Energy Efficiency and Environmental Sustainability in Rural Buildings: A Life Cycle Assessment of Photovoltaic Integration in Poultry Tunnels—A Case Study in Central Italy

Abstract

Featured Application

Abstract

1. Introduction and Background

1.1. Energy Efficiency in the Agricultural Sector

1.2. Life Cycle Analysis of Poultry Tunnels: A Proposal for an Alternative Experimentation

1.3. Climate Factors and Energy Demand

1.4. The Life Cycle of Agricultural Buildings

1.5. Hypothesis and Research Thesis

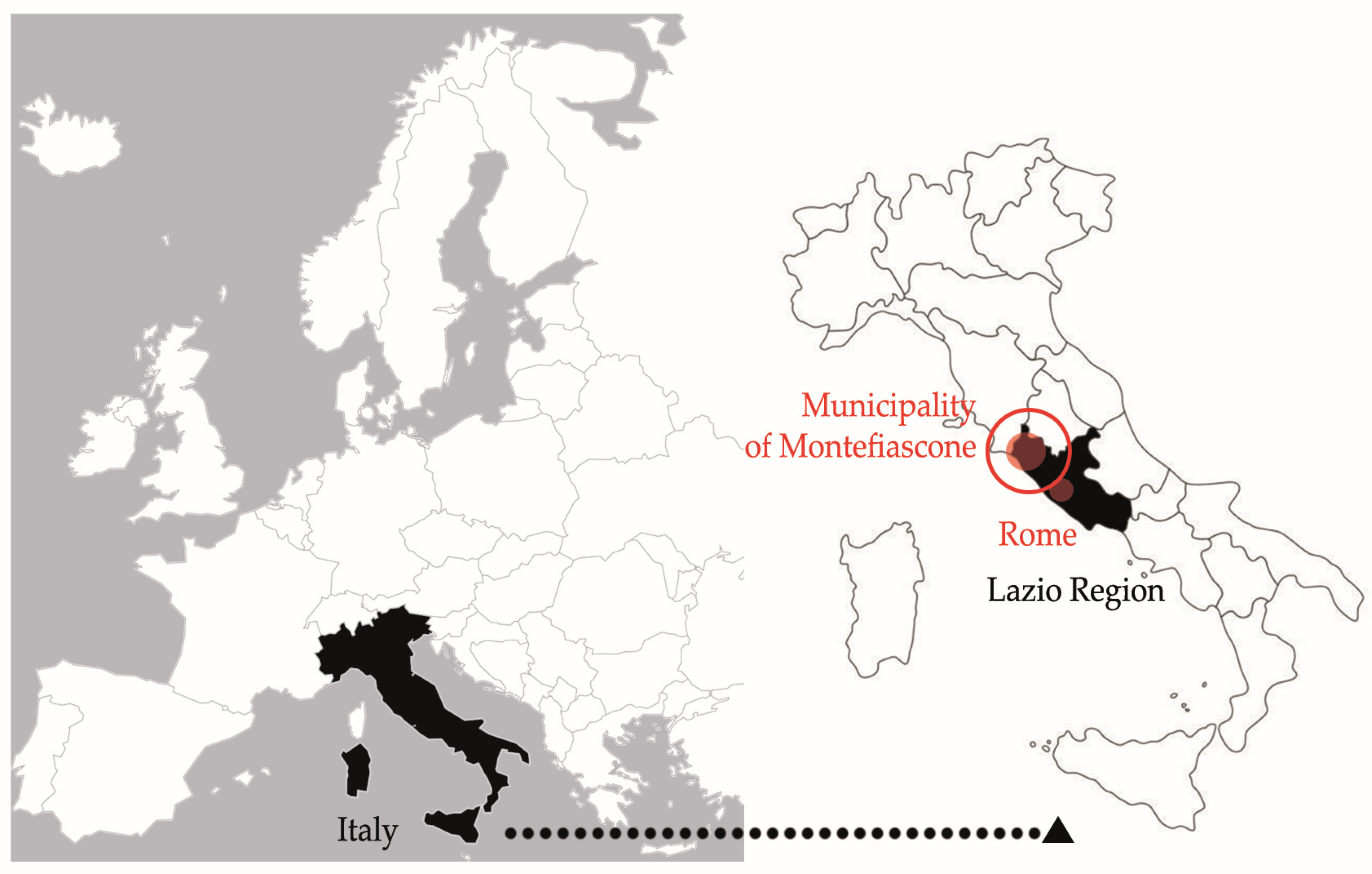

2. Research Subject

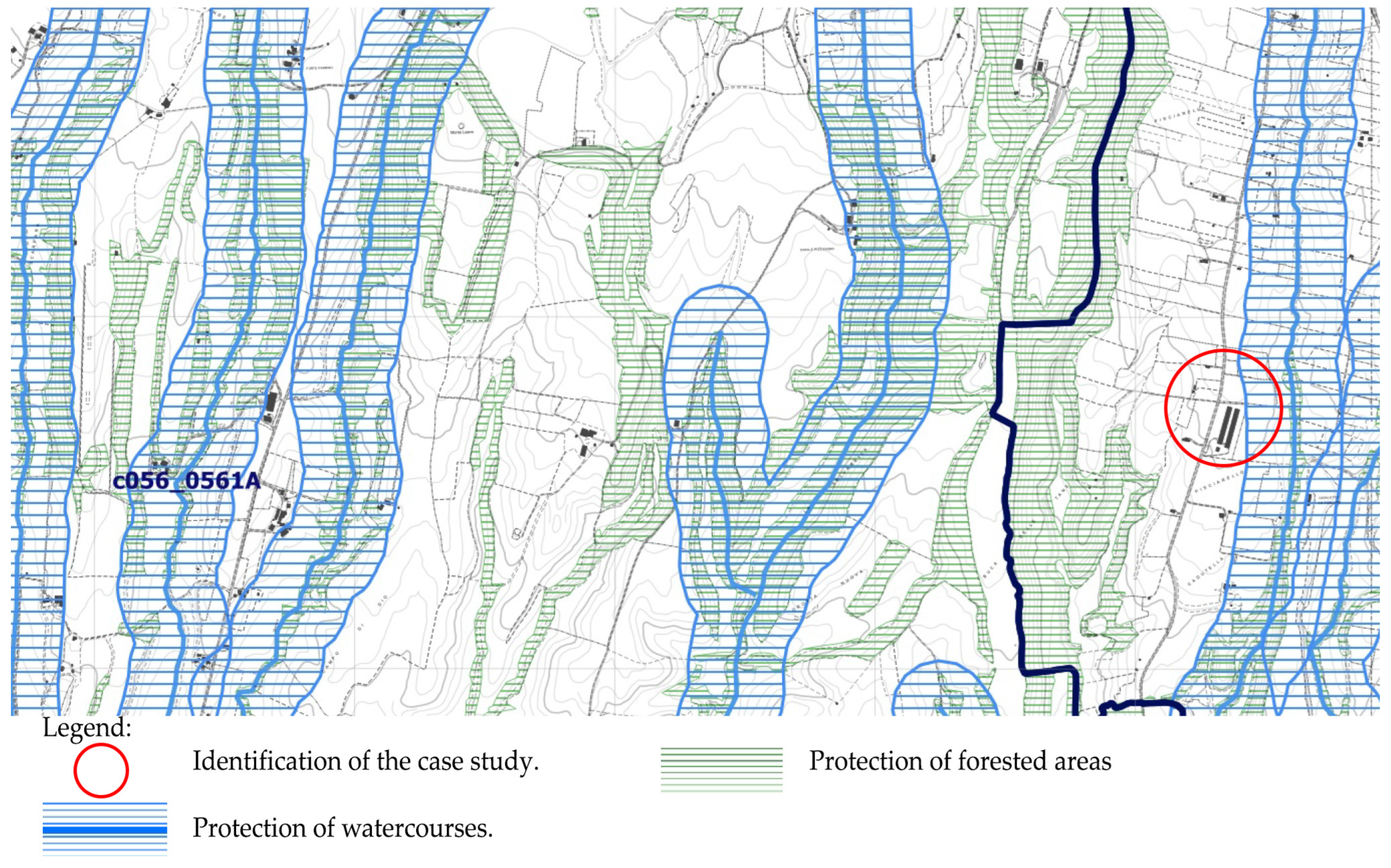

2.1. Case Study Introduction

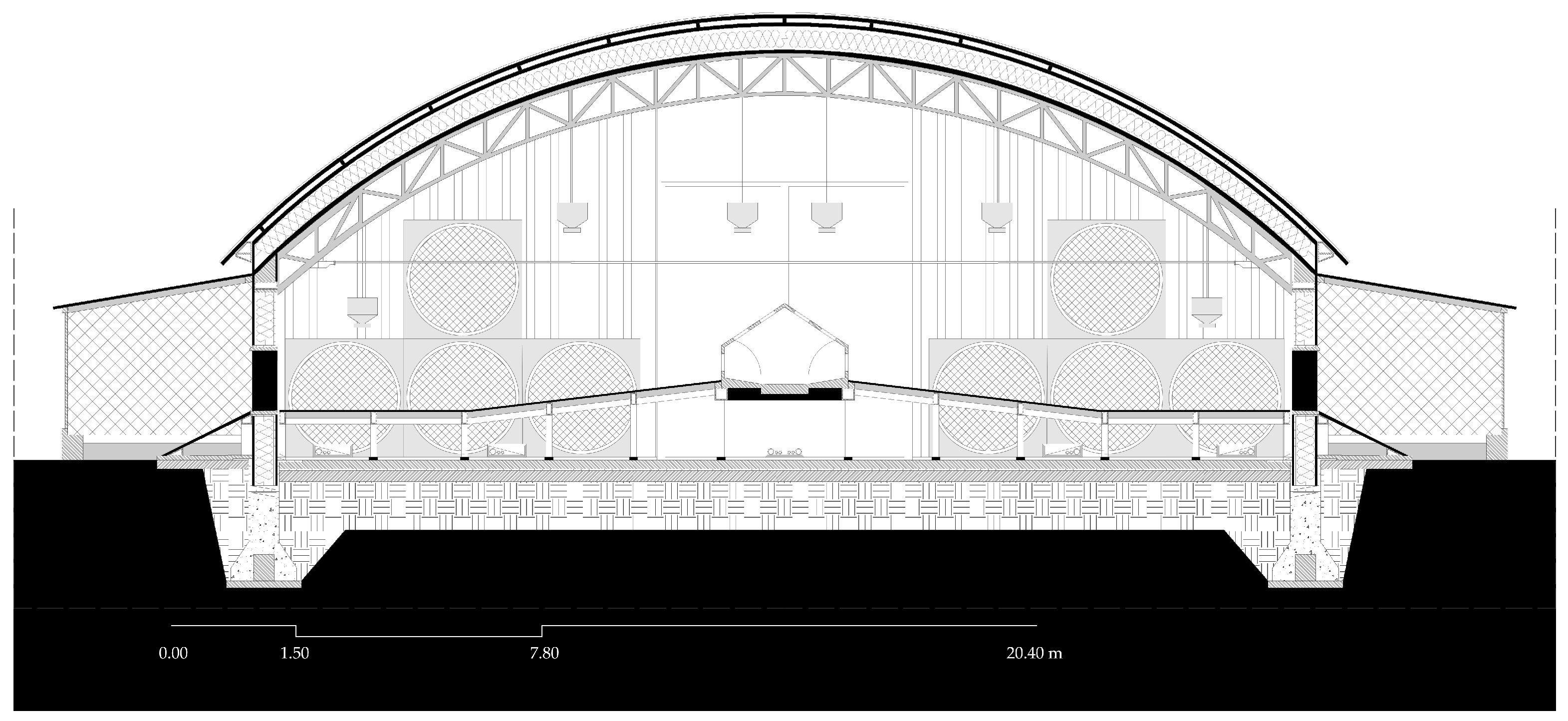

2.2. Technological Characterization and Environmental Standards

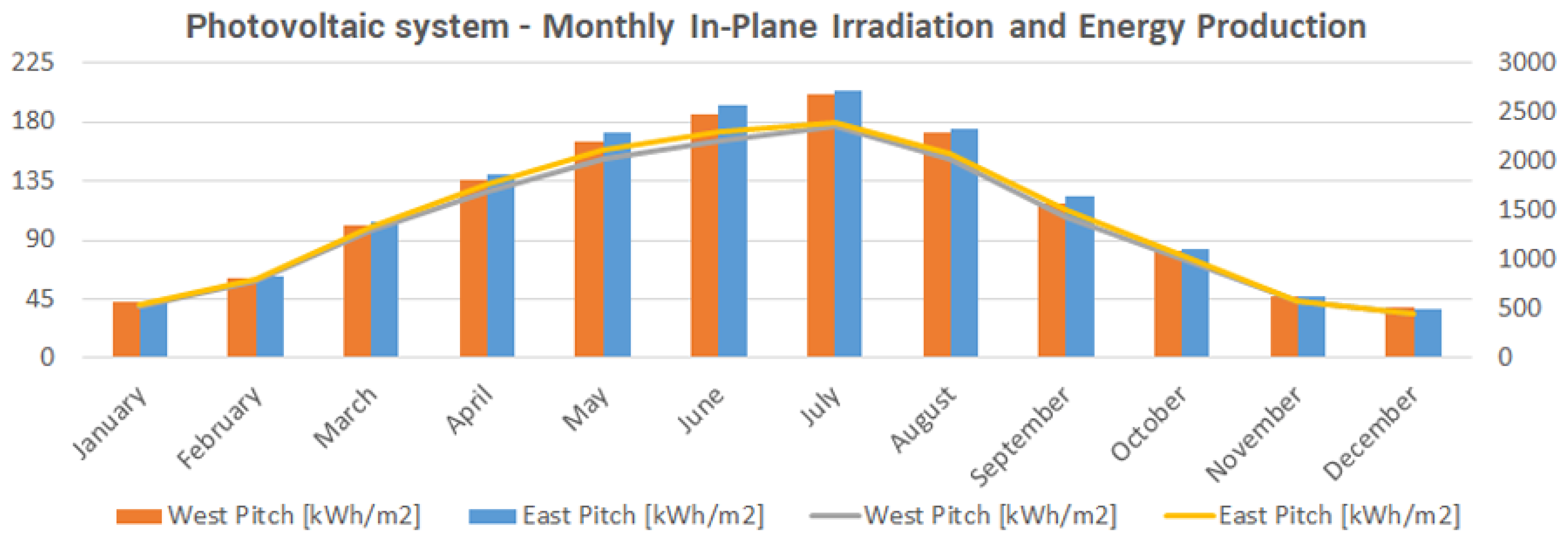

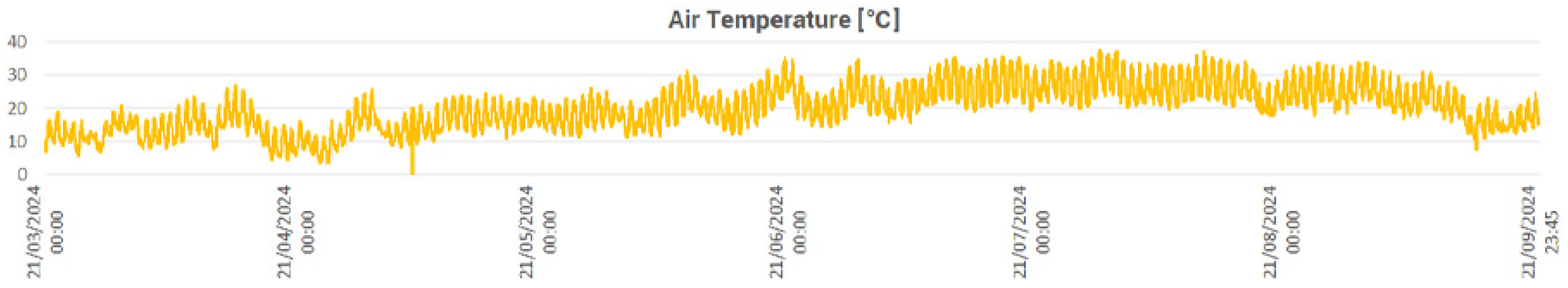

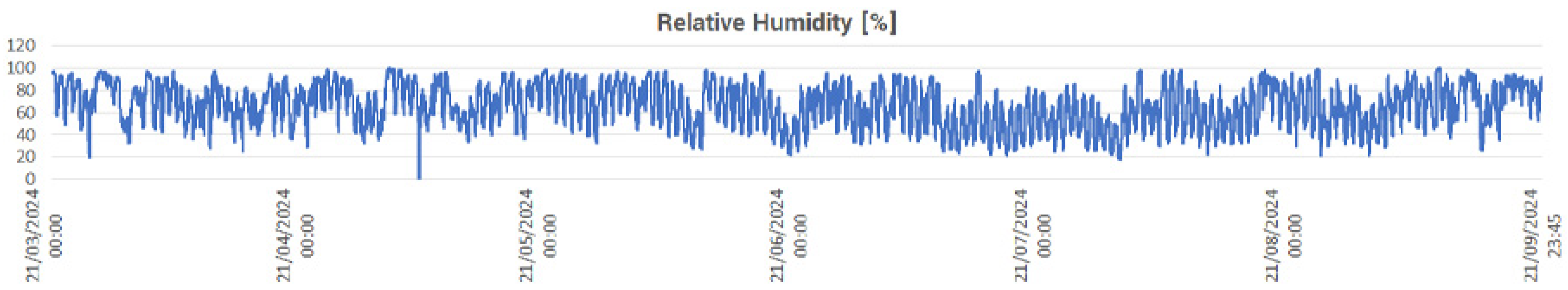

2.3. Collection and Evaluation of Energy Consumption

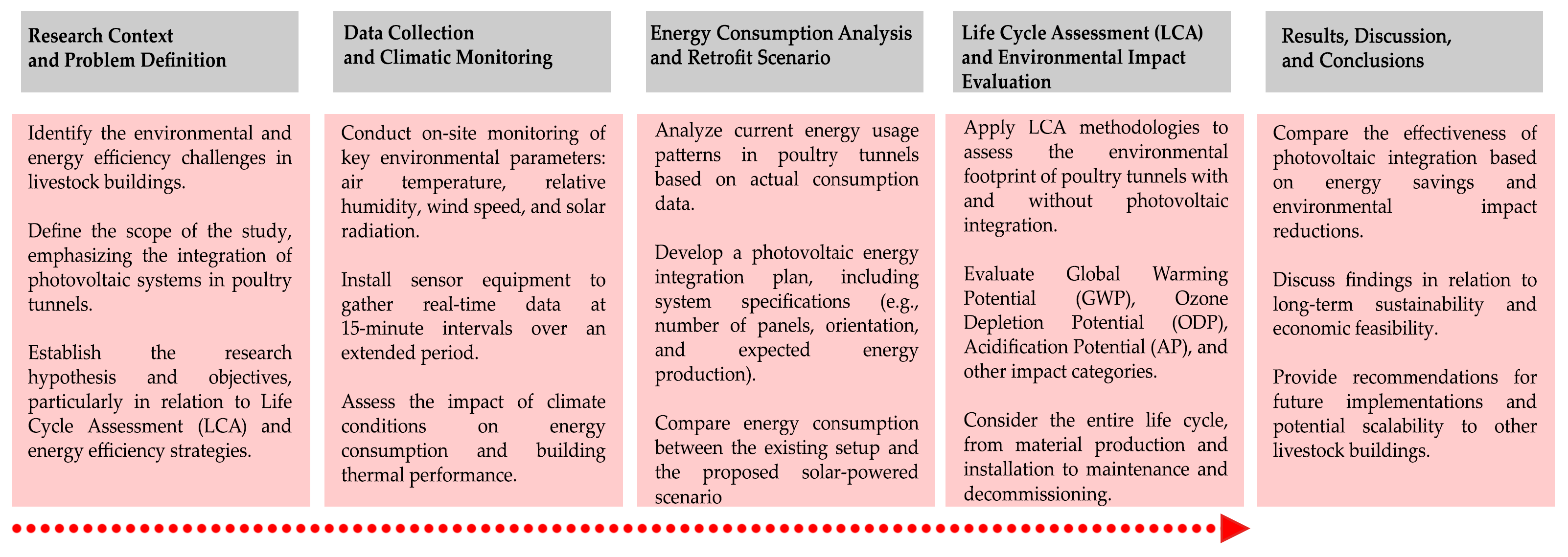

3. Materials and Methods

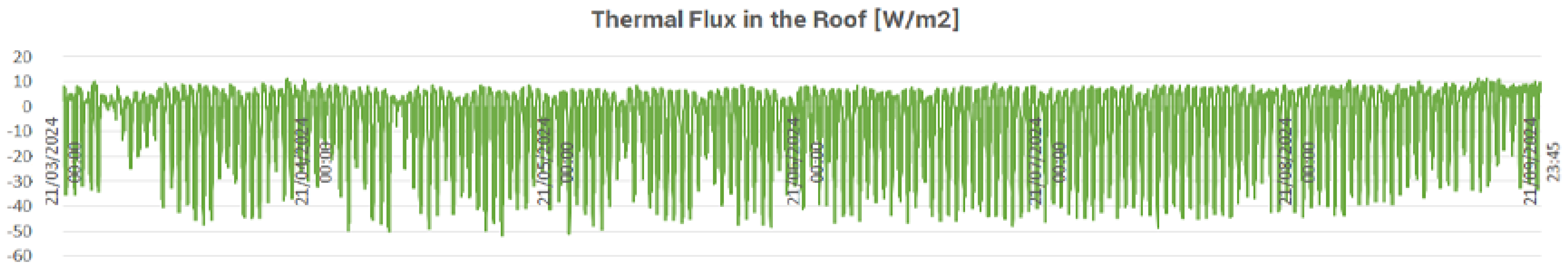

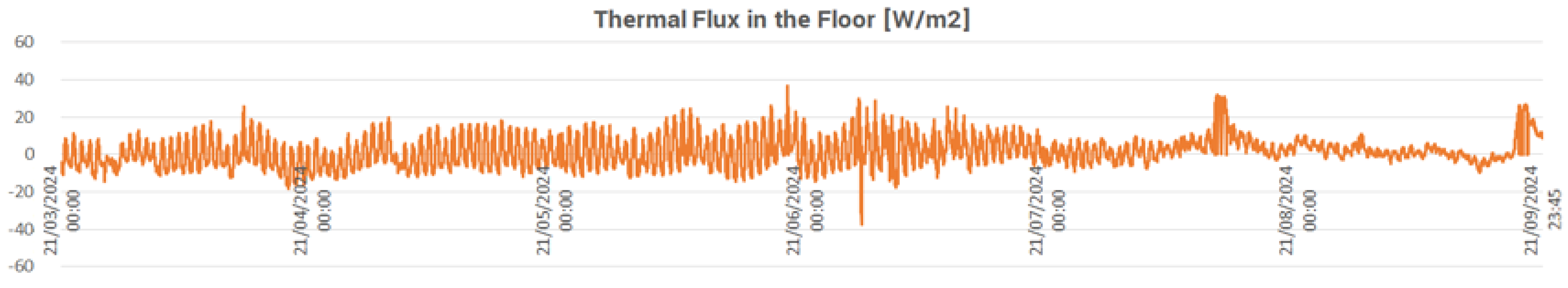

3.1. The Monitoring Results in the Spring and Summer Cases

3.2. Thermal Parameters Defining the Performance of the Building Envelope

4. Results and Discussion

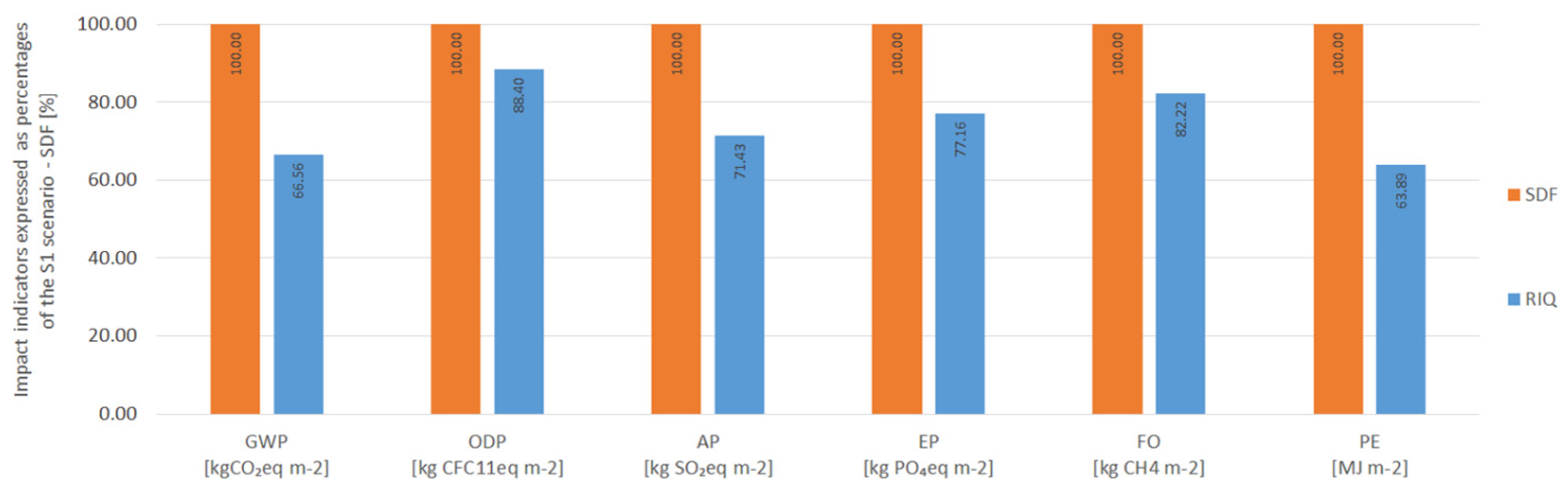

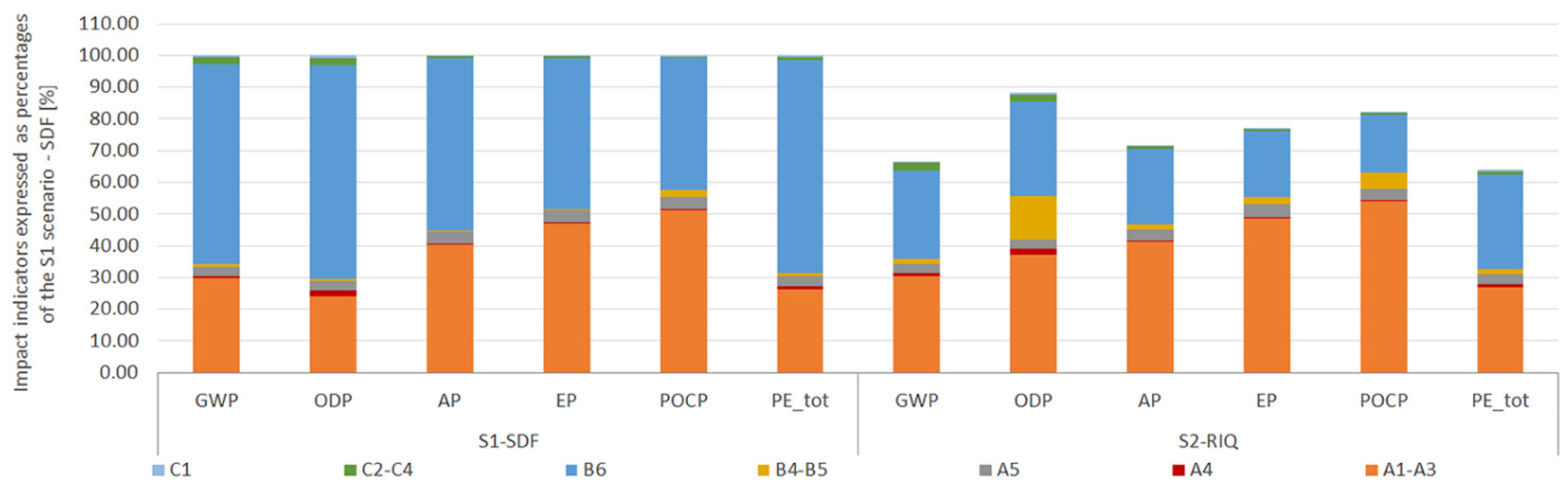

4.1. Life Cycle Assessment

4.2. Life Cycle Assessment (LCA) Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marinelli, A. From industry 4.0 to construction 5.0: Exploring the path towards human–robot collaboration in construction. Systems 2023, 11, 152. [Google Scholar] [CrossRef]

- Kim, Y. Technological Innovation, the Kyoto Protocol, and Open Innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 198. [Google Scholar] [CrossRef]

- Buzatu, R.; Ungureanu, V.; Ciutina, A.; Gireadă, M.; Vitan, D.; Petran, I. Experimental Evaluation of Energy-Efficiency in a Holistically Designed Building. Energies 2021, 14, 5061. [Google Scholar] [CrossRef]

- Rokicki, T.; Perkowska, A.; Klepacki, B.; Bórawski, P.; Bełdycka-Bórawska, A.; Michalski, K. Changes in Energy Consumption in Agriculture in the EU Countries. Energies 2021, 14, 1570. [Google Scholar] [CrossRef]

- Seddiki, M.; Bennadji, A.; Laing, R.; Gray, D.; Alabid, J.M. Review of Existing Energy Retrofit Decision Tools for Homeowners. Sustainability 2021, 13, 10189. [Google Scholar] [CrossRef]

- Hashemkhani Zolfani, S.; Kazimieras Zavadskas, E. Sustainable Development of Rural Areas’ Building Structures Based on Local Climate. Procedia Eng. 2013, 57, 1295–1301. [Google Scholar] [CrossRef]

- Maialetti, M.; Ciaschini, C.; Quaranta, G.; Salvia, R.; Scarpitta, D.; Bigiotti, S.; Chelli, F.M.; Salvati, L. Investigating ‘Land-Use Trajectories’ in Mediterranean Rural Areas with Official Statistics and a Multiway Factor Analysis. Sustainability 2024, 16, 7644. [Google Scholar] [CrossRef]

- Bigiotti, S.; Santarsiero, M.L.; Del Monaco, A.I.; Marucci, A. A Typological Analysis Method for Rural Dwellings: Architectural Features, Historical Transformations, and Landscape Integration: The Case of “Capo Due Rami”, Italy. Land 2025, 14, 374. [Google Scholar] [CrossRef]

- Bijari, M.; Aflaki, A.; Esfandiari, M. Plants Inspired Biomimetics Architecture in Modern Buildings: A Review of Form, Function and Energy. Biomimetics 2025, 10, 124. [Google Scholar] [CrossRef]

- Haller, A. Influence of Agricultural Chains on the Carbon Footprint in the Context of European Green Pact and Crises. Agriculture 2022, 12, 751. [Google Scholar] [CrossRef]

- Bigiotti, S.; Costantino, C.; Marucci, A. Decision-Making Tools for Sustainable Recovery of Rural Villages: Planning Policies and Implementation Strategies for Valorizing Small Communities in Inner Areas Under the Next Generation EU Programme. In WIT Transactions on Ecology and the Environment; Syngellakis, S., Ed.; WIT Press: Ashurst, UK, 2024; Volume 262, pp. 479–494. [Google Scholar]

- Stokes, J.E.; Mullan, S.; Takahashi, T.; Monte, F.; Main, D.C.J. Economic and Welfare Impacts of Providing Good Life Opportunities to Farm Animals. Animals 2020, 10, 610. [Google Scholar] [CrossRef] [PubMed]

- Salvucci, G.; Scarpitta, D.; Maialetti, M.; Rontos, K.; Bigiotti, S.; Sateriano, A.; Muolo, A. Measuring Data Quality from Building Registers: ACaseStudy in Italy. Geographies 2024, 4, 596–611. [Google Scholar] [CrossRef]

- Khan, S.A.; Alam, T.; Khan, M.S.; Blecich, P.; Kamal, M.A.; Gupta, N.K.; Yadav, A.S. Life Cycle Assessment of Embodied Carbon in Buildings: Background, Approaches and Advancements. Buildings 2022, 12, 1944. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Tyris, D.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy Use in the EU Livestock Sector: A Review Recommending Energy Efficiency Measures and Renewable Energy Sources Adoption. Appl. Sci. 2022, 12, 2142. [Google Scholar] [CrossRef]

- Martinopoulos, G.; Tsimpoukis, A.; Sougkakis, V.; Dallas, P.; Angelakoglou, K.; Giourka, P.; Nikolopoulos, N. A Comprehensive Approach to Nearly Zero Energy Buildings and Districts: Analysis of a Region Undergoing Energy Transition. Energies 2024, 17, 5581. [Google Scholar] [CrossRef]

- Murray, P.; Marquant, J.; Niffeler, M.; Mavromatidis, G.; Orehounig, K. Optimal Transformation Strategies for Buildings, Neighbourhoods and Districts to Reach CO2 Emission Reduction Targets. Energy Build. 2020, 207, 109569. [Google Scholar] [CrossRef]

- Evins, R. A Review of Computational Optimisation Methods Applied to Sustainable Building Design. Renew. Sustain. Energy Rev. 2013, 22, 230–245. [Google Scholar] [CrossRef]

- Sharma, S.K.; Mohapatra, S.; Sharma, R.C.; Alturjman, S.; Altrjman, C.; Mostarda, L.; Stephan, T. Retrofitting Existing Buildings to Improve Energy Performance. Sustainability 2022, 14, 666. [Google Scholar] [CrossRef]

- Chithaluru, P.; Al-Turjman, F.; Kumar, M.; Stephan, T. I-AREOR: An energy-balanced clustering protocol for implementing green IoT in smart cities. Sustain. Cities Soc. 2020, 61, 102254. [Google Scholar] [CrossRef]

- Kitsopoulou, A.; Bellos, E.; Tzivanidis, C. An Up-to-Date Review of Passive Building Envelope Technologies for Sustainable Design. Energies 2024, 17, 4039. [Google Scholar] [CrossRef]

- Jelle, B.P.; Kalnæs, S.E.; Gao, T. Low-emissivity materials for building applications: A state-of-the-art review and future research perspectives. Energy Build. 2015, 96, 329–356. [Google Scholar] [CrossRef]

- Yuk, H.; Choi, J.Y.; Yang, S.; Kim, S. Balancing preservation and utilization: Window retrofit strategy for energy efficiency in historic modern building. Build. Environ. 2024, 259, 111648. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lee, Y.-K.; Kim, S.-H.; Lee, K.-W. The Impact of Temperature and Humidity on the Performance and Physiology of Laying Hens. Animals 2021, 11, 56. [Google Scholar] [CrossRef]

- Kang, S.; Kim, D.-H.; Lee, S.; Lee, T.; Lee, K.-W.; Chang, H.-H.; Moon, B.; Ayasan, T.; Choi, Y.-H. An acute, rather than progressive, increase in temperature-humidity index has severe effects on mortality in laying hens. Front. Vet. Sci. 2020, 7, 568093. [Google Scholar] [CrossRef]

- Mazzeo, D.; Oliveti, G.; Arcuri, N. Influence of internal and external boundary conditions on the decrement factor and time lag heat flux of building walls in steady periodic regime. Appl. Energy 2016, 164, 509–531. [Google Scholar] [CrossRef]

- Katunský, D.; Bagoňa, M.; Katunská, J.; Lopušniak, M.; Rudišin, R.; Tóth, S.; Vertal’, M. Measurements of physical parameters of envelope structures in real conditions in situ. Visn. Nac. Univ. L’vivska Politech. Teor. I Prakt. Budivn. 2012, 737, 259–264. [Google Scholar]

- Flimel, M.; Duplakova, D.; Sukic, E. Implementation of Heat Flux Measuring Methods for Heat Transfer Coefficient Determination of In Situ Construction. Processes 2021, 9, 1970. [Google Scholar] [CrossRef]

- Barahmand, Z.; Eikeland, M.S. Life Cycle Assessment under Uncertainty: A Scoping Review. World 2022, 3, 692–717. [Google Scholar] [CrossRef]

- Samer, M. Towards the implementation of the Green Building concept in agricultural buildings: A literature review. Agric. Eng. Int. CIGR J. 2013, 15, 25–46. [Google Scholar]

- Srinivasan, R.S.; Ingwersen, W.; Trucco, C.; Ries, R.; Campbell, D. Comparison of energy-based indicators used in life cycle assessment tools for buildings. Build. Environ. 2014, 79, 138–151. [Google Scholar] [CrossRef]

- Costantino, C.; Benedetti, A.C.; Gulli, R. Renovation and reconstruction of built heritage. criteria, instruments, and means for energy savings at urban scale. Int. Multidiscip. Sci. GeoConf. SGEM 2022, 22, 607–614. [Google Scholar]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, drivers and decision-making process for industrial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Fresner, J.; Morea, F.; Krenn, C.; Uson, J.A.; Tomasi, F. Energy efficiency in small and medium enterprises: Lessons learned from 280 energy audits across Europe. J. Clean. Prod. 2017, 142, 1650–1660. [Google Scholar] [CrossRef]

- Dongellini, M.; Marinosci, C.; Morini, G.L. Energy audit of an industrial site: A case study. Energy Procedia 2014, 45, 424–433. [Google Scholar] [CrossRef]

- Dibene-Arriola, L.M.; Carrillo-González, F.M.; Quijas, S.; Rodríguez-Uribe, M.C. Energy efficiency indicators for hotel buildings. Sustainability 2021, 13, 1754. [Google Scholar] [CrossRef]

- Becken, S.; Frampton, C.; Simmons, D. Energy consumption patterns in the accommodation sector—The New Zealand case. Ecol. Econ. 2001, 39, 371–386. [Google Scholar] [CrossRef]

- Bigiotti, S.; Costantino, C.; Marucci, A. Agritourism Facilities in the Era of the Green Economy: A Combined Energy Audit and Life Cycle Assessment Approach for the Sustainable Regeneration of Rural Structures. Energies 2024, 17, 1101. [Google Scholar] [CrossRef]

- Bosu, I.; Mahmoud, H.; Hassan, H. Energy audit and management of an industrial site based on energy efficiency, economic, and environmental analysis. Appl. Energy 2023, 333, 120619. [Google Scholar] [CrossRef]

- Barreca, F. Use of giant reed Arundo Donax L. in rural constructions. Agric. Eng. Int. CIGR J. 2012, 14, 46–52. [Google Scholar]

- Quintana-Gallardo, A.; Clausell, J.R.; Guillén-Guillamón, I.; Mendiguchia, F.A. Waste valorization of rice straw as a building material in Valencia and its implications for local and global ecosystems. J. Clean. Prod. 2021, 318, 128507. [Google Scholar] [CrossRef]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Liuzzi, S.; Sanarica, S.; Stefanizzi, P. Use of agro-wastes in building materials in the Mediterranean area: A review. Energy Procedia 2017, 126, 242–249. [Google Scholar] [CrossRef]

- Silvestre, J.D.; Castelo, A.M.; Silva, J.J.; de Brito, J.M.; Pinheiro, M.D. Retrofitting a building’s envelope: Sustainability performance of ETICS with ICB or EPS. Appl. Sci. 2019, 9, 1285. [Google Scholar] [CrossRef]

- Costantino, C.; Bigiotti, S.; Marucci, A. Assessing energy-saving retrofit and carbon footprint reduction of rural dwellings: A case study in Tuscia, Italy. WIT Trans. Ecol. Environ. 2024, 262, 821–833. [Google Scholar]

- Llantoy, N.; Chàfer, M.; Cabeza, L.F. A comparative life cycle assessment (LCA) of different insulation materials for buildings in the continental Mediterranean climate. Energy Build. 2020, 225, 110323. [Google Scholar] [CrossRef]

- Minoofar, A.; Gholami, A.; Eslami, S.; Hajizadeh, A.; Gholami, A.; Zandi, M.; Ameri, M.; Kazem, H.A. Renewable energy system opportunities: A sustainable solution toward cleaner production and reducing carbon footprint of large-scale dairy farms. Energy Convers. Manag. 2023, 293, 117554. [Google Scholar] [CrossRef]

- Firfiris, V.K.; Martzopoulou, A.G.; Kotsopoulos, T.A. Passive cooling systems in livestock buildings towards energy saving: A critical review. Energy Build. 2019, 202, 109368. [Google Scholar] [CrossRef]

- Ecim-Djuric, O.; Topisirovic, G. Energy efficiency optimization of combined ventilation systems in livestock buildings. Energy Build. 2010, 42, 1165–1171. [Google Scholar] [CrossRef]

- Mostafa, E.; Buescher, W. Indoor air quality improvement from particle matters for laying hen poultry houses. Biosyst. Eng. 2011, 109, 22–36. [Google Scholar] [CrossRef]

- Saleeva, I.; Sklyar, A.; Marinchenko, T.; Postnova, M.; Ivanov, A. Efficiency of poultry house heating and ventilation upgrading. IOP Conf. Ser. Earth Environ. Sci. 2020, 433, 012041. [Google Scholar] [CrossRef]

- Costantino, A. Development, Validation, and Application of Building Energy Simulation Models for Livestock Houses: A Systematic Review. Agriculture 2023, 13, 2280. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, X.; Tang, S.; Chen, Y.; Yang, Y. Construction and Case Analysis of a Comprehensive Evaluation System for Rural Building Energy Consumption from an Energy–Building–Behavior Composite Perspective. Sustainability 2024, 16, 6959. [Google Scholar] [CrossRef]

- Izar-Tenorio, J.; Jaramillo, P.; Griffin, W.M.; Small, M. Impacts of Projected Climate Change Scenarios on Heating and Cooling Demand for Industrial Broiler Chicken Farming in the Eastern U.S. J. Clean. Prod. 2020, 255, 120306. [Google Scholar] [CrossRef]

- EN 14040-1:2020; Environmental Management—Life Cycle Assessment—Principles and Framework—Amendment 1. CEN—European Committee for Standardization: Brussels, Belgium, 2020.

- EN 14044-1:2020; Environmental Management—Life Cycle Assessment—Requirements and Guidelines—Amendment 2. CEN—European Committee for Standardization: Brussels, Belgium, 2020.

- Italian Government. Decreto Legislativo 22 Gennaio 2004, n. 42, Codice dei Beni Culturali e del Paesaggio; Italian Government: Roma, Italy, 2004.

- ISO 9060:2018; Solar Energy—Specification and Classification of Instruments for Measuring Hemispherical Solar and Direct Solar Radiation. International Organization for Standardization: Geneva, Switzerland, 2018.

- UNI EN ISO 7726:1998; Ergonomics of the Thermal Environment—Instruments for Measuring Physical Quantities. International Organization for Standardization: Geneva, Switzerland, 1998.

- Photovoltaic Geographical Information System (PVGIS) Online Tool. Available online: https://joint-research-centre.ec.europa.eu/photovoltaic-geographical-information-system-pvgis_en (accessed on 16 March 2025).

- EN 15978; Sustainability of Construction Works—Assessment of 983 Environmental Performance of Buildings—Calculation Method. CEN: Brussels, Belgium, 2012.

- Italian Government. Decreto del Presidente della Repubblica 26 agosto 1993, n. 412. Regolamento Recante Norme per la Progettazione, L’installazione, L’esercizio e la Manutenzione Degli Impianti Termici Degli Edifici ai Fini del Contenimento dei Consumi di Energia, in Attuazione Dell’art; 4, Comma 4, Della Legge 9 Gennaio 1991, n. 10; Italian Government: Roma, Italy, 1993.

- Olczak, P. Evaluation of degradation energy productivity of photovoltaic installations in long-term case study. Appl. Energy 2023, 343, 121109. [Google Scholar] [CrossRef]

- Costantino, C.; Bigiotti, S.; Marucci, A.; Gulli, R. Long-Term Comparative Life Cycle Assessment, Cost, and Comfort Analysis of Heavyweight vs. Lightweight Construction Systems in a Mediterranean Climate. Sustainability 2024, 16, 8959. [Google Scholar] [CrossRef]

- Bigiotti, S.; Santarsiero, M.L.; Costantino, C.; Marucci, A. Photovoltaic Technology and Rural Landscapes: A Systematic Literature Review on Challenges and Sustainable Integration. Energies 2025, 18, 2095. [Google Scholar] [CrossRef]

- Chatzipanagi, A.; Kakoulaki, G.; Szabó, S.; Jäger-Waldau, A. Overview and Perspective of Integrated Photovoltaics with a Focus on the European Union. Appl. Sci. 2024, 14, 10628. [Google Scholar] [CrossRef]

- Bianchi, S.; Richiedei, A. Territorial Governance for Sustainable Development: A Multi-Level Governance Analysis in the Italian Context. Sustainability 2023, 15, 2526. [Google Scholar] [CrossRef]

| Code | Research Questions |

|---|---|

| RQ1 | How and to what extent does the implementation of photovoltaic energy supply systems reduce the environmental impact of a livestock building compared to the construction standard that relies solely on energy supply from the national grid? |

| RQ2 | Which phases of the life cycle of a livestock facility have the greatest impact on its overall environmental footprint, and how can property management be optimized through improvement and energy qualification scenarios? |

| RQ3 | What is the potential replicability of operational scenarios derived from other case studies already present in rural environments for different building types, and what strategies could ensure their large-scale adoption? |

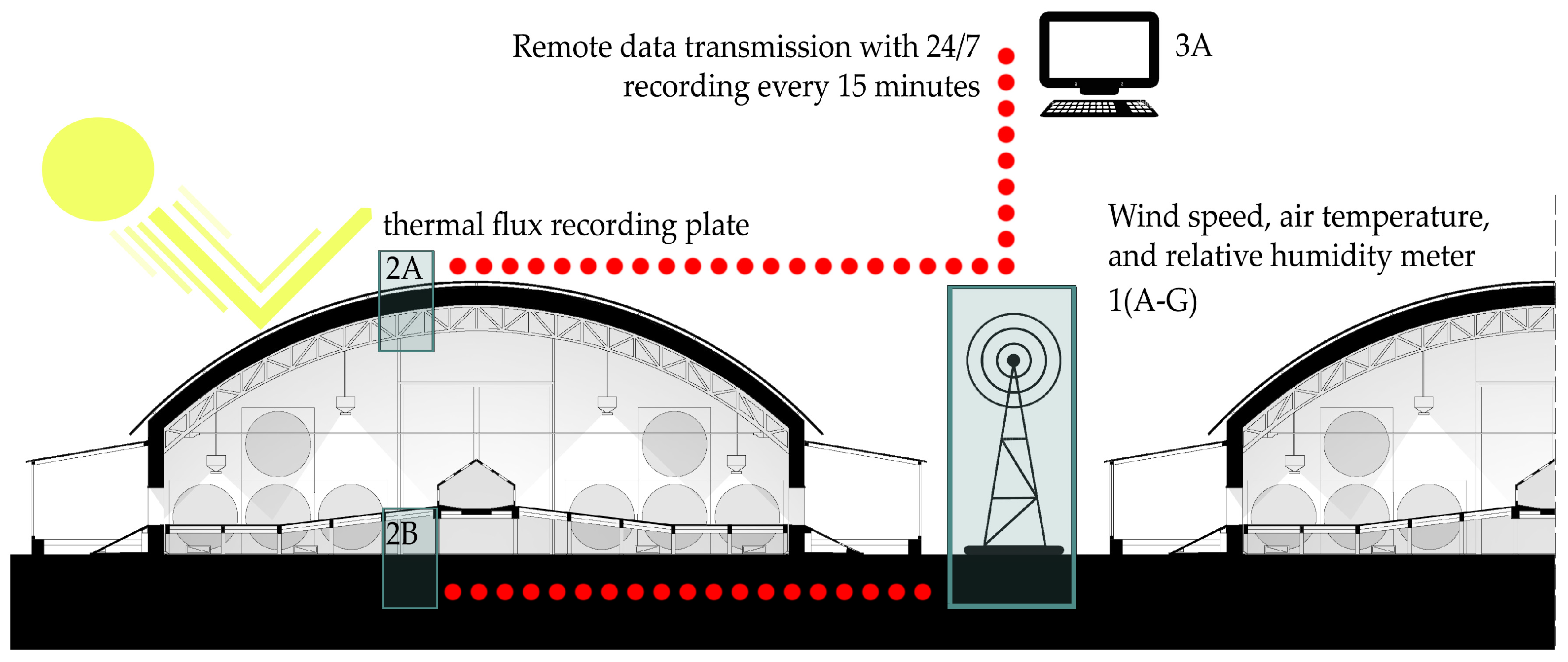

| Code | Type Model— Manufacturer | Designation | Accuracy |

|---|---|---|---|

| 1A | CR1000X—Campbell Scientific | 16-channel logger with eight I/O ports, complete with 4G router for remote control, two ethernet ports, and Wi-Fi capabilities | ±(0.04% of reading + offset) |

| 1B | CR300_422—Campbell Scientific | Basic six-channel logger with two I/O ports, integrated RF422 radio remote communication, complete with antenna | ±(0.1% of measurement + offset) |

| 1C | HFP01—Hukseflux | Heat flux plates | ±3% (k = 2, standard ISO 17025) |

| 1D | HygroVUE10_35M—Campbell Scientific | Air thermo-hygrometer. Complete with one spare sensitive element | ±0.1 °C |

| 1E | RAD10—Campbell Scientific | Protection for thermo-hygrometer, naturally ventilated multi-plate type | - |

| 1F | LPPYRA10—Delta OHM | Spectrally flat class A (secondary standard) pyranometer according to ISO 9060:2018 [58] | ±0.5% |

| 1G | WindSonic_op1—Gill distributed by Campbell Scientific | 2D sonic anemometer with RS232 interface | ±2% of reading at 12 m/s |

| 2A–2B | NR01—Hukseflux | Net radiometer with four elements (two global radiation and two infrared radiation) | ±2.4% |

| 3A | LoggerNet | Software for the comprehensive management of Campbell Scientific loggers | - |

| Energy Consumption (Electricity) | January | February | March | April | June | July | August | September | October | November | December |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Electricity bills [kWh] | 3503 | 3953 | 4714 | 4752 | 4671 | 6278 | 6931 | 6658 | 4566 | 3840 | 4247 |

| Description | Unit | Quantity | Description | Unit | Quantity |

|---|---|---|---|---|---|

| Steel frame | t | 57.79 | Wooden formwork | m2 | 108.52 |

| Rebar | t | 29.09 | PVC roofing elements | kg | 3096.98 |

| Concrete C 16/20 | m3 | 135.60 | EPS insulation | kg | 4464.36 |

| Concrete C 25/30 | m3 | 506.40 | Steel sheeting | t | 54.40 |

| Gravel | m3 | 339.00 | Raised floor system | kg | 8284.10 |

| Bentonite membrane | t | 11.75 | Photovoltaic panels | m2 | 120.00 |

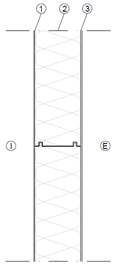

| External Wall | ||||||||

| ID | Layer | Th. [mm] | Th. Cn. [W/m K] | Th. Rs. [m2 K/W] | Mass [kg/m3] | SH. Cp. [kJ/kgK] | Vp. Rs. [-] |

| 1 | Steel plate | 0.50 | 52.0000 | 0.000 | 7800 | 0.45 | 9,999,999 | |

| 2 | EPS foam board | 120.00 | 0.0310 | 3.871 | 15 | 1.45 | 60 | |

| 3 | Steel plate | 0.50 | 52.0000 | 0.000 | 7800 | 0.45 | 9,999,999 | |

| U-value [W/m2 K] | Tot. Th. [mm] | S. Mass [kg/m2] | Yie [W/m2 K] | f [-] | Δτ [h] | W [10−12 kg/sm2Pa] | ||

| 0.246 | 121 | 10.0 | 0.245 | 0.996 | −0.6 | 0.020 | ||

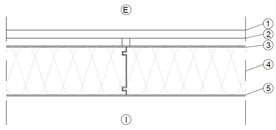

| Roof | ||||||||

| ID | Layer | Th. [mm] | Th. Cn. [W/m K] | Th. Rs. [m2 K/W] | Mass [kg/m3] | SH. Cp. [kJ/kgK] | Vp. Rs. [-] |

| 1 | PVC cladding | 20.00 | 0.1700 | 0.118 | 1390 | 0.90 | 50,000 | |

| 2 | Ventilated cavity | 20.00 | 0.1250 | 0.160 | - | - | - | |

| 3 | Steel plate | 0.50 | 52.0000 | 0.000 | 7800 | 0.45 | 9,999,999 | |

| 4 | EPS foam board | 120.00 | 0.0310 | 3.871 | 15 | 1.45 | 60 | |

| 5 | Steel plate | 0.50 | 52.0000 | 0.000 | 7800 | 0.45 | 9,999,999 | |

| U-value [W/m2 K] | Tot. Th. [mm] | S. Mass [kg/m2] | Yie [W/m2 K] | f [-] | Δτ [h] | W [10−12 kg/sm2Pa] | ||

| 0.232 | 161 | 37.0 | 0.226 | 0.973 | −1.6 | 0.018 | ||

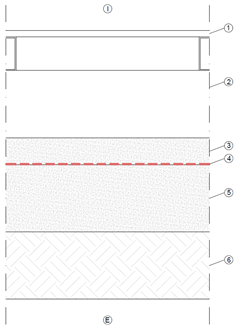

| Ground Floor Slab | ||||||||

| ID | Layer | Th. [mm] | Th. Cn. [W/m K] | Th. Rs. [m2 K/W] | Mass [kg/m3] | SH. Cp. [kJ/kgK] | Vp. Rs. [-] |

| 1 | Perforated raised floor | 20 | 52.0000 | - | 7800 | 0.45 | - | |

| 2 | Ventilated cavity | 300.00 | - | - | - | - | - | |

| 3 | Concrete screed | 80.00 | 0.3800 | - | 1000 | 1.00 | - | |

| 4 | Waterproofing membrane | 6.00 | 0.1700 | - | 1050 | 1.00 | - | |

| 5 | Reinforced concrete slab | 200.00 | 2.5000 | - | 2400 | 1.00 | - | |

| 6 | Coarse gravel | 300.00 | 0.7000 | - | 1500 | 1.00 | - | |

| U-value [W/m2 K] | Tot. Th. [mm] | S. Mass [kg/m2] | Yie [W/m2 K] | f [-] | Δτ [h] | W [10−12 kg/sm2Pa] | ||

| 0.886 | 887 | 1020.0 | 0.025 | 0.028 | −17.9 | 0.040 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bigiotti, S.; Costantino, C.; Patriarca, A.; Mancini, G.; Provolo, G.; Recanatesi, F.; Ripa, M.N.; Marucci, A. Energy Efficiency and Environmental Sustainability in Rural Buildings: A Life Cycle Assessment of Photovoltaic Integration in Poultry Tunnels—A Case Study in Central Italy. Appl. Sci. 2025, 15, 5094. https://doi.org/10.3390/app15095094

Bigiotti S, Costantino C, Patriarca A, Mancini G, Provolo G, Recanatesi F, Ripa MN, Marucci A. Energy Efficiency and Environmental Sustainability in Rural Buildings: A Life Cycle Assessment of Photovoltaic Integration in Poultry Tunnels—A Case Study in Central Italy. Applied Sciences. 2025; 15(9):5094. https://doi.org/10.3390/app15095094

Chicago/Turabian StyleBigiotti, Stefano, Carlo Costantino, Alessio Patriarca, Giulia Mancini, Giorgio Provolo, Fabio Recanatesi, Maria Nicolina Ripa, and Alvaro Marucci. 2025. "Energy Efficiency and Environmental Sustainability in Rural Buildings: A Life Cycle Assessment of Photovoltaic Integration in Poultry Tunnels—A Case Study in Central Italy" Applied Sciences 15, no. 9: 5094. https://doi.org/10.3390/app15095094

APA StyleBigiotti, S., Costantino, C., Patriarca, A., Mancini, G., Provolo, G., Recanatesi, F., Ripa, M. N., & Marucci, A. (2025). Energy Efficiency and Environmental Sustainability in Rural Buildings: A Life Cycle Assessment of Photovoltaic Integration in Poultry Tunnels—A Case Study in Central Italy. Applied Sciences, 15(9), 5094. https://doi.org/10.3390/app15095094