The Index System for the Development Level Evaluation of Regional Construction Industrialization: A Case Study in Jiangsu, China

Abstract

:1. Introduction

2. Research Objective and Methodology

2.1. Research Objectives

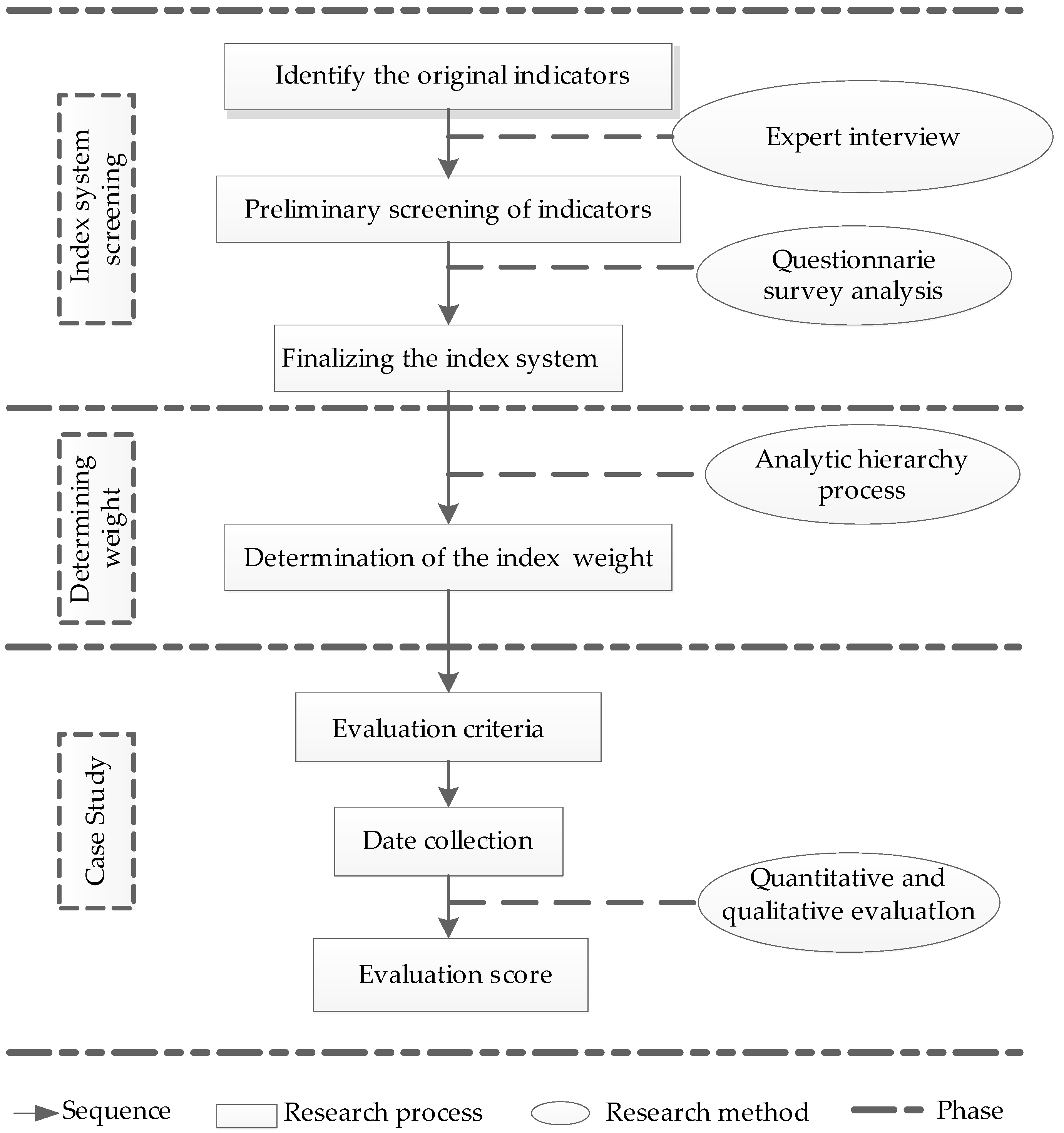

2.2. Methodology

2.3. Analytic Hierarchy Process Method

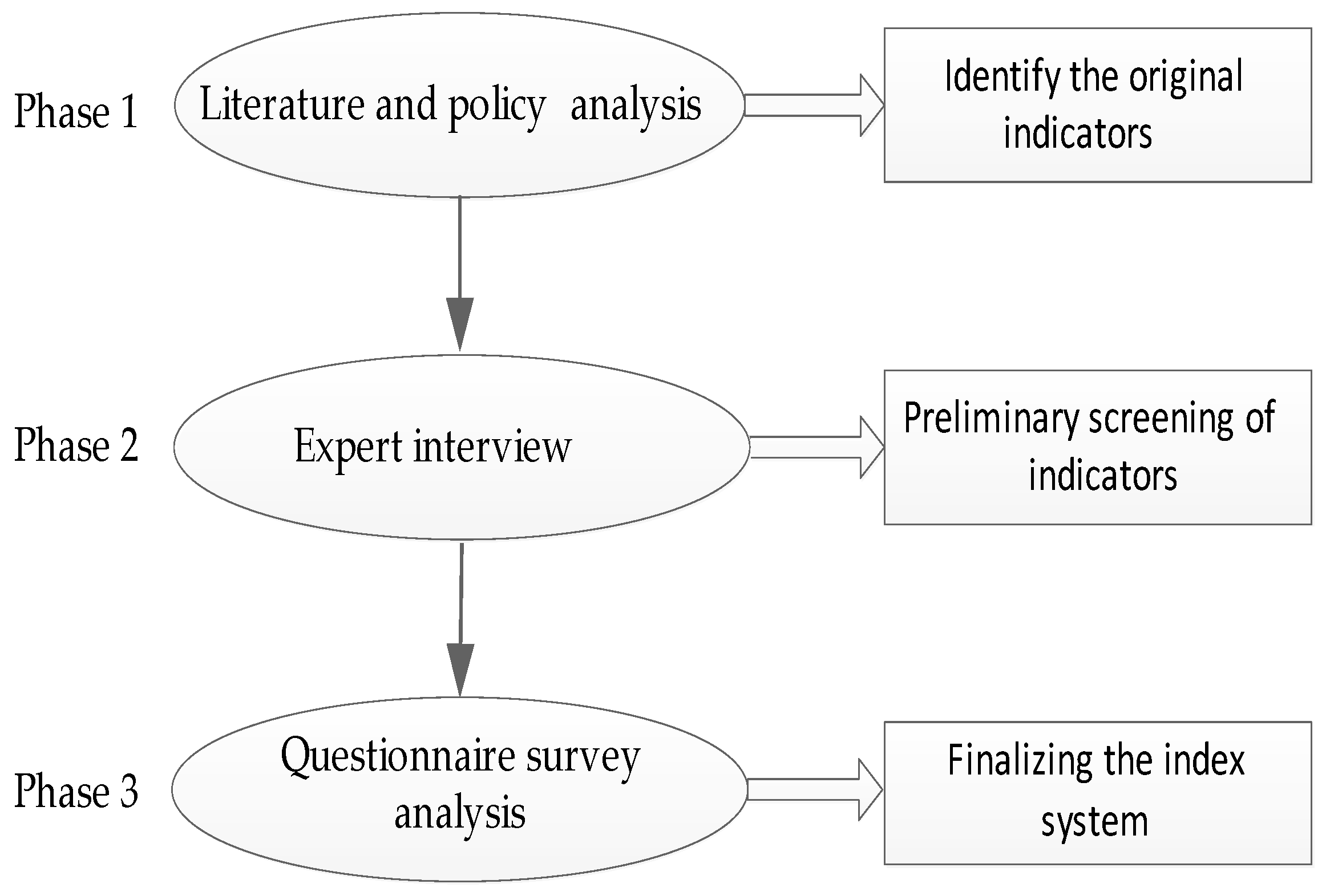

3. Index System Screening

3.1. Preliminary Screening of Indicators

3.2. Finalizing the Index System

3.2.1. Questionnaire Survey

3.2.2. Reliability Analysis

3.3.3. Mean Value and Ranking of the Indicators

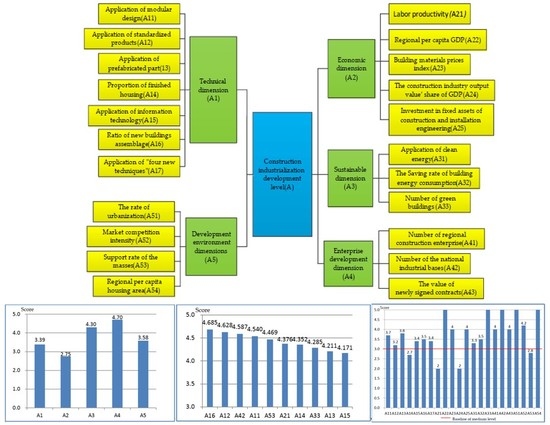

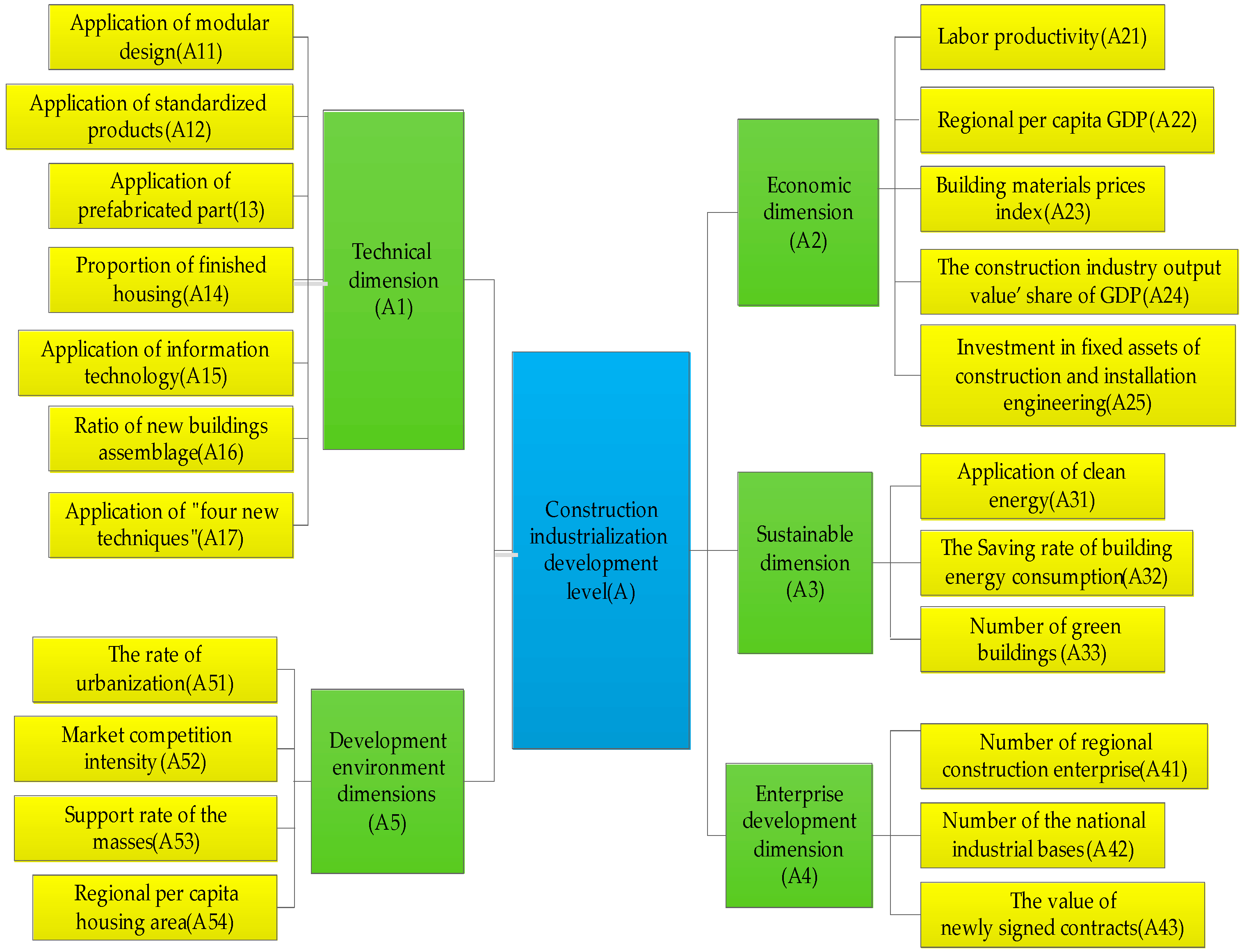

3.3.4. The Final Index System

4. Case Study

4.1. Study Area

4.2. Evaluation Criteria

4.3. Data Collection

4.4. Calculation Results of the Indicator Weight

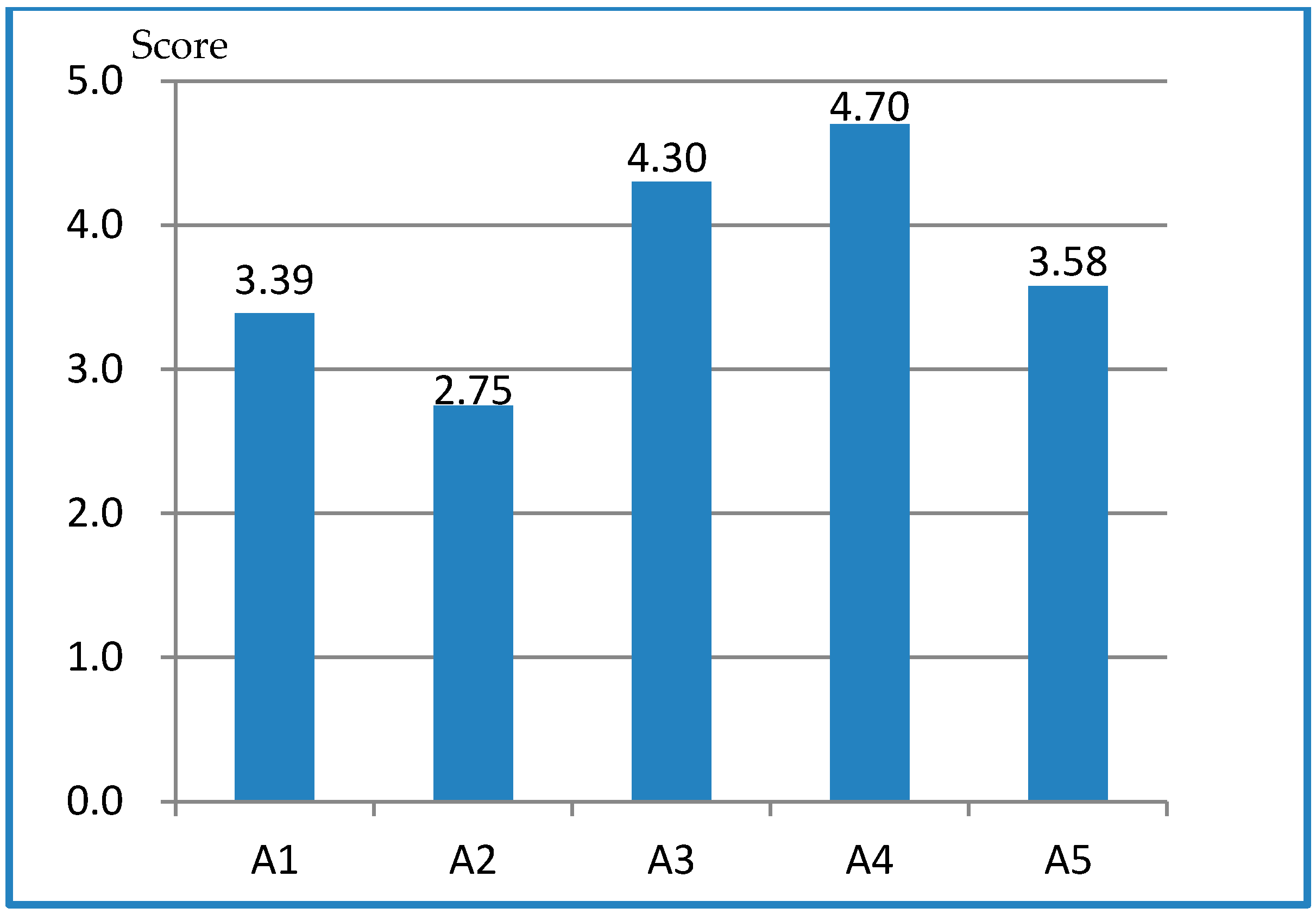

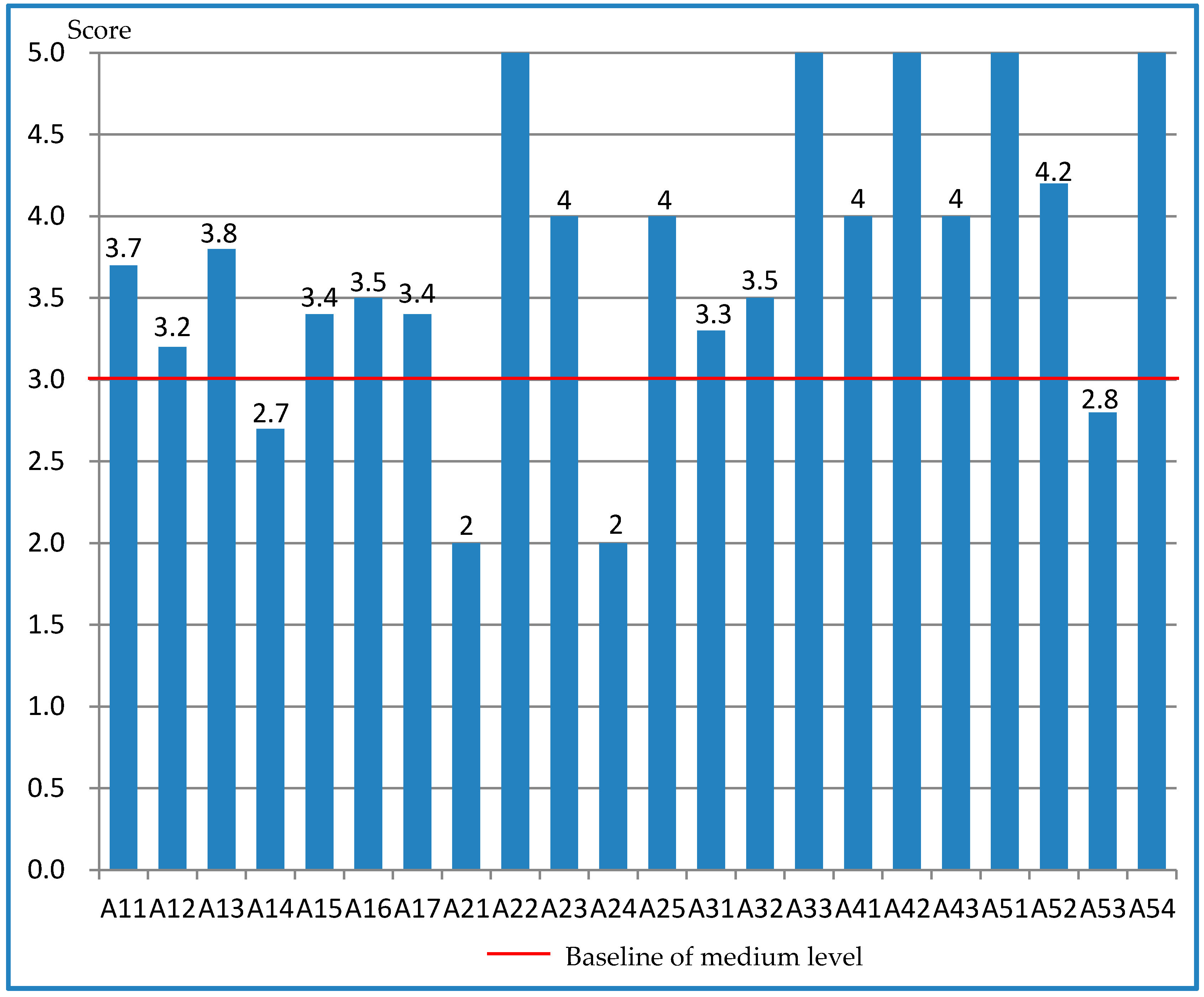

4.5. Calculation Results of Evaluation Score

5. Result Analysis

5.1. Result Analysis of Questionnaire Survey

5.2. Result Analysis of Case Study

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards adoption of prefabrication in construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Testa, C. The Industrialization of Building; Van Nostrand Reinhold Company: New York, NY, USA, 1972; pp. 13–16. [Google Scholar]

- Kale, S.; Arditi, D. Diffusion of ISO 9000 certification in the precast concrete industry. Constr. Manag. Econ. 2006, 24, 485–495. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.F.; Dainty, A.R.J. Leading UK housebuilders’ utilization of offsite construction methods. Build. Res. Inf. 2008, 36, 56–67. [Google Scholar] [CrossRef]

- Meiling, J.H.; Sandberg, M.; Johnsson, H. A study of a plan-do-check-act method used in less industrialized activities: Two cases from industrialized housebuilding. Constr. Manag. Econ. 2014, 32, 109–125. [Google Scholar] [CrossRef]

- Jonsson, H.; Rudberg, M. Classification of production systems for industrialized building: A production strategy perspective. Constr. Manag. Econ. 2014, 32, 53–69. [Google Scholar] [CrossRef]

- Goodier, C.; Gibb, A. Future opportunities for offsite in the UK. Constr. Manag. Econ. 2007, 25, 585–595. [Google Scholar] [CrossRef]

- Richard, R.B. Industrialised building systems: Reproduction before automation and robotics. Autom. Constr. 2005, 14, 442–451. [Google Scholar] [CrossRef]

- Nadim, W.; Goulding, J.S. Offsite production in the UK: The way forward? A UK construction industry perspective. Constr. Innov. 2010, 10, 181–202. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Pons, O.; Wadel, G. Environmental impacts of prefabricated school buildings in Catalonia. Habitat Int. 2011, 35, 553–563. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Baldwin, A.; Poon, C.S.; Shen, L.Y.; Austin, S.; Wong, I. Designing out waste in high-rise residential buildings: Analysis of precasting methods and traditional construction. Renew. Energy 2009, 34, 2067–2073. [Google Scholar] [CrossRef]

- Chiang, Y.H.; Chan, H.W.; Lok, K.L. Prefabrication and barriers to entry—A case study of public housing and institutional buildings in Hong Kong. Habitat Int. 2006, 30, 482–499. [Google Scholar] [CrossRef]

- Lu, A.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar]

- Sacks, R.; Kaner, I.; Eastman, C.M.; Jeong, Y.S. The Rosewood experiment—Building information modeling and interoperability for architectural precast facades. Autom. Constr. 2010, 19, 419–432. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.H.; Kim, J.T. Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Pan, N.H.; Chiu, T.C.; Chen, K.Y. Full-span Pre-cast Launching Method (FPLM) analysis with Dynamic Simulation—Case studies of Taiwan High-Speed Rail (THSR) Project. Autom. Constr. 2008, 17, 592–607. [Google Scholar] [CrossRef]

- Yin, S.Y.L.; Tserng, H.P.; Wang, J.C.; Tsai, S.C. Developing a precast production management system using RFID technology. Autom. Constr. 2009, 18, 677–691. [Google Scholar] [CrossRef]

- Ergen, E.; Akinci, B.; Sacks, R. Tracking and locating components in a precast storage yard utilizing radio frequency identification technology and GPS. Autom. Constr. 2007, 16, 354–367. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Xinhua News Agency. 2015. Available online: http://news.xinhuanet.com/finance/2015-11/03/c_1117025413.htm (accessed on 20 October 2016).

- Ji, Y.; Zhu, F.; Li, H.X.; Al-hussein, M. Construction Industrialization in China: Current Profile and the Prediction. Appl. Sci. 2017, 7, 180. [Google Scholar] [CrossRef]

- Pan, W.; Dainty, A.R.J.; Gibb, A.G.F. Establishing and Weighting Decision Criteria for Building System Selection in Housing Construction. J. Constr. Eng. Manag. 2012, 138, 1239–1250. [Google Scholar] [CrossRef]

- Nahmens, I.; Bindroo, V. Is Customization Fruitful in Industrialized Homebuilding Industry? J. Constr. Eng. Manag. 2011, 137, 1027–1035. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. Investigating waste reduction potential in the upstream processes of offshore prefabrication construction. Renew. Sustain. Energy Rev. 2013, 28, 804–811. [Google Scholar] [CrossRef]

- Song, J.; Fagerlund, W.R.; Haas, C.T.; Tatum, C.B.; Vanegas, J.A. Considering Prework on Industrial Projects. J. Constr. Eng. Manag. 2005, 131, 723–733. [Google Scholar] [CrossRef]

- Park, M.; Ingawale-Verma, Y.; Kim, W.; Ham, Y. Construction policymaking: With an example of singaporean government’s policy to diffuse prefabrication to private sector. KSCE J. Civ. Eng. 2011, 15, 771–779. [Google Scholar] [CrossRef]

- Wang, N.; Ji, Y. Analysis on Key Factors to Affect Construction Industrialization Development in China. In Proceedings of the Information Management, Innovation and Industrial Engineering, Kunming, China, 26–28 November 2010. [Google Scholar]

- Bing, X.; Chen, J.J. Research on the Measuring Model of Construction Industrialization Development Level. In Proceedings of the International Conference on Management and Service Science, Wuhan, China, 24–26 August 2010. [Google Scholar]

- Li, S.; Wu, X.; Zhou, Y.; Liu, X. A study on the evaluation of implementation level of lean construction in two Chinese fi rms. Renew. Sustain. Energy Rev. 2017, 71, 846–851. [Google Scholar] [CrossRef]

- Shi, R.; Fan, X.; He, Y. Comprehensive evaluation index system for wind power utilization levels in wind farms in China. Renew. Sustain. Energy Rev. 2017, 69, 461–471. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods; SAGE: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw-Hill: New York, NY, USA; 1980. [Google Scholar]

- Raviv, G.; Shapira, A.; Fishbain, B. AHP-based analysis of the risk potential of safety incidents : Case study of cranes in the construction industry. Saf. Sci. 2017, 91, 298–309. [Google Scholar] [CrossRef]

- Dweiri, F.; Kumar, S.; Khan, S.A.; Jain, V. Designing an integrated AHP based decision support system for supplier selection in automotive industry. Expert Syst. Appl. 2016, 62, 273–283. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Peng, Y.; Xue, F.; Fang, J.; Zou, W.; Luo, H.; Ng, S.T.; Lu, W.; Shen, G.Q.P.; Huang, G.Q. Automation in Construction Prefabricated construction enabled by the Internet-of-Things. Autom. Constr. 2017, 76, 59–70. [Google Scholar] [CrossRef]

- Eastman, C.M.; Sacks, R. Relative Productivity in the AEC Industries in the United States for On-Site and Off-Site Activities. J. Constr. Eng. Manag. 2008, 134, 517–526. [Google Scholar] [CrossRef]

- Johnson, C. Impacts of prefabricated temporary housing after disasters: 1999 earthquakes in Turkey. Habitat Int. 2007, 31, 36–52. [Google Scholar] [CrossRef]

- Pan, W.; Dainty, A.R.J.; Gibb, A.G.F. Encouraging Appropriate Use of Offsite Production (OSP): Perspectives of Designers; Hong Kong Polytechnic University: Hong Kong, China, 2004. [Google Scholar]

- Zhao, X.; Singhaputtangkul, N. Effects of Firm Characteristics on Enterprise Risk Management: Case Study of Chinese Construction Firms Operating in Singapore. J. Manag. Eng. 2016, 32, 5016008. [Google Scholar] [CrossRef]

- Shen, Y.; Koh, T.Y.; Rowlinson, S.; Bridge, A.J. Empirical Investigation of Factors Contributing to the Psychological Safety Climate on Construction Sites. J. Constr. Eng. Manag. 2015, 141, 4015038. [Google Scholar] [CrossRef]

- Statistics Bureau of Jiangsu Province. 2016. Available online: http://www.jssb.gov.cn/tjxxgk/tjsj/sjxxfb/ (accessed on 6 January 2017).

- China’s National Bureau of Statistics. 2016. Available online: http://data.stats.gov.cn/ (accessed on 8 January 2017).

- Valenzuela-Venegas, G.; Salgado, J.C.; Díaz-Alvarado, F.A. Sustainability indicators for the assessment of eco-industrial parks: Classification and criteria for selection. J. Clean. Prod. 2016, 133, 99–116. [Google Scholar] [CrossRef]

- Wang, Q.; Lu, S.; Yuan, X.; Zuo, J.; Zhang, J.; Hong, J. The index system for project selection in ecological industrial park : A China study. Ecol. Indic. 2017, 77, 267–275. [Google Scholar] [CrossRef]

- Ministry of Housing and Rural-Urban of China. National Programmer for Construction Industry Modernization. 2015. Available online: http://www.precast.com.cn/index.php/news_detail-id-4866.html (accessed on 25 October 2016).

- Jiangsu Province People’s Government. Green Building Action Plan of Jiangsu Province. 2013. Available online: http://www.jiangsu.gov.cn/jsgov/tj/bgt/201306/t20130626_387416.html (accessed on 18 October 2016).

- Jiangsu Province People’s Government. 2012. Available online: http://www.jiangsu.gov.cn/jsgov/tj/bgt/201211/t20121121_253252.html (accessed on 5 November 2016).

- Ministry of Housing and Rural-Urban of China. 2016. Available online: http://huanbao.bjx.com.cn/news/20160203/706809.shtml (accessed on 26 November 2016).

- Construction Industry Modernization Website. 2015. Available online: http://www.new-ci.com/html/43-1/1399.htm (accessed on 16 December 2016).

- Jiangsu Province People’s Government. 2015. Available online: http://xh.xhby.net/mp2/html/2016-02/25/content_1378994.htm (accessed on 27 November 2016).

| Score | Importance Description |

|---|---|

| 1 | “i” is equal important to “j” |

| 3 | “i” is weakly more important to “j” |

| 5 | “i” is strongly important to “j” |

| 7 | “i” is very strongly important to “j” |

| 9 | “i” is absolute more importance to “j” |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.52 | 0.89 | 1.12 | 1.26 | 1.36 | 1.41 | 1.46 | 1.49 |

| Target Layer | Dimension Layer | Index Layer |

|---|---|---|

| Regional construction industrialization development level | Technical dimension (A1) | Application of modular design (A11); Application of standardized products (A12); Application of prefabricated part (A13); Proportion of finished housing (A14); Application of information technology (A15); Ratio of new buildings assemblage (A16); Application of “four new techniques” (A17); 3D printing technology (A18). |

| Economic dimension (A2) | Labor productivity (A21); Regional per capita GDP (A22); Building materials prices index (A23); The construction industry output value’ share of GDP (A24); Investment in fixed assets of construction and installation engineering (A25). | |

| Sustainable dimension (A3) | Application of clean energy (A31); The saving rate of building energy consumption (A32); Number of green buildings (A33); The utilization of land resources (A34). | |

| Enterprise development dimension (A4) | Number of regional construction company (A41); Number of the national industrial bases (A42); The value of newly signed contracts (A43); Number of the employees in the regional construction industry (A44). | |

| Development environment dimension (A5) | The rate of urbanization (A51); Market competition intensity (A52); Support rate of the masses (A53); Regional per capita housing area (A54). |

| Respondents’ Characteristics | Description | N | % |

|---|---|---|---|

| Construction companies (N = 67) | Senior manager | 35 | 52.2 |

| Project manager | 21 | 31.3 | |

| Project engineer | 11 | 16.5 | |

| Government regulators (N = 85) | Leader | 62 | 72.9 |

| Staff | 23 | 27.1 | |

| Years of experience (N = 152) | <5 | 19 | 12.5 |

| 5–9 | 31 | 20.4 | |

| 10–20 | 74 | 48.7 | |

| >20 | 28 | 18.4 | |

| Regions (N = 152) | Jiangsu Province | 91 | 59.9 |

| Zhejiang Province | 17 | 11.2 | |

| Shanghai | 14 | 9.2 | |

| Others | 30 | 19.7 |

| Dimension | Indicator | Mean | Std. Dev | CV | Rank | Group Mean | Group Rank | Verification |

|---|---|---|---|---|---|---|---|---|

| Technical dimension (A1) | A11 | 4.540 | 0.61 | 0.13 | 4 | 4.383 | 1 | Pass |

| A12 | 4.628 | 0.58 | 0.13 | 2 | Pass | |||

| A13 | 4.211 | 0.78 | 0.19 | 9 | Pass | |||

| A14 | 4.352 | 0.82 | 0.19 | 7 | Pass | |||

| A15 | 4.171 | 1.21 | 0.29 | 10 | Pass | |||

| A16 | 4.685 | 0.46 | 0.10 | 1 | Pass | |||

| A17 | 4.095 | 0.86 | 0.21 | 11 | Pass | |||

| A18 | 2.875 | 1.14 | 0.40 | 23 | No | |||

| Economic dimension (A2) | A21 | 4.376 | 0.49 | 0.11 | 6 | 3.774 | 4 | Pass |

| A22 | 3.157 | 0.78 | 0.25 | 22 | Pass | |||

| A23 | 3.866 | 0.50 | 0.13 | 15 | Pass | |||

| A24 | 3.925 | 0.83 | 0.21 | 14 | Pass | |||

| A25 | 3.548 | 0.71 | 0.20 | 17 | Pass | |||

| Sustainable dimension (A3) | A31 | 3.430 | 0.83 | 0.24 | 19 | 3.892 | 3 | Pass |

| A32 | 3.961 | 0.66 | 0.17 | 13 | Pass | |||

| A33 | 4.285 | 0.87 | 0.20 | 8 | Pass | |||

| A34 | 2.601 | 0.81 | 0.31 | 24 | No | |||

| Enterprise development dimension (A4) | A41 | 3.361 | 0.74 | 0.22 | 20 | 4.002 | 2 | Pass |

| A42 | 4.587 | 1.05 | 0.23 | 3 | Pass | |||

| A43 | 4.059 | 0.67 | 0.17 | 12 | Pass | |||

| A44 | 2.473 | 0.71 | 0.29 | 25 | No | |||

| Development environment dimension (A5) | A51 | 3.774 | 0.48 | 0.13 | 16 | 3.742 | 5 | Pass |

| A52 | 3.471 | 0.85 | 0.24 | 18 | Pass | |||

| A53 | 4.469 | 0.45 | 0.10 | 5 | Pass | |||

| A54 | 3.254 | 0.62 | 0.19 | 21 | Pass |

| Index | Evaluation Criteria | Score | Rule Explained |

|---|---|---|---|

| A11, A12 A13, A15 A16, A17 | Proportion more than 20% | 5 | National programmer for construction industry modernization [47] |

| Proportion within 15–20% | 4 | ||

| Proportion within 10–15% | 3 | ||

| Proportion within 5–10% | 2 | ||

| Proportion lower than 5% | 1 | ||

| A14 | Proportion more than 60% | 5 | Compared with data of “Green building action plan of Jiangsu province” [48] |

| Proportion within 40–60% | 4 | ||

| Proportion within 20–40% | 3 | ||

| Proportion within 10–20% | 2 | ||

| Proportion lower than 10% | 1 |

| Index | Scoring Criteria | Score | Rule Explained |

|---|---|---|---|

| A21 | more than 340,000 Yuan per person | 5 | The national average is 324,026 [44] |

| within 330,000–340,000 Yuan/person | 4 | ||

| within 320,000–330,000 Yuan/person | 3 | ||

| within 290,000–320,000 Yuan/person | 2 | ||

| lower than 290,000 Yuan per person | 1 | ||

| A22 | more than 70,000 Yuan per person | 5 | The national average is 52,000 Yuan/person [44] |

| within 60,000–70,000 Yuan/person | 4 | ||

| within 50,000–60,000 Yuan/person | 3 | ||

| within 40,000–50,000 Yuan/person | 2 | ||

| lower than 40,000 Yuan/person | 1 | ||

| A23 | Price index below 90 | 5 | The national average is 100.0 [44] |

| Price index within 90–95 | 4 | ||

| Price index within 95–100 | 3 | ||

| Price index within 100–105 | 2 | ||

| Price index more than 105 | 1 | ||

| A24 | Proportion more than 7.5% | 5 | The national average is 6.86% [44] |

| Proportion within 7.0–7.5% | 4 | ||

| Proportion within 6.5–7.0% | 3 | ||

| Proportion within 6.0–6.5% | 2 | ||

| Proportion lower than 6.0% | 1 | ||

| A25 | Proportion more than 15% | 5 | The national total is 37,972 trillion Yuan [44] |

| Proportion within 7–15% | 4 | ||

| Proportion within 4–7% | 3 | ||

| Proportion within 2–4% | 2 | ||

| Proportion below 2% | 1 |

| Index | Scoring Criteria | Score | Rule Explained |

|---|---|---|---|

| A31 | A large number of projects | 5 | Expert decision |

| Within 3–5 | 4 | ||

| Several projects | 3 | ||

| Within 1–2 | 2 | ||

| No project | 1 | ||

| A32 | Ratio reaches 65% or more | 5 | Compared with data of “The twelfth Five-Year Plane of energy efficiency in buildings of Jiangsu province” [49] |

| Ratio within 55–65% | 4 | ||

| Ratio within 45–55% | 3 | ||

| Ratio within 30–45% | 2 | ||

| Ratio below 30% | 1 | ||

| A33 | Proportion more than 15% | 5 | The national total is 3636 [50] |

| Proportion within 7–15% | 4 | ||

| Proportion within 4–7% | 3 | ||

| Proportion within 2–4% | 2 | ||

| Proportion below 2% | 1 |

| Index | Scoring Criteria | Score | Rule Explained |

|---|---|---|---|

| A41 | Proportion more than 15% | 5 | The national total is 80,911 [44] |

| Proportion within 7–15% | 4 | ||

| Proportion within 4–7% | 3 | ||

| Proportion within 2–4% | 2 | ||

| Proportion below 2% | 1 | ||

| A42 | Number reaches 7 or more | 5 | The national total is 70 [51] |

| Number within 5–6 | 4 | ||

| Number within 3–4 | 3 | ||

| Number 2 | 2 | ||

| Number 1 or under | 1 | ||

| A43 | Proportion more than 15% | 5 | The national total is 18.43 trillion Yuan [44] |

| Proportion within 7–15% | 4 | ||

| Proportion within 4–7% | 3 | ||

| Proportion within 2–4% | 2 | ||

| Proportion below 2% | 1 |

| Index | Scoring Criteria | Score | Rule Explained |

|---|---|---|---|

| A51 | Ratio reaches 65% or more | 5 | The national average is 56.1% [44] |

| Ratio within 60–65% | 4 | ||

| Ratio within 55–60% | 3 | ||

| Ratio within 55–50% | 2 | ||

| Ratio below 50% | 1 | ||

| A52 | High degree of market competition | 5 | Expert decision |

| Within 3–5 | 4 | ||

| Common degree of market competition | 3 | ||

| Within 1–3 | 2 | ||

| Poor degree of market competition | 1 | ||

| A53 | High degree acceptance | 5 | Expert decision |

| Within 3–5 | 4 | ||

| Common degree acceptance | 3 | ||

| Within 1–3 | 2 | ||

| Poor degree acceptance | 1 | ||

| A54 | More than 40 m2 | 5 | The national average is 33 m2 [44] |

| Within 37–40 m2 | 4 | ||

| Within 33–37 m2 | 3 | ||

| Within 30–33 m2 | 2 | ||

| Lower than 30 m2 | 1 |

| Index | Data | Source |

|---|---|---|

| A21 | 297,437/Yuan/Year | Statistical Yearbook of Jiangsu [43] |

| A22 | 88,500 | National Bureau of Statistics of China [44] |

| A23 | 91.7 | Statistical Yearbook of Jiangsu [43] |

| A24 | 6% | National economy and social development statistical bulletin of Jiangsu [52] |

| A25 | 2.757 trillion Yuan | Statistical Yearbook of Jiangsu [43] |

| A33 | 562 | Ministry of Housing and Urban-Rural Construction of China [50] |

| A41 | 9146 | Statistical Yearbook of Jiangsu [43] |

| A42 | 8 | List of national housing industrialization base [51] |

| A43 | 2.077 trillion Yuan | Statistical Yearbook of Jiangsu [43] |

| A51 | 66.5% | National economy and social development statistical bulletin of Jiangsu [52] |

| A54 | 45.22 m2 | Statistical Yearbook of Jiangsu [43] |

| A | A1 | A2 | A3 | A4 | A5 | Weight | ||

|---|---|---|---|---|---|---|---|---|

| A1 | 1 | 1/5 | 1/4 | 1/3 | 1/5 | 5.224 | 0.47 | CI = 0.056 < 0.1 Uniform convergence |

| A2 | 5 | 1 | 3 | 4 | 1/2 | 0.08 | ||

| A3 | 4 | 1/3 | 1 | 3 | 1/2 | 0.13 | ||

| A4 | 3 | 1/4 | 1/3 | 1 | 1/4 | 0.26 | ||

| A5 | 5 | 2 | 2 | 4 | 1 | 0.06 |

| A1 | A11 | A12 | A13 | A14 | A15 | A16 | A17 | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|

| A11 | 1 | 2 | 1/4 | 1/3 | 1/5 | 3 | 1/5 | 7.264 | 0.18 | CI = 0.044 < 0.1 Uniform convergence |

| A12 | 1/2 | 1 | 1/5 | 1/4 | 1/6 | 2 | 1/6 | 0.26 | ||

| A13 | 4 | 5 | 1 | 3 | 1/2 | 5 | 1/3 | 0.06 | ||

| A14 | 3 | 4 | 1/3 | 1 | 1/3 | 4 | 1/4 | 0.10 | ||

| A15 | 5 | 6 | 2 | 3 | 1 | 6 | 1/2 | 0.04 | ||

| A16 | 1/3 | 1/2 | 1/5 | 1/4 | 1/6 | 1 | 1/7 | 0.33 | ||

| A17 | 5 | 6 | 3 | 4 | 2 | 7 | 1 | 0.03 |

| A2 | A21 | A22 | A23 | A24 | A25 | Weight | ||

|---|---|---|---|---|---|---|---|---|

| A21 | 1 | 1/5 | 1/3 | 1/3 | 1/3 | 5.104 | 0.45 | CI = 0.026 < 0.1 Uniform convergence |

| A22 | 5 | 1 | 3 | 3 | 2 | 0.07 | ||

| A23 | 3 | 1/3 | 1 | 2 | 1/2 | 0.16 | ||

| A24 | 3 | 1/3 | 1/2 | 1 | 1/2 | 0.21 | ||

| A25 | 4 | 1/2 | 2 | 2 | 1 | 0.11 |

| A3 | A31 | A32 | A33 | Weight | ||

|---|---|---|---|---|---|---|

| A31 | 1 | 3 | 4 | 3.036 | 0.13 | CI = 0.018 < 0.1 Uniform convergence |

| A32 | 1/3 | 1 | 2 | 0.32 | ||

| A33 | 1/4 | 1/2 | 1 | 0.55 |

| A4 | A41 | A42 | A43 | Weight | ||

|---|---|---|---|---|---|---|

| A41 | 1 | 7 | 3 | 3.062 | 0.09 | CI = 0.031 < 0.1 Uniform convergence |

| A42 | 1/7 | 1 | 1/4 | 0.70 | ||

| A43 | 1/3 | 4 | 1 | 0.21 |

| A5 | A51 | A52 | A53 | A54 | Weight | ||

|---|---|---|---|---|---|---|---|

| A51 | 1 | 1/2 | 4 | 1/3 | 4.075 | 0.20 | CI = 0.025 < 0.1 Uniform convergence |

| A52 | 2 | 1 | 5 | 1/2 | 0.12 | ||

| A53 | 1/4 | 1/5 | 1 | 1/6 | 0.60 | ||

| A54 | 3 | 2 | 6 | 1 | 0.08 |

| Evaluation Target (A) | Dimension (Ai) | Index (Aij) | W(ij) | SC(i) | W(i) | SC | |

|---|---|---|---|---|---|---|---|

| Regional construction industrialization development level | A1 | A11 | 3.7 | 0.18 | 3.39 | 0.47 | 3.81 |

| A12 | 3.2 | 0.26 | |||||

| A13 | 3.8 | 0.06 | |||||

| A14 | 2.7 | 0.10 | |||||

| A15 | 3.4 | 0.04 | |||||

| A16 | 3.5 | 0.33 | |||||

| A17 | 3.4 | 0.03 | |||||

| A2 | A21 | 2 | 0.45 | 2.75 | 0.08 | ||

| A22 | 5 | 0.07 | |||||

| A23 | 4 | 0.16 | |||||

| A24 | 2 | 0.21 | |||||

| A25 | 4 | 0.11 | |||||

| A3 | A31 | 3.3 | 0.13 | 4.30 | 0.13 | ||

| A32 | 3.5 | 0.32 | |||||

| A33 | 5 | 0.55 | |||||

| A4 | A41 | 4 | 0.09 | 4.70 | 0.26 | ||

| A42 | 5 | 0.70 | |||||

| A43 | 4 | 0.21 | |||||

| A5 | A51 | 5 | 0.20 | 3.58 | 0.06 | ||

| A52 | 4.2 | 0.12 | |||||

| A53 | 2.8 | 0.60 | |||||

| A54 | 5 | 0.08 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Li, Q.; Song, L.; Jia, R. The Index System for the Development Level Evaluation of Regional Construction Industrialization: A Case Study in Jiangsu, China. Appl. Sci. 2017, 7, 492. https://doi.org/10.3390/app7050492

Liu P, Li Q, Song L, Jia R. The Index System for the Development Level Evaluation of Regional Construction Industrialization: A Case Study in Jiangsu, China. Applied Sciences. 2017; 7(5):492. https://doi.org/10.3390/app7050492

Chicago/Turabian StyleLiu, Ping, Qiming Li, Liangliang Song, and Ruoyu Jia. 2017. "The Index System for the Development Level Evaluation of Regional Construction Industrialization: A Case Study in Jiangsu, China" Applied Sciences 7, no. 5: 492. https://doi.org/10.3390/app7050492

APA StyleLiu, P., Li, Q., Song, L., & Jia, R. (2017). The Index System for the Development Level Evaluation of Regional Construction Industrialization: A Case Study in Jiangsu, China. Applied Sciences, 7(5), 492. https://doi.org/10.3390/app7050492