Artificial Intelligence and MCDA in Circular Economy: Governance Strategies and Optimization for Reverse Supply Chains of Solid Waste

Abstract

1. Introduction

2. Materials and Methods

“How can the integration of Multi-Criteria Decision Analysis (MCDA) and Artificial Intelligence (AI) optimize reverse supply chains within the circular economy of solid waste, adhering to governance practices, principles, or mechanisms, in terms of operational efficiency, cost reduction, and material recovery, when compared to traditional waste management practices?”

2.1. Eligibility and Exclusion Criteria

- -

- Publication Period: published between 2015 and 2024. This timeframe was selected to capture recent advancements in AI and MCDA applications within solid waste management, driven by evolving regulations and the growing emphasis on the circular economy. It also reflects the maturation of AI technologies, such as deep learning and genetic algorithms, making them more accessible for complex waste management challenges.

- -

- Context: studies addressing circular economy and solid waste management with robust optimization methods for decision making and well-documented results.

- -

- Governance: studies focusing on governance practices, policies, principles, or mechanisms through the coordination and control of reverse solid waste supply chains within circular economy frameworks.

- -

- Study Type: empirical research articles and case studies published in peer-reviewed journals.

- -

- Methodology: studies employing MCDA, AI, or the integrated application of MCDA and AI for the optimization of solid waste management in reverse supply chains.

- -

- Relevance: studies demonstrating clear relevance to the identification of evidence concerning the research question.

- -

- Publication Date: studies published before 2015;

- -

- Publication Type: non-peer-reviewed articles or publications in journals with low impact;

- -

- Scope: systematic literature reviews with a similar scope to the current review;

- -

- Methodology: studies not involving MCDA or AI applications in solid waste management or studies with poorly described or weak methodologies;

- -

- Context: studies not applicable to the circular economy or solid waste management;

- -

- Focus: studies lacking a specific focus on solid waste optimization in reverse supply chains.

2.2. Search Strategy

(“urban solid waste” OR “municipal waste” OR “industrial waste” OR “agricultural waste”) AND (“circular economy” OR “circularity” OR “closed loop” OR “recycling” OR “upcycling” OR “valorisation”) AND (“multi-criteria decision analysis” OR “MCDA” OR “decision-making models” OR “optimization models”) AND (“artificial intelligence” OR “machine learning” OR “AI integration” OR “predictive analytics”) AND (“reverse supply chain governance” OR “reverse logistics” OR “stakeholder collaboration”) AND (“governance models” OR “decision-making governance” OR “management frameworks”) AND (“biotechnology” OR “green chemistry” OR “waste-to-energy technologies” OR “recycling technologies”) AND (“public policies” OR “private sector intervention” OR “community-based waste management” OR “socio-economic impacts” OR “sustainability policies”).

2.3. Screening and Selection of the Studies

3. Results

4. Results and Discussion

- Integration of MCDA and AI in RSCSW Optimization—Examination of how these methodologies enhance decision making and operational efficiency.

- Operational Efficiency, Cost Reduction, and Material Recovery—Analysis of how AI-driven and MCDA-based techniques contribute to economic and environmental performance.

- Framework and Roadmap for Optimizing RSCSW—Development of a structured integration model based on evidence from the reviewed studies.

- Governance and Policy Barriers—Discussion of the regulatory, financial, and technological constraints affecting implementation.

4.1. Integration of MCDA and AI in RSCSW Optimization

- -

- MCDA provides a structured framework for evaluating multiple criteria, such as economic, environmental, and social factors, enabling decision makers to balance trade-offs effectively. Techniques like TOPSIS, AHP, and BWM have been widely applied to prioritize strategies, select optimal locations for recycling centers, and evaluate the sustainability of waste treatment methods [45,49,56].

- -

- -

- Computational constraints: LeCun [38] highlights that deep neural networks require significant computational resources and large datasets for training, which can be a barrier in resource-constrained environments. This limitation is particularly relevant in developing countries, where digital infrastructure may be inadequate.

- -

- Algorithmic sensitivity: Culot et al. [35] note that genetic algorithms are highly sensitive to initialization parameters, which can lead to premature convergence or suboptimal solutions. This raises concerns about the robustness of AI-driven decision making in real-world waste management applications.

- -

- Lack of standardization: Unlike traditional MCDA methods with well-defined evaluation criteria, AI-driven approaches lack standardized frameworks for waste management applications [14]. This divergence highlights the need for more empirical validation and cross-sectoral benchmarking.

4.2. Operational Efficiency, Cost Reduction, and Material Recovery

- -

- Operational efficiency: The application of AI-based models has enabled the automation of decision-making processes, resulting in greater efficiency. For example, Meng et al. [45] demonstrated that the use of graph neural networks (GNNs) combined with TOPSIS improved ranking metrics by 5.78%, highlighting AI’s potential to enhance decision making in complex scenarios. Xia et al. [55] applied multi-objective programming with the NSGA-III algorithm to optimize reverse logistics networks, demonstrating the ability to robustly minimize costs and environmental impacts.

- -

- Cost reduction: The use of Mixed-Integer Linear Programming (MILP) and genetic algorithms has proven effective in minimizing operational costs. Lv et al. [60] proposed a p-median optimization model to determine the optimal locations for recycling centers in Shanghai, achieving a total cost reduction of CNY 144 million. Similarly, Xu et al. [59] developed a robust MILP model to handle uncertainties and carbon emission constraints, reducing costs in global reverse supply chains.

- -

- Material recovery: The integration of MCDA and AI has facilitated more efficient material recovery processes. Huang et al. [62] proposed an industrial symbiosis model that optimized the recycling and exchange of waste materials, achieving 90% material recovery efficiency. Santander et al. [63] explored the economic and environmental benefits of distributed plastic recycling for 3D printing, demonstrating the potential for material recovery in localized supply chains.

- -

- Scalability concerns: While AI-based methods optimize logistics, Kirchherr et al. [14] argue that the circular economy transition faces scalability challenges due to infrastructure gaps and regulatory fragmentation. This suggests that technological improvements alone are insufficient without broader systemic changes.

- -

- Regulatory inconsistencies: Xu et al. [59] demonstrated significant cost reductions using MILP models; however, regulatory inconsistencies often delay the implementation of optimization models, as pointed out by OECD [28]. This highlights the importance of policy alignment alongside technological advancements.

- -

- Social and ethical implications: While AI improves decision making, it may also displace low-skilled labor in waste management sectors, raising ethical concerns about job losses and the digital divide [61].

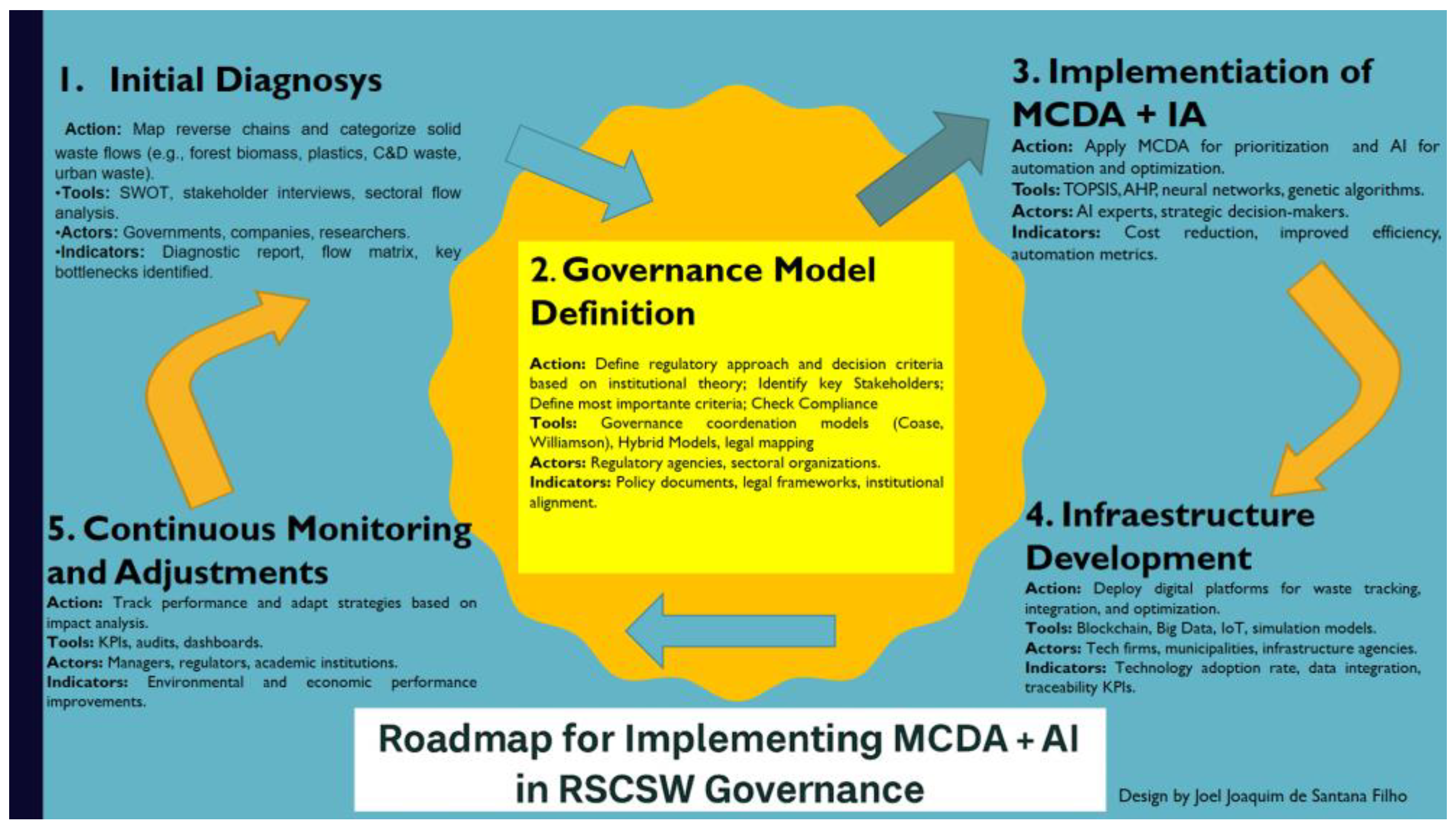

4.3. Framework and Roadmap for Optimizing RSCSW

4.4. Justification for Including a Framework and Roadmap in a Systematic Review

- -

- Bridging research and practice: Unlike traditional theoretical models, this framework offers a structured, actionable approach, addressing gaps highlighted by Kirchherr et al. [14].

- -

- Governance integration: While many AI frameworks focus on efficiency, this proposal integrates governance mechanisms such as blockchain-based traceability and policy-driven incentives, ensuring a holistic and practical approach [19]. The effectiveness of governance also depends on reducing transaction costs [24], a recurring challenge in reverse supply chains. According to Coase [23], well-defined regulatory structures can help minimize these costs and ensure greater operational efficiency. In this context, industrial symbiosis and public–private partnerships (PPPs) emerge as key solutions to financially support the implementation of advanced tracking and optimization technologies.

4.5. Governance and Policy Barriers

- -

- Regulatory fragmentation: The lack of cohesive regulatory frameworks across regions and sectors creates challenges in implementing standardized practices for waste management. Kirchherr et al. [14] identified regulatory inconsistencies as a major barrier to the circular economy, which aligns with the findings of Trochu et al. [62], who highlighted the need for accurate information and policy adjustments to improve reverse logistics networks.

- -

- Technological challenges: The integration of AI and MCDA requires significant technological infrastructure, including data collection systems, computational resources, and skilled personnel. Tseng et al. [19] emphasized the need for technological innovations to support the integration of MCDA and AI in RSCSW, which is further supported by Gardas et al. [52], who identified “Technology Integration” as a critical factor for adopting AI in supply chains.

- -

- Collaboration among stakeholders: Effective governance of RSCSW requires collaboration among diverse stakeholders, including governments, private sectors, and communities. Tseng et al. [19] highlight the role of Information and Communication Technologies (ICT), such as blockchain and the Internet of Things (IoT), in improving governance by providing greater visibility over material and waste flows.

- -

- The adoption of AI and MCDA in waste management may have significant social and ethical implications, such as the displacement of low-skilled workers. Public policies and training initiatives must be implemented to ensure a fair and inclusive transition to more advanced technologies.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Ma, X.; Azhari, L.; Wang, Y. Li-ion battery recycling challenges. Chem 2021, 7, 2843–2847. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using Waste Plastics as Asphalt Modifier: A Review. Materials 2021, 15, 110. [Google Scholar] [CrossRef] [PubMed]

- Braz, J.M.; Amaral, M.A.; Odakura, A.M.; Marcondes, A.S.; Neu, D.H. Utilização dos resíduos gerados na piscicultura. Rev. Multidiscip. De Educ. E Meio Ambiente 2021, 2, 36. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. The State of World Fisheries and Aquaculture 2024: Blue Transformation in Action; Food and Agriculture Organization of the United Nations: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- United Nations. Global Waste Management Outlook; UNEP: Nairobi, Kenya, 2020. [Google Scholar]

- Comissão Europeia. Estratégias para a Gestão de Resíduos na União Europeia; Comissão Europeia: Brussels, Belgium, 2021. [Google Scholar]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Morrissey, A.J.; Browne, J. Waste management models and their applications on sustainable solid waste management. Waste Manag. 2004, 24, 297–308. [Google Scholar] [CrossRef]

- Food and Agriculture Organization. Aquaculture Waste Management and Sustainability; FAO: Rome, Italy, 2020. [Google Scholar]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/2030agenda (accessed on 31 March 2025).

- Wilson, D.C.; Velis, C.; Cheeseman, C. Role of informal sector recycling in waste management in developing countries. Habitat Int. 2015, 50, 12–21. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Ormazabal, M. Towards a consensus on the circular economy. J. Clean. Prod. 2018, 179, 605–615. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Circular Economy: Principles and Applications; Ellen MacArthur Foundation: Wight, UK, 2019. [Google Scholar]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Tseng, M.L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.F.; Kuo, T.C. Circular economy meets industry 4.0: Can big data drive industrial symbiosis? Resour. Conserv. Recycl. 2020, 153, 104537. [Google Scholar] [CrossRef]

- Jayarathna, C.P.; Agdas, D.; Dawes, L.; Yigitcanlar, T. Multi-Objective Optimization for Sustainable Supply Chain and Logistics: A Review. Sustainability 2021, 13, 13617. [Google Scholar] [CrossRef]

- Um, N. Sustainable Waste Management in the Context of the Circular Economy. Sustainability 2025, 17, 1937. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Coase, R.H. The nature of the firm. Economica 1937, 4, 386–405. [Google Scholar] [CrossRef]

- Williamson, O.E. The Economic Institutions of Capitalism: Firms, Markets, Relational Contracting; Free Press: Los Angeles, CA, USA, 1985. [Google Scholar]

- Jessop, B. Governance and meta-governance: On reflexivity, requisite variety, and requisite irony. Gov. Int. J. Policy Adm. Inst. 2002, 15, 235–252. [Google Scholar] [CrossRef]

- Meckling, W.H.; Jensen, M.C. Theory of the firm: Managerial behavior, agency costs and ownership structure. J. Financ. Econ. 1976, 3, 305–360. [Google Scholar] [CrossRef]

- Yang, L.; Lu, L. Improving supply chain transparency: From the perspective of suppliers. Ann. Oper. Res. 2024. [Google Scholar] [CrossRef]

- OECD. G20/OECD Principles of Corporate Governance. Organisation for Economic Co-operation and Development. Disponível em: OECD Principles of Corporate Governance; OECD: Paris, France, 2015. [Google Scholar]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Rubio, S.; Chamorro, A.; Miranda, F.J. Characteristics of the research on reverse logistics (1995–2005). Int. J. Prod. Res. 2008, 46, 1099–1120. [Google Scholar] [CrossRef]

- Prahinski, C.; Kocabasoglu, C. Empirical research opportunities in reverse supply chains. Omega 2006, 34, 519–532. [Google Scholar] [CrossRef]

- Mutha, A.; Pokharel, S. Strategic network design for reverse logistics and remanufacturing using new and old product modules. Comput. Ind. Eng. 2009, 56, 334–346. [Google Scholar] [CrossRef]

- Koplin, J.; Seuring, S.; Mesterharm, M. Incorporating sustainability into supply chain management: A literature review. J. Clean. Prod. 2017, 141, 1311–1323. [Google Scholar]

- Keys, P.W.; Galaz, V.; Dyer, M.; Matthews, N.; Folke, C.; Nyström, M.; Cornell, S.E. Anthropocene risk. Nat. Sustain. 2019, 2, 667–673. [Google Scholar] [CrossRef]

- Culot, G.; Podrecca, M.; Nassimbeni, G. Artificial intelligence in supply chain management: A systematic literature review of empirical studies and research directions. Comput. Ind. 2024, 162, 104132. [Google Scholar] [CrossRef]

- Nasiri, F.; Huang, G. A fuzzy decision aid model for environmental performance assessment in waste recycling. Environ. Model. Softw. 2008, 23, 677–689. [Google Scholar] [CrossRef]

- Mardani, A.; Jusoh, A.; Nor, K.M.; Khalifah, Z.; Zakwan, N.; Valipour, A. Multiple criteria decision-making techniques and their applications—A review of the literature from 2000 to 2014. Econ. Res. Ekon. Istraživanja 2015, 28, 516–571. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Moher, D.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. PLoS Med. 2009, 6, e1000100. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Richardson, W.S.; Wilson, M.C.; Nishikawa, J.; Hayward, R.S. The well-built clinical question: A key to evidence-based decisions. ACP J. Club 1995, 123, A12–A13. [Google Scholar] [CrossRef] [PubMed]

- Covidence Systematic Review Software (2023) Veritas Health Innovation, Melbourne, Australia. Available online: www.covidence.org (accessed on 31 March 2025).

- Critical Appraisal Skills Programme (CASP). CASP Checklists. 2018. Available online: https://casp-uk.net/casp-tools-checklists/ (accessed on 31 March 2025).

- Meng, Z.; Lin, R.; Wu, B. Preference learning based on adaptive graph neural network for multi-criteria decision support. Appl. Soft Comput. 2024, 167, 112312. [Google Scholar] [CrossRef]

- Kartal, H.; Oztekin, A.; Gunasekaran, A.; Cebi, F. An integrated decision analytic framework of machine learning with multi-criteria decision making for multi-attribute inventory classification. Comput. Ind. Eng. 2016, 101, 599–613. [Google Scholar] [CrossRef]

- Oyebode, O.J.; Abdulazeez, Z.O. Optimization of supply chain network in solid waste management using a hybrid approach of genetic algorithm and fuzzy logic: A case study of Lagos State. Nat. Environ. Pollut. Technol. 2023, 22, 1707–1722. [Google Scholar] [CrossRef]

- Sengupta, D.; Das, A.; Bera, U.K.; Chen, L. A sustainable green reverse logistics plan for plastic solid waste management using TOPSIS method. Environ. Sci. Pollut. Res. 2023, 30, 97734–97753. [Google Scholar] [CrossRef]

- Ma, G.; Pan, X.; Zhang, Y.; Liu, T.; Wang, D. Empirical and simulated investigation of the solid waste reverse supply chain: A complex adaptive system perspective. J. Environ. Manag. 2024, 358, 120924. [Google Scholar] [CrossRef]

- Al-Thani, N.A.; Al-Ansari, T.; Haouari, M. Integrated TOPSIS-COV approach for selecting a sustainable PET waste management technology: A case study in Qatar. Heliyon 2022, 8, e10274. [Google Scholar] [CrossRef]

- Feitó-Cespón, M.; Costa, Y.J.; Pishvaee, M.S.; Cespón, R. A fuzzy inference-based scenario building in two-stage optimization framework for sustainable recycling supply chain redesign. Expert Syst. Appl. 2020, 165, 113906. [Google Scholar] [CrossRef]

- Gardas, R.; Narwane, S. An analysis of critical factors for adopting machine learning in manufacturing supply chains. Decis. Anal. J. 2024, 10, 100377. [Google Scholar] [CrossRef]

- Oluleye, B.I.; Chan, D.W.M.; Antwi-Afari, P. Adopting artificial intelligence for enhancing the implementation of systemic circularity in the construction industry: A critical review. Sustain. Prod. Consum. 2023, 35, 509–524. [Google Scholar] [CrossRef]

- Hu, Y.; Yu, X.; Ren, J.; Zeng, Z.; Qian, Q. Waste tire valorization: Advanced technologies, process simulation, system optimization, and sustainability. Sci. Total Environ. 2024, 942, 173561. [Google Scholar] [CrossRef] [PubMed]

- Xia, H.; Chen, Z.; Milisavljevic-Syed, J.; Salonitis, K. Uncertain programming model for designing multi-objective reverse logistics networks. Clean. Logist. Supply Chain 2024, 11, 100155. [Google Scholar] [CrossRef]

- Darzi, M.A. Evaluating e-waste mitigation strategies based on industry 5.0 enablers: An integrated scenario-based BWM and F-VIKOR approach. J. Environ. Manag. 2025, 373, 123999. [Google Scholar] [CrossRef] [PubMed]

- Hashemi, S.E. A fuzzy multi-objective optimization model for a sustainable reverse logistics network design of municipal waste-collecting considering the reduction of emissions. J. Clean. Prod. 2021, 318, 128577. [Google Scholar] [CrossRef]

- Ghosh, S.; Roy, S.K. Closed-loop multi-objective waste management through vehicle routing problem in neutrosophic hesitant fuzzy environment. Appl. Soft Comput. 2023, 148, 110854. [Google Scholar] [CrossRef]

- Xu, Z.; Elomri, A.; Pokharel, S.; Zhang, Q.; Ming, X.G.; Liu, W. Global reverse supply chain design for solid waste recycling under uncertainties and carbon emission constraint. Waste Manag. 2017, 64, 358–370. [Google Scholar] [CrossRef]

- Lv, J.Y.; Dong, H.J.; Geng, Y.; Li, H.F. Optimization of recyclable MSW recycling network: A Chinese case of Shanghai. Waste Manag. 2020, 102, 763–772. [Google Scholar] [CrossRef]

- Trochu, J.; Chaabane, A.; Ouhimmou, M. Reverse logistics network redesign under uncertainty for wood waste in the CRD industry. Resour. Conserv. Recycl. 2018, 128, 32–47. [Google Scholar] [CrossRef]

- Huang, L.F.; Zhen, L.; Yin, L.S. Waste material recycling and exchanging decisions for industrial symbiosis network optimization. J. Clean. Prod. 2020, 276, 124073. [Google Scholar] [CrossRef]

- Santander, P.; Sanchez, F.A.C.; Boudaoud, H.; Camargo, M. Closed loop supply chain network for local and distributed plastic recycling for 3D printing: A MILP-based optimization approach. Resour. Conserv. Recycl. 2020, 154, 104531. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Goh, M.; Fazlollahtabar, H.; Mamashli, Z. Modelling uncertainty in sustainable-green integrated reverse logistics network using metaheuristics. Comput. Ind. Eng. 2022, 163, 107828. [Google Scholar] [CrossRef]

- Chaube, S.; Pant, S.; Kumar, A.; Uniyal, S.; Singh, M.J.; Kotecha, K.; Kumar, A. An overview of multi-criteria decision analysis and the applications of AHP and TOPSIS methods. Int. J. Math. Eng. Manag. Sci. 2024, 9, 45–62. [Google Scholar] [CrossRef]

- Vanany, I.; Wangsa, I.D.; Savitri, N.A.; Putera, R.R.; Cholili, M.; Wibawa, B.M.; Atmaja, L.; Tseng, M.-L. Social-economic and environment impacts for a fish reverse supply chain: A mixed integer linear optimization approach. Clean. Logist. Supply Chain. 2024, 13, 100189. [Google Scholar] [CrossRef]

- Von Bertalanffy, L. General System Theory: Foundations, Development, Applications; George Braziller: New York, NY, USA, 1968. [Google Scholar]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Paul, J.; Criado, A.R. The art of writing literature review: What do we know and what do we need to know? Int. Bus. Rev. 2020, 29, 101717. [Google Scholar] [CrossRef]

- Boell, S.K.; Cecez-Kecmanovic, D. On being “systematic” in literature reviews. J. Inf. Technol. 2015, 30, 161–173. [Google Scholar] [CrossRef]

| Study | Year | Main Findings |

|---|---|---|

| Kirchherr et al. [14] | 2017 | Identifies barriers to the circular economy but does not propose advanced technological solutions. |

| Geissdoerfer et al. [15] | 2017 | Explores circular economy models without analyzing MCDA and AI in RSCSW governance. |

| Govindan et al. [18] | 2015 | MCDA improves efficiency in reverse logistics but lacks integration with AI. |

| Tseng et al. [19] | 2020 | Highlights technological innovations without an integrated approach to MCDA and AI. |

| Culot et al. [35] | 2020 | Presents AI applications in logistics without a direct connection to RSCSW. |

| Nasiri and Huang [36] | 2011 | Applies fuzzy logic to waste collection routing without a multi-criteria decision structure. |

| Mardani et al. [37] | 2015 | Comprehensive review of MCDA techniques, providing a robust theoretical basis for integration with AI. |

| LeCun et al. [38] | 2015 | Introduces deep learning, offering insights into advanced AI applications in RSCSW governance. |

| Study | Authors | Total Score (CASP) | Quality Category |

|---|---|---|---|

| 1 | Meng et al. [45] | 10/10 | High |

| 2 | Kartal et al. [46] | 10/10 | High |

| 3 | Oyebode et al. [47] | 10/10 | High |

| 4 | Sengupta et al. [48] | 10/10 | High |

| 5 | Ma et al. [49] | 10/10 | High |

| 6 | Tseng et al. [19] | 10/10 | High |

| 7 | Al-Thani et al. [50] | 10/10 | High |

| 8 | Feitó-Cespón et al. [51] | 10/10 | High |

| 9 | Gardas et al. [52] | 10/10 | High |

| 10 | Oluleye et al. [53] | 10/10 | High |

| 11 | Hu et al. [54] | 10/10 | High |

| 12 | Xia et al. [55] | 10/10 | High |

| 13 | Darzi [56] | 10/10 | High |

| 14 | Hashemi [57] | 10/10 | High |

| 15 | Ghosh et al. [58] | 10/10 | High |

| 16 | Xu et al. [59] | 10/10 | High |

| 17 | Lv et al. [60] | 10/10 | High |

| 18 | Trochu et al. [61] | 10/10 | High |

| 19 | Huang et al. [62] | 10/10 | High |

| 20 | Santander et al. [63] | 10/10 | High |

| 21 | Gholizadeh et al. [64] | 10/10 | High |

| 22 | Chaube et al. [65] | 10/10 | High |

| Ref. | Author(s) | Year | Journal | Study Title | Methodology | Key Contributions |

|---|---|---|---|---|---|---|

| [45] | Meng, Z. et al. | 2024 | Applied Soft Computing | Preference learning based on adaptive graph neural network for multi-criteria decision support. | Graph neural networks (GNN) and TOPSIS. | Adaptive method with high accuracy and interpretability. |

| [46] | Kartal, H. et al. | 2016 | Computers & Industrial Engineering | An integrated decision analytic framework of machine learning with multi-criteria decision making. | Combination of machine learning (SVM, ANN) and MCDM (AHP, VIKOR). | High accuracy in inventory classification with imbalanced data. |

| [47] | Oyebode, O.J. et al. | 2023 | Civil and Environmental Engineering | Optimization of Supply Chain Network in Solid Waste Management Using Genetic Algorithm and Fuzzy Logic. | Genetic algorithm and fuzzy logic. | Flexible model for waste management in Lagos, Nigeria. |

| [48] | Sengupta, D. et al. | 2023 | Environmental Science and Pollution Research | A sustainable green reverse logistics plan for plastic solid waste management using the TOPSIS method. | TOPSIS and mathematical modeling. | Reduction of costs and carbon emissions. |

| [49] | Ma, G. et al. | 2024 | Journal of Environmental Management | Empirical and simulated investigation of the solid waste reverse supply chain. | Agent-based modeling and regression analysis. | Identification of factors influencing waste sorting behavior. |

| [50] | Al-Thani, N.A. et al. | 2022 | Heliyon | Integrated TOPSIS-COV approach for selecting a sustainable PET waste management technology. | TOPSIS combined with a coefficient of variation (COV). | Closed-loop recycling as the optimal solution. |

| [51] | Feitó-Cespón, M. et al. | 2020 | Expert Systems with Applications | A Fuzzy Inference-based Scenario Building in Two-Stage Optimization Framework for Sustainable Recycling Supply Chain Redesign. | Fuzzy Inference System and epsilon-constraint method. | Robust solutions for redesigning sustainable reverse supply chains under uncertainty. |

| [52] | Gardas, R. et al. | 2024 | Decision Analytics Journal | An analysis of critical factors for adopting machine learning in manufacturing supply chains. | DEMATEL and qualitative analysis. | “Technology integration” and “Forecasting” as essential factors. |

| [53] | Oluleye, B.I. et al. | 2023 | Sustainable Production and Consumption | Adopting Artificial Intelligence for enhancing the implementation of systemic circularity. | Systematic review and SWOT analysis. | Framework for AI application throughout the building product lifecycle. |

| [54] | Hu, Y. et al. | 2023 | Journal of Cleaner Production | Waste tire valorization: Advanced technologies, process simulation, and system optimization. | Review of advanced technologies and sustainability assessment. | Proposal for a unified sustainability assessment system. |

| [55] | Xia, H. et al. | 2024 | Waste Management | Uncertain programming model for designing multi-objective reverse logistics networks. | Multi-objective programming with uncertainties and NSGA-III algorithm. | Robust model to minimize costs and environmental impacts. |

| [56] | Darzi, M.A. | 2024 | Journal of Environmental Management | Evaluating e-waste mitigation strategies based on Industry 5.0 enablers. | BWM (Best-Worst Method) and F-VIKOR. | “Take-back practices” as a key strategy for sustainable e-waste management. |

| [57] | Hashemi, S.E. | 2020 | Expert Systems with Applications | A fuzzy multi-objective optimization model for sustainable reverse logistics network design. | Fuzzy multi-objective programming and genetic algorithms. | Bee colony algorithm outperformed NSGA-II in solution exploration. |

| [58] | Ghosh, S. et al. | 2023 | Applied Soft Computing | Closed-loop multi-objective waste management through vehicle routing in a neutrosophic fuzzy environment. | Neutrosophic fuzzy logic and TOPSIS. | Pareto-optimal solutions for emission reduction and profit maximization. |

| [59] | Xu, Z. et al. | 2017 | Waste Management | Global reverse supply chain design for solid waste recycling under uncertainties. | Mixed-integer linear programming with robust optimization. | Robust model to handle uncertainties and carbon emission constraints. |

| [60] | Lv, J.Y. et al. | 2020 | Waste Management | Optimization of recyclable MSW recycling network: A Chinese case of Shanghai. | P-median optimization model. | Reduction of operational costs in municipal solid waste management. |

| [61] | Trochu, J. et al. | 2018 | Resources, Conservation and Recycling | Reverse logistics network redesign under uncertainty for wood waste in the CRD industry. | Mixed-integer linear programming (MILP) and scenario analysis. | Cost reduction and increased efficiency in wood recycling. |

| [62] | Huang, L. et al. | 2022 | Journal of Cleaner Production | Waste material recycling and exchanging decisions for industrial symbiosis network optimization. | Mixed-integer programming and epsilon-constraint method. | Balance between economic, environmental, and social objectives. |

| [63] | Santander, P. et al. | 2020 | Resources, Conservation and Recycling | Closed loop supply chain network for local and distributed plastic recycling for 3D printing. | Mixed-integer linear programming (MILP). | Economic and environmental benefits of distributed plastic recycling. |

| [64] | Gholizadeh, H. et al. | 2022 | Computers & Industrial Engineering | Modelling uncertainty in sustainable-green integrated reverse logistics network using metaheuristics. | Metaheuristics and fuzzy programming. | Efficient solutions for sustainable reverse logistics networks. |

| [65] | Chaube, S. et al. | 2024 | International Journal of Mathematical, Engineering and Management Sciences | An Overview of Multi-Criteria Decision Analysis and the Applications of AHP and TOPSIS Methods. | Review of MCDA methods (AHP and TOPSIS). | Detailed comparison between AHP and TOPSIS for multi-criteria decision-making. |

| [66] | Vanany et al. | 2024 | Asia University | A mathematical model for fish reverse supply chain considering social-economic and environmental impacts. | Mixed-integer linear programming (MILP). | Increased profit and reduced carbon emissions. |

| Ref | Author(s) | Population | Intervention | Comparison | Outcome |

|---|---|---|---|---|---|

| [45] | Meng, Z. et al. | Reverse supply chain of plastics | GNN + TOPSIS | Heuristic | 5.78% improvement in ranking metrics |

| [46] | Kartal, H. et al. | Inventory classification | SVM, ANN + AHP, VIKOR | Traditional | High accuracy in imbalanced data classification |

| [47] | Oyebode, O.J. et al. | Solid waste management in Lagos | Genetic algorithm + fuzzy logic | Traditional | Flexible model for waste management |

| [48] | Sengupta, D. et al. | Plastic solid waste management | TOPSIS + mathematical modeling | Traditional | Reduction of costs and carbon emissions |

| [49] | Ma, G. et al. | Solid waste reverse supply chain | Agent-based modeling + regression | Traditional | Identification of factors influencing waste sorting behavior |

| [50] | Al-Thani, N.A. et al. | PET waste management | TOPSIS + coefficient of variation (COV) | Traditional | Closed-loop recycling as the optimal solution |

| [51] | Feitó-Cespón, M. et al. | Sustainable Recycling Supply Chain Redesign | Fuzzy Inference System and epsilon-constraint method | Traditional | Robust solutions for redesigning sustainable RSC under uncertainty |

| [52] | Gardas, R. et al. | Manufacturing supply chains | DEMATEL + qualitative analysis | Traditional | Identification of critical factors for AI adoption |

| [53] | Oluleye, B.I. et al. | Building product lifecycle | Systematic review + SWOT analysis | Traditional | Framework for AI application in circularity |

| [54] | Hu, Y. et al. | Waste tire valorization | Advanced technologies + simulation | Traditional | Proposal for a unified sustainability assessment system |

| [52] | Xia, H. et al. | Multi-objective reverse logistics | Multi-obj programming + NSGA-III | Traditional | Robust model to minimize costs and environmental impacts |

| [56] | Darzi, M.A. | E-waste mitigation strategies | BWM + F-VIKOR | Traditional | “Take-back practices” as a key strategy for sustainable e-waste management |

| [57] | Hashemi, S.E. | Sustainable reverse logistics | Fuzzy multi-objective programming + genetic algorithms | Traditional | Bee colony algorithm outperformed NSGA-II in solution exploration |

| [58] | Ghosh, S. et al. | Vehicle routing in waste management | Neutrosophic fuzzy logic + TOPSIS | Traditional | Pareto-optimal solutions for emission reduction and profit maximization |

| [59] | Xu, Z. et al. | Global reverse supply chain | Mixed-int linear programming (MILP) + robust optimization | Traditional | Robust model to handle uncertainties and carbon emission constraints |

| [60] | Lv, J.Y. et al. | Municipal solid waste recycling | P-median optimization model | Traditional | Reduction of operational costs in Shanghai |

| [61] | Trochu, J. et al. | Wood waste reverse logistics | MILP + scenario analysis | Traditional | Cost reduction and increased efficiency in wood recycling |

| [62] | Huang, L. et al. | Industrial symbiosis network | MIP + epsilon-constraint method | Traditional | Balance between economic, environmental, and social objectives |

| [63] | Santander, P. et al. | Plastic recycling for 3D printing | MILP | Traditional | Economic and environmental benefits of distributed plastic recycling |

| [64] | Gholizadeh, H. et al. | Sustainable reverse logistics | Metaheuristics + fuzzy programming | Traditional | Efficient solutions for sustainable reverse logistics networks |

| [65] | Chaube, S. et al. | Multi-criteria decision analysis | Review of AHP and TOPSIS | Traditional | Detailed comparison between AHP and TOPSIS for multi-criteria decision-making |

| [66] | Vanany, I. et al. | Fish reverse supply chain | MILP | Traditional | Increased profit and reduced carbon emissions |

| RSCSW Chain | Decision Strategy (MCDA + AI) | Appropriate Governance Strategy | Observed Outcomes |

|---|---|---|---|

| Plastic Waste | TOPSIS + Neural Networks (GNN) for selecting recycling sites and route optimization. | Blockchain + Consortia: Traceability of waste flow and collaboration among municipalities. | Increased material recovery efficiency [62]. |

| Electronic Waste | BWM + F-VIKOR for prioritization of mitigation strategies (e.g., take-back practices). | Harmonized Public Policies: International regulations [28]. | Reduction in carbon emissions and increased circularity [56]. |

| Wood Waste (CRD) | Fuzzy Logic + Genetic Algorithms for optimizing reverse logistics under uncertainty. | Fiscal Incentives: Tax benefits for companies adopting wood recycling practices [61]. | Improved recycling efficiency [61]. |

| Tire Waste | NSGA-II/III: Multi-objective optimization (cost vs. environmental impact). | Public-Private Partnerships (PPP): Funding for advanced recycling technologies. | Reduction in the use of virgin raw materials [54]. |

| Organic Waste | AHP + Machine Learning (SVM): Waste generation forecasting and composting optimization. | Education and Awareness: Community programs promoting organic waste separation. | Increased organic compost production [49]. |

| Construction Waste | MILP (Mixed-Integer Linear Programming): Optimization of collection and recycling networks. | Local Regulation: Standards to reduce waste in construction sites [28]. | Reduced operational costs [59]. |

| Industrial Waste | Epsilon-Constraint + AI: Balancing economic, environmental, and social objectives. | Industrial Symbiosis: Exchange of waste among industries for reuse. | Increased waste reuse efficiency [62]. |

| Phase | Strategic Action | Tools/Methods | Responsible Entities | Success Indicators | References |

|---|---|---|---|---|---|

| 1. Initial Diagnosis | Mapping RSCSW chains and identifying logistical and regulatory bottlenecks. | SWOT Analysis, Stakeholder Interviews. | Governments, companies, researchers. | Diagnostic reports and gap analysis. | Oluleye et al. [53]: SWOT applied to lifecycle of building products; Gardas et al. [52]: Identifies critical factors via qualitative/DEMATEL analysis. |

| 2. Definition of Governance Model | Selecting regulatory approach and defining decision criteria. | Governance models (Coase, Williamson). | Regulatory agencies, sectoral organizations. | Policy documents and regulatory frameworks. | Oluleye et al. [53]: Proposes framework for AI governance; Gardas et al. [52]: Factors for AI adoption in manufacturing governance. |

| 3. Implementation of MCDA + AI | Applying MCDA for strategy prioritization and AI for automation. | TOPSIS, AHP, Neural Networks, Genetic Algorithms. | AI specialists, strategic decision-makers. | Reduction in operational costs, increased efficiency. | Meng et al. [45]: GNN + TOPSIS in plastic waste chain; Kartal et al. [46]: AI + AHP/VIKOR; Hashemi [57]: MCDA + genetic algorithms. |

| 4. Infrastructure Development | Implementing digital platforms for tracking and optimization. | Blockchain, Big Data, IoT. | Tech companies, municipalities. | Technology adoption rate and data integration levels. | Hu et al. [54]: Simulation for tire recycling; Ma et al. [49]: Agent-based modeling; Ghosh et al. [58]: AI in routing and emission control. |

| 5. Continuous Monitoring and Adjustments | Ongoing assessment of impacts and strategy refinements. | Performance Indicators (KPIs), audits. | Academics, regulators, managers. | Continuous improvement in environmental and economic indicators. | Darzi [56]: KPIs for e-waste practices; Xu et al. [60]: Robust optimization with emissions control; Gholizadeh et al. [64]: Fuzzy + metaheuristics. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Filho, J.J.d.S.; Paço, A.d.; Gaspar, P.D. Artificial Intelligence and MCDA in Circular Economy: Governance Strategies and Optimization for Reverse Supply Chains of Solid Waste. Appl. Sci. 2025, 15, 4758. https://doi.org/10.3390/app15094758

Filho JJdS, Paço Ad, Gaspar PD. Artificial Intelligence and MCDA in Circular Economy: Governance Strategies and Optimization for Reverse Supply Chains of Solid Waste. Applied Sciences. 2025; 15(9):4758. https://doi.org/10.3390/app15094758

Chicago/Turabian StyleFilho, Joel Joaquim de Santana, Arminda do Paço, and Pedro Dinis Gaspar. 2025. "Artificial Intelligence and MCDA in Circular Economy: Governance Strategies and Optimization for Reverse Supply Chains of Solid Waste" Applied Sciences 15, no. 9: 4758. https://doi.org/10.3390/app15094758

APA StyleFilho, J. J. d. S., Paço, A. d., & Gaspar, P. D. (2025). Artificial Intelligence and MCDA in Circular Economy: Governance Strategies and Optimization for Reverse Supply Chains of Solid Waste. Applied Sciences, 15(9), 4758. https://doi.org/10.3390/app15094758