Abstract

Today’s world needs highly efficient systems that can fulfill the growing demand for energy. One of the promising solutions is the fuel cell. Solid oxide fuel cell (SOFC) is considered by many developed countries as an alternative solution of energy in near future. A lot of efforts have been made during last decade to make it commercial by reducing its cost and increasing its durability. Different materials, designs and fabrication technologies have been developed and tested to make it more cost effective and stable. This article is focused on the advancements made in the field of high temperature SOFC. High temperature SOFC does not need any precious catalyst for its operation, unlike in other types of fuel cell. Different conventional and innovative materials have been discussed along with properties and effects on the performance of SOFC’s components (electrolyte anode, cathode, interconnect and sealing materials). Advancements made in the field of cell and stack design are also explored along with hurdles coming in their fabrication and performance. This article also gives an overview of methods required for the fabrication of different components of SOFC. The flexibility of SOFC in terms fuel has also been discussed. Performance of the SOFC with varying combination of electrolyte, anode, cathode and fuel is also described in this article.

1. Introduction

Self-sufficiency in energy is the assurance to excel any country’s economy. The demand of energy is growing day by day due to increasing industrialization and population. According to International Energy Agency (IEA) world energy outlook 2005, energy demand will increase by 50% by 2030. At the same time there is increasing demand for green energy in order to avoid rising green house gas emission, which results into deterioration of climate system. This overall scenario forced different countries to find alternative energy sources. One of the promising options for alternative resources is fuel cell [1,2,3,4,5,6,7,8,9,10,11].

Fuel cell is an electrochemical device that converts the chemical energy of a fuel (hydrogen, hydrocarbons, ammonia, etc.) and an oxidant (air or oxygen) into electricity very efficiently on many size scales, without combustion and with little or no emission of pollutants. They can be highly efficient and carry many diversified advantages associated with mobile and stationary power generation including both large scale centralized power production and distributed generation in individual homes and businesses, etc. [2,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19].

Fuel cell names are based on the type of electrolyte material and fuel used. Many fuel cells have been developed for operation between room temperature to 1000 °C. Fuel cells involve many benefits over the conventional ways of generating power like high density of energy, profound efficiency (40%–50% electric, 65%–70% electric for combined cycle, gas turbine and 80%–90% with heat recovery/Solid Oxide Fuel Cell (SOFC)), chemically non-pollutant, simultaneous generation of heat and electricity at output, highly maintained power with good regulation, minimum transposal/distribution mechanism and troubles, adjustable as well as fuel flexibility [6,8,9,10,11,12,18,19].

The fuel cells with low temperature involve alkaline (neutralizing), direct or indirect alcohol (liquors like methanol, ethanol) and with operating temperature typically below 100 °C are the hydrogen based polymer electrolyte membrane systems. Such fuel cells have applications in small moveable power and automobiles and have a good range in their mechanics from even less than a watt to over 100 kW. They provide quick start and shut down with unlisted thermal cycling capabilities and highly remarkable load, which are demanding characteristics particularly for automobiles. The phosphoric acid (H3PO4) fuel cell which operates at about 200–215 °C is the most commercialized technology developed mainly for stationary distributed heat and particularly for power generation applications. There are two fuel cell systems that operate at intermediate temperatures: Ceria based SOFC and Molten Carbonate which operate at 650 °C and below 600 °C respectively. Solid carbon is used as a fuel in DCFCs (Direct Carbon Fuel Cells) having a high output of CO2 content whereas SOFC uses gaseous fuels (CO, H2, CH4), and as they exit they produce stream with a very high CO2 substance. One of the most remarkable advantages of SOFCs and DCFCs is their ability to co-generate high level heat greater than 600 °C if involved in end-use applications [8,10,11,18,19]. Table 1 gives the comparison of different fuel cells (based on electrolyte type) in terms of their operating temperature, power, efficiency and applications [20].

Table 1.

Comparison of different types of Fuel Cells.

During the last decade, lot of research has been done on fuel cell systems but it will take many years to mature due to technological hurdles which are being encountered. Enhancing durability and lowering the cost are two prime challenges for the commercialization of fuel cell. The fuel cell technology must be cost competitive and better than other conventional power technologies available today. Also, as per the department of energy USA, the most challenging task for cost effective commercialization of fuel cell is the production of hydrogen. The challenge related to the production of hydrogen is the requirement of energy needed for its production. The task is to use or develop alternative sources that do not need electricity to produce hydrogen. Different processes have been explored in order to reduce the cost of hydrogen production [1,21]. The safe transportation of hydrogen is another issue on which researchers are working [1,22].

SOFCs works on gaseous fuels mostly like H2 and CO. As a fuel, the DCFC uses solid carbon and gives high efficiency providing the prominent advantage of high electric efficiency (>65%–70%) and produces a pure stream of CO2 without any extra cost of energy loss [6,10,12,18,19]. Solid oxide fuel cell is based on solid electrolyte sandwiched between two electrodes. SOFC has received more and more attention in recent years due to its better efficiency and durability. The SOFC is considered very flexible among other fuel cells in terms of fuels which is a significant advantage over the other fuel cells. In the current review, the technical and commercial status of high temperature solid oxide fuel cell is discussed. Current research in SOFC is focused on identification and synthesis of innovative materials that can reduce the manufacturing cost and enhance the lifetime of SOFC. Reduced cost and bulk production of the SOFC will make it competitive with currently available conventional power technologies [12,18,21,23,24,25,26,27,28,29].

2. Basic Operation of Solid Oxide Fuel Cell

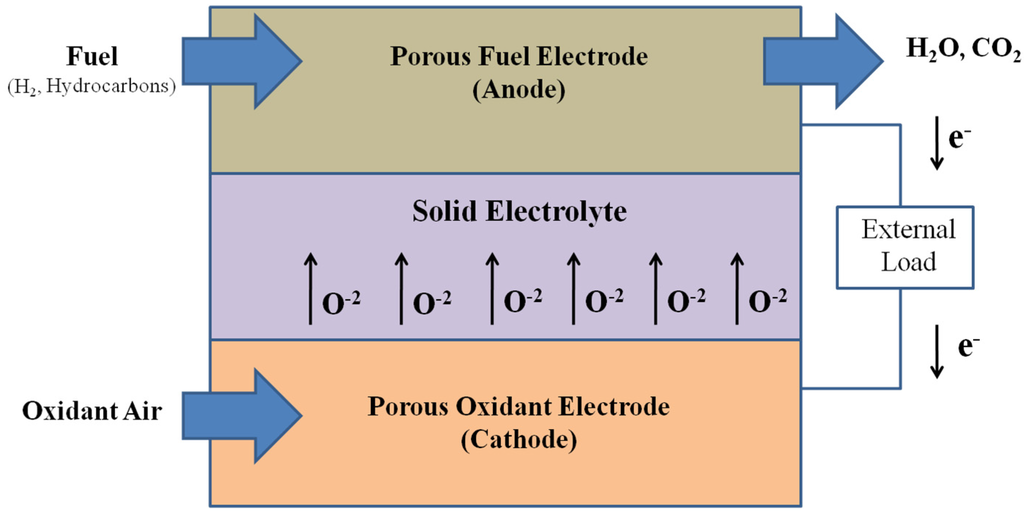

The high temperature fuel cell operates from 800 °C to 1000 °C. The basic operation involves the REDOX systematic. In SOFCs, the conducting species are Oxygen ions. Oxygen gets reduced at the cathode by taking electrons and gets ionized. In a high temperature range, Yttria Stabilized Zirconia (YSZ) electrolyte is mostly used for conduction of oxygen ion. Oxygen is supplied to the porous cathode where it gets reduced into oxygen ions which are carried to the anode through solid electrolyte. At the anode, oxygen ions combine with hydrogen and produces water along with carbon dioxide (CO2) as shown in Figure 1. Very hard and rigid materials are required for SOFC components due to the high operating temperature. In view of long term (40,000–50,000 h) efficient cell operation, chemical and thermal stability are also of utmost concentration along with first rate electrical, electrochemical properties, high chemical and thermal consonance in the fuel cell operating environments [8,12,23,24,25,30,31,32]. Two types of concentration are taken into account during the fabrication: economic and technical. Economic concentration includes lowering the fabrication cost by using low cost materials. The technical concentrations include that the design should be fabrication friendly and cost friendly. In the technical setup, economization friendly means that: the materials should be price conscious with its maximum outcomes, should easily be manufactured into the required mechanism, and be minimized structures with passivity and less investment [8].

Figure 1.

Schematic of solid oxide fuel cell.

A single basic fuel cell creates an open circuit voltage slightly above 1 V and decreases to 0.5–0.7 V approximately when load is connected to it [12,31,32,33]. During operation the current density may alter from 200 to 1000 mA/cm2 (DC). To achieve enhanced current and voltage output, many cells are connected in series or parallel to form an assembly (stack). The power plant of SOFC along with stack comprises of different sub-units such as a fuel processing unit for fuel purification, oxygen supply unit, DC to AC conversion, a unit to attain the required temperature and control/safety units. The components (anode, cathode and electrolyte) used in SOFC are all solids [8].

3. Materials

The SOFC is comprised of different components like: electrodes, electrolyte, materials for sealings (if required), interconnects and distribution system for fuel. Metal, ceramics or their composites are widely used for the construction of these components. Different criteria are required for each material in order to operate in multiple capacities [4,5,6,7,8,9,10,11,12,14,15,16,17,18,19,34,35,36]. Different materials used in different SOFC components along with their requirements are discussed below.

3.1. Cathode

The reduction of the oxygen in SOFC takes place at cathode. The reaction that takes place at cathode is given by [10,12].

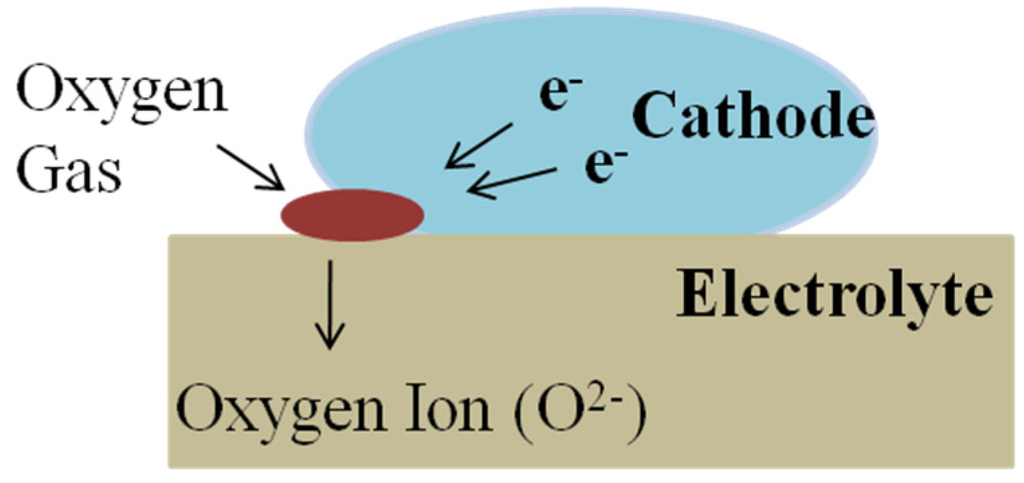

The cathode must have high electronic and oxygen ion conductivity, matching thermal expansion coefficient with electrolyte, chemical stability at operating temperatures, sufficient porosity and better catalyst for reduction reaction [10,12]. It is generally considered that electrochemical reaction takes place at triple phase boundary, i.e., at the point of contact of electronic conductor, oxygen ion conductor and gas as shown in Figure 2 [10,12,37,38]. It is liable for the significant loss of voltages in SOFC mostly due to a great deal of polarization losses connected to reduction reaction [10,37,38].

Figure 2.

Schematic of triple phase boundary.

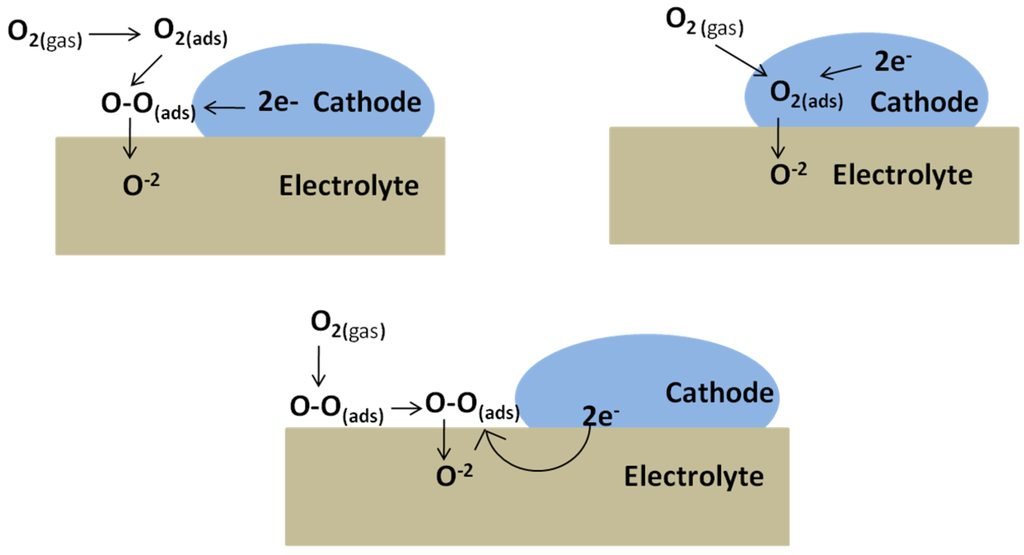

The excessively used cathode material is strontium doped lanthanum manganite (La1−xSrxMnO3 (LSM)) in high temperature SOFC [10,12,39,40,41,42,43,44,45,46]. It is associated to a manganite family of perovkites in which lanthanum is partially replaced with strontium. Perovskite structures give a great deal of variation in compositional and oxygen stoichiometry that helps in optimizing catalytic and electrical properties. This cathode material exhibits better performance at high temperatures because this efficiency is significantly good at a temperature above 800 °C. If stoichiometrically there is excess lanthanum or strontium oxide, it will result into the formation of insulating phase like La2Zr2O7 and SrZrO3 due to its interaction with yttria stabilizer zirconia leading towards poor performance. This problem can be resolved by increasing the Mn concentration and keeping fabrication temperature <1300 °C [10,12,42,45,46,47,48,49,50]. LSM has negligible oxygen ion conductivity at 900 °C with high electronic conductivity. Hence, the region of reaction is limited only to interface of electrode and electrolyte. This leads toward the necessity that cathode must be porous enough to diffuse oxygen at interface of electrode/electrolyte so that reduction of oxygen can take place. A composite layer or graded structure of LSM/YSZ is in practice to increase triple phase boundaries (TPB) [12,39,41,46]. The cathode reaction in electron conducting perovskite type materials can take place in many steps and across different paths depending upon the type of electrode material. In pristine electronic conductor materials, the most accepted mechanism is surface pathway. The bulk pathway is an accepted mechanism in mixed ionic electronic conductor (MIEC) and while electrolyte surface pathway is considered in composite materials like LSM/YSZ [10,38]. Figure 3 represents three pathways of oxygen reduction.

Figure 3.

Three reaction pathways of oxygen reduction.

A lot of efforts/concentrations are being given to increase the performance of electrode for low and intermediate temperature SOFCs [10,37,39,40,42,43,44,45,46,47]. A number of cathode materials having better electronic/ionic conductivity and increased oxygen exchange rate are investigated. It would permit the oxygen reduction action to prolong inside the cathode structure or at the fuel/cathode interconnection, which will consequently increase the reaction rate [10,12,37,39,40]. For this purpose, other perovskite materials like a La1−xSrxFe1−yCoyO3 (LSCF) are being explored. The electronic and ionic conductivity of some cathode materials (MIEC, mixed ionic and electronic conductivity) are shown in Table 2 [12,43,47,48]. Although these materials have good performance but they exhibit poor chemical stability due to their reaction (solid state) with YSZ electrolyte. To evade this problem a double layered electrolyte composed of gadolinium or samarium doped ceria/YSZ is used [8,12,47,48,49,50,51,52]. Researcher have explored LSM-YSZ (composite) and LSCF cathodes with YSZ-CGO electrolyte by current over potential measurements and impedance spectroscopy, and it is observed that LSM-YSZ has higher area specific polarization resistance (1.8 Ω-cm2) as compared to LSCF (0.4 Ω-cm2) at 850 °C [51].

Table 2.

Electronic and Ionic Conductivities of various families of SOFC cathode [8].

The solid state reaction that takes place between YSZ electrolyte and MIEC materials during synthesis can be evaded by impregnation of the cathode material into porous electrolyte structure that need low sintering temperature [8,10,12,53]. The impregnation of Perovskite can be obtained by infiltration of aqueous solution molten nitrate salt, or of nitrate salts of ionic species, or suspension of nanoparticle of the material. Similar results are reported by using either of above mention methods [10,12,54].

Similar salts can be produced by the above method. For example, Huang et al. experimented with the digestion of nitrate solution to produce LSC (La0.6Sr0.4CoO3−δ)-YSZ composite in the form of permeable YSZ disk, and after sintering it at temperature 700 °C, observed an area specific resistance (ASR) of as small on 0.03 Ω-cm2 at the same 700 °C [54]. One more way is to use chemically stable perovskite substance having good ionic and electronic flow at lower temperatures. Researchers also studied Pr1−xSrxFeO3 (PSF) group of cathode materials [10,55]. It was deduced that Pr0.8Sr0.2FeO3 perform no solid state reactivity with YSZ and offered area specific polarization reluctance of 0.204 and 0.164 Ω-cm2 respectively at 800 °C and 850 °C [55]. Another material that mainly finds application as oxygen separation membrane due its high oxygen surface exchange and diffusion characteristics is Ba0.5Sr0.5Co0.6Fe0.4O3–5 (BSCF) [8,10,56]. Both materials (PSF and BSCF) have small electronic conductivity at 800 °C that enhances with decreasing temperature [57]. Therefore, such substances are useful in low temperature as well as in intermediate temperature SOFC [56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87]. In comparison, La6.4Sr1.6Cu8O20±8 gives very good electrical conductivity but it reacts with YSZ at temperatures above 600 °C [58]. More information on cathode materials can be accessed through detailed reviews [10,12,25,50].

3.2. Electrolyte

An electrolyte is a component in a solid oxide fuel cell used for the ion transportation between electrodes. High oxygen conductivity (i.e., >0.1 S·cm−1) over a wide range of oxygen partial pressure is needed by electrolyte. A material can be a good electrolyte if it meets multifaceted property criteria. The electrolyte must be fully dense with no open porosity in order to avoid any cross diffusion of fuel and oxidant constituents. The electrolyte must be chemically inert with respect to electrodes and sealing materials as it is in contact with these materials. It must also have comparable thermal expansion coefficient (TEC) and fine mechanical properties. The electrolyte must be stable both chemically and structurally in order to make ionic transport number close to unity since it is exposed to extremely oxidizing and reducing environments at electrodes. To withstand high mechanical and thermal stress during operation and fabrication it must contain good tensile stress and toughness [10,12,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89].

A great deal of consideration has been given to four types of electrolyte, based on fully or partially stained zirconia, doped ceria, doped LaGaO3 and doped Bi2O3 [10,12,35,59,61,62]. Each system includes different sub-categories of materials with one or more dopant contents which improves their ionic conduction or phase stability. The type and concentration of dopant defines effect on phase assemblage, chemical stability, ionic conductivity, thermal and mechanical properties. A careful attention must be given to the fact that many materials are unstable under the SOFC operating conditions, exhibit low ionic conductivity and develop conductivity in reducing environment [12,35,50,59,61]. The electrolyte that fulfills most of the characteristics required for the operation of SOFC is based on Y2O3-ZrO2 with Y2O3 (3–10 mol % range). The 8 mol % Y2O3 doped ZrO2 (YSZ) composition with cubic structure has been known to have the highest ionic conductivity during SOFC operation at about 1000 °C, with about 225–300 MPa mechanical strength at room temperature and 150 MPa above 500 °C [61]. On the other hand, 3YSZ has a very high mechanical strength of about 1000 MPa at room temperature and 400 MPa above 500 °C but at the expense of ionic conductivity, and it also contains unstable and complex phase assemblage [61]. A lot of emphasis is being given to reducing SOFCs operating temperature, their cost and the severity of the materials degradation [62,63]. However, with a decrease in operating temperature from 1000 °C to 800 °C the ionic conductivity of 8YSZ reduces from 0.178 S·cm−1 to 0.052 S·cm−1 [61]. Therefore, alternative materials have been explored that can have higher ionic conductivity at lower temperatures [10,12,35,58,59,60,61,62,63].

Other electrolyte materials that are considered due to their higher ionic conductivity include Sc2O3-ZrO2, doped ceria, doped Bi2O3, lanthanum strontium magnesium gallate perovskite (LSGM) [10,12,35,43,61,62,63,64,65,66,67]. The thermal and mechanical properties of Scandia doped Zirconia are fairly similar to Yttria-Zirconia and the ionic conductivity of 9 mol % Sc2O3-ZrO3 is almost twice that of 8YSZ at 1000 °C. However, Sc2O3 is limited and expensive for practical use as an electrolyte in a large scale SOFC [59,61].

Beside Sc2O3-ZrO2, the other electrolyte families, doped ceria and doped Bi2O3, develop electronic conductivity above 600 °C and therefore often need a protection of YSZ thin layer [10,35,61,63]. The ionic conductivity of gadolinia doped ceria (CGO-Ce0.9Gd0.1O1.95) electrolyte at 600 °C is the same as that offered by YSZ at 800 °C. However, the reduction of Ce4+ ions to Ce3+ in CGO results in electron short circuiting due to electronic conduction. This reduction also causes undesirable lattice expansion [10,35,63]. It is reported that SOFC with CGO electrolyte can work at lower temperatures of about 500 °C. In this range of temperature, the contribution of electronic conductivity will be negligible. Also, low temperature ferrite supports components and sealing materials used in this temperature range [10,35,63]. Another electrolyte material that has ionic conductivity comparable to CGO is LSGM having a wider ionic window [12,63]. Despite the fact that LSGM is compelling electrolyte material in intermediate to low temperatures but attaining a single phase and stability are prominent hurdles in using LSGM [10,12,35]. LSGM, CeO2 and Bi2O3 electrolyte are considered fragile for practical devices due to poor mechanical strength [12,59,61].

An alternative approach to reduce ohmic losses is to use thin electrolyte in SOFC. The required ionic conductivity can be achieved at temperatures < 800 °C if thickness of electrolyte is less than 50 μm. An electrolyte thickness of 10 to 15 μm is considered not be diffusible if synthesized by conventional ceramic routes. Ionic conductivity value > 0.01 S·cm−1 can be achieved by this thickness in order to attain area specific resistance below 0.15 Ω-cm2. An electrolyte thickness of 10 to 15 μm can be obtained by using electrode supported cell with fabrication techniques like electrochemical vapor deposition (EVD), slurry or solution spraying, Sol-gel laser spraying, magnetron sputtering, colloidal deposition etc. [35,63]. Both anode and cathode supported cell designs have been under investigation. Other materials having pyrochlore, perovskite and brownmillerite like structures are also explored and evaluated but with limited use in fuel cell [10,12,61,62,63,64,65,66,67].

Researchers have observed that the ionic conductivities of different materials not only vary with the varying dopant and its concentration but also with temperature such as the ionic conductivities of 3, 8 and 10 mol % yttria stablized zirconia at 1000 °C are 0.058 S·cm−1, 0.178 S·cm−1 and 0.136 S·cm−1 respectively, whereas at 800 °C the observed ionic conductivities are 0.018 S·cm−1, 0.052 S·cm−1 and 0.037 S·cm−1 respectively. Similarly ionic conductivities of 8 and 9 mol % scandia stablized zirconia observed at 1000 °C are 0.31 S·cm−1 and 0.34 S·cm−1 respectively whereas at 800 °C it is 0.12 S·cm−1 and 0.109 S·cm−1 respectively. The ionic conductivities of electrolytes Ce0.8Sm0.2O1.85, Ce0.7Gd0.3O1.85 and La0.9Sr0.1Ga0.8Mg0.2O3−δ at 1000 °C are 0.25 S·cm−1, 0.25 S·cm−1 and 0.316 S·cm−1 respectively, whereas at 800 °C these were 0.096 S·cm−1, 0.093 S·cm−1 and 0.121 S·cm−1 respectively [8].

3.3. Anode

The primary objective of anode is the oxidation of fuel and to provide a path to electrons produced in oxidation reaction so they can reach at current collector. The SOFC anode should have properties like good electronic conductivity, sufficient permeability, good electro-catalytic activity, phase relevance with current collector and electrolyte, good microstructural strength to operate at SOFC working temperature and a relating comparable thermal expansion coefficient with electrolyte [12,35,43,68].

The most frequently used anode with YSZ electrolyte consists of Ni and YSZ whereas Ni doped ceria is used in case of ceria based electrolytes. Ni is a good catalyst to dissociate hydrogen at working temperature of SOFC and also bears excellent electrical conductivity of about 2 × 104 S·cm−1 [68,69,70,71,72]. NiO also has a melting temperature (1955 °C) higher than the NiO/YSZ anode fabrication temperature. Since both phases of Ni-YSZ anode contribute greatly toward its performance so there should be equilibrium in their amount for adequate outcome. Usually, Ni to YSZ phase volume ratio lies between 35:65 and 55:45 [72]. Coarsening of Ni particles can be avoided by the addition of YSZ phase in the anode and it also provides extra triple phase boundaries by extension of effective reaction region [72,73]. Along with anode composition, the properties like particle shape and size of precursor oxide powders also affect anode performance to a great extent. Different deposition techniques, processing steps and heat treatment are the factor on which optimum particle size and shape is dependent. It is reported that the ideal size of particles for excellent screen printing is 0.1 μm in case of YSZ and 0.2 μm for NiO [72,73,74]. With these initiating materials, an anodic over potential of just 90 mV was observed with a current density of 350 mA/cm2 at temperature 800 °C, and deterioration of only 1.7% after 4300 h of continuous working at 900 °C [74]. The content of impurity in the starting oxide materials NiO-YSZ is also another factor that affects the performance of anode. It has been found that when content of common impurities like Na2O and SiO2 increase from 100 ppm, it reduces the efficiency of the anode effectively within only hundred hours by intermixing the phases of glassy sodium silicate at interface of anode/electrolyte particularly [75]. The anode supported SOFCs are also under extensive research since they provide better performance as compared to conventional electrolyte supported SOFCs [10,12,68,69,70,71,72,73,74]. In anode supported SOFCs, methods like tape casting or die pressing is used to prepare anode while a number of thin film deposition techniques are used to deposit a thin layer of electrolyte over the anode. In anode supported SOFCs, careful attention is given to microstructure, porosity and thickness of the anode. The anode should be dense enough so that the electrolyte layer can be deposited on them but at the same time it should be porous enough to allow diffusion of gas through it so that it can reach at anode electrolyte interface. In Ni-YSZ anode supported SOFCs, high power densities greater than 1 W/cm2 have been reported to be needed for some commercial systems [72,74,76].

Some problems that Ni-YSZ anode encounter during its operation in SOFCs involve deterioration of Ni particles with the passage of time, low stability toward the impurities of fuel, and allows coking when fuels like natural gas and hydrocarbons are used [77]. It has been reported that the coking problem can be reduced by addition of metals like Ru, Au or Rh (1–4 mol %) which can also further reduced by using catalyst and ceria [68,72,77].

Perovskite materials based on strontium titanantes, lanthanum chromite and fluorite materials based on ceria with very low or negligible percentage of metals are the alternative potential candidates for Ni-YSZ conducting anode [35,72,78,79,80]. The excellent performance is reported in literature with La0.75Sr0.25Cr0.5Mn0.5O3 anode at 900 °C using humidified hydrogen fuel [81]. No coking is also observed when La0.8Sr0.2Cr0.97V0.03O3 anode is operated continuously 100 h using dry methane fuel [82]. Some cermet anodes also exhibit both electronic and ionic conduction known as mixed ionic electronic conduction (MIEC) and increase the reaction zone [10,35,72,79].

To improve the SOFC performance, development of new materials is in progress such as significant performance (power density > 800 mW/cm2) has been shown by double Perovskite anode Sr2Mg1−xMnxMoO6−δ (SMMO) in LSGM supported cells [83]. It is also reported that above material has shown a power density of 338 mW/cm2 with no significant carbon deposition when methane is used as fuel at 800 °C. Also, a power density greater than 900 mW/cm2 with H2 and 600 mW/cm2 with methane is reported for Pr0.4Sr0.6Co0.2Fe0.7Nb0.1O3−δ, that is another promising material with K2NiF4-type structure at 800 °C [84]. The catalytic activity of these anodes can be brought close to that of Ni-YSZ anode but their compatibility with YSZ and CGO electrolytes still needs investigation.

The electrical conductivity of cermet anodes is smaller than that of Ni-YSZ anode. This conductivity is dependent upon the fabrication methods and composition of the materials used. By using composite of ceramic and metals the conductivity of low conductive ceramic anodes can be enhanced. The bilayered designs (porous conducting layer on anode) can also enhance current collection and conduction. Table 3 summarizes the best alternative anode materials for Ni-YSZ along with their maximum electronic conductivity and polarization resistance. Detailed information about the high temperature anode materials can be found in the literature [12,35,72,73,74,75,76,77,78,79,80,81,82,83,84].

Table 3.

Polarization resistance in wet H2 and electronic conductivity (pO2 ~ 10−20) for selected anode materials [8].

3.4. Interconnect

In SOFC stack electrical connection between the adjacent cells is provided by interconnect. The materials of interconnect must have properties like high thermal conductivity, high electrical conductivity, and matching thermal expansion coefficients with other components of the cell. It must also be impermeable to gas, have high mechanical strength and phase stability in the extreme operating environment of fuel cell [35,87,88]. The interconnect materials used in SOFC operating in temperature range of 500–1000 °C are usually composed of metals, ceramics or their composites. The commonly used ceramic interconnect material is basically Perovskite lanthanum chromite (LaCrO3) in which doping of elements like Sr and Ca is done in order to obtain desired thermal and electrical properties along with the phase stability in extreme operating environments of SOFC [35,89].

Nickel and calcium doped yttrium chromites are other materials that have shown their compatibility with YSZ in terms of resistance to zirconate formation and sinterability in air. However, low thermal and electrical conductivities have been observed in case of ceramic interconnects. The high fabrication cost of ceramic interconnects limits it to tubular geometry that requires less material [90]. Thus, metallic interconnects are considered to be better option as compared to ceramic interconnects. The drawback of metallic interconnect is that they undergo oxidation (corrosion), contamination of cathode takes place due to evaporation of chromium and mismatching of thermal expansion coefficient with other ceramic materials of SOFC components. The most used materials which have matching thermal expansion coefficients with ceramic components are usually alloys of chromite and ferrite stainless steel [91]. Plansee Ducralloy (94 CrSFe/Y2O3) was the foremost chromium alloy used as ceramic material replacement [91,92]. This alloy has shown better resistance to oxidation, bears good mechanical strength and exhibits matching thermal expansion coefficient with other components of SOFC. However, cost of fabrication for this material is very high. On the other hand, although ferrite stainless steel offers low fabrication cost along with matching thermal expansion coefficient, oxidation characteristics are poor that in cathode environment, resulting in oxide scale growth. This growth leads to high area specific resistance [91]. The vapor phase of Cr6+ species reacts with LSM in the presence of oxygen/water to develop new phases. Furthermore, it diffuses to electrolyte/cathode interface and deposits chromia and other species resulting in devastating cell deterioration [87]. In order to avoid all this protective coating layer of materials like reactive element oxides, spinels, nitrides and conductive perovskites, etc., have been suggested by researchers. The best of all coatings on ferrite stainless steel is the chromium free spinel coating (Mn,Co)3O4 [35,91,92,93,94,95,96,97,98,99].

3.5. Sealing Materials

The mixing of fuel and oxidant in SOFC is avoided with the help of sealing materials. In tubular geometry of SOFCs, the sealing is not a major problem; however, in planar SOFCs it is one of the critical issues. The SOFCs seal must have matching thermal expansion coefficients with electrolyte, be non reactive in contact with SOFCs components and have thermal stability in SOFC environment. SOFCs seals can be divided into two types; compressive seals (mica sheets or metal gaskets) and rigid seals (composites of glass/ceramic or glass). The low cost and air tight seals are usually composite glass ceramic seals such as CaO-SiO2 and BaO-Al2O3-SiO2 [12,50,100,101]. Furthermore, these materials show chemical inertness toward components in contact with them as compared to bare borosilicate type glasses. No doubt glass seals perform well in SOFC operating environment for short to midterm operations but their stability for long term operations (>20,000 operating h) is still not fully known. Furthermore, the ability of thermal cycling of these materials in startup and shutdown of SOFCs is a key issue. Also, in the case of rigid seal, whole SOFC stack will also become rigid, thus if the single cell cracks, the whole stack will become useless [50,100]. On the other hand, compressive seal is much more resistant to thermal shocks and remains stable for long term operations, but if metal gaskets are used in these seal it can lead to short circuiting. An intense compression is needed in case of mica sheet seals in order to be hermetic [100]. Therefore, a hybrid approach can be taken, i.e., rigid seal along with compressive seal can be used. Minimal seal leakage with outstanding performance of thermal cycling is observed while using hybrid seals [102,103]. It is observed from the literature that no single approach is taken by R & D groups and companies toward the usage of sealing technology [12,35,100,102,103].

4. Fuel Cell Designs

From the 1960s, a great deal of SOFCs and their stack designs have been suggested by a number of different groups [103]. Many of these designs have been incorporated for various applications ranging from few watts to multiple kilowatts [10,12,35,103].

The drastic changes are achievable by altering the design of the cell and varying the dimensions of the SOFC components even if materials used are the same. Similarly, varying the stack design not only affects the performance but also life time of SOFC components. The design of the stack is directly dependent on the cell design [35,50,103].

Cell Design

The fuel cell performance can be limited by three key factors, namely the ohmic losses caused by transportation of charges, catalytic activity and losses due to mass transport due to either by flow of gas or transportation of ions through components of the cell. The limitations of mass and ohmic transportations are directly related to the thickness of the different cell components, which means they are directly connected to the fuel cell design, whereas materials used in the components of cell affect the catalytic activity of electrodes. Beside performance, other factors that are taken into account for the fuel cell design are: cost of materials and mechanical strength [8,102,103].

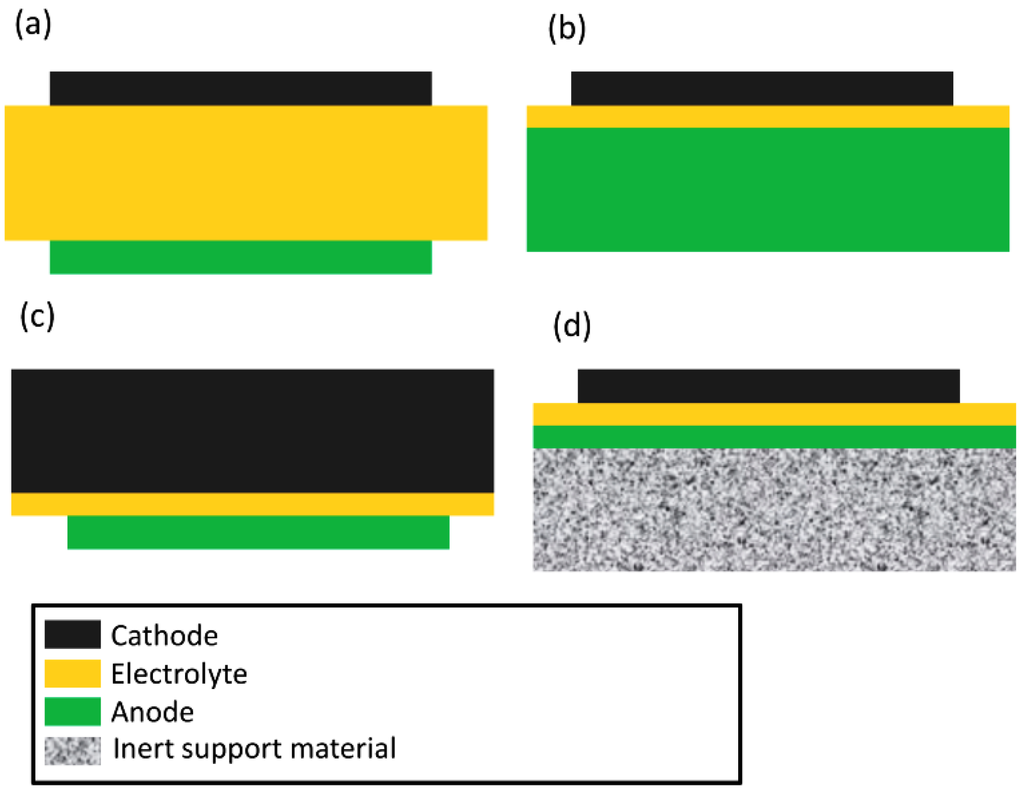

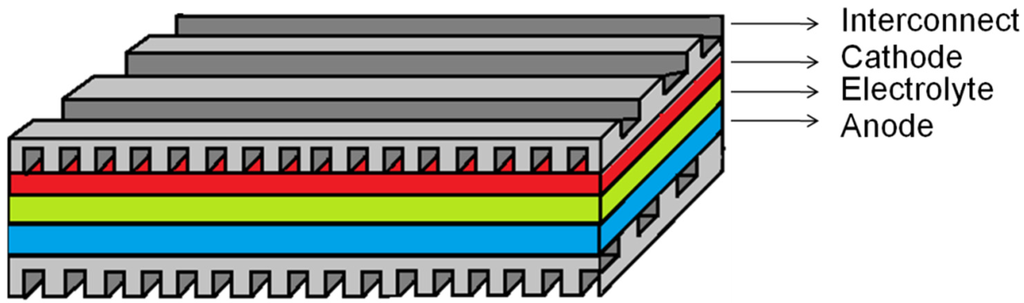

Generally, four different types of cell designs are used, namely: cathode supported, electrolyte supported, anode supported and externally supported designs shown in Figure 4. In each of the above mentioned designs, one cell component is usually thicker by about 1–5 mm than other components in order to provide mechanical support to the cell. In order to increase the cell performance, its mechanical strength and to reduce the cell cost, the thickness of different components of the cell other than support materials are small, i.e., in the range of 5–50 μm. The mechanical strength of the cell can be increased by reducing the cracks or porosity, thermo-mechanical stress that develops due to mismatched thermal expansion coefficient of the different components of the cell [8,12,102,103,104].

Figure 4.

Different types of fuel cell design: (a) electrolyte; (b) anode; (c) cathode and (d) metal or ceramic supported [8].

The electrolyte supported fuel cell is the most commonly used design. Electrolyte supported design has advantages over the other designs in terms of fabrication simplicity and mechanical strength. In this design the thickness of non porous electrolyte is of the range of 50–500 μm. The electrodes are deposited on either side by wet methods like dip coating or screen printing. Normally, electrolyte material is fired at a higher temperature on which electrodes are than deposited and fired at lower temperatures. This method helps in avoiding the reaction of materials combination with dense electrolytes at higher temperature like in the case of LSM and LSCF materials (cathode) that reacts at higher temperature with most commonly used materials. The disadvantage of this type of design is the reduced overall performance due to thicker electrolyte required for mechanical strength of the cell [102,105].

The fuel cell designs based on cathode support are considered to be an excellent design on the basis of system size being developed and operating hours with nominal degradations. This design was abandoned in early 2000 due to high cost of support materials and manufacturing cost [106]. The rare earth oxide cathode materials, i.e., lanthanum oxide, are the main cause of its high cost. The high cost along with cost of support structures developed LSM due to its low mechanical strength and high density resulted into extremely high manufacturing cost as compared to structure developed from NiO/YSZ or pristine zirconia. Also, at the high temperature that is a requirement for the conventional ceramic processing, lanthanum oxide reacts with zirconia [103,105]. In order to avoid high temperature processing routes so that reaction of lanthanum oxide with zirconia can be avoided, simple temperature processing techniques like vapor deposition is used but it increases the manufacturing cost [107]. At present, no large scale work on the basis of this design is going on but the recent advancements in the cathode materials like lesser rare earth content and development of low cost cathode manufacturing techniques like cathode infiltration may result in the revival of cathode supported design in the near future [106,108].

Fuel cell designs based on anode support in which especially NiO-YSZ cermets are extremely popular because of their high strength, low solubility of NiO in Zirconia, ease in fabrication and its high electrical conductivity with small ohmic losses. However, high thermal expansion of NiO as compared to zirconia and large change in volume due to reduction of the anode material during cell operation makes it prone to electrolyte cracking in period of fabrication and cell operation. The problem of electrolyte cracking in order to maintain performance of cell can be sorted out by controlling the thickness of electrolyte, microstructure support and carefully selecting the content of NiO in composite of NiO-YSZ [68,102,103,109].

The supported cell designs are further segregated into two sub categories namely; ceramic and metal supported designs shown in Figure 5. From these two sub categories, ceramic support materials are usually preferred for the ceramic based fuel cell due to their inertness and low thermal expansion coefficient. The cathode degradation becomes limited due to reduced use of high chrome in high temperature alloys [87].

Figure 5.

(a) Ceramic supported and (b) Metal supported cell designs [8].

The cell designs based on ceramic support materials are generally considered not to be suitable for the system that undergoes fast and continuous thermal cycles due to their high stiffness and lower toughness [8,102,103].

Cell designs based on metal support are somehow difficult to manufacture since metal cannot be heated to the high temperature which is normally needed for processing of ceramic components. Also, high temperature metal alloys are chemically unstable in the cathode’s oxidizing environment, which results in the reduction of cell’s lifetime. Beside above shortcoming of metal support design, it is still a very attractive design due to its very high electrical conductivity, high strength and fine resistance to thermal shock which helps its usage in automotive and residential micro-CHP sectors [68,102,103].

5. Stack Designs

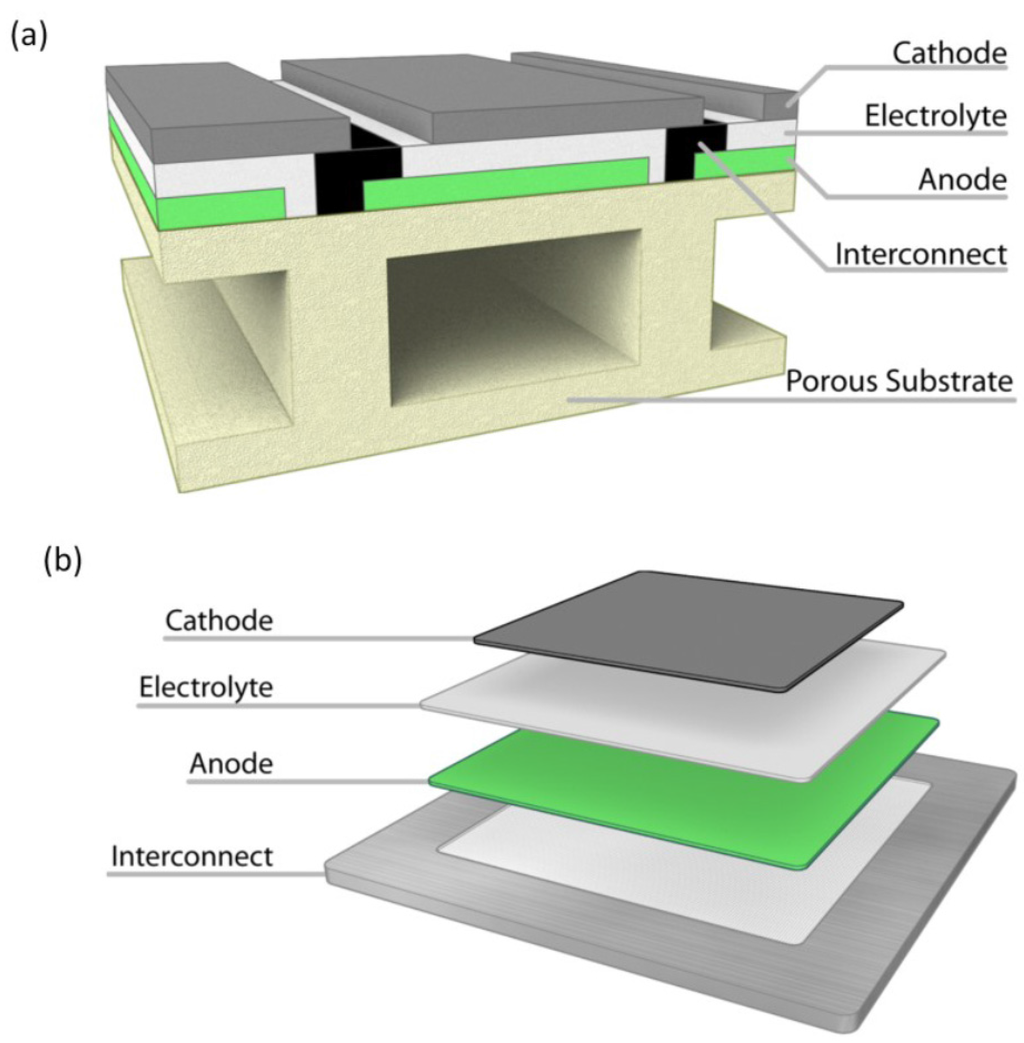

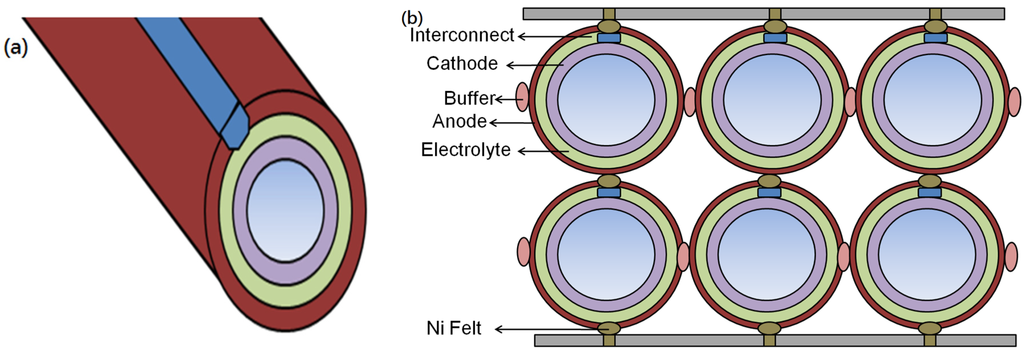

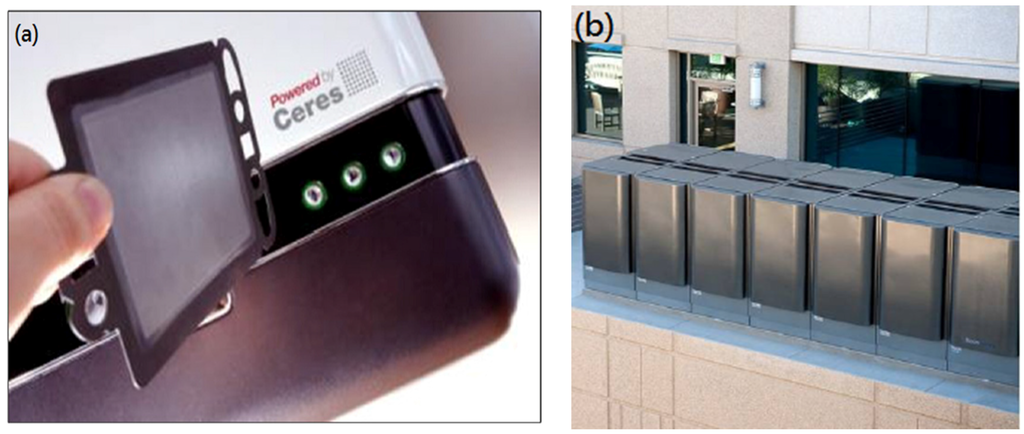

A number of stack designs are developed over a period of time but currently most focus is given to tubular, planar and hybrid designs with varying designs for the distribution system of fuel and air. Planar designs have low fabrication cost but sealing in the case of planar design is difficult due to varying thermal expansion coefficient of components of stack during thermal cycling. A suitable candidate for interconnect material is not well defined in case of planar design. On the other hand, tubular design does not demand complex sealing but cost of fabrication is very high in this design [12,102,103]. Figure 6 and Figure 7 show the schematic of tubular and planar stack design. The hybrid designs based on modified or flattened tubes eases the issues related to fabrication cost by utilization of techniques like screen printing [102,103,110]. In conclusion, currently there is no specific design that is playing a leading role. Figure 8 represents the SOFC units designed by CERES and Bloom Energy.

Figure 6.

Schematic of typical tubular Solid Oxide Fuel Cell (a) Single tubular SOFC; (b) Stack of tubular SOFCs.

Figure 7.

Schematic of typical planar type Solid Oxide Fuel Cell.

Figure 8.

(a) Ceres Planar SOFC unit (b) 200 kW Bloom Energy SOFC Stack unit [8].

6. Fabrication Technologies

Generally conventional ceramic processing techniques like dip coating, tape casting, calendar rolling, screen printing, etc., are used to fabricate high temperature SOFCs due to their number of layers with varying thickness normally in the range of 10–100 μm [12,102,103]. There are also other techniques like CVD, PLD, plasma spraying and electro-phoretic deposition that avoid chemical interaction of components but still they are unpopular due to their complexity and additional cost [12,102]. Table 4 gives the concise description of different deposition techniques used for SOFC components fabrication along with their features [12,102,111].

Table 4.

A brief description of different deposition techniques [111].

7. SOFC Fuels

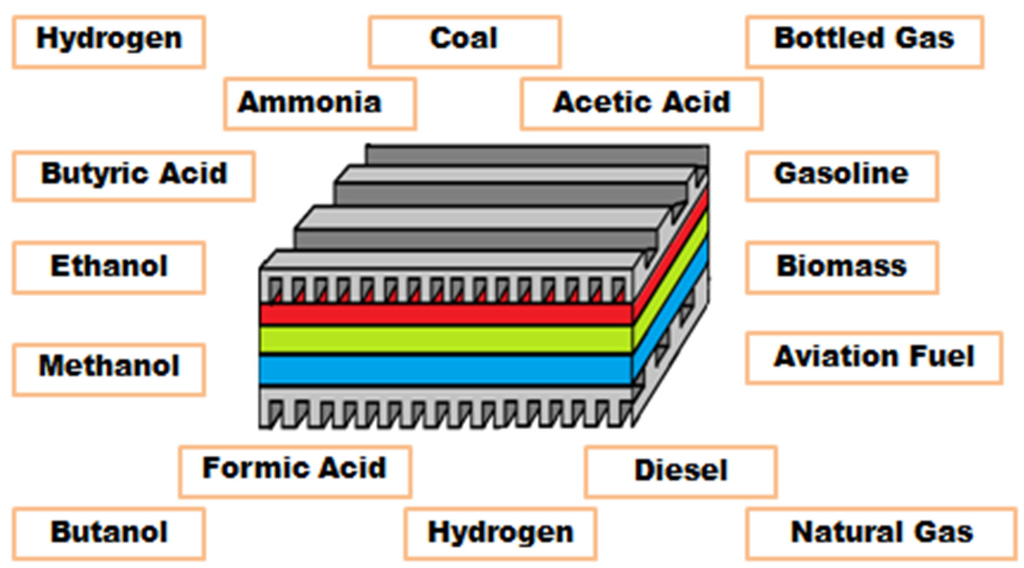

The key superiority of SOFC over other fuel cells is the flexibility in choosing fuel for its operation. One can utilize either hydrogen or hydrocarbon or hydrocarbon derived fuels. The high temperature SOFC also has another important advantage that it can operate directly on practical hydrocarbon without any complex or sophisticated external fuel reformer systems. The hydrogen and carbon monoxide are the typical fuels for high temperature fuel cell which then get oxidized at anode into water and carbon dioxide along with electrical power and large heat [12,103]. The generation of hydrogen can be done by electrolysis of water through renewable energy [112]. Natural gas is considered to be the most common fuel for stationary application. Its composition is mainly based on methane but it also contains higher hydrocarbons along with sulphur containing compounds. Both higher hydrocarbons and suplhur containing compounds result into carbon deposition and suplhur poisoning of the electrodes during SOFC operation. In this case excess of oxygen or steam is usually given in order to avoid coking and carbon deposition. Another advantage of using natural gas is that it can also be used as fuel without any reformer system in high temperature SOFC as it can internally be reformed through oxygen or co fed-steam in SOFC stacks due to high temperature. For remote and small scale applications, bottled gas such as butane or propane are used rather than methane. However, carbon deposition is difficult to avoid in the case of using bottled gas as fuel [103]. Other hydrocarbon fuels such as LPG, Napatha, kerosene, diesel, gasoline can also be used as SOFC fuel but a reformer or fuel cleaning unit is required to clean the fuel [8]. There are a wide range of practical fuels that can be used in SOFC, some of which are shown in Figure 9.

Figure 9.

Fuels for solid oxide fuel cell (SOFC).

8. Performance

The plot between potential and current density are used to evaluate the performance of cell after optimization of different parameters like type of component material, cell design, fuel, fabrication technology and appropriate temperature. Table 5 gives power densities with varying parameters such as different component materials, temperature and fuel. In the past, intense research has been carried out regarding configuration LSM-YSZ/YSZ/NiO-YSZ using hydrogen fuel. Later on LSCF is used as an alternative of LSM due to its higher ionic conductivity. Researchers also investigated the composite of electrolyte and LSCF in order to enhance ionic conductivity. A significant research has also been done to attain maximum power density with fuels other than hydrogen.

Table 5.

Electrical performance of SOFC with different materials [111].

9. Challenges on Developing Fuel Cell

During the past decade, in the development of SOFC some major goals (such as SOFC operating temperature lowered from1000 °C to 550 °C, stack cost being reduced from $1500/kW to $150/kW, life time being increased from 15,000 h to 40,000 h and attaining power densities consistently greater than 1 W/cm2) have been achieved [63,130,131,132,133,134]. However, despite all these achievements a number of challenges still remain. These challenges include further improvement of SOFC microstructure and material properties that can help to reduce the operating temperature and thus make the cell cost effective. This will help to have greater thermodynamic efficiencies, longer lifetime and quick startup times. Currently, different approaches like nanostructured thin film micro SOFCs, thick film SOFCs, strain engineered materials, etc., are being pursued to address this problem but still it is unclear which method or technology will be the ultimate one [130]. Another challenge on which researchers are working hard is to reduce the cost of production, storage and transportation of hydrogen. Researchers are trying to develop proper infrastructure that will help to rectify these problems. The production of hydrogen through electrolysis and steam methane reforming on wide scale will help to reduce the cost of hydrogen. Along cost effective hydrogen production, researchers are working on cost effective storage [21]. Beside all these accomplishments and efforts there is still a long way to travel.

10. Summary

Solid Oxide Fuel Cell technology offers an alternative efficient and environment friendly power generation source. High temperature SOFC also removes the need for a precious metal catalyst and enables internal reformation of fuels, therefore reducing the cost of fuel cell. Another advantage of SOFC is the versatility of the fuels which can be utilized by it. A significant work has been done during the last decade to attain maximum power densities. Different innovative materials have been identified/developed and tested to make fuel cell cost effective and durable in order to make SOFC suitable for commercialization. Also, these materials are replacing traditional materials for the case when SOFC uses hydrocarbon as fuel. In addition to materials, different designs and fabrication technologies are also evolving in order to meet the requirement of cost reduction for SOFC commercialization. Still there are many hurdles and challenges to overcome and this field will take years to mature.

Author Contributions

Muneeb Irshad and Anwar Ali along with Pankaj Tiwari, Asia Rafique, Muhammad Kaleem Ullah, Amjad Ali, Asrlan Usman completed this review whereas Khurram Siraj along with Rizwan Raza and Bin Zhu did supervision of this review article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Stockford, C.; Brandon, N.; Irvine, J.; Mays, T.; Metcalfe, I.; Book, D.; Ekins, P.; Kucernak, A.; Molkov, V.; Steinberger-Wilckens, R.; et al. H2FC SUPERGEN: An overview of the hydrogen and fuel cell research across the UK. Int. J. Hydrogen Energy 2015, 40, 5534–5543. [Google Scholar] [CrossRef]

- Jiang, S.P. Nanoscale and nano-structured electrodes of solid oxide fuel cells by infiltration: Advances and challenges. Int. J. Hydrogen Energy 2012, 37, 449–470. [Google Scholar] [CrossRef]

- World Energy Outlook. Available online: http://www.worldenergyoutlook.org/media/weowebsite/2008-1994/weo2005.pdf (accessed on 20 October 2015).

- Okkay, H.; Bayramoglu, M.; Öksüzömer, M.F. Ce0.8Sm0.2O1.9 synthesis for solid oxide fuel cell electrolyte by ultrasound assisted co-precipitation method. Ultrason. Sonochem. 2013, 20, 978–983. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Hu, S.; Tay, K.; Fu, Y. Electrochemical characterization of gradient Sm0.5Sr0.5CoO3−δ cathodes on Ce0.8Sm0.2O1.9 electrolytes for solid oxide fuel cells. Ceram. Int. 2012, 38, 1557–1562. [Google Scholar] [CrossRef]

- Giddey, S.; Badwal, S.P.S.; Kulkarni, A.; Munnings, C. A comprehensive review of direct carbon fuel cell technology. Prog. Energy Combust. Sci. 2012, 38, 360–399. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, M.; Ge, L.; Li, S.; Chen, H.; Guo, L. Effect of Fe2O3 on Sm-doped ceria system solid electrolyte for IT-SOFCs. J. Alloy. Compd. 2011, 509, 546–550. [Google Scholar] [CrossRef]

- Badwal, S.P.S.; Giddey, S.; Munnings, C.; Kulkarni, A. Review of progress in high temperature solid oxide fuel cells. J. Aust. Ceram. Soc. 2014, 50, 23–37. [Google Scholar]

- Zhang, X.; Chan, S.H.; Li, G.; Ho, H.K.; Li, J.; Feng, Z. A review of integration strategies for solid oxide fuel cells. J. Power Sources 2010, 195, 685–702. [Google Scholar] [CrossRef]

- Sun, C.; Hui, R.; Roller, J. Cathode materials for solid oxide fuel cells: A review. J. Solid State Electrochem. 2010, 14, 1125–1144. [Google Scholar] [CrossRef]

- Quaschning, V. Renewable Energy and Climate Change; CH-13; John Wiley Sons & Ltd.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Fergus, J.; Hui, R.; Li, X.; Wilkinson, D.P.; Zhang, J.J. Solid Oxide Fuel Cells: Materials Properties and Performance; CRC Press: London, UK, 2009. [Google Scholar]

- Ding, D.; Liu, B.; Gong, M.; Liu, X.; Xia, C. Electrical properties of samaria-doped ceria electrolytes from highly active powders. Electrochim. Acta 2010, 55, 4529–4535. [Google Scholar] [CrossRef]

- Guo, Y.; Shi, H.; Ran, R.; Shao, Z. Performance of SrSc0.2Co0.8O3−δ + Sm0.5Sr0.5CoO3−δ mixed-conducting composite electrodes for oxygen reduction at intermediate temperatures. Int. J. Hydrogen Energy 2009, 34, 9496–9504. [Google Scholar] [CrossRef]

- Fu, Y.P.; Wen, S.B.; Lu, C.H. Preparation and characterization of samaria-doped ceria electrolyte materials for solid oxide fuel cells. J. Am. Ceram. Soc. 2008, 91, 127–131. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, X.; Zhu, Z.; Ljungberg, R. Solid oxide fuel cell (SOFC) using industrial grade mixed rare-earth oxide electrolytes. Int. J. Hydrogen Energy 2008, 33, 3385–3392. [Google Scholar] [CrossRef]

- Gu, H.; Chen, H.; Gao, L.; Zheng, Y.; Zhu, X.; Guo, L. Effect of Co doping on the properties of Sr0.8Ce0.2MnO3−δ cathode for intermediate-temperature solid oxide fuel cells. Int. J. Hydrogen Energy 2008, 33, 4681–4688. [Google Scholar] [CrossRef]

- Webe, A.; Ivers-Tiffee, E. Materials and concepts for solid oxide fuel cells (SOFCs) in stationary and mobile applications. J. Power Sources 2004, 127, 273–283. [Google Scholar] [CrossRef]

- Kordesch, K.V.; Simader, G.R. Fuel Cells and Their Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 1996. [Google Scholar]

- Edwards, P.P.; Kuznetsov, V.L.; David, W.I.F.; Brandon, N.P. Hydrogen and fuel cells: Towards a sustainable energy future. Energy Policy 2008, 36, 4356–4362. [Google Scholar] [CrossRef]

- Nancy, L.G.; Dimitrios, C.P.; Joseph, M.S. Hydrogen and fuel cell technology: Progress, challenges, and future directions. Energy Procedia 2012, 28, 2–11. [Google Scholar]

- Ball, M.; Wietschel, M. The future of hydrogen—Opportunities and challenges. Int. J. Hydrogen Energy 2009, 34, 615–627. [Google Scholar] [CrossRef]

- Adams, T.A., II; Nease, J.; Tucker, D.; Barton, P.I. Energy conversion with solid oxide fuel cell systems: A review of concepts and outlooks for the short- and long-term. Ind. Eng. Chem. Res. 2013, 52, 3089–3111. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Rengaswamy, R. A review of solid oxide fuel cell (SOFC) dynamic models. Ind. Eng. Chem. Res. 2009, 48, 6068–6086. [Google Scholar] [CrossRef]

- Kilner, J.; Burriel, M. Materials for intermediate-temperature solid-oxide fuel cells. Mater. Res. 2014, 44, 365–393. [Google Scholar] [CrossRef]

- Stambouli, A.B.; Traversa, E. Solid oxide fuel cells (SOFCs): A review of an environmentally clean and efficient source of energy. Renew. Sustain. Energy Rev. 2002, 6, 433–455. [Google Scholar] [CrossRef]

- Singhal, S.C. Solid oxide fuel cells for power generation. WIREs Energy Environ. 2014, 3, 179–194. [Google Scholar] [CrossRef]

- Hajimolana, S.A.; Hussain, M.A.; Ashri Wan Daud, W.M.; Soroush, M.; Shamiri, A. Mathematical modeling of solid oxide fuel cells: A review. Renew. Sustain. Energy Rev. 2011, 15, 1893–1917. [Google Scholar] [CrossRef]

- Coddet, P.; Liao, H.L.; Coddet, C. A review on high power SOFC electrolyte layer manufacturing using thermal spray and physical vapour deposition technologies. Adv. Manuf. 2014, 2, 212–221. [Google Scholar] [CrossRef]

- Badwal, S.P.S. Stability of solid oxide fuel cell components. Solid State Ionics 2001, 143, 39–46. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, H.W. High Performance Anode Supported Solid Oxide Fuel Cell. U.S. Patent No. 20070015045 A1, 18 January 2007. [Google Scholar]

- Acres, G. Recent advances in fuel cell technology and its applications. J. Power Sources 2001, 100, 60–66. [Google Scholar] [CrossRef]

- Singhal, S.C. Advances in solid oxide fuel cell technology. Solid State Ionics 2000, 135, 305–313. [Google Scholar] [CrossRef]

- Skinner, S.J.; Laguna-Bercero, M.A.; Duncan, W.B.; Walton, R.; O’Hare, D. Advanced inorganic materials for solid oxide fuel cells. In Energy Materials; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; pp. 33–94. [Google Scholar]

- Jacobson, A.J. Materials for solid oxide fuel cells. Chem. Mater. 2010, 22, 660–674. [Google Scholar] [CrossRef]

- Orera, A.; Slater, P.R. New chemical systems for solid oxide fuel cell. Chem. Mater. 2010, 22, 675–690. [Google Scholar] [CrossRef]

- Ding, D.; Li, X.; Lai, S.Y.; Gerdes, K.; Liu, M. Enhancing SOFC cathode performance by surface modification through infiltration. Energy Environ. Sci. 2014, 7, 552–575. [Google Scholar] [CrossRef]

- Tao, S.W.; Wu, Q.Y.; Peng, D.K.; Meng, G.Y. Electrode materials for intermediate temperature proton-conducting fuel cells. J. Appl. Electrochem. 2000, 30, 153–157. [Google Scholar] [CrossRef]

- Ding, C.; Hashida, T. High performance anode-supported solid oxide fuel cell based on thin-film electrolyte and nanostructured cathode. Energy Environ. Sci. 2010, 3, 1729–1731. [Google Scholar] [CrossRef]

- Chroneos, A.; Parfitt, D.; Kilner, J.A.; Grimes, R.W. Anisotropic oxygen diffusion in tetragonal La2NiO4+δ: Molecular dynamics calculations. J. Mater. Chem. 2010, 20, 266–270. [Google Scholar] [CrossRef]

- Hauch, A.; Ebbesen, S.D.; Jensen, S.H.; Mogensen, M. Highly efficient high temperature electrolysis. J. Mater. Chem. 2008, 18, 2331–2340. [Google Scholar] [CrossRef]

- Belardi, R.M.; Deseure, J.; Brant, M.C.; Matencio, T.; Domingues, R.Z. Electrical study of cathodic activation and relaxation of La0,80Sr0,20MnO3. Ionics 2009, 15, 227–232. [Google Scholar] [CrossRef]

- Laguna-Bercero, M.A. Recent advances in high temperature electrolysis using solid oxide fuel cells: A review. J. Power Sources 2012, 203, 4–16. [Google Scholar] [CrossRef]

- Jiang, S.P. Development of lanthanum strontium manganite perovskite cathode materials of solid oxide fuel cells: A review. J. Mater. Sci. 2008, 43, 6799–6833. [Google Scholar] [CrossRef]

- Brant, M.C.; Matencio, T.; Dessemond, L.; Domingues, R.Z. Electrical and microstructural aging of porous Lanthanum Strontium Manganite/Yttria-doped cubic Zirconia Electrodes. Chem. Mater. 2001, 13, 3954–3961. [Google Scholar] [CrossRef]

- Brant, M.C.; Matencio, T.; Dessemond, L.; Domingues, R.Z. Electrical degradation of porous and dense LSM/YSZ interface. Solid State Ionics 2006, 177, 915–921. [Google Scholar] [CrossRef]

- Dutta, A.; Mukhopadhyay, J.; Basu, R.N. Combustion synthesis and characterization of LSCF-based materials as cathode of intermediate temperature solid oxide fuel cells. J. Eur. Ceram. Soc. 2009, 29, 2003–2011. [Google Scholar] [CrossRef]

- Marina, O.A.; Pederson, L.R.; Williams, M.C.; Coffey, G.W.; Meinhardt, K.D.; Nguyen, C.D.; Thomsen, E.C. Electrode performance in reversible solid oxide fuel cells. J. Elctrochem. Soc. 2007, 154, 452–459. [Google Scholar] [CrossRef]

- Uhlenbruck, S.; Moskalewicz, T.; Jordan, N.; Penkalla, H.J.; Buchkremer, H.P. Element inter diffusion at electrolyte-cathode interfaces in ceramic high-temperature fuel cells. Solid State Ionics 2009, 180, 418–423. [Google Scholar] [CrossRef]

- Holtappels, P.; Vogt, U.; Graule, V.T. Ceramic materials for advanced solid oxide fuel cells. Adv. Eng. Mater. 2005, 7, 292–302. [Google Scholar] [CrossRef]

- Bebelis, S.; Kotsionopoulos, N.; Mai, A.; Tietz, F. Electrochemical characterisation of perovskite-based SOFC cathodes. J. Appl. Electrochem. 2007, 37, 15–20. [Google Scholar] [CrossRef]

- Adijanto, L.; Küngas, R.; Bidrawn, F.; Gorte, R.J.; Vohs, J.M. Stability and performance of infiltrated La0.8Sr0.2CoxFe1−xO3 electrodes with and without Sm0.2Ce0.8O1.9 interlayers. J. Power Sources 2011, 196, 5797–5802. [Google Scholar] [CrossRef]

- Vohs, J.M.; Gorte, R.J. High-performance SOFC cathodes prepared by infiltration. Adv. Mater. 2009, 21, 943–956. [Google Scholar] [CrossRef]

- Huang, Y.; Anh, K.; Vohs, J.M.; Gorte, R.J. Characterisation of Sr-doped LaCoO3-YSZ composites prepared by impregnation methods. J. Electrochem. Soc. 2004, 151, 1592–1597. [Google Scholar] [CrossRef]

- Piao, J.; Sun, K.; Zhang, N.; Chen, X.; Xu, S.; Zhou, D. Preparation and characterisation of Pr1−xSrxFeO3 cathode materials for intermediate temperature solid oxide fuel cells. J. Power Sources 2007, 172, 633–640. [Google Scholar] [CrossRef]

- Zhao, H.; Shen, W.; Zhu, Z.; Li, X.; Wang, Z. Preparation and properties of BaxSr1−xCoyFe1−yO3−δ cathode material for intermediate temperature solid oxide fuel cells. J. Power Sources 2008, 182, 503–509. [Google Scholar] [CrossRef]

- Richter, J.; Holtappels, P.; Graule, T.; Nakamura, T.; Gauckler, L.J. Materials design for perovskite SOFC cathodes. Monatshefte Chem. 2009, 140, 985–999. [Google Scholar] [CrossRef]

- Skinner, S.J.; Munnings, C.N. Electrical properties of iron-substituted La6.4Sr1.6Cu8O20±δ. Mater. Lett. 2002, 57, 594–597. [Google Scholar] [CrossRef]

- Kharton, V.V.; Marques, F.M.B.; Atkinson, A. Transport properties of solid oxide electrolyte ceramics: A brief review. Solid State Ionics 2004, 174, 135–149. [Google Scholar] [CrossRef]

- Chroneos, A.; Yildiz, B.; Tarancón, A.; Parfitt, D.; Kilner, J.A. Oxygen diffusion in solid oxide fuel cell cathode and electrolyte materials: Mechanistic insights from atomistic simulations. Energy Environ. Sci. 2011, 4, 2774–2789. [Google Scholar] [CrossRef]

- Badwal, S.P.S.; Ciacchi, F.T. Oxygen-ion conducting electrolyte materials for solid oxide fuel cells. Ionics 2000, 6, 1–21. [Google Scholar] [CrossRef]

- Rushton, M.J.D.; Chroneos, A.; Skinner, S.J.; Kilner, J.A.; Grimes, R.W. Effect of strain on the oxygen diffusion in yttria and gadolinia co-doped ceria. Solid State Ionics 2013, 230, 37–42. [Google Scholar] [CrossRef]

- Wachsman, E.D.; Lee, K.T. Lowering the temperature of solid oxide fuel cells. Science 2011, 334, 935–939. [Google Scholar] [CrossRef] [PubMed]

- O’Brien, J.E.; Stoots, C.M.; Herring, J.S.; Hartvigsen, J. Hydrogen production performance of 10-cell planar solid-oxide electrolysis stack. J. Fuel Cell Sci. Technol. 2006, 3, 213–219. [Google Scholar] [CrossRef]

- Laguna-Bercero, M.A.; Skinner, S.J.; Kilner, J.A. Performance of solid oxide electrolysis cells based on scandia stablised zirconia. J. Power Sources 2009, 192, 126–131. [Google Scholar] [CrossRef]

- Ishihara, T.; Jirathiwathanakul, N.; Zhong, H. Intermediate temperature solid oxide electrolysis cell using LaGaO3 based perovskite electrolyte. Energy Environ. Sci. 2010, 3, 665–672. [Google Scholar] [CrossRef]

- Ishihara, T.; Kannou, T. Intermediate temperature steam electrolysis using LaGaO3 based electrolyte. Solid State Ionics 2011, 192, 642–644. [Google Scholar] [CrossRef]

- Islam, S.; Hill, J.M. Chapter 4—Anode materials development. In Solid Oxide Fuel Cells: From Materials to System Modeling: The Royal Society of Chemistry; RSC Publishing: London, UK, 2013. [Google Scholar]

- Fergus, J.W. Oxide anode materials for solid oxide fuel cells. Solid State Ionics 2006, 177, 1529–1541. [Google Scholar] [CrossRef]

- Zhu, W.Z.; Deevi, S.C. A review on the status of anode materials for solid oxide fuel cells. Mater. Sci. Eng. 2003, 362, 228–239. [Google Scholar] [CrossRef]

- Martins, R.F.; Brant, M.C.; Domingues, R.Z.; Paniago, R.M.; Sapag, K.; Matencio, T. Synthesis and characterization of NiO-YSZ for SOFCs. Mater. Res. Bull. 2009, 44, 451–456. [Google Scholar] [CrossRef]

- Sun, C.; Stimming, U. Recent anode advances in solid oxide fuel cells. J. Power Sources 2007, 171, 247–260. [Google Scholar] [CrossRef]

- Lee, J.H.; Moon, H.; Lee, H.W.; Kim, J.; Kim, J.D.; Yoon, K.H. Quantitative analysis of microstructure and its related electrical property of SOFC anode. Solid State Ionics 2002, 148, 15–26. [Google Scholar] [CrossRef]

- Jiang, S.P.; Callus, P.J.; Badwal, S.P.S. Fabrication and performance of Ni/3 mol % Y2O3–ZrO2 cermet anodes for solid oxide fuel cells. Solid State Ionics 2000, 132, 1–14. [Google Scholar] [CrossRef]

- Liu, Y.L.; Primdahl, S.; Mogensen, M. Effects of impurities on microstructure in Ni/YSZ–YSZ half-cells for SOFC. Solid State Ionics 2003, 161, 1–10. [Google Scholar] [CrossRef]

- Tietz, F.; Buchkremer, H.P.; Stover, D. Components manufacturing for solid oxide fuel cells. Solid State Ionics 2002, 152, 373–381. [Google Scholar] [CrossRef]

- McIntosh, S.; Gorte, R.J. Direct hydrocarbon solid oxide fuel cells. Chem. Rev. 2004, 104, 4845–4865. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, A.; Ciacchi, F.T.; Giddey, S.; Munnings, C.; Badwal, S.P.S.; Kimpton, J.A.; Fini, D. Mixed ionic electronic conducting perovskite anode for direct carbon fuel cells. Int. J. Hydrogen Energy 2012, 37, 19092–19102. [Google Scholar] [CrossRef]

- Goodenough, J.B.; Huang, Y.H. Alternative anode materials for solid oxide fuel cells. J. Power Sources 2007, 173, 1–10. [Google Scholar] [CrossRef]

- Vulliet, J.; Morel, B.; Laurencin, J.; Gauthier, G.; Bianchi, L.; Giraud, S.; Henry, H.Y.; Lefebvre-Joud, F. First results on a (La,Sr)CrO3 anode fed with methane. Electrochem. Soc. Proc. 2003, 2003, 803–811. [Google Scholar]

- Tao, S.; Irvine, J.T.S. A Redox-stable efficient anode for solid-oxide fuel cells. Nat. Mater. 2003, 2, 320–323. [Google Scholar] [CrossRef] [PubMed]

- Vernoux, P.; Guillodo, M.; Fouletier, J.; Hammou, A. Alternative anode material for gradual methane reforming in solid oxide fuel cells. Solid State Ionics 2000, 135, 425–431. [Google Scholar] [CrossRef]

- Huang, Y.; Dass, R.I.; Xing, Z.; Goodenough, J.B. Double perovskites as anode materials for solid-oxide fuel cells. Science 2006, 312, 254–257. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Yang, Z.; Jin, C.; Xiao, G.; Chen, F.; Han, M. Sulfur-tolerant redox-reversible anode material for direct hydrocarbon solid oxide fuel cells. Adv. Mater. 2012, 24, 1439–1443. [Google Scholar] [CrossRef] [PubMed]

- Atkinson, A.; Barnett, S.; Gorte, R.J.; Irvine, J.T.S.; McEvoy, A.J.; Mogensen, M.; Singhal, S.C.; Vohs, J. Review of anode materials development in solid oxide fuel cells. Nat. Mater. 2004, 3, 17–27. [Google Scholar] [CrossRef] [PubMed]

- Lia, X.; Zhao, H.; Xu, N.; Zhou, X.; Zhang, C.; Chen, N. Electrical conduction behavior of La, Co co-doped SrTiO3 perovskite as anode material for solid oxide fuel cells. Int. J. Hydrogen Energy 2009, 34, 6407–6414. [Google Scholar] [CrossRef]

- Badwal, S.P.S.; Deller, R.; Foger, K.; Ramprakash, Y.; Zhang, J.P. Interaction between chromia forming alloy interconnects and air electrode of solid oxide fuel cells. Solid State Ionics 1997, 99, 297–310. [Google Scholar] [CrossRef]

- Fontana, S.; Amendola, R.; Chevalier, S.; Piccardo, P.; Caboche, G.; Viviani, M.; Molins, R.; Sennour, M. Metallic interconnects for SOFC: Characterization of corrosion resistance and conductivity evaluation at operating temperature of differently coated alloys. J. Power Sources 2007, 171, 652–662. [Google Scholar] [CrossRef]

- Fergus, J.W. Lanthanum chromite-based materials for solid oxide fuel cell interconnects. Solid State Ionics 2004, 171, 1–15. [Google Scholar] [CrossRef]

- Yoon, K.J.; Cramer, C.N.; Stevenson, J.W.; Marina, A. Advanced ceramic interconnect materials for solid oxide fuel cells: Electrical and thermal properties of calcium- and nickel-doped yttrium chromites. J. Power Sources 2010, 195, 7587–7593. [Google Scholar] [CrossRef]

- Shaigan, N.; Qu, W.; Ivey, D.G.; Chen, W. A review of recent progress in coatings, surface modifications and alloy developments for solid oxide fuel cell ferritic stainless steel interconnects. J. Power Sources 2010, 195, 1529–1542. [Google Scholar] [CrossRef]

- Yang, Z. Recent Advances in metallic interconnects for solid oxide fuel cells. Int. Mater. Rev. 2008, 53, 39–54. [Google Scholar] [CrossRef]

- Wu, J.; Liu, X. Recent development of SOFC metallic interconnect. J. Mater. Sci. Technol. 2010, 26, 293–305. [Google Scholar] [CrossRef]

- Gaillard, F.; Joly, J.; Boreave, A.; Vernoux, P.; Deloume, J. Intermittent temperature-programmed desorption study of perovskites used for catalytic purposes. Appl. Surf. Sci. 2007, 253, 5876–5881. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Y.; Basu, A.; Lu, Z.; Paranthaman, M.; Lee, D.; Payzant, E. LaCrO3-based coatings on ferritic stainless steel for solid oxide fuel cell interconnect applications. Surf. Coat. Technol. 2004, 65, 177–178. [Google Scholar] [CrossRef]

- Larring, Y.; Norby, T. Spinel and perovskite functional layers between plan see metallic interconnect (Cr-5 wt % Fe-1 wt % Y2O3) and ceramic (La0.85Sr0.15)0.91 MnO3 cathode materials for solid oxide fuel cells. J. Electrochem. Soc. 2000, 147, 3251–3256. [Google Scholar] [CrossRef]

- Chen, X.; Hou, P.; Jacobson, C.; Visco, S.J.; de Jonghe, L.C. Protective coating on stainless steel interconnect for SOFCs: Oxidation kinetics and electrical properties. Solid State Ionics 2005, 176, 425–433. [Google Scholar] [CrossRef]

- Yang, Z.; Xia, G.; Simner, S.; Stevenson, J. Thermal growth and performance of manganese cobaltite spinel protection layers on ferritic stainless steel SOFC interconnects. J. Electrochem. Soc. 2005, 152, 1896–1901. [Google Scholar] [CrossRef]

- Yang, Z.; Xia, G.; Li, X.; Stevenson, J. (Mn,Co)3O4 spinel coatings on ferritic stainless steels for SOFC interconnect applications. Int. J. Hydrogen Energy 2007, 32, 3648–3654. [Google Scholar] [CrossRef]

- Weil, K.S. The state-of-the-art in sealing technology for solid oxide fuel cells. J. Mater. 2006, 58, 37–44. [Google Scholar] [CrossRef]

- Rautanen, M.; Pulkkinen, V.; Tallgren, J.; Himanen, O.; Kiviaho, J. Effects of the first heat up procedure on mechanical properties of solid oxide fuel cell sealing materials. J. Power Sources 2015, 284, 511–516. [Google Scholar] [CrossRef]

- Stolten, D. Fuel Cell Science and Engineering: Materials, Processes, Systems and Technology; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Singhal, S.C.; Kendal, K. High-Temperature Solid Oxide Fuel Cells: Fundamentals, Design and Applications; Elsevier: Philadelphia, PA, USA, 2003. [Google Scholar]

- Timurkutluk, B.; Timurkutluk, C.; Mat, M.D.; Kaplan, Y. Development of high-performance anode supported solid oxide fuel cell. Int. J. Energy Res. 2012, 36, 1383–1387. [Google Scholar] [CrossRef]

- Badwal, S.P.S.; Foger, K. Solid oxide electrolyte fuel cell review. Ceram. Int. 1996, 22, 257–265. [Google Scholar] [CrossRef]

- Lee, S.; Bevilacqua, M.; Fornasiero, P.; Vohs, J.M.; Gorte, R.J. Solid oxide fuel cell cathodes prepared by infiltration of LaNi0.6Fe0.4O3 and La0.91Sr0.09Ni0.6Fe0.4O3 in porous yttria-stabilized zirconia. J. Power Sources 2009, 193, 747–753. [Google Scholar] [CrossRef]

- Huang, K.; Singhal, S.C. Cathode-supported tubular solid oxide fuel cell technology: A critical review. J. Power Sources 2013, 237, 84–97. [Google Scholar] [CrossRef]

- Marozau, I.P.; Kharton, V.V.; Viskup, A.P.; Frade, J.R.; Samakhval, V.V. Electronic conductivity, oxygen permeability and thermal expansion of Sr0.7Ce0.3Mn1−xAlxO3−δ. J. Eur. Ceram. Soc. 2006, 26, 1371–1378. [Google Scholar] [CrossRef]

- Roehrens, D.; Han, F.; Haydn, M.; Schafbauer, W.; Sebold, D.; Menzler, N.H.; Buchkremer, H.M. Advances beyond traditional SOFC cell designs. Int. J. Hydrogen Energy 2015, 40, 11538–11542. [Google Scholar] [CrossRef]

- Agnew, G.D.; Collins, R.D.; Jorger, M.; Pyke, S.H.; Travis, R.P. The components of a rolls-royce 1 MW SOFC system. ECS Trans. 2007, 7, 105–111. [Google Scholar]

- Taroco, H.A.; Santos, J.A.F.; Domingues, R.Z.; Matencio, T. Ceramic Materials for Solid Oxide Fuel Cells, Advances in Ceramics—Synthesis and Characterization, Processing and Specific Applications; Costas, S., Ed.; INTECH Open Access Publisher: Rijeka, Croatia, 2011. [Google Scholar]

- Badwal, S.P.S.; Giddey, S.; Munnings, C. Hydrogen production via solid electrolytic routes. WIREs Energy Environ. 2013, 2, 473–487. [Google Scholar] [CrossRef]

- Lu, Z.; Zhou, X.D.; Fisher, D.; Templeton, J.; Stevenson, J.; Wu, N.; Ignatiev, A. Enhanced performance of an anode-supported YSZ thin electrolyte fuel cell with a laser-deposited Sm0.2Ce0.8O1.9 interlayer. Electrochem. Commun. 2010, 12, 179–182. [Google Scholar] [CrossRef]

- EG & G Technical Services. Fuel Cell Handbook, 5th ed.; Parsons, Inc.: Morgan, WV, USA, 2000. [Google Scholar]

- Perednis, D.; Gauckler, L.J. Solid oxide fuel cells with electrolytes prepared via spray pyrolysis. Solid State Ionics 2004, 166, 229–239. [Google Scholar] [CrossRef]

- Santillán, M.J.; Caneiro, A.; Quaranta, N.; Boccaccini, A.R. Electrophoretic deposition of La0.6Sr0.4Co0.8Fe0.2O3−δ cathodes on Ce0.9Gd0.1O1.95 substrates for intermediate temperature solid oxide fuel cell (IT-SOFC). J. Eur. Ceram. Soc. 2009, 29, 1125–1132. [Google Scholar] [CrossRef]

- Matsuda, M.; Hosomia, T.; Murata, K.; Fukui, T.; Miyake, M. Fabrication of bilayered YSZ/SDC electrolyte film by electrophoretic deposition for reduced-temperature operating anode-supported SOFC. J. Power Sources 2007, 165, 102–107. [Google Scholar] [CrossRef]

- Ding, J.; Liu, J. An anode-supported solid oxide fuel cell with spray-coated yttria-stabilized zirconia (YSZ) electrolyte film. Solid State Ionics 2008, 179, 1246–1249. [Google Scholar] [CrossRef]

- Murata, K.; Fukui, T.; Abe, H.; Naito, M.; Nogi, K. Morphology control of La(Sr)Fe(Co)O3−a cathodes for IT-SOFCs. J. Power Sources 2005, 145, 257–261. [Google Scholar] [CrossRef]

- Fan, B.; Liu, X. A-deficit LSCF for intermediate temperature solid oxide fuel cells. Solid State Ionics 2009, 180, 973–977. [Google Scholar] [CrossRef]

- Chen, J.; Liang, F.; Yan, D.; Pu, J.; Chi, B.; Jiang, S.P.; Jian, L. Performance of large-scale anode-supported solid oxide fuel cells with impregnated La0.6Sr0.4Co0.2Fe0.8O3−δ + Y2O3 stabilized ZrO2 composite cathodes. J. Power Sources 2010, 195, 5201–5205. [Google Scholar] [CrossRef]

- Liu, J.; Barnett, S.A. Thin Yttrium Stabilized zircônia electrolyte solid oxide fuel cells by centrifuge casting. J. Am. Ceram. Soc. 2002, 85, 3096–3098. [Google Scholar] [CrossRef]

- Tietz, F.; Haanappel, V.A.C.; Maim, A.; Mertens, J.; Stöver, D. Performance of LSCF cathodes in cell tests. J. Power Sources 2006, 156, 20–22. [Google Scholar] [CrossRef]

- Savaniu, C.D.; Irvine, J.T.S. La-doped SrTiO3 as anode material for IT-SOFC. Solid State Ionics 2011, 192, 491–493. [Google Scholar] [CrossRef]

- Yoo, K.B.; Choi, G.M. Performance of La-doped strontium titanate (LST) anode on LaGaO3-based SOFC. Solid State Ionics 2009, 180, 867–871. [Google Scholar] [CrossRef]

- Liu, Y.; Hashimoto, S.; Nishino, H.; Takei, K.; Mori, M. Fabrication and characterization of a co-fired La0.6Sr0.4Co0.2Fe0.8O3−δ cathode-supported Ce0.9Gd0.1O1.95 thin-film for IT-SOFCs. J. Power Sources 2007, 164, 56–64. [Google Scholar] [CrossRef]

- Hibino, T.; Hashimoto, A.; Yano, M.; Suzuki, M.; Sano, M. Ru-catalyzed anode materials for direct hydrocarbon SOFCs. Electrochim. Acta 2003, 48, 2531–2537. [Google Scholar] [CrossRef]

- Sin, A.; Kopnin, E.; Dubitsky, Y.; Zaopo, A.; Aricò, A.S.; Gullo, L.R.; La Rosa, D.; Antonucci, V. Stabilisation of composite LSFCO–GDC based anodes for methane oxidation in solid oxide fuel cells. J. Power Sources 2005, 145, 68–73. [Google Scholar] [CrossRef]

- Ruiz-Morales, J.C.; Canales-Vázquez, J.; Peña-Martínez, J.; López, D.M.; Núñez, P. On the simultaneous use of La0.75Sr0.25Cr0.5Mn0.5O3−δ as both anode and cathode material with improved microstructure in solid oxide fuel cells. Electrochem. Acta 2006, 52, 278–284. [Google Scholar] [CrossRef]

- Behling, N.H. Fuel Cells: Current Technology Challenges and Future Research Needs; Elsevier: Philadelphia, PA, USA, 2013. [Google Scholar]

- Steele, B.C.H.; Heinzel, A. Materials for fuel-cell technologies. Nature 2001, 414, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Wachsman, E.D.; Marlowe, C.A.; Lee, K.T. Role of solid oxide fuel cells in a balanced energy strategy. Energy Environ. Sci. 2012, 5, 5498–5509. [Google Scholar] [CrossRef]

- Suzuki, T.; Hasan, Z.; Funahashi, Y.; Yamaguchi, T.; Fujishiro, Y.; Awano, M. Impact of anode microstructure on solid oxide fuel cells. Science 2009, 325, 852–855. [Google Scholar] [CrossRef] [PubMed]

- Herring, J.S.; O’Brien, J.E.; Stoots, C.M.; Hawkes, G.L.; Hartvigsen, J.J.; Shahnam, M. Progress in high-temperature electrolysis for hydrogen production using planar SOFC technology. Int. J. Hydrogen Energy 2007, 32, 440–450. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).