Principles and Application of Polyimide Fiber Bragg Gratings for Surface Strain Measurement

Abstract

:1. Introduction

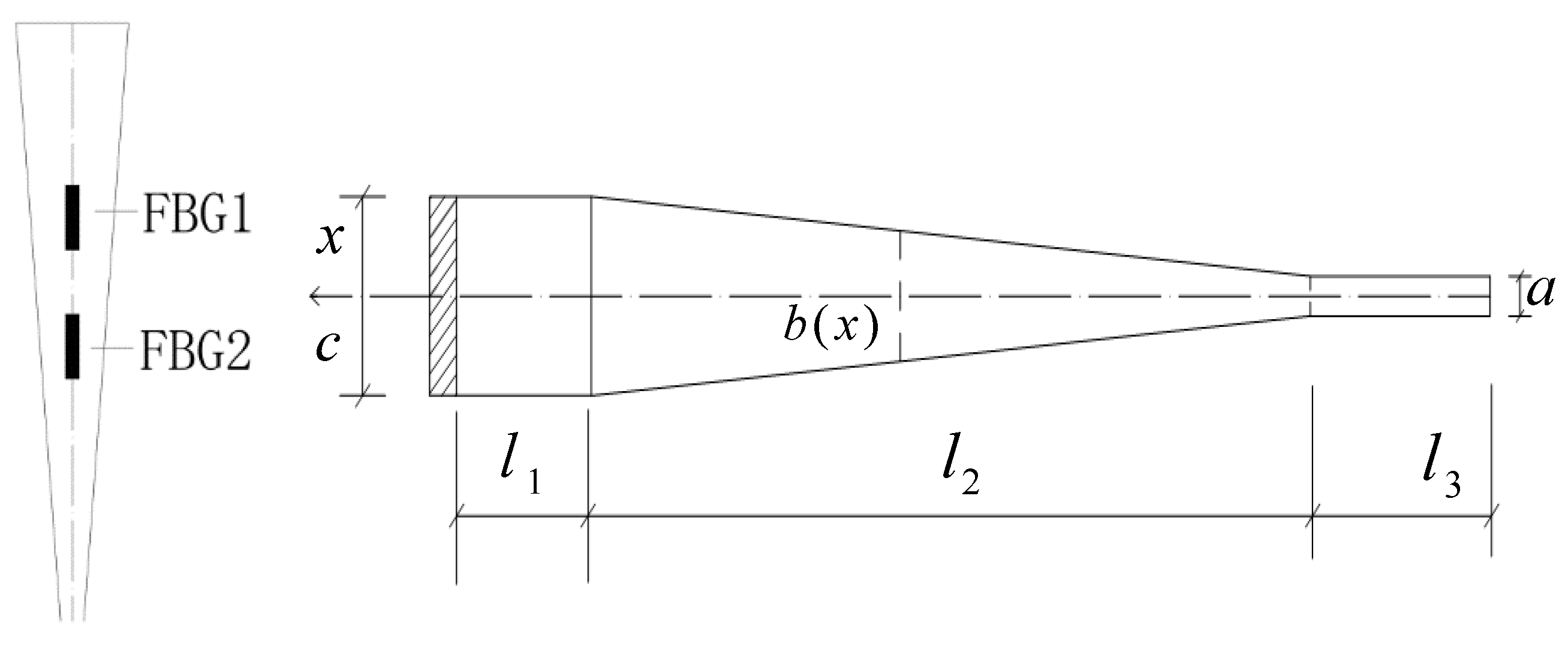

2. Research on the Strain Transfer Model

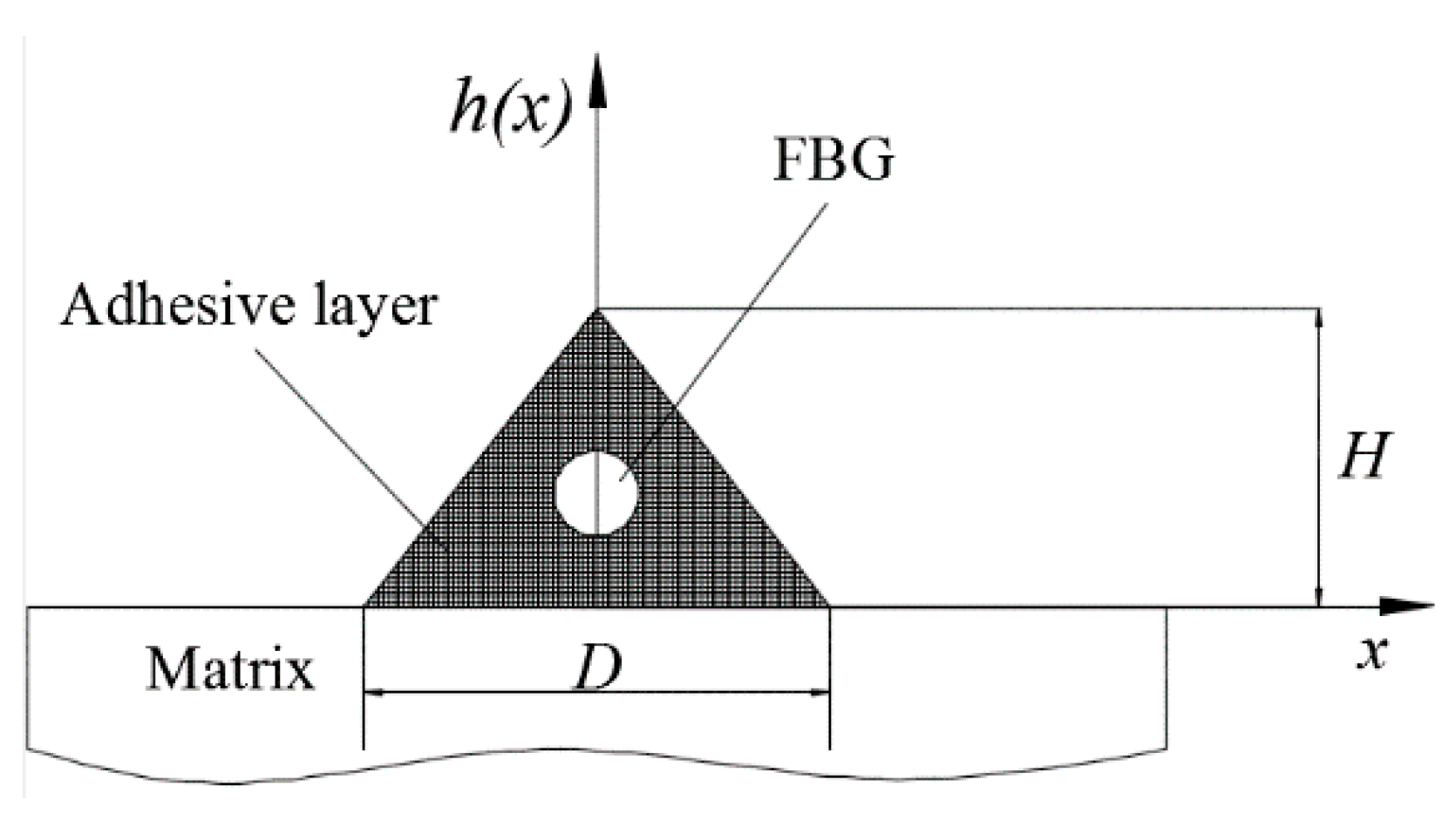

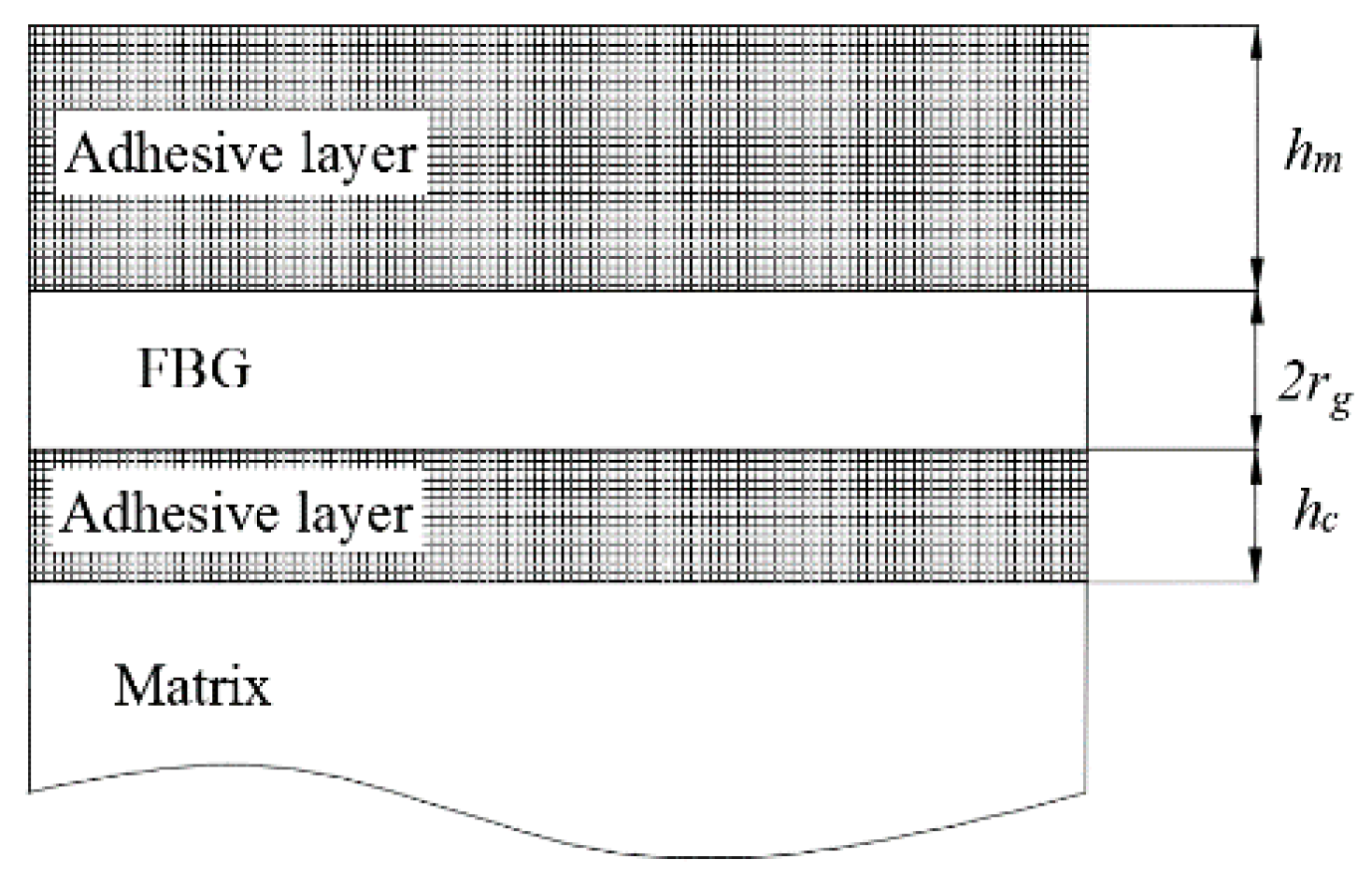

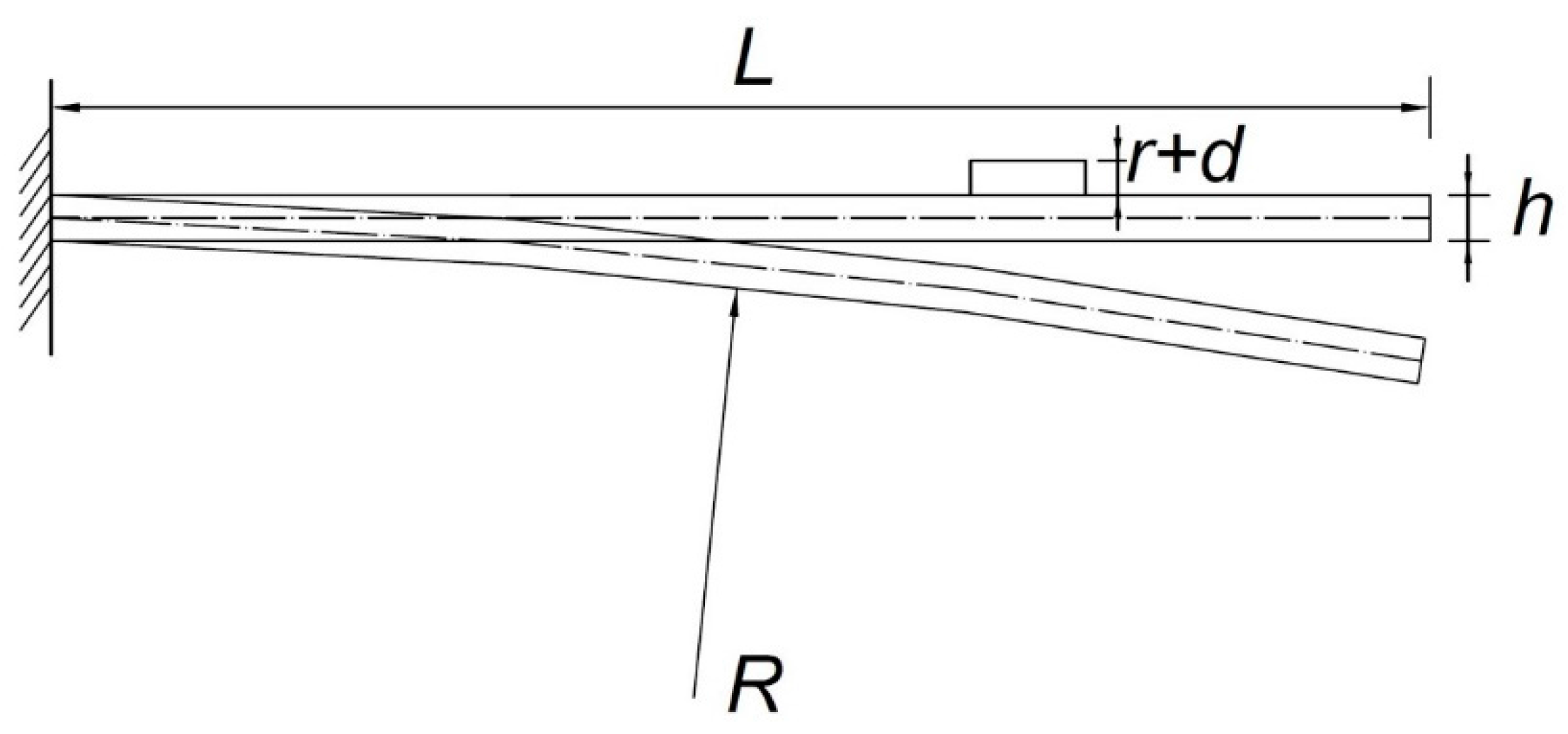

2.1. Surface-Bonding Stain Transfer Model

- (1)

- Core, bonding, and substrate are all linear elastic materials.

- (2)

- Because there is no coating, the various interfaces of core-bonding and bonding substrates can be assumed to be perfect contacts, and accordingly, the subjected axial stresses do not exceed the maximum stress, which produces a relative slip between the various interfaces.

- (3)

- Polyimide coating of the fiber can actually be neglected, as to say the polyimide FBG can be considered as uncoated FBG. The representation of the adhesive bonding structure can be considered as a triangle.

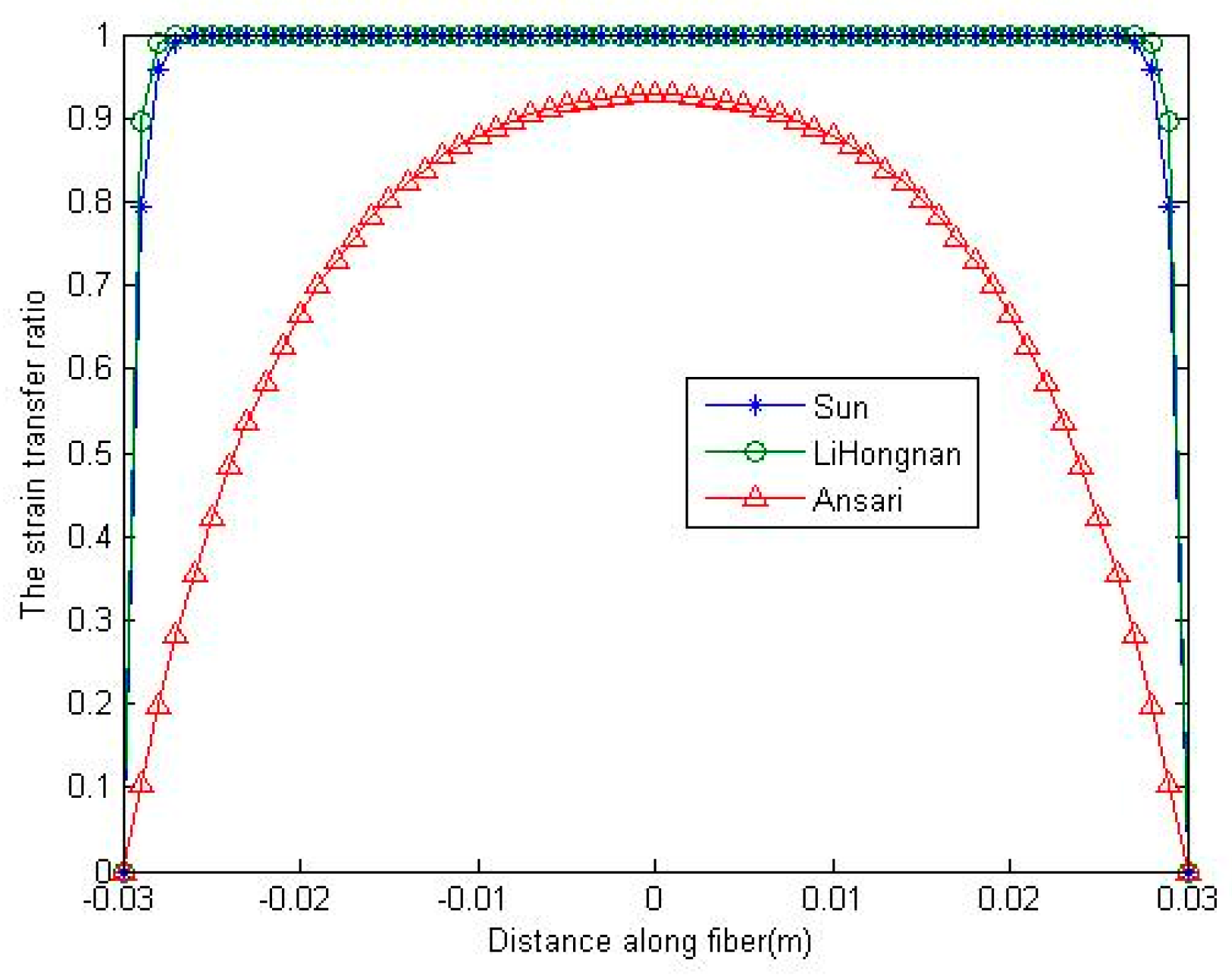

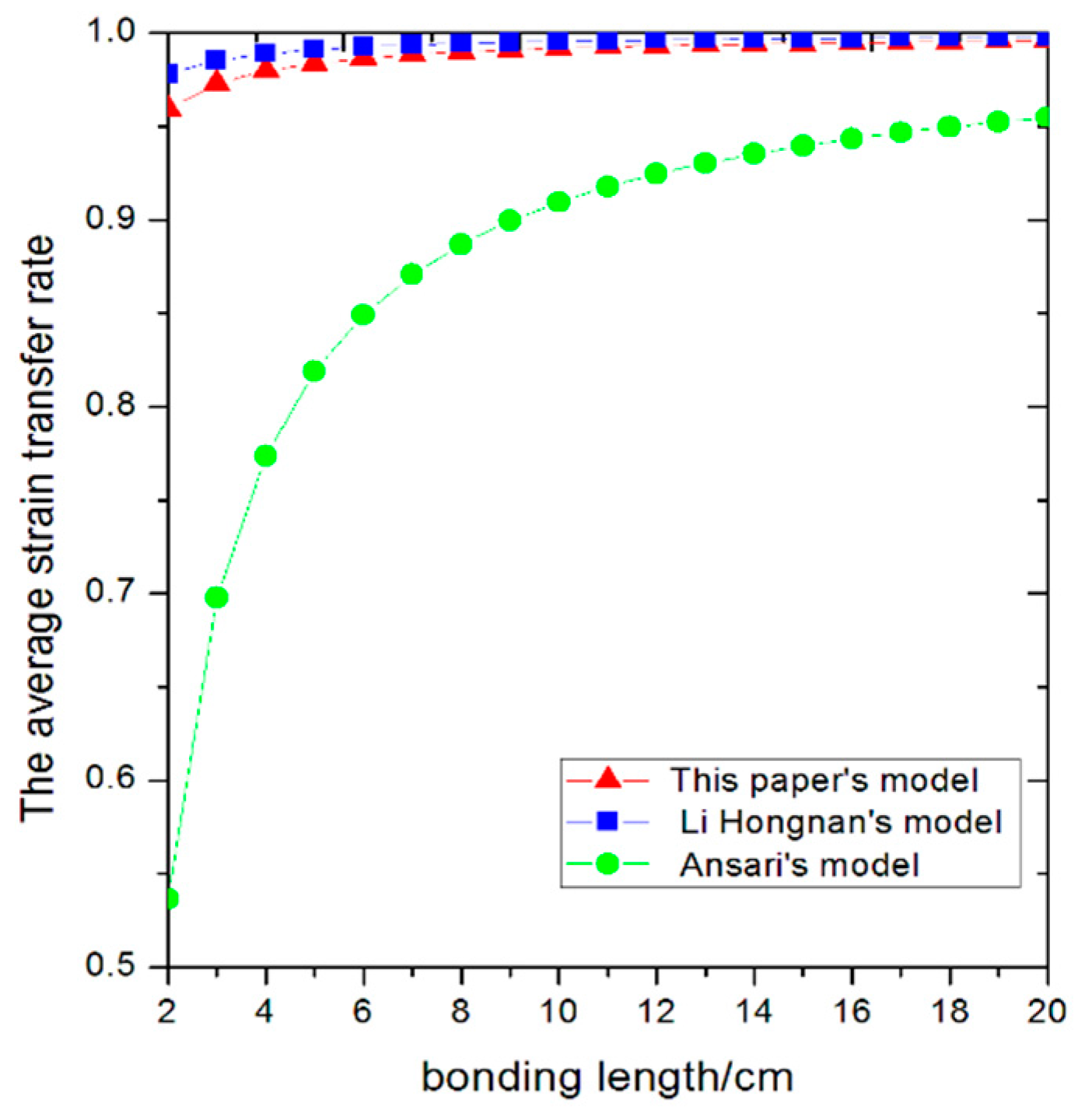

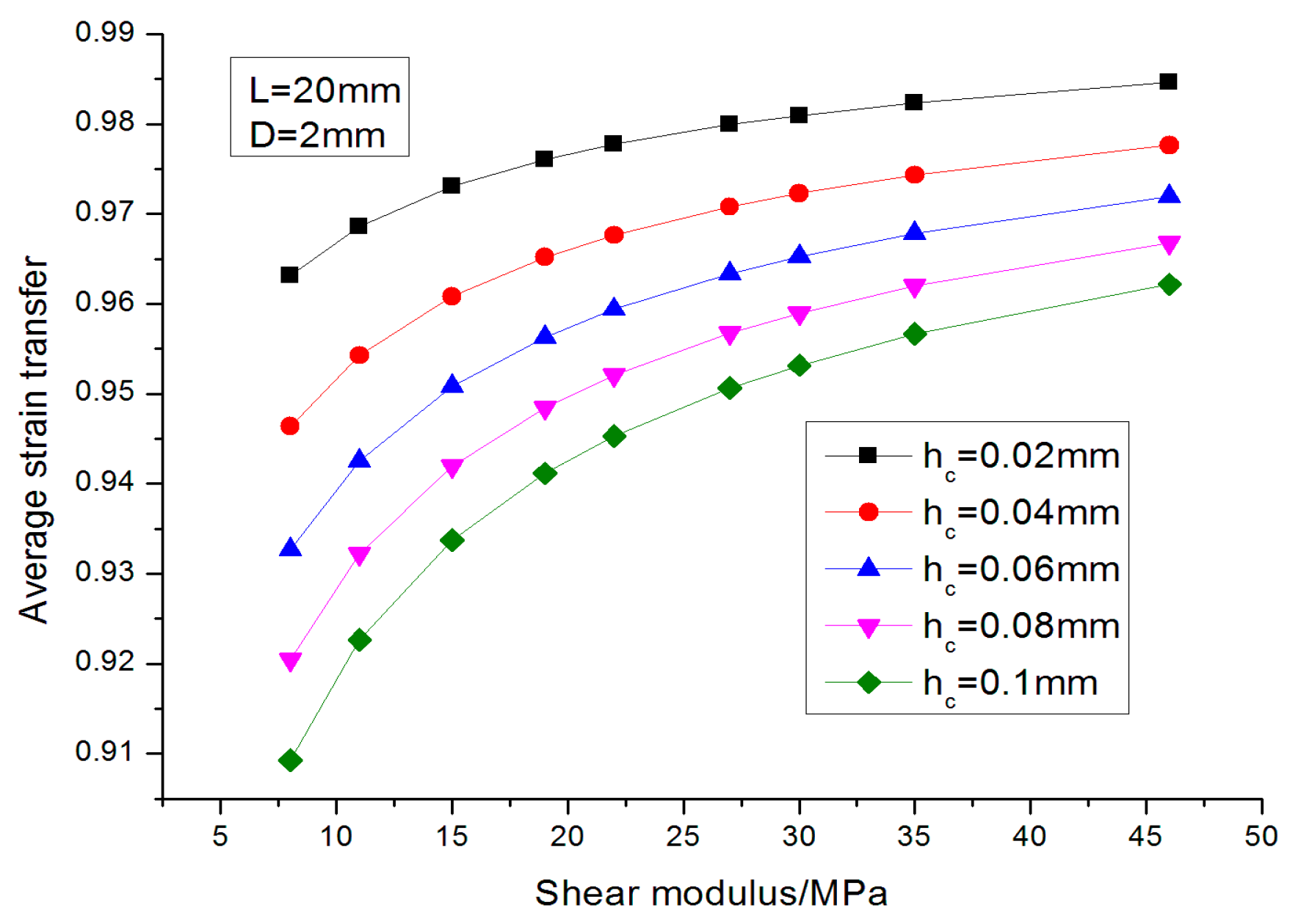

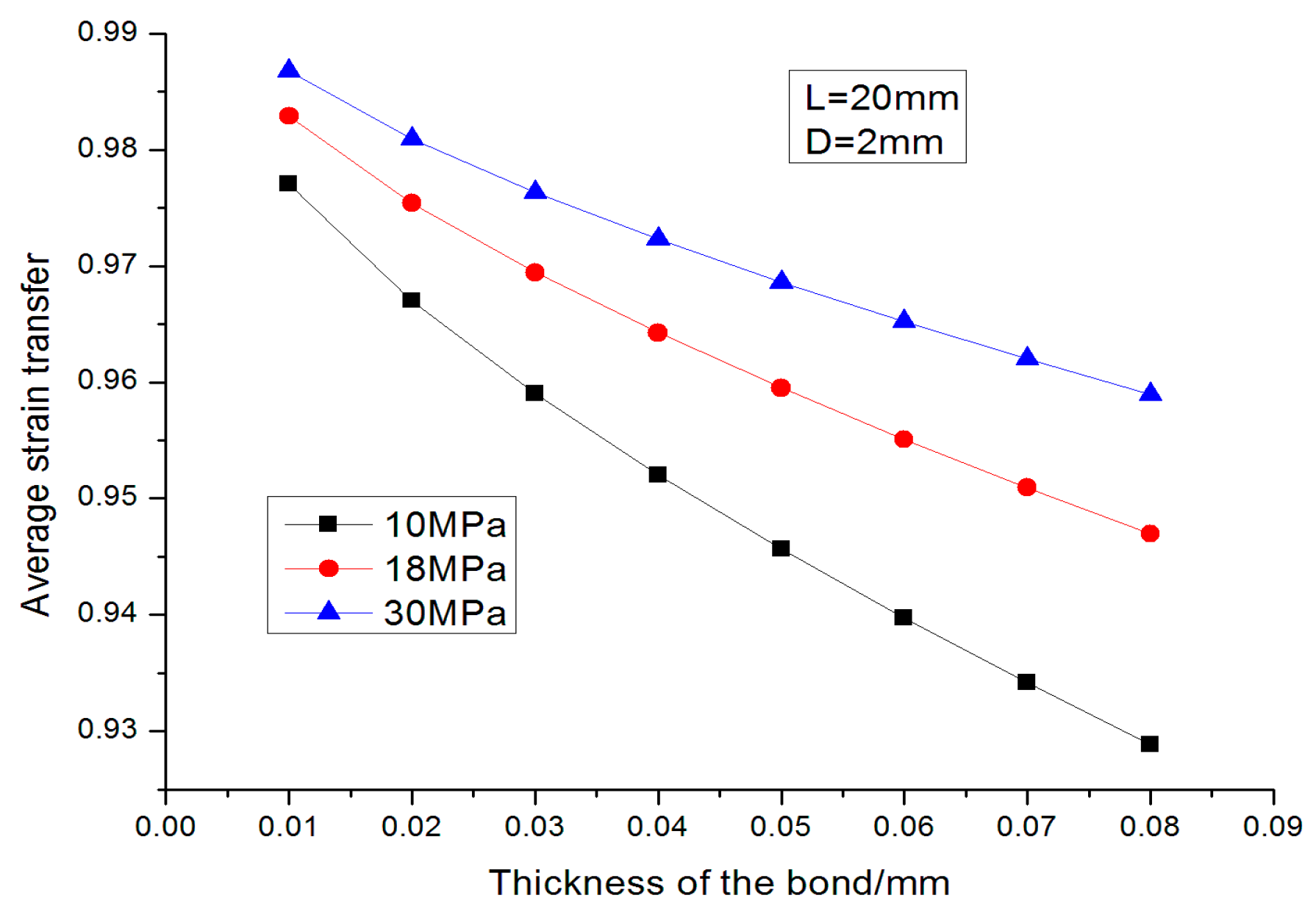

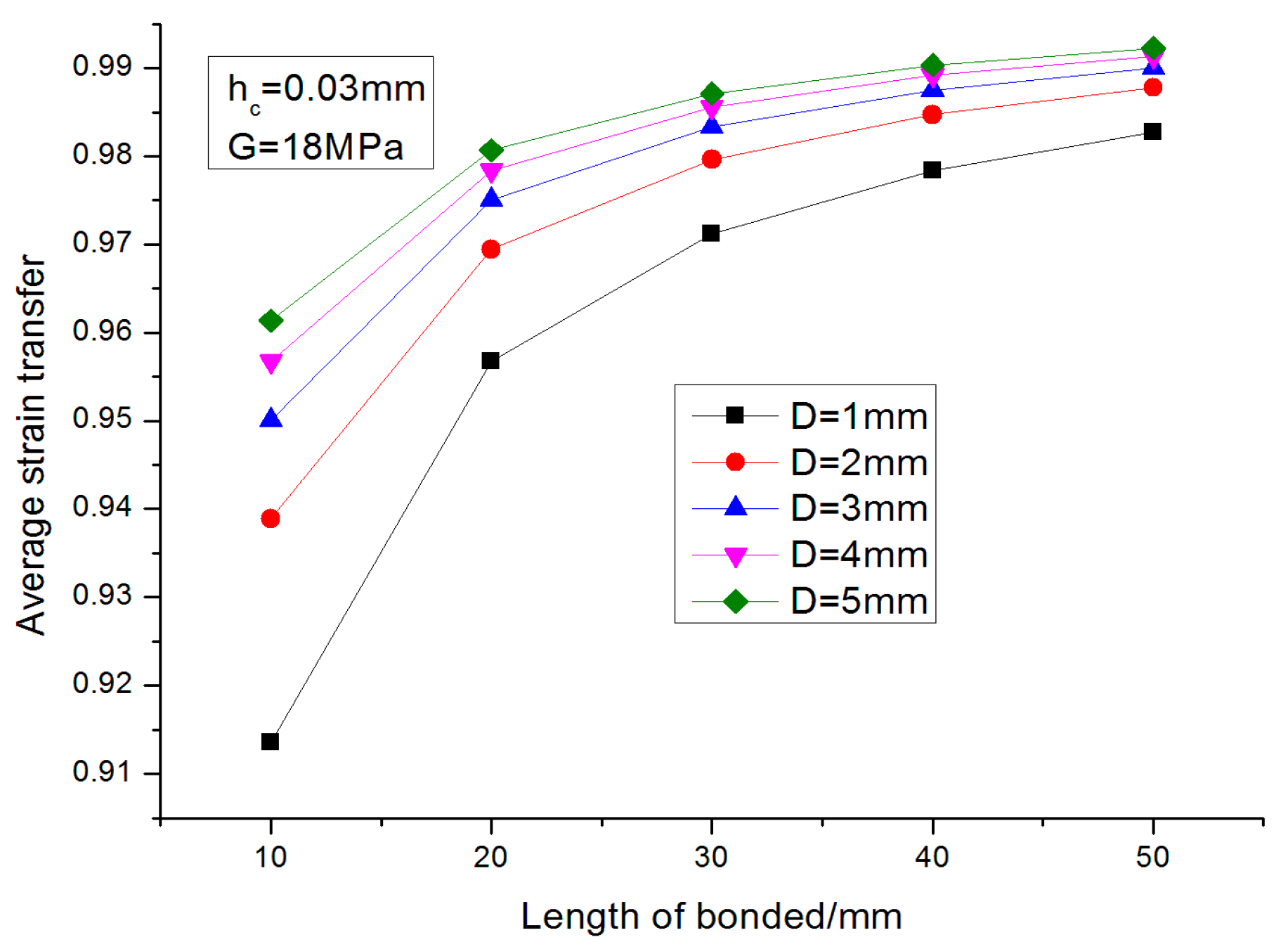

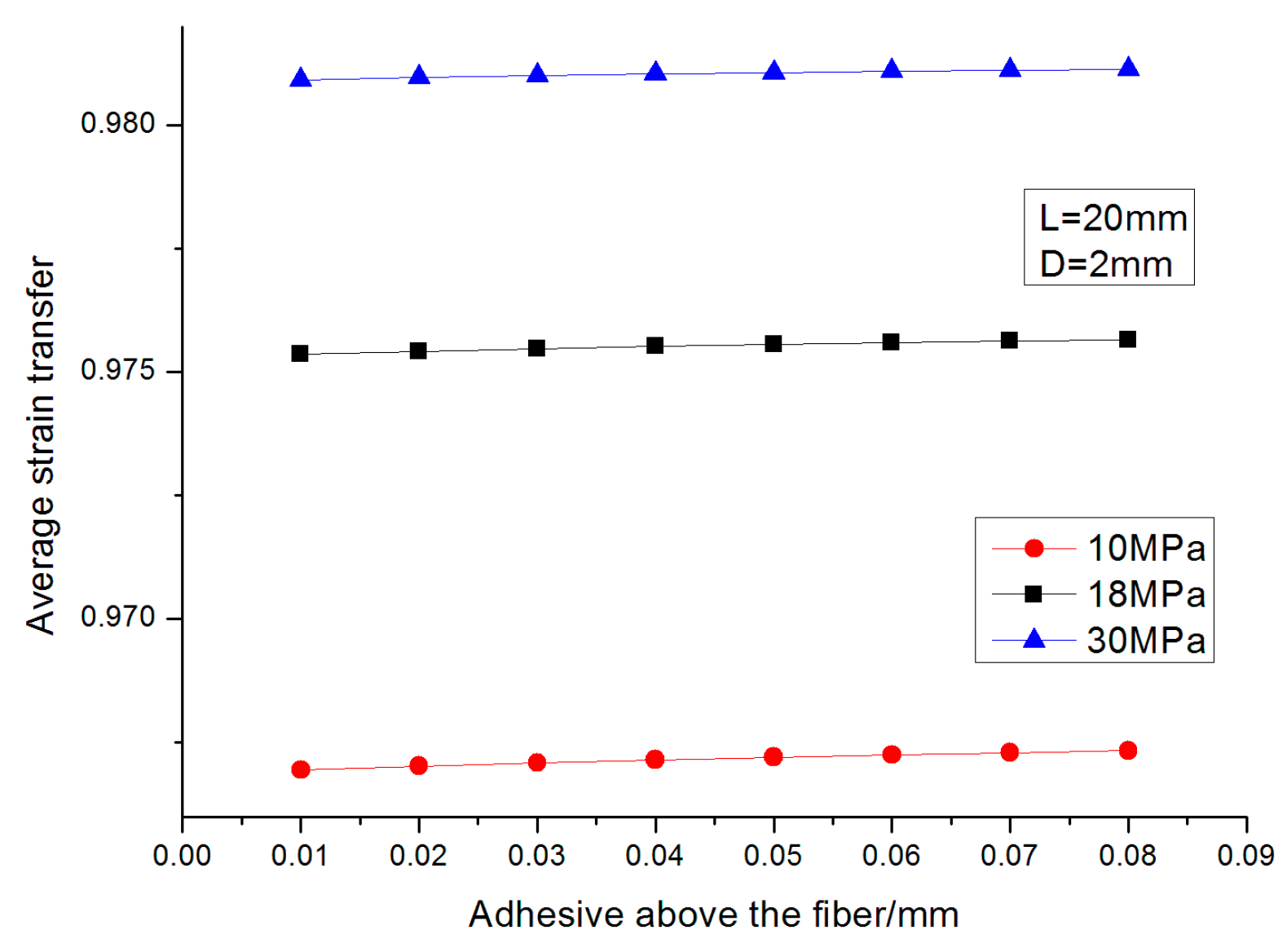

2.2. Analysis of Strain Transfer Influential Factors

3. Strain Transfer Ratio Experiment

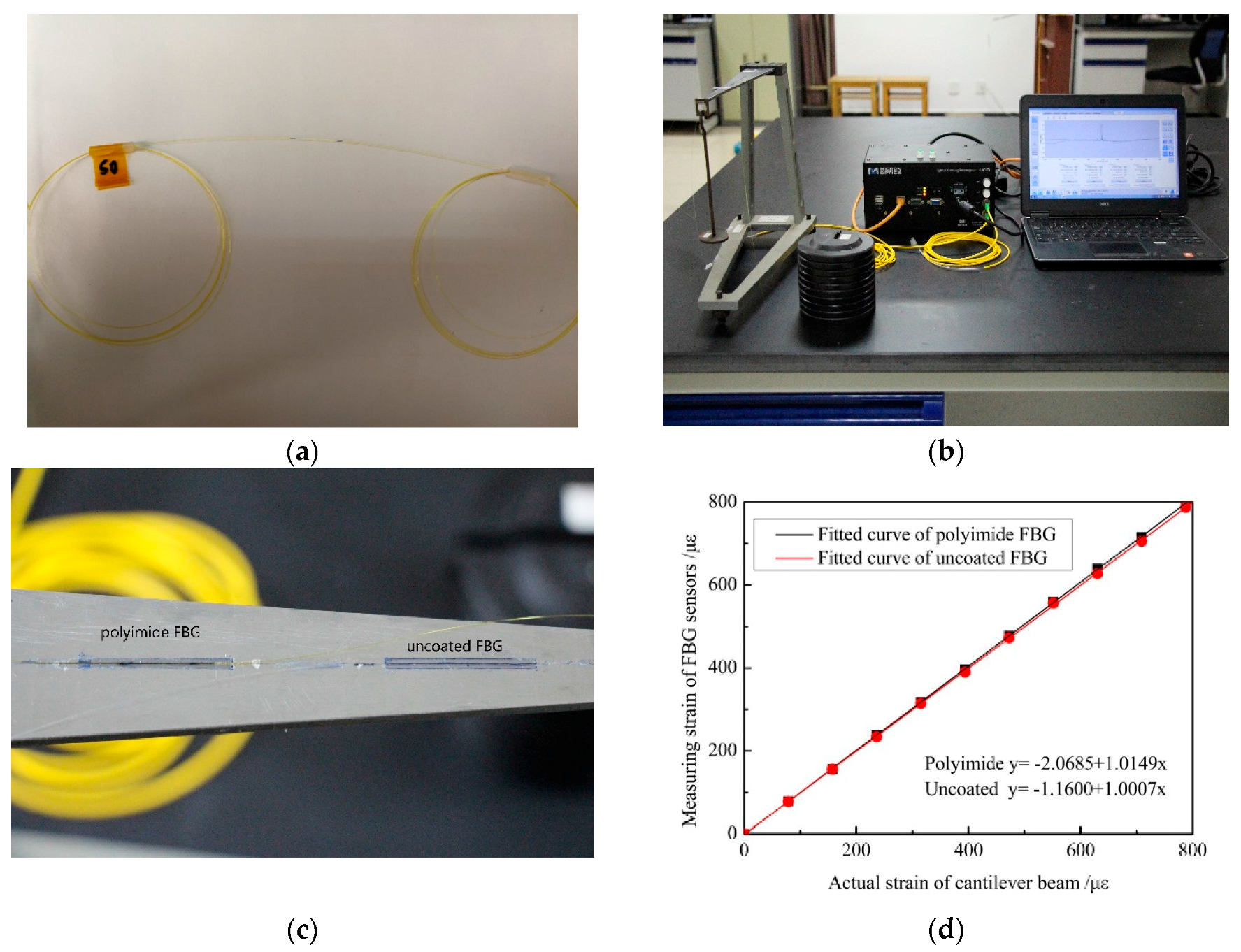

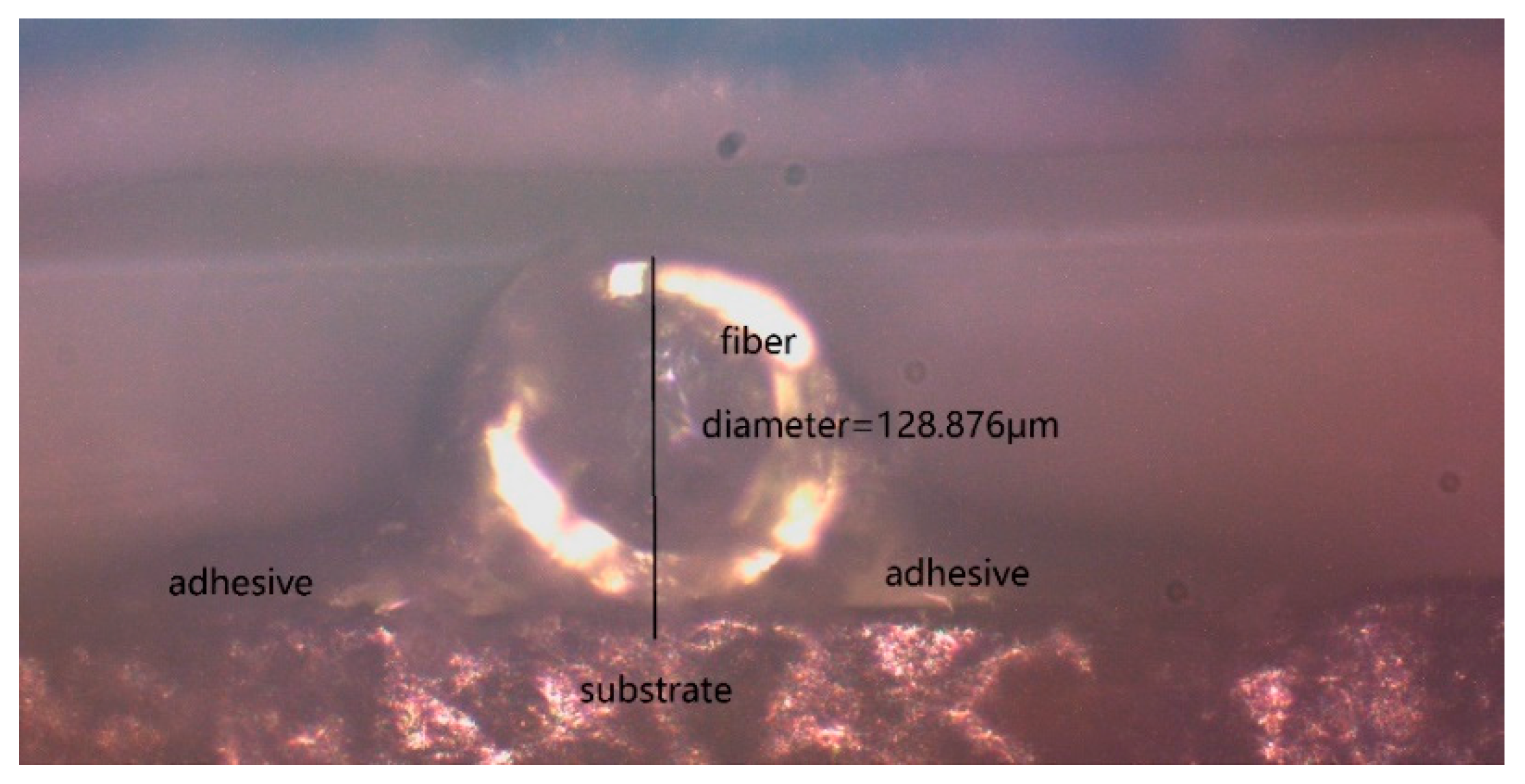

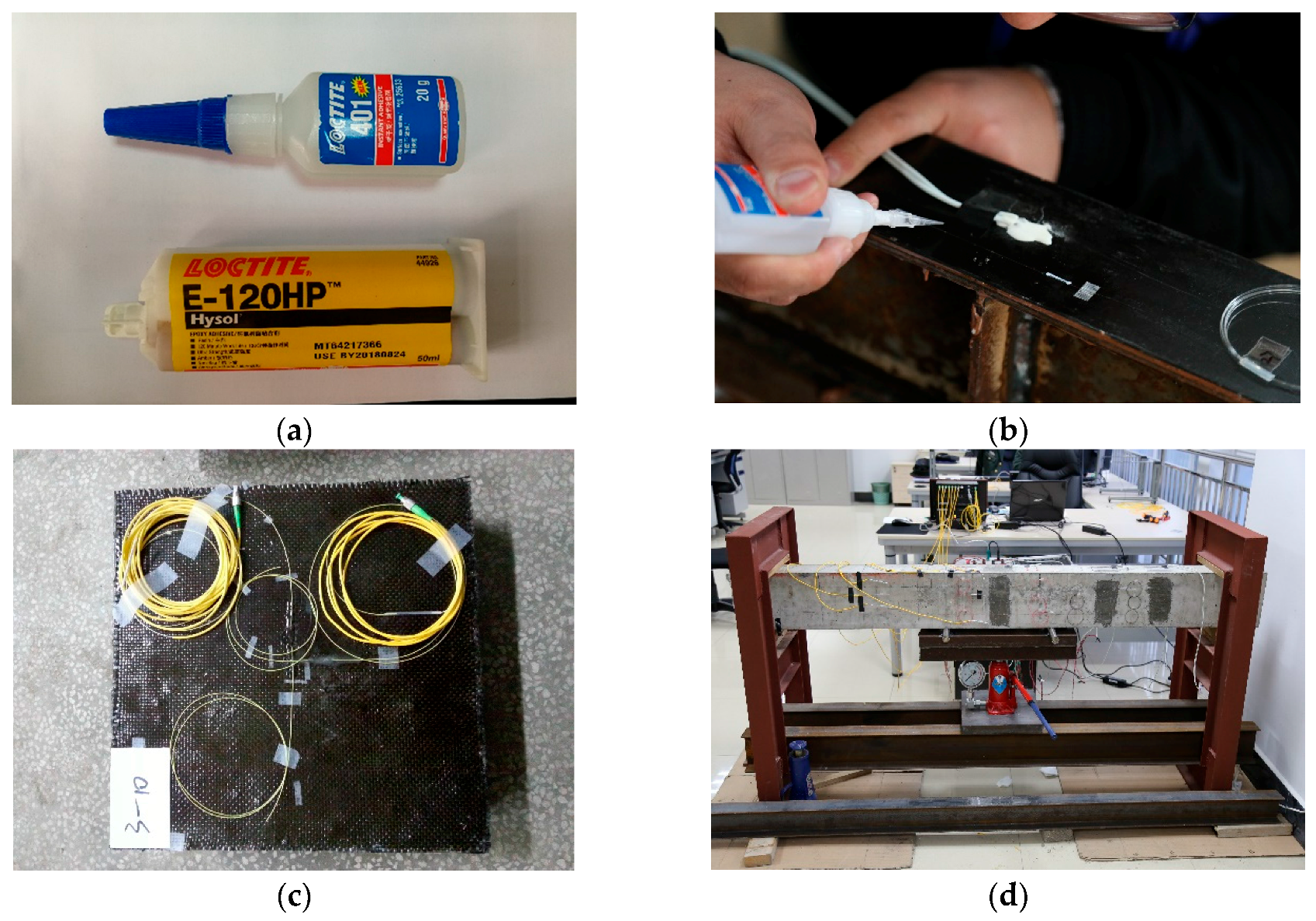

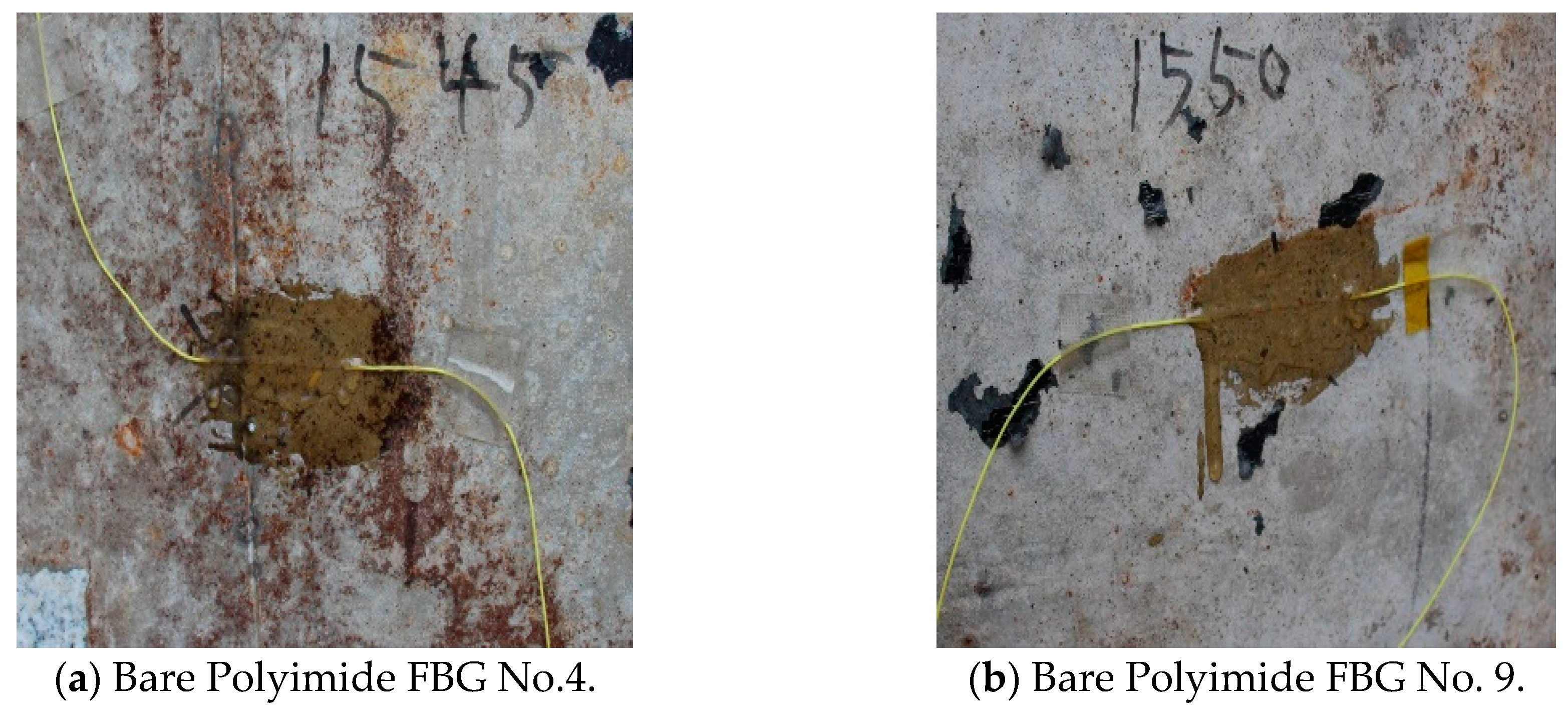

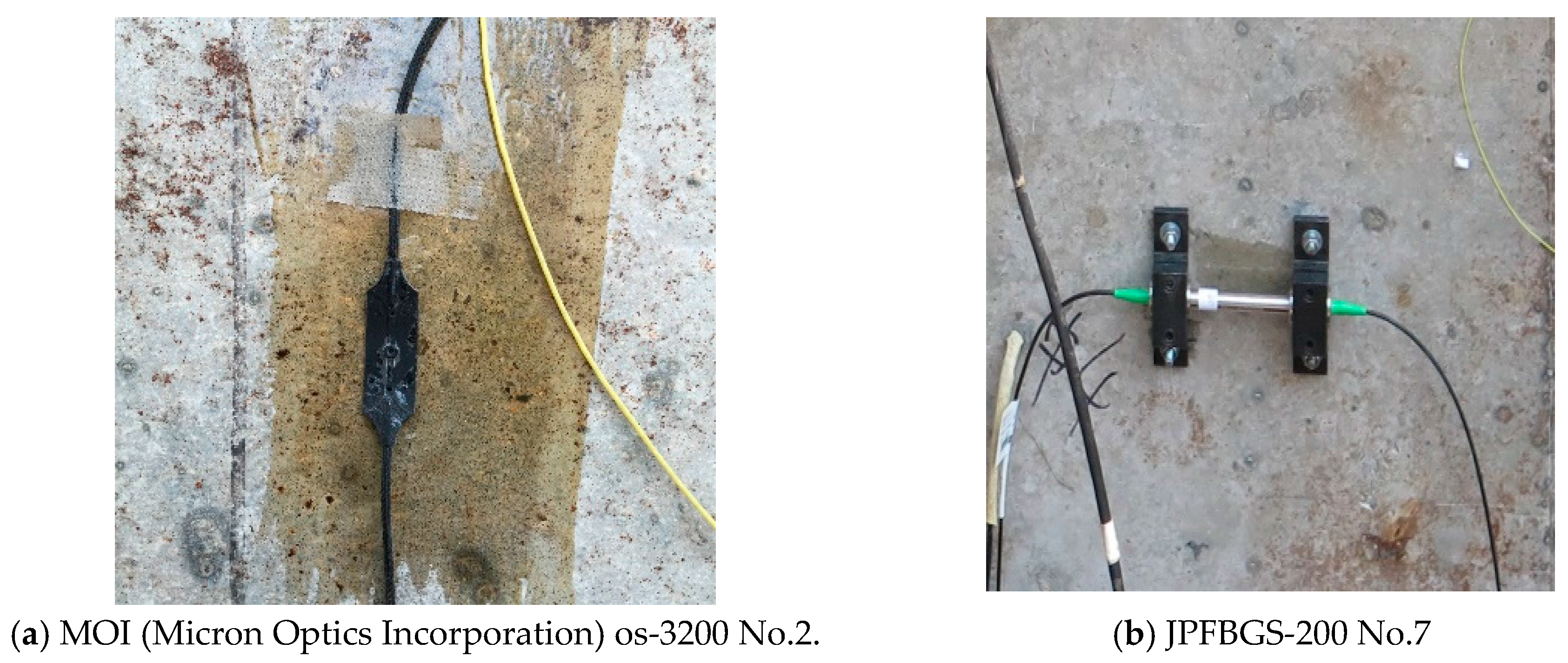

3.1. Bonding Method for Polyimide FBGs

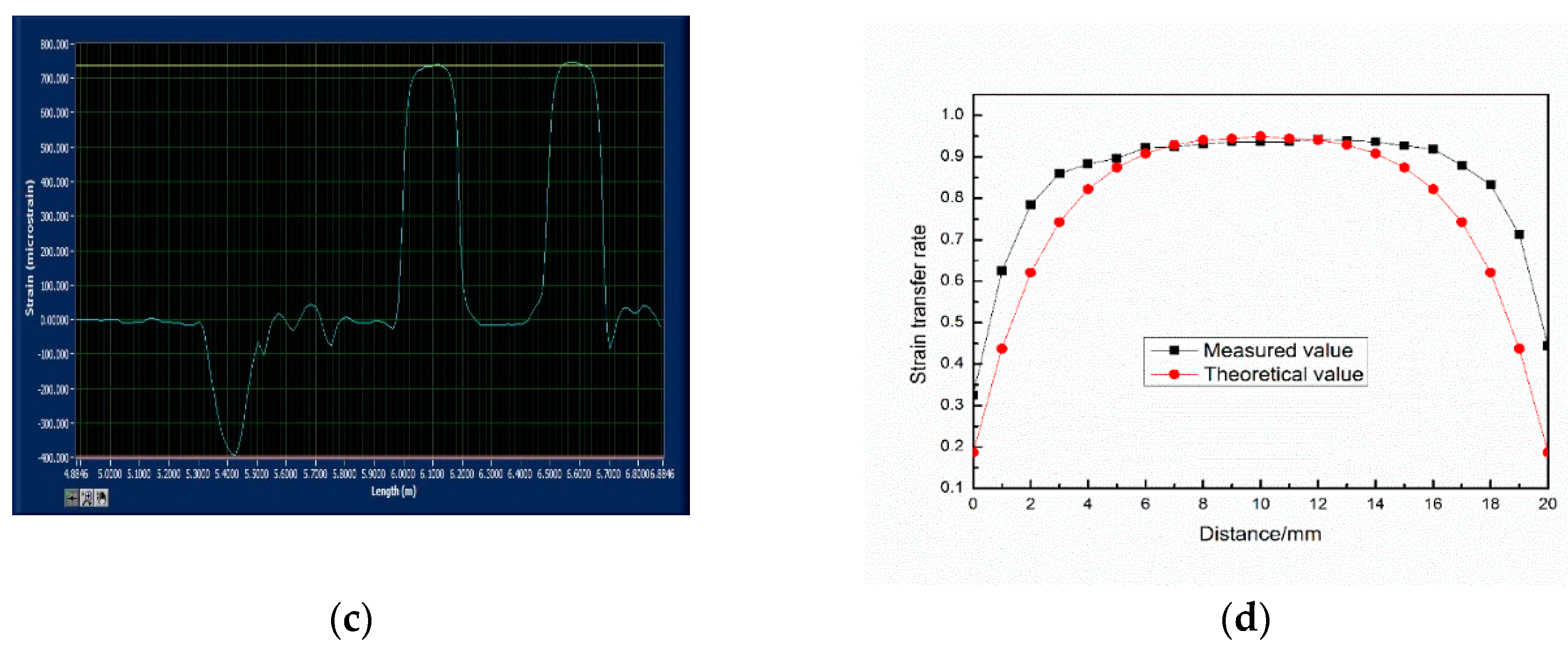

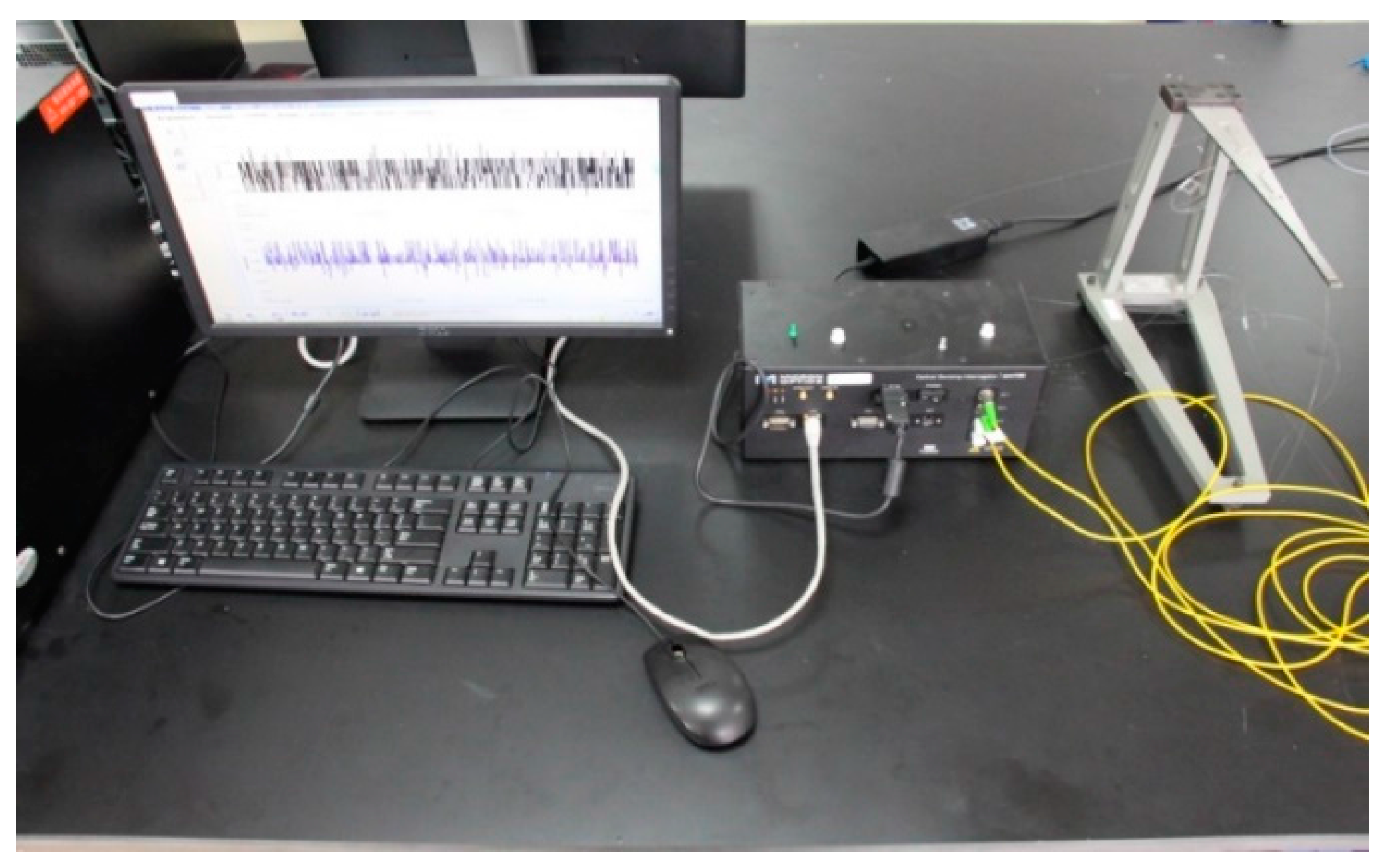

3.2. Strain Transfer Ratio Analysis

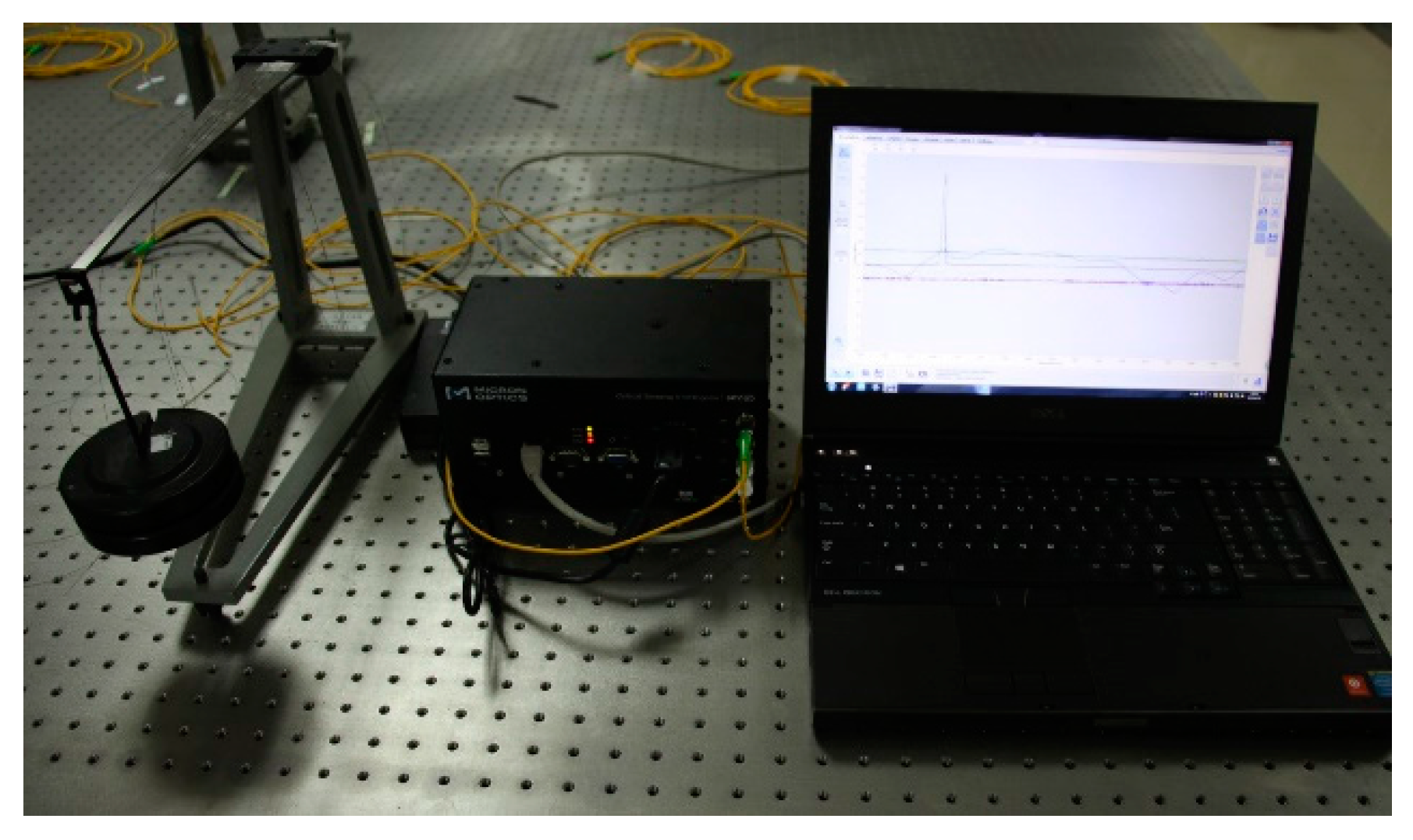

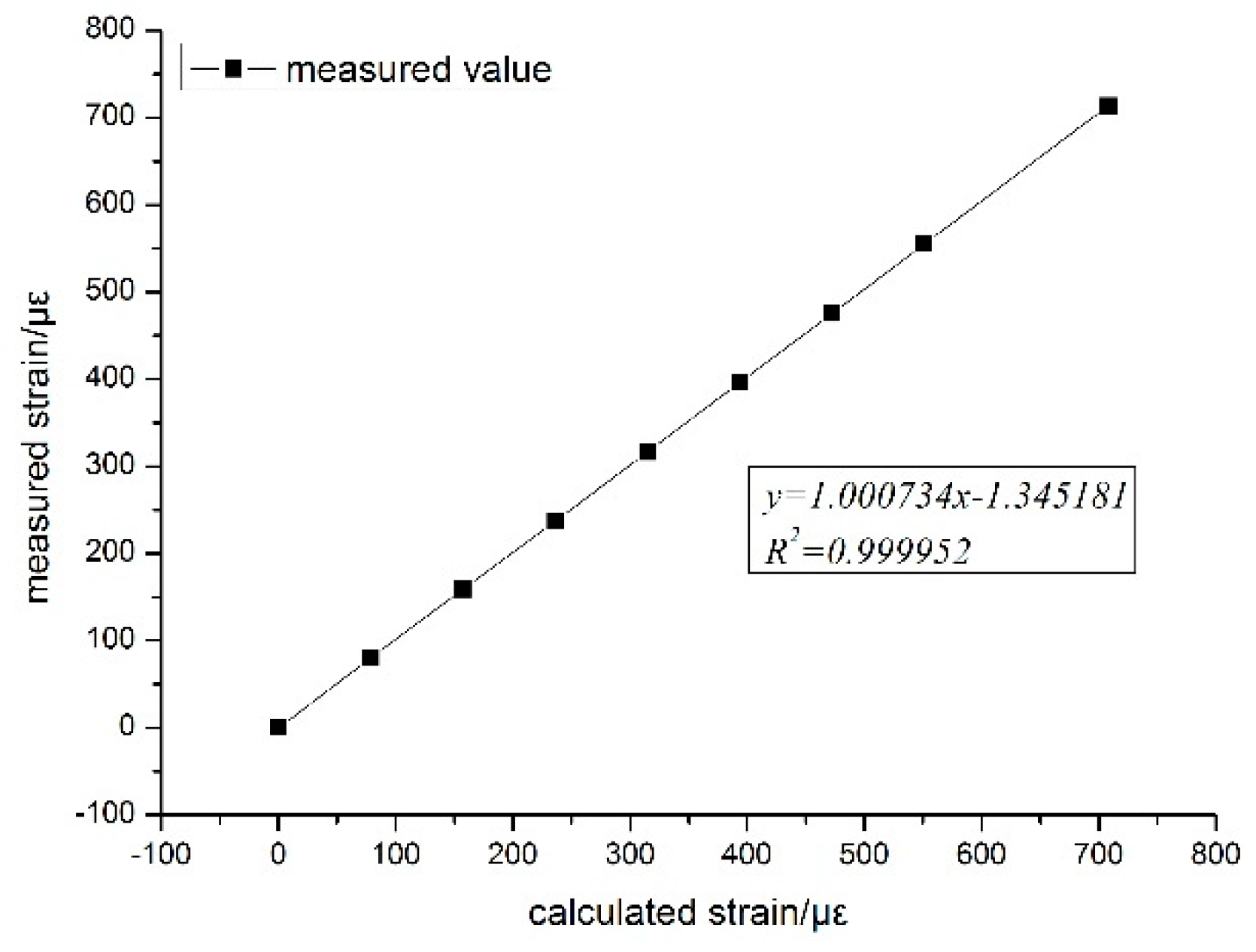

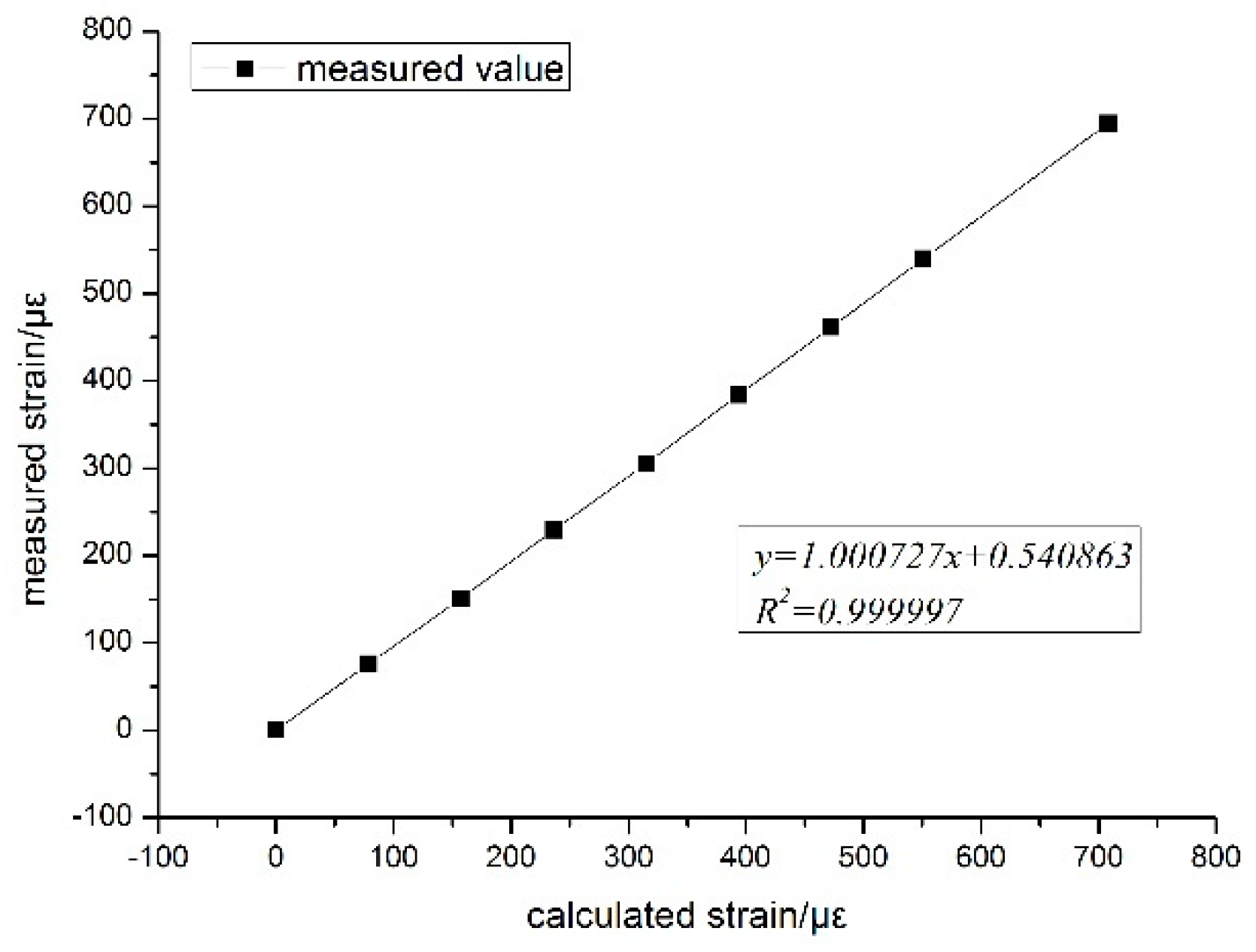

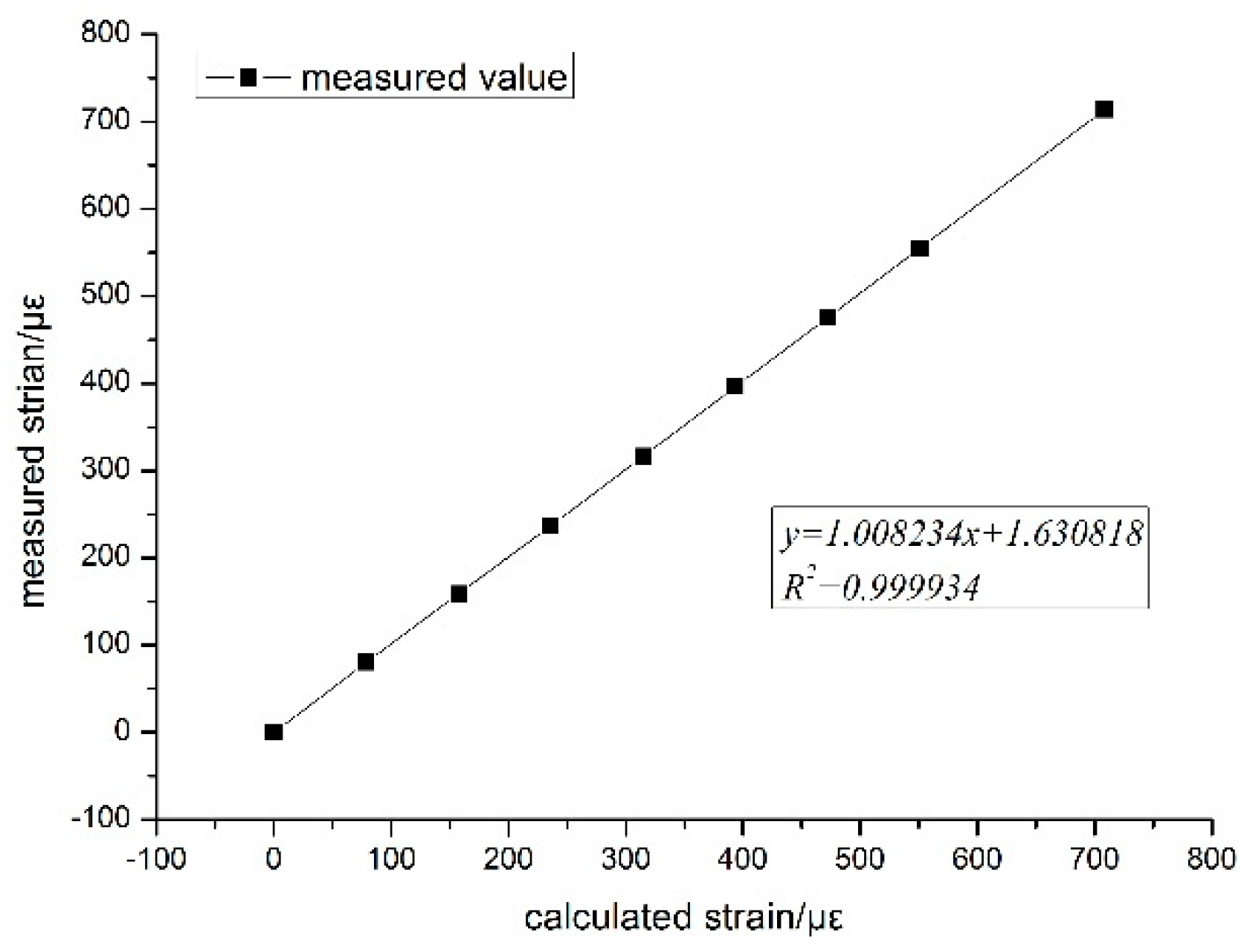

3.3. Experimental Data Analysis

4. Practicality Validation of Polyimide FBGs

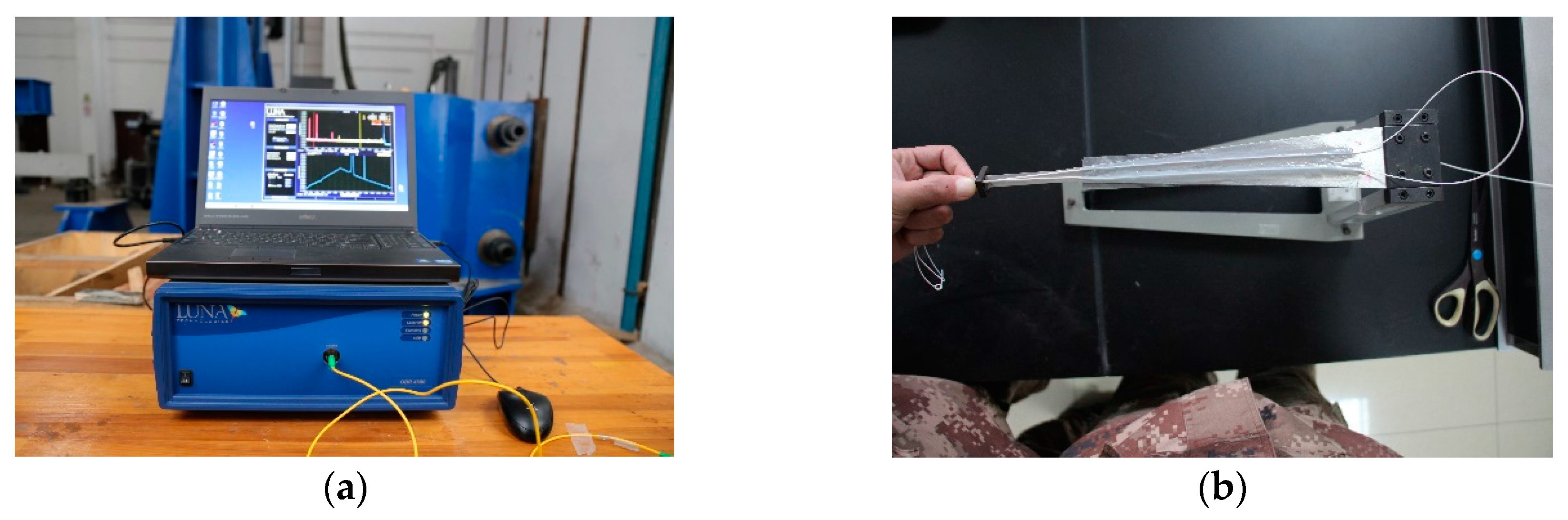

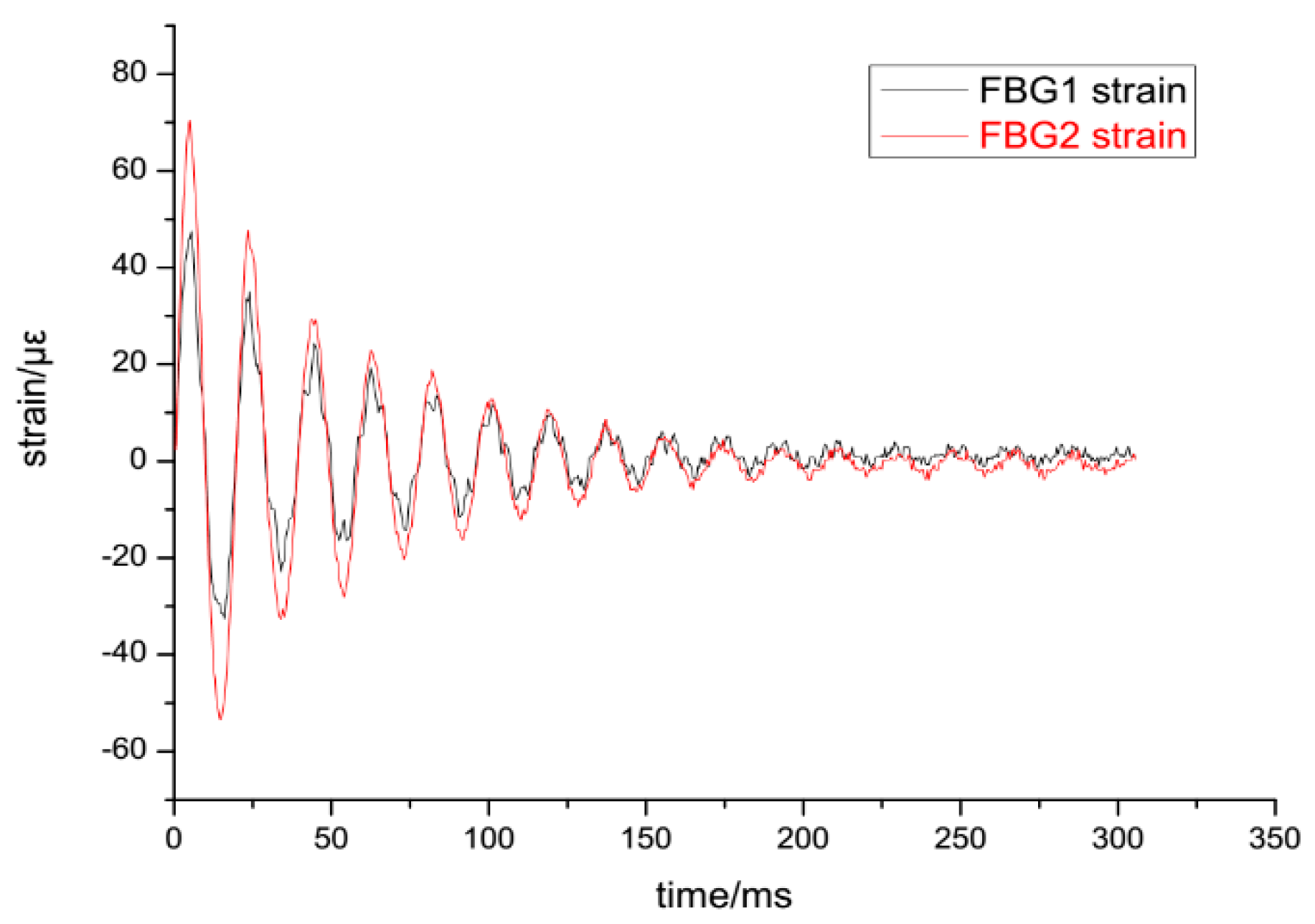

4.1. Theoretical Validation of Polyimide FBGs in Dynamic Measurement

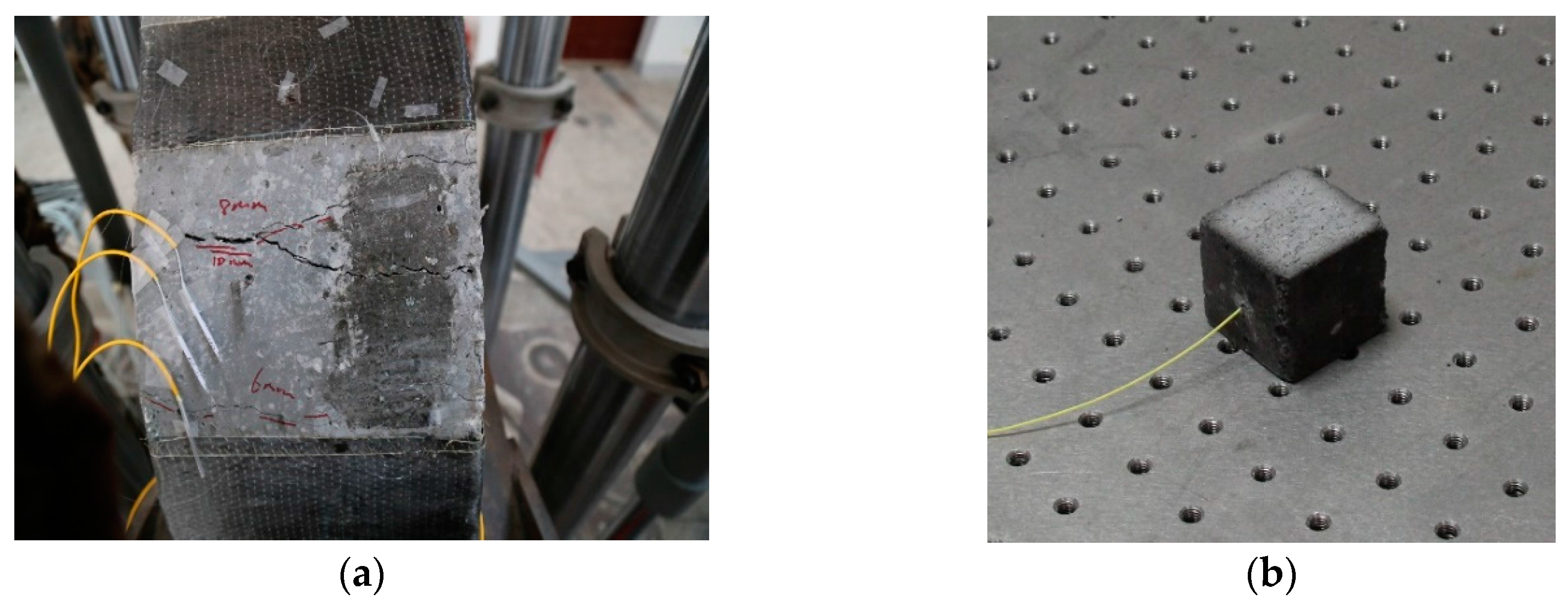

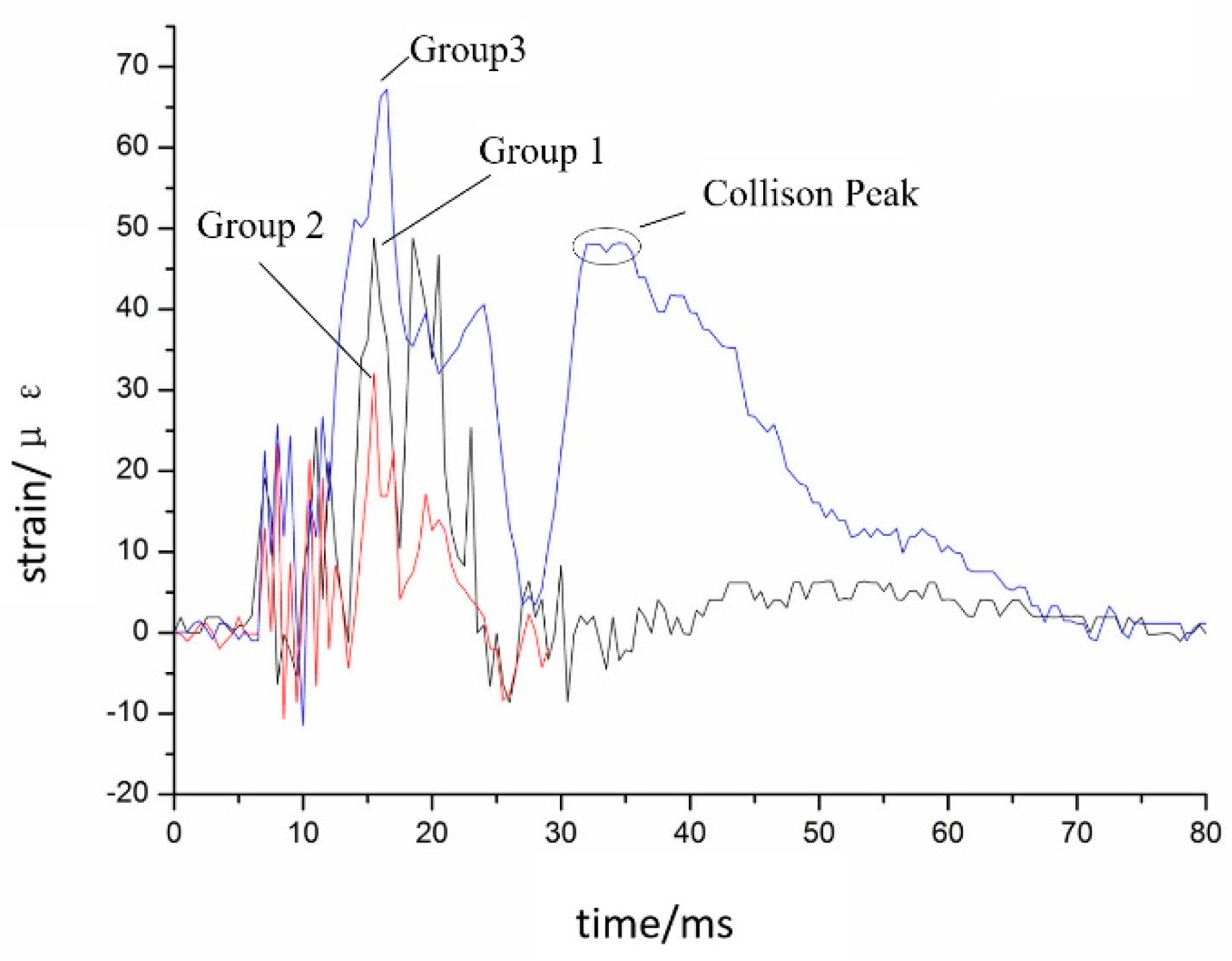

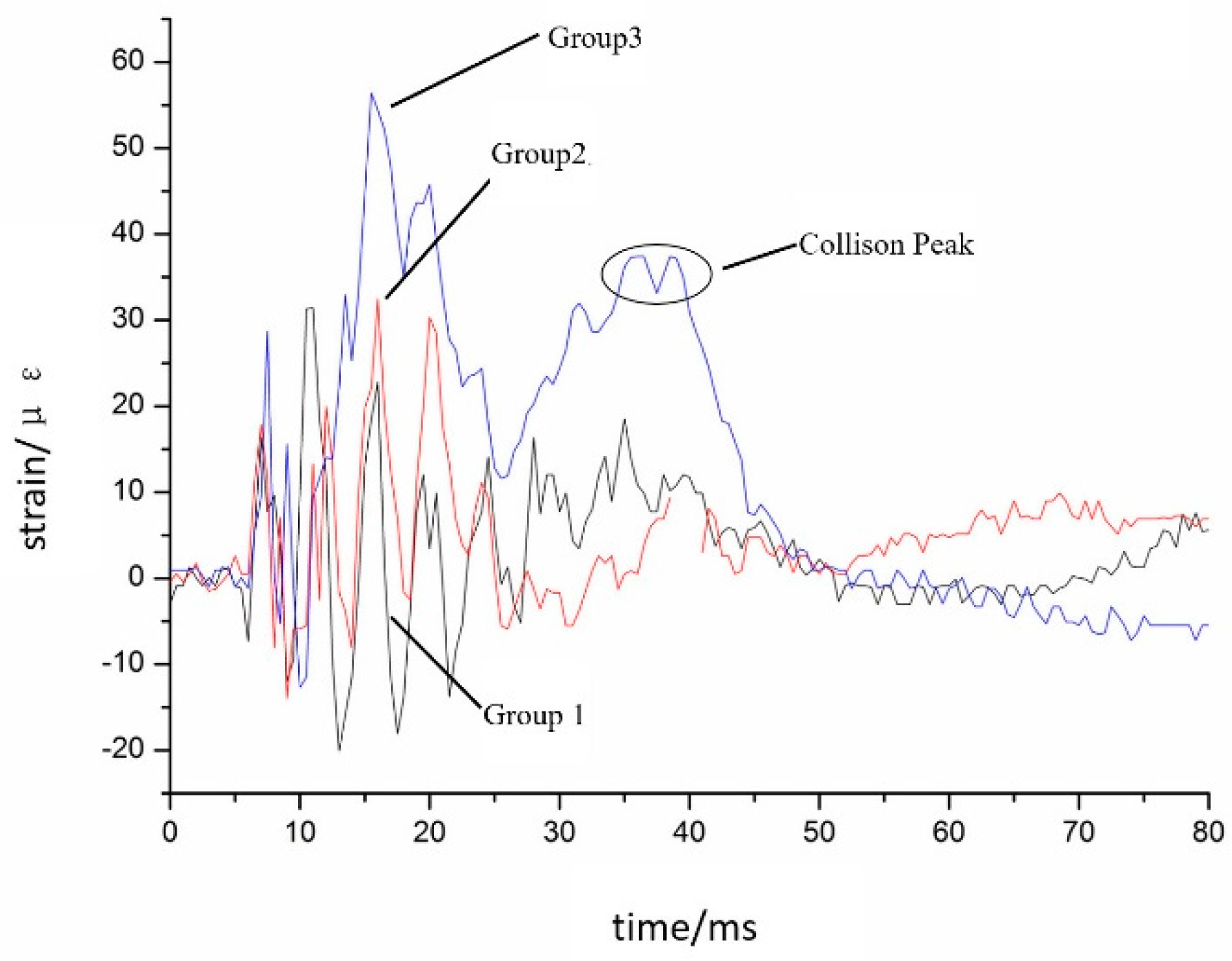

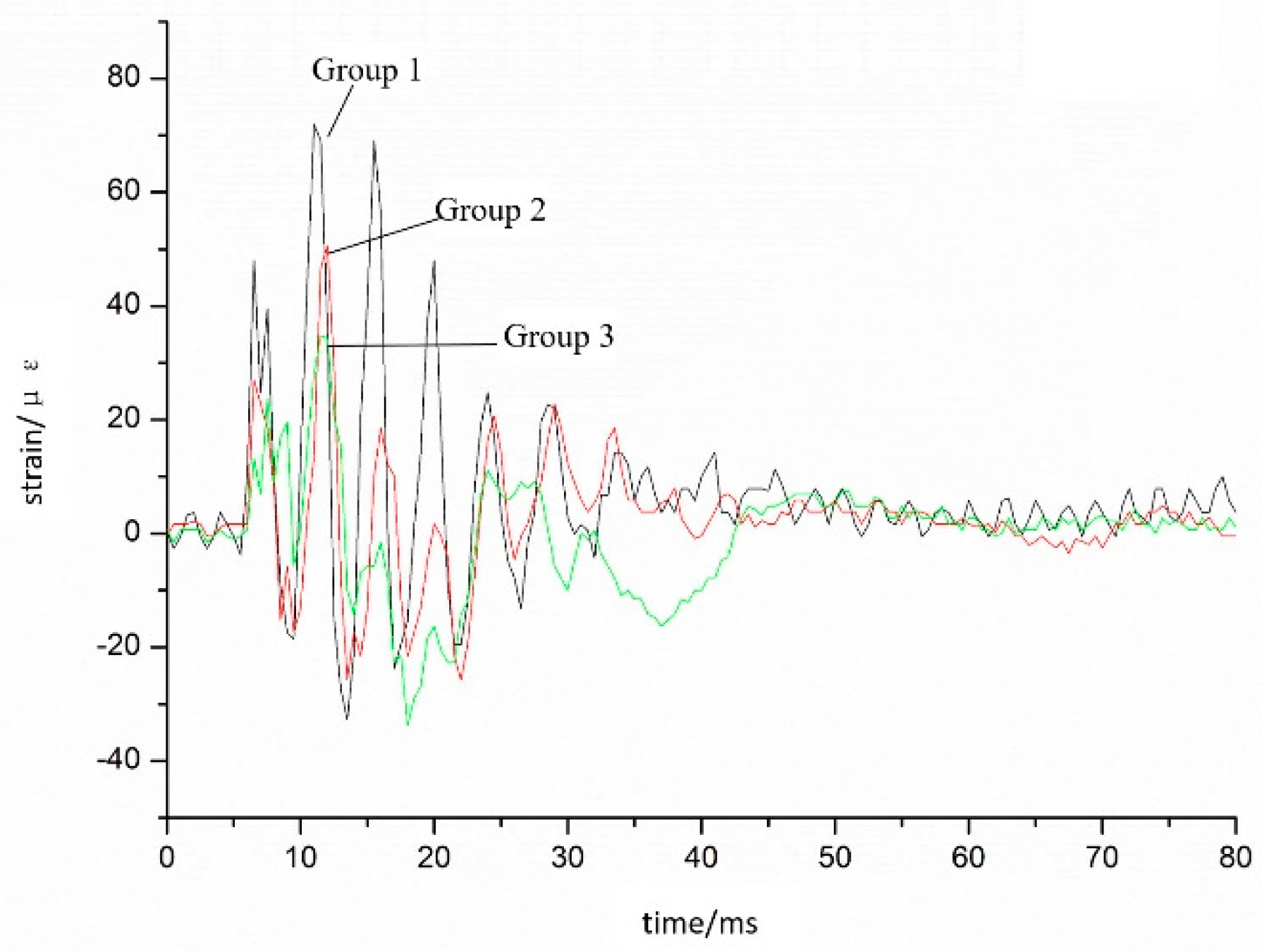

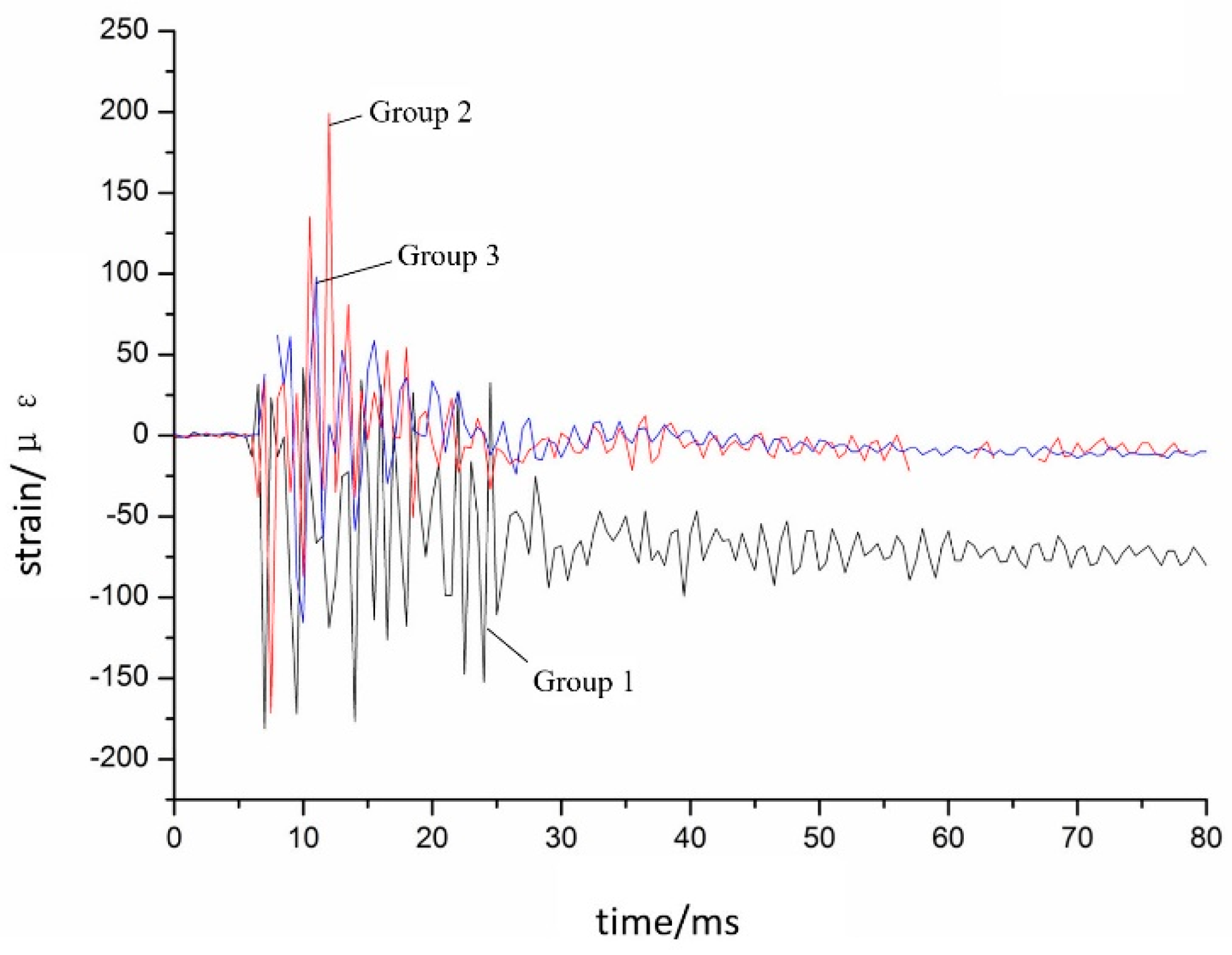

4.2. Reinforced Concrete Specimen Internal Explosion Measurement

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kersey, A.D.; Davis, M.A. Fiber grating sensors. J. Lightwave Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Song, G.B.; Wang, C.J.; Wang, B. Structure health monitoring (SHM) of civil structures. Appl. Sci. 2017, 7, 789. [Google Scholar] [CrossRef]

- Leung, C.K.Y.; Wan, K.T. Review: Optical fiber sensors for civil engineering applications. Mater. Struct. 2015, 48, 871. [Google Scholar] [CrossRef]

- Lopez-Higuera, J.M.; Cobo, L.R. Fiber optic sensors in structural health monitoring. J. Lightwave Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Liu, H.B.; Zhang, Q. Mechanical Performance Monitoring for Prestressed Concrete Piles Used in a Newly-Built High-Piled Wharf in a Harbor with Fiber Bragg Grating Sensor Technology When Pile Driving. Appl. Sci. 2017, 7, 489. [Google Scholar] [CrossRef]

- Liao, K.X.; Li, J.K. Nuclear power plant prestressed concrete containment vessel structure monitoring during integrated leakage rate test using three kinds of fiber optic sensors. Appl. Sci. 2017, 7, 419. [Google Scholar] [CrossRef]

- Ye, X.; Su, Y.; Han, J. Structural health monitoring of civil infrastructure using optical fiber sensing technology: A comprehensive review. Sci. World J. 2014, 2014, 652329. [Google Scholar] [CrossRef] [PubMed]

- Inaudi, D.; Glisic, B. Long-Range Pipeline Monitoring by Distributed Fiber Optic Sensing. J. Press. Vessel Technol. 2010, 132, 763–772. [Google Scholar] [CrossRef]

- Di Sante, R.; Donati, L.; Troiani, E. Reliability and accuracy of embedded fiber Bragg grating sensors for strain monitoring in advanced composite structures. Met. Mater. Int. 2014, 20, 537. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Ansari, F.; Libo, Y. Mechanics of bond and interface shear transfer in optical fiber sensors. J. Eng. Mech. 1998, 124, 385–394. [Google Scholar] [CrossRef]

- Li, H.N.; Zhou, G.D.; Ren, L.; Li, D.S. Strain transfer coefficient analyses for embedded fiber Bragg grating sensors in different host materials. J. Eng. Mech. 2009, 135, 1343–1353. [Google Scholar] [CrossRef]

- Li, D.; Li, H.N. Strain transferring analysis of embedded fiber Bragg grating sensors. Acta Mech. Sin. Chin. Ed. 2005, 37, 435–441. [Google Scholar]

- Sun, L. Application Analysis of Fiber Bragg Grating Sensing; Science Press: Beijing, China, 2011; pp. 23–26. ISBN 9787030327819. [Google Scholar]

- Sun, L.; Li, C. Strain Transfer Analysis of a Clamped Fiber Bragg Grating Sensor. Appl. Sci. 2017, 7, 188. [Google Scholar] [CrossRef]

- Wan, K.T.; Leung, C.K.Y. Investigation of the strain transfer for surface-attached optical fiber strain sensors. Smart Mater. Struct. 2008, 17, 035037. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, J.L. Interface strain transfer mechanism and error modification of embedded FBG strain sensors. J. Harbin Inst. Technol. 2006, 1, 49–55. [Google Scholar]

- Wu, R.; Zheng, B. Influence of layer structure for surface-bonded FBG sensor on measured strain. Opt. Precis. Eng. 2014, 22, 3183–3190. [Google Scholar]

- Takeda, S.; Minakuchi, S. Delamination monitoring of laminated composites subjected to low-velocity impact using small-diameter FBG sensors. Compos. Part A Appl. Sci. Manuf. 2005, 36, 903–908. [Google Scholar] [CrossRef]

- Okabe, Y.; Tsuji, R. Application of chirped fiber Bragg grating sensors for identification of crack locations in composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 59–65. [Google Scholar] [CrossRef]

- Okabe, Y.; Tanaka, N. Effect of fiber coating on crack detection in carbon fiber reinforced plastic composites using fiber Bragg grating sensors. Smart Mater. Struct. 2002, 11, 892–898. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Wang, Y.; Sun, Y.Y. Hilbert–Huang transform based method for monitoring the crack of concrete arch by using FBG sensors. Optik 2016, 127, 3417–3422. [Google Scholar] [CrossRef]

- You, Z.W.; Wang, Y.; Sun, Y.Y. Constitutive relation measurement of geological mechanics similar material based on fiber Bragg grating. Opt. Eng. 2017, 56, 024105. [Google Scholar] [CrossRef]

- Peters, K.; Studer, M. Embedded optical fiber Bragg grating sensor in a nonuniform strain field: Measurements and simulations. Exp. Mech. 2001, 41, 19–28. [Google Scholar] [CrossRef]

- Botsis, J.; Humbert, L. Embedded fiber Bragg grating sensor for internal strain measurements in polymeric materials. Opt. Laser. Eng. 2005, 43, 491–510. [Google Scholar] [CrossRef]

| FBG Wavelength | Measured Average Strain Transfer Rate | Theoretical Average Strain Transfer Rate | Relative Error |

|---|---|---|---|

| 1520 nm | 96.28% | 93.72% | 0.9% |

| 1525 nm | 96.18% | 93.72% | 0.8% |

| 1570 nm | 96.18% | 93.72% | 0.8% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Liu, J.; Wang, Y.; Zhang, Q.; Duan, J.; Zhang, Z.; Huang, X.; You, Z. Principles and Application of Polyimide Fiber Bragg Gratings for Surface Strain Measurement. Appl. Sci. 2017, 7, 995. https://doi.org/10.3390/app7100995

Sun Y, Liu J, Wang Y, Zhang Q, Duan J, Zhang Z, Huang X, You Z. Principles and Application of Polyimide Fiber Bragg Gratings for Surface Strain Measurement. Applied Sciences. 2017; 7(10):995. https://doi.org/10.3390/app7100995

Chicago/Turabian StyleSun, Yangyang, Jianyong Liu, Yuan Wang, Qinghua Zhang, Jianli Duan, Zhenglin Zhang, Xiaodi Huang, and Zewei You. 2017. "Principles and Application of Polyimide Fiber Bragg Gratings for Surface Strain Measurement" Applied Sciences 7, no. 10: 995. https://doi.org/10.3390/app7100995

APA StyleSun, Y., Liu, J., Wang, Y., Zhang, Q., Duan, J., Zhang, Z., Huang, X., & You, Z. (2017). Principles and Application of Polyimide Fiber Bragg Gratings for Surface Strain Measurement. Applied Sciences, 7(10), 995. https://doi.org/10.3390/app7100995