Featured Application

The evaluation model developed through the sound quality index, considering the weights of individual psychoacoustic parameters, can be applied to a specific product group of household appliances, in this case, washing machines.

Abstract

The evaluation of the acoustic quality of sound-emitting appliances is primarily conducted by measuring psychoacoustic parameters or by means of a jury study through subjective evaluation by respondents. This article aims to validate the developed model for evaluating the acoustic quality of washing machines. Three top-loading washing machines were used in three operating modes for validation. The measurement of the psychoacoustic parameters of these washing machines was carried out. Subsequently, in the evaluation process, a developed quality index was used, based on which a ranking of washing machines in terms of sound quality was determined. Subsequently, the results were validated using a questionnaire. By comparing the results of the evaluation of the questionnaire method and the application of the developed sound quality evaluation model based on the sound quality index, an almost perfect agreement is evident in determining the ranking of washing machines using both methods, as confirmed by statistical analysis. Developed a model for the evaluation of psychoacoustic quality and its application to the measured psychoacoustic parameters that can substitute the time-consuming methods of assessing sound quality through questionnaire surveys. The application of the developed method significantly reduces the evaluation time.

1. Introduction

Sound has many objectively measurable properties, but they may not provide a clear picture of what a person actually captures with their ears. Psychoacoustics is a scientific field that researches human perception of sound. Unlike general acoustics, in which we use microphones or other devices that can be calibrated to obtain data, in psychoacoustics, the only relevant “measuring tool” is the person themselves.

According to [1,2,3], in addition to its intensity, it is necessary to include other subjective parameters such as environmental conditions and psychoacoustic parameters (loudness, sharpness, roughness, fluctuation strength, and tonality) in the evaluation of sound quality. In psychoacoustics, various psychophysical methods are used to evaluate sound quality [4,5]. The most famous psychophysical law is the “Fechner law”, which states that with a geometric increase in the intensity of the stimulus, the subjective perception of the stimulus increases arithmetically. However, in the professional literature, we can more often find it under the name “the Weber–Fechner law” [6,7].

The authors’ [8] research examines the effectiveness of the acoustic metawindow unit (AMW) in terms of psychoacoustics and human perception. Subsequently, they combined soundscape-based questionnaires with an analytical physical and psychoacoustic evaluation of the AMW. Psychoacoustics [1,9,10,11] is a powerful tool for optimizing the acoustic properties of sound in machines, equipment, and products in industry. It is used to better understand how people perceive sound. In connection with the application of psychoacoustics in practice, a new scientific field of sound (acoustic) product design was created.

Reducing the noise level of household appliances such as washing machines [12,13,14], dishwashers [15], refrigerators [16], hair dryers [17], vacuum cleaners [18], air conditioners [19,20], range hoods [21], etc., has become a top priority for manufacturers due to increased user demand for such products. Noise has become one of the important factors in purchasing decisions. However, noise reduction methods can be expensive and difficult to use, forcing manufacturers to compromise on their effectiveness, longevity, and cost.

The sound quality index is one of the parameters that describes the acoustic quality of products. Most research papers examining the evaluation of the sound quality index of household appliances are based on a regression model that considers multiple linear regression between the results of subjective evaluation and psychoacoustic properties. This issue has been examined by several authors [3,16,22,23,24,25].

The authors [25] focused their research on a product-neutral approach, based on solutions to reduce the overall sound power level under different operating conditions (under IEC60704 guidelines) of a front-loading washer-dryer. The aim of the study [13] was to predict the sound quality perception of prefilled washing machines using neural networks. The pleasantness/annoyance of the sounds of the washing machine was assessed by the participants using a listening test. Based on the measurement and analysis of the sound emitted by the washing machine, the authors [26] identified critical places with the highest sound levels. The authors [27] constructed a mathematical model based on objective and subjective evaluations of sound quality. The created model turned out to be reliable for predicting human perception of the evaluated sounds of washing machines. Albero C., et al. [28] developed an experimental methodology to describe noise transmission pathways in a washing machine. In their research, they used intensity probes and vibration acceleration sensors for measurements. The sound quality index, which predicts the subjective score, was proposed in [29]. It is the result of the correlation and multiple regression analysis of the psychoacoustic parameters and subjective assessments of 30 types of refrigerators. Kuwano et al. [15] published the results of other experiments focused on assessing the sound quality of household appliances.

The results of listening tests can be compared with psychoacoustic properties, such as loudness, sharpness, roughness, etc. A common approach is to try to create a model from these properties to estimate nuisance and noise disturbance, which should be consistent with the results of the listening tests. If such a model is successful, it could be used as a system for objective evaluation without the use of questionnaire methods.

In the paper [30], the acoustic characteristics of electric vehicles using both psychoacoustic and soundscape methodologies are analyzed by three key psychoacoustic parameters. Through correlation analysis between perceived values and objective parameters, specific sound sources requiring improvement were identified, including vehicle body acoustics, wheel noise, and acceleration-related sounds. Authors in the paper [31] propose an evaluation model based on an optimized bidirectional long short-term memory using a genetic algorithm. These suggest that a genetic algorithm can greatly enhance the model’s performance by optimizing initial learnable parameters. The evaluation obtained by the optimized model is very close to the human subjective evaluation. Gao, Y.H. et al. [32] used the objective and subjective evaluation results; furthermore, a sound quality prediction model for heavy commercial vehicles was developed based on a back-propagation artificial neural network. The sound quality prediction model of heavy commercial vehicles can be used to determine the weighting of objective evaluation parameters that contribute to the results of subjective evaluation. The sound quality models in the paper [17] were established for supersonic and standard hairdryers using multiple linear regression between the discomfort and two psychoacoustic metrics: loudness and tonality. He, Z. et al. [33] fitted the evaluation vector into the subjective evaluation results of vehicle interior noise by a deep neural network. The results demonstrate that our proposed method can effectively estimate human subjective perception of vehicle interior noise.

Authors [34], based on the calculation of objective parameters, established a multiple linear regression objective evaluation model for sound quality, an objective evaluation model for sound quality based on a back propagation neural network, and an objective evaluation model for sound quality based on a radial basis function neural network.

This article aims to verify the developed model for evaluating the sound quality of washing machines based on the sound quality index. This sound quality index considers the results of both the measurement of psychoacoustic parameters and the perception of sound quality by users. This validation will demonstrate the suitability of using the developed psychoacoustic model for evaluating the quality of sounds of automatic washing machines, without conducting questionnaire surveys.

2. Materials and Methods

2.1. Description of the Validation Process

For the validation of the developed psychoacoustic model, three models of washing machines were selected. Washing machines were top-loaded models from different producers. As the first step of the validation procedure, the measurement of the sound quality was performed using a binaural measuring unit. For evaluation, three operation modes (filling, washing, and spinning) were selected. After the measurement process, the developed psychoacoustic model was applied to the measured psychoacoustic values. By the application of this developed model, the ranking of the sound quality of the evaluated automatic washing machines was compiled. Subsequently, a questionnaire survey was performed to verify the developed psychoacoustic model. Comparison of the results of the questionnaire survey with the measured values of individual psychoacoustic parameters and the application of the developed psychoacoustic model forms the core of the validation process.

2.2. Recording the Sound of Washing Machines and Their Evaluation

The sound of the washing machines was recorded in a semi-anechoic chamber at the Technical Testing Institute. Semi-anechoic chamber meets the requirements of EN ISO 3744 [35] and EN ISO 3745 [36] with background noise level less than 16 dB for frequency range 50 Hz–20 kHz. For recording a binaural measurement system (artificial head), head acoustics was used, as shown in Figure 1. The artificial head was placed at a distance of 1.0 m from the washing machine and 1.5 m above the floor level (microphone position). Behind the washing machine was a reflective pane. The whole washing cycle, Cotton 60 °C, was recorded for each washing machine. Measurements were realized in three operation modes (FILL, WASH, and SPIN). The binaural recordings were used for sound quality evaluation for these three operation modes.

Figure 1.

Recording the sound of the washing machines in a semi-anechoic chamber.

2.3. Determination of Sound Metrics

Objective evaluation of sound quality was performed by the determination of psychoacoustic sound metrics. For the validation process, the same sound metric was used as in the process of developing the psychoacoustic model. For the research, five psychoacoustic parameters were selected (Loudness, Sharpness, Roughness, Fluctuation strength, and Tonality), see Table 1. The psychoacoustic parameters were calculated and determined using Artemis Suite 11.0 software from the Head Acoustic.

Table 1.

Psychoacoustic metrics used in objective analysis.

2.4. Application of the Developed Psychoacoustics Model

In a previous paper, “Development of psychoacoustic model based on the correlation of the subjective and objective sound quality evaluation of washing machines” [12], a psychoacoustic model was developed based on the weight and importance of individual psychoacoustic parameters. After the determination of psychoacoustic parameters acquired from the sound recording, the values determined from previous research were applied to the measured psychoacoustic parameters. After application of these weights, the sound quality ranking of the three washing machines in the three operation modes was compiled.

2.5. Subjective Evaluation

Subjective evaluation was performed in the form of a questionnaire survey on 72 respondents: 24 (33%) men and 48 (67%) women. Respondents evaluated the binaural sound records of three washing machines in three operation modes. The average age of respondents was 42 years. Sound recordings were replayed to the respondents using a playback system from the Head Acoustic using headphones. Each operation mode was assessed individually. The questionnaire was developed by carefully selecting adjectives to describe the sounds, which describe their pleasantness. The sound was rated by respondents with a score ranging from 1 to 10, where 1 is the worst evaluation and 10 is the best evaluation.

The subjective evaluation scale is shown in Table 2. Based on the respondents’ evaluation, the ranking of the sound quality of individual washing machines for all three operation modes was compiled. Subjective evaluation was used for validation of the developed psychoacoustic model. The results achieved by the subjective evaluation were compared to the results achieved by applying the developed psychoacoustic model to the measured psychoacoustic values by the binaural measurement device.

Table 2.

Scale for subjective evaluation.

2.6. Statistical Methods

There are several statistical and analytical methods to compare the measured values of audio parameters, depending on the nature of the data and the type of analysis we want to perform. Different statistical analyses (regression, correlational, and multicriteria) can be used to measure the interrelationships between variables, depending on the type of data and the nature of the data. Correlation analysis examines the tightness of statistical dependence between quantitative variables. In the event of the occurrence of extreme values between two variables (ordinal, metric), we can use: Spearman’s correlation coefficient [37], Kendall’s tau coefficient [38,39], or Goodman and Kruskal’s gamma [40]. In the event of a simple correlation, we use Pearson’s correlation coefficient [38]. In some cases, when evaluating statistical dependence, we can conclude that it is not possible to use an ordinary correlation coefficient. Since we work with ordinal signs, i.e., data that make sense only in ranking, it is best to use a nonparametric method of mathematical statistics for analysis. Sometimes, in random selection, it is not possible to determine the values of these random variables precisely, but we only have the ranking of quantities X1, …, Xn and the ranking of quantities Y1, …, Yn. But if the rankings of X and Y quantities are very similar, this undoubtedly indicates a certain relationship between Xi and Yi, i = 1, …, n. An accurate expression of this idea is Spearman’s correlation coefficient, also called the ordinal correlation coefficient, which, in our case, we used to determine the relationship between different ways of evaluating washing operating modes. Regression analysis is one of the most important methods of mathematical statistics and is used independently or in conjunction with other methods in every field of empirical and applied science [41]. Multicriteria analysis, as distinct from a single-criteria analysis, is based on two or more criteria. The higher the number of criteria, the more comprehensive the analysis. Individual criteria change for different options, and it is necessary to choose the option that contains the most ideal compromise from all the options [42]. Each of these methods has its specific uses depending on the type of data and the nature of the relationships between the variables. In our case, methods of qualitative and quantitative analysis of relationships between traits (correlation analysis) and methods of multicriteria evaluation were used—comparison of subjects based on several variables (ordinal and point method, method of standardized variables).

2.7. Description and Analysis of Developed Psychoacoustic Model

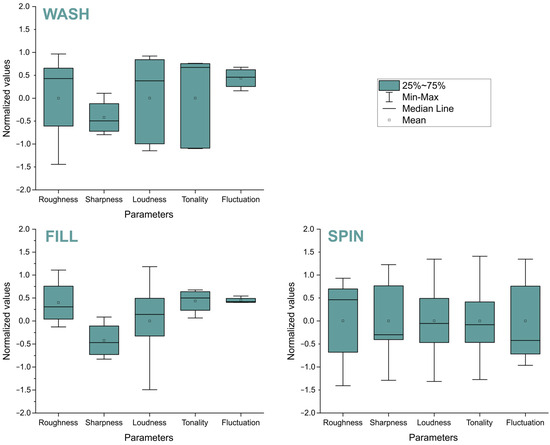

Five models of automatic washing machines in three operation modes were selected for sound quality assessment. The psychoacoustic metrics of the automatic washing machines were specified by processing audio signals recorded through the binaural measurement method. The values measured for the psychoacoustic metrics, in particular operating cycles, are presented in Figure 2. Psychoacoustic parameters are measured in different units; the graphs show the normalized values. We transpose the values of individual parameters into the standardized form.

Figure 2.

Psychoacoustic parameters—normalized values.

As all evaluated psychoacoustic parameters are measured in different units, it was important to standardize the measured values (mathematical-statistical transformation of the measured values into standard scores) so that all parameters have comparable ranges.

The normalization of z-scores (standardization) is calculated as follows:

- while maximizing the indicator:

- while minimizing the indicator:

The questionnaire survey for sound quality assessment with 81 respondents was carried out and evaluated. The results of the jury study, along with the average point scores for individual washing machines in three operation modes, are shown in Table 3.

Table 3.

Average point score according to jury study [12].

Our contribution was to determine the weights of psychoacoustic parameters by correlating the objective and subjective evaluations of the washing machine properties (based on the values of psychoacoustic parameters and the number of questionnaire scores) through the Weighted Sum Method. To determine the weights of individual indicators, we used the correlation coefficients.

Correlation coefficients and multicriteria analysis were used to analyze the relationship between objective measurements and the questionnaire survey. Correlation coefficients (the Pearson correlation coefficient) are used in statistics to measure the strength of a relationship between two variables. Correlation coefficient formulas are used to find the strength of a relationship between data; the Pearson correlation coefficient will not give you any information about the slope of the line, it only tells you whether there is a relationship. It turns out that r will always be between −1 and +1. A correlation coefficient of 1 means that for every positive increase in one variable, there is a positive increase in the other. The zero result indicates no relationship. The value of the Pearson correlation coefficient between psychoacoustic parameters and the number of scores of the questionnaire is in Table 4 for each cycle (FILL, WASH, SPIN).

Table 4.

Pearson correlation coefficients [12].

The values of correlation coefficients are calculated as follows:

where: cov(x,y)—covariance between x and y; Var(x)—variance of variable x; Var(y)—variance of variable y.

The values of correlation coefficients are the basis for determining the weights of particular psychoacoustic parameters using the weighted sum method as follows:

where: wj—weights for the j-th indicator; rj—correlation coefficient of the j-th indicator.

The weights (Table 5) of particular psychoacoustic quantities in a specific mode of operation were determined based on the correlation of objective measurements and subjective questioning. Based on the weights, the washing machine sound quality indices for the particular operation modes were determined.

Table 5.

Weights of psychoacoustic parameters [12].

Based on the obtained weights and the measured psychoacoustics parameters values, the SQi sound quality index can be calculated as follows:

where: i—operating washing mode; R—measured value of Roughness (Asper); S—measured value of Sharpness (Acum); L—measured value of Loudness (Sone); T—measured value of Tonality (t.u.); F—measured value of Fluctuation strength (Vacil).

Detailed results are shown in a previous paper, “Development of psychoacoustic model based on the correlation of the subjective and objective sound quality evaluation of washing machines” [12].

3. Results and Discussion

In the present paper, subjective and objective analyses are proposed and correlated, in analogy with the methods proposed in the literature, in particular with reference to [43,44].

On the basis of the correlation analysis, the sound sample assuring the best correlations between objective and subjective variables was identified and then used to develop psychoacoustic models. The correlation between subjective independent attributes and overall judgements was proposed. It is worth noting that in [22,43], the subjective evaluation of all selected attributes well correlated with the global judgment.

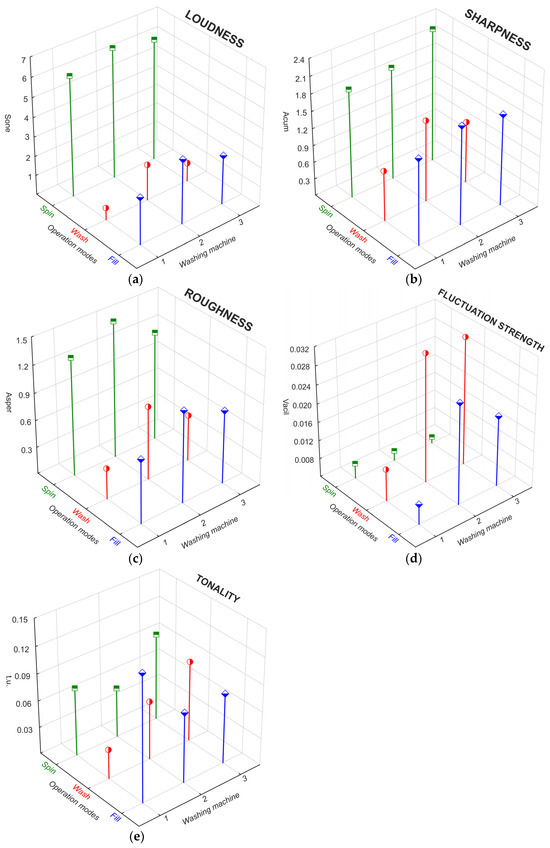

Three types of top-loading washing machines are evaluated in this article. During the measurement, the standardized washing program Cotton 60 °C—Energy Label declaration programmed was used on all evaluated washing machines. Three operating modes were assessed, namely FILL, WASH, and SPIN. The measured values of the monitored psychoacoustics parameters (Loudness, Sharpness, Roughness, Fluctuation strength, and Tonality) are graphically shown in Figure 3.

Figure 3.

Psychoacoustic parameters: (a) Loudness; (b) Sharpness; (c) Roughness; (d) Fluctuation strength; (e) Tonality.

Low-frequency noise, with a frequency range of 10 Hz to 200 Hz, has been recognized as a special environmental noise problem, particularly for sensitive people in their homes. Low-frequency noise is often emitted by household appliances and, from a psychoacoustic perspective, represents a problem, as described in the articles [45,46].

The results of the objective evaluation of the equivalent sound pressure level LAeq,T and psychoacoustics parameters for the evaluated types of top-loading washing machines and their operating washing modes are presented in Table 6.

Table 6.

Measurement results using binaural measuring technology.

The best psychoacoustic parameter values vary depending on the operating washing mode. The lowest values of all psychoacoustic parameters (except for the fluctuation strength parameter) are observed in the WASH washing mode for all evaluated washing machines, as is also evident from the functions they perform within the individual operating modes of washing. Machine–2 shows the highest values for almost all evaluated psychoacoustic parameters, except for Tonality. For the Roughness and Loudness parameters, these values are the highest for all operating modes. Machine–3 achieves relatively high Sharpness values in SPIN mode (2.350), on the contrary, other psychoacoustic parameters are the lowest in SPIN mode. Machine–1 has the lowest values for psychoacoustic parameters in WASH and FILL modes, except for the Roughness parameter in WASH mode (0.343) and Tonality in FILL mode (0.1410). From the measured values, we can conclude that, from the point of view of the evaluation of psychoacoustic parameters, the worst psychoacoustic parameters are achieved by Machine–2 and the best psychoacoustic parameters are achieved by Machine–1.

As all evaluated psychoacoustic parameters are measured in different units, it was important to standardize the measured values so that all parameters have comparable ranges.

The weights of the monitored psychoacoustic parameters for the evaluated operating modes of washing are derived from a previous evaluation of washing machines [12]. The weighting values were derived from the correlation between the objective and subjective evaluations. The determined weights are presented in Table 5. To determine the weights of psychoacoustic parameters, we used a correlation coefficient, which is an effective way to identify which parameters have the greatest impact on the final response or subjective perception of sound by users. The weights of the parameters were determined directly from the size of the correlation coefficients, the higher weights are assigned to those parameters that have higher absolute values of the correlation coefficients. In this way, all weights have been normalized to a range of 0 to 1, and their sum is 1.

The largest value of the weight factor achieved in the FILL operating mode belongs to the Sharpness parameter (0.40). In the WASH mode, it is the Roughness parameter (0.30), and finally, in the SPIN operating mode, there are two parameters, namely Roughness/Loudness (0.24). On the other hand, the lowest values close to zero were reflected in the FILL mode for the Roughness parameter (0.04) and in the WASH mode for the Tonality parameter (0.07).

The ranking of the washing machine compiled on the basis of a subjective evaluation (ranking based on the average number of points achieved in the questionnaire) and the calculated quality index (see Equation (5) and Table 5) for the evaluated operating modes of washing are given in Table 7. We rate the washing machine with the lowest SQi sound quality index as the most acceptable from the user’s point of view.

Table 7.

Established ranking of washing machines based on sound quality index and jury study results.

In FILL mode, the lowest value of SQi was calculated for Machine–1 (1.06), and the highest (1.32) was for Machine–2. In WASH and SPIN mode, the result was the same, with the same ranking of washing machines (1. place—Machine–1; 2. place—Machine–3; 3. place—Machine–2). The lowest SQi values for the above operating modes were calculated for Machine–1 (WASH—0.36, SPIN—2.13) and the highest SQi for Machine–2 (WASH—0.90, SPIN—2.31). Based on a questionnaire survey, the washing machine that received the highest number of points was the best rated. In the FILL mode, Machine–3 received the highest number of points (8.5), while Machine–1 received the lowest number (4.9). The results presented in Table 7 demonstrate a strong correlation between the subjective rating and the calculated value of the sound quality index. From the above results, it is clear that there was no agreement between the objective and subjective evaluations for the FILL operating mode. This is due to the fact that with Machine–1 in FILL mode, there was a sound of a tonal nature that respondents perceived as disturbing. This tonal sound was also confirmed by the psychoacoustic parameter Tonality in objective measurement. This phenomenon of tonal sound was not captured in the development of the psychoacoustic model for evaluating the sound quality of washing machines. As a result, there were deviations in determining the ranking of washing machines, based on these methods. On the contrary, in the WASH and SPIN modes, the results showed the same agreement not only in the ranking of the washing machines but also in the comparison between objective and subjective evaluations. Machine–2 received the lowest number of points in the listening tests for all evaluated psychoacoustic parameters (FILL—4.9, WASH—5.1, SPIN—5.2).

However, there is a great degree of variability in the washing performance of each washing machine, depending on the ongoing operating washing mode.

To verify the agreement of the ranking in each operating mode, we used the Spearman coefficient, which can be calculated as follows:

where: R—rank of the data x; Q—rank of the data y; n—file size.

Values of Spearman’s rank correlation coefficient are presented in Table 8. Values close to 0 indicate a weaker ordinal dependence between variables, while values close to 1 or −1 indicate a tighter ordinal dependence (direct or indirect).

Table 8.

Values of Spearman’s rank correlation coefficient.

Based on Spearman’s rank correlation coefficient, the ranking of the washing machines in the two operating modes (WASH, SPIN) is 100% consistent. In the FILL operating mode, the ranking match was not fully confirmed.

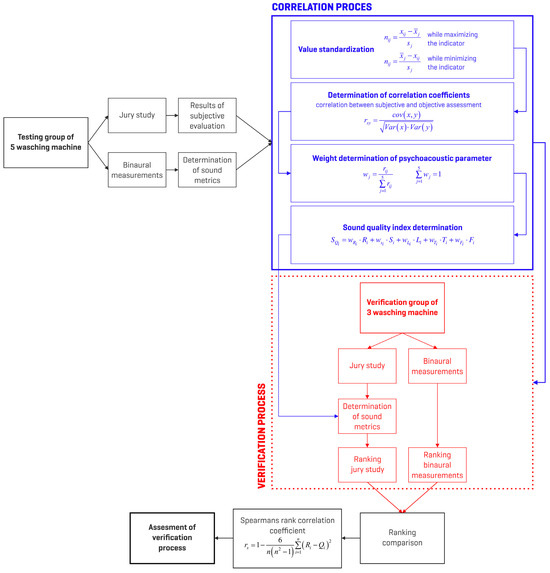

The following (Figure 4) shows the overall process of evaluating the psychoacoustic properties of automatic washing machines based on the developed psychoacoustic model and the proposed validation process.

Figure 4.

The process flowchart of validation of the developed psychoacoustic model for sound quality valuation of washing machines.

For further investigation, we recommend using machine learning to adapt psychoacoustic models based on individual listener profiles. This would allow for personalized sound quality assessments that consider hearing acuity, preferences, and even psychological state, improving the accuracy of predictions in consumer products

Deep learning integration combines human perceptual ratings with neural networks to predict sound quality metrics, such as loudness and sharpness, more accurately. Neural networks are increasingly integral to sound quality engineering, bridging the gap between objective measurements and human perception.

4. Conclusions

The evaluation of the acoustic quality of household appliances entails the comprehensive evaluation of the sounds emitted by these devices and their perception by users. In the process of sound evaluation, the basic tool for determining psychoacoustic quantities is a binaural measuring device, also known as an artificial head. Questionnaire methods are used to discover the opinions of users of individual devices, where respondents evaluate the sounds of these devices. In previous research [12], a correlation was found between the measured psychoacoustic parameters and the results of the questionnaire survey. The result was the determination of weighting factors for individual psychoacoustic variables. By applying these weighting factors to the measured values, it is then possible to determine the quality of sounds even without a questionnaire survey. The validation process of the developed model was carried out on three top-loading washing machines. After determining the psychoacoustic quantities, the ranking of washing machines was compiled based on their sounds. Subsequently, the sound quality indices for these washing machines were determined with the already applied weight factors for individual psychoacoustic variables, and the ranking of the sounds of these washing machines was reconstructed. A questionnaire survey was conducted to verify the evaluation of sound quality based on the developed model and the application of weighting factors. Based on the questionnaire survey, the ranking of the sound quality of washing machines was again calculated. The final step of the validation was a comparison of the results of the quality ranking of washing machine sounds, based on a questionnaire survey and the application of weighting factors to the measured psychoacoustic parameters. The results show an almost perfect match in the ranking of sounds based on respondents’ opinions and through the sound quality index. The ordinal correlation was different in the FILL mode, which was due to the appearance of an atypical tonal sound, which was not considered in the developed psychoacoustic model for evaluating the quality of washing machine sounds. The experimental evaluation conducted in this work follows a widely used methodology, inspired by regulatory guidelines for statistical data analysis in analytical method validation, to optimize the number of assays and meet the validation criteria requirements. The agreement in determining the ranking was also confirmed by Spearman’s correlation coefficient. In conclusion, we can conclude that the developed model for the evaluation of psychoacoustic quality and its application to measured psychoacoustic parameters can replace the lengthy methods of assessing sound quality through questionnaire surveys. The developed evaluation model through the sound quality index, considering the weights of individual psychoacoustic parameters, can only be applied to a specific product group of household appliances, in this case, washing machines.

Based on the steps taken, a proposal was made for the overall process of evaluating the psychoacoustic properties of automatic washing machines based on the developed psychoacoustic model and the proposed validation process.

Author Contributions

Conceptualization, M.M., M.P. and G.I.; methodology, M.M., M.P., G.I. and M.B.; software, G.I. and M.M.; validation, M.M., M.P. and G.I.; formal analysis, M.P. and L.S.; investigation, M.M., M.P. and G.I.; resources, M.M. and G.I.; data curation, M.M. and M.P.; writing—original draft preparation, M.M., M.P., M.B. and G.I.; writing—review and editing, M.M., M.P., L.S. and G.I.; visualization, M.P.; supervision, M.M. and M.B.; project administration, M.B.; funding acquisition, M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

This work was supported by the projects of the Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic, project KEGA No. 032TUKE-4/2025 and project UNIVNET No. 0201/0082/19.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fastl, H.; Zwicker, E. Psychoacoustics: Facts and Models, 3rd ed.; Springer: Berlin, Germany, 2007; pp. 203–261. [Google Scholar] [CrossRef]

- Nowakowski, T.; Komorski, P. Tram noise annoyance: The role of different psychoacoustic measures in the assessment of noise. Appl. Acoust. 2024, 219, 109946. [Google Scholar] [CrossRef]

- Kumar, S.; Wing, W.S.; Lee, H.P. Psychoacoustic analysis of vacuum cleaner noise. Acoustics 2021, 3, 545–558. [Google Scholar] [CrossRef]

- Blauert, J.; Butler, R.A. Spatial Hearing: The Psychophysics of Human Sound Localization by Jens Blauert. J. Acoust. Soc. Am. 1985, 77, 334–335. [Google Scholar] [CrossRef]

- Hellbrück, J.; Ellermeier, W. Hören: Physiologie, Psychologie und Pathologie, 2nd ed.; Hogrefe Verlag: Göttingen, Germany, 2004; p. 354. [Google Scholar]

- Algom, D. The Weber–Fechner law: A misnomer that persists but that should go away. Psychol. Rev. 2021, 128, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K.O.; Hsiao, S.S.; Yoshioka, T. Neural coding and the basic law of psychophysics. Neuroscientist 2002, 8, 111–121. [Google Scholar] [CrossRef] [PubMed]

- Fusaro, G.; Kang, J.; Asdrubali, F.; Chang, W.-S. Assessment of acoustic metawindow unit through psychoacoustic analysis and human perception. Appl. Acoust. 2022, 196, 108885. [Google Scholar] [CrossRef]

- Howard, D.M.; Angus, J.A.S. Acoustics and Psychoacoustics, 5th ed.; Taylor & Francis Group: New York, NY, USA, 2017; p. 518. [Google Scholar] [CrossRef]

- Fastl, H. The Psychoacoustics of Sound-Quality Evaluation. Acustica 1997, 83, 754–764. [Google Scholar]

- Lentz, J.J. Psychoacoustics: Perception of Normal and Impaired Hearing with Audiology Applications, 1st ed.; Plural Publishing Inc.: San Diego, CA, USA, 2020; p. 238. [Google Scholar]

- Moravec, M.; Izarikova, G.; Liptai, P.; Badida, M.; Badidova, A. Development of psychoacoustic model based on the correlation of the subjective and objective sound quality assessment of automatic washing machines. Appl. Acoust. 2018, 140, 178–182. [Google Scholar] [CrossRef]

- Altinsoy, M.; Ercan, S. A sound quality model for washing machine sounds based on artificial neural network. In Proceedings of the 22nd International Congress on Acoustics, Buenos Aires, Argentina, 5–9 September 2016. [Google Scholar]

- Wang, S.; Nerse, C.; Kim, H.W. Vibro-acoustic noise analysis of a washing machine. In Proceedings of the Society for Experimental Mechanics Serie, Garden Grove, CA, USA, 30 January 30–2 February 2017. [Google Scholar]

- Kuwano, S.; Namba, S.; Fastl, H.; Putner, J. Continuous judgment of sound quality of electric home appliances. In Proceedings of the INTERNOISE 2014—43rd International Congress on Noise Control Engineering: Improving the World Through Noise Control, Melbourne, Australia, 16–19 November 2014. [Google Scholar]

- Sato, S.; You, J.; Jeon, J.Y. Sound quality characteristics of refrigerator noise in real living environments with relation to psychoacoustical and autocorrelation function parameters. J. Acoust. Soc. Am. 2007, 122, 314–325. [Google Scholar] [CrossRef]

- Huang, Y.; Zheng, Q. Sound quality modelling of hairdryer noise. Appl. Acoust. 2022, 197, 108904. [Google Scholar] [CrossRef]

- An, K.Y.; Kwon, H.; Jang, J.Y.; Song, K. Acoustic metamaterial design for noise reduction in vacuum cleaner. J. Mech. Sci. Technol. 2022, 36, 5353–5362. [Google Scholar] [CrossRef]

- Susini, P.; McAdams, S.; Winsberg, S.; Perry, I.; Vieillard, S.; Rodet, X. Characterizing the sound quality of air-conditioning noise. Appl. Acoust. 2004, 65, 763–790. [Google Scholar] [CrossRef]

- Love, J.; Sung, W.; Francis, A.L. Psychophysiological responses to potentially annoying heating, ventilation, and air conditioning noise during mentally demanding work. J. Acoust. Soc. Am. 2021, 150, 3149–3163. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Chen, Q.; Cheng, J.; Zhang, S. Specific psychacoustic metrics and their application to range hoods. Appl. Acoust. 2021, 179, 108079. [Google Scholar] [CrossRef]

- Jeong, U.C.; Kim, J.S.; Jeong, J.E.; Yang, I.H.; Oh, J.E. Development of a sound quality index for the wash cycle process of front-loading washing machines considering the impacts of individual noise sources. Appl. Acoust. 2015, 87, 183–189. [Google Scholar] [CrossRef]

- Altinsoy, M.E.; Gül, M.; Kuyumcuoglu, A. Sound quality of household appliances for life quality—An investigation on tumble dryer sound quality. In Proceedings of the 22nd International Congress on Sound and Vibration, Florence, Italy, 12–16 July 2015. [Google Scholar]

- Atamer, S.; Ercan Altinsoy, M. Sound quality of dishwashers: Annoyance perception. Appl. Acoust. 2021, 108099, 180. [Google Scholar] [CrossRef]

- Barpanda, D.; Tudor, J. Solutions-Based Approach for Reducing Noise in Washing Machines. Sound Vib. 2009, 43, 6–10. [Google Scholar]

- Liu, B.; Feng, T.; Wu, X.; Li, N. Noise radiation characteristics of the washing machine based on sound intensity measurement. Adv. Mater. Res. 2012, 482–484, 1406–1409. [Google Scholar] [CrossRef]

- Orhon, B.E.; Belek, H.T. Sound quality in washing machines. In Proceedings of the 39th International Congress on Noise Control Engineering, Lisbon, Portugal, 13–16 June 2010. [Google Scholar]

- Albero, C.; Sánchez-Tabuenca, B. Experimental Methodology to Characterize the Noise Paths in a Horizontal-Axis Washing Machine. Acoustics 2023, 5, 476–489. [Google Scholar] [CrossRef]

- Jeon, J.Y.; You, J.; Chang, H.Y. Sound radiation and sound quality characteristics of refrigerator noise in real living environments. Appl. Acoust. 2007, 68, 1118–1134. [Google Scholar] [CrossRef]

- Zakri, K.W.; Sarwono, R.S.J.; Santosa, S.P.; Soelami, F.X.N. Modeling and Validation of Acoustic Comfort for Electric Vehicle Using Hybrid Approach Based on Soundscape and Psychoacoustic Methods. World Electr. Veh. J. 2025, 16, 64. [Google Scholar] [CrossRef]

- Yang, L.; Wang, P.; Wang, J. Research on evaluation model for vehicle interior sound quality based on an optimized BiLSTM using genetic algorithm. Mech. Syst. Signal Process. 2023, 204, 110827. [Google Scholar] [CrossRef]

- Gao, Y.H.; Qian, K.; Liang, J.; Liu, Q.; Zhao, J. Interior sound quality evaluation model of heavy commercial vehicles. J. Vibroengineering 2016, 18, 595–605. [Google Scholar]

- He, Z.; Guo, H.; Liu, H.; Zhao, Y.; Zhang, Z.; Yang, S. A Sound Quality Evaluation Method for Vehicle Interior Noise Based on Auditory Loudness Model. Sound Vib. 2024, 58, 47–58. [Google Scholar] [CrossRef]

- Zuo, Y.; Liao, L.; Meng, H.; Wu, S. Contrastive Analysis of Car Interior Sound Quality Evaluation Models. In Proceedings of the 2016 International Conference on Civil, Transportation and Environment, Guangzhou, China, 30–31 January 2016; Atlantis Press: Dordrecht, The Netherlands, 2016; pp. 1105–1110. [Google Scholar] [CrossRef][Green Version]

- EN ISO 3744; Acoustics. Determination of Sound Power Levels and Sound Energy Levels of Noise Sources Using Sound Pressure. Engineering Methods for an Essentially Free Field over a Reflecting Plane. International Organisation for Standardisation: Geneva, Switzerland, 2010.

- EN ISO 3745; Acoustics. Determination of Sound Power Levels and Sound Energy Levels of Noise Sources Using Sound Pressure. Precision Methods for Anechoic Rooms and Hemi-Anechoic Rooms. International Organisation for Standardisation: Geneva, Switzerland, 2012.

- Ali, K.; Al-Hameed, A. Spearman’s correlation coefficient in statistical analysis. Int. J. Nonlinear Anal. Appl 2022, 13, 3249–3255. [Google Scholar] [CrossRef]

- El-Hashash, E.F.; Shiekh, R.H.A. A Comparison of the Pearson, Spearman Rank and Kendall Tau Correlation Coefficients Using Quantitative Variables. Asian J. Probab. Stat. 2022, 20, 36–48. [Google Scholar] [CrossRef]

- Dehling, H.; Vogel, D.; Wendler, M.; Wied, D. Testing for changes in Kendall’s tau. Econom. Theory 2017, 33, 1352–1386. [Google Scholar] [CrossRef]

- van der Ark, L.A.; van Aert, R.C.M. Comparing confidence intervals for Goodman and Kruskal’s gamma coefficient. J. Stat. Comput. Simul. 2015, 85, 2491–2505. [Google Scholar] [CrossRef]

- Morrison, J. Statistics for Engineers: An Introduction, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009; p. 192. [Google Scholar]

- Zopounidis, C.; Pardalos, P.M. Handbook of Multicriteria Analysis; Springer: Berlin, Germany, 2010; p. 480. [Google Scholar]

- Volandri, G.; Di Puccio, F.; Forte, P.; Mattei, L. Psychoacoustic analysis of power windows sounds: Correlation between subjective and objective evaluations. Appl. Acoust. 2018, 134, 160–170. [Google Scholar] [CrossRef]

- Nykänen, A.; Sirkka, A. Specification of component sound quality applied to automobile power windows. Appl. Acoust. 2009, 70, 813–820. [Google Scholar] [CrossRef]

- Leventhall, G.H. Low frequency noise and annoyance. Noise Healrh 2004, 6, 59–72. [Google Scholar]

- Bae, S.-G.; Lee, W.-H.; Bae, M.-J. A Study on Sound Characteristics of Home appliances Noise using Psychoacoustics Parameters. Int. J. Eng. Technol. 2016, 8, 1606–1610. [Google Scholar] [CrossRef][Green Version]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).