Stuck Pipe Detection in Oil and Gas Drilling Operations Using Deep Learning Autoencoder for Anomaly Diagnosis

Abstract

1. Introduction

1.1. General Background

1.2. Challenges in Traditional Detection Methods

1.3. Literature Survey

1.4. Contributions of This Study

- Implementation of an unsupervised parameter-sensitive deep learning autoencoder trained exclusively on normal drilling conditions to enhance anomaly detection accuracy and reduce false positives and validated against traditional AI methods.

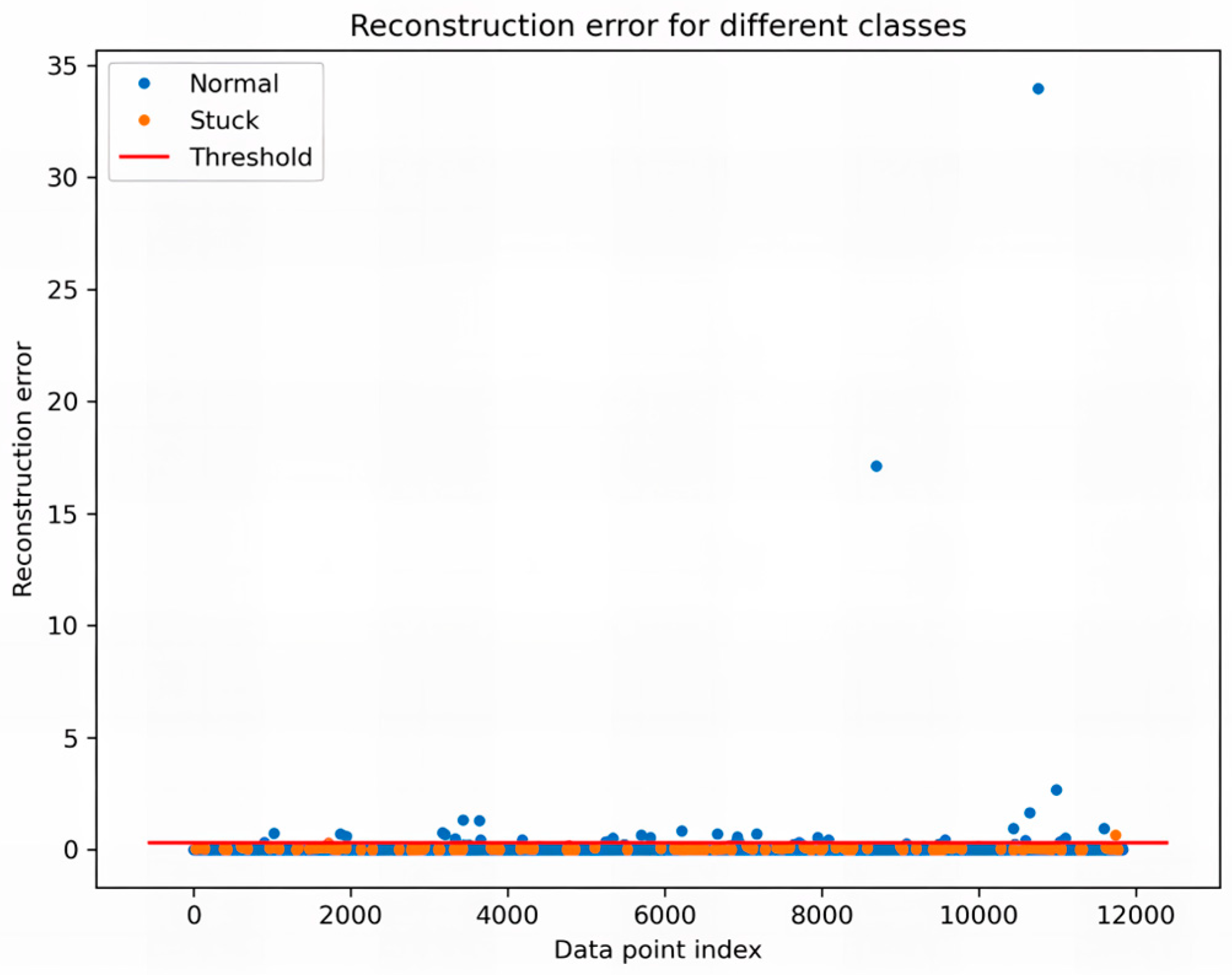

- Development of a reconstruction error-based detection threshold that ensures improved sensitivity to subtle variations in the drilling parameters.

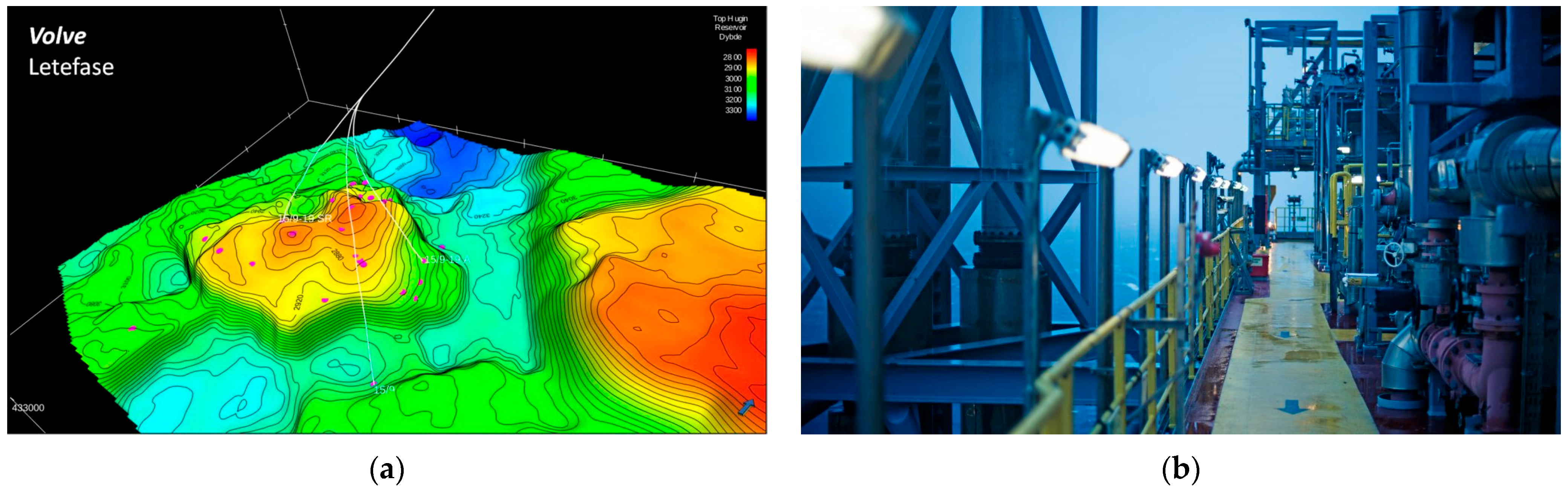

- Comprehensive evaluation using real-world drilling data from the Volve field to demonstrate the model’s effectiveness in predicting stuck pipe events with minimal computational overhead.

2. Data Description and Preparation

2.1. Data Source and Characteristics

2.2. Data Processing

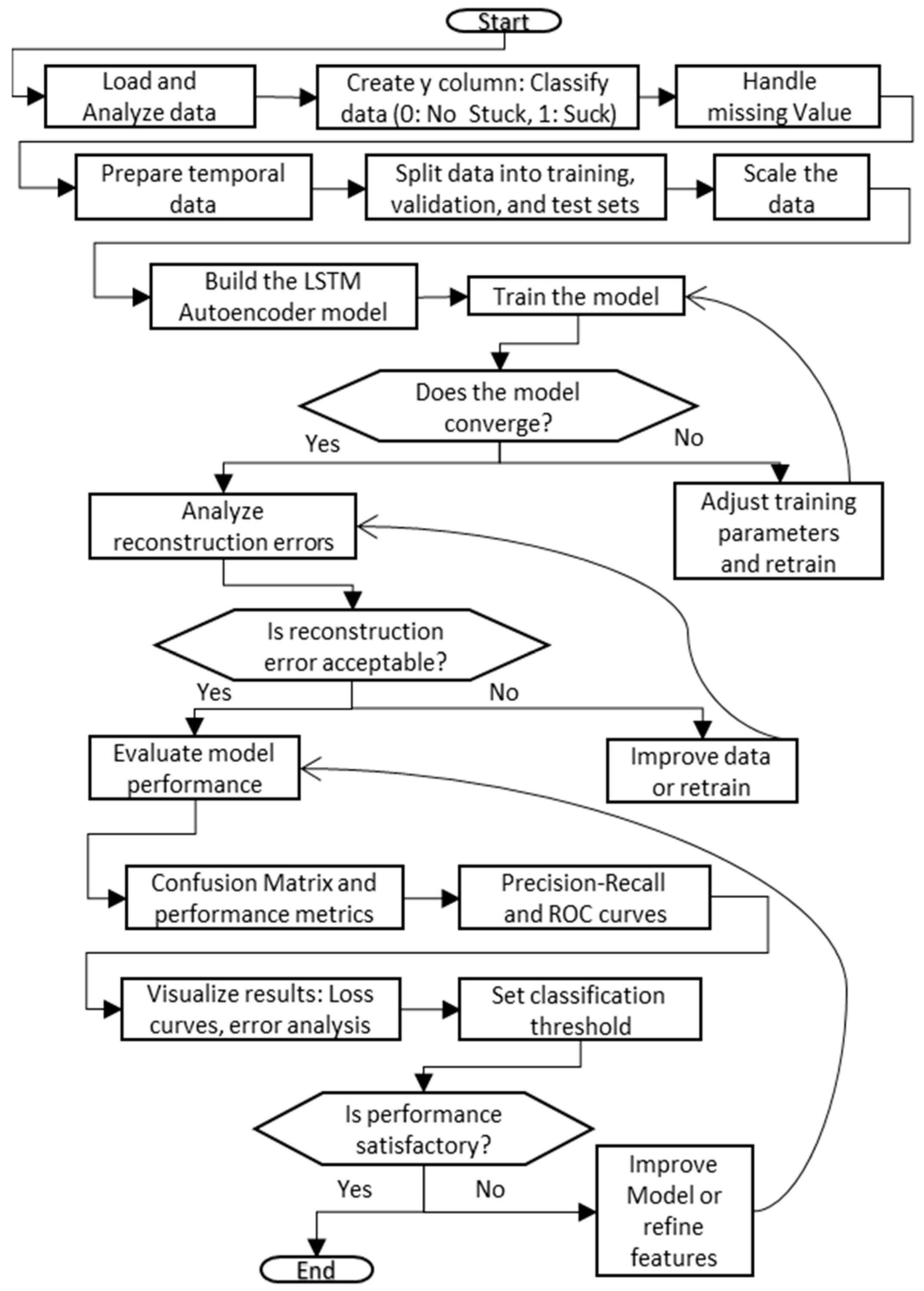

3. Methodology

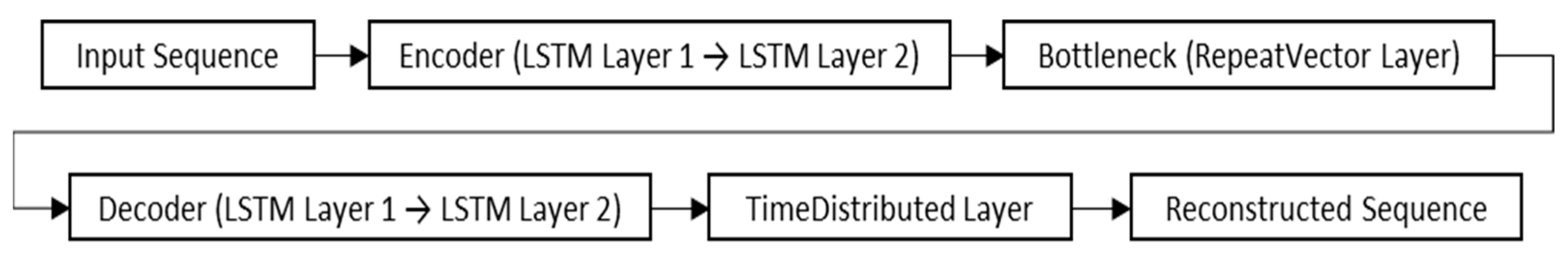

3.1. LSTM Autoencoder

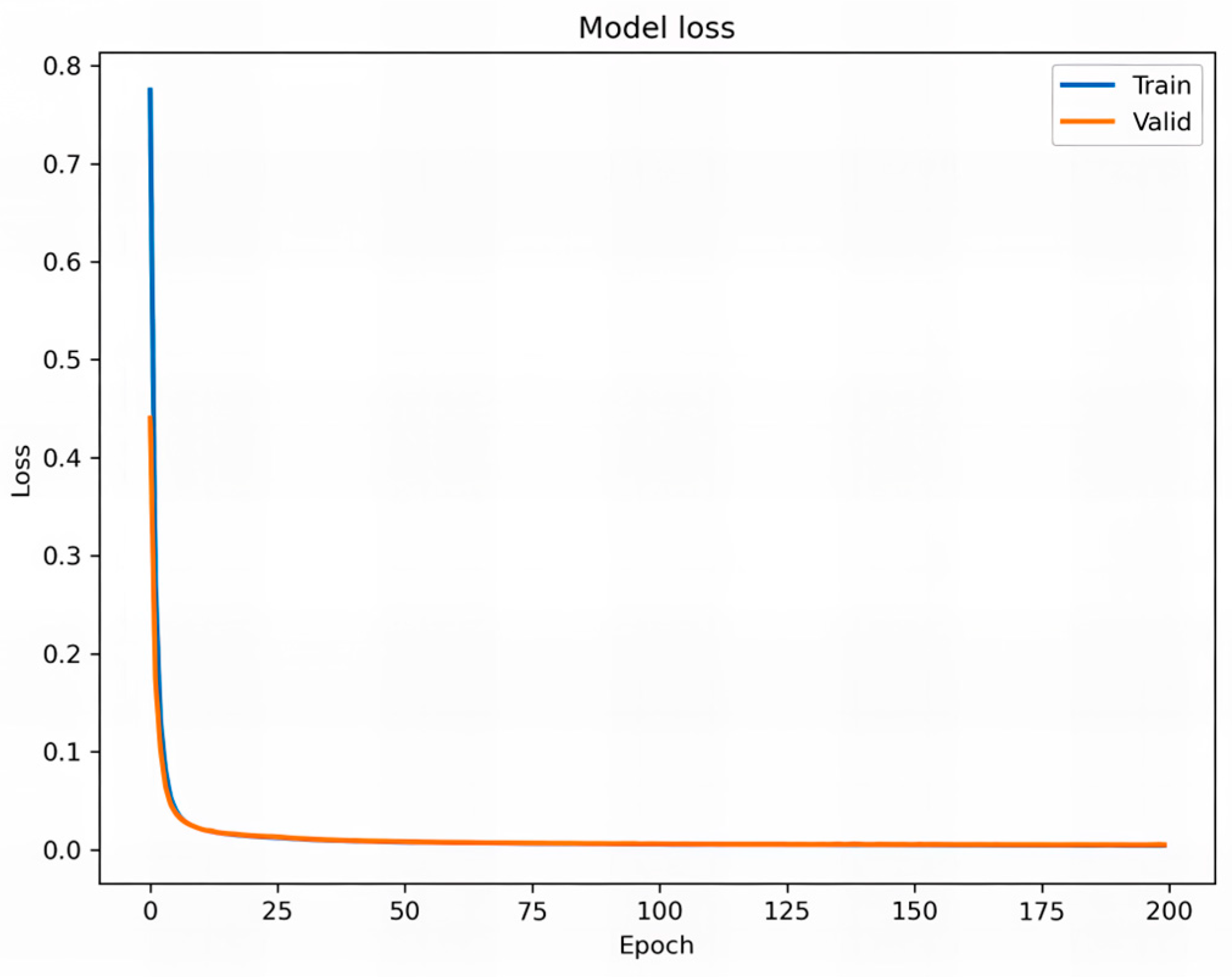

3.2. Model Training and Optimization

3.3. Evaluation Metrics

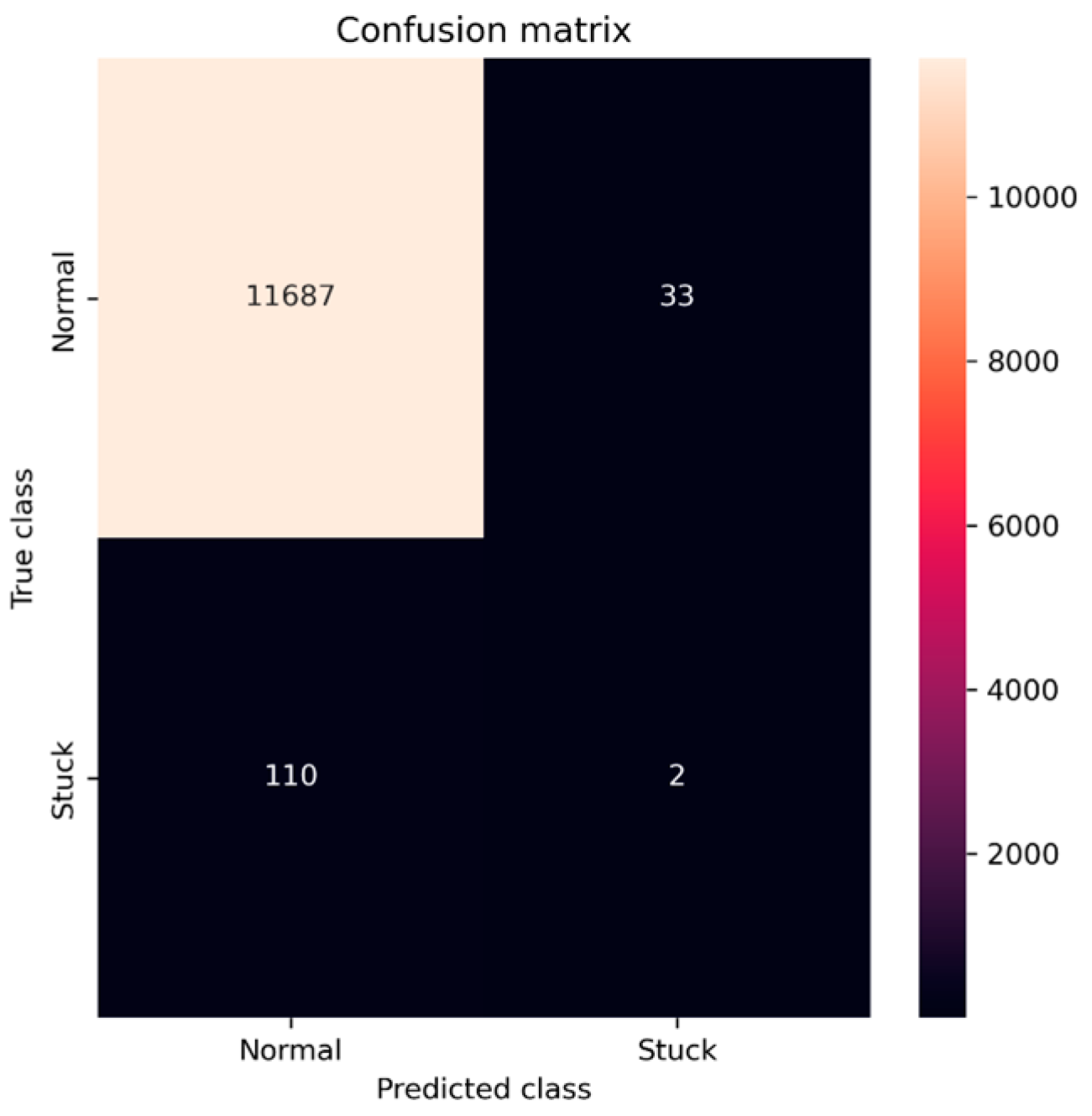

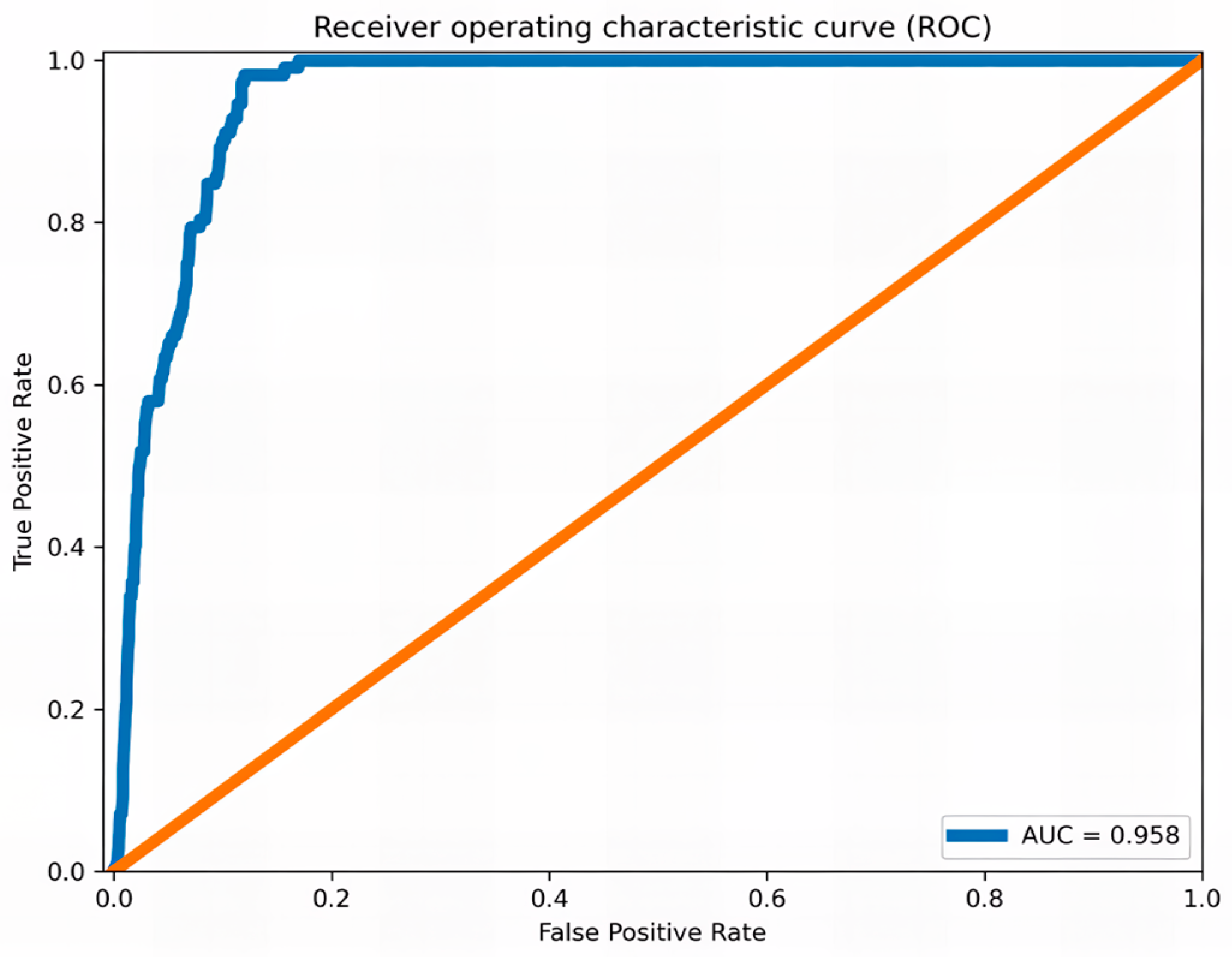

4. Results and Discussion

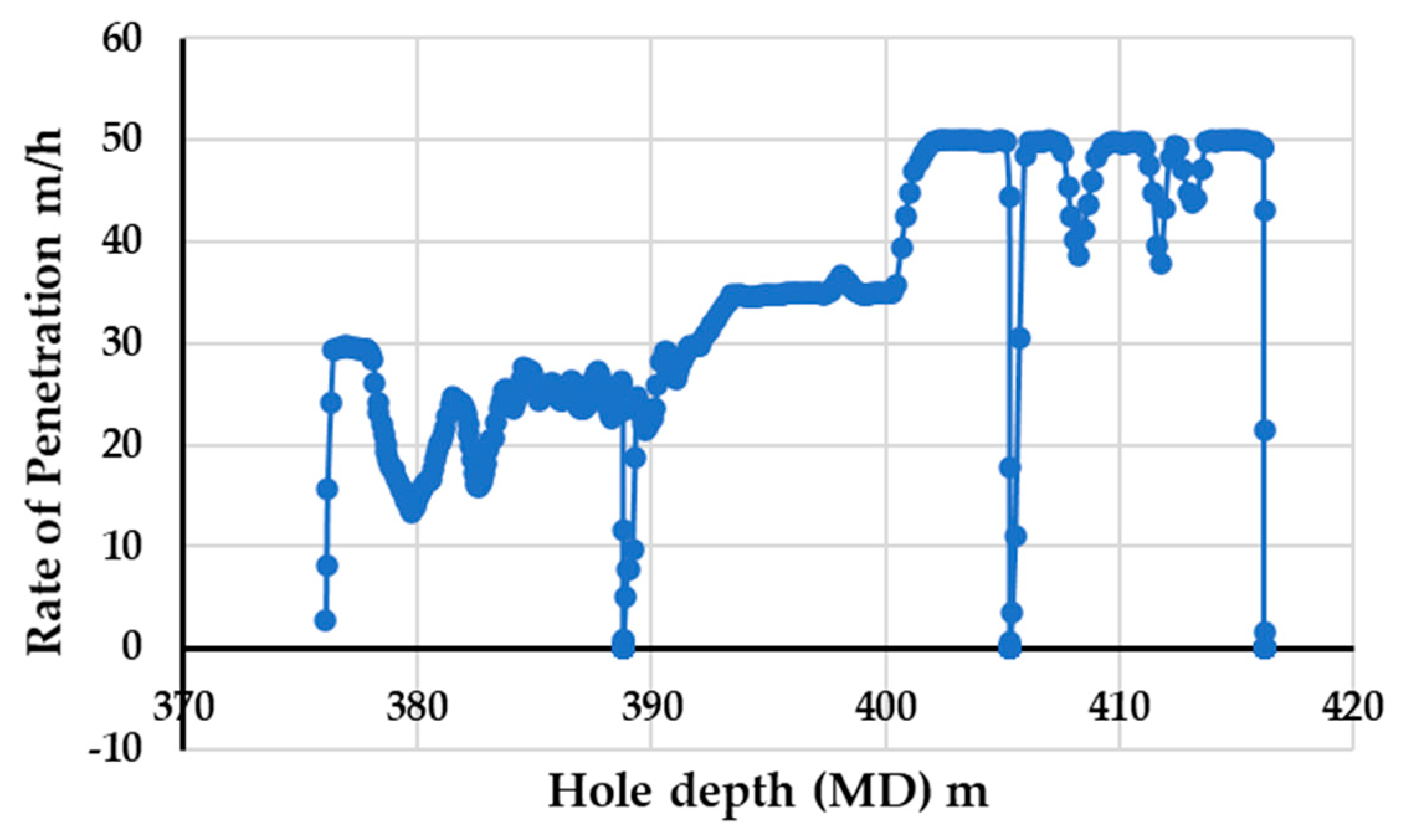

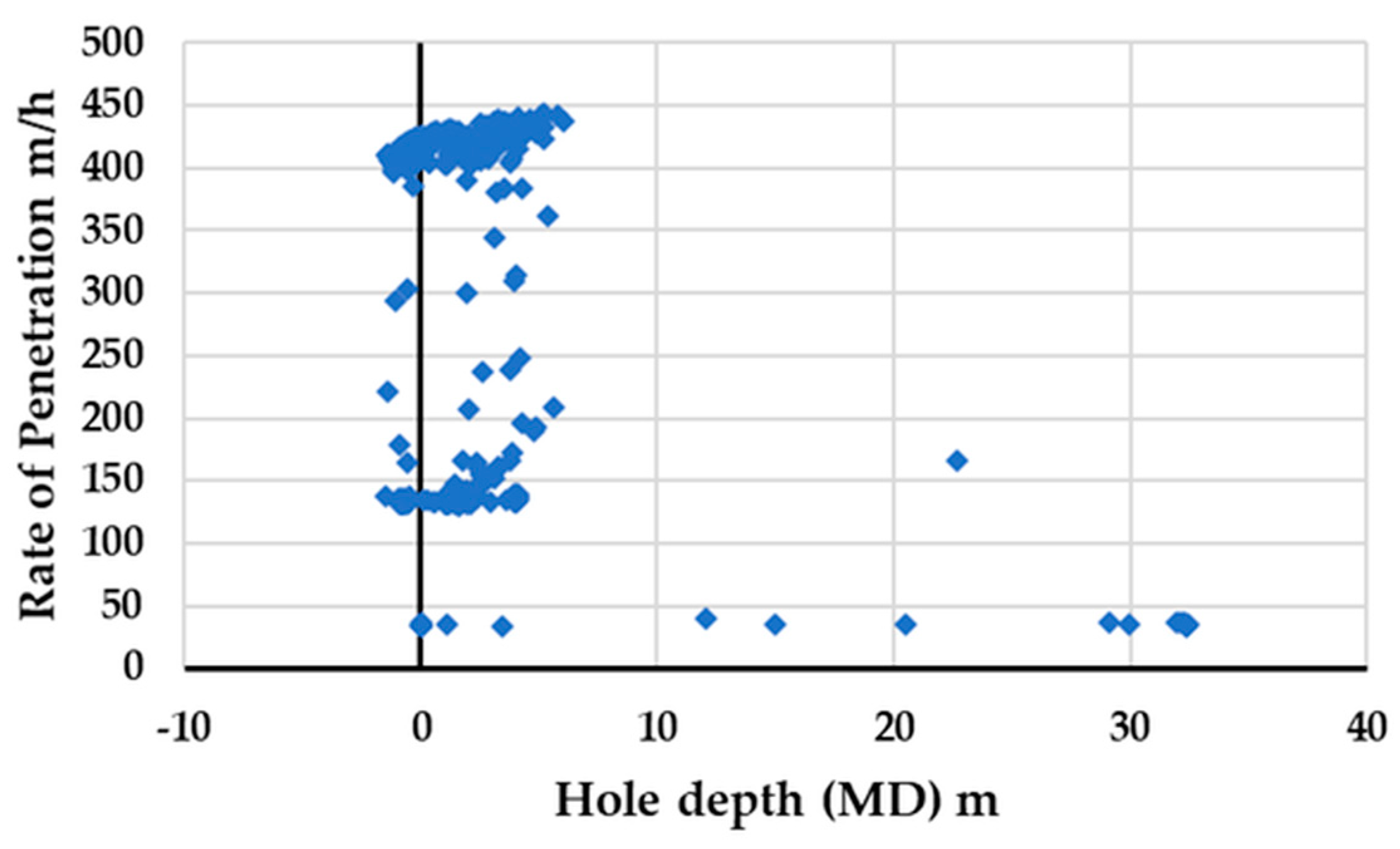

4.1. General Visualization

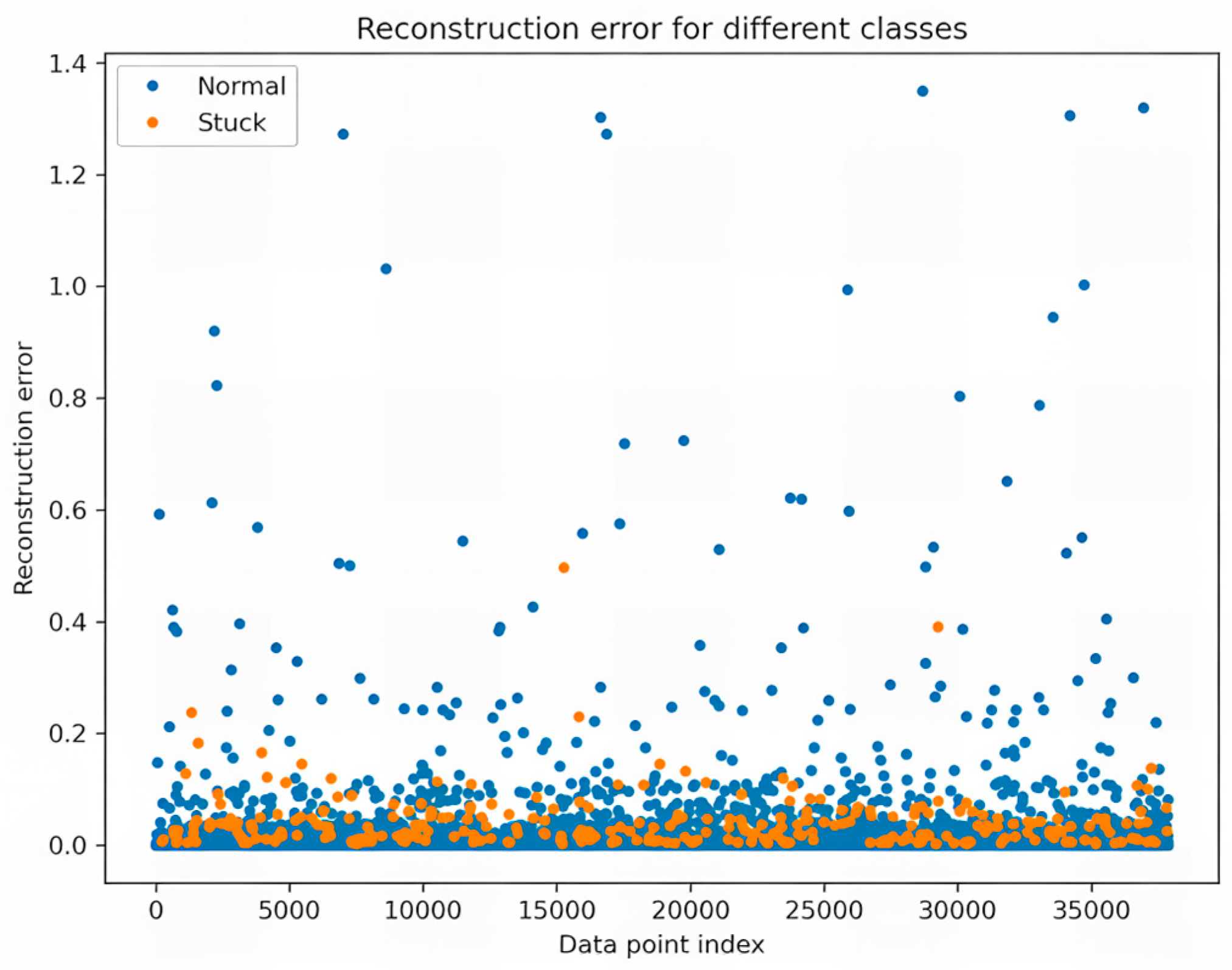

4.2. Model Performance Evaluation

4.3. Challenges and Limitations

4.4. Practical Implications

4.5. Deployment Considerations

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LSTM | Long Short-Term Memory |

| ROC | Receiver Operating Characteristic |

| AUC | Area Under the Curve |

| MD | Measured Depth |

| RPM | Revolutions Per Minute |

| kPa | Kilopascal |

| KN·m | Kilonewton Meter |

| m/h | Meters per Hour |

| T | Threshold |

| ANN | Artificial Neural Network |

| CFD | Computational Fluid Dynamics |

| DPD | Dissipative Particle Dynamics |

| HPAM | Hydrolyzed Polyacrylamide |

| SGD | Stochastic Gradient Descent |

| CNN | Convolutional Neural Network |

| SVM | Support Vector Machine |

| MSE | Mean Squared Error |

| RMSE | Root Mean Squared Error |

| MAE | Mean Absolute Error |

| MAPE | Mean Absolute Percentage Error |

| CVRMSE | Coefficient of Variation of RMSE |

| IoU | Intersection over Union |

| CF | Comfort Factor |

| THI | Temperature Humidity Index |

| WCF | Wind Chill Factor |

References

- Yin, B.; Ding, T.; Zhang, X.; Wang, Z.; Sun, B. Pressure Drop Predicting Model for Gas and Oil-Based Drilling Fluid Two Phase Flow in Vertical Annulus. Microgravity Sci. Technol. 2024, 36, 8. [Google Scholar] [CrossRef]

- Saldivar, B.; Mondié, S.; Niculescu, S.-I.; Mounier, H.; Boussaada, I. A Control Oriented Guided Tour in Oilwell Drilling Vibration Modeling. Annu. Rev. Control. 2016, 42, 100–113. [Google Scholar] [CrossRef]

- Applications in Oil and Gas Drilling. In Artificial Intelligence and Data Analytics for Energy Exploration and Production; Scrivener Publishing: Beverly, MA, USA, 2022; pp. 239–270. ISBN 9781119879893.

- Wang, J.; Tang, S.-X.; Krstic, M. Adaptive Output-Feedback Control of Torsional Vibration in off-Shore Rotary Oil Drilling Systems. Automatica 2020, 111, 108640. [Google Scholar] [CrossRef]

- Su, H.; Hu, H.; Li, Z.; Yan, G.; Wang, L.; Xiang, D.; Zhao, C.; Wu, Y.; Chen, J.; Wang, C. Pre-Oxidized PAN Nanofibrous Membrane to Efficiently and Continuously Separate Large-Scale Viscous Oil-in-Water Emulsions Under Harsh Conditions with Ultra-Long-Term Oil-Fouling Recovery. Adv. Fiber Mater. 2024, 6, 852–864. [Google Scholar] [CrossRef]

- Chen, C.; Jiang, R.; Guo, Z. Bionic Functional Membranes for Separation of Oil-in-Water Emulsions. Friction 2024, 12, 1909–1928. [Google Scholar] [CrossRef]

- Yang, L.; Ge, J.; Wu, H.; Li, X.; Zhang, X.; Zhang, G. Study on Oil-in-Water Emulsions Stabilized by SiO2 Nanoparticles for Enhancing Oil Recovery in Harsh Reservoirs. Colloid Polym. Sci. 2024, 302, 1985–1998. [Google Scholar] [CrossRef]

- Shi, X.; Jiao, Y.; Yang, X.; Liu, J.; Zhuo, Y. Establishment of Drill-String System Dynamic Model with PDM and Influence of PDM Parameters on Stick–Slip Vibration. Arab. J. Sci. Eng. 2024, 49, 8727–8739. [Google Scholar] [CrossRef]

- Ejike, C.; Obuobi, I.F.; Avinu, S.; Abid, K.; Teodoriu, C. Investigation and Analysis of Influential Parameters in Bottomhole Stick–Slip Calculation during Vertical Drilling Operations. Energies 2024, 17, 622. [Google Scholar] [CrossRef]

- Yan, B.; Tian, J.; Meng, X.; Zhang, Z. Stick–Slip Vibration Characteristics Study of the Drill String Based on PID Controller. Energies 2023, 16, 7902. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Guo, X.; Dai, L.; Zhang, C.; Zhu, H. Investigation on Axial-Lateral-Torsion Nonlinear Coupling Vibration Model and Stick-Slip Characteristics of Drilling String in Ultra-HPHT Curved Wells. Appl. Math. Model. 2022, 107, 182–206. [Google Scholar] [CrossRef]

- Tian, J.; Tang, L.; Yang, Y.; Dai, L.; Xiong, C. Drill String Dynamics and Experimental Study of Constant Torque and Stick-Slip Reduction Drilling Tool. Pet. Sci. Technol. 2024, 42, 407–427. [Google Scholar] [CrossRef]

- Fang, X.; Feng, H.; Wang, Y.; Liu, X.; Liu, X.; Xu, S.; Wang, Y.; Ni, X. Drilling-Vibration Response Characteristics of Rocks Based on Hilbert–Huang Transform. J. Pet. Explor. Prod. Technol. 2023, 13, 2417–2436. [Google Scholar] [CrossRef]

- Sun, Z.; Geng, D.; Guo, H.; Zhang, Q.; Liu, Y.; Liu, L.; Jiang, X.; Zhang, D. Introducing Transversal Vibration in Twist Drilling: Material Removal Mechanisms and Surface Integrity. J. Mater. Process. Technol. 2024, 325, 118296. [Google Scholar] [CrossRef]

- Suresh Kumar, B.; Baskar, N.; Rajaguru, K. Drilling Operation: A Review. Mater. Today Proc. 2020, 21, 926–933. [Google Scholar] [CrossRef]

- Han, X.; Li, P.; Xue, L.; Xu, J. Stick-Slip Vibration Characteristics of Drilling Tool during Drilling in Coal Seam with Gangue. Sci. Prog. 2022, 105, 00368504221086698. [Google Scholar] [CrossRef]

- Wang, D.; Li, Z.; Tian, S.; Li, T. Study on Dynamic Drilling Forces of CFRP/Ti Stacks during Longitudinal-Torsional Ultrasonic Vibration Drilling. Int. J. Adv. Manuf. Technol. 2023, 126, 2989–3004. [Google Scholar] [CrossRef]

- Guzek, A.; Shufrin, I.; Pasternak, E.; Dyskin, A. V Influence of Drilling Mud Rheology on the Reduction of Vertical Vibrations in Deep Rotary Drilling. J. Pet. Sci. Eng. 2015, 135, 375–383. [Google Scholar] [CrossRef]

- Tian, J.; Zhou, Y.; Yang, L.; Hu, S. Analysis of Stick-Slip Reduction for a New Torsional Vibration Tool Based on PID Control. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2019, 234, 82–94. [Google Scholar] [CrossRef]

- Kessai, I.; Benammar, S.; Doghmane, M.Z.; Tee, K.F. Drill Bit Deformations in Rotary Drilling Systems under Large-Amplitude Stick-Slip Vibrations. Appl. Sci. 2020, 10, 6523. [Google Scholar] [CrossRef]

- Choe, Y.-M.; Kim, G.-S.; Kim, I.-S.; Cha, J.-C.; Ri, K.-W.; Han, Y.-S.; Kang, C.-H. Influence of Torsional Stick-Slip Vibration on Whirl Behavior in Drill String System. Geoenergy Sci. Eng. 2023, 227, 211931. [Google Scholar] [CrossRef]

- Ritto, T.G.; Ghandchi-Tehrani, M. Active Control of Stick-Slip Torsional Vibrations in Drill-Strings. J. Vib. Control 2018, 25, 194–202. [Google Scholar] [CrossRef]

- He, T.; Zhong, H.; Liao, K.; Liao, J.; Zhao, S.; He, G.; Zhang, J. Quantitative Study on Magnetic Flux Leakage Internal Detection Signal of Defects on the Outer Wall of Bimetal Composite Pipes. Int. J. Press. Vessel. Pip. 2025, 214, 105438. [Google Scholar] [CrossRef]

- Zhong, Z.; Li, C.; Liu, X.; Xiong, Y.; Fan, Y.; Liang, N. Assessment of Experimental Friction Parameters and Contact Property of Pipe String for the Estimation and Verification of a Solution for Pipe Stuck in the China’s First Rock Pipe Jacking. Tunn. Undergr. Space Technol. 2021, 107, 103671. [Google Scholar] [CrossRef]

- Rao, P.; Yelgaonkar, V.N.; Tiwari, C.B.; Dhakar, V.; Panicker, M.C. Locating Block Caused by Stuck PIGs in Multi Product Pipeline Using Combination of Radioisotope Techniques. Appl. Radiat. Isot. 2023, 193, 110660. [Google Scholar] [CrossRef] [PubMed]

- Shoukat, S.; Gao, T.; Javeed, D.; Saeed, M.S.; Adil, M. Trust My IDS: An Explainable AI Integrated Deep Learning-Based Transparent Threat Detection System for Industrial Networks. Comput. Secur. 2025, 149, 104191. [Google Scholar] [CrossRef]

- Ullah, S.; Li, J.; Ullah, F.; Chen, J.; Ali, I.; Khan, S.; Ahad, A.; Leung, V.C.M. The Revolution and Vision of Explainable AI for Android Malware Detection and Protection. Internet Things 2024, 27, 101320. [Google Scholar] [CrossRef]

- Liu, K.; Fang, J.; Zhao, S.; Liu, Y.; Dai, H.; Ye, L.; Peng, Q. Battery State-of-Health Estimation: An Ultrasonic Detection Method with Explainable AI. Energy 2025, 319, 134923. [Google Scholar] [CrossRef]

- Saleh, T.A. Advanced Trends of Shale Inhibitors for Enhanced Properties of Water-Based Drilling Fluid. Upstream Oil Gas Technol. 2022, 8, 100069. [Google Scholar] [CrossRef]

- Yongwang, L.; Zhichuan, G.; Hongning, Z.; Baoping, L.; Guangjun, M.; Deyang, L. Study on Vibration Energy Conversion Efficiency of the Drill String Absorption & Hydraulic Supercharging Device. Chem. Technol. Fuels Oils 2022, 58, 340–348. [Google Scholar] [CrossRef]

- Wang, W.; Li, S.; Yuan, X. Effect of Power-V on the Stick–Slip Vibration of a Drill String. Chem. Technol. Fuels Oils 2023, 59, 202–212. [Google Scholar] [CrossRef]

- Khan, J.A.; Irfan, M.; Irawan, S.; Yao, F.K.; Abdul Rahaman, M.S.; Shahari, A.R.; Glowacz, A.; Zeb, N. Comparison of Machine Learning Classifiers for Accurate Prediction of Real-Time Stuck Pipe Incidents. Energies 2020, 13, 3683. [Google Scholar] [CrossRef]

- Kumar, G.; Singh, V.P.; Pandey, S.K. Assessing Gas Leakage Detection Performance Using Machine Learning with Different Modalities. Trans. Electr. Electron. Mater. 2024, 25, 653–664. [Google Scholar] [CrossRef]

- Mardanirad, S.; Wood, D.A.; Zakeri, H. The Application of Deep Learning Algorithms to Classify Subsurface Drilling Lost Circulation Severity in Large Oil Field Datasets. SN Appl. Sci. 2021, 3, 785. [Google Scholar] [CrossRef]

- Dang, T.; Nguyen, T.T.; Liew, A.W.-C.; Elyan, E. Event Classification on Subsea Pipeline Inspection Data Using an Ensemble of Deep Learning Classifiers. Cogn. Comput. 2024, 17, 10. [Google Scholar] [CrossRef]

- Zhu, S.; Song, X.; Zhu, Z.; Yao, X.; Liu, M. Intelligent Prediction of Stuck Pipe Using Combined Data-Driven and Knowledge-Driven Model. Appl. Sci. 2022, 12, 5282. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Rubaii, M.; Wood, D.A.; Al-Shargabi, M.; Mehrad, M.; Rukavishnikov, V.S. Hybrid Machine-Learning Model for Accurate Prediction of Filtration Volume in Water-Based Drilling Fluids. Appl. Sci. 2024, 14, 9035. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, P.; Yang, Y.; Zhang, Q.; Sun, Y.; Song, X.; Zhu, Z. Identification Method of Stuck Pipe Based on Data Augmentation and ATT-LSTM. Processes 2024, 12, 1296. [Google Scholar] [CrossRef]

- Al-Rubaii, M.; Al-Shargabi, M.; Al-Shehri, D. A Novel Automated Model for Evaluation of the Efficiency of Hole Cleaning Conditions during Drilling Operations. Appl. Sci. 2023, 13, 6464. [Google Scholar] [CrossRef]

- Siqueira, V.S.d.M.; Cuadros, M.A.S.L.; Munaro, C.J.; de Almeida, G.M. Expert System for Early Sign Stuck Pipe Detection: Feature Engineering and Fuzzy Logic Approach. Eng. Appl. Artif. Intell. 2024, 127, 107229. [Google Scholar] [CrossRef]

- Mopuri, K.R.; Bilen, H.; Tsuchihashi, N.; Wada, R.; Inoue, T.; Kusanagi, K.; Nishiyama, T.; Tamamura, H. Early Sign Detection for the Stuck Pipe Scenarios Using Unsupervised Deep Learning. J. Pet. Sci. Eng. 2022, 208, 109489. [Google Scholar] [CrossRef]

- Bayazitova, G.; Anastasiadou, M.; dos Santos, V.D. Oil and Gas Flow Anomaly Detection on Offshore Naturally Flowing Wells Using Deep Neural Networks. Geoenergy Sci. Eng. 2024, 242, 213240. [Google Scholar] [CrossRef]

- Song, L.; Cui, X.; Han, X.; Gao, Y.; Liu, F.; Yu, Y.; Yuan, Y. A Non-Metallic Pipeline Leak Size Recognition Method Based on CWT Acoustic Image Transformation and CNN. Appl. Acoust. 2024, 225, 110180. [Google Scholar] [CrossRef]

- Equinor Volve Field Dataset in Norway. Available online: https://www.equinor.com/news/archive/14jun2018-disclosing-volve-data (accessed on 16 January 2025).

- Bo, C.; Yu, S.; Feng, X.; Fukang, P. Development of Time Series Drilling Datasets for Stuck Pipe Prediction Using Volve Field Data. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Singapore, 9–14 June 2024; American Society of Mechanical Engineers: New York, NY, USA, 2024; Volume 87868, p. V008T11A027. [Google Scholar]

- Abdulameer, A.G.; Mrah, M.M.; Bazerkan, M.; Al-Haddad, L.A.; Al-Karkhi, M.I. Machine Learning-Driven Power Prediction in Continuous Extrusion of Pure Titanium for Enhanced Structural Resilience under Extreme Loading. Discov. Mater. 2025, 5, 7. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Łukaszewicz, A.; Majdi, H.S.; Holovatyy, A.; Jaber, A.A.; Al-Karkhi, M.I.; Giernacki, W. Energy Consumption and Efficiency Degradation Predictive Analysis in Unmanned Aerial Vehicle Batteries Using Deep Neural Networks. Adv. Sci. Technol. Res. J. 2025, 19, 21–30. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Jaber, A.A.; Dhahir, M.K.; Nagim, H.Y.; Algburi, Z.I. Characterization and Prediction of Femtosecond Laser Induced Tracks in Silver-Containing Zinc Phosphate Glass. In Proceedings of the CEUR Workshop Proceedings, Conference: SYSYEM 2024: 10th Scholar’s Yearly Symposium of Technology, Engineering and Mathematics, Rome, Italy, 2–5 December 2024; Volume 3870, pp. 10–19. [Google Scholar]

- Sarow, S.A.; Flayyih, H.A.; Bazerkan, M.; Al-Haddad, L.A.; Al-Sharify, Z.T.; Ogaili, A.A.F. Advancing Sustainable Renewable Energy: XGBoost Algorithm for the Prediction of Water Yield in Hemispherical Solar Stills. Discov. Sustain. 2024, 5, 1–15. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Jaber, A.A. An Intelligent Fault Diagnosis Approach for Multirotor UAVs Based on Deep Neural Network of Multi-Resolution Transform Features. Drones 2023, 7, 82. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Alawee, W.H.; Basem, A. Advancing Task Recognition towards Artificial Limbs Control with ReliefF-Based Deep Neural Network Extreme Learning. Comput. Biol. Med. 2023, 169, 107894. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Giernacki, W.; Basem, A.; Khan, Z.H.; Jaber, A.A.; Al-Haddad, S.A. UAV Propeller Fault Diagnosis Using Deep Learning of Non-Traditional Χ2-Selected Taguchi Method-Tested Lempel–Ziv Complexity and Teager–Kaiser Energy Features. Sci. Rep. 2024, 14, 18599. [Google Scholar] [CrossRef]

- Al-Haddad, L.A.; Kahachi, H.A.H.; Ur Rehman, H.Z.; Al-Zubaidi, A.A.; Al-Karkhi, M.I.; Al-Oubaidi, B. Advancing Sustainability in Buildings Using an Integrated Aerodynamic Façade: Potential of Artificial Intelligence. Terra Joule J. 2024, 1, 1. [Google Scholar]

- Abdul-Zahra, A.S.; Ghane, E.; Kamali, A.; Farhan Ogaili, A.A. Power Forecasting in Continuous Extrusion of Pure Titanium Using Naïve Bayes Algorithm. Terra Joule J. 2024, 1, 2. [Google Scholar]

- Li, D.; Gao, H.; Yang, K.; Zhou, F.; Shi, X. Abnormal Identification of Oil Monitoring Based on LSTM and SVDD. Wear 2023, 526–527, 204793. [Google Scholar] [CrossRef]

- Al-Haddad, A.A.; Al-Haddad, L.A.; Al-Haddad, S.A.; Jaber, A.A.; Khan, Z.H.; Rehman, H.Z.U. Towards Dental Diagnostic Systems: Synergizing Wavelet Transform with Generative Adversarial Networks for Enhanced Image Data Fusion. Comput. Biol. Med. 2024, 182, 109241. [Google Scholar] [CrossRef] [PubMed]

- Al-Haddad, S.A.; Al-Haddad, L.A.; Jaber, A.A. Environmental Engineering Solutions for Efficient Soil Classification in Southern Syria: A Clustering-Correlation Extreme Learning Approach. Int. J. Environ. Sci. Technol. 2024, 22, 2177–2190. [Google Scholar] [CrossRef]

- Mejbel, B.G.; Sarow, S.A.; Al-Sharify, M.T.; Al-Haddad, L.A.; Ogaili, A.A.F.; Al-Sharify, Z.T. A Data Fusion Analysis and Random Forest Learning for Enhanced Control and Failure Diagnosis in Rotating Machinery. J. Fail. Anal. Prev. 2024, 24, 2979–2989. [Google Scholar] [CrossRef]

| Ref. | Deep Learning Approach | Application/Parameters | Key Finding | # Parameters Used | Training Data Type |

|---|---|---|---|---|---|

| [32] | ANN, SVM | Stuck pipe prediction from real-time drilling data | ANN outperformed SVM with 88.89% accuracy | 19 | Both |

| [33] | ML Models | Gas leak detection via sensors & IR thermography | High classification precision demonstrated | 12 | Both |

| [34] | CNN, GRU, LSTM | Lost circulation severity classification | CNN achieved 98% accuracy | 20 | Both |

| [35] | Ensemble DL Models | Subsea pipeline anomaly classification | Ensemble achieved up to 99% accuracy | 18 | Abnormal |

| [36] | ANN, Fuzzy Logic | Stuck pipe prediction via friction probability | F1-score of 0.98, 1% false alarms | 10 | Normal |

| [37] | RBFNN, MELM | Filtration volume prediction in drilling fluids | RMSE of 0.6396 mL achieved | 2 | Normal |

| [38] | ATT-LSTM | Stuck pipe detection with data augmentation | Accuracy improved by 21.31% | 10 | Normal |

| [39] | Automated DL Model | Hole cleaning efficiency evaluation | ROP improved by 52% | 3 | Normal |

| [40] | Fuzzy Expert System | Early stuck pipe detection | 92% of stuck cases predicted | 7 | Normal |

| [41] | Autoencoder (Unsupervised) | Early stuck pipe detection | Promising results for anomaly detection | 15 | Normal |

| [42] | DNN, GA, GRU | Flow anomaly detection in offshore wells | F1-score of 0.97 | 20 | Abnormal |

| [43] | CNN + CWT | Pipeline leak size classification | Achieved 95% accuracy | 8 | Abnormal |

| Parameter | Unit |

|---|---|

| Date | Date/Time |

| Average Hookload | Kkgf |

| Hole depth (MD) | M |

| Weight on Bit | Kkgf |

| Block Position | M |

| Rate of Penetration | m/h |

| Average Rotary Speed | Rpm |

| Average Surface Torque | KN·m |

| Rate of Penetration (5ft avg) | m/h |

| Bit Depth (MD) | M |

| Average Standpipe Pressure | kPa |

| Mud Flow In | L/min |

| Stuck cases | Categorical |

| Method | Accuracy | Precision | Recall | F1-Score | Remarks |

|---|---|---|---|---|---|

| K-Nearest Neighbors (KNN) | 85.20% | 86.00% | 81.50% | 83.70% | Performance stable but sensitive to outliers |

| Support Vector Machine (SVM) | 88.40% | 89.10% | 84.20% | 86.60% | Good for high-dimensional data, less adaptive |

| Decision Tree (DT) | 84.10% | 85.00% | 80.40% | 82.60% | Interpretable but may overfit on small sets |

| Random Forest (RF) | 90.60% | 91.50% | 87.30% | 89.30% | Balanced performance, ensemble strength |

| Artificial Neural Network (ANN-Deep, 3 Layers) | 93.10% | 92.00% | 89.80% | 90.90% | Better feature learning but slower convergence |

| Convolutional Neural Network (CNN) | 94.60% | 93.50% | 91.20% | 92.30% | Strong pattern extraction, needs more computation |

| Proposed LSTM Autoencoder (Current Study) | 99.06% | 97.12% | 91.34% | 94.15% | Real-Time Compatible, Trained on Normal Only |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mamoori, H.N.; Tian, J.; Ma, H. Stuck Pipe Detection in Oil and Gas Drilling Operations Using Deep Learning Autoencoder for Anomaly Diagnosis. Appl. Sci. 2025, 15, 5042. https://doi.org/10.3390/app15095042

Al-Mamoori HN, Tian J, Ma H. Stuck Pipe Detection in Oil and Gas Drilling Operations Using Deep Learning Autoencoder for Anomaly Diagnosis. Applied Sciences. 2025; 15(9):5042. https://doi.org/10.3390/app15095042

Chicago/Turabian StyleAl-Mamoori, Hasan N., Jialin Tian, and Haifeng Ma. 2025. "Stuck Pipe Detection in Oil and Gas Drilling Operations Using Deep Learning Autoencoder for Anomaly Diagnosis" Applied Sciences 15, no. 9: 5042. https://doi.org/10.3390/app15095042

APA StyleAl-Mamoori, H. N., Tian, J., & Ma, H. (2025). Stuck Pipe Detection in Oil and Gas Drilling Operations Using Deep Learning Autoencoder for Anomaly Diagnosis. Applied Sciences, 15(9), 5042. https://doi.org/10.3390/app15095042