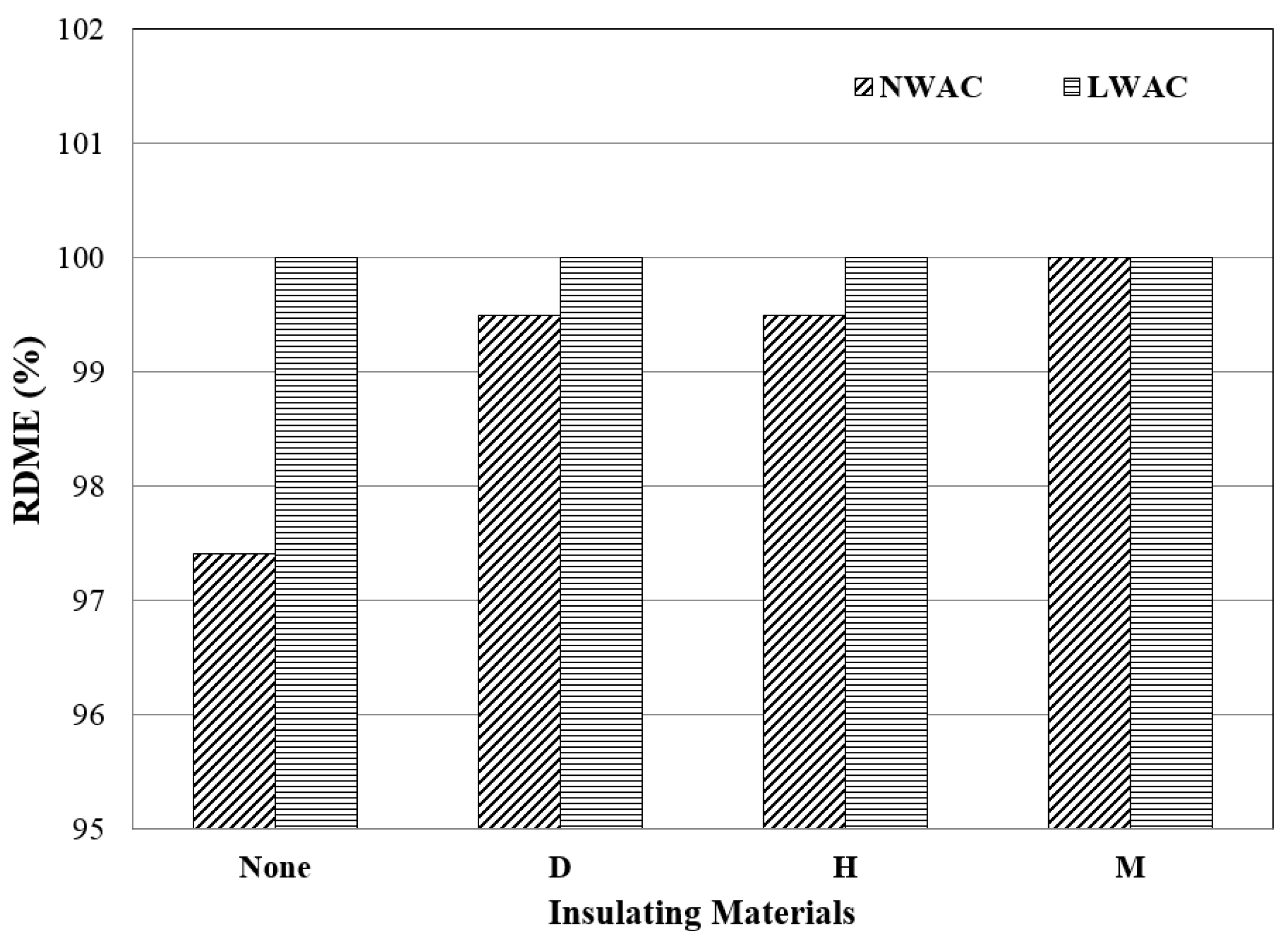

3.5. Resistance to Freeze-Thaw Cycles

4. Conclusions

- (1)

- The effect of diatomite powder, hollow micro-spheres, and a micro-foam agent on thermal insulation and durability of concrete was proved. Diatomite powder failed to increase the strength due to its poor pozzolanic reaction than expected. In the case of the micro-foam agent, a higher cement content and a lower water-to-cement ratio should be applied to compensate for the strength.

- (2)

- For both normalweight aggregate concrete (NWAC) and lightweight aggregate concrete (LWAC), the concretes with the thermal insulating materials showed superior thermal insulation. The thermal conductivity measured from GHW was somewhat lower than that from QTM due to oven-drying the pore water and an increase in vacant pores.

- (3)

- The experimental results of compressive strength at 28 days and air-dry density show the close relationship with thermal conductivity and thermal transmission.

- (4)

- The reduction ratios of thermal transmission for all specimens were not large compared with the thermal conductivity from QTM and GHW. This is because CHB was related to the convection by the movement of heat flow or continuous circulation while, for QTM and GHW, the conduction was via directly physical contact.

- (5)

- Durability performance on carbonation and freeze-thaw attacks were experimentally examined. Firstly, carbonation rates of thermally-enhanced concretes using various insulation materials were higher than normal concretes regardless of aggregate types and mixtures due to the increased permeability and higher pores. Thus, additional methods to protect the concrete from carbonation, such as an increase in cover depth, is needed for thermally-enhanced concretes with various insulation materials.

- (6)

- Secondly, the addition of air-entraining agent and increased pores had a good influence on the resistance to freeze-thaw attack. This is because the test specimens had enough voids to absorb the volume expansion due to the freezing of the pore water.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Korean Government. Intended Nationally Determined Contribution for 2030; Korean Government: Seoul, Korea, 2015.

- British Petroleum. Statistical Review of World Energy; British Petroleum: London, UK, 2015. [Google Scholar]

- Korea Energy Agency. The Annual Energy Consumption in 2014; Korea Energy Agency: Yongin, Korea, 2015. [Google Scholar]

- Sørensen, L.S. Heat Transmission Coefficient Measurements in Buildings Utilizing a heat Loss measuring Device. Sustainability 2013, 5, 3601–3614. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Yun, T.S.; Jeong, Y.J.; Han, T.S.; Youm, K.S. Evaluation of thermal conductivity for thermally insulated concretes. Energy Build. 2013, 61, 125–132. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Alani, A.; MacMullen, J.; Telik, O.; Zhang, Z.Y. Investigation into the thermal performance of recycled glass screed for construction purposes. Constr. Build. Mater. 2012, 29, 527–532. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef]

- Meshgin, P.; Xi, Y. Multi-scale composite models for the effective thermal conductivity of PCM-concrete. Constr. Build. Mater. 2013, 48, 371–378. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Gustavsen, A.; Jacobsen, S. Aerogel-incorporated concrete: An experimental study. Constr. Build. Mater. 2014, 52, 130–136. [Google Scholar] [CrossRef]

- Degirmenci, N.; Yilmaz, A. Use of diatomite as partial replacement for Portland cement in cement mortars. Constr. Build. Mater. 2009, 23, 284–288. [Google Scholar] [CrossRef]

- Chung, S.Y.; Elrahman, M.A.; Stephan, D. Effect of Different Gradings of Lightweight Aggregate on the Porperties of Concrete. Appl. Sci. 2017, 7, 585. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM C177: Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus, Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- American Society for Testing and Materials. ASTM C1113: Standard Test Method for Thermal Conductivity of Refractories by Hot Wire (Platinum Resistance Thermometer Technique), Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- American Society for Testing and Materials. ASTM D5334: Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- American Society for Testing and Materials. ASTM C1363: Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus, Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- European Standard. EN ISO 8990, Thermal Insulation—Determination of Steady-State Thermal Transmission Properties—Calibrated and Guarded Hot Box; International Organization for Standardization (ISO): Geneva, Switzerland, 1994. [Google Scholar]

- Karthick, S.P.; Muralidharan, S.; Saraswathy, V.; Kwon, S.-J. Effect of different alkali salt additions on concrete durability property. J. Struct. Integr. Maint. 2016, 1, 35–42. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-High Performance Concrete: Mechanical Performance, Durability, Sustainability and Implementation Challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Ergün, A. Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 318-11 Building Code Requirements, Structural Concrete and Commentary; ACI Committee 318: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Yun, T.S.; Jeong, Y.J.; Youm, K.S. Effect of surrogate aggregates on the thermal conductivity of concrete at ambient and elevated temperatures. Sci. World J. 2014, 2014, 939632. [Google Scholar] [CrossRef] [PubMed]

- Pepe, M.; Filho, R.D.T.; Koenders, E.A.B.; Martinelli, E. A novel mix design methodology for recycled aggregate concrete. Constr. Build. Mater. 2016, 122, 363–372. [Google Scholar] [CrossRef]

- Nevile, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: Edinburgh, UK, 2011. [Google Scholar]

- Hens, H. Building Physics—Heat, Air and Moisture; Ernst & Sohn: Berlin, Germany, 2007. [Google Scholar]

- Asdrubali, F.; Baldinelli, G. Thermal transmission measurements with the hot box method: Calibration, experimental procedures, and uncertainty analyses of three different approaches. Energy Build. 2011, 43, 1618–1626. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Skalny, J. Chemical Resistance of Concrete, STP 169D Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM International: West Conshohocken, PA, USA, 2006; pp. 253–273. [Google Scholar]

- Chávez-Ulloa, E.; Camacho-Chab, R.; Sosa-Baz, M.; Castro-Borges, P.; Pérez-López, T. Corrosion Process of Reinforced Concrete by Carbonation in a Natural Environment and an Accelerated Test Chamber. Int. J. Electrochem. Sci. 2013, 8, 9015–9029. [Google Scholar]

- Dunster, A.M. Accelerated Carbonation Testing of Concrete; Building Research Establishment Ltd.: Watford, UK, 2000. [Google Scholar]

- British Standards. BS EN 13295:2004, Products and Systems for the Protection and Repair of Concrete Structures —Test Methods—Determination of Resistance to Carbonation; BSI: London, UK, 2004. [Google Scholar]

- RILEM Committee. CPC-18 Measurement for Hardened Concrete Carbonated Depth. Mater. Struct. 1998, 21, 453–455. [Google Scholar]

- Nmai, C.K. Freezing and Thawing, STP 169D Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM International: West Conshohocken, PA, USA, 2006; pp. 154–163. [Google Scholar]

- American Society for Testing and Materials. ASTM C666: Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing, Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Chen, B.; Liu, N. A novel lightweight concrete-fabrication and its thermal and mechanical properties. Constr. Build. Mater. 2013, 44, 691–698. [Google Scholar] [CrossRef]

- Youm, K.S.; Moon, J.H.; Cho, J.Y.; Kim, J.J. Experiment study on strength and durability of lightweight aggregate concrete containing silica fume. Constr. Build. Mater. 2016, 144, 517–527. [Google Scholar] [CrossRef]

- Chandar, S.; Bentsson, L. Lightweight Aggregate Concrete; Noyes Publications: Norwich, NY, USA, 2003. [Google Scholar]

| Density (g/cm3) | pH | Viscosity (cPs) | Solid Content (%) | Color |

|---|---|---|---|---|

| 2.15 | 6.97 | 80 | 15.6 | White Translucent |

| Materials | Density (g/cm3) | Absorption (%) | No. 140 * (% Retained) | Color | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

| diatomite powder | 1.1 | 0.5 | 0.5 | Light red | 0.014 |

| Hollow micro-sphere | 0.125 | 0.0 | - | white | 0.044 |

| Items | Type of Aggregates | ||

|---|---|---|---|

| Normalweight Fine | Normalweight Coarse | Lightweight Coarse | |

| Source | Cleaned sea-sand | Crushed stone | Slate |

| Fineness modulus | 2.83 | 6.84 | - |

| Dry bulk density (kg/m3) | 1480 | 1680 | 800 |

| Specific gravity | 2.60 | 2.61 | 1.46 |

| Gmax * (mm) | - | 25.4 | 12.5 |

| Thermal conductivity (W/m·K) | 3.5 | 2.75 | 0.106 |

| Label | Description | Volume Replacement Ratio of Coarse Aggregate (%) | Remark |

|---|---|---|---|

| NN | Reference for NWAC 1 | - | None |

| LN | Reference for LWAC 2 | - | None |

| D | Diatomite powder | 15 | |

| H | Hollow micro-sphere | 40 | |

| M | Micro-foam agent | - | Chemical additive |

| Coarse Aggregate Type | Labels | W/C (%) | Ingredients * (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| W | C | H | D | S | G | M ** | |||

| Normal (N) | NN | 55.0 | 215 | 390 | - | - | 887 | 852 | - |

| ND | 55.0 | 215 | 391 | - | 61 | 887 | 715 | - | |

| NH | 55.0 | 215 | 391 | 9 | - | 813 | 679 | - | |

| NM | 30.0 | 144 | 479 | - | - | 753 | 1059 | 19.2 | |

| Light (L) | LN | 55.0 | 215 | 390 | - | - | 802 | 543 | - |

| LD | 55.0 | 215 | 391 | - | 61 | 802 | 393 | - | |

| LH | 55.0 | 215 | 391 | 9 | - | 813 | 366 | - | |

| LM | 30.0 | 144 | 479 | - | - | 753 | 575 | 19.2 | |

| Coarse Aggregate Type | Labels | Insulation Materials | Air Content (%) | Air-Dry Density (kg/m3) | Compressive Strength (MPa) | ||

|---|---|---|---|---|---|---|---|

| 3 Days | 7 Days | 28 Days | |||||

| Normal (N) | NN | None | 4.3 | 2267 | 24.9 | 32.0 | 37.3 |

| ND | Diatomite | 7.6 | 1971 | 12.4 | 16.9 | 25.4 | |

| NH | Hollow micro-sphere | 6.2 | 1843 | 13.5 | 16.1 | 23.2 | |

| NM | Micro-form agent | 10.0 | 2080 | 20.5 | 29.0 | 33.2 | |

| Light (L) | LN | None | 5.2 | 1806 | 23.7 | 29.1 | 36.2 |

| LD | Diatomite | 7.4 | 1691 | 13.6 | 18.0 | 26.3 | |

| LH | Hollow micro-sphere | 4.9 | 1599 | 10.1 | 13.4 | 20.2 | |

| LM | Micro-form agent | 10.0 | 1769 | 21.1 | 27.9 | 32.8 | |

| Coarse Aggregate Type | Labels | Insulation Materials | QTM (W/m·K) | GHW (W/m·K) | CHB (W/m2·°C) |

|---|---|---|---|---|---|

| Normal (N) | NN | None | 1.94 | 1.5876 | 2.94 |

| ND | Diatomite | 1.15 | 1.2745 | 2.67 | |

| NH | Hollow micro-sphere | 1.15 | 0.9742 | 2.42 | |

| NM | Micro-form agent | 1.37 | 1.1581 | 2.67 | |

| Light (L) | LN | None | 1.22 | 0.9894 | - |

| LD | Diatomite | 0.87 | 0.8148 | 2.38 | |

| LH | Hollow micro-sphere | 0.81 | 0.7033 | 2.27 | |

| LM | Micro-form agent | 1.00 | 0.7533 | 2.33 |

| Coarse Aggregate Type | Labels | Insulation Materials | Average Carbonation Depth (mm) | ||

|---|---|---|---|---|---|

| 7 Days | 28 Days | 56 Days | |||

| Normal (N) | NN | None | 4.6 | 5.7 | 10.1 |

| ND | Diatomite | 8.6 | 12.9 | 18.6 | |

| NH | Hollow micro-sphere | 8.9 | 17.9 | 21.7 | |

| NM | Micro-form agent | 7.6 | 13.5 | 20.9 | |

| Light (L) | LM | None | 2.5 | 5.1 | 8.2 |

| LD | Diatomite | 8.6 | 13.9 | 18.2 | |

| LH | Hollow micro-sphere | 9.2 | 16.0 | 20.9 | |

| LM | Micro-form agent | 8.7 | 11.3 | 16.8 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, Y.-W.; Koh, T.-H.; Youm, K.-S.; Moon, J. Experimental Evaluation of Thermal Performance and Durability of Thermally-Enhanced Concretes. Appl. Sci. 2017, 7, 811. https://doi.org/10.3390/app7080811

Jeong Y-W, Koh T-H, Youm K-S, Moon J. Experimental Evaluation of Thermal Performance and Durability of Thermally-Enhanced Concretes. Applied Sciences. 2017; 7(8):811. https://doi.org/10.3390/app7080811

Chicago/Turabian StyleJeong, Yong-Wook, Tae-Hoon Koh, Kwang-Soo Youm, and Jiho Moon. 2017. "Experimental Evaluation of Thermal Performance and Durability of Thermally-Enhanced Concretes" Applied Sciences 7, no. 8: 811. https://doi.org/10.3390/app7080811

APA StyleJeong, Y.-W., Koh, T.-H., Youm, K.-S., & Moon, J. (2017). Experimental Evaluation of Thermal Performance and Durability of Thermally-Enhanced Concretes. Applied Sciences, 7(8), 811. https://doi.org/10.3390/app7080811