Abstract

Nano-modified concrete has attracted wide attention due to its improved mechanical properties. Among them, compressive strength is the most critical indicator. However, testing nano-concrete is costly and complex because it requires control over many factors, such as nanoparticle content and dispersion. Machine learning offers a data-driven way to predict compressive strength more efficiently. It reduces trial-and-error efforts and supports mix design optimization. Currently, machine learning is more adept at handling complicated datasets than experimental and traditional statistical models. In this article, the development of machine learning research in predicting the strength of concrete enhanced by nanoparticles is reviewed. First, we systematically outline a three-phase ML framework encompassing data curation, model development, and validation protocols; next, popular algorithms and their uses in predicting the strength of nano-modified concrete are evaluated, such as Artificial Neural Networks, K-Nearest Neighbor, Random Forest, etc. Ultimately, the article offers a forward-looking perspective on how future machine learning advancements can foster and accelerate the development of nano-modified concrete.

1. Introduction

Concrete strength is key to evaluating the stability of reinforced concrete structures. Pressure testing is a standard method used to determine this strength. It depends on cement ratios, aggregates, and moisture content. However, testing is expensive. ML algorithms are now used for predicting strength based on data [1,2,3,4,5]. ML uses statistical methods to learn from existing data and produce accurate predictions [6]. Traditional mix designs rely on regression models. But these are less accurate for modern cement composites. As a result, ML models are being introduced to improve prediction accuracy.

In recent years, with the development of Big Data, artificial intelligence (AI), and other technologies, ML prediction of some properties of concrete has gradually emerged in the construction industry [7,8,9,10]. As the material of choice for infrastructure construction, concrete’s mechanical properties are a primary evaluation index. Prediction models based on ML have been widely investigated to evaluate concrete’s compressive strength and other related properties [11,12].

The high cost of mechanical property testing and lack of reliable prediction models for nano-modified concrete constitute a critical research challenge in construction materials science. Traditional concrete strength evaluation relies on standardized pressure testing based on cement–aggregate ratios and moisture content. However, testing nano-modified concrete involves additional complexities including nanoparticle dispersion uniformity, dosage optimization (e.g., 0–1.5% nano-silica content [13]), and multi-phase interface effects, leading to exponentially increased experimental costs. This creates an urgent need for accurate predictive models to guide material design and application.

Nanomaterials are materials with at least one dimension under 100 nanometers. They have high surface energy, reactivity, and strength due to their size. These features improve composite materials. For example, Rashid et al. [14] reviewed nanotechnology in fiber-reinforced polymer composites.

Nanomaterials help concrete in three main ways. First, their chemical makeup matters. For example, nano-silica reacts with calcium hydroxide forming an extra C-S-H gel, which makes the concrete stronger. Second, their tiny size lets them fill in pores, making the concrete denser and stronger. Third, the shape of the particles also matters. Round particles fill gaps, and long or thin particles can connect cracks and improve toughness.

The use of nanomaterials to improve the typical properties of concrete has garnered a lot of interest. Nanomaterials possess properties such as high surface activity due to their small particle size but the large specific surface area, and ordinary concrete needs to be compounded with other materials due to its natural defects. In terms of enhancing the durability and mechanical properties of cementitious composites, the report of RILEM Technical Committee 197-Nanotechnology in Construction Materials (TC 197-NCM) [15] explores related applications. The application of nanoscience and nanotechnology to cementitious composites was reported as early as the late 1980s and research in this area has been active for almost two decades [16]. Nano-metallic and non-metallic oxide cementitious composites were first used to modify or enhance the properties of cementitious materials [17]. After recognizing the nanoscale structure and discovering that substituting nano-silica (NS) for cement reduces the cost of concrete and reduces the carbon footprint of the concrete product [13], work was initiated on silica nanoparticles and nanofibers to improve the strength of cementitious materials, etc. [18]. NS can increase the hydration reaction rate and improve the hydration effect of cement, and nanoscale particle filling can improve the performance of composites. It was found that the compressive strength of concrete increased significantly when the NS dosage ranged from 0 to 1.5%, and gradually increased with the increase in NS dosage. Researchers used NS and nanofibers to improve the strength, durability, and processability of cement composites [19]. Nano calcium carbonate can improve the early hydration reaction of cement and enhance the early strength, and the synergistic use of nano-concrete (NC) to improve the resistance to chloride penetration with polypropylene fibers (PPFs) can provide better durability performance for recycled aggregate concrete (RAC) [20]. Nano titanium dioxide not only improves the mechanical properties of concrete, but also improves durability, especially compressive strength, and the gradient lifting model more accurately predicts the compressive strength of nano titanium-based concrete [21]. Other than nano-silica, other nanomaterials are also been used to improve concrete. Carbon nanotubes (CNTs) can bridge cracks and improve toughness. Nano-alumina speeds up cement hydration and increases early strength. Nano-iron oxide helps reduce pores and improves resistance to chloride. Nano-clay makes the mix denser and more waterproof. Nano-calcium carbonate works as a nucleation site and helps early C-S-H formation. These materials improve concrete by filling pores, enhancing hydration, or strengthening the transition zone. Using different nano-additives together can further boost strength and durability, as shown in Table 1.

Table 1.

Overview of nanomaterials used for concrete modification.

The cost of testing nano-modified concrete is relatively high. At present, the design of mechanical properties is mainly based on experience and specifications, and there is no widely used prediction model.

Machine learning has been used in many other engineering fields. In structural health monitoring, ML helps detect cracks and predict damage. In geotechnical engineering, it is used to forecast soil behavior and slope stability. ML also supports material design by predicting strength, durability, and thermal properties. These successful cases show that ML can handle complex, multi-factor problems. This makes it suitable for predicting the compressive strength of nano-modified concrete.

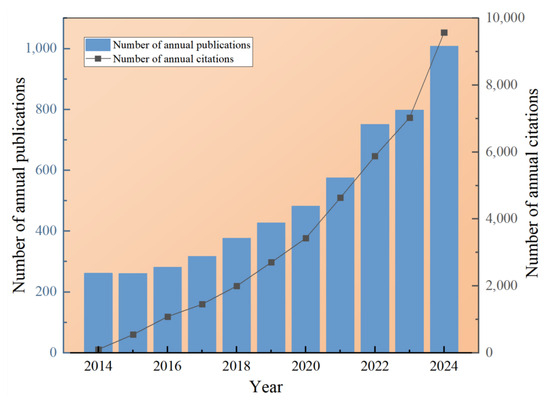

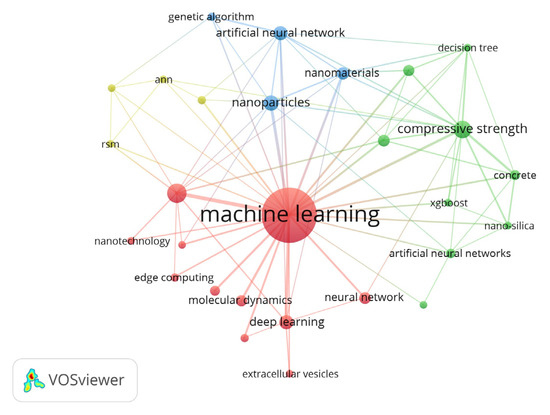

With the rise in artificial intelligence in recent years, it has become a common practice to use ML methods in engineering problems [28,29,30,31,32]. ML is a subfield of AI that has many applications beyond simple data analysis. The regression function in ML has been used in multiple instances, one of which is to predict the compressive strength of concrete. ML uses algorithms that learn from input data and produce highly accurate output data compared to more traditional regression techniques [33]. Artificial Neural Networks (ANNs) and Support Vector Machines (SVMs) are the most popular machine-learning techniques for predicting the compressive strength of concrete. Dantas et al. [34] used an artificial neural network to predict the compressive strength of construction and demolition waste (CDW) concrete. Chou et al. [35,36] explored several ML methods including ANNs and SVMs for predicting the compressive strength of concrete. Mustapha and Mohamed [37] applied a weighted SVM-based prediction method to a more complex problem to predict the unconfined compressive strength of high-performance concrete (HPC). Pham et al. [38] improved the least squares SVM with meta-heuristic optimization. Naderpour et al. [7] used ANN to predict the environmental strength of concrete. Ashrafian et al. [39] predicted the strength of fiber concretes and ultrasonic pulse velocity based on heuristic regression methods. The analysis of the Web Of Science data from 2014 to 2024 is shown in Figure 1, which shows a significant increase in ML publications related to nano-modified concrete, and further, as shown in Figure 2, it is seen that the most relevant topics for nano-modified concrete in the last 10 years are DT, eXtreme Gradient Boosting (XGB), and ANN; the ML, nanomaterials, and machine learning part of the model are shown by visualization, which shows that the diverse applications of ML in nano-modified concrete. To support this review, a structured literature search was conducted. Sources were mainly retrieved from Web of Science. We used general combinations of keywords such as (“nano”OR “nano concrete”) AND “machine learning”. The publication years were limited to 2014–2024. Only English peer-reviewed journal articles and relevant conference papers were considered. The search results were manually screened based on titles and abstracts to exclude duplicates and unrelated studies.

Figure 1.

Machine learning publications related to nanomodified concrete in the last decade.

Figure 2.

Machine learning and nano-modified concrete related topics.

This article first outlines the steps and common algorithms for developing ML models for concrete strength prediction. It then examines the advancements made in applying ML to the prediction of nano-modified concrete strength and provides an outlook for the future direction of ML in nano-modified concrete.

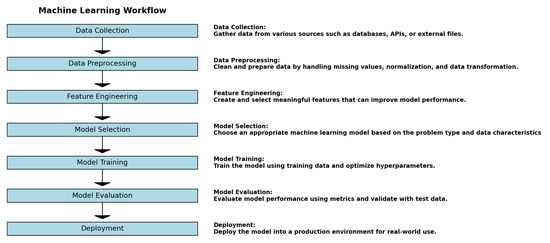

2. Conventional Process of Machine Learning

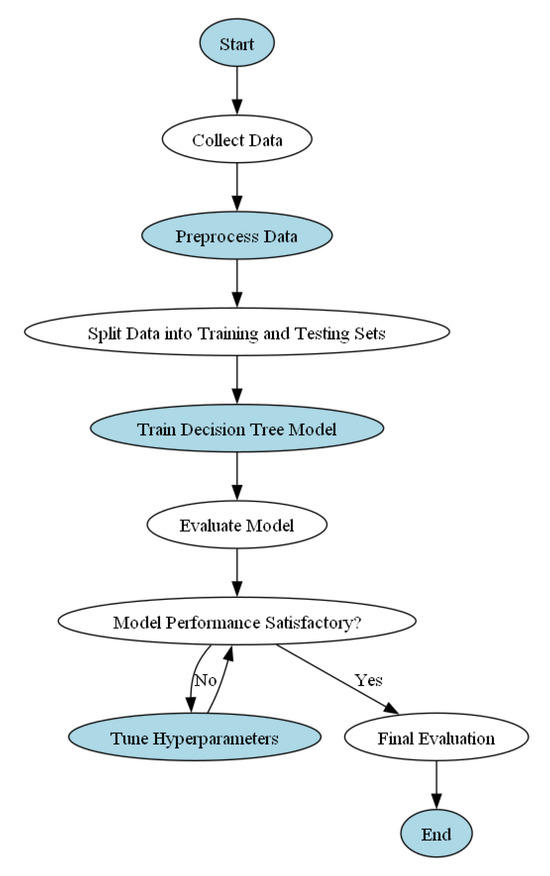

The process of creating ML prediction models mainly involves three steps: data collection, model establishment, and model evaluation.

- (1)

- In the data collection phase, data quality checks ensure data integrity by addressing missing values, outliers, and duplicates. Missing values can be removed or imputed using statistical methods; extreme outliers may be excluded if they significantly impact results. Data are partitioned into training, validation, and testing sets to facilitate effective model training, tuning, and evaluation. For certain cases, specific values such as 0 or −1 can be used to fill missing values.

- (2)

- In the model establishment phase, ML algorithms are chosen based on problem type and data. Common algorithms include supervised, unsupervised, and reinforcement learning. Model structure and parameters are defined, and the model is trained to minimize loss. Feature selection narrows down the feature set for high-precision and actionable insights. Classic feature selection methods include genetic algorithms, evolutionary algorithms like particle swarm optimization, and stochastic methods like Monte Carlo.

- (3)

- The final step involves interpreting, testing, and evaluating the model. Model evaluation in ML is the process of measuring and analyzing the performance of the trained model. It aims to assess the model’s performance and accuracy in solving problems and provides metrics to evaluate its performance. Model evaluation measures performance using metrics like root mean square (RMSE), mean absolute error (MAE), mean absolute percentage (MAPE), and correlation coefficient (R2) on the testing set to assess accuracy and problem-solving capabilities.

Figure 3.

Machine learning rough flowchart.

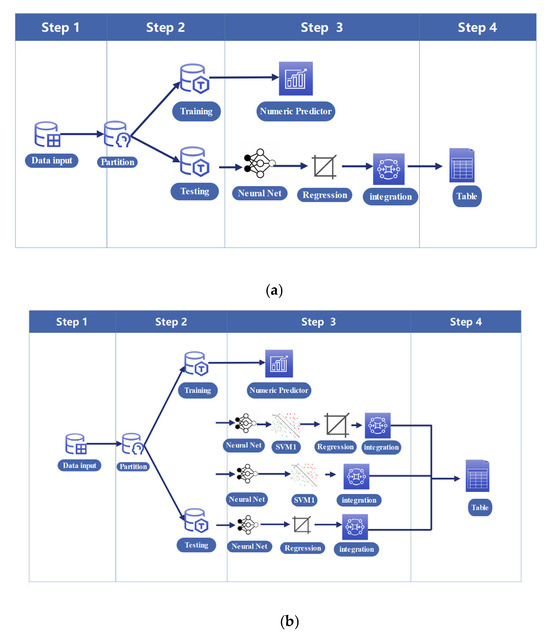

Figure 4.

(a) Individual model prediction flowchart. (b) Integrated model prediction flowchart.

3. Common Algorithms for Machine Learning

3.1. Artificial Neural Networks (ANNs)

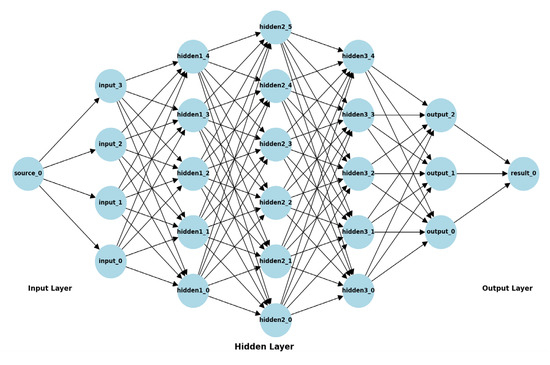

Artificial Neural Networks (ANNs) are well-suited for handling large and complex machine learning tasks. An ANN consists of interconnected layers of edges and nodes, known as neurons, with weighted values. Multiple hidden layers can be inserted between the input and output layers. In this review, ANN models, as shown in Figure 5, use three hidden layers. ANN’s capabilities extend to deep learning, enabling the construction of multi-layered perceptrons that simulate the information transmission mechanism of biological neurons. Through training on input data, ANN learns the relationship between inputs and outputs. If the network’s predictions are inaccurate, the system adjusts the weights, gradually improving its ability to recognize patterns after sufficient training [40,41].

Figure 5.

ANN schematic diagram.

3.2. K-Nearest Neighbor (KNN)

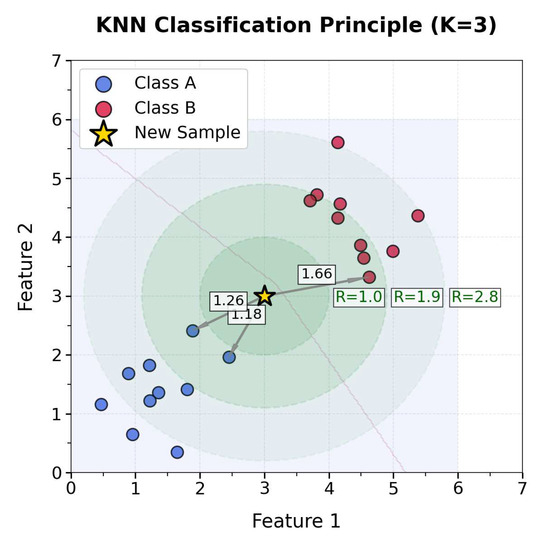

The K-nearest neighbor (Figure 6) is a basic classification and regression method. It is one of the simplest algorithms in data mining technology, and its core function is to solve the supervised classification problem. The selection of the k value is also very important, in the application, if the k value is selected too large, it can easily cause underfitting, while too small can easily cause overfitting. Cross-validation results further reveal the prediction characteristics of the KNN model on the nano-concrete dataset (Data volume = 1030). When k = 3, the model shows sensitivity to outliers, particularly at a nano-SiO2 dosage of 0.5%, resulting in a relatively high MAE of 3.2 MPa. Conversely, using k = 10 leads to over-smoothing, which increases prediction deviation in the high dosage range (1–2%), with an MAE of 4.5 MPa. The best performance is achieved at k = 5, where the model reaches an optimal MAE of 2.8 MPa [42]. We generally select a smaller value, usually using cross-validation to select the optimal k value. The advantages of the algorithm are as follows: 1. simple, good implementation, no need to estimate the parameters, no need to train; 2. suitable for multi-classification problems (objects with multiple class labels), KNN performs better than SVMs in these cases. In small-scale nanomaterial datasets (e.g., n < 500), KNN demonstrates strong performance but is sensitive to feature scaling. It is recommended to apply Min–Max normalization to parameters with significant differences in magnitudes, such as nanoparticle size (nm) and specific surface area (m2/g). However, the KNN algorithm has the following drawbacks: (1) When the samples are unbalanced, such as a large sample capacity of one class and a small sample capacity of other classes, it is possible to lead to a majority of samples of large-capacity classes among the K neighbors of the sample when a new sample is input. (2) A large amount of computational effort, and for each sample to be classified, the distance from it to the full set of known samples has to be computed in order to find its K nearest neighbors [43,44]. Although the current application of KNN in nano-modified concrete is limited, its performance on small datasets and multi-label tasks shows potential. As more nanomaterial datasets become available, KNN may gain broader application in this field. Therefore, it is included here for completeness and future research reference.

Figure 6.

KNN schematic diagram.

3.3. Decision Tree (DT)

A decision tree (Figure 7) maps input features to outcomes through step-by-step splits. It is simple to understand, needs little data preparation, and works well for rule extraction. In nano-concrete studies (Figure 6), it has been used to identify patterns, but tends to overfit complex interactions (R2 gap > 0.25 in many cases) and performs poorly with high-dimensional inputs. Random forests [42], which combine hundreds of decision trees with bootstrapping and random feature selection, offer better stability and prediction accuracy.

Figure 7.

Decision tree diagram.

To prevent overfitting in decision trees, the following strategies are considered:

- Limit the depth of the tree (e.g., using max_depth) to avoid overly complex models;

- Set minimum samples for splitting and leaf nodes (e.g., min_samples_split and min_samples_leaf) to prevent overly fine splits;

- Control the maximum number of leaf nodes (max_leaf_nodes) to restrict tree size;

- Apply pruning techniques (such as setting ccp_alpha for cost complexity pruning) to remove redundant branches;

- Use ensemble methods (like Random Forest and Gradient Boosting Trees) to reduce variance and improve generalization;

- Clean the data and select relevant features to eliminate noise and reduce the risk of overfitting;

- Increase the amount of training data or use cross-validation to enhance model robustness and generalization ability.

However, decision trees can be sensitive to irrelevant or noisy features in high-dimensional spaces, which may lead to unstable model structures and unreliable predictions. To address this issue, we propose the following solutions: (1) performing feature selection or dimensionality reduction to retain the most informative features; (2) using ensemble methods such as Random Forest or Gradient Boosting Trees to reduce the instability of individual trees; and (3) incorporating regularization techniques, such as limiting the tree depth or setting minimum samples for splits, to control model complexity.

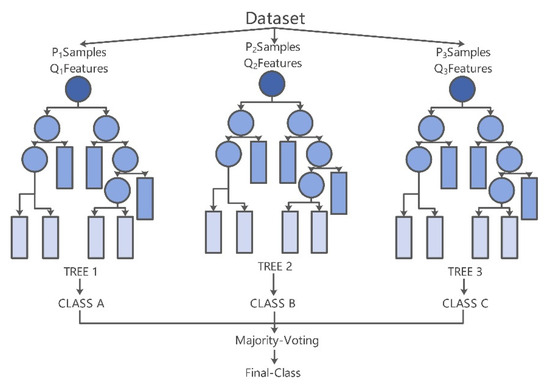

3.4. Random Forest (RF)

Before introducing Random Forest (RF), we need to introduce the concept of Bagging, also known as bootstrap aggregating, which is an integrated technique for training classifiers on the original dataset by re-selecting k new datasets through put-back sampling. RF is a kind of Bagging algorithm, RF has its own rules and designs for some of the details of Bagging. RF (Figure 8) uses a classification regression tree as a weak learner, while the general classification regression tree will select all the features for modeling. Therefore, not only the features are random, but also the feature randomness is guaranteed. That is, better generalization ability and resistance to overfitting (low variance) can be achieved. However, the fit for the training set will be worse [22,45,46].

Figure 8.

Random Forest schematic diagram.

The advantage of RF is that training can be highly parallelized and there is an improvement in training speed for samples with large capacity. After training, the importance of each feature for the output can be given, and due to the use of random sampling, the variance of the trained model is small and the generalization ability is high. However, for engineering applications, the interpretability of RF can be a crucial factor in understanding the relationships between input variables and the predicted outcomes. Although the RF model is often regarded as a “black-box” approach, there are techniques, such as feature importance analysis and partial dependence plots, that can help elucidate how different variables contribute to the model’s predictions. These interpretability tools can improve the trust and applicability of RF models in real-world scenarios, making them more valuable for decision-making in concrete design.

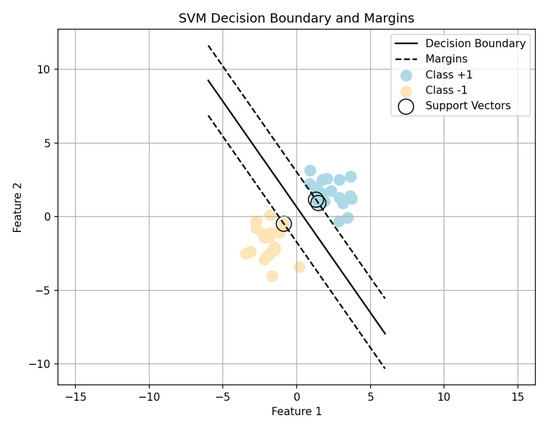

3.5. Support Vector Machine (SVM)

SVM is a supervised learning algorithm used for classification and regression analysis. It can perform linear or nonlinear classification as well as regression analysis. The basic principle of SVM (Figure 9) is to find an optimal hyperplane (which is a straight line in two-dimensional space) that separates the samples of different categories and maximizes the distance from the nearest sample point to the hyperplane. Due to its excellent generalization ability, SVM usually performs well on small sample datasets, but for large-scale datasets, the training time is long, so to use SVM, an appropriate kernel function is preferred [47,48,49].

Figure 9.

SVM schematic diagram.

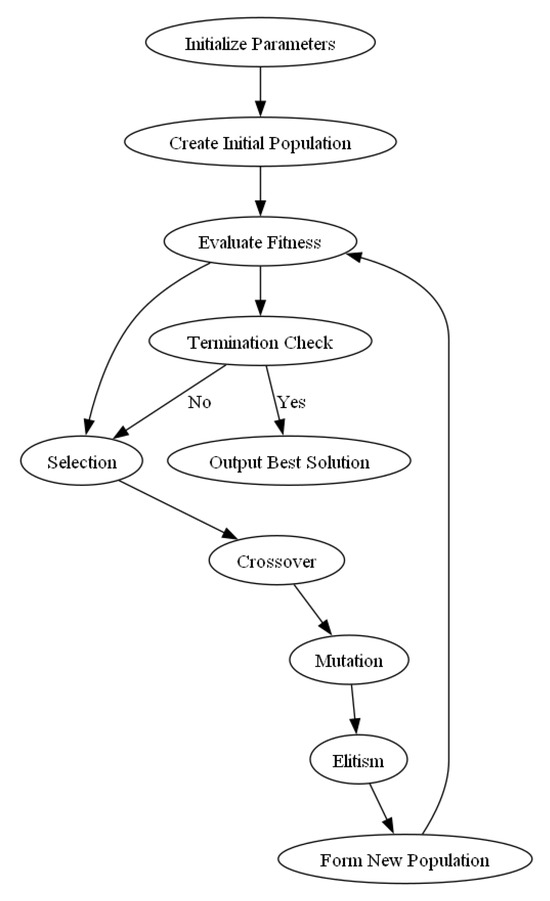

3.6. Gene Expression Programming (GEP)

Gene Expression Programming (GEP) is an evolutionary algorithm that combines the features of genetic algorithms (GAs) and Genetic Programming (GP) to automatically discover a model or function for solving a problem by simulating the process of biological evolution and gradually optimizing it through selection, crossover, and mutation operations starting from a randomly generated initial population of solution. GEP (Figure 10) has significant advantages in terms of structural flexibility, efficiency of genetic operations, interpretability, adaptability, and robustness. These advantages enable GEP to provide efficient, interpretable, and robust solutions when dealing with complex problems. However, GEP also has its limitations, such as parameter selection, overfitting problems, local optimal solution problems, and computational complexity, which need to be carefully considered and adapted in practical applications [29,50,51].

Figure 10.

GEP schematic diagram.

In practical applications, Gene Expression Programming (GEP) faces several challenges that may affect its performance, including the sensitivity to parameter settings, the risk of overfitting, and the computational demands associated with its evolutionary process. To address these issues, we adopted the following strategies.

First, since GEP performance is closely tied to its parameter configuration—such as head length, the number of genes, and mutation rates—we employed a combination of empirical tuning and automated search techniques to identify suitable parameter values. Cross-validation was also used to ensure the selected parameters generalized well beyond the training data.

Second, to mitigate overfitting, we introduced complexity control during the evolution process. This included penalizing overly long or overly complex expressions in the fitness function, as well as setting limits on the depth and size of the evolved trees. Additionally, we monitored validation performance and applied early stopping when necessary to prevent the model from adapting too closely to the training data.

Lastly, considering the computational complexity of GEP—especially when dealing with larger datasets or a high number of generations—we optimized the runtime by reducing the dimensionality of the input space and limiting the number of chromosomes per generation. Where possible, we parallelized the evolution process to accelerate convergence without compromising model quality.

These strategies helped improve the stability, generalization, and efficiency of the GEP model in our study.

4. The Application of Machine Learning in Nano-Modified Concrete

Currently, ML has gradually matured in the prediction of ordinary concrete properties, the application of nano-modified concrete mechanical properties prediction also shows a growing trend, the performance prediction model is constantly optimized to promote the development of nano-modified concrete properties and material proportioning reverse design, this paper summarizes several algorithms and their applications which are more representative in the prediction of nano-modified concrete strength, as shown in Table 2.

Table 2.

Summary of machine learning models used for predicting compressive strength of nano-modified concrete.

4.1. Artificial Neural Network (ANN) Algorithm

Artificial Neural Networks have the advantage of high parallel distributed processing capability, distributed storage and learning capability, ability to adequately approximate complex nonlinear relationships, associative memory capabilities, and so on. The input layer receives characteristic parameters such as nanomaterial dosage and water-cement ratio, the hidden layer implements nonlinear mapping through activation functions, and the output layer generates a predicted value of compressive strength. This hierarchical information processing mode is similar to the hierarchical response mechanism of cerebral cortical neurons, but focuses more on mathematical modeling rather than biological mechanism reproduction. As demonstrated by Mughees et al., the ANN model with a network structure (three hidden layers, 12 neurons per layer) effectively captured the nonlinear relationship between nano-TiO2 dosage (0–2%) and compressive strength, achieving an R2 of 0.94. This validated the ANN’s capability in characterizing the interfacial effects of nanomaterials.

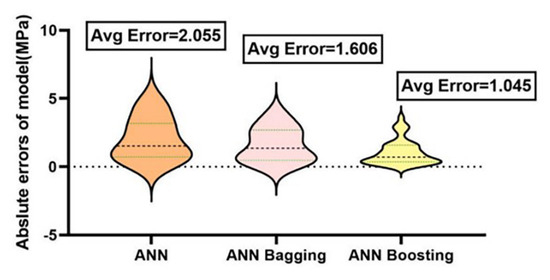

Muliauwan et al. [52] conducted a study to establish accurate correlations between input and output variables of concrete mixes by employing various AI methods. The three AI methods used in this study were ANN, SVM, and Linear Regression (LR). The effectiveness of the models was evaluated through a sample dataset of 1030 concrete compressive strength tests conducted at the University of California, Irvine. Simulation results show that these AI methods can build reliable predictive models and reduce expensive and time-consuming laboratory tests. Zaman et al. [22] used ANN and integration methods to combine individual learners to form a powerful learner. The overall accuracy was improved by incorporating the weak learner with the smallest prediction error and the strongest correlation. As shown in Figure 11, the integrated ANN model achieved a prediction error (MAE = 1.2 MPa) for nano-SiO2 cement paste that was 58% lower than that of the single model, demonstrating the advantage of feature cross-interaction in capturing the interfacial transition zone (ITZ) effects between nanoparticles and cement. Figure 11 explains the significantly lower error of the ANN-based integration model showing its superiority in predicting the properties of nano-silica cement paste. The ANN models presented in Figure 11 reflect different structures and training strategies used in previous studies. Some adopt conventional feedforward neural networks, while others incorporate optimization techniques such as genetic algorithms (GA-ANN) or particle swarm optimization (PSO-ANN) to improve performance. These variations lead to differences in predictive accuracy and model stability.

Figure 11.

Comparison of ANN models [51].

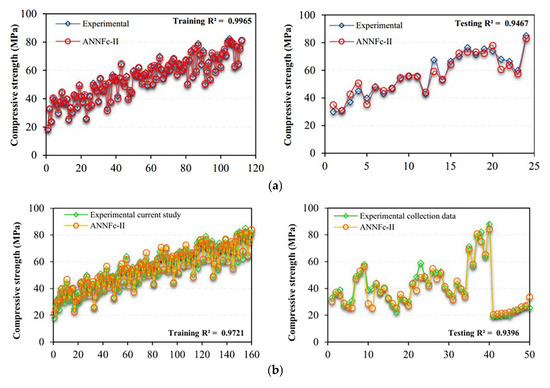

Kooshkaki et al. [54] proposed a multi-objective ANN model (MOANN model) to illustrate the effect of different porosities on the compressive and flexural strength of cement mortar hardened specimens containing micro-silica (MS) and NS, and the modeling results showed that the MOANN-II model predicts the compressive and flexural strength of cement mortar at the same time by taking porosity as an input parameter with high prediction accuracy. Emamian et al. [25] used the ANN to predict the compressive strength of MS and NS cement mortar, but the prediction with ANN I model did not include porosity as an input parameter, which resulted in a high error rate, so the ANN II model was developed by considering the effect of porosity, and the developed model was validated with the collected dataset in Figure 12. The x-axis in Figure 12 refers to the series number of the experimental samples. This follows the format used in the original study by Emamian et al. [25]. Each number corresponds to a distinct mix design tested in their dataset.

Figure 12.

(a) Evaluation of experimental and predicted results by ANN-II model: compressive strength [25]. (b) Validation of ANN-II model using collected dataset: compressive strength [25].

Mughees et al. [21] used ANN and Gradient Boosting (GB) modeling to evaluate the effect of important parameters W/C, Flash Ash (FA), etc., on the compressive strength of nano-titanium-based concrete composites. Based on the modeled evaluation of the parameters, it was found that Gradient Boosting (GB) modeling was the most effective in accurately predicting the compressive strength (CS), especially in determining the mix ratios at the desired CS. El-Sayed et al. [27] developed an intelligent modeling ANN for predicting residual compressive strength (RCS) and gamma ray linear attenuation coefficient (μ) of different concrete mixtures, where type and proportion of nano-additives, temperature and high temperature exposure time were the input variables of the neural network and RCS and μ values were the outputs. The predictive ability of the developed model is better as compared to regression analysis. Khan et al. [55] explored how the dose of colloidal nano-silica (CNS) and its surface area affects the mechanical properties of cement mortar composites by using response surface methodology (RSM) and ANN, and the ANN model was found to outperform the RSM model in terms of performance by comparison. Maherian et al. [56] explored the effectiveness of advanced ML algorithms in predicting the CS of concrete modified with nano-silica and supplemental cementitious materials. The final results showed that the RF (R2 = 0.93) and ANN (R2 = 0.92) models outperformed the RF and ANN (R2 = 0.92) models in terms of accuracy, which implies that experimental savings can be achieved in the future.

4.2. Support Vector Machine (SVM) Algorithm

The advantage of SVM is that it is very effective in solving classification and regression problems with high-dimensional features, and still has good results when the feature dimension is larger than the number of samples, without having to rely on all the data; when the number of samples is not a huge amount of data, the classification accuracy is high, and the generalization ability is strong.

SVMs were utilized to develop a predictive model for CS of nano-silica concrete. The input variables include cement content, aggregate, nano-silica properties, water-to-cement ratio (W/B), and prediction duration. The results showed that SVM performed better in CS prediction [24]. For nanomaterials in concrete and cementitious composites, a single ML algorithm (e.g., SVM) is commonly used to construct a prediction model. The boosting models of the SVM algorithm exhibit a strong and resilient relationship with the target values, as indicated by their high R2 value of 0.88. The error distribution plot further confirms that the SVM boosting models have a small maximum error of approximately 5.77 MPa and a minimum error of only 0.05 MPa. Finally, a graphical user interface was also created [31]. Shahab et al. [57] utilized experimental studies and ML techniques to evaluate the CS and resistivity of graphene nanosheet concrete. Three ML methods, Gene Expression Programming (GEP), Random Forest Regression (RFR), and SVM were developed using eight input variables. Five different AI models, namely multivariate adaptive regression spline curve (MARS), M5P model tree (M5P-MT), least squares support vector machine (LS-SVM), multilayer perceptron neural network (MLP-NN), and multivariate linear regression (MLR), were used to predict the CS of fiber-reinforced concrete (FRC) containing nano-silica, among which LS-SVM performed better [31]. The effectiveness of the model was evaluated by employing various AI methods to establish accurate correlations between the input and output variables of the concrete mix, a sample dataset of 1030 concrete compressive strength tests conducted at the University of California, Irvine. Simulation results show that SVM can build reliable predictive models that reduce expensive and time-consuming laboratory tests [58,59].

4.3. Decision Tree (DT) Algorithm

The decision tree (Figure 7) constructs classification rules through feature threshold partitioning (e.g., nano-CaCO3 dosage ≤ 1.5%). Leaf nodes output strength prediction values (e.g., 45.3 MPa), forming an explicit decision path from material parameters to mechanical properties.

The advantages of decision tree are that it has low computational complexity and are easy to interpret; the data preprocessing stage is relatively simple and can handle missing data; and decision trees can be constructed for datasets with many attributes.

By comparing the performance of depth AutoEncoder (AE), DT, Extreme Learning Machine, and hybrid deep learning models for predicting compressive strength of nano-silica modified Engineered Cementitious Composites (ECC) at elevated temperatures, Tanyildizi et al. [53] found that the accuracy of the hybrid depth AE-DT model for estimating the CS was 94.28%, so it is recommended to use the hybrid depth learning model of AE-DT for predicting the ECC strength of concrete. Jiao H. et al. [23] built a model of compressive strength of concrete modified using carbon nanotubes (CNTs) by individual predictions of DT, multilayer perceptron neuron network, and SVM, as well as an integrated learning model, Ada-boost-based DT, and ultimately finds that the integrated learning model has the smallest error and good overall performance. A single decision tree is prone to overfitting due to excessive subdivision of nanomaterial interactions (e.g., training set R2 = 0.98, test set R2 = 0.72). As shown in Figure 8, the random forest model improves the test set R2 to 0.89 and reduces variance by 62% through Bootstrap sampling (80% of samples) and random subspace selection to construct 300 subtrees.

4.4. Random Forest (RF) Algorithm

The advantage of RF is that training can be highly parallelized and there is an improvement in training speed for samples with large capacity. After training, the importance of each feature for the output can be given, and due to the use of random sampling, the variance of the trained model is small and the generalization ability is high.

Zaman et al. [22] used an RF-based integration method to combine to form a powerful learner. The overall accuracy will be improved by incorporating the weak learner with the smallest prediction error and the strongest correlation, where the best performing RF with an R2 of 0.97, and a new expression for predicting the 28-day CS of nanocomposites doped with silica content based on the database was developed. RF in predicting the CS of concrete modified with nano-silica and supplemental cementitious materials, performed well in terms of accuracy, which means that in the future, savings can be made in the expenditures related to experimental evaluations [23]. Shahab et al. [57] utilized experimental studies and ML techniques to evaluate the CS and resistivity of graphene nanosheet concrete. A Random Forest Regression (RFR) machine learning method was developed using eight input variables, but the RFR model can be used as a reliable predictor without providing a mathematical expression.

4.5. Gene Expression Programming (GEP) Algorithm

GEP is a symbolic regression method based on evolutionary algorithms. It is flexible and adaptive and applicable to various optimization problems. GEP has wide applications in the fields of function approximation, symbolic regression, feature selection, and image processing.

An empirical GEP model was developed by the Gene Expression Programming technique. The model was validated using statistical evaluation. The trend of the GEP model was consistent with the general trend of experimental results in the literature. The GEP model predicted that the compressive strength of concrete increased with the addition of carbon nanotubes (CNTs), NS, and NC, while the compressive strength decreased with the increase in NC [24]. Emamian et al. [26] study experimentally investigated the effect of freeze–thaw cycles on the compressive and flexural strengths of cement mortars containing NS and MS and predicted and calculated the porosity, compressive and flexural strengths of cement mortars using the new GEP model, which showed a high correlation between the target values and the predicted results. Rezaei et al. [60] first used Response Surface Methodology (RSM) to maximize the mechanical properties and durability of concrete containing recycled coarse aggregate and nano-silica, and then predicted the compressive capacity of concrete with recycled coarse aggregate and nano-silica volcanic ash powder by using Gene Expression Programming (GEP) technique. An integrated approach to ANN, GEP, and RF was combined and formed a powerful learner. A new expression for predicting the 28-day compressive strength of nanocomposites doped with silicon content was also developed based on a database [61].

5. Conclusions and Outlook

The future outlook of ML in the field of nano-modified concrete compressive strength is extremely promising, especially in exploring and optimizing the properties of new materials. Estimating compressive strength is a complex problem as it depends on a variety of factors including the type, dosage and homogeneity of its components, curing conditions, compaction, curing time, environmental conditions, equipment used, etc. The integration of nanoparticles (NSs) into concrete mixtures amplifies this complexity, and the use of ML models to deal with this complex problem may provide reliable results, ultimately reducing the costs associated with traditional methods.

However, the reliability of ML predictions still depends on model stability. This is especially important when dealing with limited or noisy data. Techniques such as cross-validation can improve generalization. Regularization also helps reduce overfitting and control model complexity. These strategies are essential to ensure robust and trustworthy results in practical applications.

In addition, future research should focus on identifying the most influential input variables and propose standardized protocols for their selection and use. Standardizing the selection and application of these variables can significantly enhance model generalization and improve performance. This will lead to more consistent and reliable predictions, which are crucial for advancing the application of ML in concrete strength estimation.

- Models for predicting the compressive strength of nano-modified concrete usually use a combination of integrated ML models such as neural network, SVM, DT, RF, etc. As far as individual models are concerned, ANNs have the best generalization ability.

- The compressive strength of concrete is mainly affected by two factors: water-cement ratio and age, and nano-modified concrete is also affected by the amount of nanomaterials due to their incorporation, which reduces the effectiveness above a certain threshold, and we found that the dataset used significantly affects the identification of the most critical factors for compressive strength.

- The selection of algorithmic models varies with the size of data. In summary, it is found DT and RF, SVM, and KNN are usually used when the database size is small; neural network is often used in medium-sized databases; and Gradient Boosting tree (GBT), deep learning (DL) stochastic gradient descent (SGD) are often used when the data size is large.

Based on the research and applications in recent years, we believe that the following algorithms perform better in predicting the compressive strength of nano-modified concrete: RF, SVM, and ANN. The following are the areas where the advancement of ML technology is anticipated to have a major impact on nano-modified concrete:

- Optimized Mix Design: ML can process large amounts of data, thus quickly identifying the optimal formulation of nanomaterial additives. By analyzing historical data and experimental results, ML models can predict how different types and dosages of nanomaterials affect the compressive strength of concrete. This will greatly reduce trial and error time and costs, accelerating the development process of new materials.

- Multi-objective optimization: According to the specific needs of the project and environmental conditions, when multiple objectives cannot reach the optimal solution at the same time, the use of genetic algorithms, particle swarm optimization, and other algorithms may figure out the best compromise among multiple objectives, such as enhanced compressive strength while achieving the least cost and so on.

- Quality control and performance prediction: ML models can accurately predict the long-term performance of concrete under different environmental conditions, such as durability and compressive strength. By monitoring the state of concrete and environmental conditions in real time, ML can help adjust the construction process to changing conditions promptly.

- Sustainability and environmental impact assessment: ML is instrumental in evaluating and optimizing the environmental footprint of nano-modified concrete. Analyzing life cycle costs and carbon footprints, can help develop more sustainable building materials and reduce waste generation and energy consumption.

Despite these advancements, some challenges remain. One issue is the lack of high-quality datasets, especially for new or rare nanomaterials. Poor data leads to weak predictions. Also, some models, like deep neural networks, are hard to interpret. This makes them risky in real projects. To improve this, combining ML with material science knowledge is helpful. Using hybrid or physics-based models can also make predictions more reliable. Finally, open collaboration between data scientists and engineers is key. These steps will help ML become more useful and trusted in real-world concrete applications.

Funding

This research was funded by the National Natural Science Foundation of China (No. 52178202), the Natural Science Foun-dation of Jiangsu Province (No. BK20231464), Guangdong Basic and Applied Basic Research Foundation (No. 2024A1515011026), and Shenzhen Science and Technology Program (No. JCYJ20220530115407016).

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Bishara, D.; Xie, Y.; Liu, W.K.; Li, S. A state-of-the-art review on machine learning-based multiscale modeling, simulation, homogenization and design of materials. Arch. Comput. Methods Eng. 2023, 30, 191–222. [Google Scholar] [CrossRef]

- Tapeh, A.T.G.; Naser, M.Z. Artificial intelligence, machine learning, and deep learning in structural engineering: A scientometrics review of trends and best practices. Arch. Comput. Methods Eng. 2023, 30, 115–159. [Google Scholar] [CrossRef]

- Tumrate, C.S.; Saini, D.K.; Gupta, P.; Mishra, D. Evolutionary Computation Modelling for Structural Health Monitoring of Critical Infrastructure. Arch. Comput. Methods Eng. 2023, 30, 1479–1493. [Google Scholar] [CrossRef]

- Kumar, S.; Gopi, T.; Harikeerthana, N.; Gupta, M.K.; Gaur, V.; Krolczyk, G.M.; Wu, C. Machine learning techniques in additive manufacturing: A state of the art review on design, processes and production control. J. Intell. Manuf. 2023, 34, 21–55. [Google Scholar] [CrossRef]

- Vajire, S.L.; Singh, A.P.; Saini, D.K.; Mukhopadhyay, A.K.; Singh, K.; Mishra, D. Novel machine learning-based prediction approach for nanoindentation load-deformation in a thin film: Applications to electronic industries. Comput. Ind. Eng. 2022, 174, 108824. [Google Scholar] [CrossRef]

- Tumrate, C.S.; Chowdhury, S.R.; Mishra, D. Development of Regression Model to Predicting Yield Strength for Different Steel Grades. IOP Conf. Ser. Earth Environ. 2021, 796, 012033. [Google Scholar] [CrossRef]

- Naderpour, H.; Rafiean, A.H.; Fakharian, P. Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J. Build. Eng. 2018, 16, 213–219. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Zhou, S.; Yu, Y.; Cheng, H.; Wu, X. Compressive strength prediction of recycled concrete based on deep learning. Constr. Build. Mater. 2018, 175, 562–569. [Google Scholar] [CrossRef]

- Getahun, M.A.; Shitote, S.M.; Gariy, Z.C.A. Artificial neural network based modelling approach for strength prediction of concrete incorporating agricultural and construction wastes. Constr. Build. Mater. 2018, 190, 517–525. [Google Scholar] [CrossRef]

- Nguyen, T.; Kashani, A.; Ngo, T.; Bordas, S. Deep neural network with high-order neuron for the prediction of foamed concrete strength. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 316–332. [Google Scholar] [CrossRef]

- Nunez, I.; Marani, A.; Flah, M.; Nehdi, M.L. Estimating compressive strength of modern concrete mixtures using computational intelligence: A systematic review. Constr. Build. Mater. 2021, 310, 125279. [Google Scholar] [CrossRef]

- Shi, T.; Liu, Y.; Zhao, X.; Wang, J.; Zhao, Z.; Corr, D.J.; Shah, S.P. Study on mechanical properties of the interfacial transition zone in carbon nanofiber-reinforced cement mortar based on the PeakForce tapping mode of atomic force microscope. J. Build. Eng. 2022, 61, 105248. [Google Scholar] [CrossRef]

- Quercia, G.; Brouwers, H.J.H. Application of nano-silica (nS) in concrete mixtures. In Proceedings of the 8th fib PhD Symposium, Kgs, Lyngby, Denmark, 20–23 June 2010; pp. 431–436. [Google Scholar]

- Rashid, A.B.; Haque, M.; Islam, S.M.M.; Labib, K.R.U. Nanotechnology-enhanced fiber-reinforced polymer composites: Recent advancements on processing techniques and applications. Heliyon 2024, 10, e24692. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Bartos, P.J.M.; Porro, A. Application of nanotechnology in construction: Summary of a State-of-the-art Report. Mater. Struct. 2004, 37, 649–658. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Wang, J.; Ou, J.; Han, B.; Ding, S.; Wang, J.; Ou, J. Current Progress of Nano-Engineered Cementitious Composites. In Nano-Engineered Cementitious Composites; Springer: Singapore, 2019; pp. 97–398. [Google Scholar]

- Han, B.; Zhang, L.; Zeng, S.; Dong, S.; Yu, X.; Yang, R.; Ou, J. Nano-core effect in nano-engineered cementitious composites. Compos. Part A Appl. Sci. Manuf. 2017, 95, 100–109. [Google Scholar] [CrossRef]

- Sobolev, K.; Shah, S.P. Nanotechnology in Construction: Proceedings of NICOM5; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Jayapalan, A.R.; Lee, B.Y.; Kurtis, K.E. Can nanotechnology be ‘green’? Comparing efficacy of nano and microparticles in cementitious materials. Cem. Concr. Compos. 2013, 36, 16–24. [Google Scholar] [CrossRef]

- Chen, X.; Ai, Y.; Wu, Q.; Cheng, S.; Wei, Y.; Xu, X.; Fan, T. Potential use of nano calcium carbonate in polypropylene fiber reinforced recycled aggregate concrete: Microstructures and properties evaluation. Constr. Build. Mater. 2023, 400, 132871. [Google Scholar] [CrossRef]

- Mughees, A.; Sharma, A.; Ansari, S.S.; Ibrahim, S. Prediction of the compressive strength of nano-titanium based concrete composites using machine learning. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Zaman, A.; Alyami, M.; Shah, S.; Rehman, M.F.; Hakeem, I.Y.; Farooq, F. Forecasting the strength of micro/nano silica in cementitious matrix by machine learning approaches. Mater. Today Commun. 2023, 37, 107066. [Google Scholar] [CrossRef]

- Jiao, H.; Wang, Y.; Li, L.; Arif, K.; Farooq, F.; Alaskar, A. A novel approach in forecasting compressive strength of concrete with carbon nanotubes as nanomaterials. Mater. Today Commun. 2023, 35, 106335. [Google Scholar] [CrossRef]

- Murad, Y. Compressive strength prediction for concrete modified with nanomaterials. Case Stud. Constr. Mater. 2021, 15, e00660. [Google Scholar] [CrossRef]

- Emamian, S.A.; Eskandari-Naddaf, H. Effect of porosity on predicting compressive and flexural strength of cement mortar containing micro and nano-silica by ANN and GEP. Constr. Build. Mater. 2019, 218, 8–27. [Google Scholar] [CrossRef]

- Emamian, S.A.; Eskandari-Naddaf, H. Genetic programming based formulation for compressive and flexural strength of cement mortar containing nano and micro silica after freeze and thaw cycles. Constr. Build. Mater. 2020, 241, 118027. [Google Scholar] [CrossRef]

- El-Sayed, A.A.; Fathy, I.N.; Tayeh, B.A.; Almeshal, I. Using artificial neural networks for predicting mechanical and radiation shielding properties of different nano-concretes exposed to elevated temperature. Constr. Build. Mater. 2022, 324, 126663. [Google Scholar] [CrossRef]

- Albaijan, I.; Fakhri, D.; Mohammed, A.H.; Mahmoodzadeh, A.; Ibrahim, H.H.; Elhag, A.B.; Rashidi, S. Several machine learning models to estimate the effect of an acid environment on the effective fracture toughness of normal and reinforced concrete. Theor. Appl. Fract. Mech. 2023, 126, 103999. [Google Scholar] [CrossRef]

- Fakhri, D.; Mahmoodzadeh, A.; Mohammed, A.H.; Khodayari, A.; Ibrahim, H.H.; Rashidi, S.; Karim, S.H.T. Forecasting failure load of Sandstone under different Freezing-Thawing cycles using Gaussian process regression method and grey wolf optimization algorithm. Theor. Appl. Fract. Mech. 2023, 125, 103876. [Google Scholar] [CrossRef]

- Li, R.; Wu, X.; Tian, H.; Yu, N.; Wang, C. Hybrid memetic pretrained factor analysis-based deep belief networks for transient electromagnetic inversion. IEEE Trans. Geosci. Remote Sens. 2022, 60, 1–20. [Google Scholar] [CrossRef]

- Mahmoodzadeh, A.; Fakhri, D.; Mohammed, A.H.; Mohammed, A.S.; Ibrahim, H.H.; Rashidi, S. Estimating the effective fracture toughness of a variety of materials using several machine learning models. Eng. Fract. Mech. 2023, 286, 109321. [Google Scholar] [CrossRef]

- Mahmoodzadeh, A.; Nejati, H.R.; Mohammadi, M.; Ibrahim, H.H.; Khishe, M.; Rashidi, S.; Ali, H.F.H. Prediction of Mode-I rock fracture toughness using support vector regression with metaheuristic optimization algorithms. Eng. Fract. Mech. 2022, 264, 108334. [Google Scholar] [CrossRef]

- Salehi, H.; Burgueño, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- Dantas, A.T.A.; Leite, M.B.; de Jesus Nagahama, K. Prediction of compressive strength of concrete containing construction and demolition waste using artificial neural networks. Constr. Build. Mater. 2013, 38, 717–722. [Google Scholar] [CrossRef]

- Chou, J.S.; Chiu, C.K.; Farfoura, M.; Al-Taharwa, I. Optimizing the prediction accuracy of concrete compressive strength based on a comparison of data-mining techniques. J. Comput. Civil. Eng. 2011, 25, 242–253. [Google Scholar] [CrossRef]

- Chou, J.S.; Tsai, C.F.; Pham, A.D.; Lu, Y.-H. Machine learning in concrete strength simulations: Multi-nation data analytics. Constr. Build. Mater. 2014, 73, 771–780. [Google Scholar] [CrossRef]

- Mustapha, R.; Mohamed, E.A. High-performance concrete compressive strength prediction based weighted support vector machines. Int. J. Eng. Res. Appl. 2017, 7, 68–75. [Google Scholar] [CrossRef]

- Pham, A.D.; Hoang, N.D.; Nguyen, Q.T. Predicting compressive strength of high-performance concrete using metaheuristic-optimized least squares support vector regression. J. Comput. Civil. Eng. 2016, 30, 06015002. [Google Scholar] [CrossRef]

- Ashrafian, A.; Amiri, M.J.T.; Rezaie-Balf, M.; Ozbakkaloglu, T.; Lotfi-Omran, O. Prediction of compressive strength and ultrasonic pulse velocity of fiber reinforced concrete incorporating nano silica using heuristic regression methods. Constr. Build. Mater. 2018, 190, 479–494. [Google Scholar] [CrossRef]

- Lin, C.J.; Wu, N.J. An ANN model for predicting the compressive strength of concrete. Appl. Sci. 2021, 11, 3798. [Google Scholar] [CrossRef]

- Ahmad, M.; Al Mehedi, M.A.; Yazdan, M.M.S.; Kumar, R. Development of machine learning flood model using artificial neural network (ANN) at Var River. Liquids 2022, 2, 147–160. [Google Scholar] [CrossRef]

- Charbuty, B.; Abdulazeez, A. Classification based on machine learning decision tree algorithm. Appl. Sci. Technol. Dyn. 2021, 2, 20–28. [Google Scholar] [CrossRef]

- Wen, X.; Li, D.Y. Attribute-weighted ML-KNN method. J. Shandong Univ. 2024, 59, 107–117. [Google Scholar]

- Zhang, S.; Li, X.; Zong, M.; Zhu, X.; Cheng, D. Learning k for KNN classification. ACM Trans. Intell. Syst. Technol. 2017, 8, 43. [Google Scholar]

- Han, Q.; Gui, C.; Xu, J.; Lacidogna, G. Generalized method to predict the compressive strength of high-performance concrete by improved random forest algorithm. Constr. Build. Mater. 2019, 226, 734–742. [Google Scholar] [CrossRef]

- Gupta, S.M. Support vector machines based modelling of concrete strength. Int. J. Intel. Technol. 2007, 3, 12–18. [Google Scholar]

- Kumar, A.; Arora, H.C.; Kapoor, N.R.; Mohammed, M.A.; Kumar, K.; Majumdar, A.; Thinnukool, O. Compressive strength prediction of lightweight concrete: Machine learning models. Sustainability 2022, 14, 2404. [Google Scholar] [CrossRef]

- Azimi-Pour, M.; Eskandari-Naddaf, H.; Pakzad, A. Linear and non-linear SVM prediction for fresh properties and compressive strength of high volume fly ash self-compacting concrete. Constr. Build. Mater. 2020, 230, 117021. [Google Scholar] [CrossRef]

- Ling, H.; Qian, C.; Kang, W.; Liang, C.Y.; Chen, H.C. Combination of Support Vector Machine and K-Fold cross validation to predict compressive strength of concrete in marine environment. Constr. Build. Mater. 2019, 206, 355–363. [Google Scholar] [CrossRef]

- Chu, H.H.; Khan, M.A.; Javed, M.; Zafar, A.; Khan, M.I.; Alabduljabbar, H.; Qayyum, S. Sustainable use of fly-ash: Use of gene-expression programming (GEP) and multi-expression programming (MEP) for forecasting the compressive strength geopolymer concrete. Ain Shams Eng. J. 2021, 12, 3603–3617. [Google Scholar] [CrossRef]

- Al-ashem, M.N.; Amin, M.N.; Raheel, M.; Khan, K.; Alkadhim, H.A.; Imran, M.; Ullah, S.; Iqbal, M. Predicting the compressive strength of concrete containing fly ash and rice husk ash using ANN and GEP models. Materials 2022, 15, 7713. [Google Scholar] [CrossRef]

- Muliauwan, H.N.; Prayogo, D.; Gaby, G.; Harsono, K. Prediction of concrete compressive strength using artificial intelligence methods. J. Phys. Conf. Ser. 2020, 1625, 012018. [Google Scholar] [CrossRef]

- Tanyildizi, H. Prediction of compressive strength of nano-silica modified engineering cementitious composites exposed to high temperatures using hybrid deep learning models. Expert Syst. Appl. 2024, 241, 122474. [Google Scholar] [CrossRef]

- Kooshkaki, A.; Eskandari-Naddaf, H. Effect of porosity on predicting compressive and flexural strength of cement mortar containing micro and nano-silica by multi-objective ANN modeling. Constr. Build. Mater. 2019, 212, 176–191. [Google Scholar] [CrossRef]

- Khan, K.; Johari, M.A.M.; Amin, M.N.; Khan, M.I.; Iqbal, M. Optimization of colloidal nano-silica based cementitious mortar composites using RSM and ANN approaches. Results Eng. 2023, 20, 101390. [Google Scholar] [CrossRef]

- Maherian, M.F.; Baran, S.; Bicakci, S.N. Machine learning-based prediction of compressive strength of concrete incorporating nano-silica. Comput. Concr. 2022, 29, 459–467. [Google Scholar]

- Shahab, Z.; Anwar, W.; Alyami, M.; Hammad, A.W.; Alabduljabbar, H.; Nawaz, R.; Javed, M.F. Experimental investigation and predictive modeling of compressive strength and electrical resistivity of graphene nanoplatelets modified concrete. Mater. Today Commun. 2024, 38, 107639. [Google Scholar] [CrossRef]

- Garg, A.; Aggarwal, P.; Aggarwal, Y.; Belarbi, M.O.; Chalak, H.D.; Tounsi, A.; Gulia, R. Machine learning models for predicting the compressive strength of concrete containing nano silica. Comput. Concr. 2022, 30, 33. [Google Scholar]

- Liu, G.; Zhao, H.; Amin, M.N.; Zaman, A.; Hassan, A.M.; Ali, M.; Rehman, M.F. Strength predictive models of cementitious matrix by hybrid intrusion of nano and micro silica: Hyper-tuning with ensemble approaches. J. Mater. Res. Technol. 2023, 26, 1808–1832. [Google Scholar] [CrossRef]

- Rezaei, F.; Memarzadeh, A.; Davoodi, M.R.; Dashab, M.-A.; Nematzadeh, M. Mechanical features and durability of concrete incorporating recycled coarse aggregate and nano-silica: Experimental study, prediction, and optimization. J. Build. Eng. 2023, 73, 106715. [Google Scholar] [CrossRef]

- Shahmansouri, A.A.; Bengar, H.A.; Ghanbari, S. Compressive strength prediction of eco-efficient GGBS-based geopolymer concrete using GEP method. J. Build. Eng. 2020, 31, 10132. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).