Investigation into the Vibrational Responses of Cylinder Liners in an IC Engine Fueled with Biodiesel

Abstract

:1. Introduction

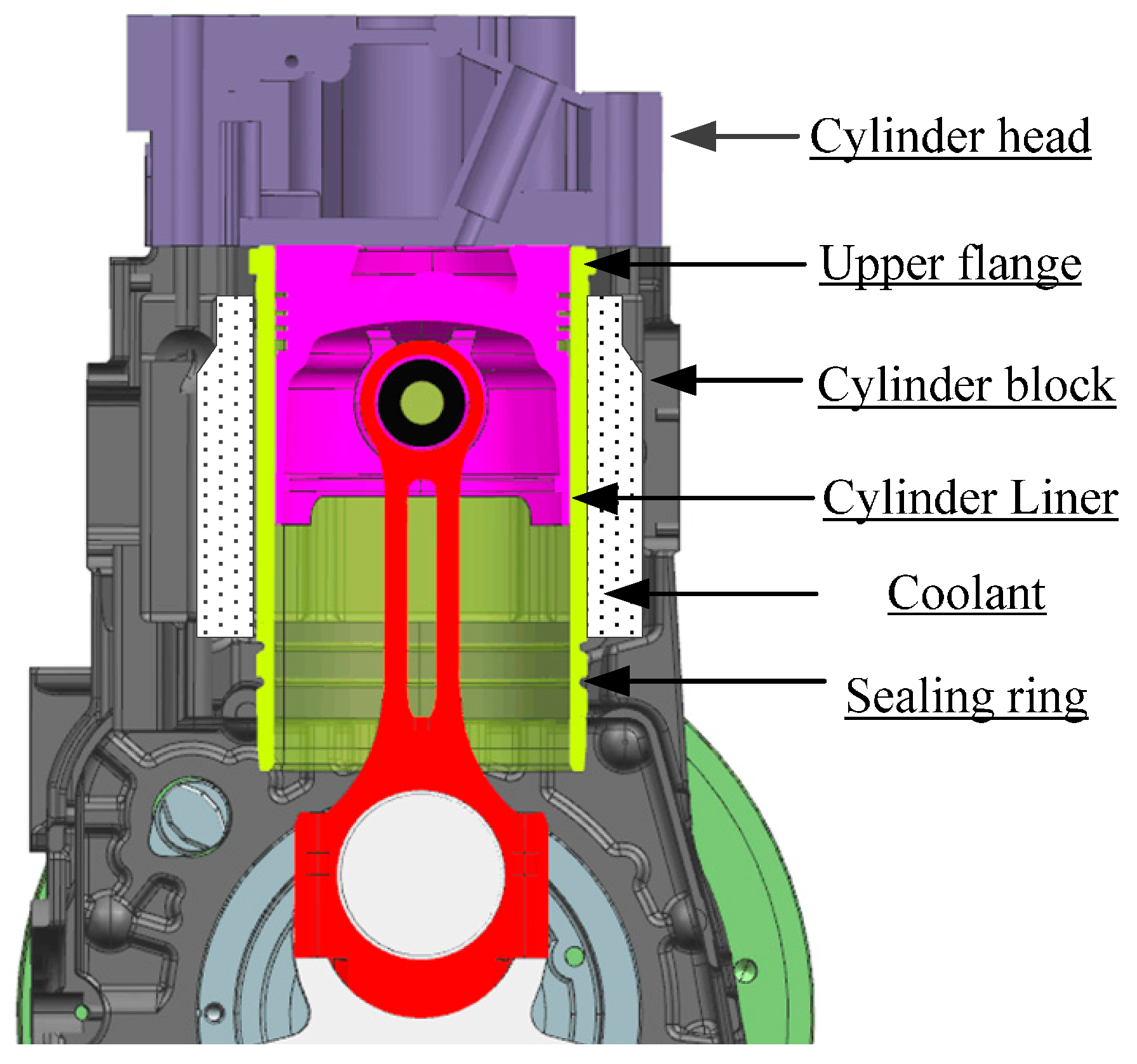

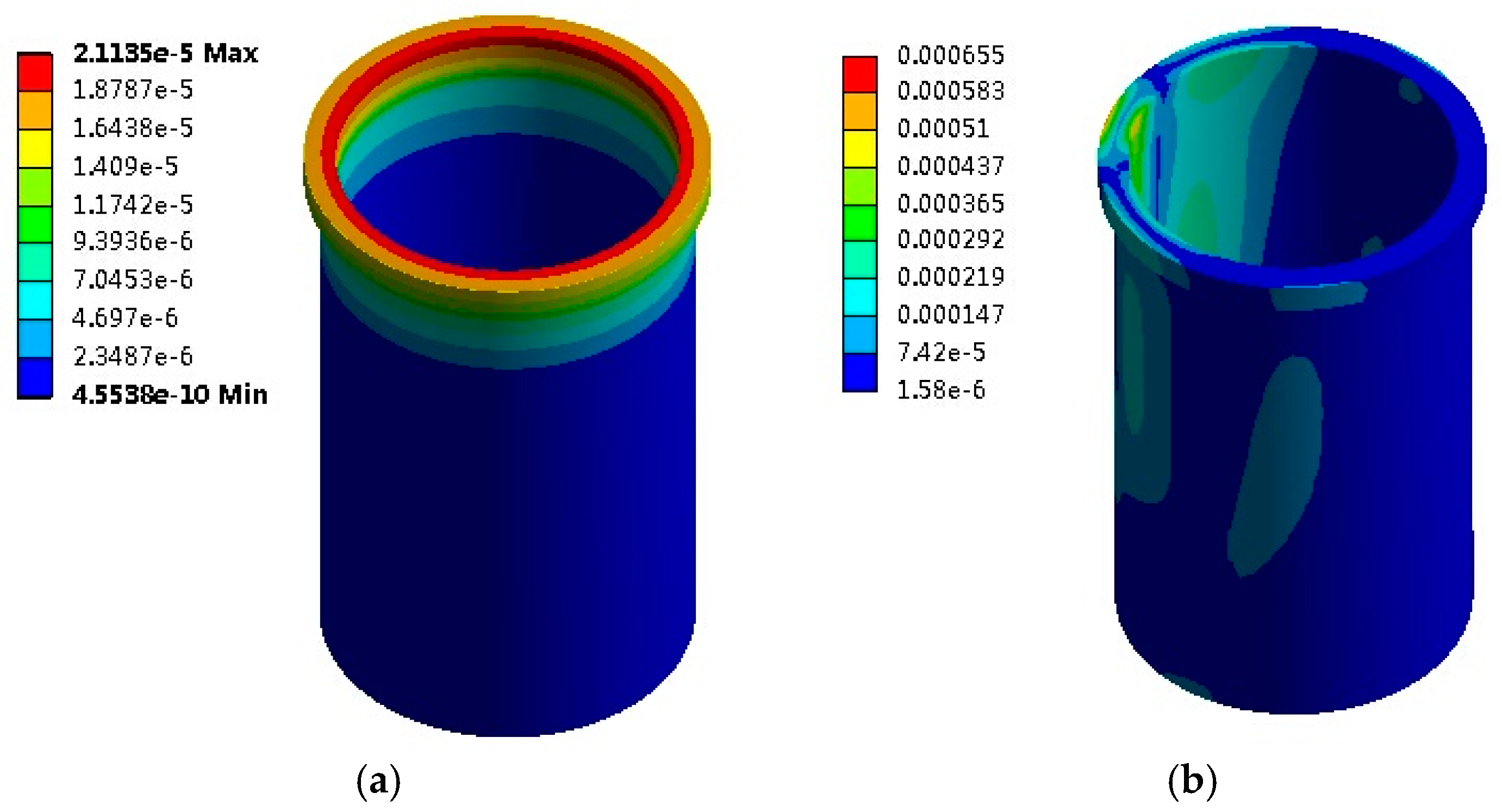

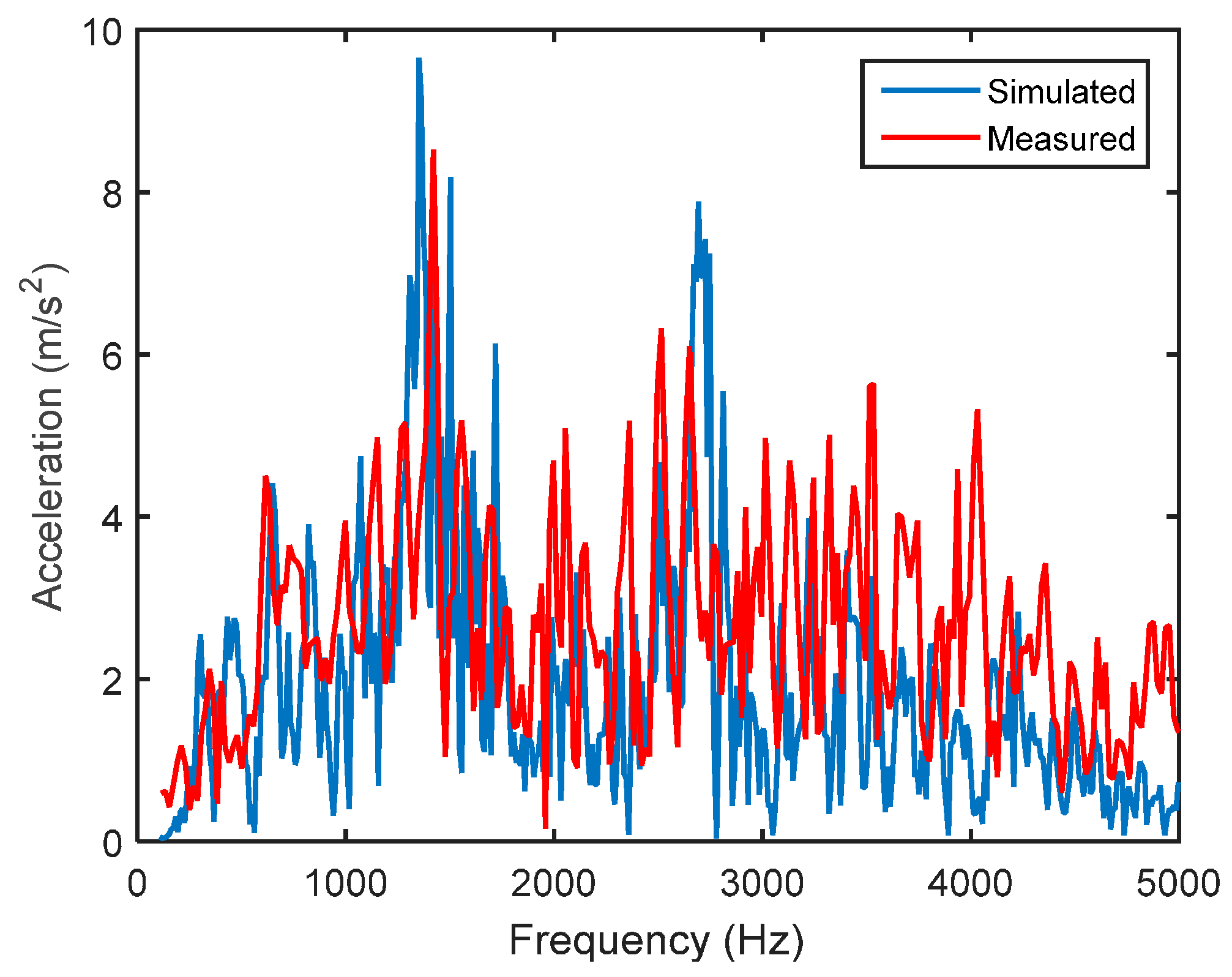

2. Structural Characteristics and Dynamic Behaviors of Cylinder Liners

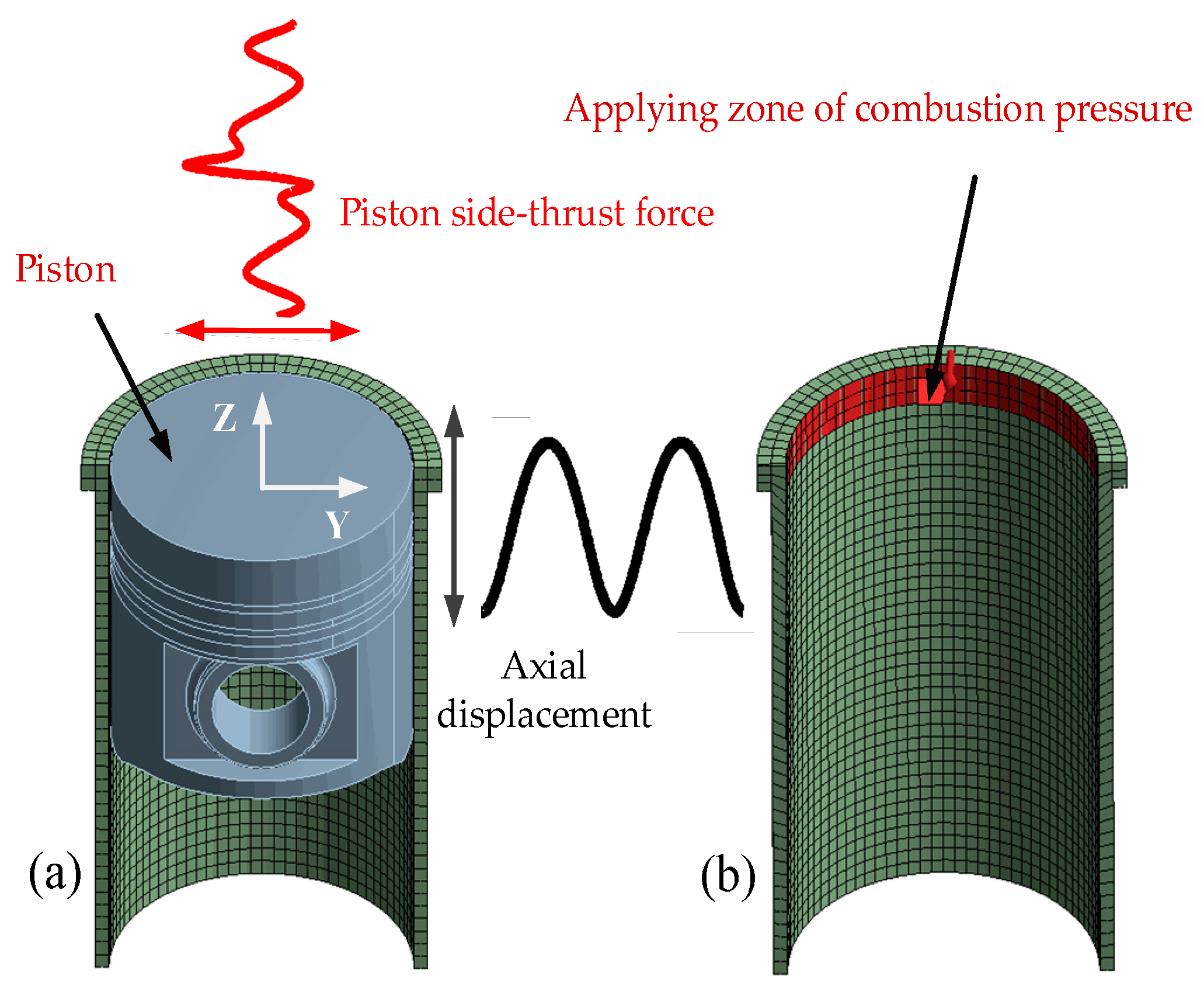

2.1. Meshing and Boundary Conditions

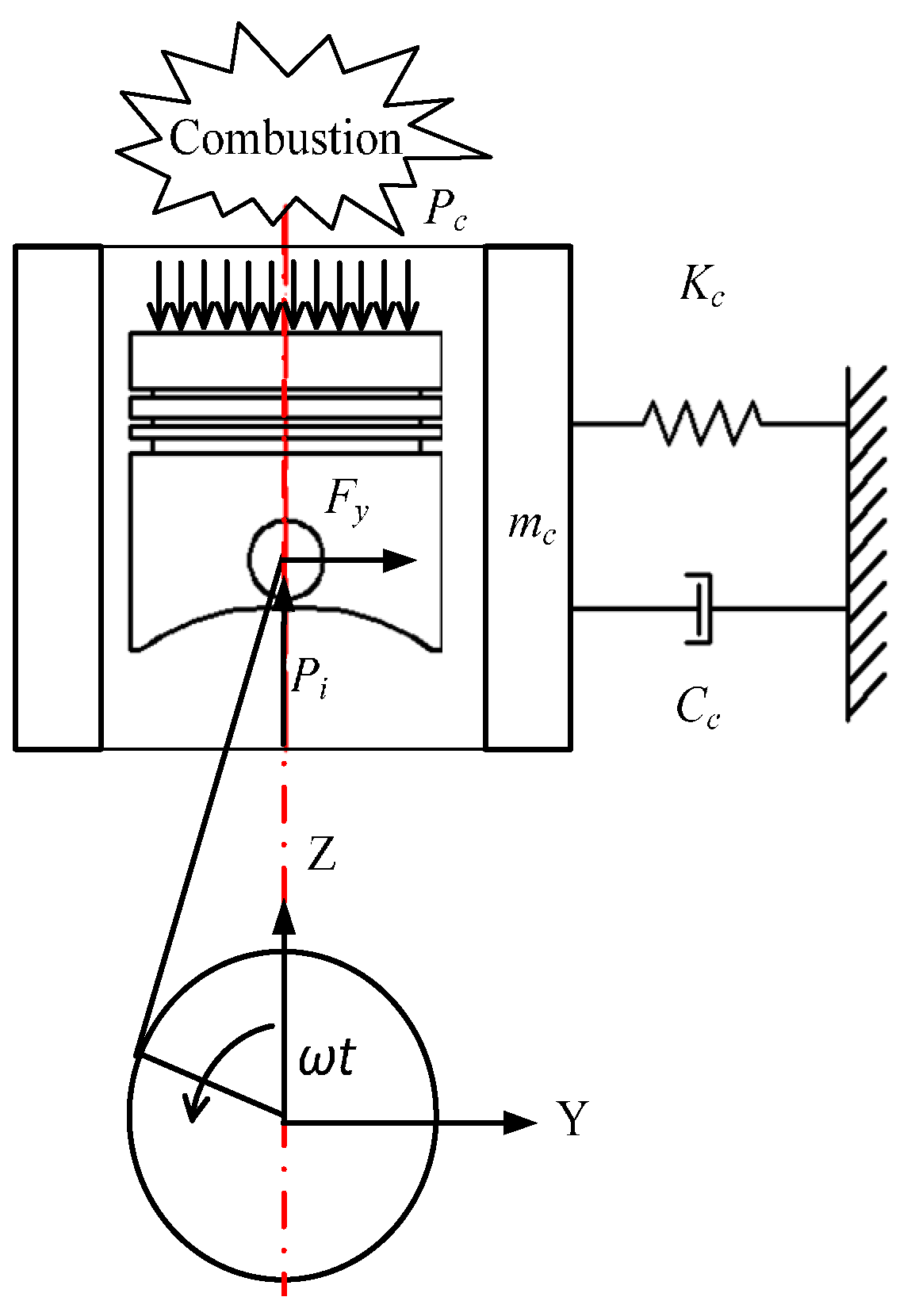

2.2. Excitation Configurations

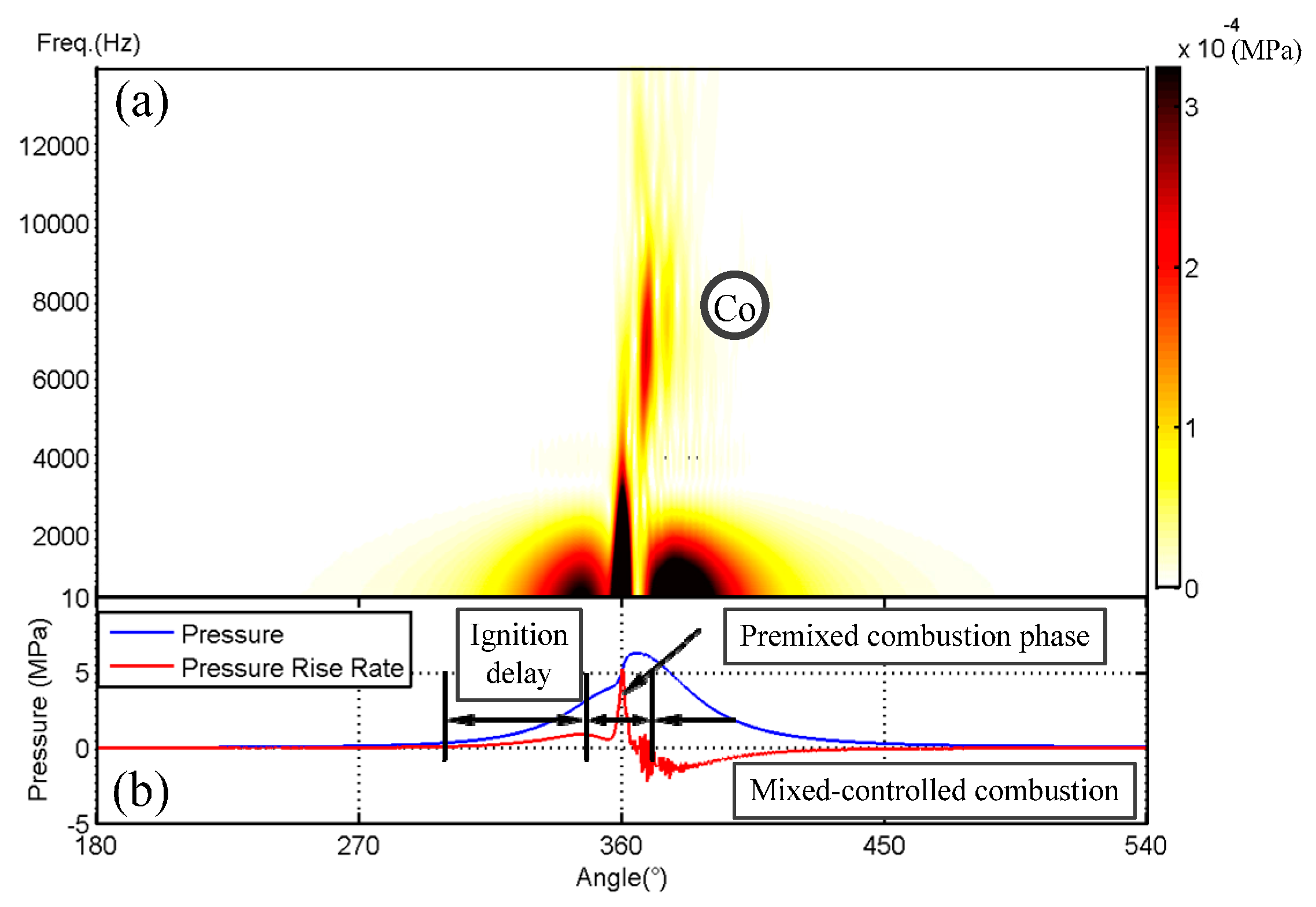

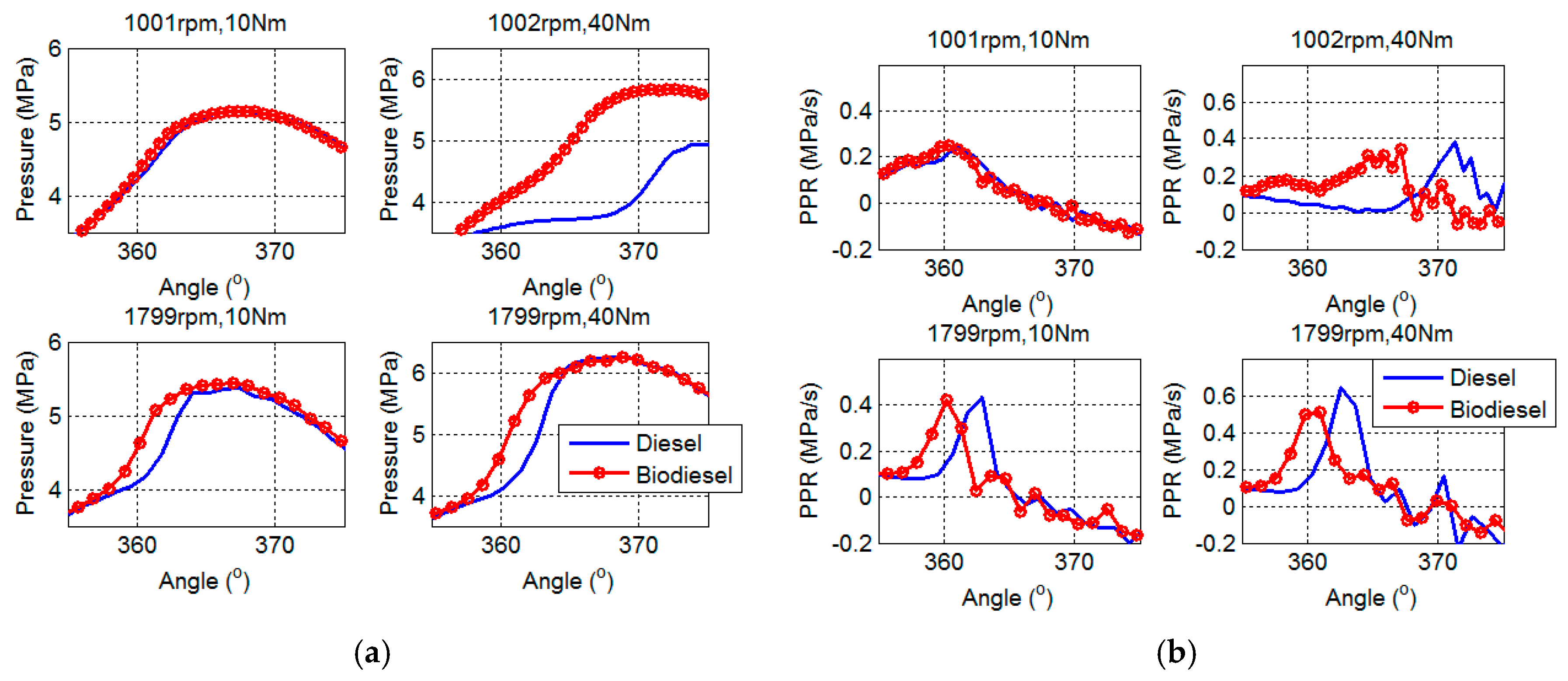

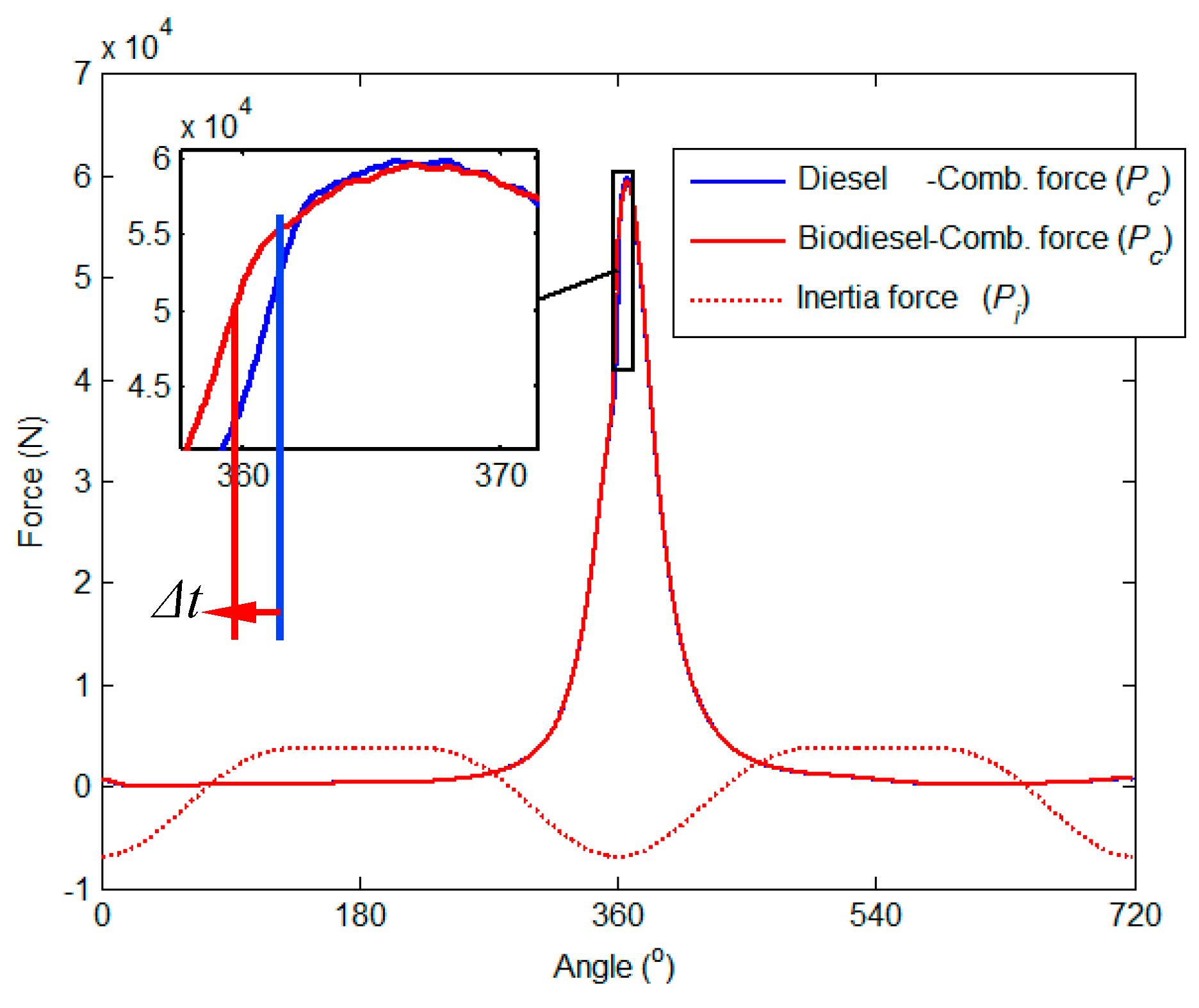

2.2.1. Combustion Shock

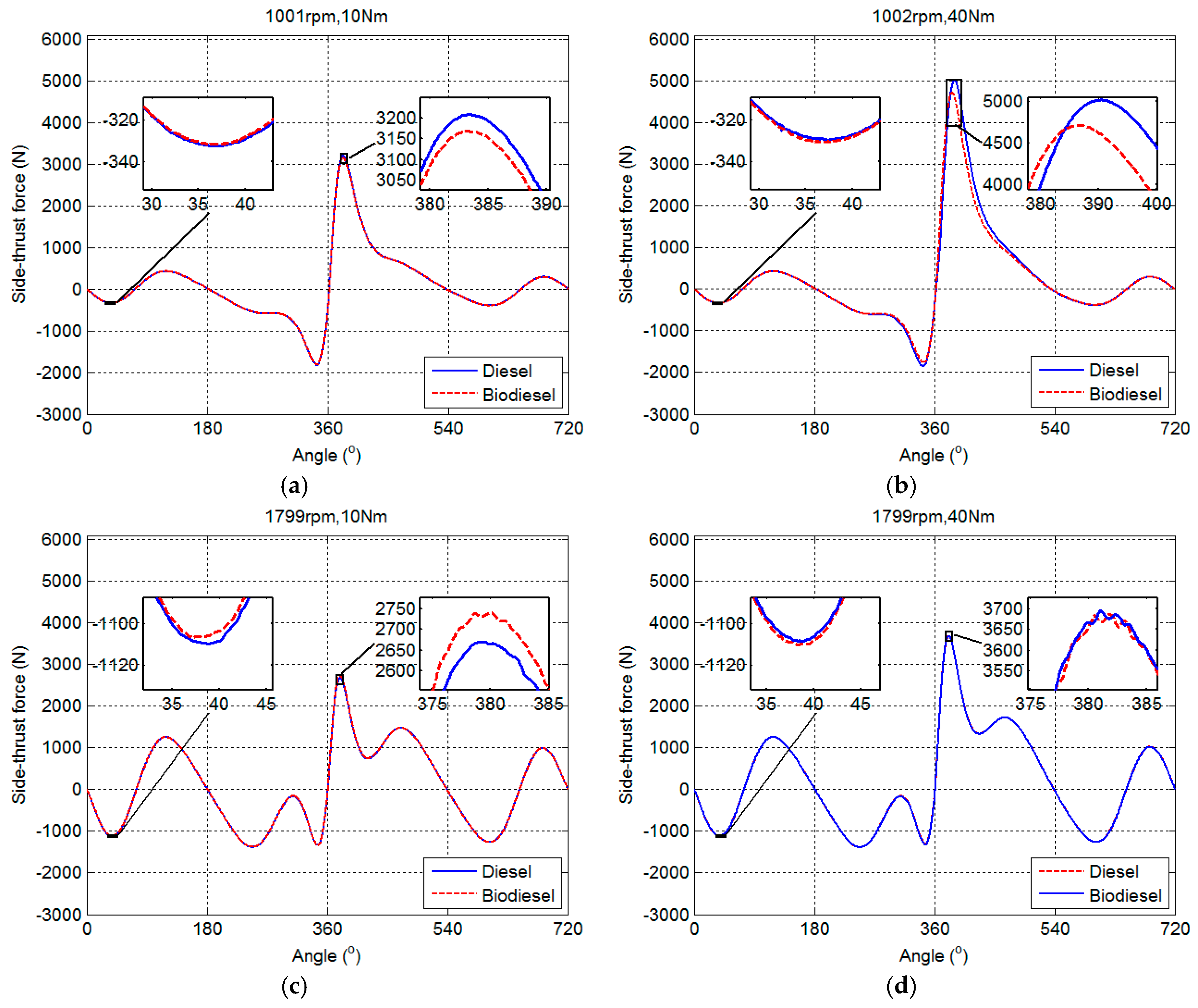

2.2.2. Piston Side Thrust

3. Numerical Analysis

3.1. Physicochemical Properties of Biodiesel

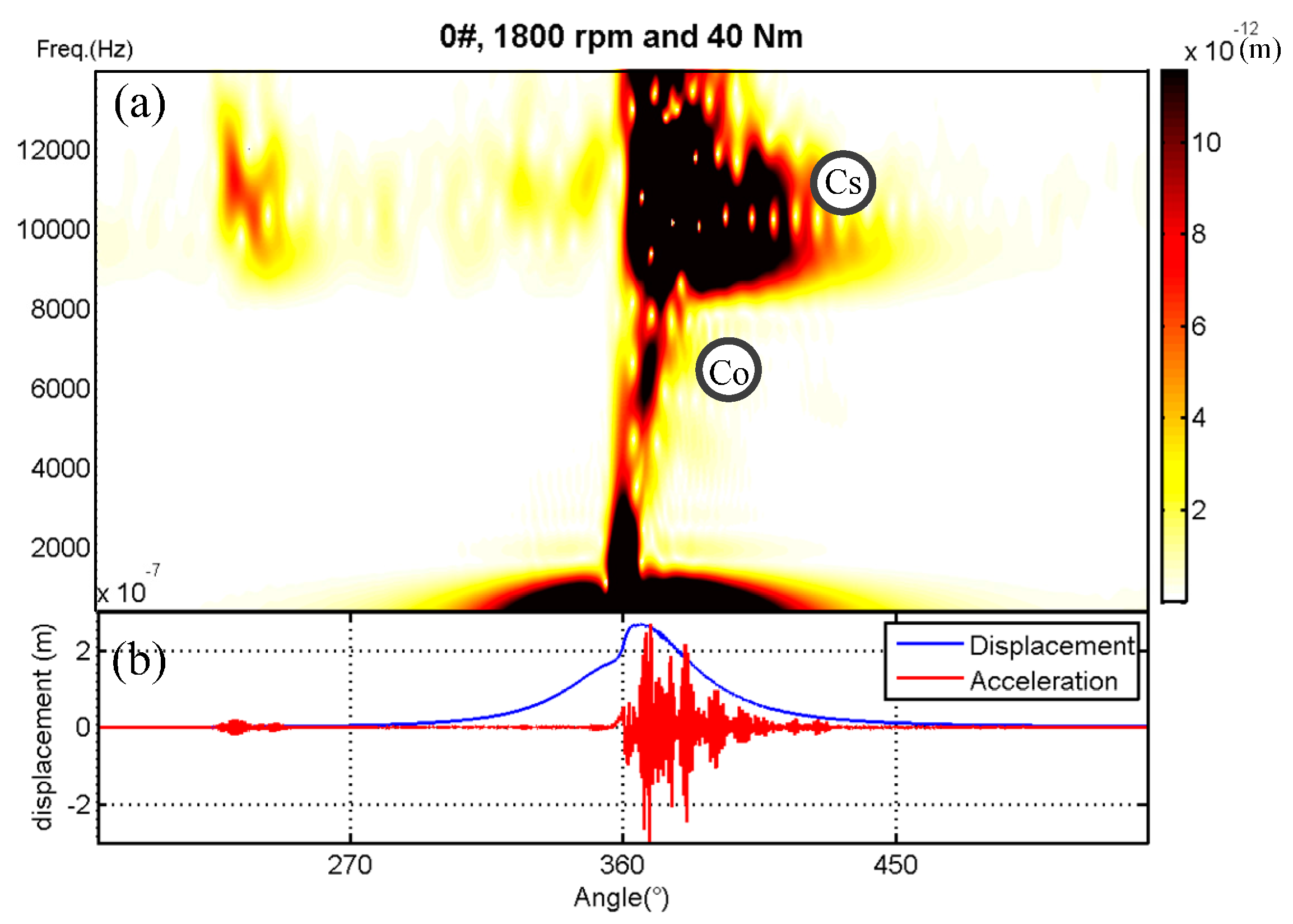

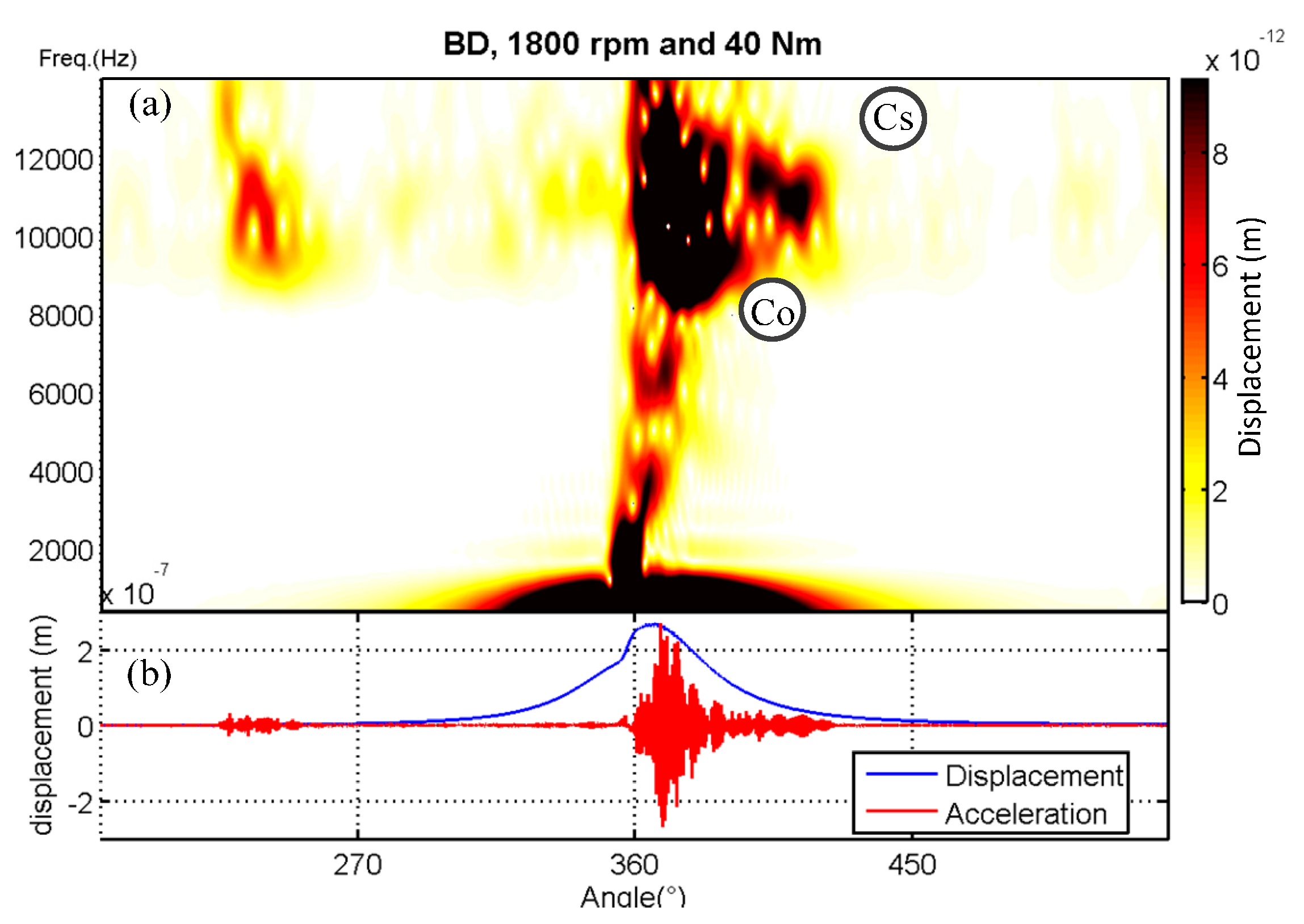

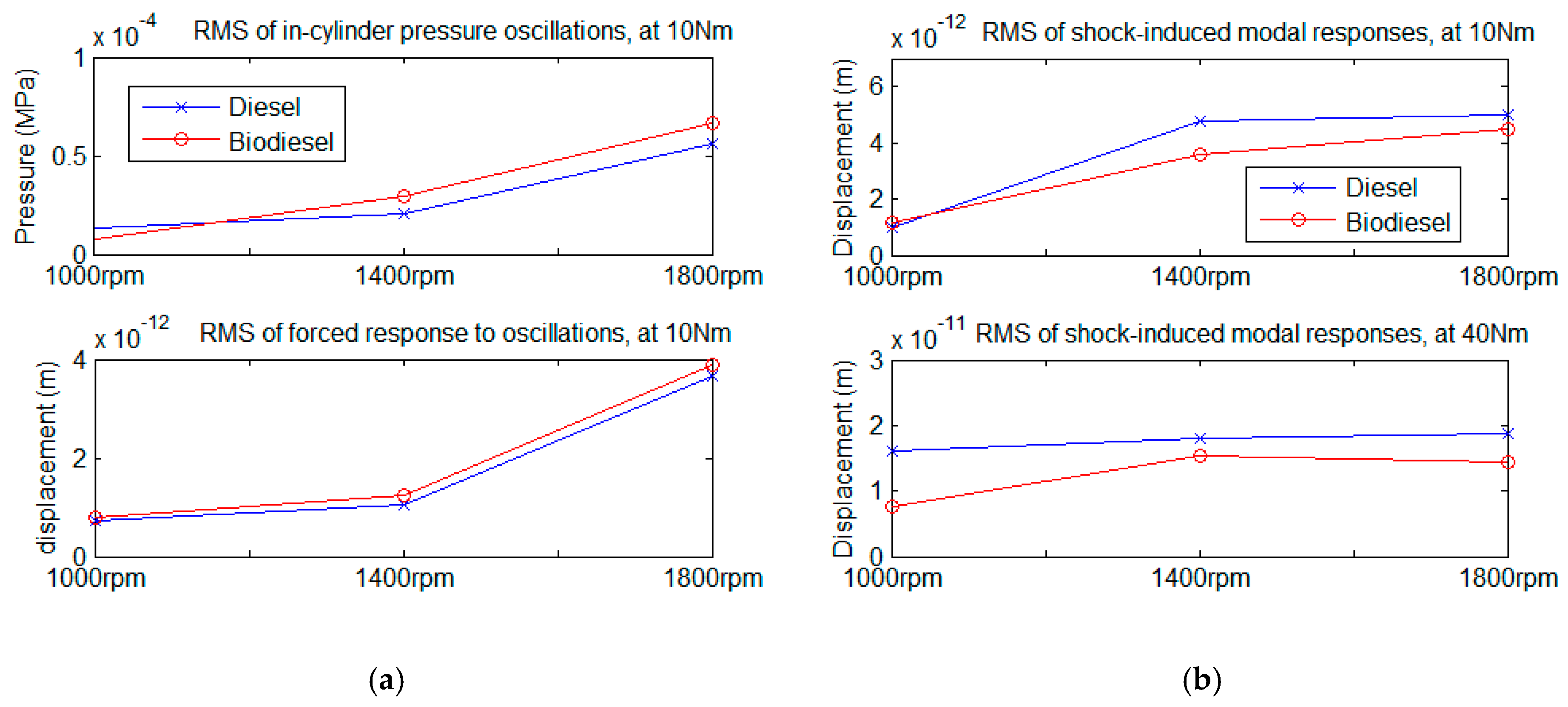

3.2. Dynamic Responses to Combustion Forces

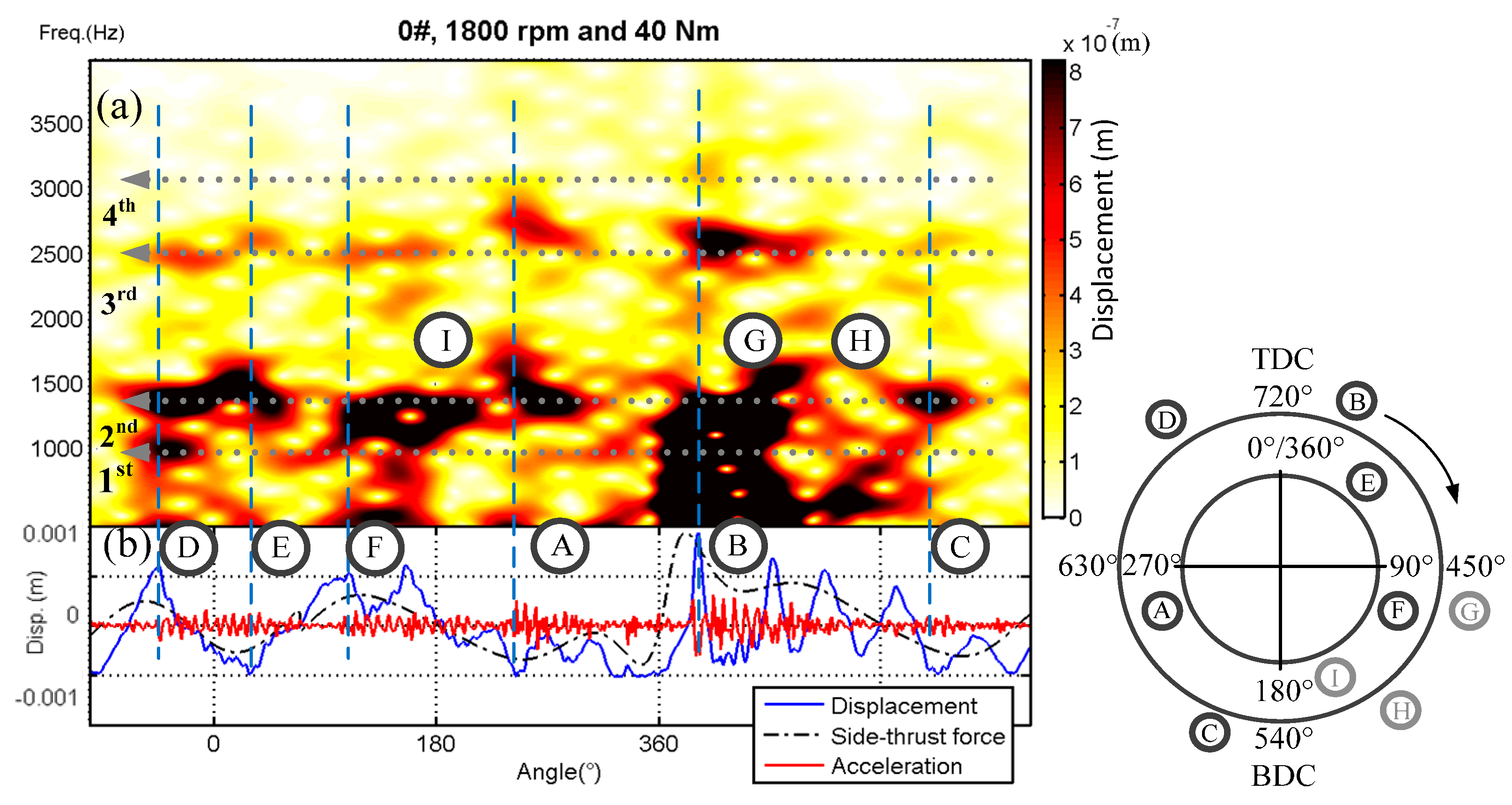

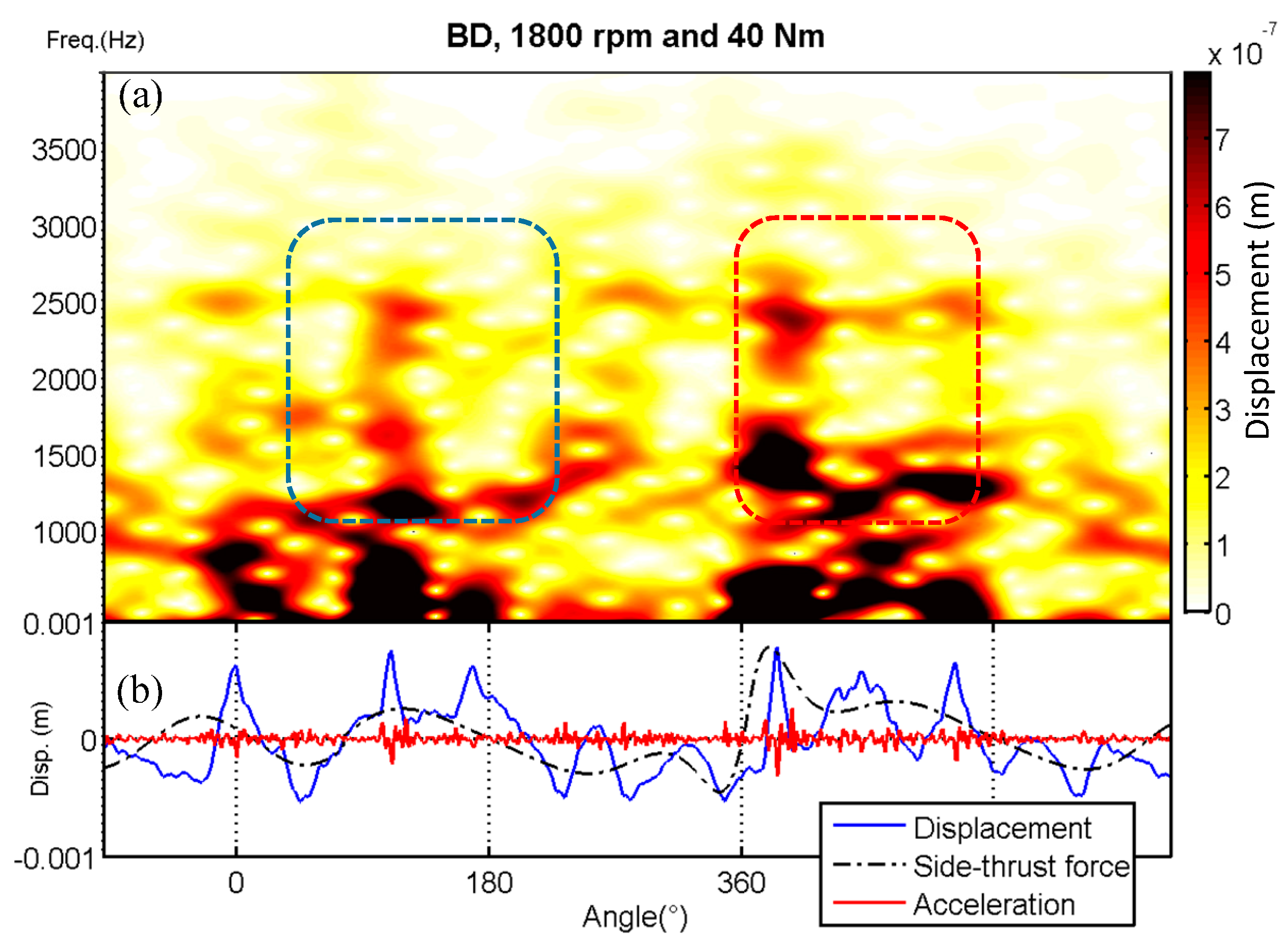

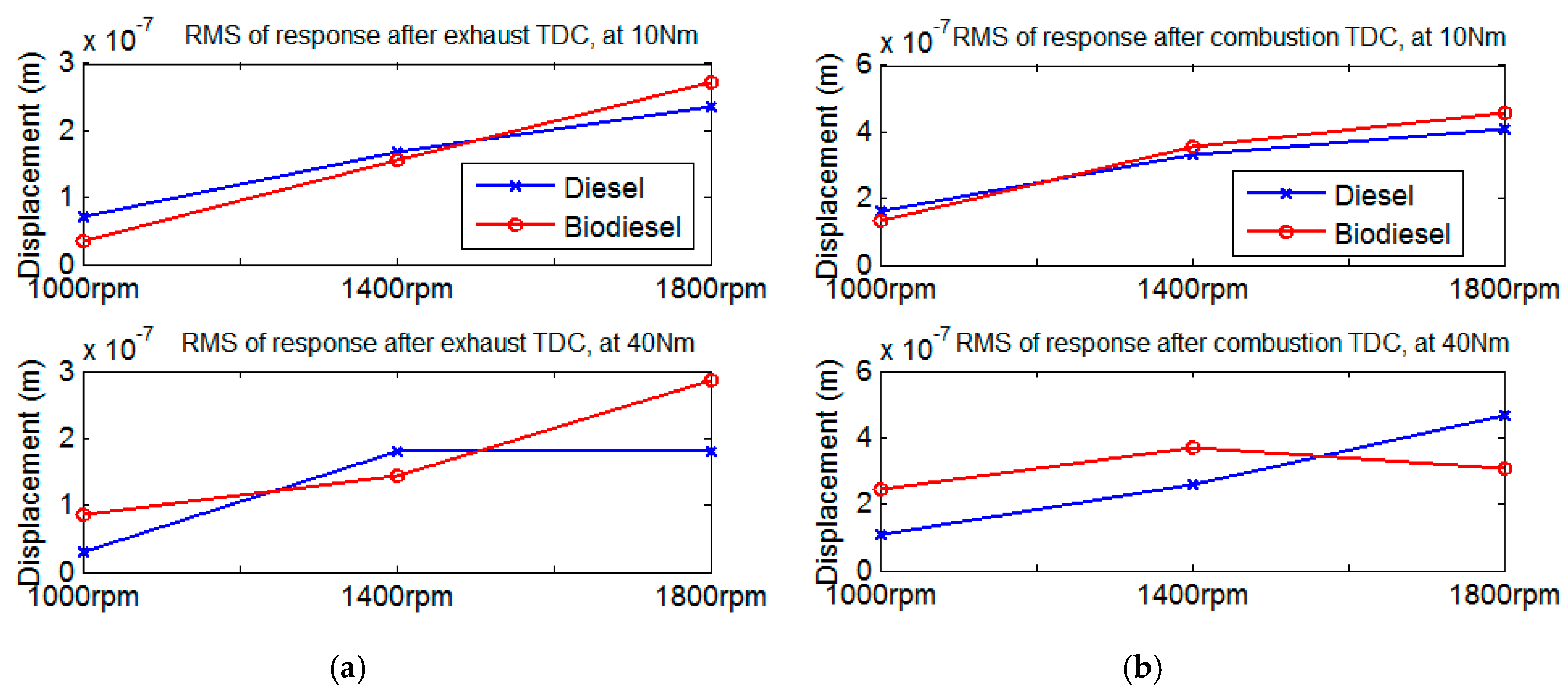

3.3. Dynamic Responses to Piston Slaps

3.4. Diagnostic Analysis

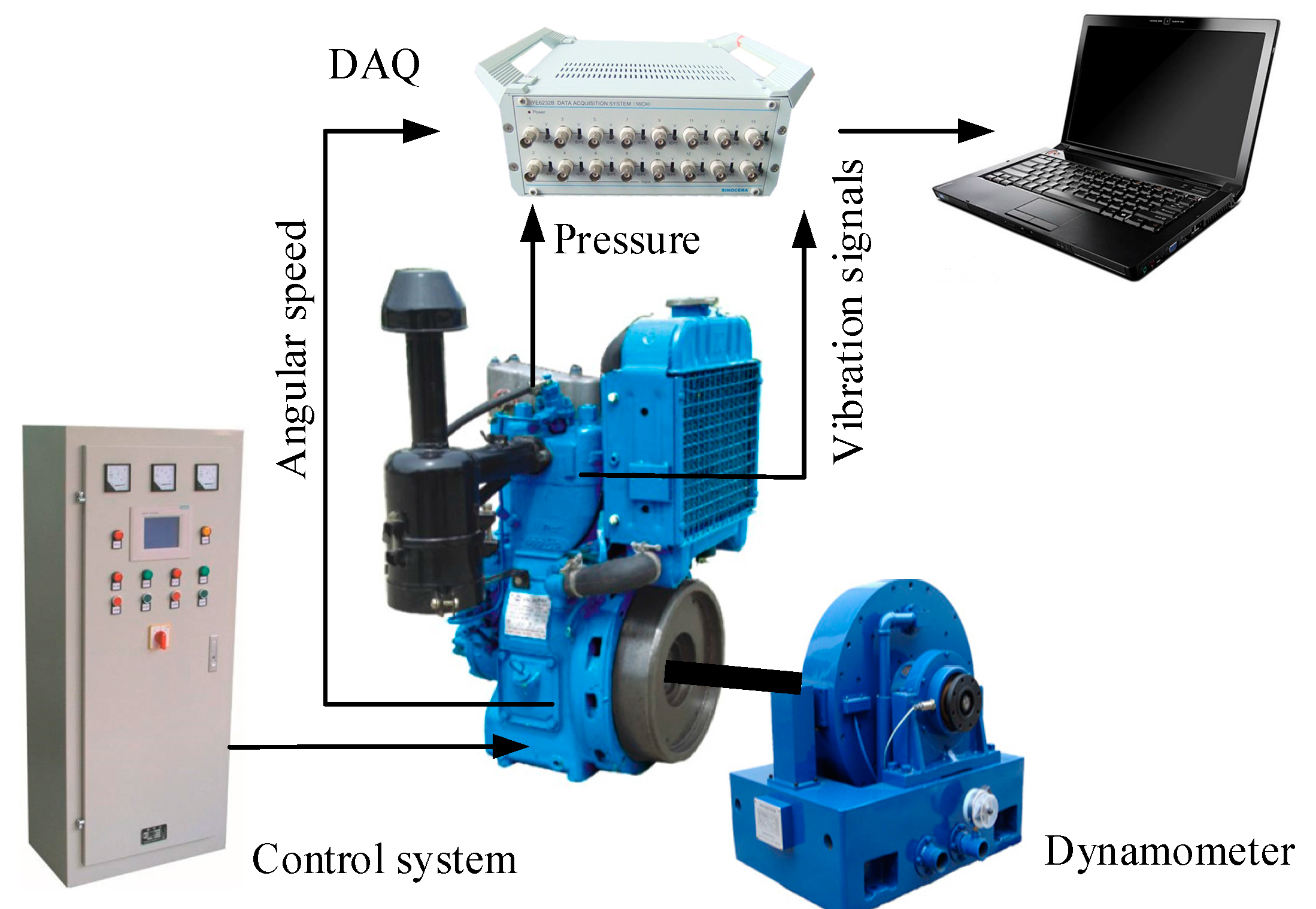

4. Design of Experiments

5. Experimental Results and Discussion

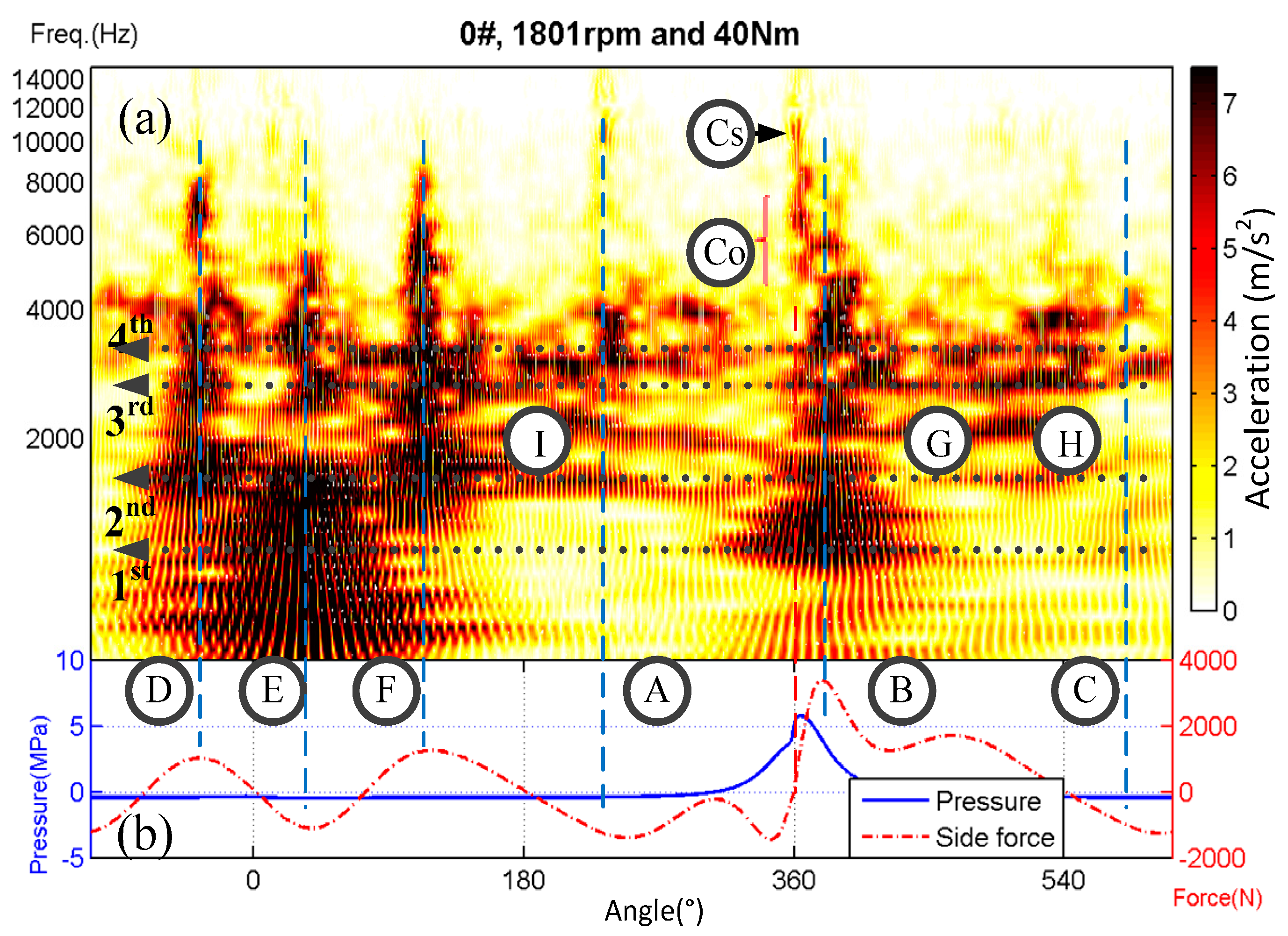

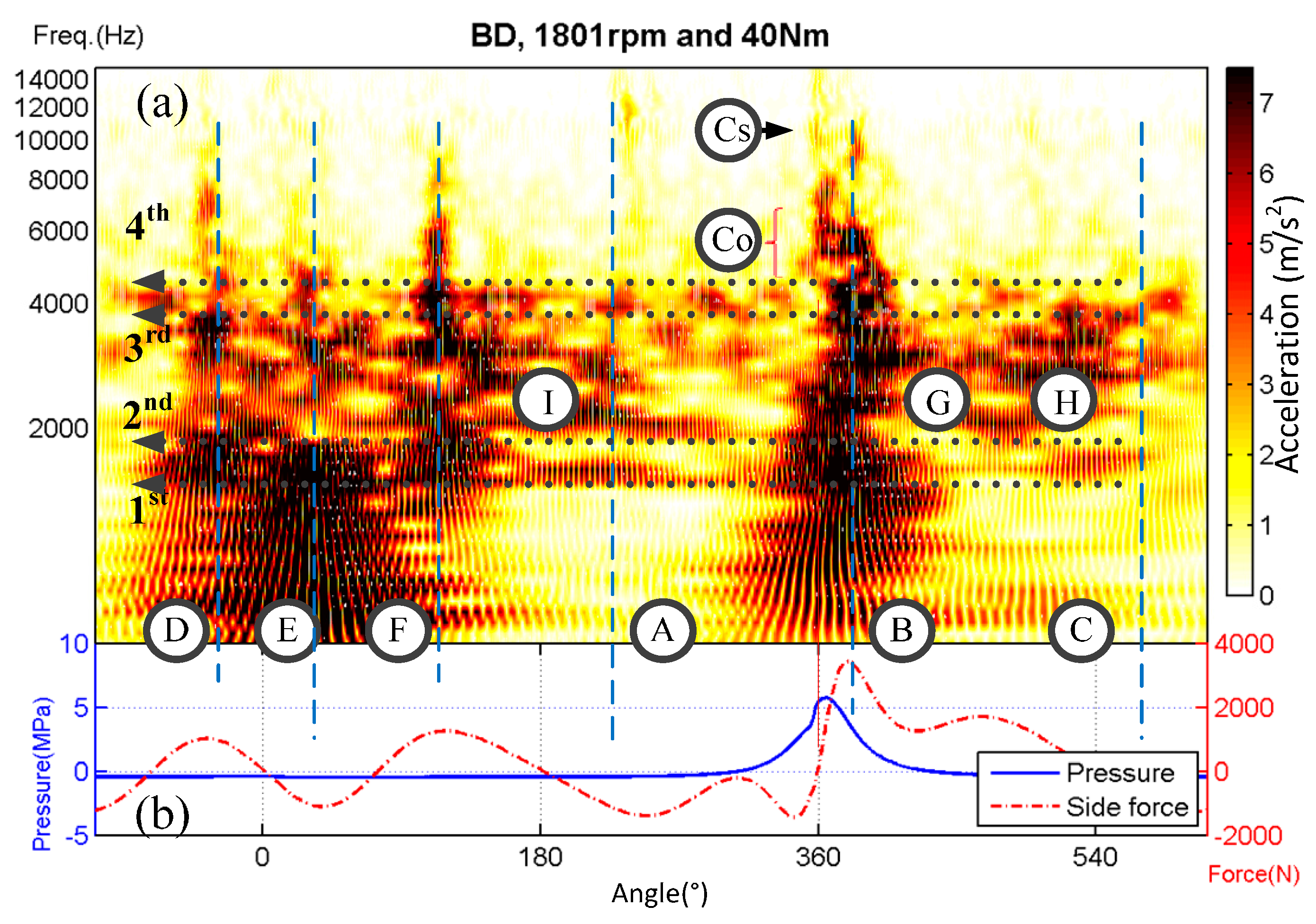

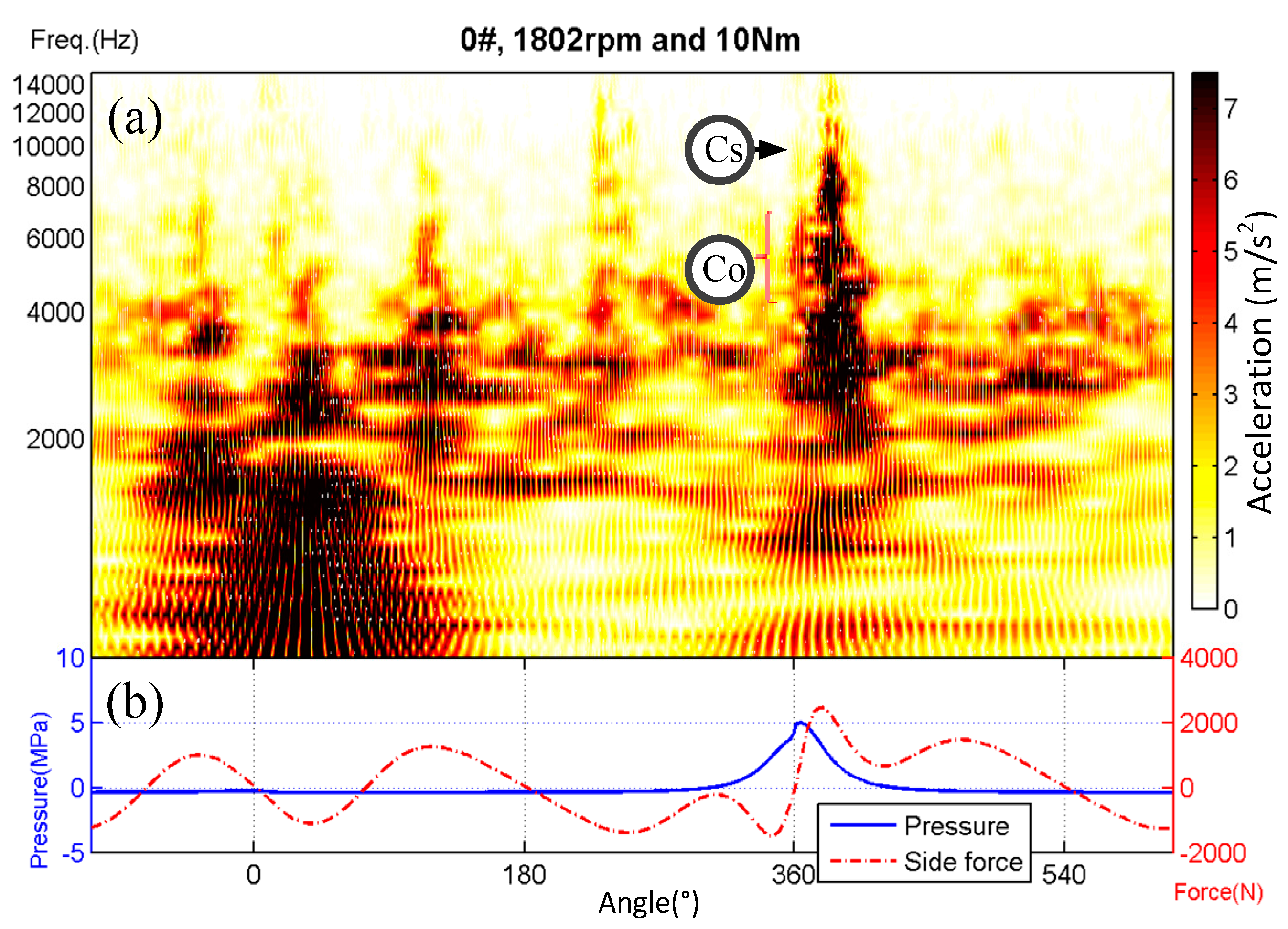

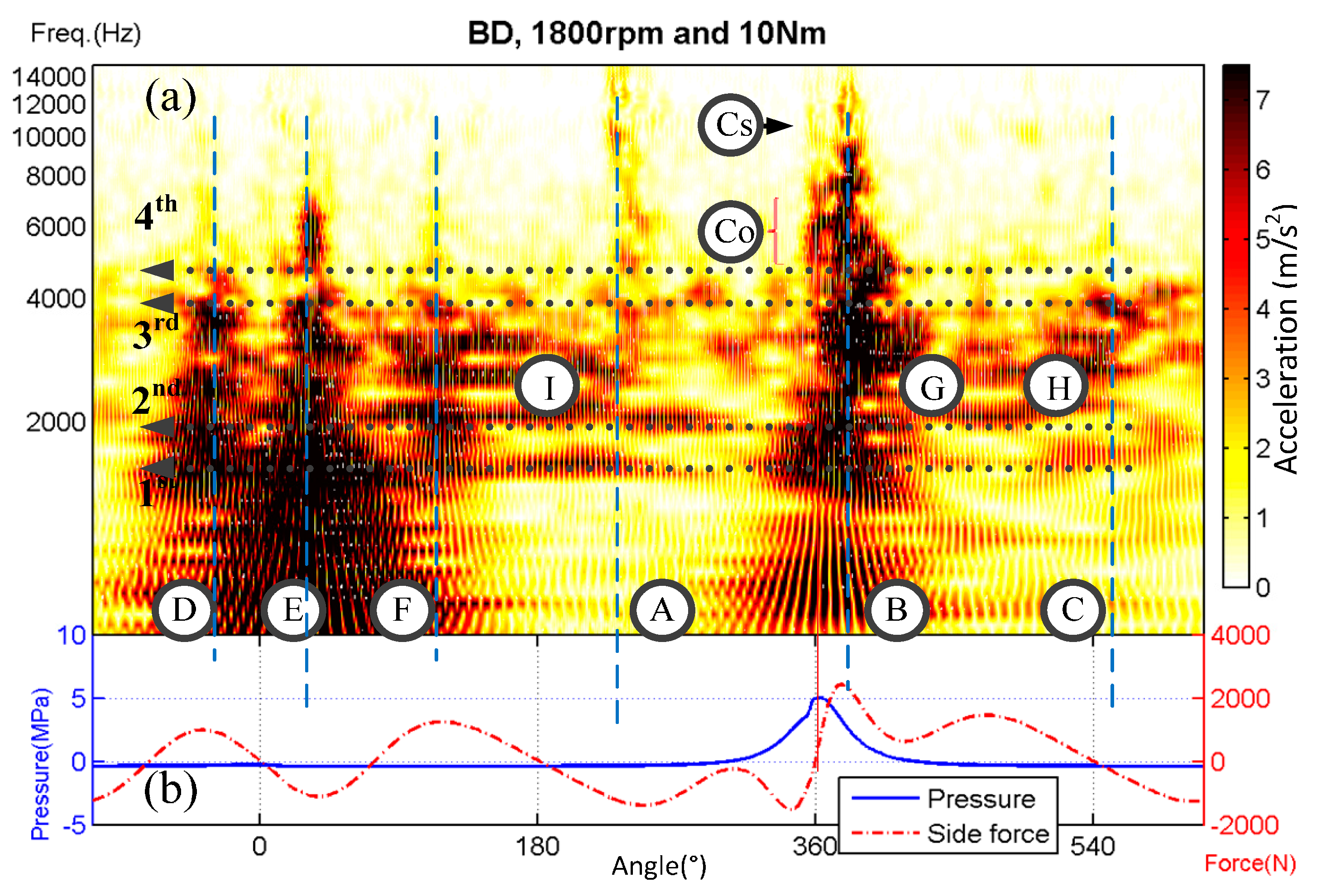

5.1. CWT Analysis

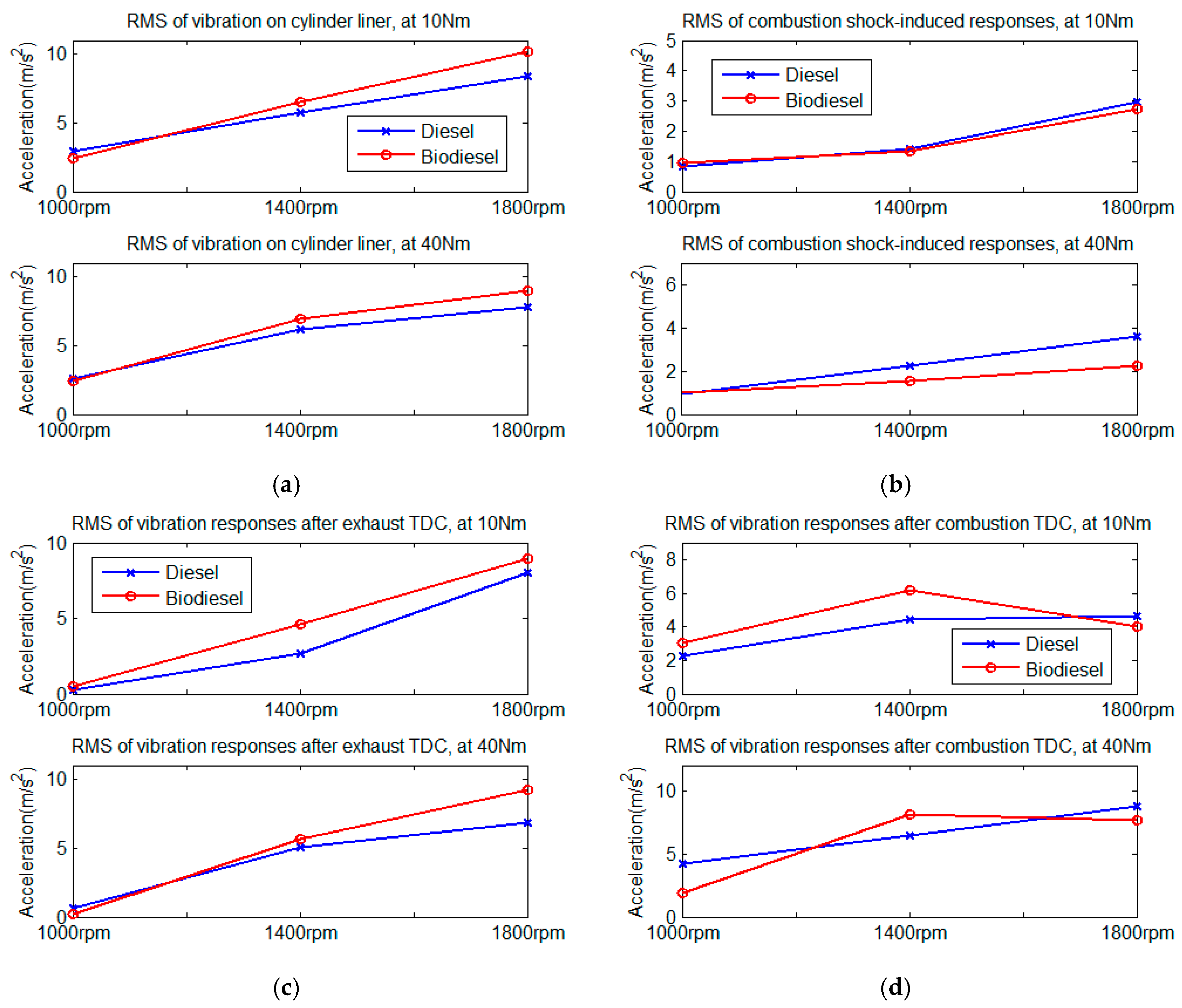

5.2. Diagnostics of the Impacts of Different Fuels

6. Conclusions

- The dynamic responses of the cylinder liner to combustion shocks appear in a higher frequency band from 4 to 12 kHz, whereas those of the piston impacts are in a lower frequency range from 1 to 4 kHz. Furthermore, the predicted amplitude of local responses is at the order of 0.01 microns due to the combustion shocks, which may be negligible to affect lubrications. However, piston slaps can lead to deformation as high as 0.1 micros, being about 20% of roughness amplitude.

- The variation trends of combustion shock-induced responses can well correspond to the combustion characteristics of biodiesel regarding to the peak value of the pressure rise rate. The frequency contents of in-cylinder combustion pressure fueled with biodiesel are less than the fossil diesel, and insufficient to cause a clearer modal responses.

- The extended combustion duration of biodiesel can cause a relative increase in the kinetic energy of piston lateral movement, thereby leading to a rise of vibration intensity close to the exhaust top dead center (TDC).

- Due to the compound effect between the combustion force and piston inertia force, the rise rate of the piston side-thrust force close to the combustion top dead center (TDC) shows a nonlinear decrease with the increase in speeds, thereby resulting in a nonlinear trend in the root mean square curve of liner local responses.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ge, J.C.; Yoon, S.K.; Kim, M.S.; Choi, N.J. Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine. Appl. Sci. 2016, 7, 34. [Google Scholar] [CrossRef]

- Tashtoush, G.; Al-Widyan, M.I.; Al-Shyoukh, A.O. Combustion performance and emissions of ethyl ester of a waste vegetable oil in a water-cooled furnace. Appl. Therm. Eng. 2003, 23, 285–293. [Google Scholar] [CrossRef]

- Aydin, H.; Bayindir, H. Performance and emission analysis of cottonseed oil methyl ester in a diesel engine. Renew. Energy 2010, 35, 588–592. [Google Scholar] [CrossRef]

- Murillo, S.; Míguez, J.L.; Porteiro, J.; Granada, E.; Morán, J.C. Performance and exhaust emissions in the use of biodiesel in outboard diesel engines. Fuel 2007, 86, 1765–1771. [Google Scholar] [CrossRef]

- Salvi, B.L.; Subramanian, K.A.; Panwar, N.L. Alternative fuels for transportation vehicles: A technical review. Renew. Sustain. Energy Rev. 2013, 25, 404–419. [Google Scholar] [CrossRef]

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Taghizadeh-Alisaraei, A.; Ghobadian, B.; Tavakoli-Hashjin, T.; Mohtasebi, S.S.; Rezaei-asl, A.; Azadbakht, M. Characterization of engine’s combustion-vibration using diesel and biodiesel fuel blends by time-frequency methods: A case study. Renew. Energy 2016, 95, 422–432. [Google Scholar] [CrossRef]

- Uludamar, E.; Tosun, E.; Aydın, K. Experimental and regression analysis of noise and vibration of a compression ignition engine fuelled with various biodiesels. Fuel 2016, 177, 326–333. [Google Scholar] [CrossRef]

- Geng, Z.; Chen, J. Investigation into piston-slap-induced vibration for engine condition simulation and monitoring. J. Sound Vib. 2005, 282, 735–751. [Google Scholar] [CrossRef]

- Dolatabadi, N.; Theodossiades, S.; Rothberg, S.J. On the identification of piston slap events in internal combustion engines using tribodynamic analysis. Mech. Syst. Signal Process. 2015, 58–59, 308–324. [Google Scholar] [CrossRef]

- Cho, J.R.; Moon, S.J. A numerical analysis of the interaction between the piston oil film and the component deformation in a reciprocating compressor. Tribol. Int. 2005, 38, 459–468. [Google Scholar] [CrossRef]

- Jafari, A.A.; Khalili, S.M.R.; Azarafza, R. Transient dynamic response of composite circular cylindrical shells under radial impulse load and axial compressive loads. Thin-Walled Struct. 2005, 43, 1763–1786. [Google Scholar] [CrossRef]

- Murakami, H.; Nakanishi, N.; Ono, N.; Kawano, T. New Three-Dimensional Piston Secondary Motion Analysis Method Coupling Structure Analysis and Multi Body Dynamics Analysis; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Farshidianfar, A.; Farshidianfar, M.H.; Crocker, M.J.; Smith, W.O. Vibration analysis of long cylindrical shells using acoustical excitation. J. Sound Vib. 2011, 330, 3381–3399. [Google Scholar] [CrossRef]

- ISO 1083:2004—Spheroidal Graphite Cast Irons—Classification, ISO. Available online: http://www.iso.org/iso/catalogue_detail.htm?csnumber=33243 (accessed on 31 July 2016).

- Kanda, H.; Okubo, M.; Yonezawa, T. Analysis of Noise Sources and Their Transfer Paths in Diesel Engines; SAE Technical Paper 900014; SAE International: Warrendale, PA, USA, 1990. [Google Scholar]

- Wei, H.; Wei, J.; Shu, G. Calculation on cylinder pressure fluctuation by using the wave equation in KIVA program. Chin. J. Mech. Eng. 2012, 25, 362–369. [Google Scholar] [CrossRef]

- Hartog, J.P.D. Mechanical Vibrations; Courier Corporation: North Chelmsford, MA, USA, 1985. [Google Scholar]

- Ting, L.L.; Mayer, J.E. Piston Ring Lubrication and Cylinder Bore Wear Analyses, Part II—Theory Verification. J. Lubr. Technol. 1974, 96, 258–266. [Google Scholar] [CrossRef]

- ASTM. ASTM D6751-09, Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels; ASTM International: West Conshohocken, PA, USA, 2009; Available online: www.astm.org (accessed on 4 July 2017).

- Badaoui, M.E.; Danière, J.; Guillet, F.; Servière, C. Separation of combustion noise and piston-slap in diesel engine—Part I: Separation of combustion noise and piston-slap in diesel engine by cyclic Wiener filtering. Mech. Syst. Signal Process. 2005, 19, 1209–1217. [Google Scholar] [CrossRef]

- Servière, C.; Lacoume, J.-L.; El, M. Badaoui, Separation of combustion noise and piston-slap in diesel engine—Part II: Separation of combustion noise and piston-slap using blind source separation methods. Mech. Syst. Signal Process. 2005, 9, 1218–1229. [Google Scholar] [CrossRef]

- Singer, I.L.; Pollock, H. Fundamentals of Friction: Macroscopic and Microscopic Processes; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

| Density (kg/m3) | Young’s Modulus (Pa) | Poisson’s Ratio | Bulk Modulus (Pa) | Shear Modulus (Pa) |

|---|---|---|---|---|

| 7120 | 1.69 × 1011 | 0.286 | 1.316 × 1011 | 6.5708 × 1010 |

| No. | Simulated Frequencies (Hz) | Measured Frequencies (Hz) | Error (%) | No. | Simulated Frequencies (Hz) | Measured Frequencies (Hz) | Error (%) |

|---|---|---|---|---|---|---|---|

| 1 | 929.0 | 974.7 | 4.62 | 9 | 6673.2 | 6569.7 | 1.58 |

| 2 | 1229.7 | 1217.5 | 1.04 | 10 | 6979.5 | 6896.1 | 1.21 |

| 3 | 2567.3 | 2584.8 | 0.68 | 11 | 7926.9 | 7872.2 | 0.69 |

| 4 | 3128.7 | 3195.2 | 2.08 | 12 | 8732.6 | 8559.4 | 2.02 |

| 5 | 4191.4 | 4117.7 | 1.78 | 13 | 9011.1 | 8956.7 | 0.61 |

| 6 | 4301.5 | 4324.5 | 0.53 | 14 | 9321.0 | 9177.1 | 1.57 |

| 7 | 4847.0 | 4711.5 | 2.88 | 15 | 9879.4 | 9760.0 | 1.22 |

| 8 | 5832.1 | 5785.3 | 0.81 | 16 | 9939.9 | 10,012.5 | 0.72 |

| Properties | Density (20 °C)/(g/cm3) | Heat of Vaporization (kJ/kg) | Lower Heating Value (MJ/kg) | Kinematic Viscosity (mm2/s) | Surface Tension (mN/m) | Cetane |

|---|---|---|---|---|---|---|

| Diesel | 0.831 | 250 | 42.6 | 2.6 | 31.1 | 55 |

| Biodiesel | 0.884 | 320.2 | 37.4 | 5.2 | 30.4 | 59 |

| Manufacturer | Quanjiao Power Co., Ltd., Quanjiao, China |

|---|---|

| Engine type | QCH1125 |

| Number of cylinders | One |

| Combustion system | Direct injection, toroidal combustion chamber |

| Bore/stroke | 125/115 mm |

| Displacement volume | 1.093 L |

| Compression ratio | 18:1 |

| Cylinder liners | Cast iron replaceable wet liner |

| Start of fuel injection | 14 ± 2 degrees before top dead center (BTDC) |

| Rated power | 14.7/2400 kW/r/min |

| Piston clearance | 0.5 mm |

| Piston-pin offset | 0 mm |

| Fuel Type | Speed (rpm) | Load (Nm) |

|---|---|---|

| Diesel | 1000, 1400, 1800 | 10, 40 |

| Biodiesel | 1000, 1400, 1800 | 10, 40 |

| Property | Measured | Units |

|---|---|---|

| Composition | 77 | % C |

| 12 | % H | |

| 11 | % O | |

| Density | 879 | Kg/m3 |

| LHV, KJ/Kg | 38.5 | MJ/Kg |

| Kinematic Viscosity | 4.9 | mm2/s |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Gu, F.; Wang, T.; You, J.; Ball, A. Investigation into the Vibrational Responses of Cylinder Liners in an IC Engine Fueled with Biodiesel. Appl. Sci. 2017, 7, 717. https://doi.org/10.3390/app7070717

Li G, Gu F, Wang T, You J, Ball A. Investigation into the Vibrational Responses of Cylinder Liners in an IC Engine Fueled with Biodiesel. Applied Sciences. 2017; 7(7):717. https://doi.org/10.3390/app7070717

Chicago/Turabian StyleLi, Guoxing, Fengshou Gu, Tie Wang, Jianjun You, and Andrew Ball. 2017. "Investigation into the Vibrational Responses of Cylinder Liners in an IC Engine Fueled with Biodiesel" Applied Sciences 7, no. 7: 717. https://doi.org/10.3390/app7070717

APA StyleLi, G., Gu, F., Wang, T., You, J., & Ball, A. (2017). Investigation into the Vibrational Responses of Cylinder Liners in an IC Engine Fueled with Biodiesel. Applied Sciences, 7(7), 717. https://doi.org/10.3390/app7070717