Vibration Mitigation for an Underwater Circulating Towing System Using Simulated Annealing Particle Swarm Optimization

Abstract

1. Introduction

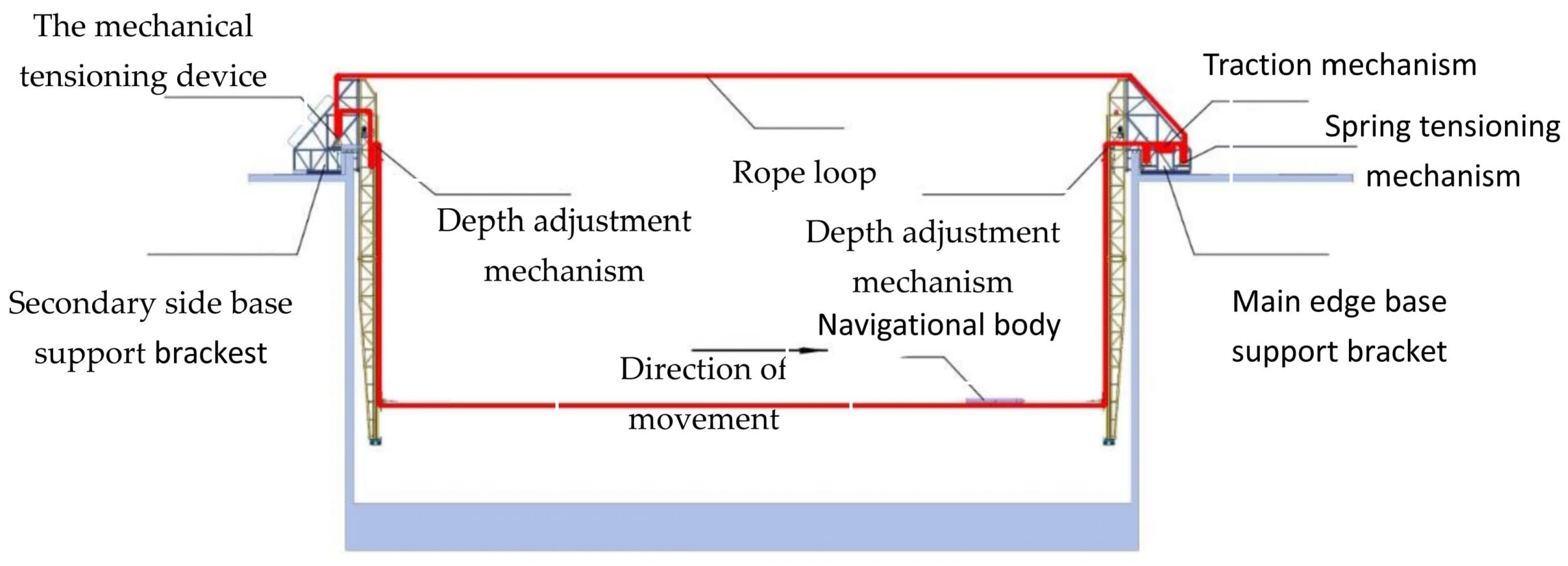

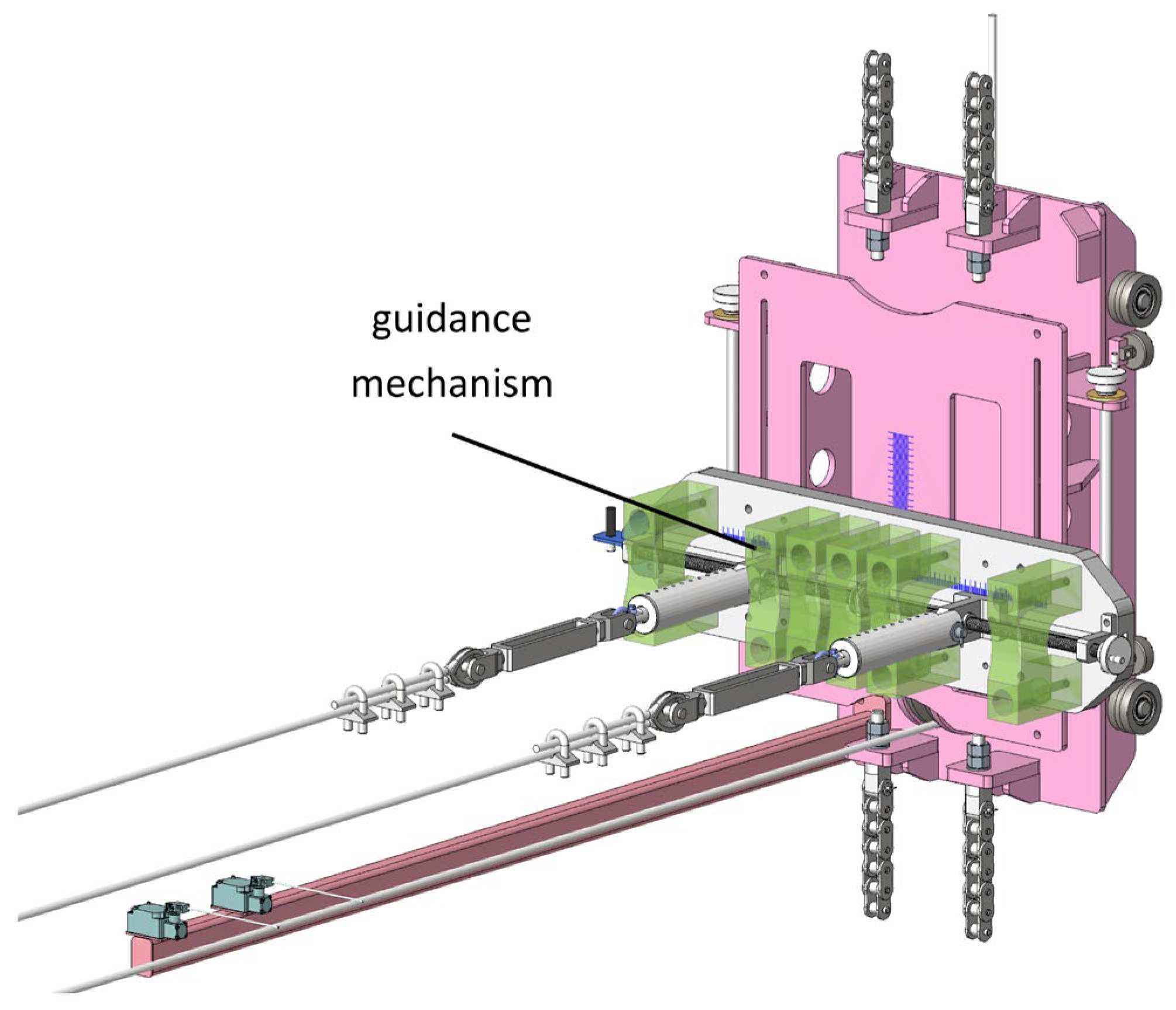

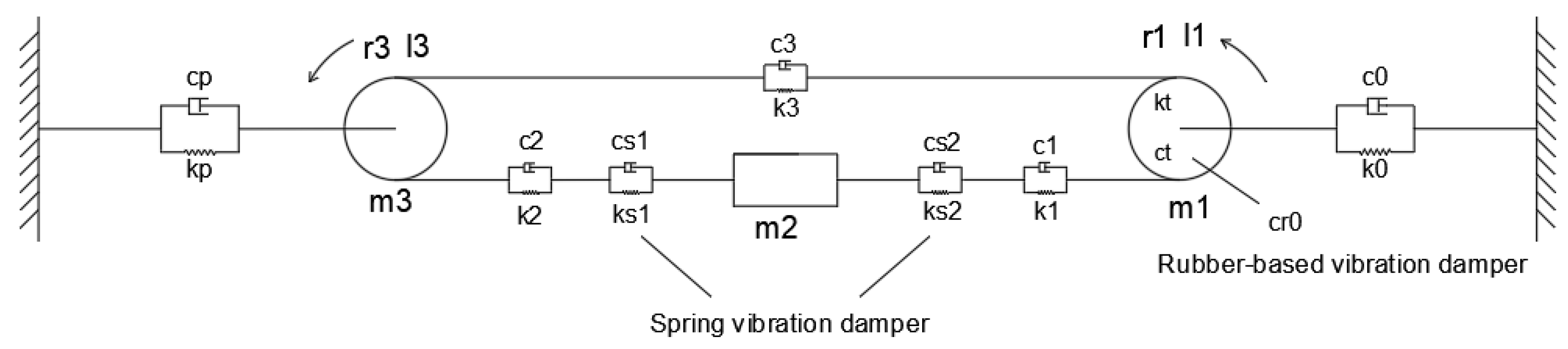

2. The Composition and Dynamic Modeling of Underwater Towing Systems

2.1. System Dynamics Modeling

- —Equivalent stiffness and damping of the spring tensioning device.

- —Equivalent mass of the main-side base structure, equivalent radius, and equivalent moment of inertia of the traction wheel.

- —Equivalent stiffness and damping of the ropes on both sides of the vehicle.

- —Equivalent mass of the underwater vehicle.

- —Equivalent mass of the auxiliary-side base structure, equivalent radius, and equivalent moment of inertia of the tensioning wheel.

- —Equivalent stiffness and damping of the mechanical tensioning device.

- —Equivalent stiffness and damping of the rope connecting the auxiliary-side and main-side base structures.

2.2. Dynamic Model Parameters of the Underwater Towing System

2.2.1. System Stiffness Parameters

- E—elastic modulus of the rope

- A—cross-sectional area of the rope

- L(t)—length of the rope segment

2.2.2. Analysis of System Damping Parameters

2.2.3. Description of the External Excitation Force in the System

3. Analysis of the Vibration Characteristics of Underwater Towing Systems

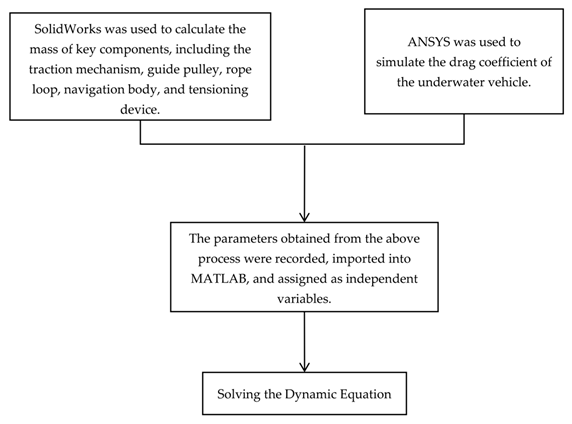

3.1. Theoretical Methodology

3.1.1. Modal Analysis

3.1.2. Added Mass Effect

3.1.3. Fluid Damping

3.2. Parameters of the Underwater Towing System

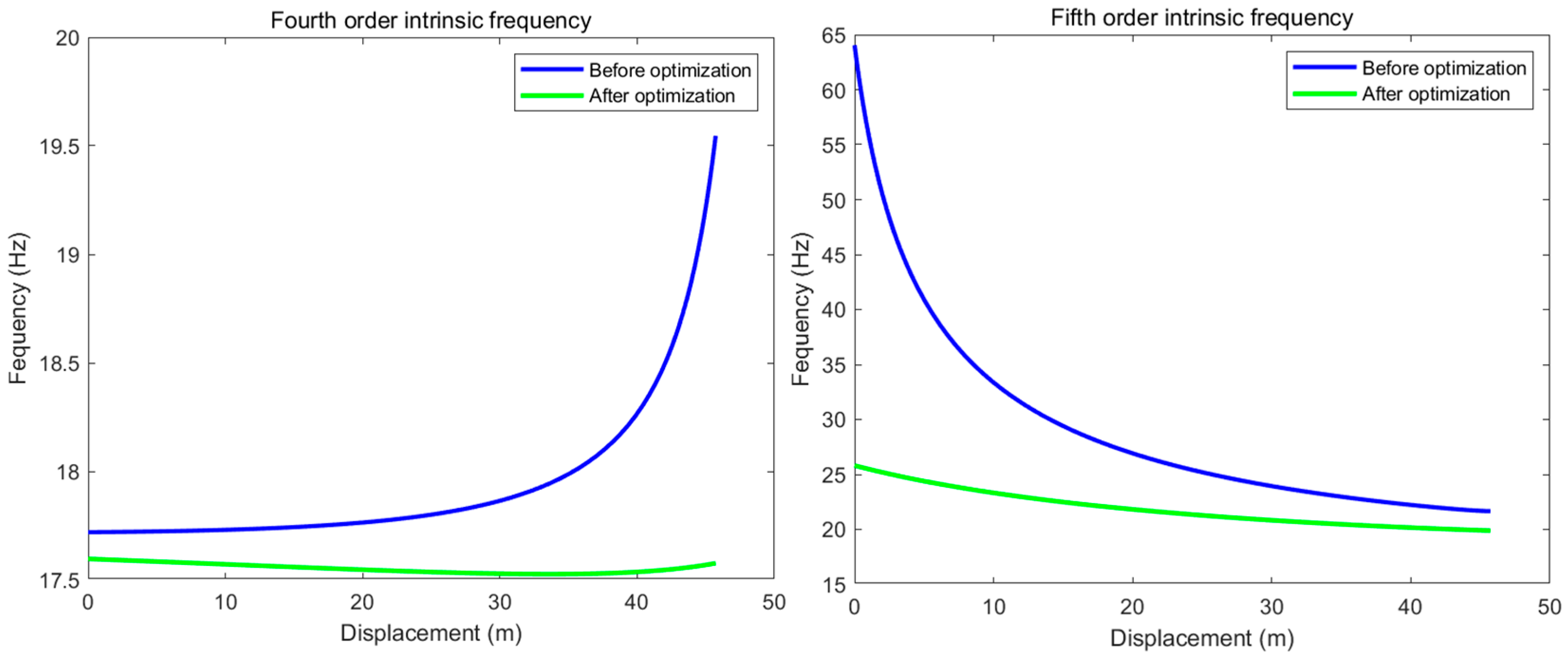

3.3. Analysis of the Natural Frequencies of the Underwater Towing System

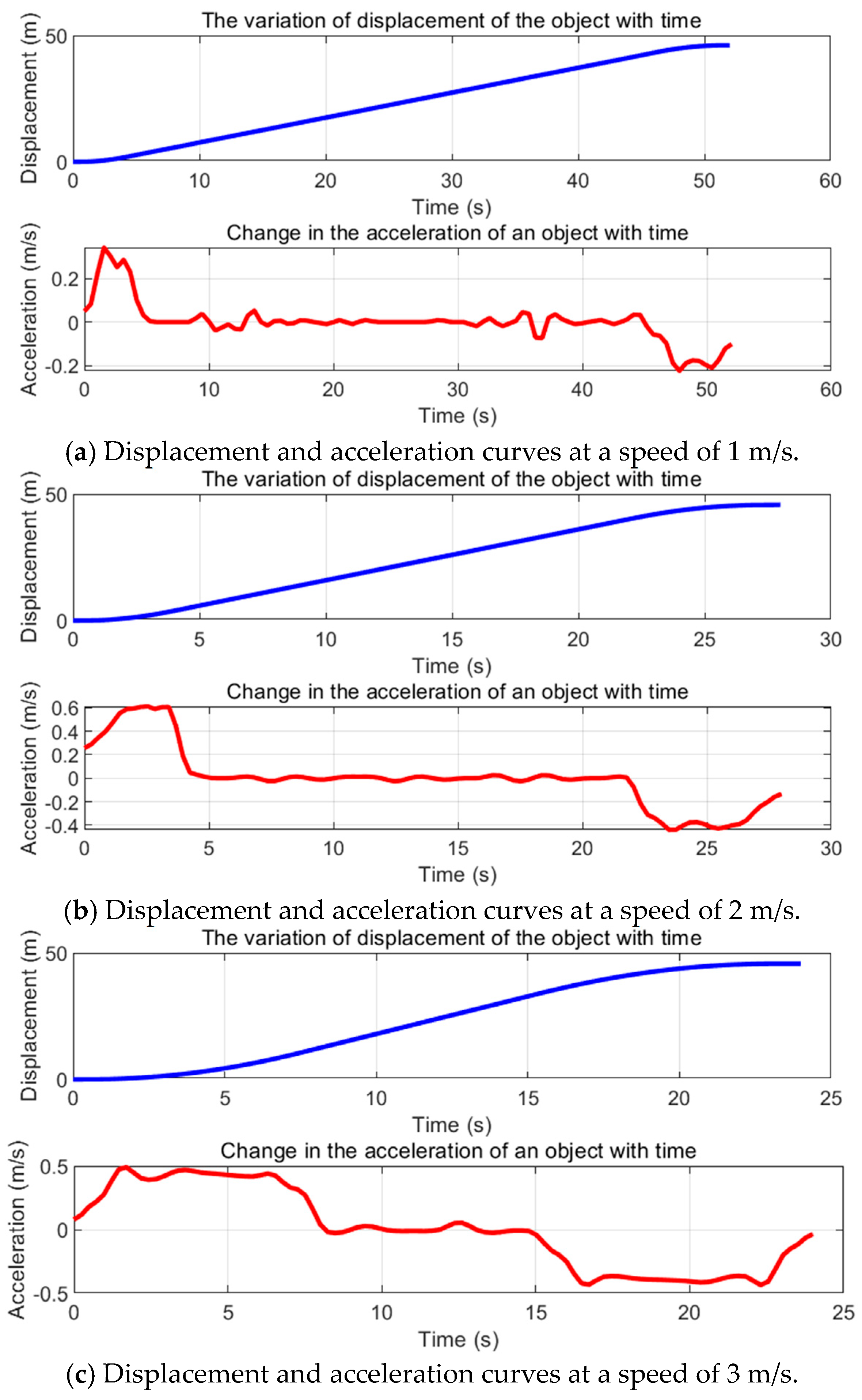

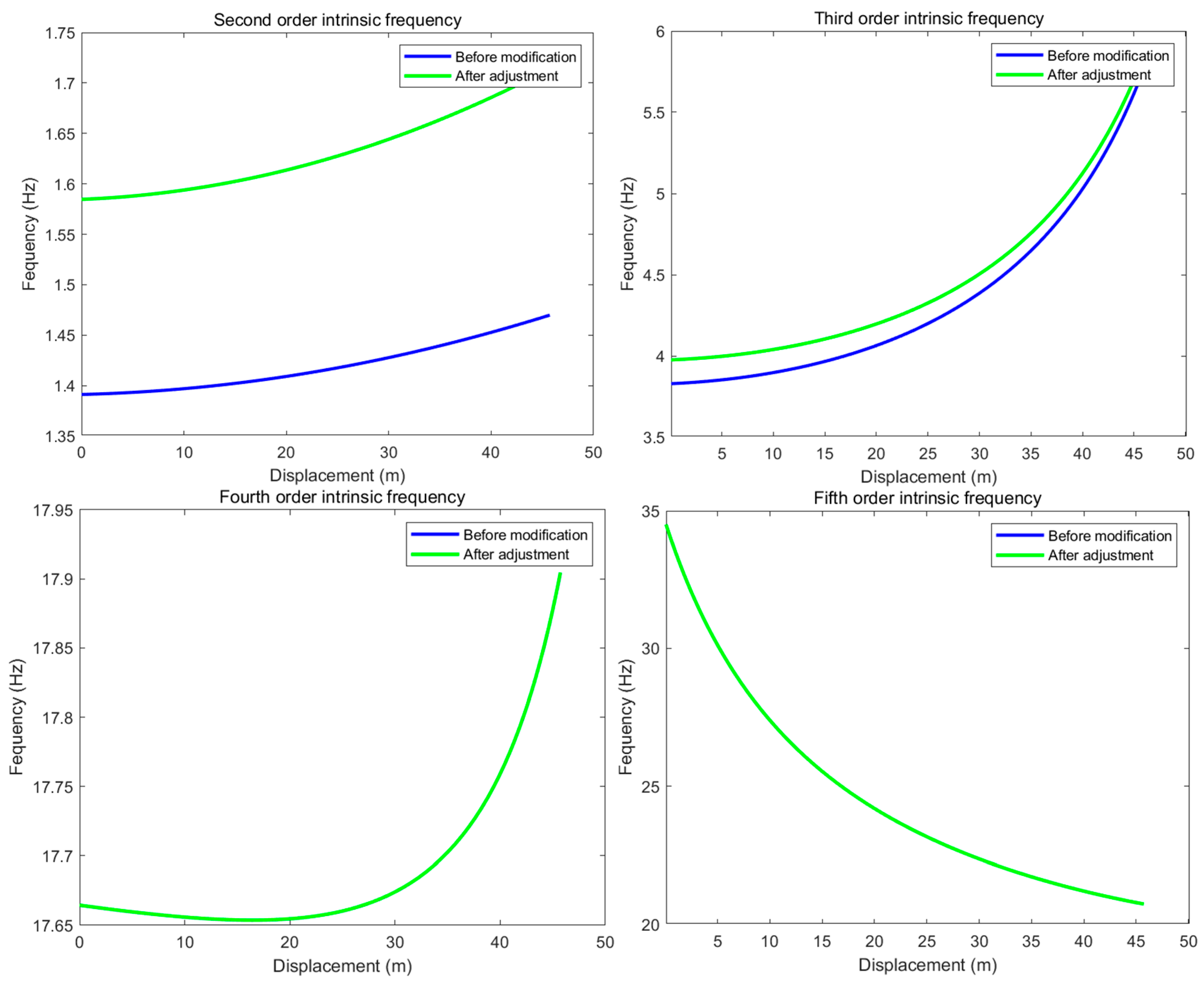

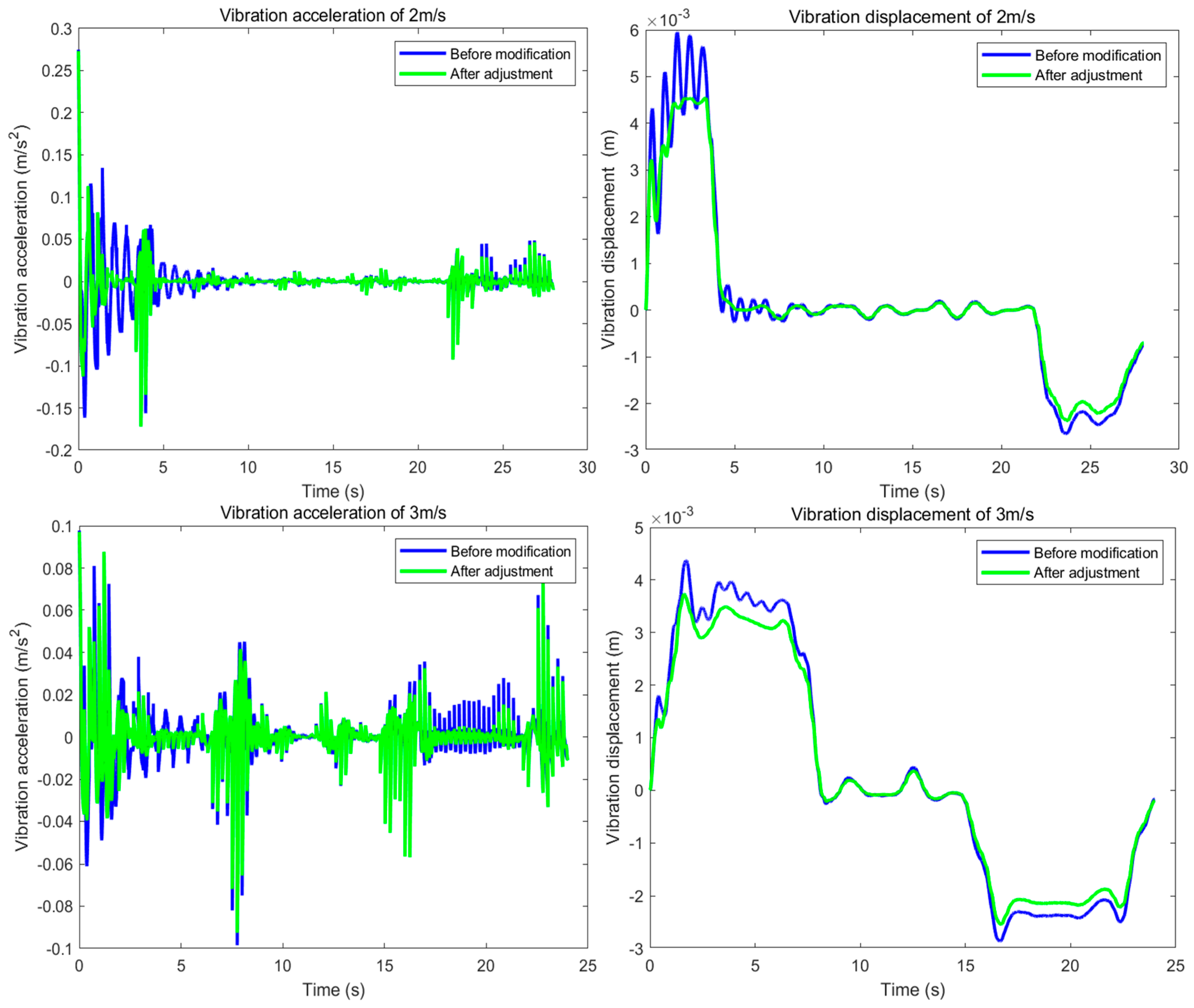

3.4. Analysis of the Transient Vibration Response of the Underwater Circulating Towing System

4. Vibration Mitigation Measures for Underwater Towing Systems

4.1. Analysis of Mitigation Measures

4.2. Analysis of Vibration Damping Effectiveness

4.3. Effect of Tensioning Spring Stiffness on System Vibration

5. Parameter Optimization of the Underwater Circulating Towing System Using Simulated Annealing Particle Swarm Optimization

5.1. Simulated Annealing Particle Swarm Optimization

- Initialize the particle swarm with an initial inertia weight w0 = 0.9 and learning factors c1 = 2.4 and c2 = 1.6.

- Based on the initial population, compute the fitness value of each particle. Record the personal best position (pbest) for each particle, the swarm’s global best position (gbest), and its fitness value (fgbest).

- The initial temperature is set as . This conventional formulation helps maintain a balance between the algorithm’s convergence speed and final solution quality.

- Update the position and velocity of each particle. To ensure algorithm convergence, the traditional velocity update formula is modified, while other components remain unchanged. The modified formula is:

- 5.

- Following Step 4, the new particles are evaluated. This involves updating pbest and gbest based on fitness comparison, followed by a probabilistic acceptance check using the Metropolis criterion. The temperature is then iterated using the following scheme:

- 6.

- Update the inertia weight as follows:

- 7.

- Repeat Steps 4, 5, and 6 until the algorithm reaches either the maximum number of iterations or the specified minimum temperature. When either condition is satisfied, the algorithm terminates and returns the global best position and its fitness value.

5.2. Selection of the Objective Function

5.3. Parameter Range Constraints

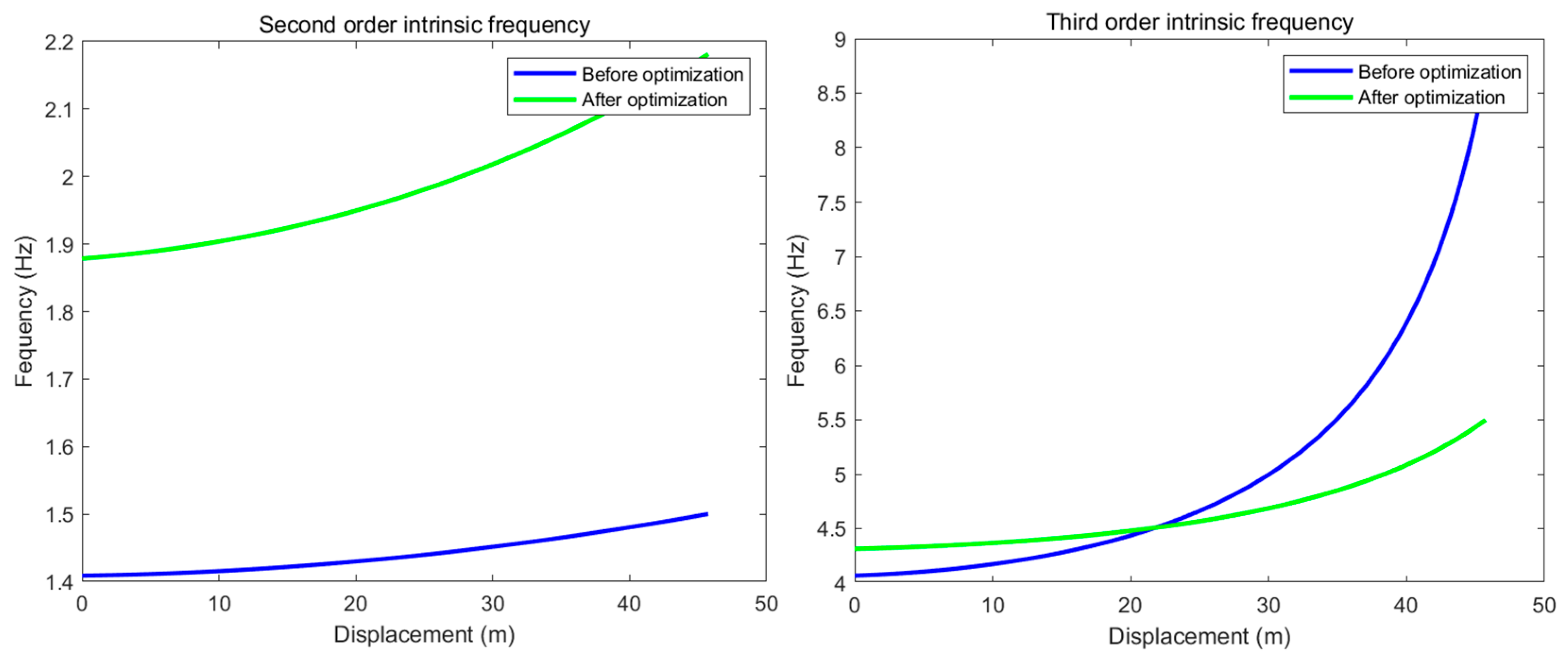

5.4. Optimization Process and Analysis of Results

6. Conclusions

- (1)

- Although incorporating spring-damper elements and a rubber damper can reduce vibration amplitude and enhance vehicle stability, this strategy has a significant limitation: it drives the system’s third-order natural frequency closer to the external excitation frequency, thereby increasing the risk of resonance.

- (2)

- Adjusting the stiffness of the tensioning spring, in addition to employing dampers, not only further reduces the vehicle’s vibration amplitude but also increases the system’s third-order natural frequency. This effectively prevents resonance and enhances operational stability and safety.

- (3)

- The vibration reduction strategy was further refined using the Simulated Annealing Particle Swarm Optimization algorithm. The optimization results show a 6% increase in the system’s third-order natural frequency, effectively preventing resonance, and reductions in the vehicle’s average vibration displacement and acceleration by 45.8% and 20%, respectively, thereby improving operational stability. Moreover, the proposed approach demonstrates strong adaptability, allowing for performance adjustments to meet specific requirements in various environments. It thus provides an effective solution for vibration control in such systems and holds significant potential for widespread application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vangi, M.; Topini, E.; Liverani, G.; Topini, A.; Ridolfi, A.; Allota, B. Design, Development, and Testing of an Innovative Autonomous Underwater Reconfigurable Vehicle for Versatile Applications. IEEE J. Ocean. Eng. 2025, 50, 509–526. [Google Scholar] [CrossRef]

- Neha, B.; Krishnan, A.S.; Younas, M.T.A.; Sunil, A.; Raji, T.R. Marine Inspection: Implementation and Advanced Applications of a Remotely Operated Underwater Robot for Exploration in Challenging Marine Environments. In Proceedings of the 2024 Second International Conference on Smart Technologies for Power and Renewable Energy (SPECon), Ernakulam, India, 2–4 April 2024; IEEE: New York, NY, USA, 2024; pp. 1–4. [Google Scholar] [CrossRef]

- Wu, J.; Yang, X.; Xu, S.; Han, X. Numerical Investigation on Underwater Towed System Dynamics Using a Novel Hydrodynamic Model. Ocean. Eng. 2022, 247, 110632. [Google Scholar] [CrossRef]

- Tian, L.; Chen, X.X.; Zhu, Z.L. Numerical Calculation and Analysis of Low-Noise Towing Test Platform. Mech. Electr. Eng. Technol. 2022, 51, 185–190. [Google Scholar]

- Oladele, O.; Brizzolara, S. Modeling the Dynamics of an Autonomous Underwater Vehicle (AUV) Towing Another AUV with a Marine Cable. In Proceedings of the OCEANS 2022, Hampton Roads, VA, USA, 17–20 October 2022. [Google Scholar]

- Yang, J.; He, L.; Shuai, C. Experimental Study on U-Turn Motion of Underwater Towing System. J. Naval Univ. Eng. 2018, 30, 26–31. [Google Scholar]

- Park, J.; Rhee, S.H.; Im, J.; Ji, B.; Lee, S. Experimental Study on the Towing Stability of a Towed Underwater Object. Int. J. Nav. Archit. Ocean. Eng. 2023, 15, 100539. [Google Scholar] [CrossRef]

- Tian, Z.; Liu, Q. Design of Hoisting Winch for Underwater Towing System. Mech. Manag. Dev. 2015, 30, 13–15. [Google Scholar]

- Schuch, E.M.; Linklater, A.C.; Lambeth, N.W.; Wooslez, C.A. Design and Simulation of a Two Stage Towing System. In Proceedings of the OCEANS 2005 MTS/IEEE, Washington, DC, USA, 17–23 September 2005. [Google Scholar]

- Wu, J.; Jin, X.; Chen, J.; Xu, Y.; Lu, L.; Chen, Y. Experimental Observation on a Controllable Underwater Towed Vehicle with Vertical Airfoil Main Body. In ASME 2015, Proceedings of the 34th International Conference on Ocean, Offshore and Arctic Engineering, St. John’s, NL, Canada, 21 May–5 June 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015. [Google Scholar]

- Pallayil, V.; Chitre, M.A.; Deshpande, P.D. A Digital Thin Line Towed Array for Small Autonomous Underwater Platforms. In Proceedings of the Oceans 2007, Vancouver, BC, Canada, 29 September–4 October 2007. [Google Scholar]

- Sakai, H.; Tanaka, T. Underwater Observation System Using Autonomous Towed Vehicle. In Proceedings of the Oceans ’04 MTS/IEEE Techno-Ocean ’04, Kobe, Japan, 9–12 November 2004. [Google Scholar]

- Zhauyt, A.; Musayev, J.; Bazanova, I.; Mustapaev, K. Equations of Motion for the Rigid and Elastic Double Pendulum Using Lagrange’s Equations. Vibroeng. Proc. 2025, 58, 154–160. [Google Scholar] [CrossRef]

- Rieman, L.P.; Buckley, R.M.; Shinde, N.S.; Wheeler, S.J. A modified linear-elastic model for calibration of resonant column devices accommodating drive system compliance. Geotechnique 2025, 75, 622–636. [Google Scholar] [CrossRef]

- Sun, J.; Xu, P.; Chen, M.; Xue, J. Forced Vibration of Time-Varying Elevator Traction System. Stroj. Vestn.-J. Mech. Eng. 2024, 75, 170–180. [Google Scholar] [CrossRef]

- Li, X.; Wu, L.; Li, L. Analysis of the Dynamic Characteristics of Elevator Mechanical Systems. Mech. Eng. 2007, 41–43. [Google Scholar] [CrossRef]

- Wang, Z.B. Dynamics and Design of Marine Towing Systems; Defense Industry Press: Beijing, China, 2019. [Google Scholar]

- Wu, J. Research and Optimization Design of the Vertical Vibration Dynamic Characteristics of Elevator Car. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2020. [Google Scholar]

- Almohimd, T.; Bhalla, S.; Madan, A. Simplified Operational Modal Analysis Using Piezo Sensors: Leveraging Minimal Sensors and Field-Centric. e-J. Nondestruct. Test. 2025, 30, 9–12. [Google Scholar] [CrossRef] [PubMed]

- Perrault, D.; Bose, N.; O’Young, S.; Williams, C.D. Sensitivity of AUV Added Mass Coefficients to Variations in Hull and Control Plane Geometry. Ocean. Eng. 2003, 30, 645–671. [Google Scholar] [CrossRef]

- Pan, X. Fluid Mechanics and Heat Transfer; Jiangxi Higher Education Press: Nanchang, China, 2019. [Google Scholar]

- Yang, R.; Clement, B.; Mansour, A.; Li, M.; Wu, N. Modeling of a Complex-Shaped Underwater Vehicle for Robust Control Scheme. J. Intell. Robot. Syst. 2015, 80, 491–506. [Google Scholar] [CrossRef]

- Yao, Z.; Liu, B.; Zeng, Y.; Bai, M.; Wang, F. Vibration Damping Measurement and Simulation of a Rotating Disk in Water. Trans. Beijing Inst. Technol. 2024, 44, 377–385. [Google Scholar]

- Moraga, G.; Xia, X.; Roig, S.; Valero, C.; Valentin, D.; Egusquiza, M.; Zhou, L.; Egusquiza, E.; Presas, A. Experimental study on the influence of vibration amplitude on the fluid damping of a submerged disk. J. Sound Vib. 2024, 569, 118099. [Google Scholar] [CrossRef]

- Gai, D. Research on the Energy Dissipation and Suppression Mechanism of Orthogonal Structural Viscous Damping. Ph.D. Thesis, Jilin University, Changchun, China, 2024. [Google Scholar]

- Ucar, H.; Basdogan, I. Dynamic Characterization and Modeling of Rubber Shock Absorbers: A Comprehensive Case Study. J. Low Freq. Noise Vib. Act. Control. 2018, 37, 509–518. [Google Scholar] [CrossRef]

- Shreehari, J. Vibration Damping through Natural Rubber and NBR Rubber. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Wu, H. Study on the Dynamic Characteristics of High-Speed Traction Elevator. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2013. [Google Scholar]

- Miao, Q. Study on the Vibration Damping Performance of the Rubber Floor Vibration Damping System for High-Speed Trains. Master’s Thesis, Qingdao University of Science and Technology, Qingdao, China, 2017. [Google Scholar]

- Fontes, D.B.M.M.; Homayouni, S.M.; Goncalves, J.F. A Hybrid Particle Swarm Optimization and Simulated Annealing Algorithm for the Job Shop Scheduling Problem with Transport Resources. Eur. J. Oper. Res. 2023, 306, 1140–1157. [Google Scholar] [CrossRef]

- Harjian, M.R.; Penangsang, O.; Aryani, N.K. Economic Dispatch Steam Power Plant Jeranjang and Sambelia Using Hybrid Algorithm Particle Swarm Optimization and Simulated Annealing. In Proceedings of the 2023 International Seminar on Intelligent Technology and Its Applications (ISITIA), Surabaya, Indonesia, 26–27 July 2023; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Lai, Y.; Wu, J.; Wang, K. Optimization Design of Vertical Vibration Parameters for High-Speed Elevators Based on Multi-Objective Genetic Algorithm. J. Univ. Jinan (Nat. Sci. Ed.) 2023, 37, 108–115. [Google Scholar]

- Zhang, Y. Discussions on Mechanical Vibration; Science Press: Beijing, China, 2010. [Google Scholar]

| Parameter Description | Meaning | Unit | Parameter Value |

|---|---|---|---|

| Equivalent Mass of the Towing System | 1678.1 | ||

| Mass of the Underwater Vehicle | 1200 | ||

| Equivalent Mass of the Secondary Structure | 1392.2 | ||

| Equivalent Radius of the Towing Wheel | 0.17 | ||

| Equivalent Radius of the Tensioning Wheel | 0.1 | ||

| Equivalent Rotational Inertia of the Towing Wheel | 31.2 | ||

| Equivalent Rotational Inertia of the Tensioning Wheel | 0.27 | ||

| Elastic Modulus of the Rope | 1.06 × 1011 | ||

| Cross-Sectional Area of the Rope | 1.13 × 10−4 | ||

| Equivalent Stiffness of the Tensioning Spring | 2.86 × 105 |

| Variable | ||||

|---|---|---|---|---|

| Lower limit value | ||||

| Upper limit |

| Variable | ||||

|---|---|---|---|---|

| outcome |

| Before Modification | Before Optimization | After Optimization | Optimization Rate: Before Modification vs. After Optimization | |

|---|---|---|---|---|

| The third-order natural frequency of the system | ||||

| The average vibration displacement of the vehicle | ||||

| The average vibration acceleration of the vehicle |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Long, S.; Wang, Q. Vibration Mitigation for an Underwater Circulating Towing System Using Simulated Annealing Particle Swarm Optimization. Appl. Sci. 2026, 16, 1393. https://doi.org/10.3390/app16031393

Long S, Wang Q. Vibration Mitigation for an Underwater Circulating Towing System Using Simulated Annealing Particle Swarm Optimization. Applied Sciences. 2026; 16(3):1393. https://doi.org/10.3390/app16031393

Chicago/Turabian StyleLong, Shihao, and Quan Wang. 2026. "Vibration Mitigation for an Underwater Circulating Towing System Using Simulated Annealing Particle Swarm Optimization" Applied Sciences 16, no. 3: 1393. https://doi.org/10.3390/app16031393

APA StyleLong, S., & Wang, Q. (2026). Vibration Mitigation for an Underwater Circulating Towing System Using Simulated Annealing Particle Swarm Optimization. Applied Sciences, 16(3), 1393. https://doi.org/10.3390/app16031393