1. Introduction

The study of the mechanical properties of the soil–structure interface is crucial for understanding the interaction between soil and underground engineering structures, making it a hot topic in geotechnical engineering [

1,

2,

3]. In recent years, the artificial freezing method has been widely used in underground engineering construction, such as coal mine shafts, subway connecting passages, and tunnel shield originating or receiving. Consequently, the physical and mechanical properties of the frozen–thawed soil–structure interface have attracted increasing attention from researchers [

4,

5,

6,

7]. Understanding the shear behavior of the frozen–thawed soil and structure is of great significance in artificial freezing engineering design and construction.

Several researchers have explored and identified significant differences in mechanical behavior between frozen soil and other soil types. In the realm of laboratory testing, Wen et al. studied the shear stress–strain relationship and strength characteristics of the Qinghai–Tibet silt–concrete interface through direct shear tests under varying moisture content and temperature conditions [

8]. Zhao et al. developed a multifunctional cyclic direct shear system for the frozen soil–structure interface and conducted shear tests under different boundary conditions [

9]. Theoretical models have also been advanced. Zhou et al. established a Duncan–Chang constitutive model describing the stress–strain properties of frozen loess [

10]. Liu proposed a new twin-shear strength criterion, elucidating the relationship among single-shear, twin-shear, and triple-shear strength criteria [

11]. These achievements have significantly advanced the understanding of the frozen soil–structural interface. However, it should be noted that in deep underground construction using the artificial freezing method, stress in the soil increases with depth, and frost heave force is also significant under freezing conditions. Under such high stress conditions, the mechanical properties of the frozen soil–structure interface will differ significantly from those formed under conventional stress conditions.

Recently, with the development of big data mining technology and machine learning (ML) algorithms, researchers have introduced these techniques into the study of frozen soil. For instance, evolutionary polynomial regression has been used to establish the constitutive function of frozen soil [

12], and artificial neural networks (ANNs) have been employed to assess soil thermal conduction [

13] and to estimate various soil samples under freeze–thaw conditions [

14]. The mechanical behavior of the frozen soil–structure interface is complex and difficult to describe using ordinary mathematical models [

15]. Intelligent ML algorithms provide a reasonable, fast, and rigorous solution to this issue. Moreover, establishing ML models based on existing historical data is more economical than conducting laboratory measurements each time to study the mechanical behavior of the frozen soil–structure interface [

2,

16]. The modeling of frozen–thawed soil–structure interface shear behaviors using machine learning based on extensive indoor shear test data is limited, which deserves further exploration. In this paper, test data obtained from high normal stress and freeze–thaw direct shear tests were used to train and validate an integrated CART-based ML model. The CART algorithm is particularly suitable for small datasets and has high tolerance for data distribution. It demonstrates that the CART-based ML model has a better ability to describe the shear stress–strain relationship and strain softening phenomenon of the frozen–thawed soil–structure interface.

This paper is organized as follows:

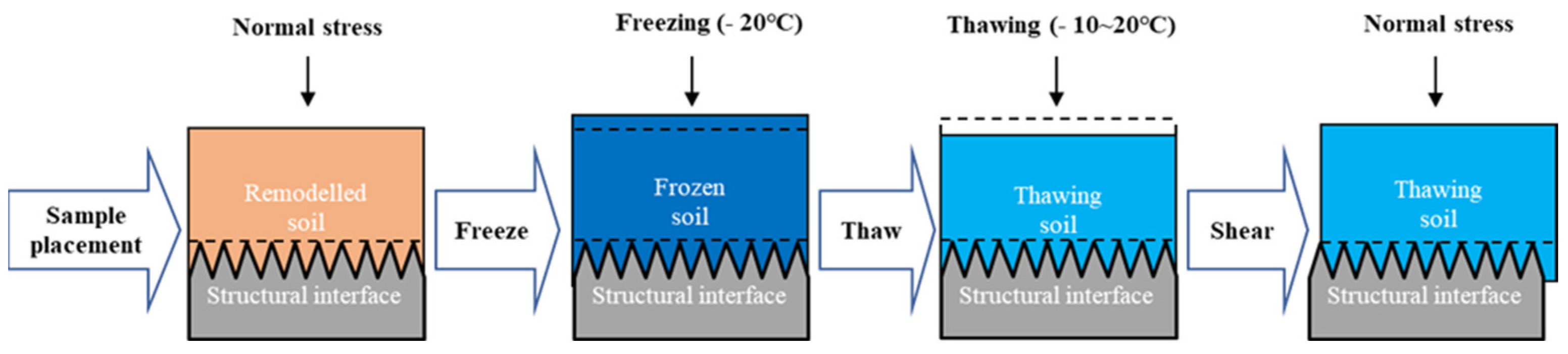

Section 2 introduces the high-stress frozen–thawed soil–structure shear test.

Section 3 details the CART algorithm used in the study.

Section 4 describes the process of establishing the CART-based ML model.

Section 5 presents the model’s predictive performance on the stress–strain curves and analyzes the importance of various input parameters. Finally,

Section 6 discusses the results.

3. The CART-Based Methods

The CART-based integrated algorithms, random forest (CART-RF) and adaptive boosting (CART-AdaBoost), are used to train a prediction model for the shear behavior of frozen–thawed soil–structure interface. Next, we introduce the CART and explain its integration algorithms.

3.1. CART-Based Integrated Algorithms

3.1.1. CART Algorithm

The decision tree is a tree structure in which each internal node represents a test on an attribute, each branch represents a test output, and each leaf node represents a category [

19]. The most famous CART algorithm assumes that the decision tree is a binary tree and uses discretization methods to discretize continuous variables so that the model can be used for both classification and regression problems. For regression problems, the regression tree selects the minimum square error criterion as the index for evaluating split attributes. Suppose training data

, where

x is the input instance, y is the output variable, then divide the input into M regions (

R1,

R2,

Rm), the output value of each area is

c1,

c2, …,

cm. It is important to find the optimal regression tree model.

The squared error is as follows:

Find the optimal cut-off point for each area to minimize the model’s square error. A single decision tree selects feature variables only once at each node, lacking an iterative feedback process. This can lead to overfitting and low generalization ability on the test set. Additionally, a decision tree’s structure changes drastically with changes in the sample. To address these inherent flaws of a single model, the current popular approach involves using bagging or boosting methods to create an ensemble learning model. Among the most representative algorithms are the random forest (RF) and AdaBoost algorithms. The schematic diagram is shown in

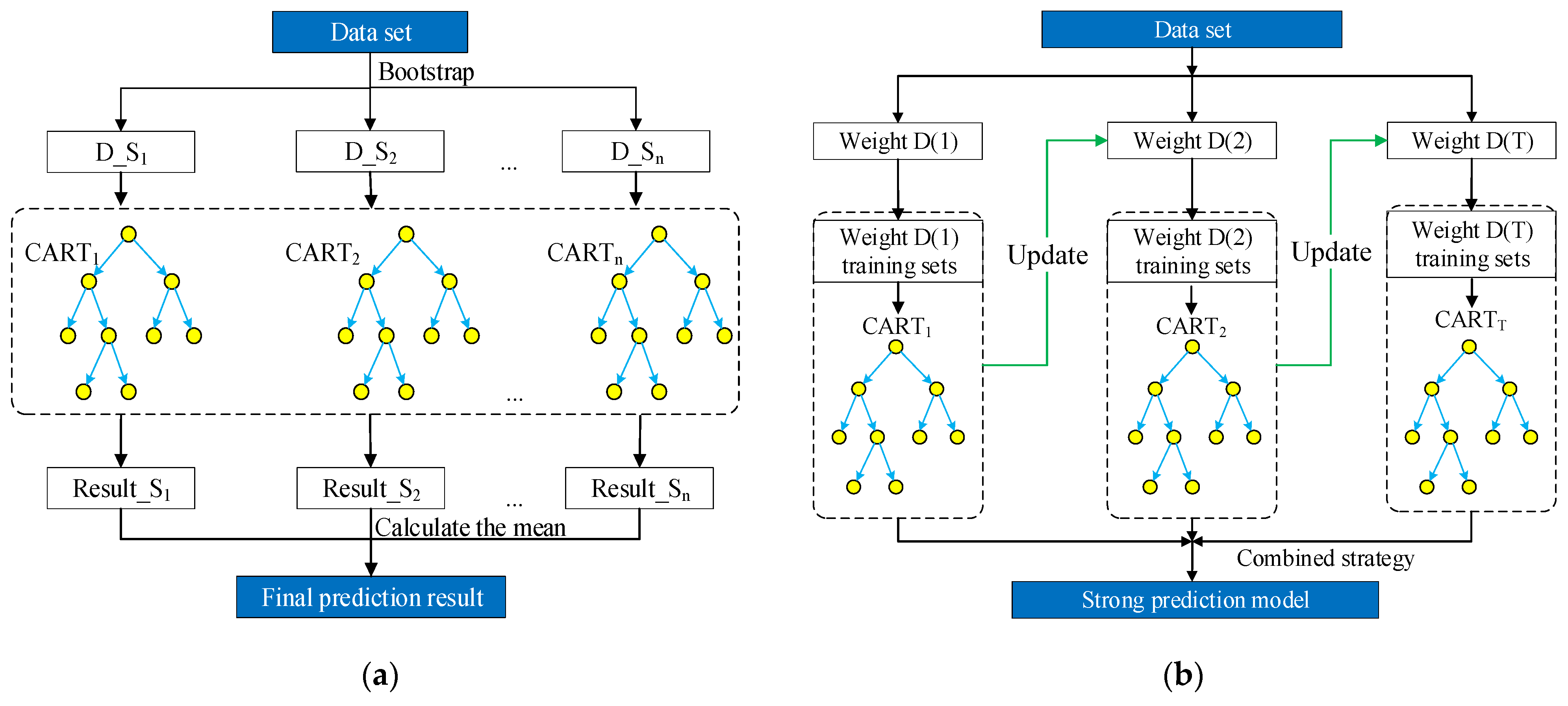

Figure 4.

3.1.2. CART-RF Algorithm

As a representative of the bagging algorithm, the CART-RF algorithm is a meta-estimator. Numerous theoretical and case studies have demonstrated that the CART-RF algorithm offers high prediction accuracy and robust tolerance for abnormal data. Using bootstrap resampling technology, multiple classification decision tree models are built on various sub-samples of the dataset. The average of these models is then used to improve predictive accuracy and control overfitting. As shown in

Figure 4a, bootstrap resampling extracts

n subsets from the original dataset, which serve as the training data for

n CART models. The final prediction is obtained by averaging the predictions of the

n CART models. The output of the CART-RF algorithm can be expressed as follows:

where

is the individual prediction of a tree for an input

x, and

n is the total number of decision trees. By taking the average of the decision trees’ predictions, some errors can be canceled out. The CART-RF algorithm achieves a reduced variance by combining diverse trees, sometimes at the cost of slightly increasing bias [

20]. Therefore, it is still necessary to combine domain knowledge and select reasonable model parameters to lay a good foundation for subsequent model training.

3.1.3. CART-AdaBoost Algorithm

In contrast to the bagging algorithm, the boosting method dynamically adjusts the distribution of the original training dataset, allowing base regression models to focus on challenging instances [

21,

22]. AdaBoost’s core concept involves training various classifiers (weak classifiers) on the same training set and subsequently combining them to create a more robust final classifier [

23]. Currently, the most prevalent approach is the AdaBoost integrated algorithm, which employs CARTs as base learners. As depicted in

Figure 4b, unlike the CART-RF algorithm, which selects certain variables as split variables, the CART-AdaBoost algorithm increases the likelihood of selecting samples prone to misclassification during variable selection. It then assigns weights to the output of each CART to produce the final model prediction [

24]. By adjusting the distribution of sample weights, the accuracy of weak learners is enhanced.

3.2. Model Analysis Framework

Generally, two strategies can be employed to train the CART integration algorithm for modeling the behavior of frozen–thawed soil structure interfaces. One strategy involves an incremental shear stress–strain approach, gradually utilizing input and output data, while the other maintains a direct correspondence between input and output in shear stress–strain behavior [

12,

25]. In this study, the latter strategy is adopted for a more intuitive establishment of the relationship between input and output parameters.

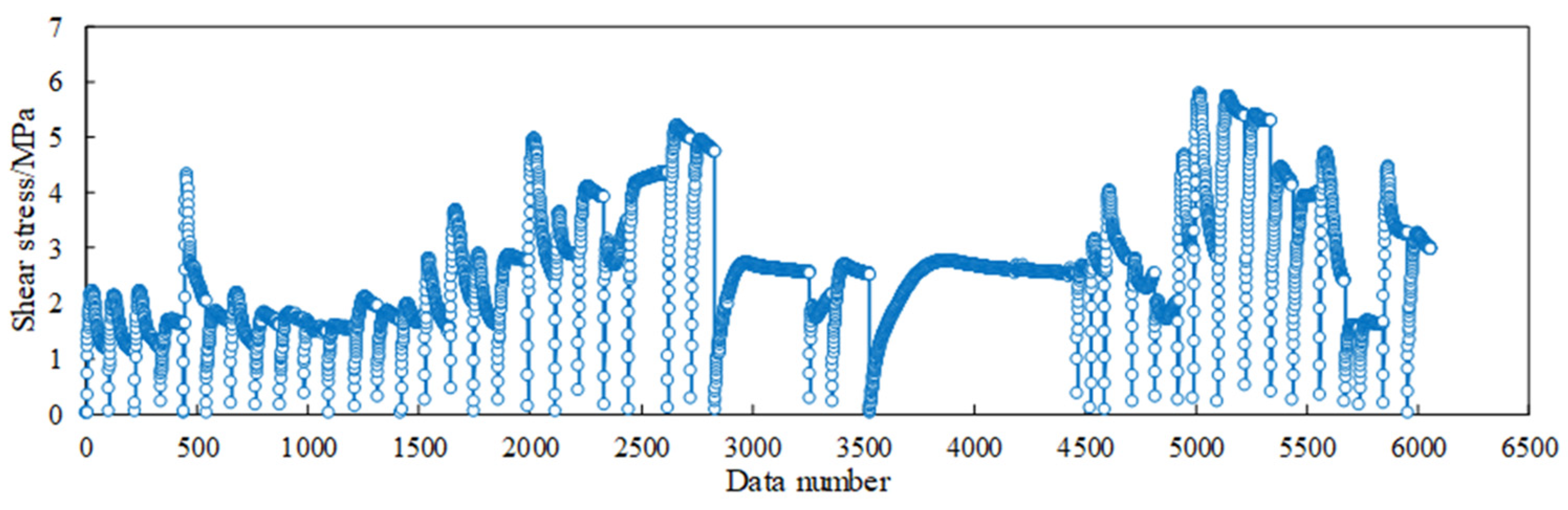

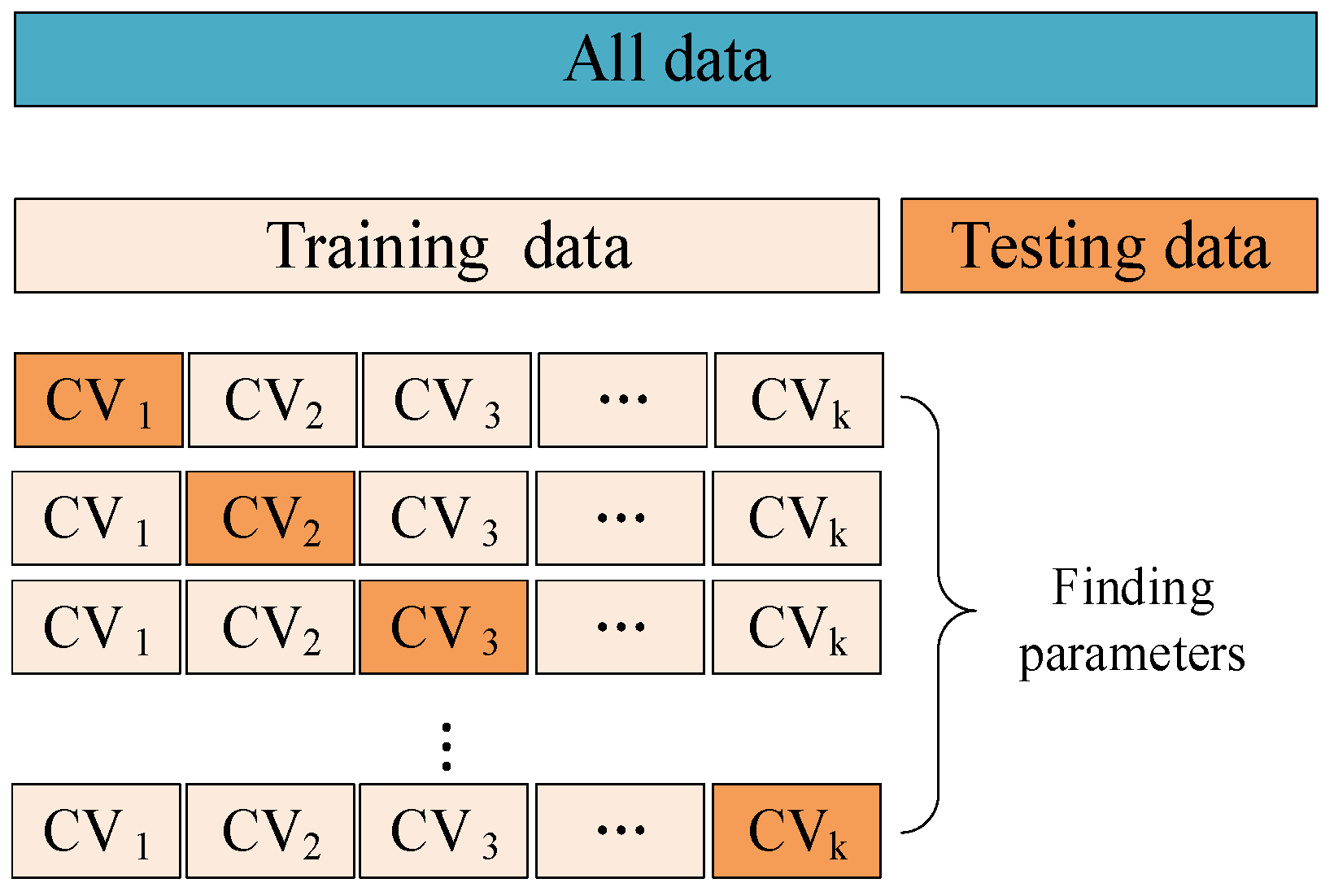

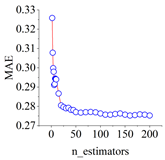

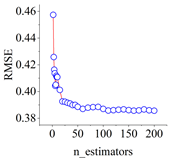

The complete model training and evaluation process for the shear stress–strain of frozen–thawed soil–structure interfaces begins with the results of the direct shear test. A data package is established, and input and output parameters are determined based on these results. The dataset is then divided into training and test sets. Subsequently, cross-validation is employed to determine the optimal hyperparameters of the model. Finally, the CART integrated prediction model, capable of describing the shear stress–strain behavior, is generated.

3.3. Model Evaluation Index

To evaluate the performance of the CART integrated model, this study uses three different indicators, namely, mean absolute error (

MAE), average root mean square error (

RMSE), and coefficient of determination (

R2).

MAE,

RMSE, and

R2 are defined as follows:

where

is the true value of the sample;

is the predicted value of the model;

n is the number of prediction samples;

is the average of the true values of the sample;

is the average of the predicted values.

As indicators of regression accuracy, the RMSE and MAE are indicator types that represent the difference between model output and actual value. If the values of these indicators are particularly small, it means that the predicted output matches the recorded output well. The R2 represents the proportion of variance that has been explained by the independent variables in the model. When the R2 value is larger, it means that there is a strong correlation between the model output and the actual value. In the actual model, we expect lower RMSE and MAE and higher R2.

3.4. Variable Importance Measures

To evaluate the importance of each input variable, this study compares the variable importance measures (

VIM) of the Gini index calculated by the decision trees. The calculation method of

VIM is obtained using the following equations:

where

is the

VIM of the

th in the node z;

and

are the Gini indices of the two new nodes after splitting. The

VIM of

in the ith tree is as follows:

The

VIM of

in the integrated model is as follows:

where

M is the node set of the

jth parameters appearing;

n is the number of decision trees in the integrated model. The higher the

VIM value is, the more vital the input parameters are.

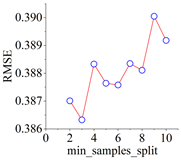

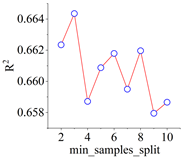

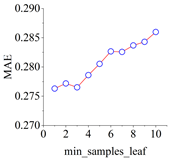

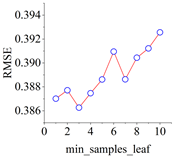

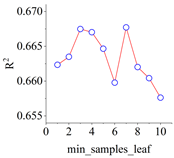

5. Results and Discussion

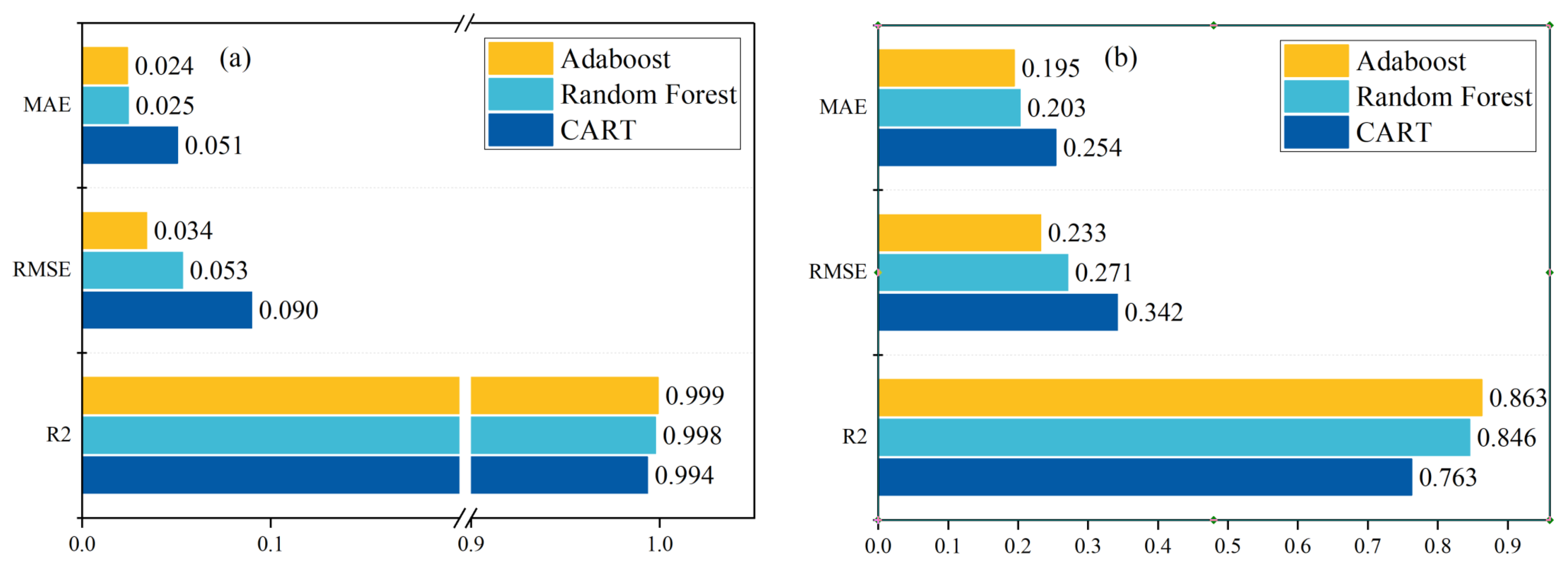

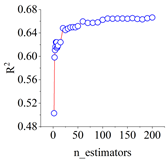

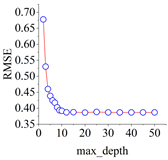

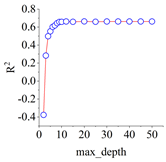

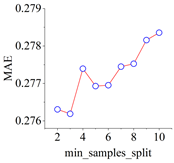

The stress–strain dataset, which has not been introduced to the model-building process, is used to test the predictive performance of the model. The prediction results of different models for the test set are summarized in

Table 7. To more intuitively illustrate the predictive effect of the model, the stress–strain curves of the test set are plotted in

Figure 7.

One can notice that the prediction effects are different between different models and the same model on different test sets. Both the ensemble algorithms, the CART-RF algorithm and the CART-AdaBoost algorithm, have good predictive performance for stress–strain curves under different test conditions, whether it is strain softening at high pressure with −5 °C (

Figure 7a) or strain hardening at high pressure with 20 °C (

Figure 7c). However, it can be seen that the prediction accuracy of the CART-AdaBoost algorithm is higher, and the predicted values were observed to essentially match the trends of the shear test results. The model can reflect the phenomenon of stress convergence in the later process of shearing. Although CART has better predictions under some experimental conditions (

Figure 7b), the overall prediction performance of a single decision tree is poor.

As shown in

Figure 8, the accuracy of CART on the training set is

R2 = 0.994, while the accuracy on the test set is low (

R2 = 0.763), indicating that CART has poor generalization. It should be noted that, like other big data learning algorithms, the CART-RF algorithm and the CART-AdaBoost algorithm may not be able to accurately predict the material behavior outside the range of training data.

Given the size of the training dataset used in this study, we used a shallow neural network to predict the frozen–thawed soil–structure shear stress–strain curves. As we know, artificial neural network (ANN) is one of the most commonly used prediction algorithms, consisting of an input layer, hidden layers, and an output layer. According to the number of hidden layers, it is divided into a shallow or a deep neural network (DNN).

Table 6 shows the performance comparison of the ANN model and the CART-based model in the dataset. For the shear stress–strain curve, the prediction effect of ANN is generally lower than that of the CART-based model, and the accuracy of ANN on the training set is much higher than the test set. Therefore, for a small dataset, we believe that the integrated CART algorithm has more advantages. Faced with big data, the ANN model may be a good choice.

As mentioned before, the

VIM of the input variables is presented in

Table 8. Under the test conditions, normal pressure scores the highest, followed by thawing temperature and the structural interface, while the influence of shear rate is nearly zero across different models. This indicates that the primary factors influencing the stress–strain curve are normal pressure and thawing temperature, followed by the structural interface. The VIM of input variables such as strains and vertical displacement is also high, demonstrating a strong correlation with the output.

6. Conclusions

The indoor testing method to characterize the shear behavior of frozen–thawed soil–structure interfaces often demands specialized equipment and controlled environments, making it costly, time-consuming, and sometimes unavailable. Hence, leveraging the direct shear test, we developed a CART-based integrated learning model. Through cross-validation, optimal hyperparameters of the CART-based model were determined, and subsequent comparison of the model’s prediction performance was discussed. The key findings of this study can be summarized as follows:

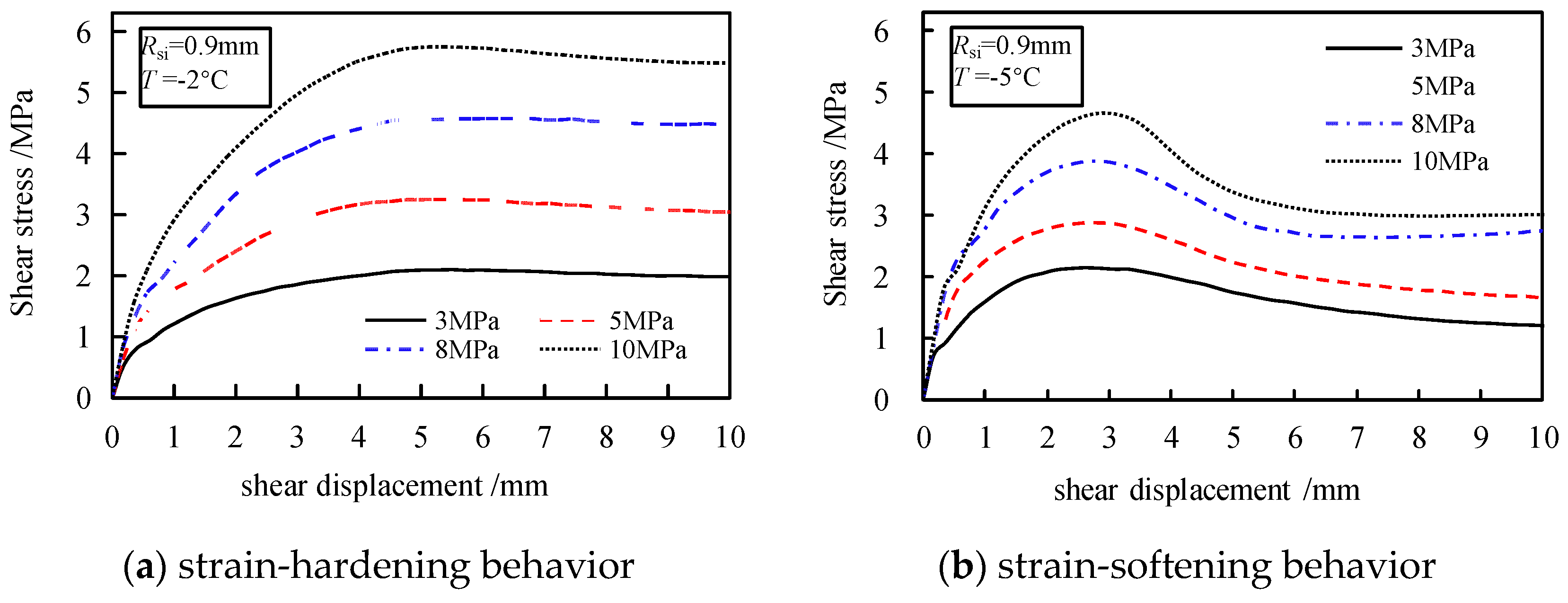

With the increasing thawing degree of frozen soil, the shear stress–strain curves of the frozen–thawed soil–structure interfaces evolve from exhibiting characteristics of strain softening with distinct shear stress peaks to demonstrating ideal plasticity and strain hardening traits.

While the prediction accuracy of a single decision tree proved ineffective, the integrated algorithm models (CART-RF and CART-AdaBoost) adeptly simulated the nonlinear shear behavior of a high-stress frozen–thawed soil–structure interface, successfully predicting entire shear stress–strain curves.

Importance ranking of the influence parameters revealed that normal pressure and thawing temperature emerged as significant influencing factors for the shear behaviors of frozen–thawed soil–structure interfaces under high stress conditions.

This study represents an initial endeavor to utilize data obtained from direct shear tests. A scientifically grounded interpretation of shear stress–strain relationships, particularly employing modern machine learning technology, offers valuable insights for practitioners lacking access to testing facilities to directly simulate the mechanical behavior of thawing soil–structure interfaces. Furthermore, the pursuit of more accurate results necessitates additional experimental data, which will be addressed in subsequent research endeavors.