1. Introduction

As urban underground space development moves towards the ultra-shallow burial orientation, underground excavation of pilot tunnels poses critical challenges to the safe operation of adjacent underground pipelines. Although the shallow tunneling method can reduce ground traffic interference, under ultra-shallow burial conditions, the stratum stress arch effect is significantly weakened, which easily causes asymmetric stratum deformation, thereby leading to complex settlements (even heave) of adjacent underground pipelines and posing a critical threat to pipeline safety. Therefore, it is necessary to improve the computation theory of pipeline settlement under ultra-shallow burial conditions. Notably, soil cover (or burial depth) is a universally critical factor affecting the interaction between underground structures and strata. Maleska and Beben [

1] confirmed that soil cover depth significantly influences the response of underground structures through their study on corrugated steel plate (CSP) bridges, which supports the focus on pilot tunnel burial depth as a core factor in this research.

The Winkler foundation beam model, as a Classic method for parsing pipeline-structure interaction [

2], simulates the stratum as a series of standalone springs to characterize soil-pipe interaction. However, its accuracy is critically dependent on the accuracy of the input ground surface settlement curve. In general deep and shallow burial cases, the Peck formula and its improved formulas are often consumed. Based on the Winkler foundation beam theory, Yu Jian et al. [

3] proposed a theoretical formula for foundation modulus considering the buried depth of elastic foundation beams through a two-stage analysis method, overcoming the limitations of traditional elastic foundation beam theory that requires assuming the surface of an elastic half-space and vertical forces must act on the center. Based on the modified Winkler foundation model considering the influence of pipeline burial depth, Wang Haitao et al. [

4] conducted Fourier series unwrapping on the stratum settlement and pipeline deformation functions using a two-stage analysis method, deduced their mechanical relationship, defined the displacement delivery matrix, and proposed a simplified formula for pipeline displacement prediction based on Peck stratum settlement. Based on the Winkler elastic foundation beam model and the landslide thrust landscape distribution model, Wang Rongyou et al. [

5] considered the equivalent axial force, established a simplified mechanical model of pipeline stress and deformation under the action of landscape landslides, and obtained calculated expressions such as deflection and rotation angle by solving the bending differential equation. The results show that the pipeline stress is maximum at the landslide boundary and the deformation is maximum in the middle. Based on the measured data of the shield-driven twin tunnels of Beijing Subway, Wu Fengbo et al. [

6] adopted the numerical Simulation method to conduct analysis on the influence of tunnel center burial depth, horizontal pitch and other factors on surface landscape deformation. Based on the Peck Equation, they first defined the relative pitch coefficient and established the surface deformation forecasting Equation. They considered that under the condition of vertical tunnel undercrossing, the vertical deformation of pipelines can be described using a normal distribution curve, and proposed the value range of the width argument for the pipeline settlement slot. Wang Limin [

7] conducted improvements on the basis of the Peck Equation. When ignoring pipeline stiffness, the deformation curve of upper pipelines caused by twin tunnel excavation was obtained. He considered that stratum settlement needs to be forecasted through superposition and fitting of two Peck curves, and the weakest location of the pipeline is where the first derivative of its deformation curvature reaches the maximum value.

The stochastic medium theory has high applicability under ultra-shallow buried conditions. Since it was proposed by Litwiniszyn J [

8] and a complete system was established by Liu Baochen [

9], it has been widely applied to surface settlement computation. Subsequent improvements such as the non-uniform convergence model [

10] and elliptical deformation mechanism [

11] have enhanced its adaptability to complex construction conditions. Based on the stochastic medium theory, Shao Zhushan [

12] deduced a non-uniform convergence prediction model for different tunnel sections, optimized the model parameters using the Islands annealing genetic algorithm, and verified through the cases of the horseshoe-shaped shallow tunnel of Xi’an Metro Line 8 and the circular shallow tunnel of Mulingguan. The model prediction results are consistent with the measured data and numerical computation laws. Liu Bo et al. [

13] assumed uniform convergence of the tunnel excavation section based on the Classic stochastic medium theory, proposed a parameterized non-uniform convergence pattern with superposition of 3 deformation patterns, established a surface settlement prediction model and deduced relevant prediction formulas. Back analysis combined with a shallow tunnel project in a certain section of Beijing Metro shows that the settlement slot considering non-uniform convergence is narrower and deeper, and this pattern has better prediction effect and provides empirical values of parameters. Zhang et al. [

14] studied the mechanism of surface heave in ultra-shallow pipe-roof dehydrate tunneling using stochastic medium theory, proposing that when the development depth of the frozen wall exceeds the thickness of the overburden layer, the ground surface will transform into heave. Shang et al. [

15], based on traditional stochastic medium theory, equated the settlement of the existing structure’s backplane to that of the overlying soil, divided the horseshoe-shaped tunnel cross-section into 8 arcing segments, considered the influence of variable cross-section of the tunnel and existing structures, treated the stratum loss at the tunnel connection as a linear transition, and introduced the concept of variable cross-section linear transition segment, thereby improving the applicability of stochastic medium theory in the excavation of variable cross-section tunnels. Wang et al. [

16] established an analytical solution for forecasting surface settlement caused by shield tunnel construction in sandy cobble stratum based on stochastic medium theory. They studied the influence of tunnel geometric parameters, stratum influence angle, and volume loss on the characteristics of ground settlement through back-analysis method, and proposed an improved forecasting equation by analyzing the statistical characteristics of maximum settlement, settlement slot width, and stratum loss. In the forecasting of surface settlement induced by ultra-shallow pilot tunnel excavation using traditional stochastic medium theory, it is necessary to resolve the discontinuous settlement curve through numerical integral, which makes it difficult to directly embed into the Winkler foundation beam model to conduct pipeline deformation calculation. The settlement curve cannot be resolved analytically, and the General settlement analytical solution cannot describe the surface heave deformation caused by ultra-shallow pilot tunnels, resulting in limited accuracy of pipeline deformation forecasting. To address these critical limitations, this study proposes a novel coupled approach: integrating the polynomial-fitted continuous settlement solution (derived from stochastic medium theory) with the Winkler elastic foundation beam model. This innovation breaks the technical bottleneck of discontinuous solution embedding and establishes a dedicated calculation system for ultra-shallow burial scenarios, which has not been systematically realized in previous studies. Therefore, an efficient and accurate calculation method is required.

2. Elastic Foundation Beam Solution for the Impact of Super Shallow Buried Hidden Excavation Pilot Tunnel on Pipelines

The excavation of the super-shallow-buried concealed tunnel will cause ground surface deformation, with subsidence directly above the tunnel and significant uplift near the center. In this case, the Peck settlement trough theory is less applicable, while the random medium theory has a strong ability to describe the ground surface deformation with uplift features. A numerical solution for ground surface deformation based on the random medium theory will be established, and an approximate analytical solution will be obtained through polynomial fitting. Subsequently, it will be substituted into the elastic foundation beam model to derive the pipeline response solution.

The underground pipeline is regarded as a Winkler elastic foundation beam. The calculation assumptions are as follows: ① The settlement of the soil layer near the pipeline is obtained by the random medium theory. ② The pipeline is rigid, and the material is linear elastic, uniform, and isotropic. ③ The soil around the foundation beam is a linear elastic, uniform medium. ④ The soil around the foundation beam deforms in coordination with it and remains in contact at all times.

Notably, to overcome the discontinuity of the stochastic medium settlement solution (a key limitation of traditional methods), this study introduces a critical innovative step: 17 equidistant monitoring points are sampled along the pipeline length, and the discontinuous settlement values are converted into a continuous analytical solution via 8th-degree polynomial fitting (R2 = 0.998). This continuous solution enables direct embedding into the Winkler model, realizing the effective coupling of the two theories.

The elastic foundation beam is perpendicular and orthogonal to the underpass tunnel. A coordinate system as shown in

Figure 1 is established, with the point mapped from the tunnel axis to the foundation beam in the positive upward direction as the origin, the vertical downward direction as the positive z-axis, the excavation direction as the positive x-axis, and the horizontal right direction as the positive y-axis.

According to Winkler’s theory of elastic foundation beams, the settlement of foundation soil caused by tunnel excavation can be regarded as a distributed load applied to the foundation beam. The magnitude of the distributed load on the foundation beam is

q(

y) =

Kf(

y), where

f(

y) is the settlement of foundation soil beneath the foundation beam caused by tunnel excavation. Finally, the numerical solution of the random medium fitted by polynomial is introduced.

K is the reaction modulus of the foundation bed (unit: N/m

2), and the calculation formula is:

Among them, Eg is the elastic modulus of the foundation soil; μg is the Poisson’s ratio of the foundation soil; EP is the elastic modulus of the foundation beam. IP is the moment of inertia of the cross-section of the foundation beam. d is the cross-sectional thickness of the foundation beam. When deriving, take the unit length.

The differential equation of the deflection line of the pipeline micro-section is obtained as:

In the formula,

WP represents the deflection of the pipeline at y, and the meanings of the other symbols are the same as above. To simplify the derivation process, the characteristic coefficient

β is introduced, which is defined as:

The general solution

WP of Equation (2) consists of the general solution

WP1 and the particular solution

WP2. The direct solution process for it is cumbersome, so the initial parameter method is introduced to assist in the solution: taking the right half of the foundation beam as the research object, and using the conditions at the left boundary of the right half beam (i.e., the origin), the relationship of the initial parameters can be derived. From mathematical knowledge, the general solution

WP1 can be obtained. By using the transformation of Euler’s formula and the hyperbolic function relationship to simplify the general solution

WP1, substituting the initial parameter expression, and then rewriting the form of the general solution

WP1 with the Krylov function, the following is obtained:

Among them,

W0 is the initial deflection of the foundation beam at the origin,

θ0 is the initial rotation angle of the foundation beam at the origin,

M0 is the initial bending moment of the foundation beam at the origin, and

Q0 is the initial shear force of the foundation beam at the origin. The specific form of the Krylov function in Equation (4) is as follows:

After the special solution in the form of

WP2 is obtained, the initial parameters are solved for. Distributed loads can be regarded as multiple concentrated force loads. According to mathematical knowledge, the specific solution term of each concentrated force load is known. Suppose the range of distributed loads is from the origin to section

y. A micro-segment d

u is taken at a distance of

u from the origin on the left side of Section

y, and the magnitude of the load on the micro-segment is

qd

u. The specific solution term

WP2 caused by all distributed loads on the left side of section

y is:

By superimposing Equations (4) and (6), the full solution of Equation (2) can be obtained:

Four initial parameters are calculated based on the boundary conditions as follows. Considering the left boundary condition, that is, at the origin

y = 0, according to the basic principles of structural mechanics,

θ0 = 0 and

Q0 = 0 can be obtained. Regarding the right boundary condition, from a mathematical perspective, the rotation angle and deflection of the beam should be zero only when y approaches positive infinity. However, in actual engineering, at a certain distance from the tunnel axis, the rotation angle and deflection values are so small that they can be approximately regarded as zero. Assuming the effective foundation beam length within the influence range of the tunnel settlement trough is 2

L, we have:

Solving the system of linear equations in two variables (8) yields the expressions of the remaining two initial parameters:

During the solution process, Equations (9) and (10) are simply substituted back into the full solution expression. Among the equations, L should be selected based on the actual situation. For the settlement formula of discontinuous stochastic media, polynomial fitting is performed, and an approximate continuous settlement formula f(u) is obtained.

3. Engineering Case Analysis

3.1. Project Overview

The Xueyuan South Road Station of Beijing Metro Line 13 is planned to be constructed using the 6-way tunnel column method. The small way tunnels will be excavated under ultra-shallow burial conditions, with a soil cover thickness of 4.5 m on the arch top. The soil layers that the way tunnels pass through from top to bottom are sandy silt, clayey silt, fine silt, and clayey clay in sequence. The cross-section of the pilot tunnel is horseshoe-shaped, with a width of 4 m. The rectangular part is 3.4 m high, the circular part is 1.7 m high, and the central burial depth is 5.5 m. There is a vertical water supply pipeline buried 1 m deep spanning the pilot tunnel. The material of the pipeline is cast iron pipe, with a cut line modulus of 140 GPa. The diameter of the pipeline is 100 mm, the thickness is 6 mm, and the effective pipe length is set at 16 m. The elastic modulus of the soil layer near the pipeline is 9 MPa, and the Poisson’s ratio of the soil layer near the pipeline is taken as 0.3. To monitor the impact of construction on the pipeline, four settlement measurement points were arranged at the top of the pipeline, with an interval of 5 m between adjacent points. The spatial positions of the pilot tunnel and the pipeline, as well as the measurement points, are shown in

Figure 2 step by step. The three settlement measurement points on the surface and the pipeline settlement measurement points are separated by 15 m along the direction of the pilot tunnel excavation.

3.2. Surface Settlement Analysis Based on Stochastic Media

A prediction model for ground settlement caused by ultra-shallow-buried concealed tunnel construction based on random medium [

17] was established. The calculation formula for the surface deformation value

W(

x) is as follows:

a-

h ‘is the integral boundary for uniform contraction and the second contraction of the horseshoe-shaped cross-section.

η represents the depth coordinates of the excavated micro-soil element, and

ξ represents the horizontal axis coordinates of the excavated micro-soil element. The values of the surface settlement calculation parameters are as follows:

H = 5.5 m,

A = 4 m,

B = 3.4 m,

C = 1.7 m, Δ

R = 11.85 mm, tan

β = 0.45,

δ = 57.65 mm. The measured values of surface settlement at a horizontal distance of 0 m along the central axis of the pilot tunnel are compared with the numerical solutions of stochastic media as shown in

Figure 3. Looking from left to right, the theoretical calculation curve first drops and then rises, while the measured data shows the same trend. At a horizontal distance of −5.2 m, the measured settlement is −8.0 mm, while the theoretical calculated value is −8.2 mm. At a horizontal distance of 0 m, the measured settlement is −9.8 mm, while the theoretical calculated value is −10.0 mm. At a horizontal distance of 10.3 m, the measured settlement is −4.0 mm, while the theoretical calculated value is −4.4 mm. Overall, the theoretical calculated settlement is 0.2 to 0.4 mm greater than the measured settlement, and the calculation results are slightly conservative. Through comparison with the measured settlement data, it is found that the theoretical calculation results have relatively high accuracy and can reflect the overall variation law of settlement.

The calculation parameters for the settlement curve of the soil layer near the pipeline are as follows:

H = 4.5 m,

A = 4 m,

B = 3.4 m,

C = 1.7 m, Δ

R = 11.85 mm, tan

β = 0.45,

δ = 57.65 mm. After obtaining the numerical solution of the settlement curve at the pipeline height, Seventeen points were sampled at equal intervals along the horizontal distance and substituted into the numerical solution formula, and the settlement values at the corresponding positions were obtained, as shown by the red circle in

Figure 4. Then, polynomial fitting was used, and the fitting curve is shown on the solid line in

Figure 4. The specific form of the numerical solution transformed into the analytical solution [

18,

19] through polynomial fitting is as follows:

Equation (13) is a continuous analytical solution obtained by converting the numerical solution of the settlement curve at the pipeline height through polynomial fitting. The fitting data is derived from the settlement calculation values of 17 equidistant monitoring points on the distance from the central line. After multiple trials, the 8th-degree polynomial is determined by comprehensively considering the fitting accuracy and model simplicity, with a goodness of fit R2 = 0.998, which can highly accurately reproduce the variation law of the original numerical solution. At the same time, the value range of the variable y (distance from the central line) is clearly defined as [−16.5 m, 16.5 m], which is slightly larger than the effective influence range of the pipeline in the engineering case [−16 m, 16 m].

3.3. Pipeline Deformation Analysis Based on Elastic Foundation Beams

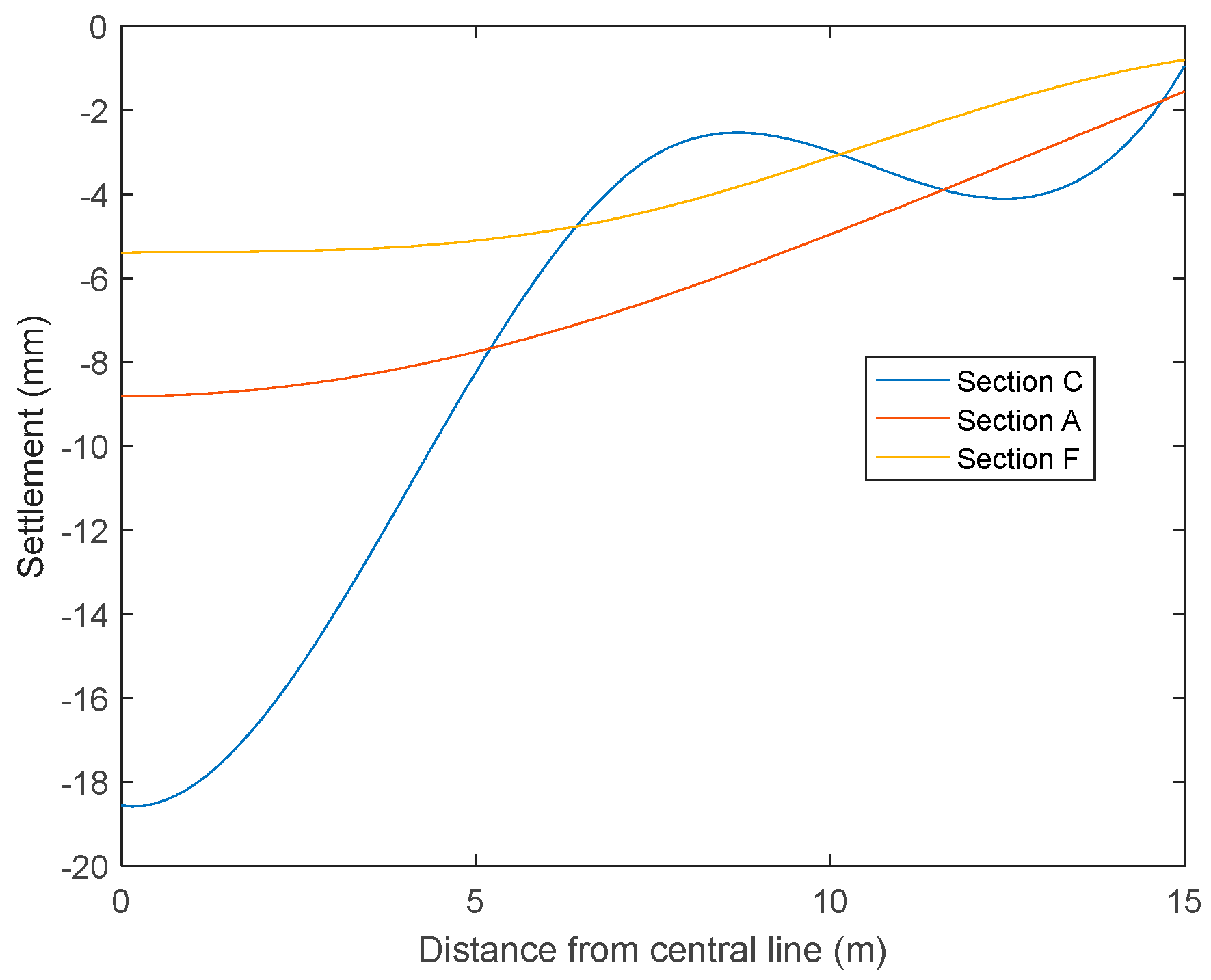

Based on the stratum parameters, pipeline parameters, and the analytical expression of stratum settlement near the pipeline, a Winkler elastic foundation beam model was established. The numerical solution of settlement at a specific point on the pipeline was derived through the model. After multiple calculations, the theoretical settlement curve of the pipeline was obtained. The comparison between the theoretical value and the measured settlement of the pipeline is shown in

Figure 5. The central axis of the pilot tunnel is at a horizontal distance of 0 m.

By analyzing

Figure 5, it can be seen that the pipeline directly above the pilot tunnel has the greatest settlement. As the horizontal distance increases, the settlement value of the pipeline decreases. The measured maximum value of settlement is −8.6 mm, and the theoretical calculated maximum value is −10.9 mm. At a horizontal distance of 5 m, the measured value is −4.1 mm, and the theoretical calculated value is −9.2 mm. Here, the error between the measured value and the theory is the largest, with the theoretical value being 5.2 mm larger. Subsequently, as the horizontal distance increased, the error gradually decreased. At a horizontal distance of 10 m, the measured value was −2.3 mm, the theoretical calculated value was −4.2 mm, and the minimum error value was 2.0 mm. Subsequently, the theoretical settlement continued to decrease and tended to be 0 mm at a horizontal distance of 15 m, while the measured uplift here was 2.7 mm. The error between the theory and the measured value increased again. The causes of errors, especially those at the edges, are as follows: The fundamental reason is the inaccuracy of the numerical solution of stratum settlement near the pipeline derived from the stochastic medium theory. The first reason is that the parameters used in the random medium theory were not taken from the mileage where the pipeline was located. The parameters used in the random medium theory were obtained through reverse analysis of three settlement measurement points. In fact, the three settlement measurement points are 20 m apart from the pipeline measurement points along the direction of the pilot tunnel excavation. The slight difference in the characteristics of the two strata is magnified under the action of ultra-shallow burial excavation. Another reason is the lack of key data on surface settlement. Due to actual reasons, settlement measurement points were not set up near a horizontal distance of 15 m. The nearest measurement point is 5 m away. As can be seen from

Figure 4, based on the three known points, the settlement at a horizontal distance of 15 m is −0.7 mm. It can be reasonably inferred that the surface deformation at this location is at least a heave of 2.7 mm or more instead of settlement. It is speculated that a bulge of 2.7 mm is actually measured for the pipeline at this location. The measured maximum settlement of −8.6 mm and the theoretical calculated maximum settlement of −10.9 mm are both less than the safety limit of 30 mm for the water supply pipeline [

20]. After calculation, the MAE (Mean Absolute Error) is 3.0 mm, the RMSE (Root Mean Square Error) is 3.24 mm, indicating good overall stability of the model. The Bias is 3.0 mm, meaning the theoretical values of the model are generally 3.0 mm larger than the measured values, indicating that the settlement predicted by the theoretical model is more significant and the model is conservative. The 95% confidence interval is [1.2 mm, 4.8 mm], indicating that the error range is controllable.

As can be seen from

Figure 6, starting from the center of the pipeline, the absolute value of the rotation angle increases at a constant rate with the increase in the horizontal distance. At a horizontal distance of 9.3 m, the pipeline rotation angle has a maximum value of −0.066°, and the maximum rotation angle is less than the local rotation angle limit of the water supply pipe at the welded joint [

21] 0.340°. Within the horizontal distance range of 9.3 m to 14 m, the absolute value of the rotation angle decreases as the horizontal distance increases. As can be seen from

Figure 7, starting from the center of the pipeline, the bending moment of the pipeline increases slowly with the increase in the horizontal distance. There is an extreme value of 40 N·m at a horizontal distance of 5 m. As the horizontal distance continues to increase, the positive bending moment value gradually decreases until it drops to zero at a horizontal distance of 9 m. When the horizontal distance continues to increase from 9 m, the negative bending moment keeps increasing. At a horizontal distance of 15.5 m, the negative bending moment of the pipeline reaches the maximum value of −137.4 N·m.

3.4. Surface Settlement Analysis Based on Finite Element Software GTS NX

The finite element software GTS NX(2022 R1) was used to simulate the pilot tunnel excavation process of Beijing Rail Transit Line 13. According to Saint-Venant’s principle, tunnel excavation affects the stratum within 3~5 times the tunnel diameter. Considering comprehensively, the model was set to 56 m in width, 24 m in height, and 30 m in length. The soil layer was modeled with solid elements and adopted the modified Mohr-Coulomb constitutive model, with different physical parameters assigned according to the geological survey report.

Before tunnel excavation, advanced small pipe grouting was used to reinforce the surrounding soil. During modeling, the effect of grouting reinforcement was converted into an enhancement of the physical and mechanical parameters of the soil in the reinforced area through equivalent calculation. According to previous research results, the elastic modulus of the undisturbed soil was doubled, and both cohesion and internal friction angle were increased by 30% on the original basis to reflect the effect of grouting reinforcement. The effective reinforcement range is considered to form a reinforcement ring of approximately 0.6–0.8 m around the excavation face.

When considering the effect of initial support, the elastic modulus of the steel mesh can be neglected compared with the grid steel arch frame, serving as a minor strength reserve. According to the principle of equivalent compressive stiffness, the grid steel frame was equivalent to concrete and superimposed with the original shotcrete strength, calculated as follows:

where

E is the equivalent elastic modulus of the converted initial support;

E0 is the elastic modulus of the original C25 shotcrete;

Sg is the cross-sectional area of the grid steel frame;

Eg is the elastic modulus of the grid steel frame;

S0 is the cross-sectional area of the original shotcrete.

The equivalent initial shotcrete and advanced small pipes are considered as linear elastic materials. The equivalent initial shotcrete adopts plate elements, the advanced small pipes use embedded trusses, and the equivalent reinforcement layer uses three-dimensional solid elements. To ensure the accuracy of the calculation results, the mesh size of the pilot tunnel and initial support is 1 m, and the stratum is divided into 2 m. The three-dimensional elements adopt mixed meshes, and the two-dimensional elements use cyclic meshes. The four sides of the model are constrained for displacement perpendicular to the side direction, the bottom surface is constrained for vertical displacement, and the upper surface is a free boundary. The model has a total of 4 elements and 6 nodes, as shown in

Figure 8. When simulating construction excavation, the advanced small pipes are first installed, then the equivalent reinforcement layer is activated by simulating grouting, followed by the excavation of the outer ring soil, core soil, and lower bench, and finally the equivalent initial shotcrete is activated, with a total of six steps in one cycle, as shown in

Figure 9.

The measured, theoretical model-calculated, and numerical calculated values of surface settlement are shown in

Figure 10. The measured maximum surface settlement is −9.8 mm, the numerical calculated maximum is −10.2 mm, with the smallest error (the numerical calculated value is 0.4 mm larger). At a distance from the central line of −5.2 m, the measured value is −8.0 mm, and the numerical calculated value is −5.3 mm, where the error between the measured and numerical values is the largest (the numerical calculated value is 2.7 mm smaller). Subsequently, the error gradually increases with the increase of distance from the central line. At a distance from the central line of 10.3 m, the measured value is −4.0 mm, the theoretical calculated value is −0.4 mm, and the numerical calculated value is −0.4 mm, with the largest error here (the numerical calculated value is 3.6 mm smaller). The settlement results calculated by the stochastic medium theory have been consistently small compared with the measured values. The settlement results obtained by the stochastic medium theory at distances from the central line of 0 m, −5.2 m, and 10.3 m are −10.0 mm, −8.2 mm, and −4.4 mm respectively, with the largest error of 0.4 mm (the stochastic medium result is 0.4 mm larger) at a distance from the central line of 10.3 m.

The measured, theoretical model-calculated, and numerical calculated values of pipeline settlement are shown in

Figure 11. The measured maximum pipeline settlement is −8.6 mm, the numerical calculated maximum is −10.9 mm, with the numerical calculated result 2.3 mm larger. At a distance from the central line of 5 m, the measured value is −4.1 mm, and the numerical calculated value is −5.3 mm, where the error between the measured and numerical values is the smallest (the numerical calculated value is 1.2 mm larger). Subsequently, the error gradually increases with the increase of distance from the central line. At a distance from the central line of 10 m, the measured value is −2.3 mm, and the numerical calculated value is −0.2 mm, with the numerical calculated result 2.1 mm smaller. Afterwards, the numerically calculated settlement decreases slowly and tends to 0 mm at a distance from the central line of 15 m, while the measured heave here is 2.7 mm, and the numerical calculation error reaches the maximum (the result is 2.7 mm smaller than the measured value).

To verify the reliability of the theoretical method, a benchmark comparison with a numerical model (GTS NX) was introduced. The quantitative statistical results of all pipeline monitoring points are shown in the

Table 1:

It can be seen from the analysis that the MAE between the theoretical method and the measured values is 3.0 mm, the RMSE is 3.24 mm, and the R2 reaches 0.89, indicating that the model can reproduce the pipeline settlement law with high accuracy. The Bias is +3.0 mm, meaning the theoretical values are generally larger than the measured values, reflecting a conservative characteristic that is suitable for engineering safety assessment needs. The benchmark comparison with the mature numerical model shows that the numerical model has slightly better accuracy (RMSE = 2.45 mm), but both have R2 ≥ 0.89, indicating good consistency. The RMSE between the theoretical method and the numerical model is only 2.82 mm, with controllable errors, indicating that the simplified assumptions of the theoretical method (polynomial fitting of stochastic medium, Winkler elastic foundation) do not deviate from reality and do not introduce significant additional errors. In summary, the prediction accuracy of the theoretical method meets engineering requirements and has the advantage of conservatism, making it a reliable prediction tool for pipeline settlement induced by ultra-shallow pilot tunnel excavation.