A Review of Failures and Malfunctions in Hydraulic Sandblasting Perforation Guns

Abstract

1. Introduction

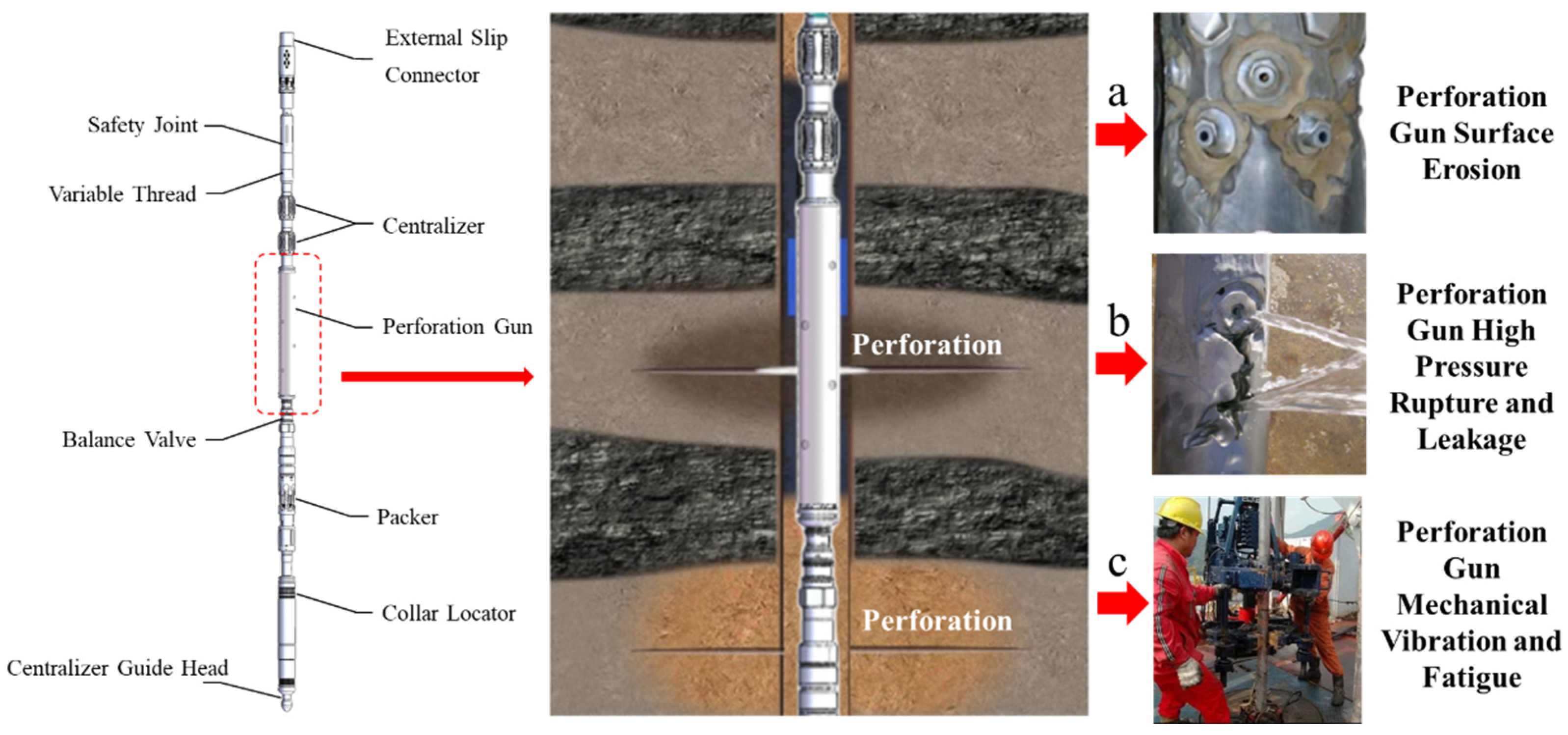

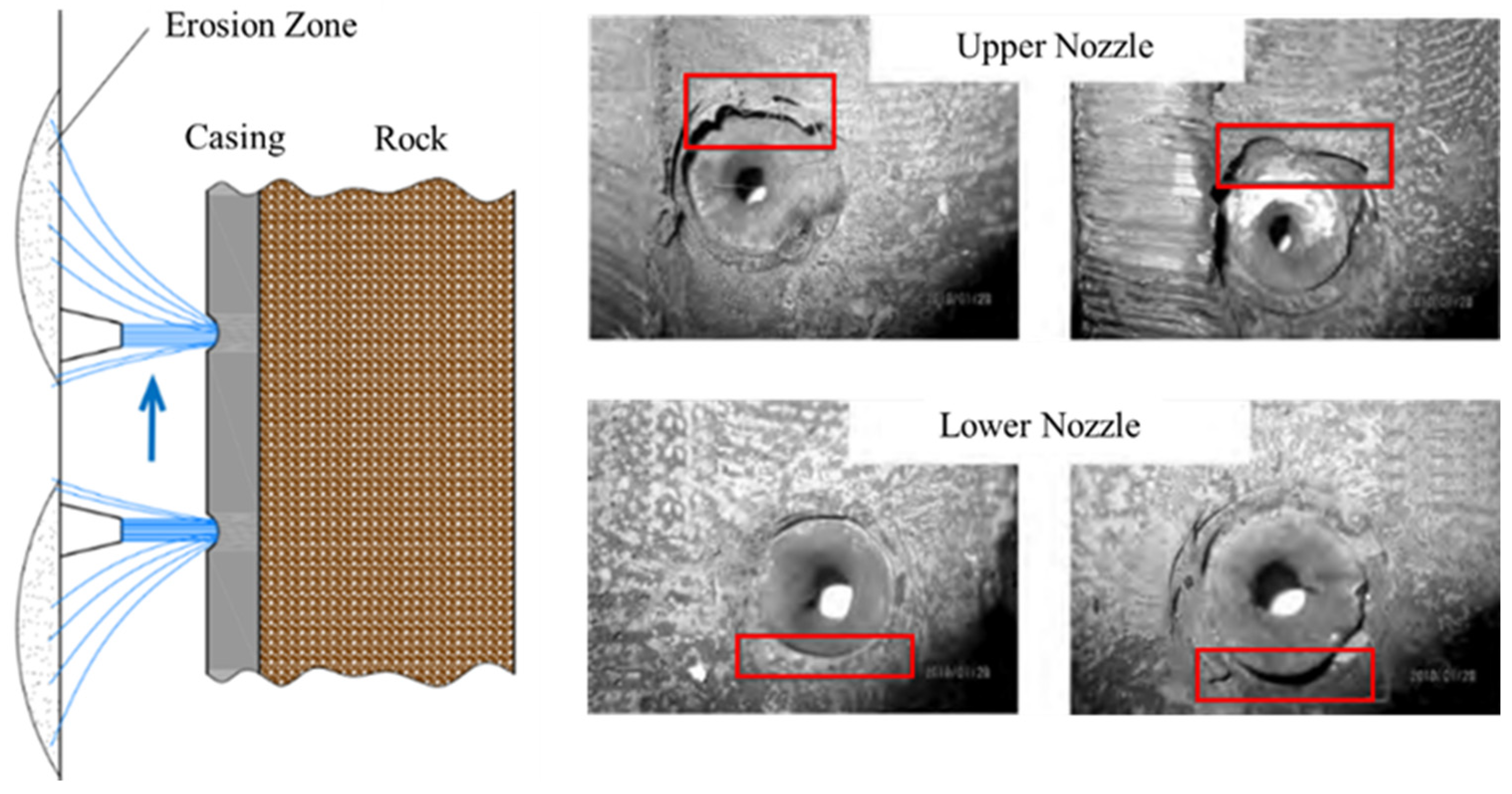

2. Erosion Wear of the Perforation Gun

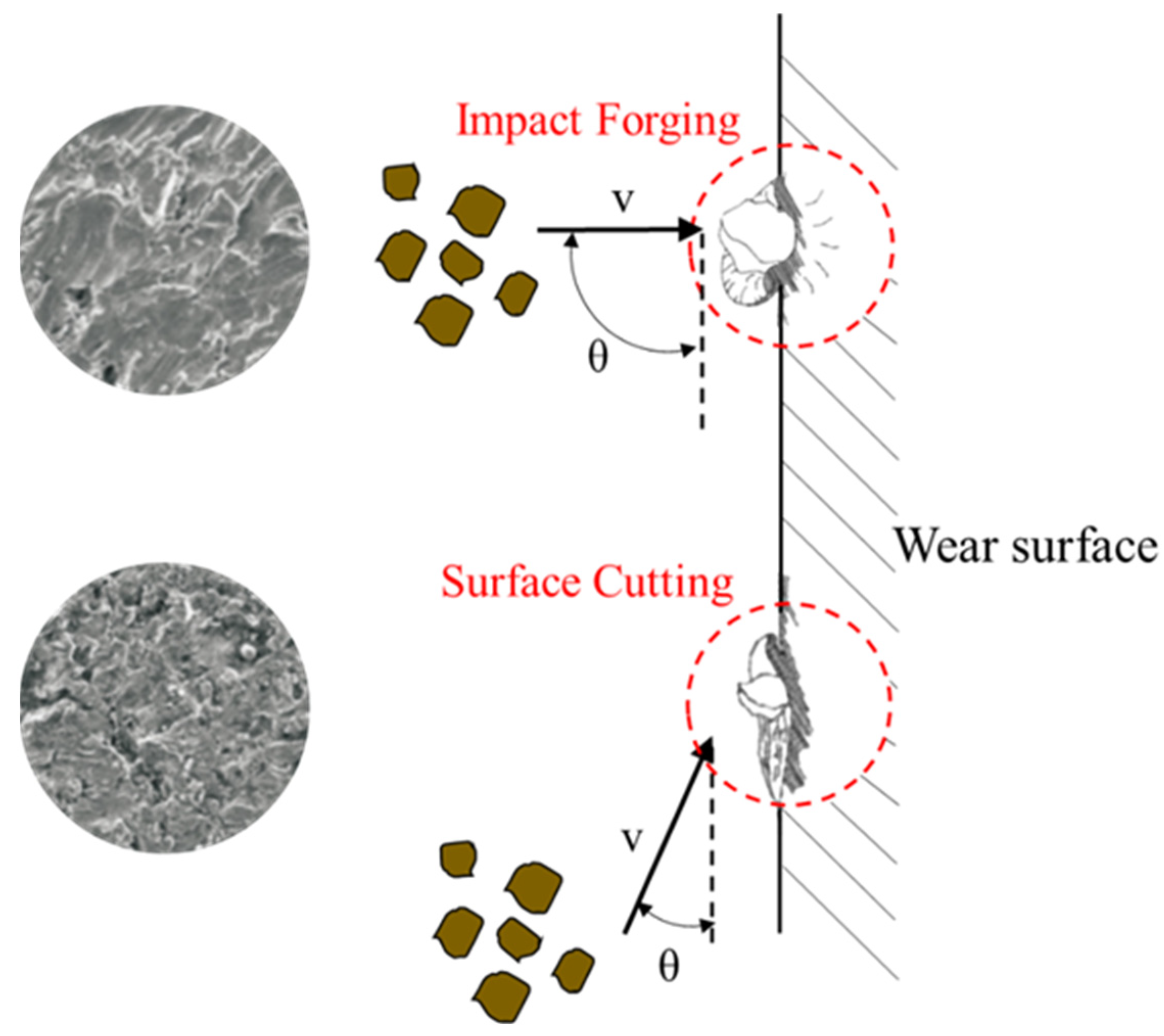

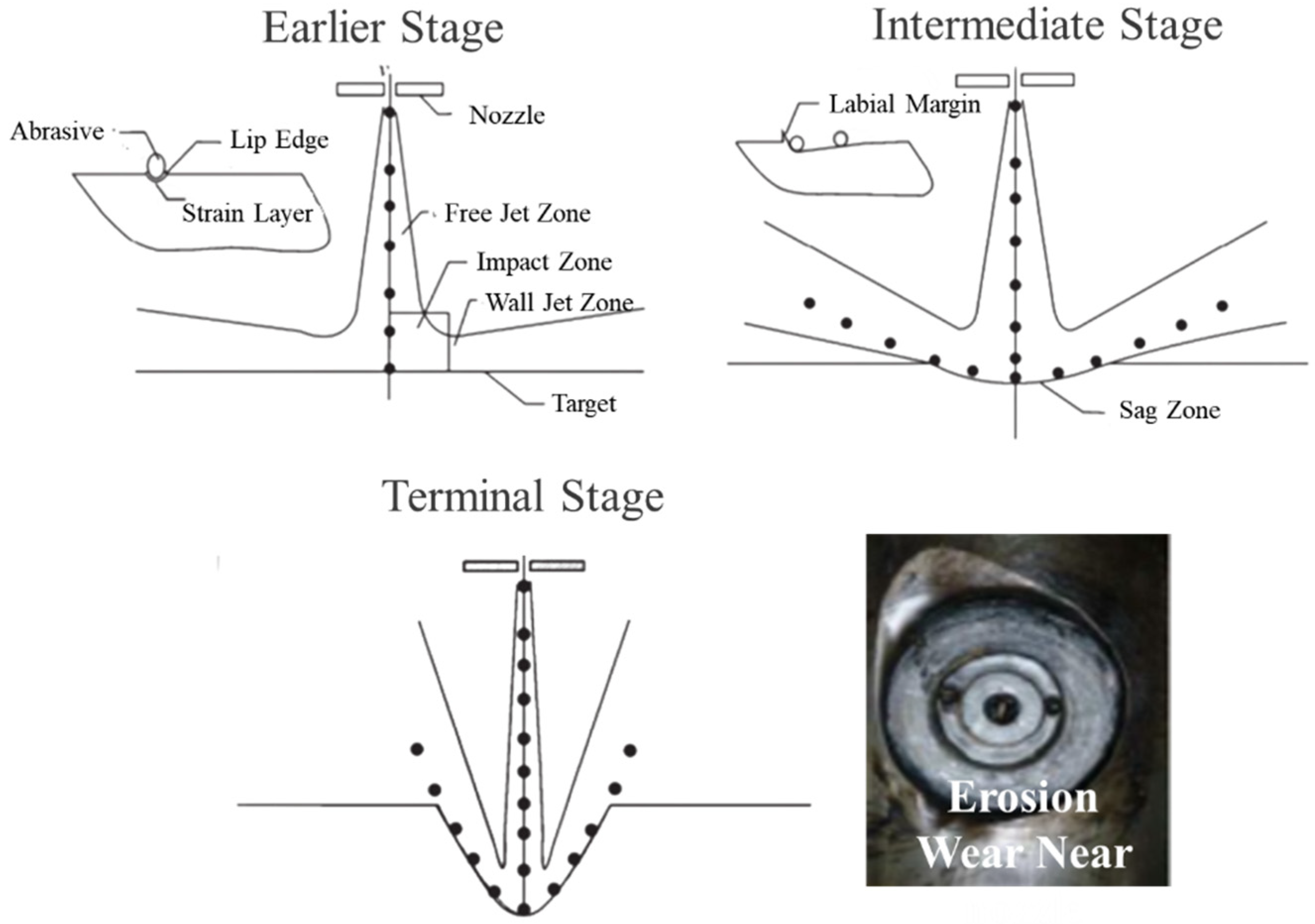

2.1. Erosion Wear Mechanisms on the Gun Surface

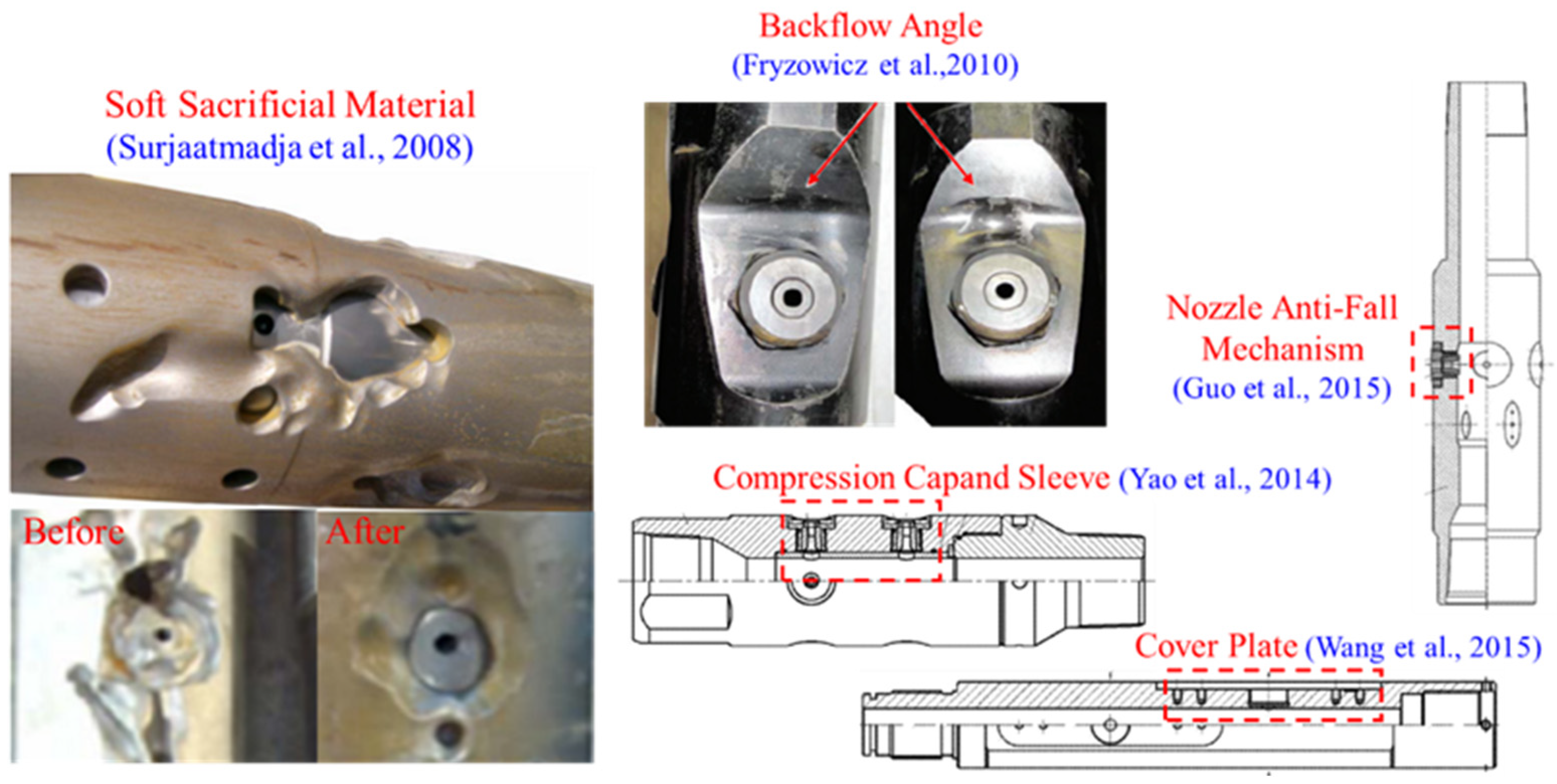

2.2. Erosion Prevention Measures on the Gun Surface

2.3. Representative Data and FEM Approaches

3. High-Pressure Leakage in Perforation Guns

3.1. Causes of High-Pressure Leakage

3.2. Measures to Prevent High-Pressure Leakage

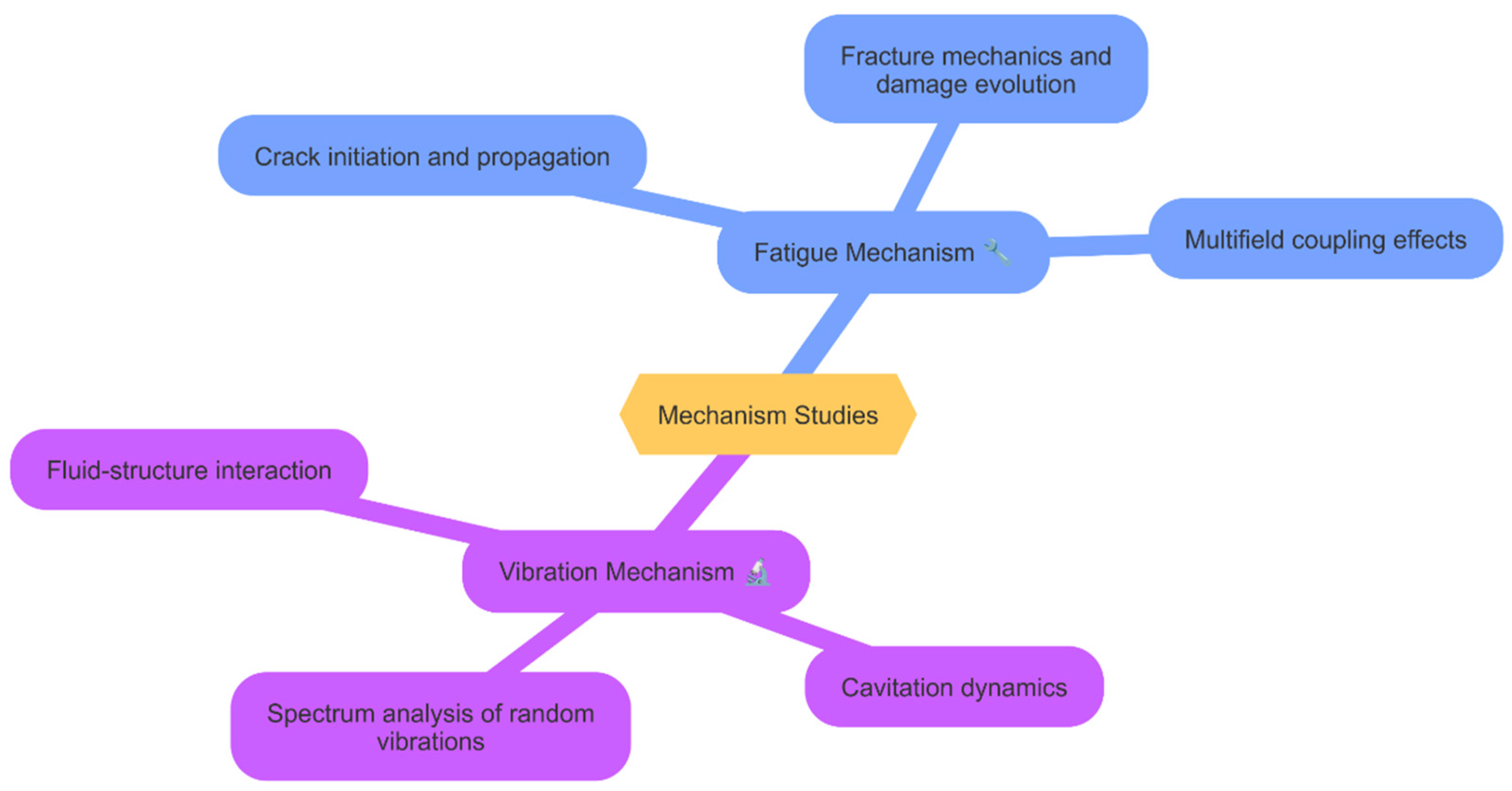

4. Vibration and Fatigue in the Perforation Gun

4.1. Vibration and Fatigue Mechanisms of the Gun

4.2. Mitigation Measures for Vibration-Induced Fatigue

5. Intelligent Diagnosis of Gun Failure Causes and Future Prospects

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dotson, T.; Farr, J.; Findley, E. Advances in sand jet perforating. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference/Low-Permeability Reservoirs Symposium, Denver, CO, USA, 14–16 April 2009; SPE: Calgary, AB, Canada, 2009. [Google Scholar]

- Tariq, M.; Khan, Z.; Liu, J. Water jet perforation techniques: Status and prospects. J. Nat. Gas Sci. Eng. 2019, 62, 107020. [Google Scholar] [CrossRef]

- Li, Z.; Gao, H.; Wang, Y. Efficiency of water-based sand jet perforation. Pet. Res. 2018, 3, 123–135. [Google Scholar]

- Zhao, J.; Xu, L.; Wang, S. Optimization of hydraulic jet perforation tools. Eng. Appl. Comput. Fluid Mech. 2017, 11, 765–780. [Google Scholar]

- Yang, T.; Zhang, W.; Chen, R. Study of perforating guns and sand jet performance in oil and gas operations. J. Pet. Sci. Eng. 2021, 196, 107780. [Google Scholar]

- Wang, J.; Feng, X.N.; Dou, J.T. Practice of hydraulic sandblasting perforation fracturing technology in well testing process. China Pet. Chem. Stand. Qual. 2013, 33, 169. [Google Scholar]

- Andrews, T.D.; Brine, F.E. Hydraulic testing of ordnance components. J. Armament Technol. 2006, 128, 162–167. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Q.D.; Li, B.X.; Guan, Z. Numerical simulation study of hydraulic fracturing nozzle erosion in deep well. Front. Phys. 2022, 10, 947094. [Google Scholar] [CrossRef]

- Zeng, D.; Zhang, S.; Liu, J.; Tian, G.; Zhang, X.; Yu, H.; Li, X.G. An experimental study on casing perforation erosion during sand fracturing. Wear 2023, 528, 204980. [Google Scholar] [CrossRef]

- Surjaatmadja, J.B.; East, L.E.; Luna, J.B.; Hernandez, J.O. An effective hydrajet-fracturing implementation using coiled tubing and annular stimulation fluid delivery. In Proceedings of the SPE/ICoTA Well Intervention Conference and Exhibition, The Woodlands, TX, USA, 5–6 April 2005. SPE, 2005. [Google Scholar]

- Wang, Z.; Zhang, J.; Shirazi, S.A.; Dou, Y. Experimental and numerical study of erosion in a non-Newtonian hydraulic fracturing fluid. Wear 2019, 422, 1–8. [Google Scholar] [CrossRef]

- Sheng, M.; Huang, Z.W.; Tian, S.C.; Zhang, Y.; Gao, S.W.; Jia, Y.P. CFD analysis and field observation of tool erosion caused by abrasive waterjet fracturing. Pet. Sci. 2020, 17, 701–711. [Google Scholar] [CrossRef]

- Shi, S.; Zhang, S.; Cheng, N.; Tian, G.; Zeng, D.; Yu, H.; Zhang, X. Erosion characteristics and simulation charts of sand fracturing casing perforation. Pet. Sci. 2023, 20, 3638–3653. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Y.; Wang, Z.D.; Chen, Z.; Zhang, G.W. Analysis on nozzle wear of hydraulic sandblast fracturing tools. Oil Field Equip. 2010, 39, 25–28. [Google Scholar]

- Nakhwa, A.D.; Loving, S.W.; Ferguson, A.; Shah, S.N. Oriented perforating using abrasive fluids through coiled tubing. In Proceedings of the SPE/ICoTA Well Intervention Conference and Exhibition, The Woodlands, TX, USA, 20–21 March 2007. [Google Scholar]

- Xu, Z.; Cui, X.; Zhang, J.; Shen, K.; Wu, X.; Zhang, Y. Numerical simulation on erosion and stress on a small-diameter hydrajet fracturing tool. ACS Omega 2024, 9, 11686–11700. [Google Scholar] [CrossRef] [PubMed]

- Surjaatmadja, J.B.; Bezanson, J.; Lindsay, S.D.; Ventosilla, P.; Rispler, K. New hydra-jet tool demonstrates improved life for perforating and fracturing applications. World Oil 2008, 229, 11. [Google Scholar]

- Hong, S.; Mei, D.; Wu, J.; Lin, J.; Wu, Y.; Li, J.; Zheng, Y. Hydro-abrasive erosion and cavitation-silt erosion characteristics of HVOF sprayed WC-Ni cermet coatings under different flow velocities and sand concentrations. Ceram. Int. 2023, 49, 74–83. [Google Scholar] [CrossRef]

- Singh, J.; Satish, K.; Mohapatra, S.K. Erosion wear performance of Ni-Cr-O and NiCrBSiFe-WC (Co) composite coatings deposited by HVOF technique. Ind. Lubr. Tribol. 2019, 71, 610–619. [Google Scholar] [CrossRef]

- Gao, Y.; Zhenqiang, X.; Kaixiang, S. Jet characteristics and optimization of a cavitation nozzle for hydraulic fracturing applications. Fluid Dyn. Mater. Process. 2024, 20, 179. [Google Scholar] [CrossRef]

- Fryzowicz, R.; Naughton-Rumbo, R.; Schrama, E. Application of CT-conveyed perforating with sand jetting technology on North Sea deep horizontal tight gas producer. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 5–6 October 2010. [Google Scholar]

- Guo, Q.; Qiang, H.; Hu, J.T.; Cheng, Y.F.; Yang, J.J.; Zhang, S.C.; Ge, D.K.; Han, Q.Q.; Wen, Y.; She, D.Y. Sandblasting Perforator with Nozzle Anti-Detachment Device. CN204627565U, 9 September 2015. [Google Scholar]

- Yao, J.F.; Lu, C.F.; Ge, X.; Li, J.B.; Tong, Z.Y.; Zhang, D.W.; Wang, X.B. High Reliability Hydraulic Jet Device. CN103953317A, 30 July 2014. [Google Scholar]

- Wang, D.J.; Fei, C.J.; Liu, J.; Wu, W.; Xia, X.B.; Ding, K. A Casing Well Sandblasting Perforator. CN204283372U, 22 April 2015. [Google Scholar]

- Lindsley, B.A.; Marder, A.R. The effect of velocity on the solid particle erosion rate of alloys. Wear 1999, 225, 510–516. [Google Scholar] [CrossRef]

- Greaves, R.H.; Abram, H.H.; Rees, S.H. The erosion of guns. J. Iron Steel Inst. 1929, 117, 113–117. [Google Scholar]

- Anderson, M.; Chiovelli, S.; Llewellyn, R. The use of tungsten carbide materials for oilsand wear applications. In International Proceedings Conference Thermal Spray; ASM International: Orlando, FL, USA, 2003. [Google Scholar]

- Thapa, B. Sand Erosion in Hydraulic Machinery. 2004. Available online: http://hdl.handle.net/11250/231204 (accessed on 5 March 2025).

- Yamabe, J.; Fujiwara, H.; Nishimura, S. Fracture analysis of rubber sealing material for high pressure hydrogen vessel. J. Environ. Eng. 2011, 6, 53–68. [Google Scholar] [CrossRef]

- Wu, B.; Zheng, J.; Bai, X.L.; Si, D.Y.; Luo, T.F.; Zou, Z.Q. Fatigue crack propagation in thick-walled pressure vessels under hydraulic testing condition. J. Phys. Conf. Ser. 2023, 2478, 122052. [Google Scholar] [CrossRef]

- Simion, P.; Dia, V.; Istrate, B.; Hrituleac, G.; Hrituleac, I.; Munteanu, C. Study of fatigue behavior of longitudinal welded pipes. IOP Conf. Ser. Mater. Sci. Eng. 2016, 145, 022032. [Google Scholar] [CrossRef]

- Zhang, F.; Shui, H.; Yang, J.M. Sealing performance and fatigue life of the fracturing packer rubber of various materials. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 6157–6166. [Google Scholar] [CrossRef]

- Wu, B.; Zheng, J.; Luo, T.F.; Wang, T.; Zhou, Y.C.; Huang, X. Damage and fracture of gun barrel under wear-fatigue interaction. J. Phys. Conf. Ser. 2020, 1507, 102034. [Google Scholar] [CrossRef]

- Karakouzian, M.; Karami, M.; Nazari-Sharabian, M.; Ahmad, S. Flow-induced stresses and displacements in jointed concrete pipes installed by pipe jacking method. Fluids 2019, 4, 34. [Google Scholar] [CrossRef]

- Chen, M.B.; Jiang, Y.R. Fatigue crack propagation analysis of X60 pipeline steel pipelines with defects. Adv. Mater. Res. 2011, 284, 1148–1151. [Google Scholar] [CrossRef]

- Dama, E.; Karamanos, S.A.; Gresnigt, A.M. Failure of locally buckled pipelines. J. Press. Vessel. Technol. 2006, 129, 272–279. [Google Scholar] [CrossRef]

- Takahashi, S.; Xu, Q.; Takamura, N.; Morita, R.; Uchiyama, Y.; Watanabe, S. Evaluation of jet impact region and fluid force generated from ruptured pipes: 2—Evaluation using CFD analysis. In Proceedings of the International Conference on Nuclear Engineering, Charlotte, NC, USA, 26–30 June 2016. [Google Scholar]

- Zheng, J.; Li, H.J.; Wu, B. Low cycle fatigue damage of gun barrel and its monitoring for prevention of fracture. In Proceedings of the 4th International Conference on Electron Device and Mechanical Engineering (ICEDME), Guangzhou, China, 19–21 March 2021. [Google Scholar]

- Clark, G. Fatigue crack growth through residual stress fields—Theoretical and experimental studies on thick-walled cylinders. Theor. Appl. Fract. Mech. 1984, 2, 111–125. [Google Scholar] [CrossRef]

- Audino, M.J. Fatigue Life Assessment of 155-mm M284 Cannon Tubes; ARCCB-TR-93036; Army Armament Research, Development and Engineering Center Report: Watervliet, NY, USA, 1993. [Google Scholar]

- Cuamatzi-Meléndez, R.; Flores-Cuamatzi, E. Modelling fluid-structure interaction of water recirculating flow to predict damage and/or failure in a jet-pump assembly of a nuclear boiling water reactor. Eng. Struct. 2020, 206, 110155. [Google Scholar] [CrossRef]

- Ma, Z.S.; Fu, L.H.; Yang, L.; Zhou, Y.C.; Lu, C. Finite element simulations on erosion and crack propagation in thermal barrier coatings. High Temp. Mater. Process. 2015, 34, 387–393. [Google Scholar] [CrossRef]

- Singh, P.K.; Mishra, S.B. Erosion wear characteristics of HVOF sprayed WC-Co-Cr and CoNiCrAlY coatings on IS-2062 structural steel. Mater. Res. Express 2018, 5, 095508. [Google Scholar] [CrossRef]

- Mamoo, M.S.; Goharrizi, A.S.; Abolpour, B. CFD simulation of erosion by particle collision in U-bend and helical type pipes. J. Serbian Soc. Comput. Mech. 2020, 14, 1–13. [Google Scholar] [CrossRef]

- Gan, L.; Men, X.; Tao, F.; Li, Y. Blow-by erosion model for the saddle-type degradation of high pressure gun bore. In Proceedings of the 31st International Symposium on Ballistics, Hyderabad, India, 4–8 November 2019. [Google Scholar]

- Hölzle, J. Influence of the “critical velocity” phenomenon on chromium-plated gun barrels. J. Press. Vessel Technol. 2003, 125, 352–354. [Google Scholar] [CrossRef]

- Dai, Z.; Liao, H.; Yang, K.; Sun, F. Experimental study on pore forming characteristics of simulated hydrate broken by high pressure water jet. J. Phys. Conf. Ser. 2021, 2108, 012094. [Google Scholar] [CrossRef]

- Purwaningsih, H.; Rochiem, R.; Suchaimi, M.; Jatimurti, W.; Wibisono, A.T.; Kurniawan, B.A. A review of various nozzle range of wire arc spray on FeCrBMnSi metal coating. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2018; Volume 1945. [Google Scholar]

- Sharma, V.; Kaur, M.; Bhandari, S. Slurry erosion performance study of high velocity flame sprayed Ni–Al2O3 coating under hydro accelerated conditions. Mater. Res. Express 2019, 6, 076436. [Google Scholar] [CrossRef]

- Hoshino, A.; Fujii, T.; Yamazaki, M. Influence of environmental factors on erosion-corrosion resistance of stainless steels. Corros. Eng. 1986, 35, 212–218. [Google Scholar] [CrossRef][Green Version]

- Ye, X.; Luo, B.; Deng, L. Semi-physical simulation model for leakage prediction of aviation pipeline. J. Phys. Conf. Ser. 2023, 2437, 012025. [Google Scholar] [CrossRef]

- Morita, R.; Watanabe, S.; Takahashi, S.; Takamura, N. Numerical evaluation of affected region by flashing jet flow. In Proceedings of the International Conference on Nuclear Engineering, Surabaya, Indonesia, 3 April 2018. [Google Scholar]

- Tsay, L.W.; Chi, M.Y.; Chen, H.R.; Chen, C. Investigation of hydrogen sulfide stress corrosion cracking of PH 13-8 Mo stainless steel. Mater. Sci. Eng. A 2006, 416, 155–160. [Google Scholar] [CrossRef]

- Chen, W.E.; Mei, Y.U.; Songmei, L.I.; Xiangcheng, L.I.; Jianhua, L.I. Effects of hydrogen on stress corrosion cracking behavior of ultra-high strength steel 23Co14Ni12Cr3Mo. Int. J. Electrochem. Sci. 2014, 9, 5803–5811. [Google Scholar]

- Warke, W.R. Stress-corrosion cracking. In Failure Analysis and Prevention; ASM International: Almere, The Netherlands, 2002; pp. 823–860. [Google Scholar]

- Jiang, H. Design and performance of a novel dynamic rotary sealing device for roadheader with high-pressure water-jets assistance. Recent Pat. Mech. Eng. 2016, 9, 337–342. [Google Scholar] [CrossRef]

- Liu, Z.; Du, C.; Liu, S.; Jiang, H. Failure analysis of the multi-level series rotary seal device under high-pressure water. Stroj. Vestn.—J. Mech. Eng. 2017, 63, 275–283. [Google Scholar] [CrossRef][Green Version]

- Baumann, C.; Damm, D.; Escudero, J.; Smart, M.; Yang, X.T.; Liu, J.Y.; Wei, Z. New low-shock low-debris gun technology with reliable gunshock simulation and optimization. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019. [Google Scholar]

- Wang, J.; Hao, H. The sealing performance of PTFE O-rings at low temperature. J. Phys. Conf. Ser. 2024, 2842, 012014. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, C.; Zou, B.; Li, L. Sealing performances research on PTFE rotating seal under deep-sea environment. Open Mech. Eng. J. 2015, 9, 475–482. [Google Scholar] [CrossRef]

- Zhao, X.W.; Zhang, X.Z.; Zhao, X.H. The design of new water jet spray gun. Adv. Mater. Res. 2011, 328, 667–671. [Google Scholar] [CrossRef]

- Meribout, M.; Khezzar, L.; Azzi, A.; Ghendour, N. Leak detection systems in oil and gas fields: Present trends and future prospects. Flow Meas. Instrum. 2020, 75, 101772. [Google Scholar] [CrossRef]

- ISO 13628-7; Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems—Part 7: Completion/Workover Riser Systems. International Organization for Standardization: Geneva, Switzerland, 2005.

- API 6A; Specification for Wellhead and Christmas Tree Equipment. American Petroleum Institute: New York, NY, USA, 2016.

- Quan, L.; Che, S.; Guo, C.; Gao, H.; Guo, M. Axial vibration characteristics of fluid-structure interaction of an aircraft hydraulic pipe based on modified friction coupling model. Appl. Sci. 2020, 10, 3548. [Google Scholar] [CrossRef]

- Zhou, J.; Shen, A.; Karney, B.W.; Zhang, J. Numerical-based studies on hydraulic vibration of pipe flow in hydropower systems. J. Hydraul. Res. 2022, 60, 557–567. [Google Scholar] [CrossRef]

- Zhang, T.; Cui, J. Analytical method for fluid-solid coupling vibration analysis of hydraulic pipeline system with hinged ends. Shock Vib. 2021, 2021, 8846869. [Google Scholar] [CrossRef]

- Zhou, Z.J.; Liu, A.J.; Zhou, L.Y. Study on vibration characteristics of hydraulic pipes in case of internal pulsating fluid excitation. J. Phys. Conf. Ser. 2023, 2449, 012019. [Google Scholar] [CrossRef]

- Ren, J.; Yue, P.; Wang, X. Fatigue simulation analysis of semi-open thick-walled cylinder under cyclic loading. IOP Conf. Ser. Mater. Sci. Eng. 2019, 631, 032029. [Google Scholar] [CrossRef]

- Liao, Z.; Zhai, G.; Tang, J. Dynamic simulation analysis of aircraft hydraulic pipeline system under different pressure. J. Phys. Conf. Ser. 2022, 2280, 012051. [Google Scholar] [CrossRef]

- Jia, X.; Liao, H.; Hu, Q.; He, Y.; Wang, Y.; Niu, W. Optimization method of jet pump process parameters and experimental study on optimal parameter combinations. Processes 2023, 11, 2841. [Google Scholar] [CrossRef]

- Jiang, R.L.; Wang, Y.H.; Fan, C.F.; Duan, M.J. Dynamic response analysis of the hydraulic pipe under jets of the aircraft tire burst. Adv. Mater. Res. 2013, 798, 341–344. [Google Scholar] [CrossRef]

- Eisinger, F.L. Piping Systems Providing Minimal Acoustically-Induced Structural Vibrations and Fatigue. U.S. Patent No. 5,711,350, 27 January 1998. [Google Scholar]

- Liu, Y.X.; Lao, D.Z.; Liu, Y.H.; Yang, C.; Ma, C.C. The unsteady flow and forced response for a variable nozzle turbine. Adv. Mater. Res. 2014, 871, 296–303. [Google Scholar] [CrossRef]

- Ziada, S.; Sperling, H.; Fisker, H. Vibration of a high-pressure piping system due to flow in a spherical elbow. J. Fluids Struct. 2001, 15, 751–767. [Google Scholar] [CrossRef]

- Otsuka, K.; Ogawa, N.; Iio, S.; Kitahora, T.; Choi, Y.D.; Inagaki, M. Characteristics and suppression of vibration in cross-flow turbine with a cavity. J. Phys. Conf. Ser. 2022, 2217, 012063. [Google Scholar] [CrossRef]

- Wachel, J.C.; Morton, S.J.; Atkins, K.E. Piping vibration analysis. In Proceedings of the 19th Turbomachinery Symposium, San Antonio, TX, USA, 1990; Available online: https://hdl.handle.net/1969.1/163563 (accessed on 5 March 2025).

- Lv, H.; Qiu, Y.Y.; Ying, Y. Fatigue analysis of the aircraft’s hydraulic pipes based on fluid–structure interaction. Adv. Mater. Res. 2011, 299, 917–920. [Google Scholar] [CrossRef]

- Eisinger, F.L.; Francis, J.T. Acoustically induced structural fatigue of piping systems. J. Pressure Vessel Technol. 1999, 121, 438–443. [Google Scholar] [CrossRef]

- Saunders, K.L.; Onorato, M. Piping snubber failure experience and mitigation. In Proceedings of the Pressure Vessels and Piping Conference, Las Vegas, NV, USA, 17–22 July 2022. [Google Scholar]

- Shani, L.; Lautman, R.S.; Nishri, B. Effect of nozzles’ characteristics on PV aeromechanical systems. Adv. Fluid Mech. XII 2018, 120, 229. [Google Scholar]

- Gao, Y.; Xu, Z.; Shen, K.; Wu, S. Jet characteristics and optimal design of hydraulic perforating nozzles for natural gas hydrate reservoirs. Adv. Mech. Eng. 2023, 15, 16878132231197488. [Google Scholar] [CrossRef]

- Cai, M.; Cheng, X.Y.; Chen, X.H.; Zhu, C.J.; Zhang, Y. Study on nozzle structure of hydraulic jet fracturing. J. Phys. Conf. Ser. 2023, 2594, 012068. [Google Scholar] [CrossRef]

- Gu, B.; Hu, R.; Wang, L.; Xu, G. Study on the influence rule of high-pressure water jet nozzle parameters on the effect of hydraulic slotting. Geofluids 2022, 2022, 4510194. [Google Scholar] [CrossRef]

- Wen, J.; Qi, Z.; Behbahani, S.S.; Pei, X.; Iseley, T. Research on the structures and hydraulic performances of the typical direct jet nozzles for water jet technology. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 570. [Google Scholar] [CrossRef]

- Liao, W.T.; Deng, X.Y. Study on flow field characteristics of nozzle water jet in hydraulic cutting. IOP Conf. Ser. Earth Environ. Sci. 2017, 81, 012167. [Google Scholar] [CrossRef]

- Zhang, L.; Qi, Q.; Ma, T.; Sun, L.; Wang, Y.; Chai, J. Flow field characteristic of water jet with air ring protective layer under submerged environment and the orthogonal optimization of nozzle structure. Energy Sci. Eng. 2023, 11, 227–240. [Google Scholar] [CrossRef]

- Liu, F.; Yan, H. Study of mixing enhancement in helium jet/shock interaction by laser pulses. AIAA J. 2022, 60, 4113–4125. [Google Scholar] [CrossRef]

- Ioannou, V.; Laizet, S. Numerical investigation of plasma-controlled turbulent jets for mixing enhancement. Int. J. Heat Fluid Flow 2018, 70, 193–205. [Google Scholar] [CrossRef]

- Ho, C.C.; Shen, K.Y.; Chen, C.S.; Chang, Y.J.; Hsu, J.C.; Kuo, C.L. Swirling gas jet-assisted laser trepanning for a galvanometer-scanned CO2 laser. Appl. Sci. 2017, 7, 502. [Google Scholar] [CrossRef]

- Deshpande, K.; Knoeller, M.; Patkar, V. Digital solutions to optimize jet pump technology for production enhancement. In Proceedings of the SPE Western Regional Meeting, San Jose, CA, USA, 23–26 April 2019. [Google Scholar]

- Xie, X.P.; Wang, Y.A. Design of a three-nozzle for air spraying based on jet interference effect and numerical study of spraying process. SN Appl. Sci. 2022, 4, 177. [Google Scholar] [CrossRef]

- Holburg, J.; Müller, M.; Mann, K. Improved gas-jet based extreme ultraviolet, soft x-ray laser plasma source. Opt. Express 2021, 29, 6620–6628. [Google Scholar] [CrossRef]

- Li, Z.; Gao, P.; Zhao, D.; Liu, J. Fault diagnosis and location of the aero-engine hydraulic pipeline based on Kalman filter. Adv. Mech. Eng. 2017, 9, 1687814017742811. [Google Scholar] [CrossRef]

- Lu, Z.; Cao, C.; Ge, Y.; He, J.; Yu, Z.; Chen, J.; Zheng, X. Research on improving the working efficiency of hydraulic jet submarine cable laying machine. J. Mar. Sci. Eng. 2021, 9, 745. [Google Scholar] [CrossRef]

- Lou Toua, V. The Effect of Aircraft Manufacturing Riveting Tools on Hand-Arm Vibrations and Muscle Fatigue; Louisiana State University and Agricultural & Mechanical College: Baton Rouge, LA, USA, 2020. [Google Scholar]

- Yan, Z.; Liu, N.; Yang, K.; Hui, W. Visualization of hydraulic sandblasting perforation in horizontal Wells. In Proceedings of the 2022 4th International Conference on Intelligent Control, Measurement and Signal Processing (ICMSP), Hangzhou, China, 8–10 July 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Ma, W.; Jin, H.; Pan, Z.; Ling, Q.; Deng, J. Monitoring system design for intelligent hydraulic safety based on the IoT. IOP Conf. Ser. Earth Environ. Sci. 2021, 676, 012071. [Google Scholar]

- Ramírez, M.; Torres, F.J.; López, F.; Cervantes, F.A.; Ramírez, C.A.; Núñez, D.A. A cloud remote monitoring system of hydraulic pressure by a minicomputer. In Proceedings of the 2022 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 9–11 November 2022. [Google Scholar]

- Kumar, D.M.; Jagadeep, T. Water pipeline leakage detection and monitoring system using smart sensor with IoT. J. Phys. Conf. Ser. 2022, 2267, 012122. [Google Scholar] [CrossRef]

- Liu, B.J.; Yang, Q.W.; Xiang, W.; Fang, S.D.; Guo, F.; Pla, A.A. Application of multi-sensor information fusion in the fault diagnosis of hydraulic system. Int. J. 2017, 22, 12–20. [Google Scholar]

- Bani, N.A.; Noordin, M.K.; Hidayat, A.A.; Kamil, A.S.; Amran, M.E.; Kasri, N.F.; Muhtazaruddin, M.N.; Muhammad-Sukki, F. Development of predictive maintenance system for haemodialysis reverse osmosis water purification system. In Proceedings of the 2022 4th International Conference on Smart Sensors and Application (ICSSA), Kuala Lumpur, Malaysia, 26–28 July 2022. [Google Scholar]

- Yang, T.; Li, G.; Wang, T.; Yuan, S.; Yang, X.; Yu, X.; Han, Q. A novel 1D-convolutional spatial-time fusion strategy for data-driven fault diagnosis of aero-hydraulic pipeline systems. Mathematics 2023, 11, 3113. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, S.; Shi, J.; Zhang, C. Fault diagnosis of hydraulic actuator based on improved convolutional neural network. In Proceedings of the 2020 Asia-Pacific International Symposium on Advanced Reliability and Maintenance Modeling (APARM), Vancouver, BC, Canada, 20–23 August 2020. [Google Scholar]

- Yan, T.; Niu, W.; Zhao, Y. A fault diagnosis method of aircraft hydraulic system based on CNN-LSTM. In Proceedings of the Second International Conference on Electronic Information Engineering, Big Data, and Computer Technology (EIBDCT 2023), Xishuangbanna, China, 6–8 January 2023; SPIE: Bellingham, WA, USA, 2023. [Google Scholar]

- Feng, D.; Jiang, C.; Lu, M.; Li, S.; Ye, C. Fault diagnosis of hydraulic system of aircraft landing gear based on CNN-SVM. In Proceedings of the 2022 International Conference on Intelligent Transportation, Big Data & Smart City (ICITBS), Hengyang, China, 26–27 March 2022. [Google Scholar]

- Bondoc, A.E.; Tayefeh, M.; Barari, A. Learning phase in a LIVE digital twin for predictive maintenance. Auton. Intell. Syst. 2022, 2, 13. [Google Scholar] [CrossRef]

- Liu, J.; Xin, Y.; Hou, Y.; Xu, Z.; Ma, X.; Zhao, L. Device fault diagnosis method based on digital twin server. J. Phys. Conf. Ser. 2023, 2612, 012002. [Google Scholar] [CrossRef]

- Cui, J.; Song, X.; Cui, X.; Du, W.; Liu, D.; Yu, M.; Jiang, L.; Wang, J. A fault diagnosis method of aircraft hydraulic system based on SSA-DBN. In Proceedings of the 2022 34th Chinese Control and Decision Conference (CCDC), Hefei, China, 15–17 August 2022. [Google Scholar]

- Zhang, Z.; Chen, M.; Ren, Z.; Shi, W. Research on water jet fault diagnosis model based on PNN network. In Proceedings of the 2021 IEEE 4th International Conference on Information Systems and Computer Aided Education (ICISCAE), Dalian, China, 24–26 September 2021. [Google Scholar]

- Solorio, J.A.; Garcia-Bravo, J.M. Machine learning for fault diagnosis and operation mode detection in hydraulic cylinders. In Proceedings of the Fluid Power Systems Technology (ASME Conference), Sarasota, FL, USA, 16–18 October 2023; Volume 87431. [Google Scholar]

- Bennett, K.W.; Robertson, J. Remote sensing: Leveraging cloud IoT and AI/ML services. In Artificial Intelligence and Machine Learning for Multi-Domain Operations Applications III; SPIE: Bellingham, WA, USA, 2021; Volume 11746. [Google Scholar]

- Chen, N.; Shi, H.; Liu, R.; Li, Y.; Li, J.; Xu, Z.; Wang, D.; Lu, G.; Jing, B.; Hou, Y. A 5G cloud platform and machine learning-based mobile automatic recognition of transportation infrastructure objects. IEEE Wirel. Commun. 2023, 30, 76–81. [Google Scholar] [CrossRef]

- Zhu, J.; Zeng, L. Intelligent pressure control system on drilling process. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2020. [Google Scholar]

- Das, K.; Das, S.; Darji, R.K.; Mishra, A. Energy efficient model for the sensor cloud systems. In Proceedings of the 2017 2nd IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT), Bangalore, India, 19–20 May 2017. [Google Scholar]

| Material Type | Representative Material/Coating | Main Characteristics | Drawbacks | Application Scenarios |

|---|---|---|---|---|

| Hard Alloy Materials | WC-Co | High hardness, wear-resistant | High manufacturing cost, complex machining | Nozzles under high-pressure jet operations |

| Wear-Resistant Coatings | Ceramic Coating | Excellent wear resistance, stable at high temperatures | Brittle, prone to cracking, limited performance under dynamic impacts | High-temperature, high-wear conditions |

| Metal-Based Composite Coatings | Metal-Ceramic Composite | Wear-resistant, impact-tolerant, adaptable to complex conditions | High technical requirements for bonding, limited coating adhesion | High-impact, high-velocity fluid environments |

| Study | Material | Flow Velocity (m/s) | Particle Size (µm) | Erosion Rate (mg/kg) | Key Findings |

|---|---|---|---|---|---|

| [25] | 13Cr Steel | 35–60 | 150–250 | 0.8–2.5 | Higher velocity leads to near-exponential rise in erosion; synergy with corrosion observed. |

| [26] | Inconel | 25–45 | 100–200 | 0.3–1.2 | More stable erosion rate under 300 °C; micro-cracks formed along grain boundaries. |

| [27] | WC-Co | 30–50 | 180–300 | 0.1–0.3 | Exhibits superior resistance due to harder coating; minor spallation at edges. |

| Research Direction | Specific Technologies and Materials | Achievements | Limitations |

|---|---|---|---|

| Seal Structure Optimization | Dynamic seals, metal-to-metal hard seals, optimized seal groove geometry | Dynamic seals are widely used in high-pressure environments; metal-to-metal hard seals address rubber aging under high-temperature, high-pressure conditions; optimizing seal groove geometry reduces leakage risk | Hard metal-to-metal seals demand high machining precision and cost; dynamic seals face wear issues under high-frequency motion and limited service life |

| Seal Material Development | PTFE, PEEK, nano-fillers (carbon nanotubes, graphene), metal elastic seals | PTFE’s excellent corrosion and high-temperature resistance make it a prime choice; nano-fillers notably improve wear resistance and anti-aging properties; metal elastic seals adapt well to complex conditions | Specialized materials incur high costs; uniform dispersion and large-scale production of nano-fillers remain challenging; high-performance materials must be further validated under extreme conditions |

| Leakage Detection Technologies | Pressure fluctuation monitoring, ultrasonic sensors, fiber-optic sensors | Pressure fluctuation monitoring enables rapid detection of abnormal flow; ultrasonic and fiber-optic sensors can precisely identify minute leaks and trigger alarms, significantly improving monitoring accuracy | Initial equipment investment is high; these sensors’ long-term stability and anti-interference performance under extreme conditions require further optimization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, Z.; Zhong, L.; Feng, W.; Li, J.; Gao, Z.; Li, J. A Review of Failures and Malfunctions in Hydraulic Sandblasting Perforation Guns. Appl. Sci. 2025, 15, 4892. https://doi.org/10.3390/app15094892

Luan Z, Zhong L, Feng W, Li J, Gao Z, Li J. A Review of Failures and Malfunctions in Hydraulic Sandblasting Perforation Guns. Applied Sciences. 2025; 15(9):4892. https://doi.org/10.3390/app15094892

Chicago/Turabian StyleLuan, Zhengxuan, Liguo Zhong, Wenqi Feng, Jixiang Li, Zijun Gao, and Jiaxin Li. 2025. "A Review of Failures and Malfunctions in Hydraulic Sandblasting Perforation Guns" Applied Sciences 15, no. 9: 4892. https://doi.org/10.3390/app15094892

APA StyleLuan, Z., Zhong, L., Feng, W., Li, J., Gao, Z., & Li, J. (2025). A Review of Failures and Malfunctions in Hydraulic Sandblasting Perforation Guns. Applied Sciences, 15(9), 4892. https://doi.org/10.3390/app15094892