Evaluation of Disassembling Process Inference Based on Positional Relations Matrix

Abstract

1. Introduction

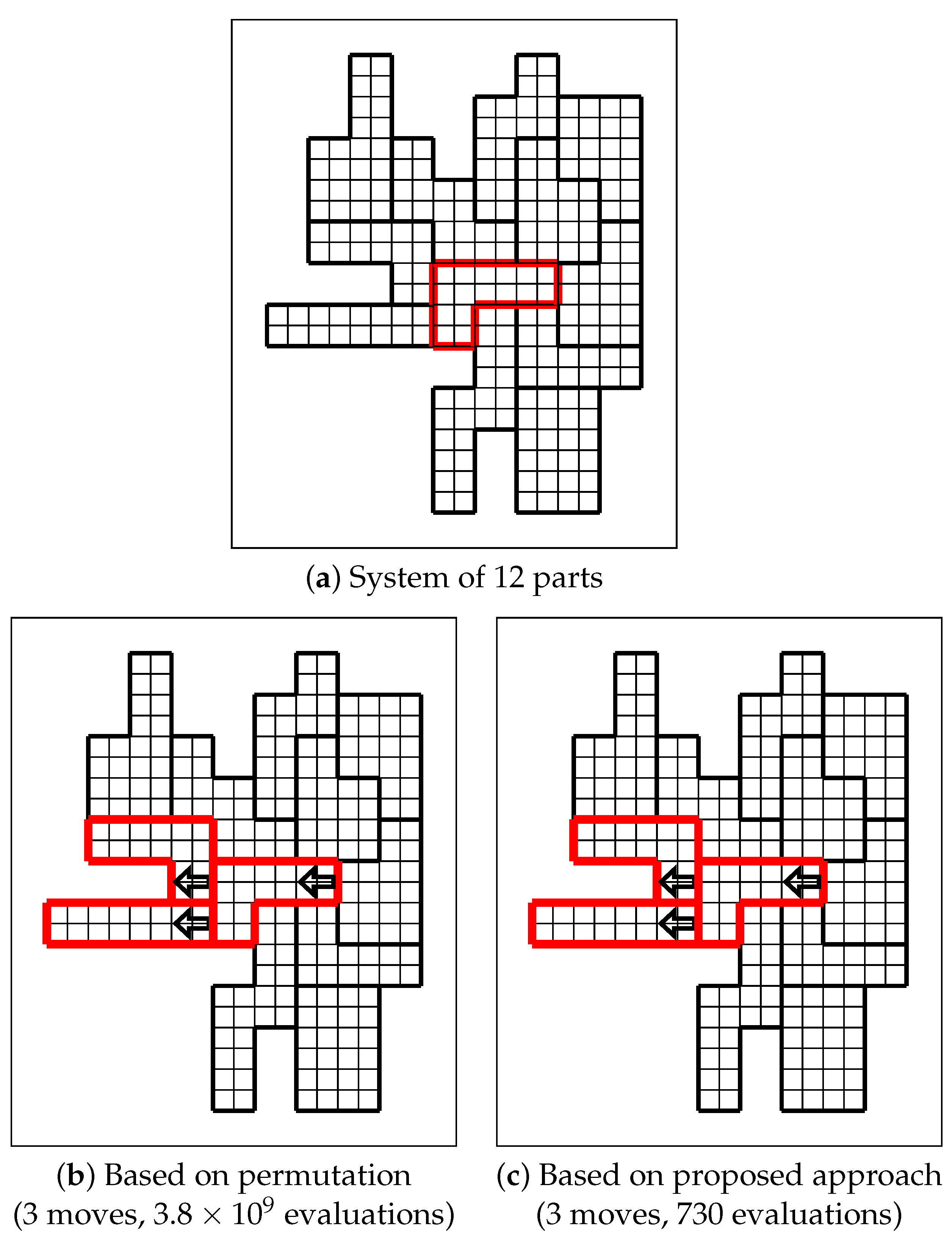

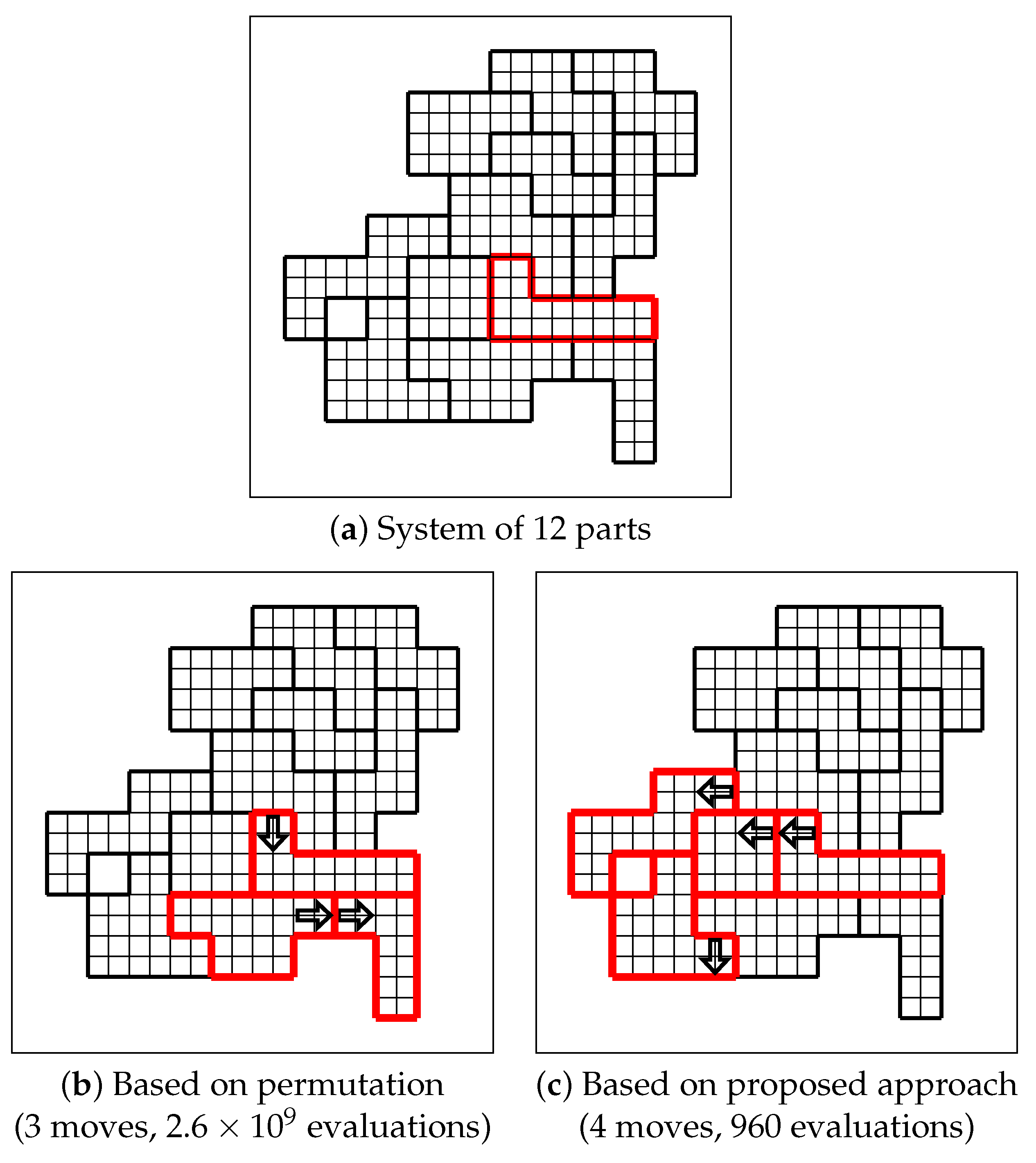

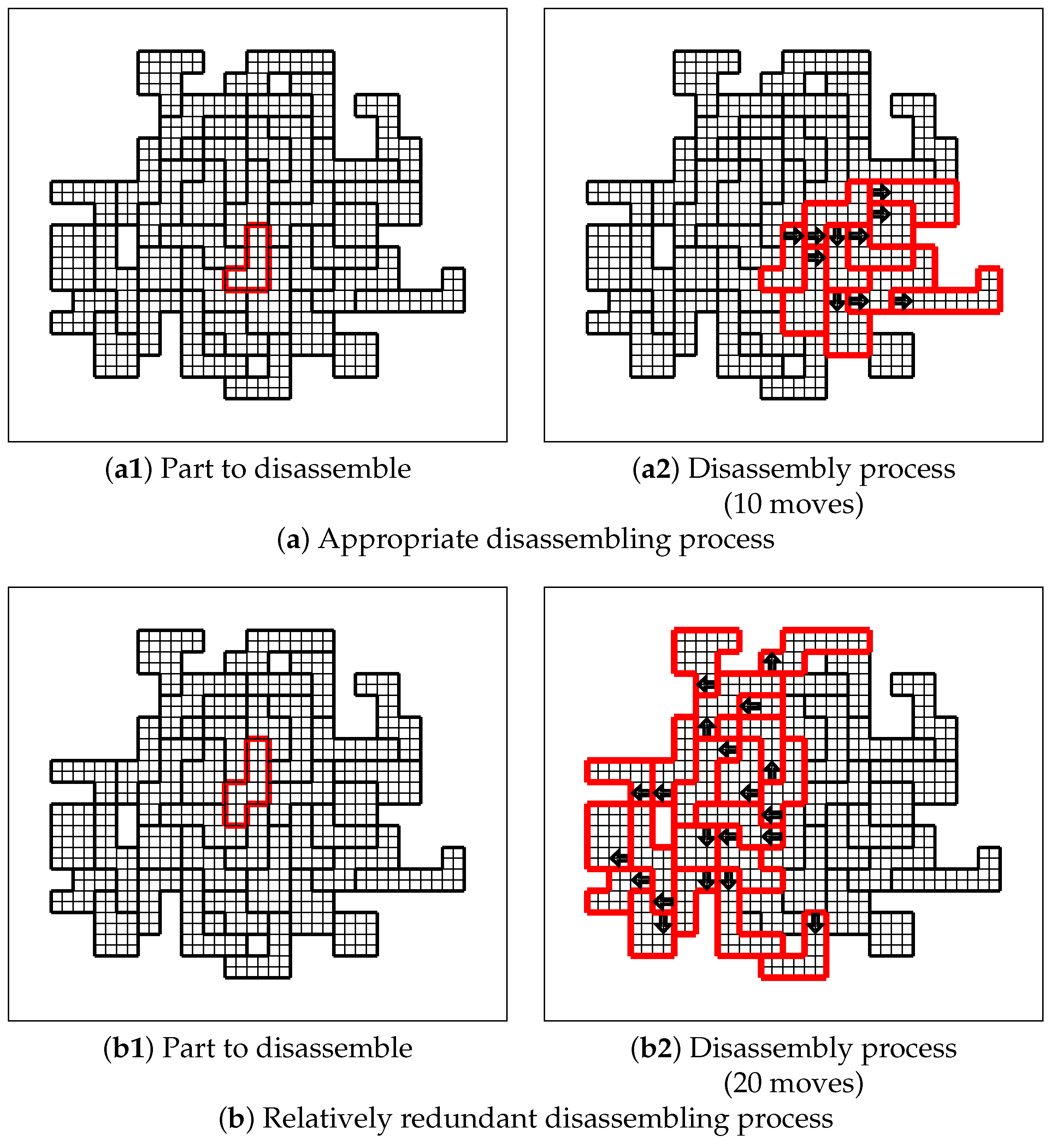

2. Disassembling Process Inference Based on Positional Relations Matrix

2.1. Positional Relations Matrix

2.2. Disassembling Process Inference

2.2.1. Preparation of Disassembly-Move Sets and Disassembly-Part Sets

2.2.2. Generation of Disassembling Process for Specified Parts

- Procedure: Disassembling Process (J)

- (1)

- Search for a disassembly move corresponding to the specified part J. The search of such is conducted from to , since a move that is available in earlier stage is expected to have fewer impeding parts. Adopt the first detected .

- (2)

- Use Sub-Procedure A as Mark Move () to mark the disassembly moves required to be performed in order to make move feasible.

- (3)

- Use Sub-Procedure B as Generate Sequence (J) to generate the sequence of disassembly moves, finally achieving move .

- Sub-Procedure A: Mark Move ()

- (1)

- Mark .

- (2)

- If , then the specified move is immediately feasible. Terminate this sub-procedure.

- (3)

- () There are impeding parts for move . For each part i, such that , search for a disassembly move corresponding to part i from to and use this procedure in a recursive manner as Mark Move ().

- Sub-Procedure B: Generate Sequence (J)

- (0)

- Set initial values as (stage number), (sequence length), (sequence (empty)), (already disassembled-part set (empty)).

- (1)

- For all the marked move , if then add the move at the end of sequence as . Increment sequence length as and update the disassembled-part set .

- (2)

- If , that is, the disassembly of the target part is achieved, then the required sequence of moves is accomplished as where is the target part; terminate this sub-procedure.

- (3)

- Increment stage number as and repeat from step (1).

2.3. Generating Optimal Disassembling Process

3. Evaluating Disassembling Process Inference

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- U.S. Bureau of Labor Statistics. National Census of Fatal Occupational Injuries in 2021. Available online: https://www.bls.gov/news.release/archives/cfoi_12162022.pdf (accessed on 17 January 2023).

- Vongbunyong, S.; Chen, W.H. General Disassembly Process. In Disassembly Automation: Automated Systems with Cognitive Abilities (Sustainable Production, Life Cycle Engineering and Management); Springer: Berlin/Heidelberg, Germany, 2015; pp. 9–24. [Google Scholar]

- Santochi, M.; Dini, G.; Failli, F. Computer aided disassembly planning: State of the art and perspectives. Proc. CIRP Ann. 2002, 51, 507–529. [Google Scholar] [CrossRef]

- Zhu, B.; Sarıgeçili, M.İ.; Roy, U. Disassembly information model incorporating dynamic capabilities for disassembly sequence generation. Robot. Comput. Integr. Manuf. 2013, 29, 396–409. [Google Scholar] [CrossRef]

- Go, T.F.; Wahab, D.A.; Ab Rahman, M.N.; Ramli, R.; Hussain, A. Genetically optimised disassembly sequence for automotive component reuse. Expert Syst. Appl. 2012, 39, 5409–5417. [Google Scholar] [CrossRef]

- Parsa, S.; Saadat, M. Intelligent selective disassembly planning based on disassemblability characteristics of product components. Int. J. Adv. Manuf. Technol. 2019, 104, 1769–1783. [Google Scholar] [CrossRef]

- Brogan, D.P.; DiFilippo, N.M.; Jouaneh, M.K. Deep learning computer vision for robotic disassembly and servicing applications. Array 2021, 12, 100094. [Google Scholar] [CrossRef]

- Guo, X.; Bi, Z.; Wang, J.; Qin, S.; Liu, S.; Qi, L. Reinforcement Learning for Disassembly System Optimization Problems: A Survey. Int. J. Netw. Dyn. Intell. 2023, 2, 1–14. [Google Scholar] [CrossRef]

- Nakamura, K.; Yamamoto, Y.; Nishimura, M.; Shiono, Y.; Shirasawa, R.; Nakano, T.; Aoki, T. Regularizing Oversmoothing of Temporal Convolutional Networks for Action Segmentation into Human Assembly Operations. J. Signal Process. 2023, 27, 75–79. [Google Scholar] [CrossRef]

- Kumar, M.R.M.; Ravi, C. A Novel Deep Reinforcement Learning Approach for Stability-Based Parallel Disassembly Sequence Planning Problem. SN Comput. Sci. 2025, 6, 265. [Google Scholar] [CrossRef]

- Frizziero, L.; Liverani, A.; Caligiana, G.; Donnici, G.; Chinaglia, L. Design for Disassembly (DfD) and Augmented Reality (AR): Case Study Applied to Gearbox. Machines 2019, 7, 29. [Google Scholar] [CrossRef]

- De Fazio, F.; Bakker, C.; Flipen, B.; Balkenende, R. The Disassembly Map: A new method to enhance design for product repairability. J. Clean. Prod. 2021, 320, 128552. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, S.; Jiang, Z.; Yan, W.; Wang, Y.; Zhang, H. A rule-driven method for disassembly sequence real-time planning of intelligent mixed-flow disassembly line. Comput. Ind. Eng. 2024, 198, 110666. [Google Scholar] [CrossRef]

- Ren, Y.; Meng, L.; Tian, G.; Li, Z.; Li, Y. An Efficient m-Step Lookahead Rollout Algorithm for Profit-Oriented Selective Disassembly Sequence Planning with Operation Stochastic Failure. Eng. Appl. Artif. Intell. 2025, 145, 11017. [Google Scholar] [CrossRef]

- Kunishi, D.; Iwahara, R.; Ishikawa, H.; Tsuruta, R.; Takeda, M.; Fukuhara, T.; Hamabe, T.; Nagai, T. Initiatives for Making Vehicles and Parts Easier to Dismantle. TOYOTA Tech. Rev. 2025, 70, 11–21. [Google Scholar]

- Shinoda, S.; Shimozawa, K.; Niwa, A.; Kawase, T.; Matsumoto, T.; Mizumachi, T. A proposal for prototype free production preparation processes utilizing 3DCG animations. Ind. Eng. Manag. Syst. 2009, 8, 109–120. [Google Scholar]

- Yamada, K.; Monma, T.; Hanahara, K. Disassembling process inference using positional relations matrix for complicated machines. Mech. Eng. Res. 2023, 11, 1–8. [Google Scholar] [CrossRef]

- Hanahara, K.; Yamada, K. Generating benchmark problems for disassembling process inference. Manuf. Syst. Div. Conf. 2024, 2024, 168–171. (In Japanese) [Google Scholar] [CrossRef]

- Shannon, R.E. Systems Simulation (the Art and Science); Prentice-Hall: Englewood Cliffs, NJ, USA, 1975; Section 2.10. [Google Scholar]

| Number of parts | 10 | 30 | 100 | 300 | 1000 |

| Computational cost |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hanahara, K.; Yamada, K. Evaluation of Disassembling Process Inference Based on Positional Relations Matrix. Appl. Sci. 2025, 15, 4736. https://doi.org/10.3390/app15094736

Hanahara K, Yamada K. Evaluation of Disassembling Process Inference Based on Positional Relations Matrix. Applied Sciences. 2025; 15(9):4736. https://doi.org/10.3390/app15094736

Chicago/Turabian StyleHanahara, Kazuyuki, and Kaori Yamada. 2025. "Evaluation of Disassembling Process Inference Based on Positional Relations Matrix" Applied Sciences 15, no. 9: 4736. https://doi.org/10.3390/app15094736

APA StyleHanahara, K., & Yamada, K. (2025). Evaluation of Disassembling Process Inference Based on Positional Relations Matrix. Applied Sciences, 15(9), 4736. https://doi.org/10.3390/app15094736