3.1. Macroscopic Properties of Rejuvenating Agents on Aged Modified Asphalt

It is well known that the stiffness of modified asphalt will increase after aging, resulting in attenuation of the low-temperature property and improvement for the high-temperature property. Consequently, modified asphalt recycling should focus on the recovery of low-temperature properties.

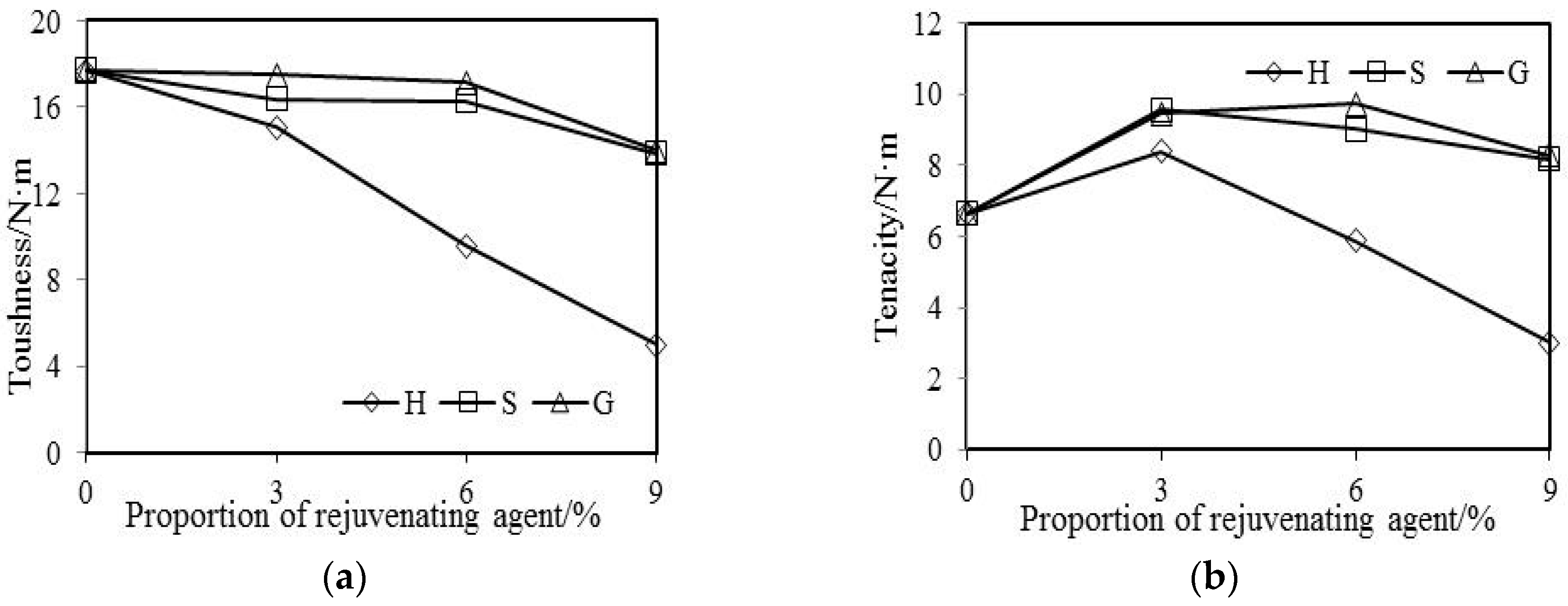

Table 6 and

Figure 3 and

Figure 4 show the results of different types of rejuvenating agents on aged modified asphalt.

Table 6 shows that: with the increasing of rejuvenating agent proportion, softening point and viscosity decrease, while penetration and ductility increase. When the proportion of H, S, G is 9%, the ductility of modified asphalt blends increases from brittle fracture to 39.3 cm, 29.6 cm and 35.7 cm respectively, which indicates that the rejuvenating agent can recover the low-temperature property of modified asphalt. Satisfactory results can be achieved which indirectly prove the sufficient feasibility of modified asphalt recycling.

From

Figure 3, the toughness decreases continuously as the rejuvenating agent proportion increases, and the trend of tenacity is different. When the proportion of rejuvenating agent is small, the tenacity increases at first, and then decreases when the proportion increases continuously, probably because the rejuvenating agent is beneficial to the improvement of swelling effect between polymer SBS and asphalt. Moreover, it can partially improve the mechanical properties of modified asphalt. The tenacity increase can also indirectly prove the feasibility of modified asphalt recycling. When the proportion of rejuvenating agent increases further, the tenacity of modified asphalt blends begins to decrease due to reduced viscosity.

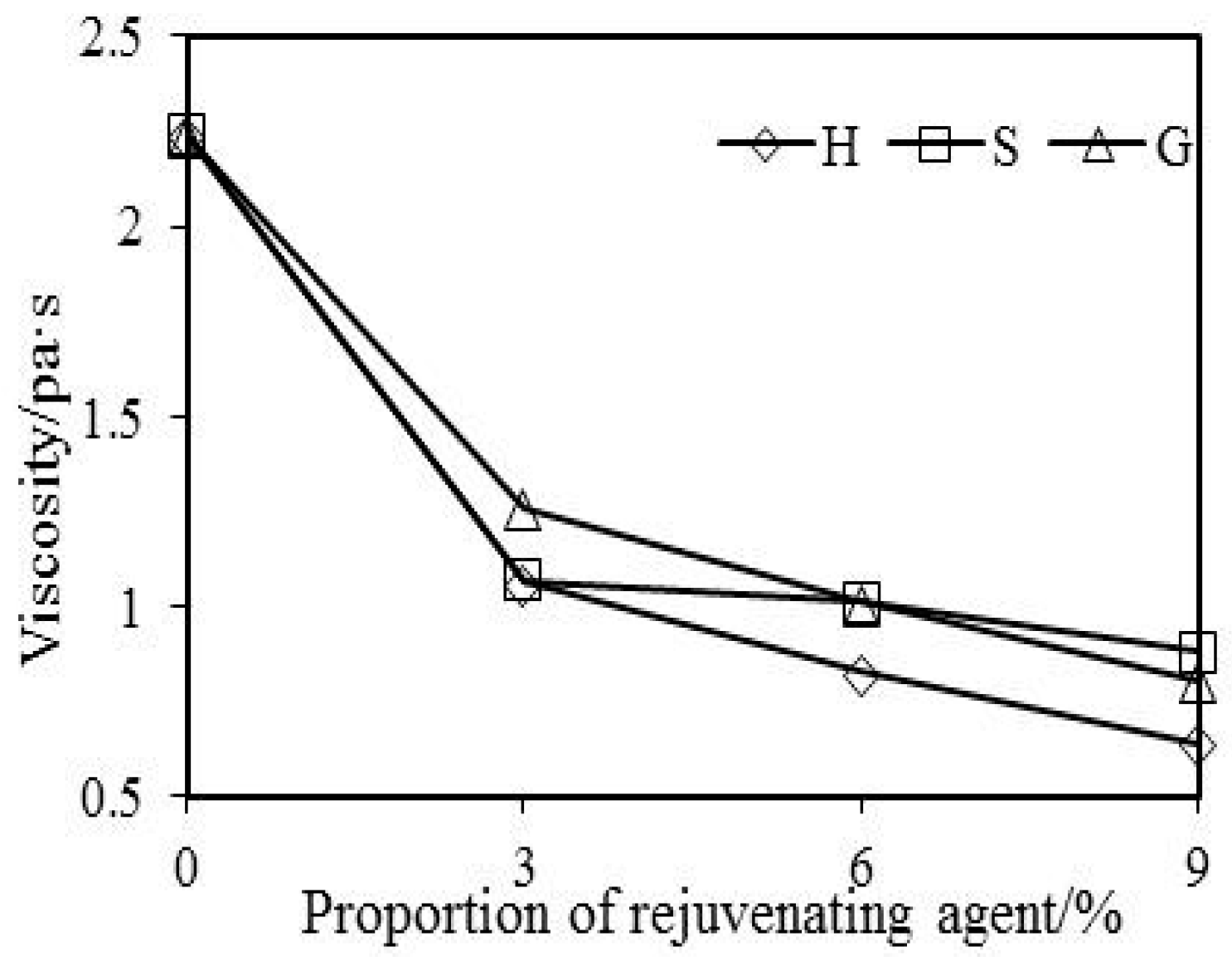

Figure 4 indicates that the penetration of modified asphalt blends increases with the decreasing of viscosity, but the trend is not linear. When the viscosity of modified asphalt blends is more than 1.1 Pa·s, the change of penetration along with the viscosity is not obvious. However, the penetration increases noticeably with the decreasing of viscosity, roughly showing linear relationship when the viscosity of modified asphalt blends is less than 1.1 Pa·s. This phenomenon indicates that the viscosity must be less than a certain value for the change of penetration to be obvious, and this result is similar to the conclusion of reference [

29].

In conclusion, the rejuvenating agent can partially or completely recycle the properties of aged modified asphalt. Increasing the proportion of rejuvenating agent can better improve the low-temperature ductility. However, the correlation of penetration, ductility and softening point indicates that increasing the proportion of rejuvenating agent to improve ductility will lead to a sharp increase of penetration and a decrease of softening point. For example, when the proportion of H is 6%, the penetration of modified asphalt blend is 85 (0.1 mm). However, the ductility is still relatively small. The results indicate that the recycling of penetration and ductility is not synchronous and it is not appropriate to use the penetration and ductility to carry on the design of modified asphalt recycling at the same time.

3.2. Anti-Aging Property of Modified Asphalt Blends

To examine the anti-aging property of modified asphalt blends, the thin film oven test (TFOT) was conducted. According to the recycling effect and economy of the above-mentioned three rejuvenating agents H, S, G, the proportion of rejuvenating agent for TFOT were set to 3%, 6%, 6% respectively. The test results are shown in

Table 7.

Table 7 shows that the penetration ratio and weight change of modified asphalt blends after TFOT meet the requirements of China’s specifications, except in terms of ductility. The results indicate that, although the properties of aged modified asphalt blended with rejuvenating agent can be recycled, the low-temperature property often cannot meet the requirements after aging, indicating that the modifier has lost part of the original modified effect.

Therefore, modified asphalt recycling should focus on its low-temperature property, requiring rejuvenating agent not only to effectively recover the colloidal structure of aged modified asphalt, but also to repair and supplement the aged modifier. Ultimately, the objective is to recover both the low-temperature cracking resistance and high-temperature rutting resistance of modified asphalt.

3.3. Phase Characteristics of Rejuvenating Agents on Aged Modified Asphalt

Polymer SBS in asphalt absorbs light oil to form the polymer phase. Under the fluorescence excitation, the polymer phase reflects longer wavelength light, appearing white. In contrast, the asphalt phase does not reflect any light, appearing black. So the asphalt phase and polymer phase are clearly distinguished by fluorescence microscope. As the reflected light field is applied, there is no damage to the polymer phase distribution in the asphalt. Hence, the fluorescence microscope gets highly reproducible asphalt micrographs. By analyzing the morphological structure and dispersion state of polymer SBS in asphalt, it is possible to effectively evaluate the role of rejuvenating agent on the aged modified asphalt, and establish the relationship between macroscopic mechanical properties and microscopic characteristics of modified asphalt blends.

To ensure the reliability of fluorescence images and avoid the particularity of individual samples, three slides were made in parallel for each sample. Four representative fluorescence images were taken for each slide.

Table 8 shows the fluorescent micrographs of aged modified asphalt and modified asphalt blends with different types and proportions of rejuvenating agents.

Table 8 shows that the polymer SBS in aged modified asphalt are spherical particles distributed in the asphalt, and this modified asphalt belongs to a single-phase continuous structure, with polymer SBS as dispersed phase and asphalt phase as continuous phase. Compared with modified asphalt blended with different types and proportions of rejuvenating agents, recycling did not change its phase structure, still belonging to single-phase continuous structure. The SBS particle’s uniformity is satisfactory. With the naked eye only, one cannot see the difference of SBS particle in appearance and shape. The images have to be further processed to quantify potential differences.

Professional image processing software (Image-Pro Plus) is applied to analyze and process the fluorescence images of modified asphalt blends, which can segment, count and measure the images. The area ratio of polymer SBS particles is the quantitative evaluation indexes to describe the phase characteristics and recycling mechanism of modified asphalt. Here the area ratio refers to the percentage of polymer SBS particles area to total area, indirectly reflecting the SBS swelling degree in the asphalt.

Table 9 shows the phase characteristics of modified asphalt blended with different proportions of rejuvenating agents.

From

Table 9, the area ratio of polymer SBS particles increases at first and then decreases, presumably because the proportion of rejuvenating agent was small, and the swelling effect of SBS particles continued with the action of light oil. With the increasing of the proportion of rejuvenating agent, the swelling effect reaches a certain extent, and excess of rejuvenating agent decreases the relative content of SBS particles in asphalt, resulting in the area ratio of SBS particles beginning to decrease.

A comparison was made of the relationship of macroscopic properties shown in the

Section 3.1 and the microscopic characteristics of modified bitumen blends shown in

Table 9 based on the connection points of rejuvenating agent proportion. The comparison indicates that the variation of area ratio of SBS particles is consistent with the variation in tenacity.

It is concluded that with an increase of proportion of rejuvenating agent, the trend of area ratio is similar to tenacity, but this may be just an apparent phenomenon. Software statistical analysis was conducted at bivariate significance level of 0.05. The results of modified asphalt blends are shown in

Table 10.

Table 10 shows that the correlation coefficient between area ratio of SBS particles and tenacity are all over than 0.95, indicating that the positive correlation is strong. The significance parameters are all less than 0.05, indicating that the two indexes have significant correlation.

According to the above research into penetration, softening point, 5 °C ductility, viscosity, and tenacity of recycled asphalt and economy, the proportion of rejuvenating agent S for recycled mixtures is set to 6%.

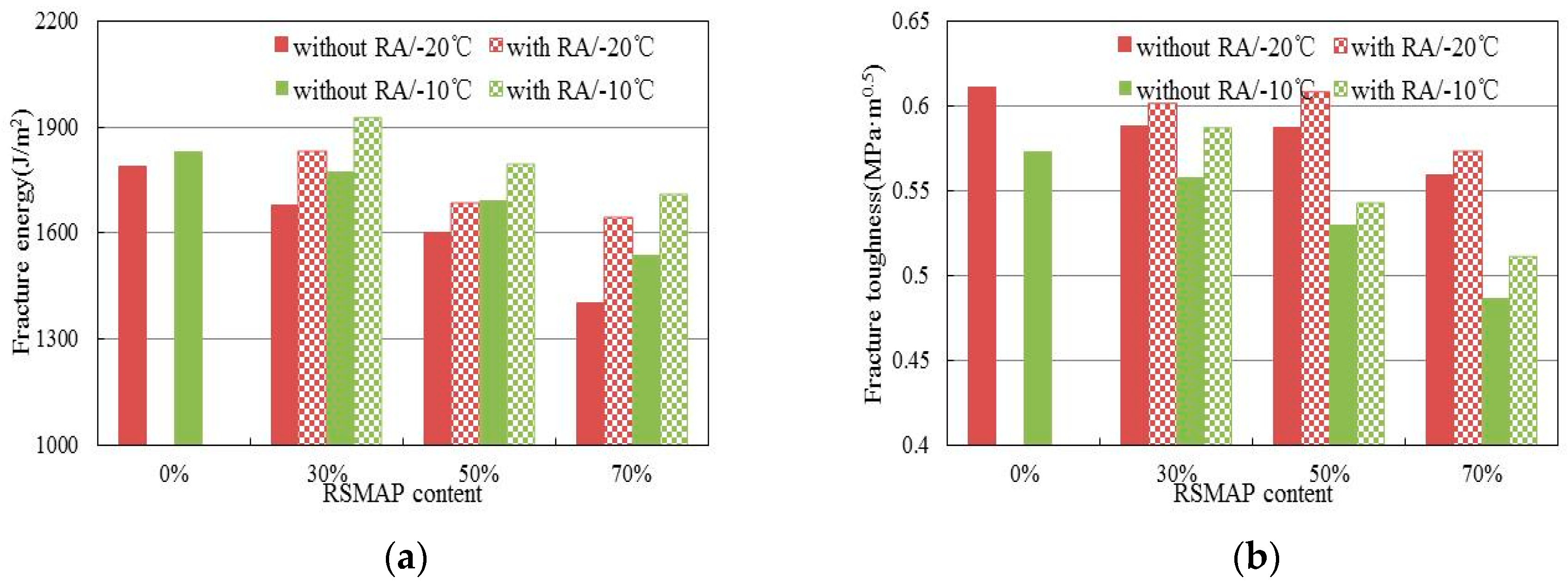

3.5. Semi-Circular Bending Test Results

Figure 5 graphically illustrates the fracture energy (

Gf) and fracture toughness (

Kc) of recycled mixtures in SCB test, and RA in the

Figure 5 represents rejuvenating agent.

Figure 5 shows that the trends for SCB fracture energy and fracture toughness are decreasing with increasing RSMAP content in the mixture at the two temperatures. As the test temperature increases, the fracture energy increases and fracture toughness decreases. When the RSMAP content is 70%, the fracture energy and fracture toughness of recycled mixture without rejuvenating agent decrease by 22% and 9% compared with the control mixtures (RSMAP is 0%). By adding rejuvenating agent, both indexes are improved. However, the two indexes of recycled mixtures with high RSMAP contents are not easy to recover to HMA level.

This indicates that RSMAP has a negative impact on low-temperature properties of recycled mixtures, and the lower the temperature is, the greater the negative impact is. The rejuvenating agent can improve the fracture energy and fracture toughness of recycled mixtures including high RSMAP contents.

3.6. Dynamic Modulus Test Results

The dynamic modulus master curve model parameters (Equation (4)), developed for different recycled mixtures, are presented in

Table 12.

From

Table 12 and based on the nonlinear fitting statistics, it is evident that the dynamic modulus models used for developing the master curves are highly related. The temperature shift factors for a reference temperature 20 °C are shown in

Table 13.

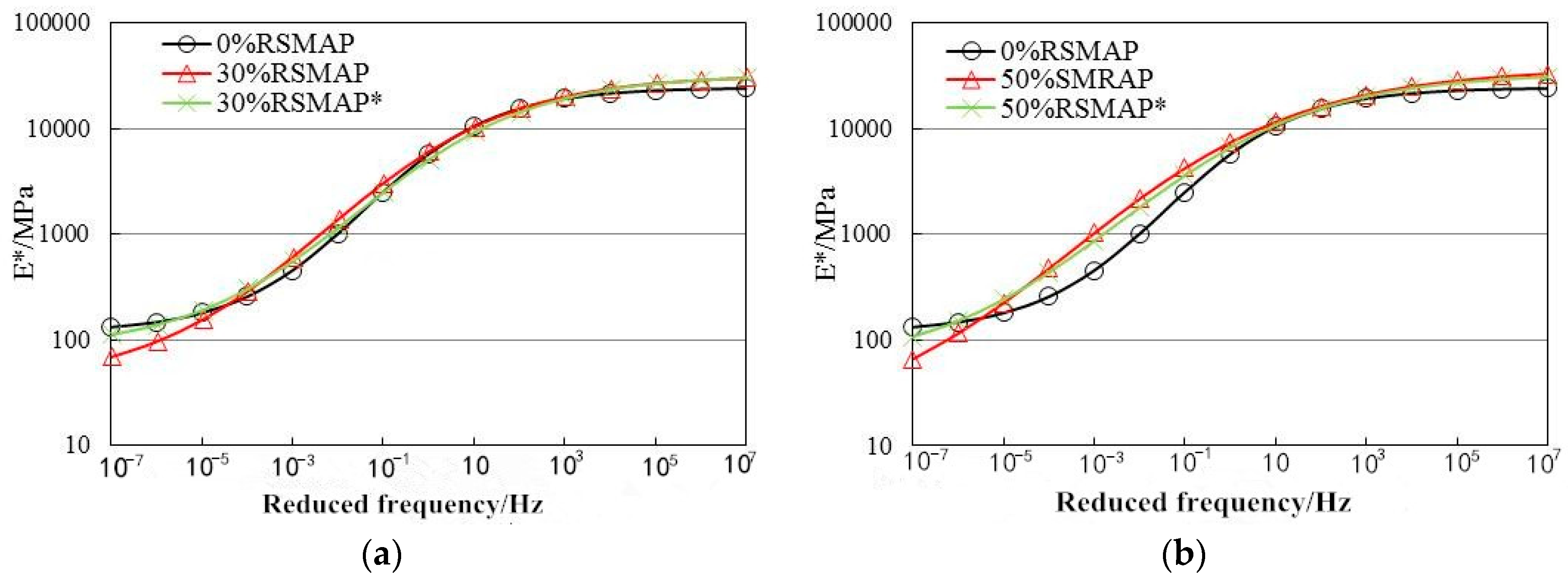

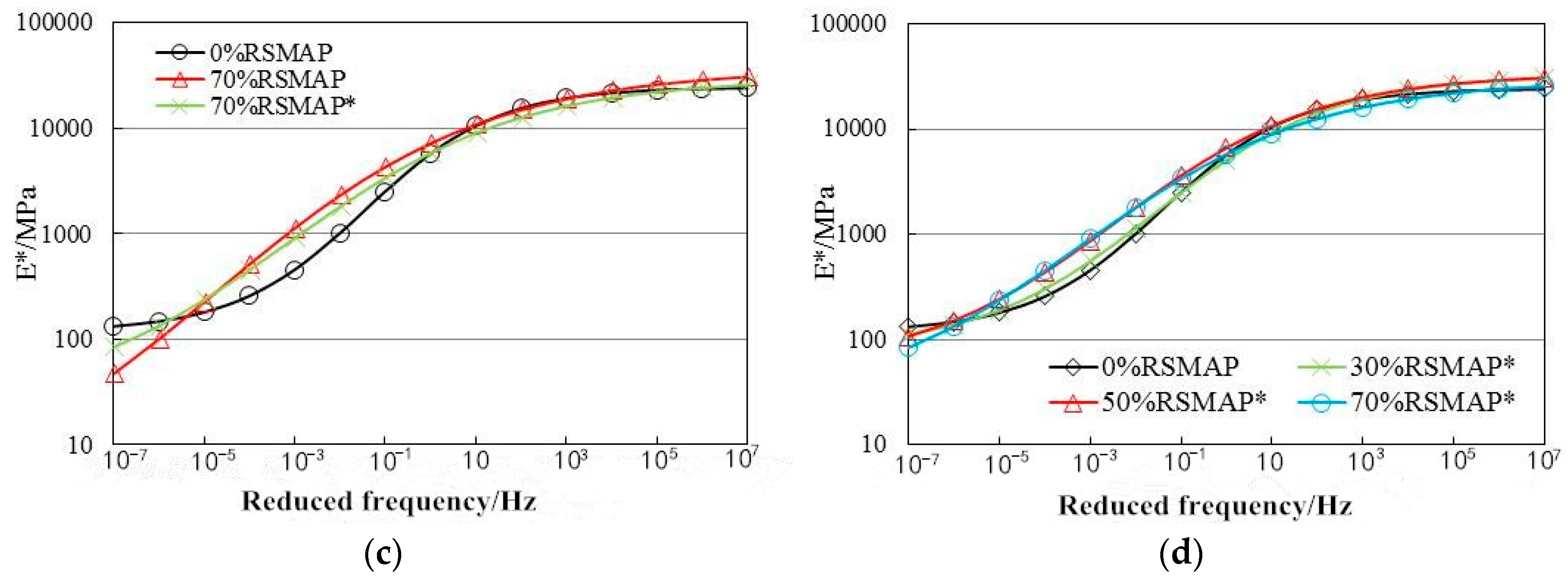

The dynamic modulus master curves of recycled mixtures with different RSMAP contents are provided in

Figure 6. To facilitate comparison, the master curve of control mixture is also provided in

Figure 6.

From

Figure 6a–c, it’s observed that dynamic modulus of all mixtures tested increases with the increase of the loading frequency. In general, the dynamic modulus values of recycled mixtures are significantly higher than control mixture, and the difference is greater with higher RSMAP content. By adding rejuvenating agent, the dynamic modulus decreases slightly.

Figure 6d shows that at higher loading frequency, there is no notable difference between the dynamic modulus of the recycled mixtures and control mixture. The results indicate that the rejuvenating agent has an effect on the stiffness of the recycled mixtures generally, but the effect is not obvious. In addition, when the loading frequency reaches a greater value, the difference of recycled mixtures and control mixture tend to be consistent, and include high RSMAP content.