Ion-Implanted Diamond Blade Diced Ridge Waveguides in Pr:YLF—Optical Characterization and Small-Signal Gain Measurement

Abstract

1. Introduction

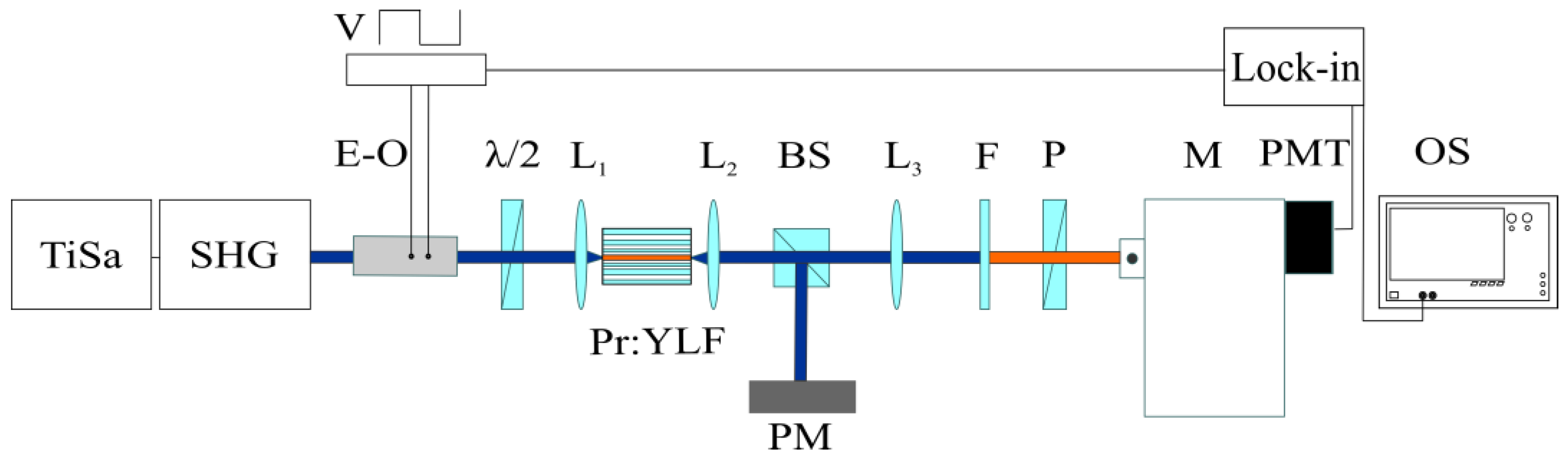

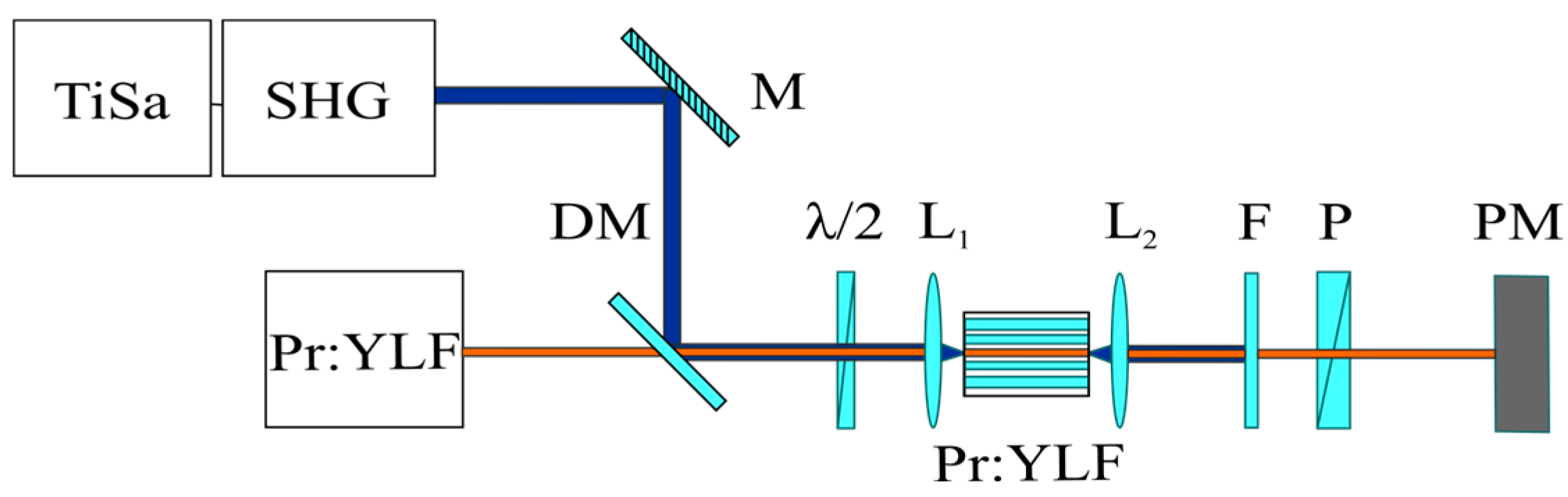

2. Experimental Methods

3. Results and Discussion

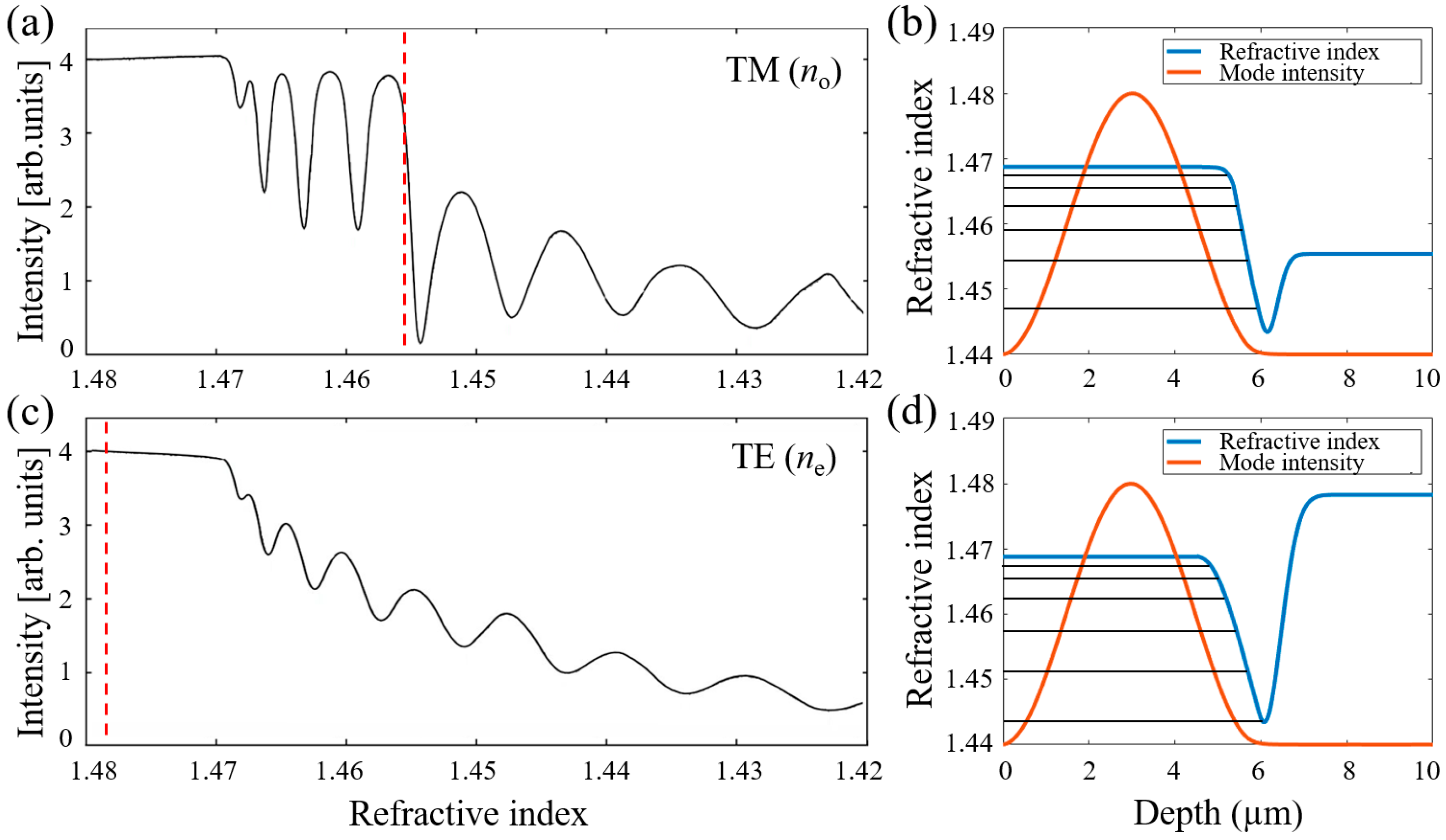

3.1. Planar Waveguide Characterization—Induced Refractive Index Changes

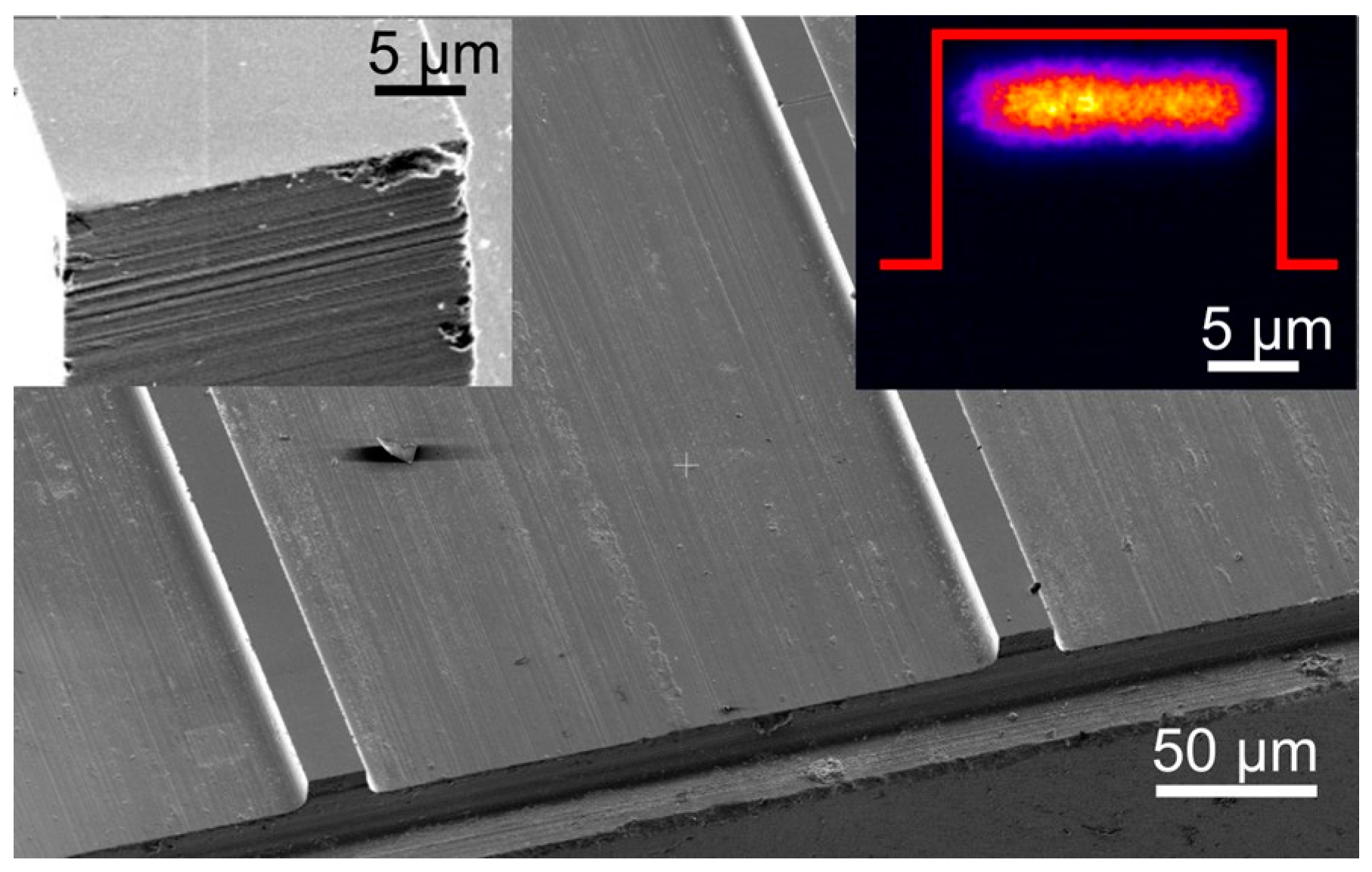

3.2. Ridge Waveguide Characterization

3.3. Fluorescence and Lifetime Measurement

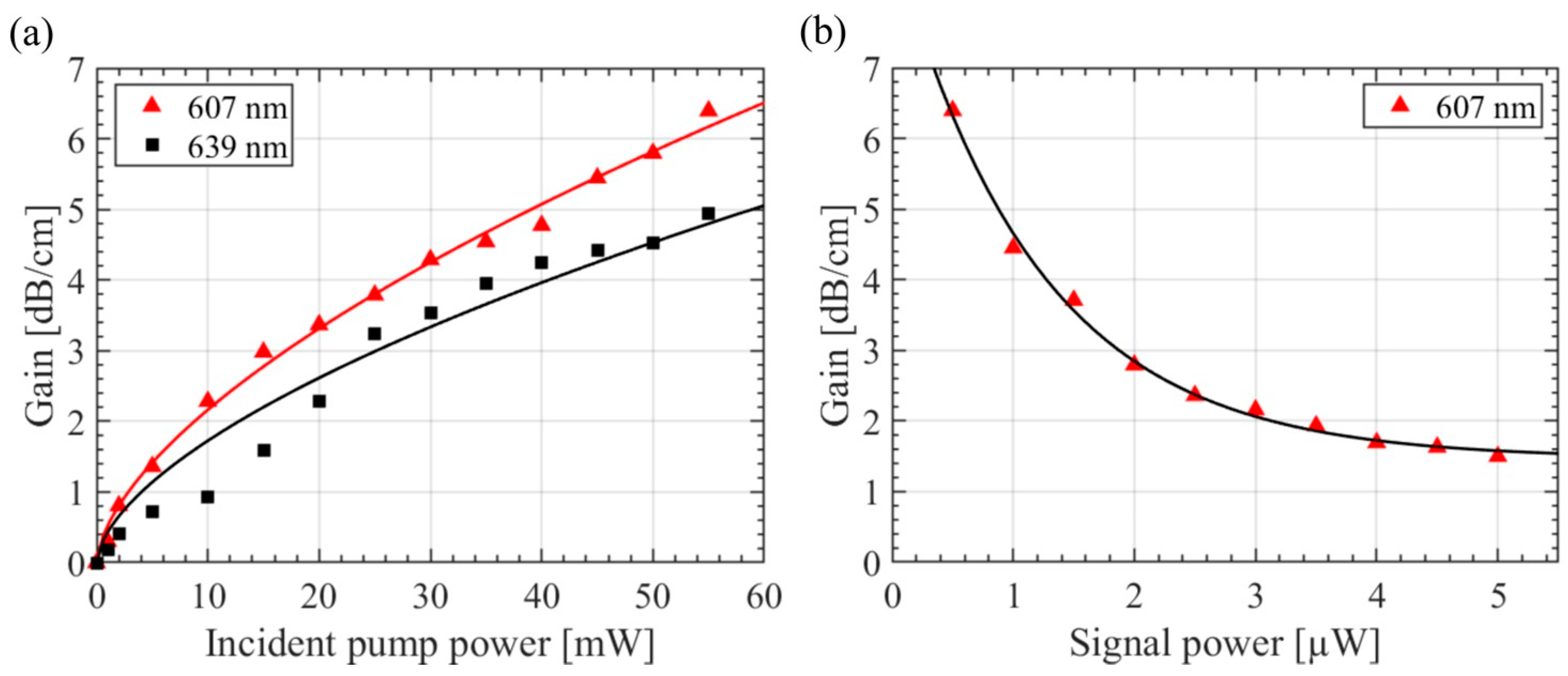

3.4. Small-Signal Amplification Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Kong, W.; Chen, F. Femtosecond laser-inscribed optical waveguides in dielectric crystals: A concise review and recent advances. Adv. Photonics 2002, 4, 024002. [Google Scholar] [CrossRef]

- Gow, P.C.; Bannerman, R.H.S.; Mennea, P.L.; Holmes, C.; Gates, J.C.; Smith, P.G.R. Direct UV written integrated planar waveguides using a 213 nm laser. Opt. Express 2019, 27, 29133–29138. [Google Scholar] [CrossRef] [PubMed]

- Dong, N.N.; Chen, F.; Jaque, D. Carbon ion implanted Nd:MgO:LiNbO3 optical channel waveguides: An intermediate step between light and heavy ion implanted waveguides. Opt. Express 2010, 18, 5951–5956. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Wang, X.L.; Wang, K.M. Development of ion-implanted optical waveguides in optical materials: A review. Opt. Mater. 2007, 29, 1523–1542. [Google Scholar]

- Chen, F.; Amekura, H.; Jia, Y. Ion Irradiation of Dielectrics for Photonic Applications; Springer Series in Optical Sciences; Springer: Berlin/Heidelberg, Germany, 2020; Volume 231. [Google Scholar]

- Bányász, I.; Szilágyi, E.; Rajta, I.; Nagy, G.U.L.; Pelli, S.; Conti, G.N.; Berneschi, S.; Havránek, V.; Vosecek, V.; Nagy, N.; et al. Fabrication of low loss channel waveguide in tungsten-tellurite glass by 11 MeV carbon ion microbeam for telecom C band. Opt. Mater. X 2019, 4, 100035. [Google Scholar] [CrossRef]

- Hukriede, J.; Kip, D.; Krätzig, E. Permanent narrow-band reflection holograms for infrared light recorded in LiNbO3:Ti:Cu channel waveguides. Appl. Phys. B 2001, 72, 749–753. [Google Scholar]

- Suntsov, S.; Rüter, C.E.; Brüske, D.; Kip, D. Watt-level 775 nm SHG with 70% conversion efficiency and 97% pump depletion in annealed/reverse proton exchanged diced PPLN ridge waveguides. Opt. Express 2021, 29, 11386–11393. [Google Scholar]

- Kränkel, C.; Marzahl, D.T.; Moglia, F.; Huber, G.; Metz, P.W. Out of the blue: Semiconductor laser pumped visible rare-earth doped lasers. Laser Photon. Rev. 2016, 10, 548–568. [Google Scholar]

- Tanaka, H.; Kalusniak, S.; Badtke, M.; Demesh, M.; Kuleshov, N.V.; Kannari, F.; Kränkel, C. Visible solid-state lasers based on Pr3+ and Tb3+. Prog. Quant. Electron. 2022, 84, 100411. [Google Scholar] [CrossRef]

- Richter, A.; Heumann, E.; Osiac, E.; Huber, G.; Seelert, W.; Diening, A. Diode pumping of a continuous-wave Pr3+ doped LiYF4 laser. Opt. Lett. 2004, 29, 2638. [Google Scholar] [CrossRef]

- Gün, T.; Metz, P.; Huber, G. Power scaling of laser diode pumped Pr3+:LiYF4 cw lasers: Efficient laser operation. Opt. Lett. 2011, 36, 1002–1004. [Google Scholar] [CrossRef] [PubMed]

- Calmano, T.; Siebenmorgen, J.; Reichert, F.; Fechner, M.; Paschke, A.G.; Hansen, N.O.; Petermann, K.; Huber, G. Crystalline Pr:SrAl12O19 waveguide laser in the visible spectral region. Opt. Lett. 2011, 36, 4620–4622. [Google Scholar] [CrossRef] [PubMed]

- Müller, S.; Calmano, T.; Metz, P.; Hansen, N.O.; Kränkel, C.; Huber, G. Femtosecond-laser-written diode-pumped Pr:LiYF4 waveguide laser. Opt. Lett. 2012, 37, 5223. [Google Scholar] [CrossRef]

- Baillard, A.; Loiko, P.; Romero, C.; Arroyo, V.; Vázquez de Aldana, J.R.; Fromager, M.; Braud, A.; Camy, P.; Mateos, X. Orange surface waveguide laser in Pr:LiYF4 produced by femtosecond laser writing. Opt. Lett. 2023, 48, 6212–6215. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Cui, Z.; Sun, L.; Wang, C.; Liu, H.; Cai, Y. Laser emission from low-loss cladding waveguides in Pr:YLF by femtosecond laser helical inscription. Chin. Opt. Lett. 2022, 22, 122201. [Google Scholar] [CrossRef]

- Baiocco, D.; Lopez-Quintas, I.; Vázquez de Aldana, J.R.; Tonelli, M.; Tredicucci, A. Comparative performance analysis of femtosecond-laser-written diode-pumped Pr:LiLuF4 visible waveguide lasers. Photonics 2023, 10, 377. [Google Scholar] [CrossRef]

- Bolaños, W.; Brasse, G.; Starecki, F.; Braud, A.; Doualan, J.; Moncorgé, R.; Camy, P. Green, orange, and red Pr3+:YLiF4 epitaxial waveguide lasers. Opt. Lett. 2014, 39, 4450–4453. [Google Scholar] [CrossRef]

- Calmano, T.; Müller, S. Crystalline waveguide lasers in the visible and near-infrared spectral range. IEEE J. Quantum Electron. 2015, 21, 401–4130. [Google Scholar] [CrossRef]

- Calmano, T.; Paschke, A.G.; Müller, S.; Kränkel, C.; Huber, G. Curved Yb:YAG waveguide lasers, fabricated by femtosecond laser inscription. Opt. Express 2013, 21, 25501–25508. [Google Scholar] [CrossRef]

- Wang, M.; Wu, R.; Lin, J.; Zhang, J.; Fang, Z.; Chai, Z.; Cheng, Y. Chemo-mechanical polish lithography: A pathway to low loss large-scale photonic integration on lithium niobate on insulator. Quantum Eng. 2019, 1, e9. [Google Scholar] [CrossRef]

- Zhao, J.H.; Fan, L.; Li, B.Y.; Zang, W.Z.; Liu, A.J.; Mao, J.H.; Yue, Y.; Li, S.; Yao, Y.C.; Yue, Q.Y. Planar and ridged waveguide preparation on erbium pre-implanted fused silica by multi-energy helium ion implantation and femtosecond laser ablation. Appl. Opt. 2024, 63, 5018–5022. [Google Scholar] [CrossRef]

- Zhao, J.H.; Liu, X.H.; Huang, Q.; Liu, P.; Wang, X.L. Lithium niobate ridge waveguides fabricated by ion implantation followed by ion beam etching. J. Light. Technol. 2010, 28, 1913–1916. [Google Scholar] [CrossRef]

- Ziegler, J.F. Srim-2003. Nucl. Instr. Meth. Phys. Res. B 2004, 219/220, 1027–1036. [Google Scholar] [CrossRef]

- Fallahkhair, A.B.; Li, K.S.; Murphy, T.E. Vector finite difference modesolver for anisotropic dielectric waveguides. J. Light. Technol. 2008, 26, 1423–1431. [Google Scholar] [CrossRef]

- Barnes, N.P.; Gettemy, D.J. Temperature variation of the refractive index of lithium fluoride. J. Opt. Soc. Am. 1980, 70, 1244–1247. [Google Scholar] [CrossRef]

- Geng, X.; Li, L.; Qian, C.; Luo, S. A full spectroscopic study of Pr:YLF crystals used in lasers. Spectroscopy 2020, 35, 39–45. [Google Scholar]

- Esterowitz, L.; Bartoli, F.J.; Allen, R.E.; Wortman, D.E.; Morrison, C.A.; Leavitt, R.P. Energy levels and line intensities of Pr3+ LiYF4. Phys. Rev. B 1979, 19, 6442–6455. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altaher, O.; Hasse, K.; Suntsov, S.; Tanaka, H.; Kränkel, C.; Bányász, I.; Mikšová, R.; Kip, D. Ion-Implanted Diamond Blade Diced Ridge Waveguides in Pr:YLF—Optical Characterization and Small-Signal Gain Measurement. Appl. Sci. 2025, 15, 4956. https://doi.org/10.3390/app15094956

Altaher O, Hasse K, Suntsov S, Tanaka H, Kränkel C, Bányász I, Mikšová R, Kip D. Ion-Implanted Diamond Blade Diced Ridge Waveguides in Pr:YLF—Optical Characterization and Small-Signal Gain Measurement. Applied Sciences. 2025; 15(9):4956. https://doi.org/10.3390/app15094956

Chicago/Turabian StyleAltaher, Omer, Kore Hasse, Sergiy Suntsov, Hiroki Tanaka, Christian Kränkel, Istvan Bányász, Romana Mikšová, and Detlef Kip. 2025. "Ion-Implanted Diamond Blade Diced Ridge Waveguides in Pr:YLF—Optical Characterization and Small-Signal Gain Measurement" Applied Sciences 15, no. 9: 4956. https://doi.org/10.3390/app15094956

APA StyleAltaher, O., Hasse, K., Suntsov, S., Tanaka, H., Kränkel, C., Bányász, I., Mikšová, R., & Kip, D. (2025). Ion-Implanted Diamond Blade Diced Ridge Waveguides in Pr:YLF—Optical Characterization and Small-Signal Gain Measurement. Applied Sciences, 15(9), 4956. https://doi.org/10.3390/app15094956