Thermoforming Process Effect on Performances of Thermoplastic/Recycled Carbon Fiber Composites

Abstract

1. Introduction

2. Materials and Methods

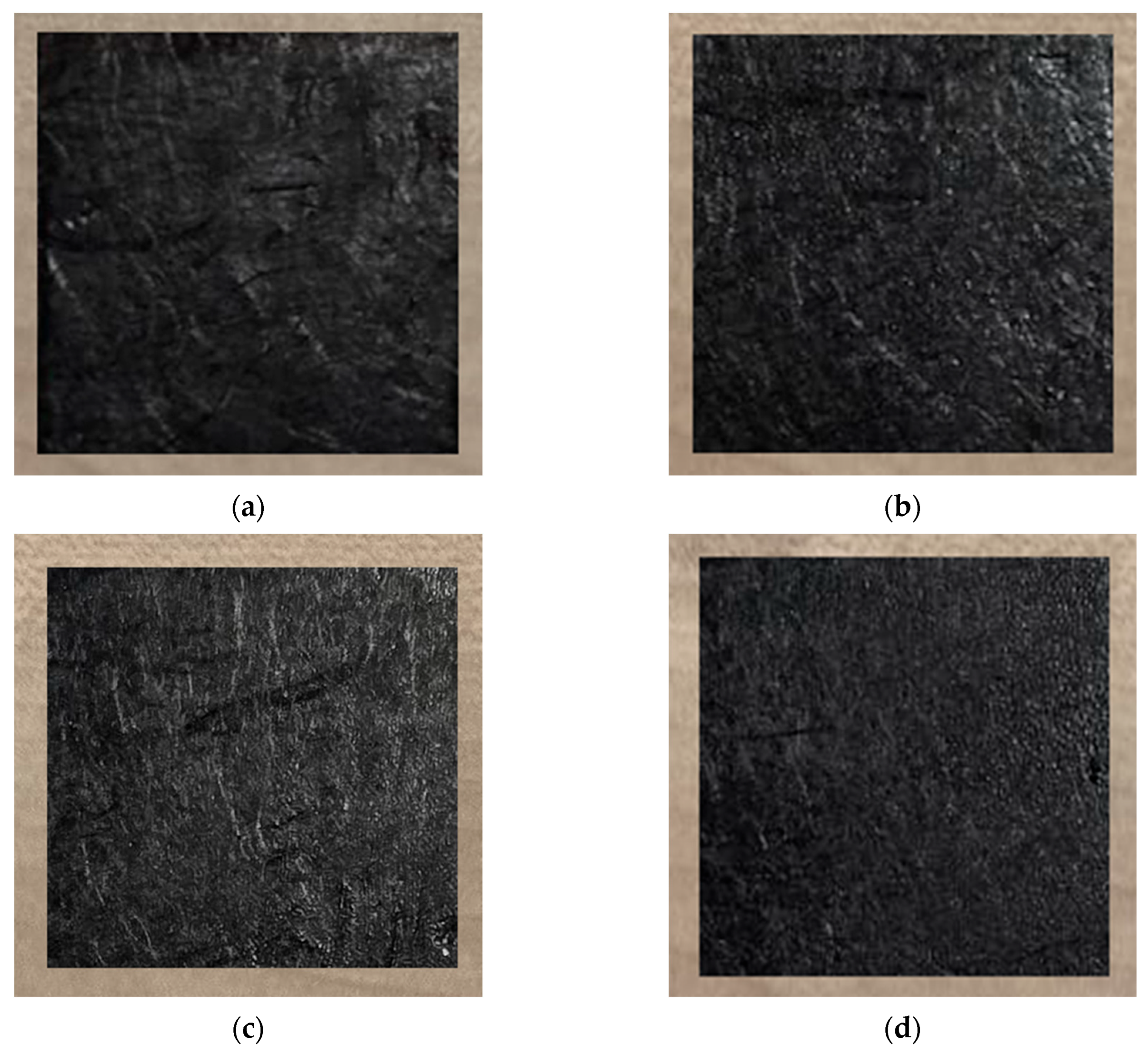

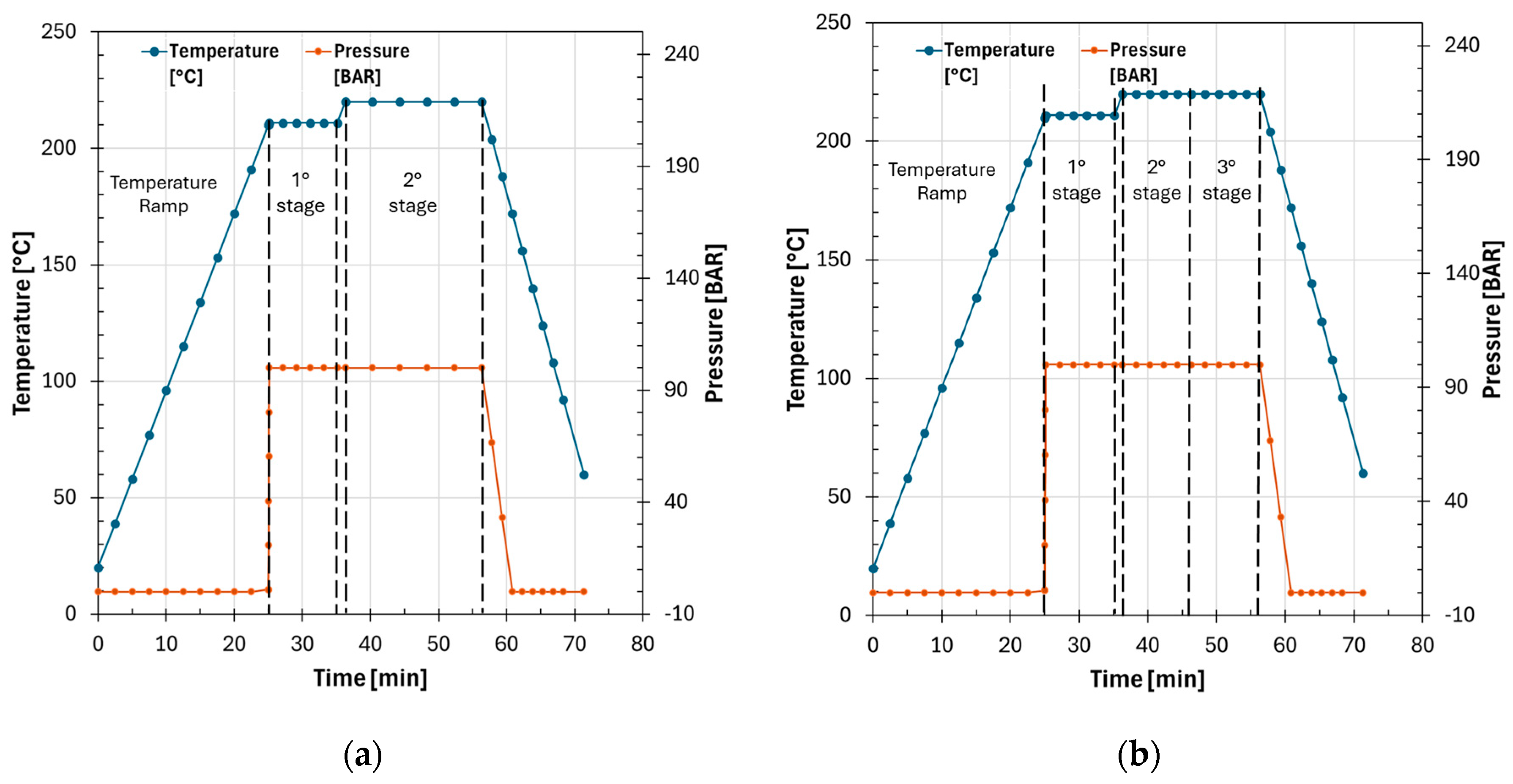

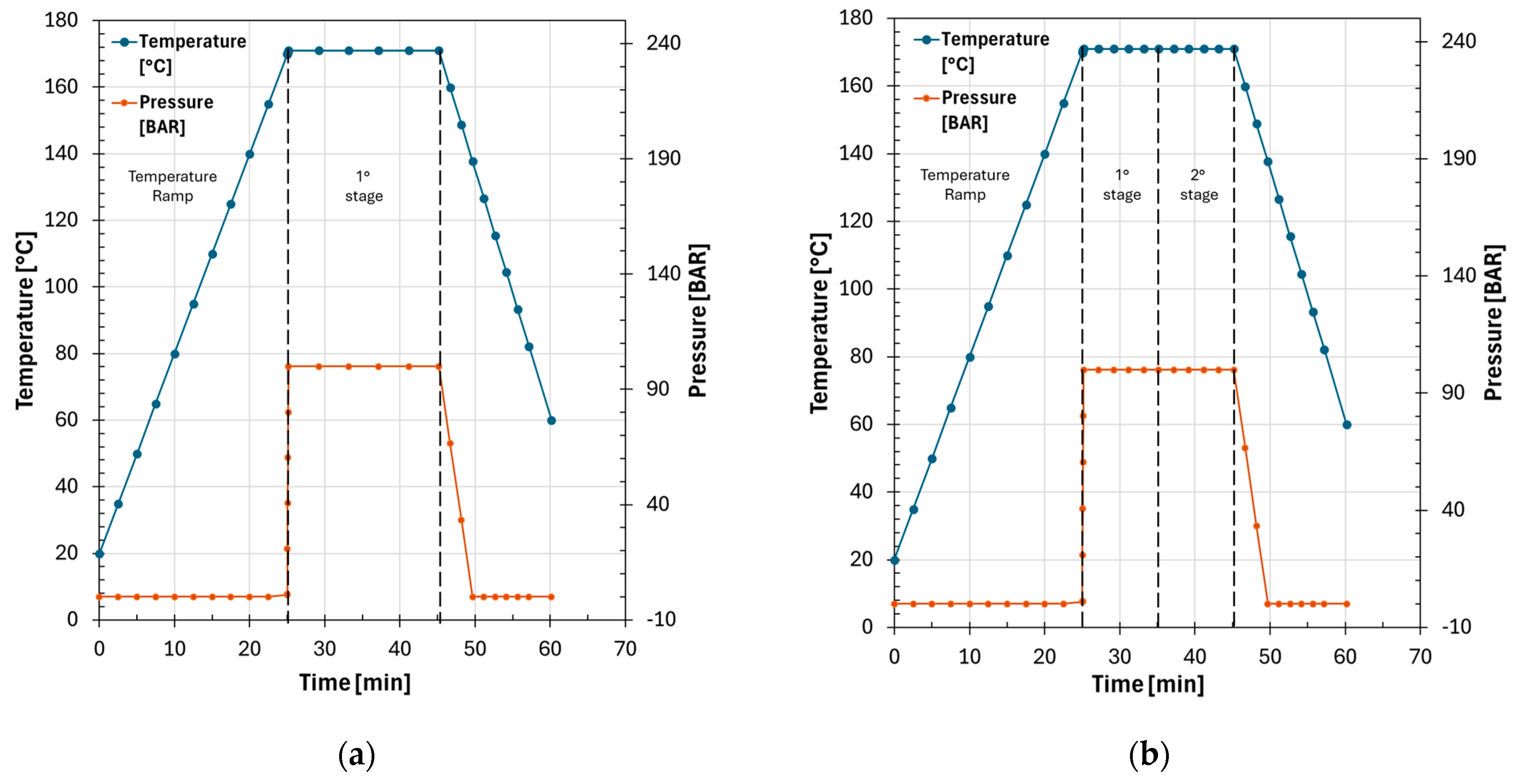

2.1. Sample Preparation

2.2. Experimental Characterization

3. Results and Discussion

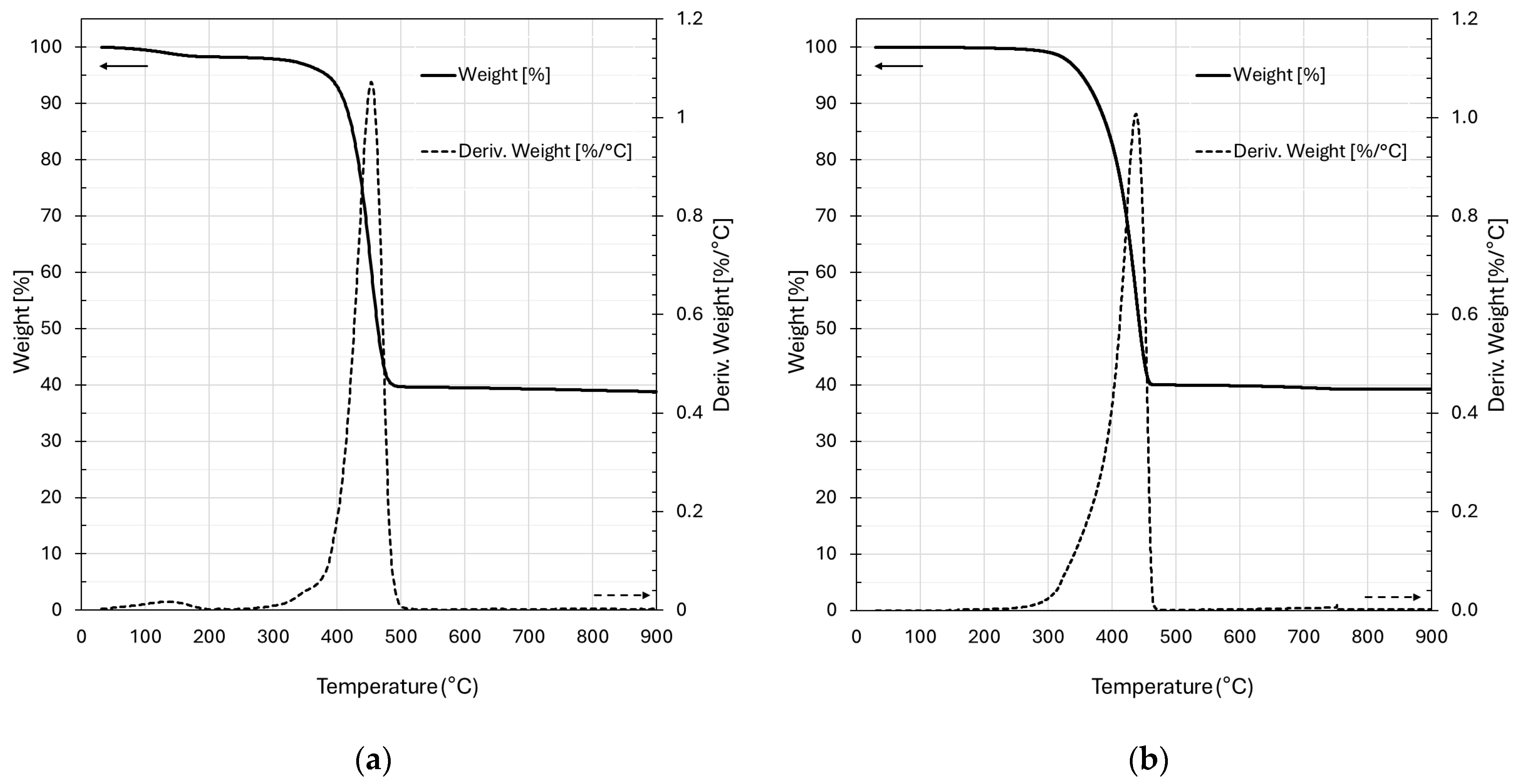

3.1. Thermal Characterization

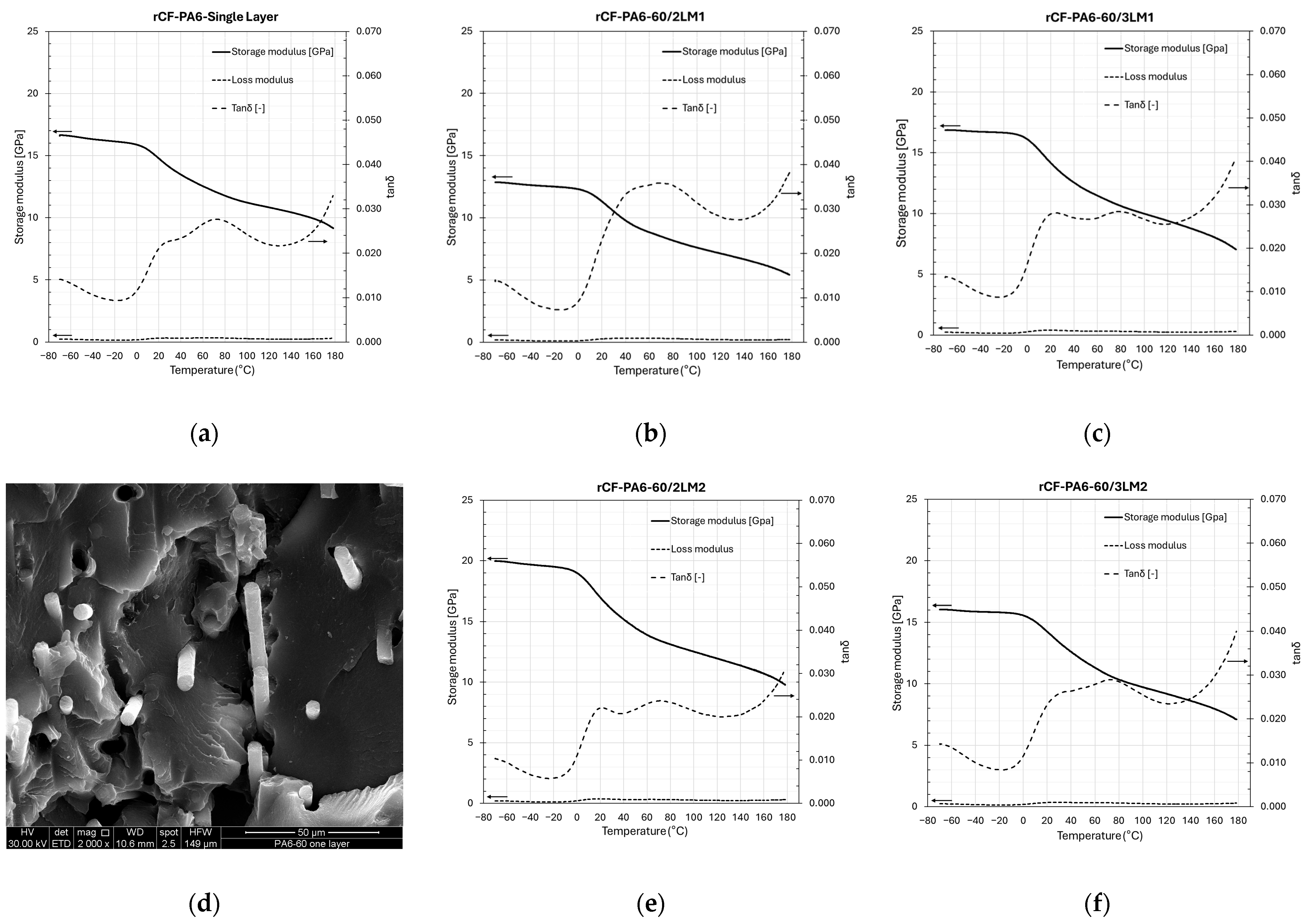

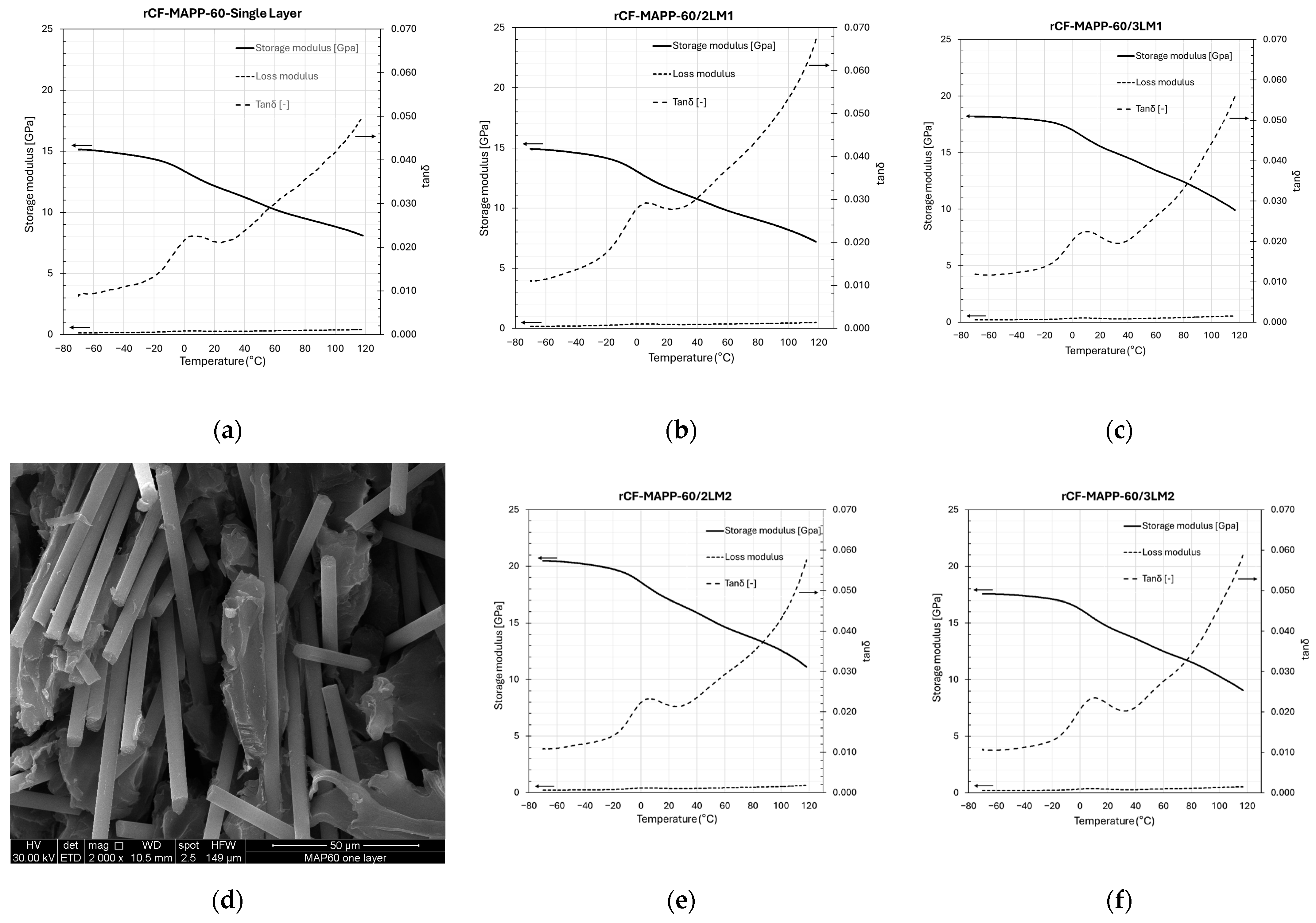

3.2. Viscoelastic Characterization

3.3. Effect of Molding Process on Crystallinity

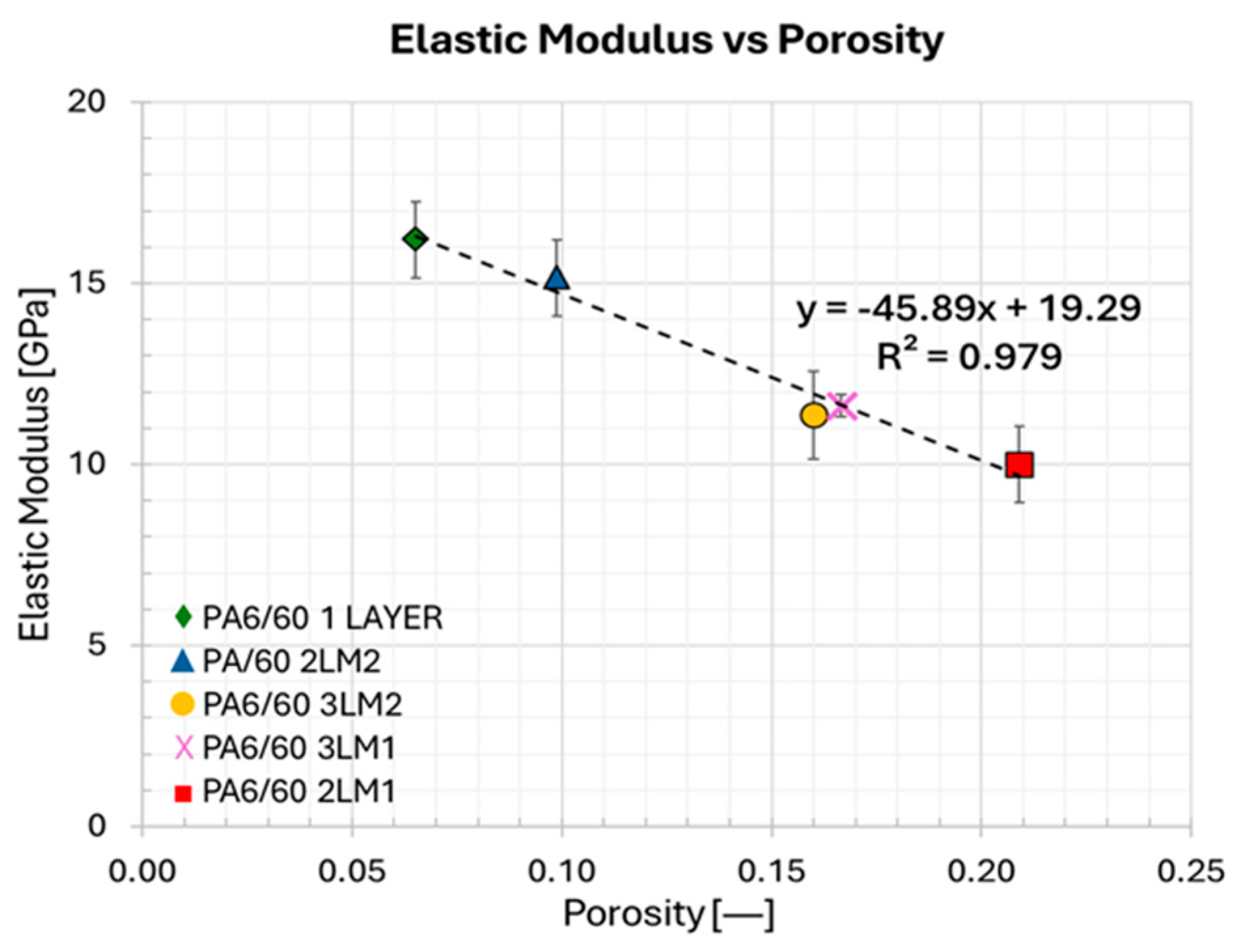

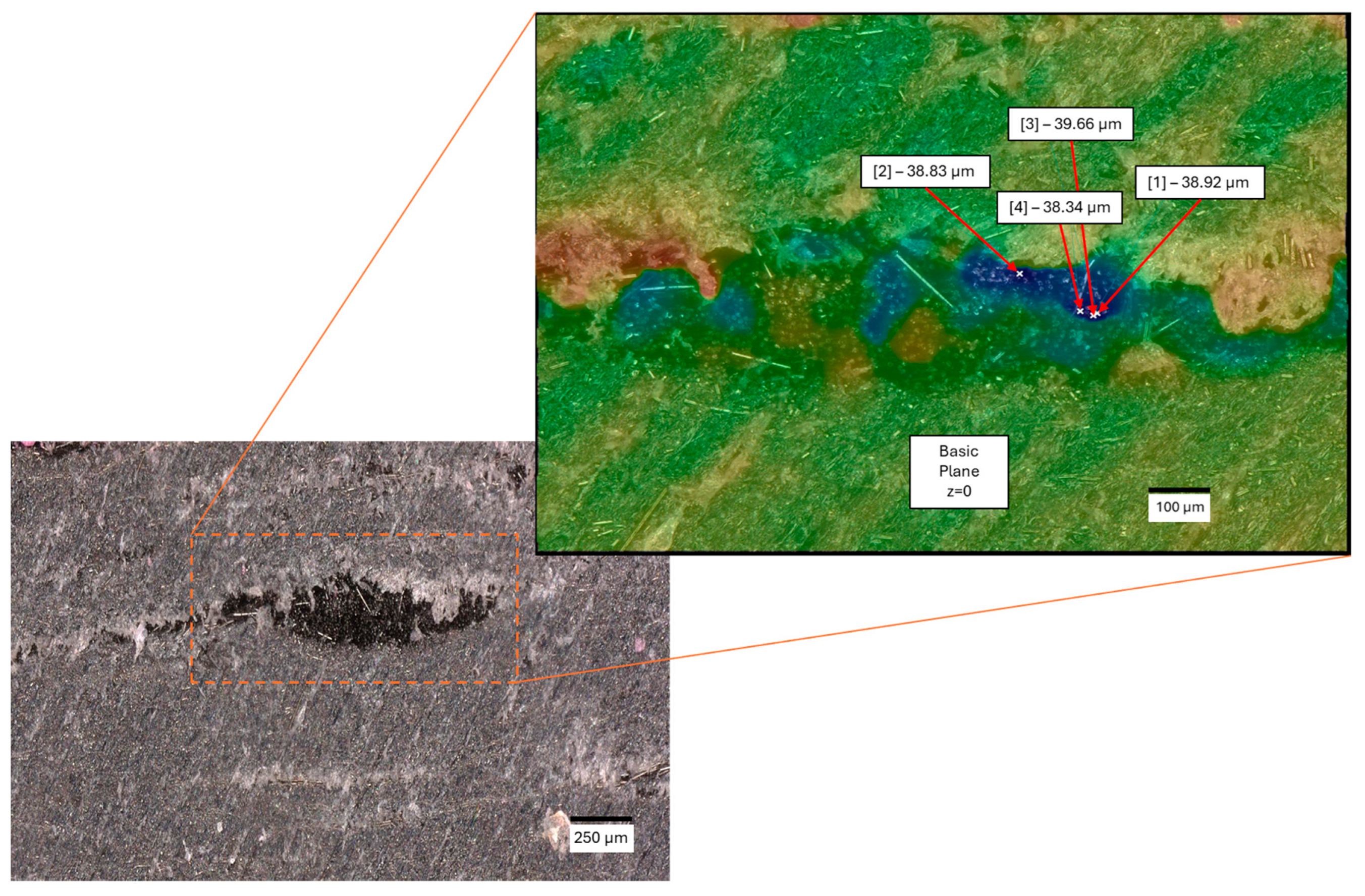

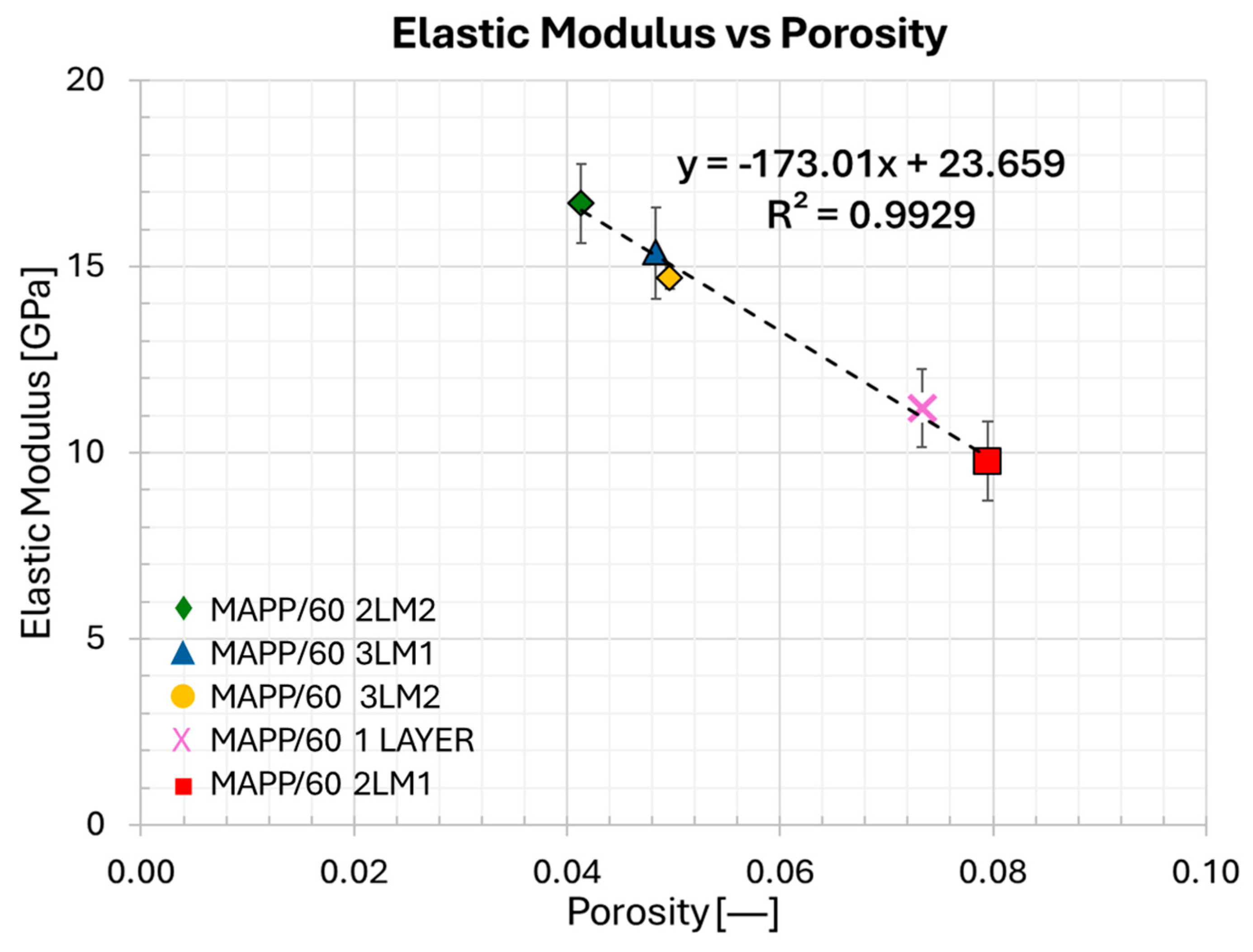

3.4. Effect of Porosity on the Storage Modulus

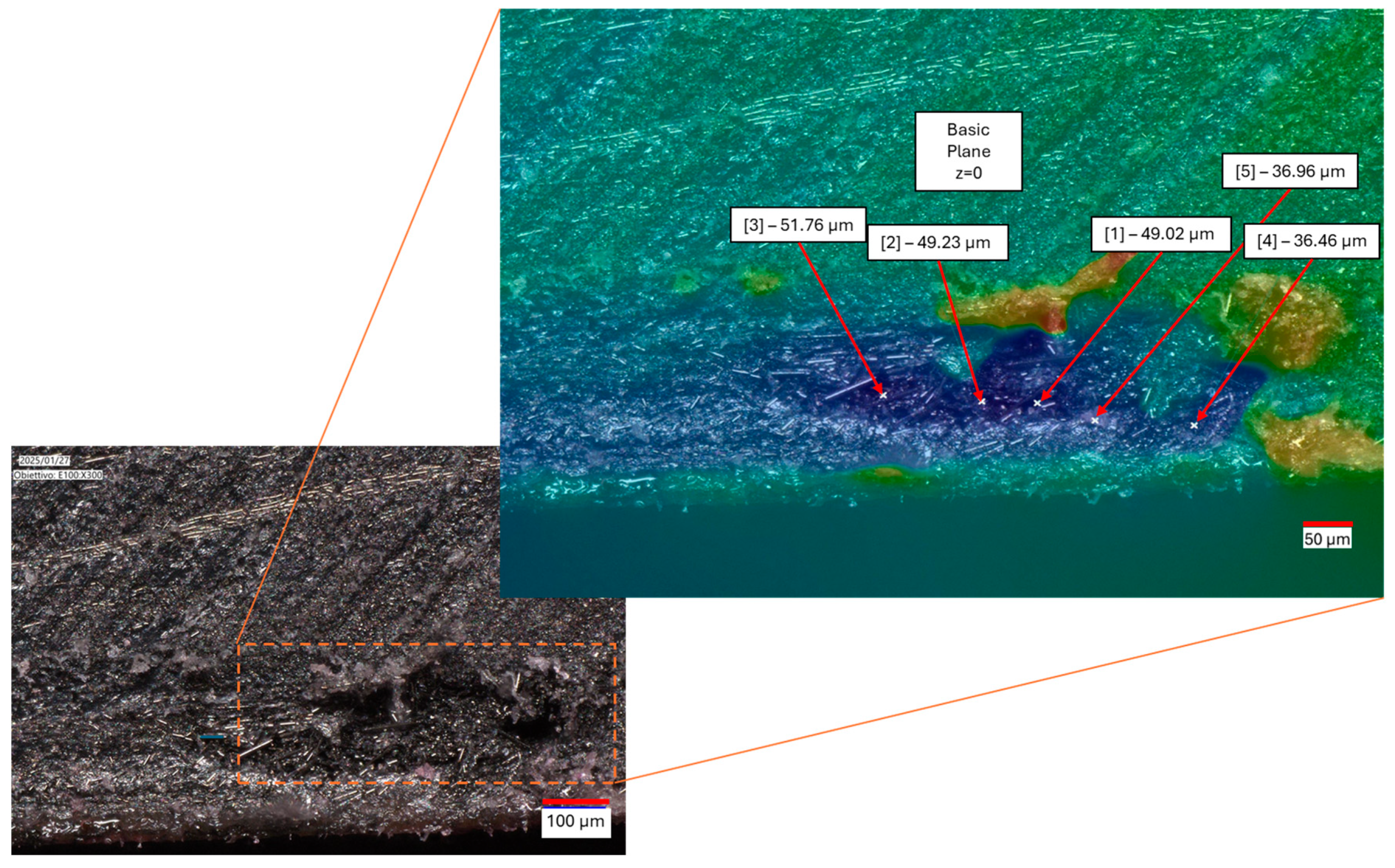

3.5. Effect of Compatibility Between Polymer Matrix and rCF

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prashanth, S.; Subbaya, K.M.; Nithin, K.; Sachhidananda, S. Fiber Reinforced Composites—A Review. J. Mater. Sci. Eng. 2017, 6, 2–6. [Google Scholar] [CrossRef]

- Van De Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively Manufactured Carbon Fiber-Reinforced Composites: State of the Art and Perspective. Addit. Manuf. 2020, 31, 100962. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Mineral-Impregnated Carbon Fiber Composites as Novel Reinforcement for Concrete Construction: Material and Automation Perspectives. Autom. Constr. 2020, 110, 103002. [Google Scholar] [CrossRef]

- Hazell, P.J.; Stennett, C.; Cooper, G. The Effect of Specimen Thickness on the Shock Propagation along the In-Fibre Direction of an Aerospace-Grade CFRP Laminate. Compos. Part. A Appl. Sci. Manuf. 2009, 40, 204–209. [Google Scholar] [CrossRef]

- Friedrich, K. Carbon Fiber Reinforced Thermoplastic Composites for Future Automotive Applications. In Proceedings of the VIII International Conference on “Times of Polymers and Composites”: From Aerospace to Nanotechnology, Naples, Italy, 19–23 June 2016; p. 020001. [Google Scholar]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent Advances in Carbon-Fiber-Reinforced Thermoplastic Composites: A Review. Compos. B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Stieven Montagna, L.; Ferreira de Melo Morgado, G.; Lemes, A.P.; Roberto Passador, F.; Cerqueira Rezende, M. Recycling of Carbon Fiber-Reinforced Thermoplastic and Thermoset Composites: A Review. J. Thermoplast. Compos. Mater. 2023, 36, 3455–3480. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current Status of Carbon Fibre and Carbon Fibre Composites Recycling. Compos. B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance), Official Journal of the European Union L 312/3 22.11.2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098 (accessed on 13 March 2025).

- Bernatas, R.; Dagreou, S.; Despax-Ferreres, A.; Barasinski, A. Recycling of Fiber Reinforced Composites with a Focus on Thermoplastic Composites. Clean. Eng. Technol. 2021, 5, 100272. [Google Scholar] [CrossRef]

- Türker, Y.S.; Öztürk, F.; Öz, Y. Review of Recycling Methods of Thermoplastic Composite Materials. Polym.-Plast. Technol. Mater. 2024, 63, 1693–1713. [Google Scholar] [CrossRef]

- Grigore, M. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Sun, H.; Guo, G.; Memon, S.A.; Xu, W.; Zhang, Q.; Zhu, J.-H.; Xing, F. Recycling of Carbon Fibers from Carbon Fiber Reinforced Polymer Using Electrochemical Method. Compos. Part. A Appl. Sci. Manuf. 2015, 78, 10–17. [Google Scholar] [CrossRef]

- Ye, S.Y.; Bounaceur, A.; Soudais, Y.; Barna, R. Parameter Optimization of the Steam Thermolysis: A Process to Recover Carbon Fibers from Polymer-Matrix Composites. Waste Biomass Valorization 2013, 4, 73–86. [Google Scholar] [CrossRef]

- Deng, J.; Xu, L.; Liu, J.; Peng, J.; Han, Z.; Shen, Z.; Guo, S. Efficient Method of Recycling Carbon Fiber from the Waste of Carbon Fiber Reinforced Polymer Composites. Polym. Degrad. Stab. 2020, 182, 109419. [Google Scholar] [CrossRef]

- Palmieri, B.; Borriello, C.; Rametta, G.; Iovane, P.; Portofino, S.; Tammaro, L.; Galvagno, S.; Giordano, M.; Ambrosio, L.; Martone, A. Investigation on Stress Relaxation of Discontinuous Recycled Carbon Fiber Composites. J. Mater. Eng. Perform. 2023, 32, 3938–3945. [Google Scholar] [CrossRef]

- Tammaro, L.; Martone, A.; Palmieri, B.; Borriello, C.; Portofino, S.; Iovane, P.; Cilento, F.; Giordano, M.; Galvagno, S. Reinforcing Efficiency of Recycled Carbon Fiber PLA Filament Suitable for Additive Manufacturing. Polymers 2024, 16, 2100. [Google Scholar] [CrossRef] [PubMed]

- Demski, S.; Misiak, M.; Majchrowicz, K.; Komorowska, G.; Lipkowski, A.; Stankiewicz, K.; Dydek, K.; Waśniewski, B.; Boczkowska, A.; Ehrlich, H. Mechanical Recycling of CFRPs Based on Thermoplastic Acrylic Resin with the Addition of Carbon Nanotubes. Sci. Rep. 2024, 14, 11550. [Google Scholar] [CrossRef]

- Barnett, P.R.; Ghossein, H.K. A Review of Recent Developments in Composites Made of Recycled Carbon Fiber Textiles. Textiles 2021, 1, 433–465. [Google Scholar] [CrossRef]

- Kessel, F.; Klopsch, L.; Jehle, V.; Biller, N.-J.; Frieß, M.; Shi, Y.; Cepli, D.; Keck, M.; Jemmali, R. Wet-Laid Nonwoven Based Ceramic Matrix Composites: An Innovative and Highly Adaptable Short Fiber Reinforcement for Ceramic Hybrid and Gradient Materials. J. Eur. Ceram. Soc. 2021, 41, 4048–4057. [Google Scholar] [CrossRef]

- Raghvendra, K.M.; Sravanthi, L. Fabrication Techniques of Micro/Nano Fibres Based Nonwoven Composites: A Review. Mod. Chem. Appl. 2017, 5, 2. [Google Scholar] [CrossRef]

- Quan, D.; Liu, J.; Yao, L.; Dransfeld, C.; Alderliesten, R.; Zhao, G. Interlaminar and Intralaminar Fracture Resistance of Recycled Carbon Fibre/PPS Composites with Tailored Fibre/Matrix Adhesion. Compos. Sci. Technol. 2023, 239, 110051. [Google Scholar] [CrossRef]

- Ma, Y.; Yan, C.; Xu, H.; Liu, D.; Shi, P.; Zhu, Y.; Liu, J. Enhanced Interfacial Properties of Carbon Fiber Reinforced Polyamide 6 Composites by Grafting Graphene Oxide onto Fiber Surface. Appl. Surf. Sci. 2018, 452, 286–298. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Mahmud, N.; Habib, A.; Rana, M.M.; Khan, S.A.; Hossain, M.D. Research and Application of Polypropylene: A Review. Discov. Nano 2024, 19, 2. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, A.; Urushisaki, M.; Uematsu, H.; Sakaguchi, T.; Hashimoto, T. Effects of Different Types of Maleic Anhydride-Modified Polypropylene on the Interfacial Shear Strengths of Carbon Fiber-Reinforced Polypropylene Composites. Polym. J. 2023, 55, 153–161. [Google Scholar] [CrossRef]

- Holmes, M. Recycled Carbon Fiber Composites Become a Reality. Reinf. Plast. 2018, 62, 148–153. [Google Scholar] [CrossRef]

- Ivars, J.; Labanieh, A.R.; Soulat, D. Influence of the Thermoplastic Fiber Ratio on the Mechanical Properties of Recycled Carbon Fibers During the Carding Process. Materials 2025, 18, 302. [Google Scholar] [CrossRef]

- ASTM E1131-20; Standard Test Method for Compositional Analysis by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D3418-21; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Available online: https://www.keyence.com/products/microscope/digital-microscope/ (accessed on 11 April 2025).

- Available online: https://www.gen2carbon.com/product/g-tex-tm/ (accessed on 11 April 2025).

- Harper, D.P.; Laborie, M.P.G.; Wolcott, M.P. The Impact of Polypropylene-Graft-Maleic Anhydride on the Crystallization and Dynamic Mechanical Properties of Isotactic Polypropylene. J. Appl. Polym. Sci. 2009, 111, 753–758. [Google Scholar] [CrossRef]

- Song, B.; Wang, Y.; Bai, H.; Liu, L.; Li, Y.; Zhang, J.; Zhou, Z. Crystallization and Melting Behaviors of Maleic Anhydride Grafted Poly(Propylene) Nucleated by an Aryl Amide Derivative. J. Therm. Anal. Calorim. 2010, 99, 563–570. [Google Scholar] [CrossRef]

- Cilento, F.; Martone, A.; Pastore Carbone, M.G.; Galiotis, C.; Giordano, M. Nacre-like GNP/Epoxy Composites: Reinforcement Efficiency Vis-à-Vis Graphene Content. Compos. Sci. Technol. 2021, 211, 108873. [Google Scholar] [CrossRef]

- Lee, T.H.; Boey, F.Y.C. On the Determination of Polymer Crystallinity for a Thermoplastic PPS Composite by Thermal Analysis. Compos. Sci. Technol. 1995, 53, 259–274. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, J.; Wu, H.; Guo, S.; Qiu, J. Constructing Highly Aligned Crystalline Structure to Enhance Sliding Wear Performance of Bulk Polyamide 6. Polymer 2021, 237. [Google Scholar] [CrossRef]

- Simaafrookhteh, S.; Van Thillo, T.; Lomov, S.V.; Ivens, J. Crystallinity of Neat and Carbon Fiber-Reinforced Polyamide-6 Processed at Different Cooling Rates. Compos. Part. A Appl. Sci. Manuf. 2025, 188, 108520. [Google Scholar] [CrossRef]

- Zheng, Y.; Gu, F.; Wang, B.; Wang, Z.; Gao, C.; Zhou, Y.; Hall, P. Thermal and Mechanical Behaviour of Recycled Short Milled Carbon Fibre Reinforced Polypropylene and Recycled Polypropylene Composites: A Comparative Study. J. Mater. Res. Technol. 2024, 32, 4221–4233. [Google Scholar] [CrossRef]

- Canopoli, L.; Coulon, F.; Wagland, S.T. Degradation of Excavated Polyethylene and Polypropylene Waste from Landfill. Sci. Total Environ. 2020, 698, 134125. [Google Scholar] [CrossRef]

- Andersons, J.; Spārniņš, E.; Joffe, R. Stiffness and Strength of Flax Fiber/Polymer Matrix Composites. Polym. Compos. 2006, 27, 221–229. [Google Scholar] [CrossRef]

- Jannerfeldt, G.; Törnqvist, R.; Rambert, N.; Boogh, L.; Månson, J.-A.E. Matrix Modification for Improved Reinforcement Effectiveness in Polypropylene/Glass Fibre Composites. Appl. Compos. Mater. 2001, 8, 327–341. [Google Scholar] [CrossRef]

- Szpieg, M.; Wysocki, M.; Asp, L. Mechanical Performance and Modelling of a Fully Recycled Modified CF/PP Composite. J. Compos. Mater. 2012, 46, 1503–1517. [Google Scholar] [CrossRef]

- Tam, D.K.Y.; Ruan, S.; Gao, P.; Yu, T. High-Performance Ballistic Protection Using Polymer Nanocomposites. In Advances in Military Textiles and Personal Equipment; Woodhead Publishing: Cambridge, UK, 2012; pp. 213–237. [Google Scholar]

- Yan, J.; Demirci, E.; Gleadall, A. Are Classical Fibre Composite Models Appropriate for Material Extrusion Additive Manufacturing? A Thorough Evaluation of Analytical Models. Addit. Manuf. 2023, 62, 103371. [Google Scholar] [CrossRef]

- Nevare, M.R.; Tatiya, P.D.; Mahulikar, P.P.; Gite, V.V. Effect of Maleated Polypropylene as a Compatibilizer and Hyperbranched Polyester as a Processing Aid on Polypropylene-wood Flour Biocomposites. J. Vinyl Addit. Technol. 2018, 24, 179–184. [Google Scholar] [CrossRef]

| Description | Weight Loss @ 250 °C [%] | T@ Maximum Decomposition [°C] |

|---|---|---|

| PA6/60 | 1.7 ± 0.5 | 440.9 ± 0.5 |

| MAPP/60 | 0.5 ± 0.2 | 425.4 ± 0.5 |

| Description | Tg, DSC [°C] | Tm, DSC [°C] | Density [g/cm3] | Porosity [%] |

|---|---|---|---|---|

| PA6/60 1L | 50.2 ± 0.3 | 216.0 ± 0.5 | 1.2 ± 0.08 | 6.5 ± 0.02 |

| PA6/60 2LM1 | 54.4 ± 0.3 | 220.4 ± 0.6 | 1.1 ± 0.15 | 13.2 ± 0.07 |

| PA6/60 2LM2 | 54.3 ± 0.4 | 220.4 ± 0.5 | 1.2 ± 0.02 | 9.9 ± 0.02 |

| PA6/60 3LM1 | 50.5 ± 0.5 | 221.5 ± 0.6 | 1.1 ± 0.11 | 14.0 ± 0.05 |

| PA6/60 3LM2 | 48.8 ± 0.4 | 220.5 ± 0.7 | 1.1 ± 0.01 | 16.7 ± 0.01 |

| MAPP/60 1L | 46.4 ± 0.3 | 163.9 ± 0.4 | 0.9 ± 0.03 | 7.3 ± 0.01 |

| MAPP/60 2LM1 | 51.4 ± 0.6 | 165.8 ± 0.3 | 0.9 ± 0.2 | 8.0 ± 0.03 |

| MAPP/602LM2 | 53.1 ± 0.4 | 163.9 ± 0.5 | 1.0 ± 0.02 | 4.1 ± 0.02 |

| MAPP/60 3LM1 | 46.5 ± 0.6 | 164.4 ± 0.7 | 0.9 ± 0.02 | 4.8 ± 0.02 |

| MAPP/60 3LM2 | 45.3 ± 0.5 | 164.9 ± 0.4 | 1.0 ± 0.01 | 5.0 ± 0.01 |

| Description | E′ @ 50 °C [GPa] | E″ @ 50 °C [GPa] | Tanδ @ 50 °C [-] |

|---|---|---|---|

| PA6/60 1L | 16.2 ± 1.10 | 0.40 ± 0.03 | 0.025 ± 0.0029 |

| PA6/60 2LM1 | 10.0 ± 1.06 | 0.36 ± 0.04 | 0.036 ± 0.0029 |

| PA6/60 2LM2 | 15.2 ± 1.06 | 0.34 ± 0.05 | 0.023 ± 0.0014 |

| PA6/60 3LM1 | 11.4 ± 1.22 | 0.32 ± 0.05 | 0.028 ± 0.0020 |

| PA6/60 3LM2 | 11.6 ± 0.31 | 0.32 ± 0.01 | 0.028 ± 0.0005 |

| Description | E′ @ 20 °C [GPa] | E″ @ 20 °C [GPa] | Tanδ @ 20 °C [-] |

|---|---|---|---|

| MAPP/60 1L | 11.2 ± 1.41 | 0.2 ± 0.03 | 0.021 ± 0.0003 |

| MAPP/60 2LM1 | 10.8 ± 1.36 | 0.3 ± 0.05 | 0.027 ± 0.0014 |

| MAPP/602LM2 | 16.7 ± 0.57 | 0.4 ± 0.02 | 0.021 ± 0.0007 |

| MAPP/60 3LM1 | 15.4 ± 0.40 | 0.3 ± 0.01 | 0.022 ± 0.0009 |

| MAPP/60 3LM2 | 14.7 ± 1.31 | 0.3 ± 0.03 | 0.023 ± 0.0011 |

| Description | 1st Reaction Enthalpy [J/g] | 2nd Reaction Enthalpy [J/g] | 1st DOC [%] | 2nd DOC [%] | Δ DOC [%] |

|---|---|---|---|---|---|

| PA6/60 1L | 74.5 ± 1.0 | 63.4 ± 1.2 | 32.4 | 27.6 | 4.8 |

| PA6/60 2LM1 | 73.1 ± 1.4 | 58.2 ± 1.6 | 31.8 | 25.3 | 6.5 |

| PA6/60 2LM2 | 71.0 ± 1.3 | 64.2 ± 1.8 | 30.9 | 27.9 | 3.0 |

| PA6/60 3LM1 | 72.1 ± 1.2 | 65.1 ± 1.2 | 31.3 | 28.3 | 3.0 |

| PA6/60 3LM2 | 70.0 ± 1.1 | 66.4 ± 1.0 | 30.4 | 28.9 | 1.6 |

| Description | 1st Reaction Enthalpy [J/g] | 2nd Reaction Enthalpy [J/g] | 1st DOC [%] | 2nd DOC [%] | Δ DOC [%] |

|---|---|---|---|---|---|

| MAPP/60 1L | 108.0 ± 1.6 | 92.2 ± 1.1 | 51.7 | 44.1 | 7.6 |

| MAPP/60 2LM1 | 109.6 ± 1.0 | 97.6 ± 1.2 | 52.4 | 46.7 | 5.7 |

| MAPP/602LM2 | 104.1 ± 1.2 | 93.2 ± 1.5 | 49.8 | 44.6 | 5.2 |

| MAPP/60 3LM1 | 105.8 ± 1.3 | 94.2 ± 1.7 | 50.6 | 45.1 | 5.6 |

| MAPP/60 3LM2 | 103.1 ± 1.1 | 92.9 ± 1.3 | 49.3 | 44.5 | 4.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canneva, A.; Palmieri, B.; Cilento, F.; Giordano, M.; Martone, A. Thermoforming Process Effect on Performances of Thermoplastic/Recycled Carbon Fiber Composites. Appl. Sci. 2025, 15, 4403. https://doi.org/10.3390/app15084403

Canneva A, Palmieri B, Cilento F, Giordano M, Martone A. Thermoforming Process Effect on Performances of Thermoplastic/Recycled Carbon Fiber Composites. Applied Sciences. 2025; 15(8):4403. https://doi.org/10.3390/app15084403

Chicago/Turabian StyleCanneva, Alessandro, Barbara Palmieri, Fabrizia Cilento, Michele Giordano, and Alfonso Martone. 2025. "Thermoforming Process Effect on Performances of Thermoplastic/Recycled Carbon Fiber Composites" Applied Sciences 15, no. 8: 4403. https://doi.org/10.3390/app15084403

APA StyleCanneva, A., Palmieri, B., Cilento, F., Giordano, M., & Martone, A. (2025). Thermoforming Process Effect on Performances of Thermoplastic/Recycled Carbon Fiber Composites. Applied Sciences, 15(8), 4403. https://doi.org/10.3390/app15084403