Abstract

Fermentation temperature plays a critical role in defining the chemical and sensory characteristics of wine. This study evaluates the thermal distribution and energy consumption of two fermentation techniques, Sequential Air-Modulated Injection System (AMI system) and pumping-over, during Syrah must fermentation. Temperature measurements at different depths of the fermentation tanks revealed that the AMI system maintained a more homogeneous thermal profile, reducing temperature gradients that could affect yeast metabolism. In contrast, the pumping-over system exhibited greater temperature fluctuations, potentially impacting fermentation kinetics. Energy consumption analysis showed that the AMI system required less external cooling, leading to lower energy demands compared to the pumping-over system. These results suggest that the AMI system offers advantages in terms of energy efficiency and temperature management, making it a viable alternative for sustainable winemaking. The findings highlight the need for optimized fermentation strategies to balance thermal control and energy use, ultimately improving wine quality.

1. State of the Art

In recent years, the carbon footprint has become an increasingly important topic in the context of production systems in the wine industry [1]. Aspects such as climate impact, energy efficiency, the use of chemicals, and the quality of our diet are closely linked to the challenges of globalization. In general, energy efficiency is actively pursued on a global scale [2,3]. Sustainability in the wine sector encompasses various aspects, including certification, responsible water and soil use, the climate impact of production, energy efficiency throughout the supply chain, limitations on chemical use, and waste management [4]. Improving energy efficiency is a fundamental goal to reduce costs and the environmental impact in wineries [5,6]. Scientific studies have explored solutions such as CO2 production control, water management, the use of renewable energy sources [7,8,9], different bottling technologies and materials [10,11], and the adoption of good winemaking practices [12].

Optimizing energy efficiency in wineries involves factors such as monitoring machines and production lines, temperature control, thermal vector management, production technology, and energy self-generation and recovery [13]. Colombié et al. (2007) [14] developed a mathematical model to simulate the thermal behavior of must during fermentation and, indirectly, assess the energy required to cool the must [14,15]. Other researchers have developed models to simulate system operation [16,17,18] and must thermal behavior, aiming to optimize energy used for cooling [19]. However, their practical application remains limited. The success of red wine production is closely related to the extraction of compounds from grape skins and the regular digestion of sugars by yeasts. Color and tannin structure are key factors defining red wine quality [20]. These depend on various factors, including changes in the must during fermentation and tank properties, such as geometry, construction material, cooling system, and winery location. Winery design and improvement measures can contribute to energy savings and reduced CO2 emissions. The strategic layout of processing areas, using gravity for transfers and reducing fermenters’ sun exposure, can lead to significant energy savings [21]. Genc et al. (2017) [5] conducted an energy analysis of a red wine production line and defined energy destruction rates to evaluate sustainability. The system’s thermal efficiency was 57.2%, while its energy efficiency was 41.8%. The overall energy destruction rate increased with both grape flow rate and fermentation temperature. Alcoholic fermentation is not uniform across the tank, as yeasts are more abundant in the cap. It is also crucial to avoid the excessive extraction of astringent or bitter tannins or the formation of undesirable compounds. Proper cap dispersion prevents solidification that can promote aerobic microorganisms responsible for acetic acid production. Breaking up the grape skins also helps homogenize the temperature in the vessel, ensuring optimal fermentation. During tumultuous red wine fermentation, the must circulation system within the cap greatly influences winemaking performance qualitatively, functionally, energetically, and economically [22]. In 2020, Mencarelli studied the “disruptive wave” effect in fermentation tanks generated by innovative AMI system [23]. These systems use modulated air jets injected through nozzles in precise sequences to create a wave that breaks up the cap, enhancing extraction. This induces the agitation, flooding, and immersion of the cap, reducing thermal gradients and increasing the release of antioxidant, aromatic, and coloring compounds. An experiment conducted in Spain [24,25] on Tempranillo grapes during the 2014 harvest in 1500 hL tanks compared extractions using air jets with those obtained through pumping-over and délestage. Fermentation with disruptive waves led to a 17–21% increase in the color intensity and more efficient early extraction, an advantage for wineries needing to shorten maceration times. Catalano et al. (2023) [22] compared the energy and functional performance of two must circulation systems during red wine fermentation with crushed Primitivo grapes, known for thin skins and used for ready-to-drink wines. The study compared an AMI system with a traditional pumping-over system. The air-based cap-breaking system proved suitable for rapid, low-cost wine production while maintaining essential oenological traits. Reported advantages included production and fermentation speed and significantly reduced energy use throughout the process. The resulting wines showed similar physicochemical characteristics to those from the traditional method [26,27,28]. Moreover, short-term aeration in wine fermentation is nevertheless a possible means of improving the yeast metabolism, aromatic diversity, and quality of the wine [29]. In particular, Giametta et al. (2024) [26] performed similar evaluations on crushed Negramaro grapes, which have among the thickest skins of Apulian cultivars. The results were consistent with those obtained with Primitivo grapes [22]. Analytical and functional parameters were similar; notably, racking was possible 16 h earlier with the Air-Modulated Injection System. For musts with thick skins, energy consumption was lower during phases dominated by the liquid phase, where traditional fermentation was disadvantaged. No substantial energy differences were observed during the pressing phase. This study extended the comparison between the traditional and AMI system to crushed Syrah grapes, which have “moderately consistent” skins among Apulian cultivars not as thick as Negramaro but not as thin as Primitivo. This research aimed to assess thermal variations in large-capacity fermenters and differences in temperature stabilization speed during pumping-overs or cap-breaking interventions. It also compared energy consumption during fermentation and racking, vinification times, and the main analytical characteristics of the wines. These aspects are particularly relevant in wine production, where fermentation regularity, tank thermal conditioning, and the rapid attainment of key parameters are essential. This study presents an experimental comparison of the AIRMIXING M.I. system and the traditional system from both energy and functional perspectives during the red wine fermentation of crushed Syrah grapes.

2. Materials and Methods

2.1. Studied Plants

The experimental trials were conducted at Cantine Paolo Leo, located in San Donaci (BR) (Figure 1), on a red winemaking line processing Syrah grape.

Figure 1.

Paololeo Winery, San Donaci (BR), site of the experiment.

The characteristics of the receiving and winemaking line used are reported in Table 1.

Table 1.

Main characteristics of the vinification line related to tanks 11A and 21A.

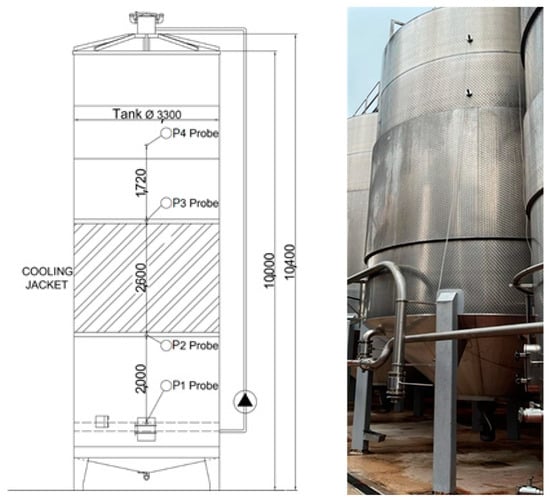

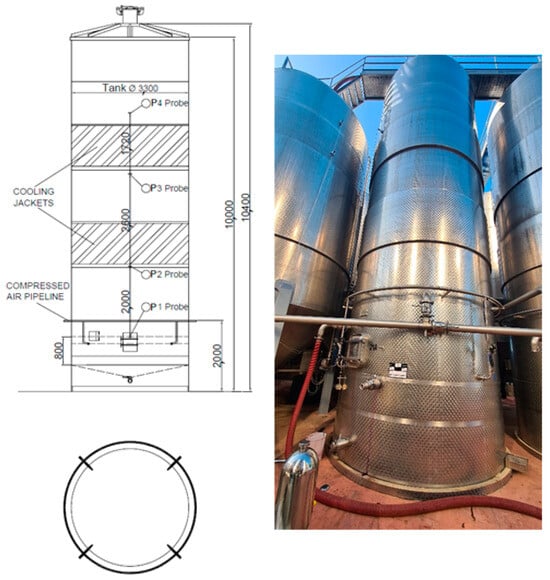

Two stainless-steel fermenters, made of AISI 304 and 316 for parts in contact with the product, were used. These fermenters were identical in model and capacity, both equipped with the same heat exchange surface for circulating the cooling solution produced in the chiller (Table 1; Figure 2 and Figure 3). However, they were equipped with different cap-breaking systems: Fermenter 11A was fitted with a traditional cap irrigation system for pumping-over and a single cooling jacket (Table 1; Figure 2). Fermenter 21A had two cooling jackets and was equipped with the AIRMIXING M.I.® system, patented by Parsec S.r.l. (Sesto Fiorentino, FI, Italy), for cap-breaking (Table 1; Figure 3).

Figure 2.

Fermenter tank 11A (pumping-over system) with probe placement.

Figure 3.

Fermenter tank 21A (Air-Modulated Injection System) with the circular compressed air pipeline and probe placement.

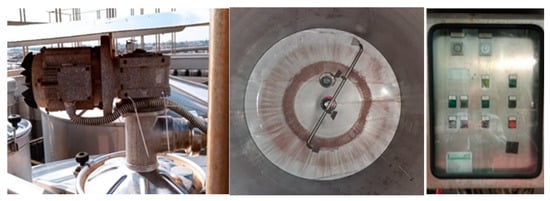

In Fermenter 21A, a circular conduit was installed around the external lateral surface, at 2.0 m from the base and connected to the centralized compressed air network. From this conduit, four radial pipes, each 50.0 cm long, extended into the tank, terminating in four injection nozzles (Figure 3 and Figure 4; Table 1).

Figure 4.

Fermenter tank 21A: external compressed air pipeline (left) and internal view of an air injection nozzle (right).

Each nozzle was equipped with a fast-opening valve, designed to open and close sequentially relative to the others. The opening times corresponded to a few hundred milliseconds, following predetermined combinations.

Compressed air (4–6 bar) was injected through each nozzle, following a specific pulse sequence that generated waves. This, in turn, caused the must to agitate and the cap to break up. The program allowed for 15 extraction levels, each characterized by a precise pulse sequence and a defined volume of injected air.

The pumping-over system of Fermenter 11A consisted of a recessed impeller electric pump, an external pipe, and a diffuser equipped with a gear motor and an inverter, which irrigated the cap (Figure 2, Figure 3, Figure 4 and Figure 5; Table 1).

Figure 5.

Fermenter tank No. 11A (traditional system). (Left): recessed impeller centrifugal pump; (center): diffuser unit; (right): control panel.

2.2. Experimental Trials

The trials on fermenter A21 were conducted by shutting down all other compressed air users to evaluate the actual power consumption of the compressor throughout the process. Four extraction levels of compressed air were tested multiple times during fermentation: Extraction level 4, corresponding to an air flow rate of 1.1 m3/cycle; extraction level 7, corresponding to an air flow rate of 2.1 m3/cycle; and extraction level 8, corresponding to an air flow rate of 2.8 m3/cycle.

The air injection program was structured into three phases: a series of injections every 3 h for the first 3.5 days; a series of injections every 4 h for 1 day; and a series of injections every 6 h until the end of fermentation, for a total duration of 9 days. The compressor operated autonomously to maintain the air pressure in the tank within the 4–6 bar range.

For fermenter A11, the pumping-over program was structured into three phases: a pumping-over cycle lasting 15–20 min every 3–4 h during the first 6 days, and a pumping-over cycle lasting 10–12 min every 8 h until the end of fermentation, for a total duration of 10 days.

The following functional parameters were determined:

- Temperature variations inside the fermenters;

- Energy consumption of the equipment used in each cap management process;

- Total fermentation time.

Each fermenter was equipped with four temperature probes at different heights: probe P1 at 1.5 m from the bottom (Figure 2 and Figure 3); probe P2 at 3.6 m from the bottom, located under the cooling jacket in fermenter A11 (Figure 2) and under the lower cooling jacket in fermenter A21 (Figure 3); probe P3 at 5.4 m from the bottom, located above the cooling jacket in fermenter A11 (Figure 2) and under the upper cooling jacket in fermenter A21 (Figure 3); and probe P4 at 8.2 m from the bottom, immersed in the grape cap (Figure 6).

The evolution of fermentation temperatures inside each fermenter was monitored using the SAEn5000 Parsec platform, a multifunctional, multiprocessor system designed for enological process control.

To measure the active electrical power absorbed by the motors of the machines, a Power Quality Meter & Analyzer with data logger function (YOKOGAWA, model CW121) was used. This instrument allows the measurement of energy consumption for both single-phase and three-phase loads, considering the potential load imbalance on each phase. The measurements were conducted by inserting the instrument’s connections into the electrical line between the control panel and the motor of the target machine (Figure 7), while also recording the actual operating time.

Figure 7.

Energy consumption-measuring instrument used for data acquisition.

During the monitoring period, the energy consumption of the pumping-over system (pump and irrigator) and the winery’s air compressor were recorded. Since the winery operates a centralized compressed air system, all other compressed air users were disabled during the compressor consumption measurements, leaving only fermenter A21 active. The actual operating time of the machine was recorded.

Knowing the volume of air delivered at each extraction level in fermenter A21, the total air consumption was determined by considering the number of cycles performed at each extraction level.

2.3. Qualitative Analysis

Both fermenters were filled with 700 q of destemmed Syrah grapes from the same batch. The fermentation process in fermenter 11A (pumping-over system) began on 28 September, while in fermenter 21A (AMI system), it started on 25 September.

Samples of fermenting must be collected at three key points: at the beginning of fermentation; at mid-fermentation; and before racking.

For each sample, the following analyses were performed: ethanol content (% Vol.); total acidity (g/L); pH; optical density (620 nm); and color hue.

The analytical assessments were conducted using WineScan™ SO2 (FOSS). For the evaluation of quality parameters in the must samples, statistical analysis was performed using Statistics 12.0 software (StatSoft Inc., Tulsa, OK, USA). A variance analysis (ANOVA) was carried out and the results were compared using Tukey’s multiple range test with a significance level of α = 0.05 [13].

3. Results

3.1. Temperature Analysis

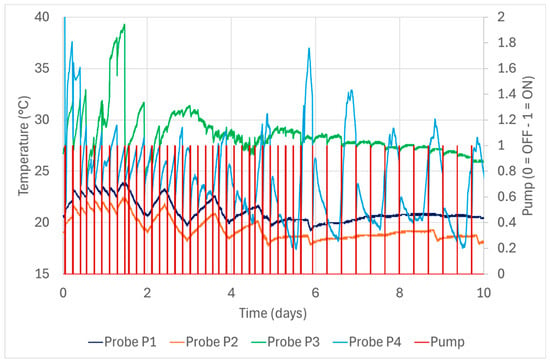

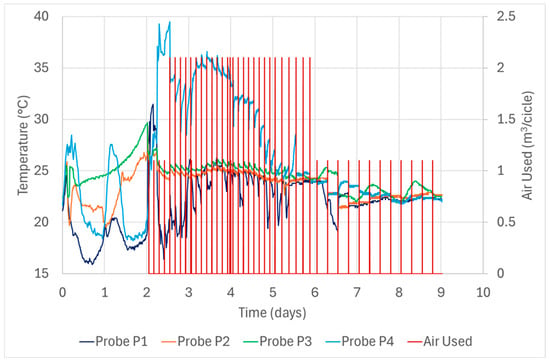

Figure 8 and Figure 9 illustrate the temporal trends of temperatures at different measurement points for the fermenter equipped with the traditional pumping-over system and the fermenter with the AMI system, respectively, along with the intervention times of the pump–diffuser unit. In both cases, probes P1, P2, and P4 are positioned at the must sampling/injection point, at the lowest point of the cooling jackets, and in the cap of grape marc, respectively, while probe P3 is located at the height of the cooling jackets, specifically at the highest point of the cooling jacket in tank A11 (traditional system) and at the lowest point of the second (upper) cooling jacket in tank A21 (AMI system).

Figure 8.

Temperature trends over time in tank 11A (pumping-over system).

Figure 9.

Temperature trends over time in tank 21A (Air-Modulated Injection System).

Considering that the cooling jackets are supplied with cold glycolate water through a ring system maintaining an almost constant temperature over time and between the two tanks, probe P3 does not register significant differences due to the different jacket arrangement, as the space between the two jackets in tank 21A is minimal.

It can be observed that the traditional system completed fermentation with maceration of the grape marc over a total period of 10 days, during which the pumping-over system operated at regular intervals. This system was able to maintain relatively uniform must temperatures, with approximately 21 °C recorded by probe P1 and around 19 °C by probe P2 (Figure 8) during the final four days of fermentation, when the pumping-over interventions occurred at intervals slightly exceeding 8 h.

In contrast, during the first six days, both temperature profiles exhibited oscillations of approximately 3 °C, with overall fluctuation ranges of 19.2–23.9 °C and 17.7–22.5 °C for probes P1 and P2, respectively, despite the average interval between successive pumping-overs being around 3.5 h. This behavior is certainly linked to the temperature fluctuations both in the must near the cooling jacket and in the grape marc cap, as indicated by probes P3 and P4, which registered variations exceeding 10 °C, with peak values exceeding 35 °C in the early days.

Subsequently, while the cap temperature was cyclically and rapidly reduced due to the diffusion of cooled must drained at the temperature indicated by probe P1, the temperature of the must in the upper section, despite gradually decreasing over time, did not drop below 26 °C until the end of the process. Specifically, during the resting periods of the cap, its temperature (averaging around 28 °C) tended to increase due to the exothermic reactions of fermentation and was only reduced during the pumping-over interventions.

The thermal gradient between the bottom of the fermentation tank and the cap remained high, even during the last six days of the process and the pumping-over system was unable to enhance convective movements effectively. Therefore, these findings confirm that, in the tank utilizing the pumping-over system, the region most subjected to thermal stress is the area near the grape marc cap. This limitation may influence all parameters affected by inadequate mixing.

The fermentation process using the AMI system was completed in 9 days, 1 day less than the traditional system. During the first two days, the cap formation phase took place. In this case, a greater uniformity of temperatures was observed throughout the process, especially in the final days. This uniformity is likely due to the more effective action of the AMI system compared to the traditional one. The AMI system operates by sequentially injecting modulated air into the lower part of the fermentation tank, generating bubbles and liquid waves that induce both vertical convective movements within the must and the disintegration of the cap.

During the first four days of operation of the AMI system, only the must temperature at the bottom of the fermentation tank exhibited wider fluctuations, within the range of 17–25 °C (Figure 9), likely due to the short interval of only 3 h between successive interventions. In contrast, during the last three days of fermentation, the interval was extended to 6 h, which is still more frequent than in the final days of the process using the traditional system. In this case, only minor temperature fluctuations were observed during this final phase, always with a slight temperature reduction coinciding with each intervention of the Air-Modulated Injection System, but significantly lower than the fluctuations recorded with the traditional system.

Overall, it can be stated that in the tank equipped with the AMI system, after an initial period of temperature fluctuations, the temperature remained stable throughout fermentation. After the fifth day, the AMI system interventions no longer caused abrupt temperature variations (Figure 9). Therefore, the AMI system ensures better and more effective temperature homogenization during vinification across the entire must volume, while also reducing thermal fluctuations and stresses. This facilitates smooth progression of alcoholic fermentation.

The above result is particularly significant considering that it was achieved in a high-capacity fermenter, where water and energy consumption for mass conditioning using traditional systems can be substantial. This is especially relevant for wineries in Southern Italy, where such costs can significantly impact the final product price and the market competitiveness of both high-quality and ready-to-drink wines.

3.2. Energy Consumption

Tank A11 (traditional) operated for a total of 32 pumping-over cycles during the first 6 days of the process, with an overall pumping-over system operating time of 9.2 h. Additionally, it performed 12 pumping-over cycles with a total duration of 2.3 h. In both cases, the power consumption remained nearly constant at approximately 2.85 kW for the pump and 0.65 kW for the spreader.

In tank A21, the AMI system was activated 26 times during the first 4 days and 16 times in the final phase, resulting in total compressor operating times of 18.8 min and 5.1 min, respectively, with a nearly constant power consumption of approximately 28.7 kW.

Table 2 summarizes the energy consumption for the two systems: the traditional pumping-over system and the AMI system.

Table 2.

Energy and functional parameters of the two vinification lines.

These findings are confirmed by the results related to energy consumption. In fact, in the AMI system, the electricity consumption of the centralized compressor during fermentation is 11.4 kWh, which is approximately 25% of the energy consumption of the pumping-over unit: 40.3 kWh (Table 2). This is due to the methodology adopted for breaking the cap in the AMI system, where only 23.9 min of compressor operation were sufficient to disintegrate a solid mass that, in an 800 hL fermenter, can exceed a thickness of 1.5 m. Therefore, the installed system does not suffer from the use of an oversized machine for its operation, as its interventions are limited to very short periods.

These results are consistent with those obtained in previous studies conducted on Negramaro and Primitivo grapes [22,26], which have skins with different consistency compared to the Syrah cultivar. They tend to confirm that, even with caps composed of skins of intermediate consistency, the AMI system proves to be more efficient and sustainable than the traditional pumping-over system, with energy consumption nearly four-times lower and, consequently, with a lower environmental impact.

In terms of energy consumption, the AMI system proves to be superior to the pumping-over system, consuming nearly four-times-less energy. This, in turn, leads to a lower environmental impact.

3.3. Must Quality

Table 3 shows the values of representative parameters of alcoholic fermentation and winemaking functionality for fermenters 11A and 21A.

Table 3.

Analytical evaluations of the crushed grapes in fermenters equipped with the different circulation systems studied.

Volatile acidity, starting from the third day of vinification (Table 3), tends to increase in the fermenting must with the traditional system (11A), reaching a final value of 0.35 g/L acetic acid. This is 14% higher than the final value observed in the must drained from the tank equipped with the Air-Modulated Injection System (21A), which recorded a final value of 0.3 g/L acetic acid. From a qualitative standpoint, a lower volatile acidity enhances the characteristics of the resulting wine and contributes to the formation of the red wine bouquet, both in terms of aroma and palate.

Although the grapes processed belonged to the same batch, the initial sugar content of the two musts on the second day was slightly different: 190.0 g/L for tank 11A and 160.0 g/L for tank 21A. However, by the end of fermentation, the sugar-to-alcohol conversion in the must–wine from tank 21A was more complete, with a final alcohol volume of 13.7% vol compared to 13.5% vol in the must–wine from tank 11A. Additionally, it should be noted that the yeasts used in the must fermented with the traditional system benefited from a preliminary treatment with Diammonium Phosphate (DAP) as an activator, unlike those in the AMI system. This further confirms that sugar conversion was more efficient in tank 21A.

This difference in microbial activity may also be attributed to the different must–wine movement systems in the solid phase within the two tanks studied. The convective motions generated by waves formed through air injections enabled better leveling of thermal gradients, as well as improved sugar distribution throughout the fermenting mass, thereby creating an optimal living environment for the yeasts [27].

Other monitored analytical parameters, such as total acidity, pH, and color intensity, did not show significant differences at the end of vinification. Additionally, both systems were treated with 20 g/q of SO2, 1 g/q of enzyme and 10 g/q of tannin. However, it is important to note that, in the fermenter equipped with the AMI system, all measured analytical parameters were reached at least 24 h earlier than in the traditional system (Table 3).

These results, obtained from crushed Syrah grapes characterized by thin skins, align with the findings from studies conducted on other Apulian cultivars with particularly thin or thick skins [22,26].

4. Conclusions

In this study, thermal, energy, and analytical performance were evaluated in two identical fermenters, where the only variable in red winemaking was the cap management system: pumping-overs or Air-Modulated Injection cap-breaking. It is an innovative solution that has been proposed for several years and by several companies at the industrial level as an alternative to traditional pumping-over. The effects of this technique on energy consumption and on the distribution of temperatures during the tumultuous fermentation of grapes with different skin consistency have not been sufficiently studied. The experimentation was carried out on a full-scale plant in industrial working conditions, and all the results are transferable to an industrial level at least for the grapes used in these experimental trials.

Fermentation was completed in ten days in the tank using a pumping-over system, whereas the Air-Modulated Injection cap-breaking system resulted in a shorter fermentation duration of nine days, indicating improved efficiency. Energy consumption during fermentation differed significantly between the two methods. The AMI system required 11.4 kWh, more than four-times lower than the 40.3 kWh consumed by the pumping-over system. This substantial reduction underscores the superior energy efficiency of Air-Modulated Injection cap-breaking, making it a more sustainable and cost-effective approach for winemaking.

From an analytical standpoint, the pumping-over system proved effective in enhancing yeast activity and promoting color extraction, particularly for grape varieties with thinner or less-consistent skin. However, the wines obtained using the AMI system exhibited physicochemical characteristics that were comparable to, or in some cases superior to, those produced through pumping-overs. This positive outcome is further reinforced by the favorable thermal, energy, and functional performance of the AMI system.

This study highlights the importance of integrating energy assessments into winemaking processes to ensure efficiency without compromising product quality. By optimizing energy consumption, wineries can enhance sustainability while maintaining competitiveness in the market. These findings suggest that energy efficiency should be regarded as a key factor in the production of high-quality wines at accessible costs.

Author Contributions

Conceptualization, F.G., F.C., G.T. and B.B.; methodology, F.G. and B.B.; software, F.C.; validation, B.B., G.T. and F.C.; formal analysis, F.G., F.C. and B.B.; investigation, F.C., G.T.; data curation, F.G., G.T. and B.B.; writing—original draft, F.C., G.T. and B.B.; writing—review and editing, F.G. and B.B.; visualization, G.T. and F.C.; supervision, F.G. and B.B.; funding acquisition, F.G. and B.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding authors.

Acknowledgments

We would like to thank Cantine PaoloLeo s.r.l. (San Donaci, (BR)), represented by the Administrator, Paolo Leo, for allowing the experimentation to take place, and Oenologist Nicola Leo for providing access to the laboratory and collaborating in conducting chemical analyses during the vinification process. We also extend our gratitude to Giuseppe Floridia (PARSEC s.r.l., Florence) for his contribution to the development of the measurement chains and the monitoring of the data during the vinification process.

Conflicts of Interest

Author Filippo Catalano is a partner of the company CTS s.r.l.-Spin-Off, Department of Agriculture, Environment and Food, University of Molise. All the authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Baiano, A. An Overview on Sustainability in the Wine Production Chain. Beverages 2021, 7, 15. [Google Scholar] [CrossRef]

- Garwood, T.L.; Hughes, B.R.; Oates, M.R.; O’Connor, D.; Hughes, R. A Review of Energy Simulation Tools for the Manufacturing Sector. Renew. Sustain. Energy Rev. 2018, 81, 895–911. [Google Scholar] [CrossRef]

- Tamborrino, A.; Catalano, F.; Berardi, A.; Bianchi, B. New Modelling Approach for the Energy and Steam Consumption Evaluation in a Fresh Pasta Industry. Chem. Eng. Trans. 2021, 87, 409–414. [Google Scholar] [CrossRef]

- Tamborrino, A.; Perone, C.; Catalano, F.; Squeo, G.; Caponio, F.; Bianchi, B. Modelling Energy Consumption and Energy-Saving in High-Quality Olive Oil Decanter Centrifuge: Numerical Study and Experimental Validation. Energies 2019, 12, 2592. [Google Scholar] [CrossRef]

- Genc, M.; Genc, S.; Goksungur, Y. Exergy analysis of wine production: Red wine production process as a case study. Appl. Therm. Eng. 2017, 117, 511–521. [Google Scholar] [CrossRef]

- Perone, C.; Bianchi, B.; Catalano, F.; Orsino, M. Experimental Evaluation of Functional and Energy Performance of Pneumatic Oenological Presses for High Quality White Wines. Sustainability 2022, 14, 8033. [Google Scholar] [CrossRef]

- Catalano, F.; Perone, C.; Iannacci, V.; Leone, A.; Tamborrino, A.; Bianchi, B. Energetic analysis and optimal design of a CHP plant in a frozen food processing factory through a dynamical simulation model. Energy Convers. Manag. 2020, 225, 113444. [Google Scholar] [CrossRef]

- Kasaeian, A.; Nouri, G.; Ranjbaran, P.; Wen, D. Solar collectors and photovoltaics as combined heat and power systems: A critical review. Energy Convers. Manag. 2018, 156, 688–705. [Google Scholar] [CrossRef]

- Malvoni, M.; Congedo, P.M.; Laforgia, D. Analysis of Energy Consumption: A Case Study of an Italian Winery. Energy Procedia 2017, 126, 227–233. [Google Scholar] [CrossRef]

- Manan, Z.A.; Mohd Nawi, W.N.R.; Wan Alwi, S.R.; Klemeš, J.J. Advances in Process Integration research for CO2 emission reduction—A review. J. Clean. Prod. 2017, 167, 1–13. [Google Scholar] [CrossRef]

- Kubule, A.; Zogla, L.; Ikaunieks, J.; Rosa, M. Highlights on Energy Efficiency Improvements: A Case of a Small Brewery. J. Clean. Prod. 2016, 138, 275–286. [Google Scholar] [CrossRef]

- Carillo, M.; Formato, A.; Fabiani, A.; Scaglione, G.; Pucillo, G.P. An inertizing and cooling process for grapes cryomaceration. Electron. J. Biotechnol. 2011, 14. Available online: https://www.ejbiotechnology.info/index.php/ejbiotechnology/article/view/v14n6-10 (accessed on 18 March 2025). [CrossRef]

- Catalano, F.; Bianchi, B.; Berardi, A.; Leone, A.; Tamborrino, A. Experimental Trials and Dynamical Simulation of the Potential Biogas Production in a Frozen Food Industry. Chem. Eng. Trans. 2021, 87, 295–300. [Google Scholar] [CrossRef]

- Colombié, S.; Malherbe, S.; Sablayrolles, J.M. Modeling of Heat Transfer in Tanks during Wine-Making Fermentation. Food Control 2007, 18, 953–960. [Google Scholar] [CrossRef]

- Bianchi, B.; Molino, B.; Catalano, F.; Giametta, F.; Molino, A.J. A Novel Approach to Optimize the Industrial Process of Membrane Concentration of Grape Musts. Chem. Eng. 2023, 7, 48. [Google Scholar] [CrossRef]

- Bianchi, B.; Catalano, F.; Oliveto, R.; Ricciardi, R. Dynamic simulation driven design and management of production facilities in agricultural/food industry. Acta Hortic. 2019, 1311, 241–248. [Google Scholar] [CrossRef]

- Catalano, F.; Diaz, M.; Romaniello, R.; Semeraro, G.; Pirlo, G. Interconnected Systems Modelling in Food Industry: General Solution Scheme and Stability Conditions for Linear Time-Invariant Systems. Appl. Sci. 2023, 13, 5740. [Google Scholar] [CrossRef]

- Catalano, F.; Leone, A.; Bianchi, B.; Tamborrino, A. A New Tool for Food Industrial Plant Simulation and IoT Control. Chem. Eng. Trans. 2021, 87, 367–372. [Google Scholar] [CrossRef]

- Le Roux, J.M.W.; Purchas, K.; Nell, B. Refrigeration Requirements for Precooling and Fermentation Control in Wine Making. S. Afr. J. Enol. Vitic. 2017, 7, 6–13. [Google Scholar] [CrossRef][Green Version]

- Glories, Y. Recherches Sur La Matiere Colorant Des Vins Rouges. Ph.D. Thesis, Université de Bordeaux II, Bordeaux, France, 1978. [Google Scholar]

- Mainardis, M.; Gubiani, R. Energy Use and Management in the Winery. In Improving Sustainable Viticulture and Winemaking Practices; Elsevier: Amsterdam, The Netherlands, 2022; pp. 221–238. [Google Scholar] [CrossRef]

- Catalano, F.; Romaniello, R.; Orsino, M.; Perone, C.; Bianchi, B.; Giametta, F. Experimental Tests in Production of Ready-to-Drink Primitive Wine with Different Modes of Circulation of the Fermenting Must. Appl. Sci. 2023, 13, 5941. [Google Scholar] [CrossRef]

- Mencarelli, F. L’effetto ad onde disgreganti. VVQ Vigne Vini Qual. 2020, 5, 14–17. (In Italian) [Google Scholar]

- Pettinelli, S.; Pardini, L.; De Angeli, G.; Bianchi, A.; Najar, B.; Cerreta, R.; Bellincontro, A.; Floridia, G.; Mencarelli, F. Innovative “Soft” Maceration Techniques in Red Grape Fermentation. Beverages 2022, 8, 62. [Google Scholar] [CrossRef]

- Guerrini, S.; Barbato, D.; Mangani, S.; Mari, E.; Buscioni, G.; Ganucci, D.; Galli, V.; Granchi, L. Utilization of the AIRMIXING M.I.™ System in Producing RedWine without Added Sulphites. Fermentation 2023, 9, 812. [Google Scholar] [CrossRef]

- Giametta, F.; Catalano, F.; Perone, C.; Bianchi, B. Energetic Comparison between Pneumatic and Traditional Disintegration in the Vinification of Negroamaro Grapes. Sustainability 2024, 16, 4360. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Dubourdieu, D.; Lonvaud, A.; Donèche, B. Handbook of Enology Volume 1: The Microbiology of Wine and Vinifications, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; ISBN 0-470-01034-7. [Google Scholar]

- De Vita, P.; De Vita, G. Manuale Di Meccanica Enologica: Richiami Di Fisica, Saldature, Cantina, Vasi Vinari, Vendemmia, Ammostatura, Chiarifica, Vinificatori, Filtri, Impianti Solari, per Concentrazione Mosti, Elettrici, Di Refrigerazione, Di Pastorizzazione, per Spumanti, Di Imbottigliamento, Distillazione, Depurazione, Pompe, Normative Specifiche; Hoepli: Milan, Italy, 2011. [Google Scholar]

- Yana, P.; Zhang, B.; Joseph, L.; Waterhouse, A.L. Effects of initial oxygenation on chemical and aromatic composition of wine in mixed starters of Hanseniaspora vineae and Saccharomyces cerevisiae. Food Microbiol. 2020, 90, 103460. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).