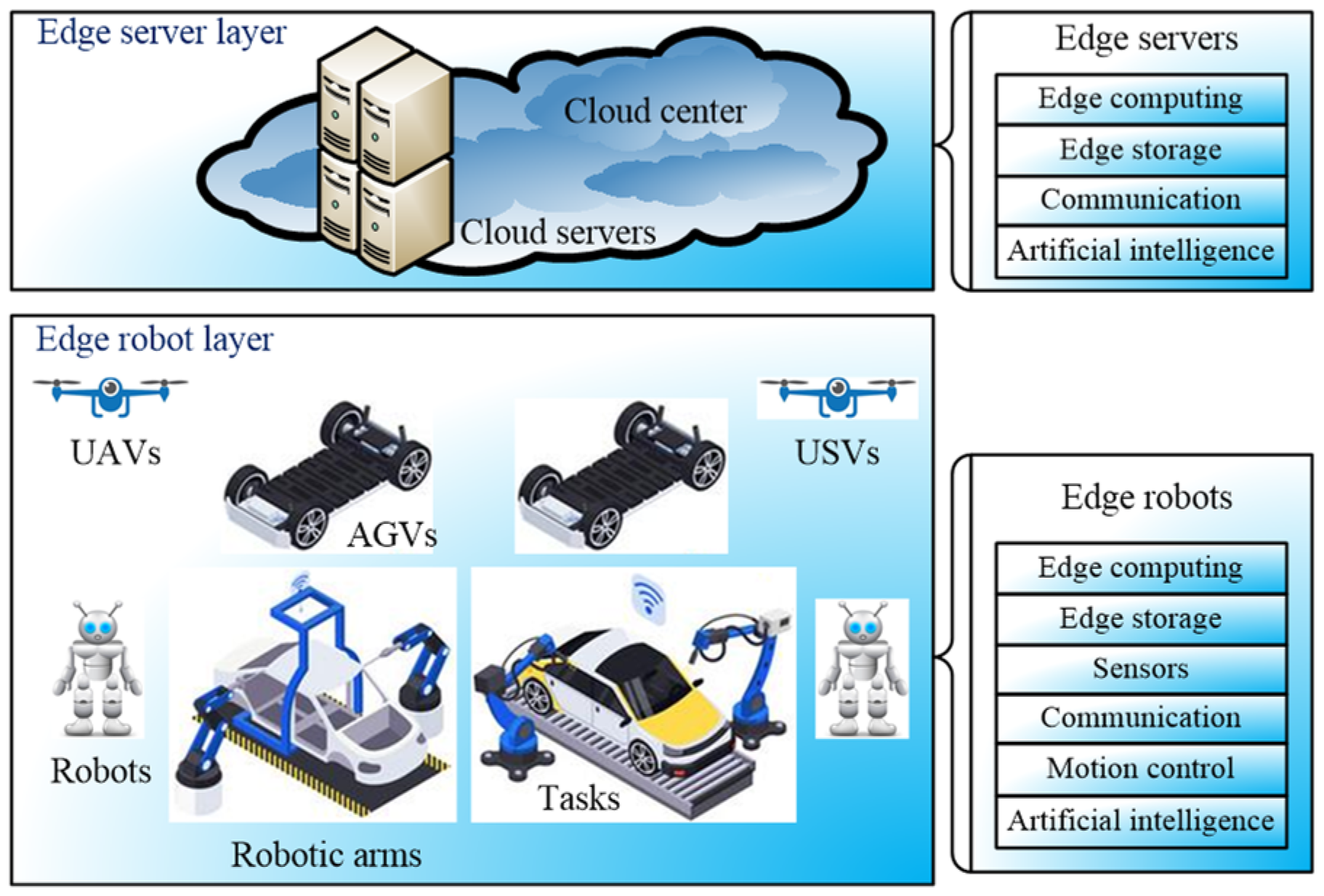

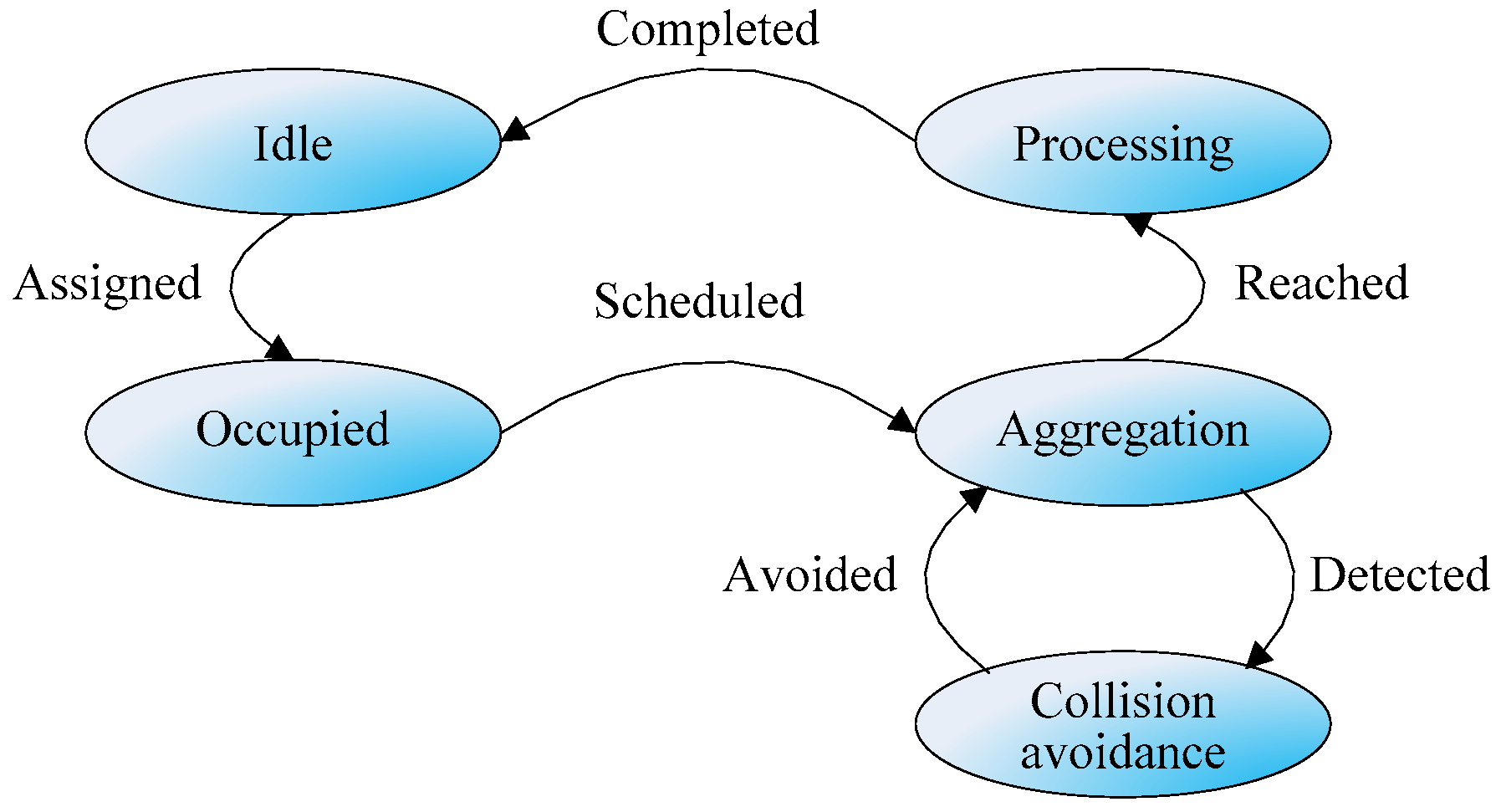

This section describes the collision-free multi-robot aggregation problem, which integrates the multi-robot aggregation problem and collision-free multi-robot problem. The notations and their descriptions are given first, followed by the multi-objective function of the CMAP. Then, the constraints of the proposed CMAP model are discussed.

4.1. Notation and Description

The notations used in this article are described in

Table 2.

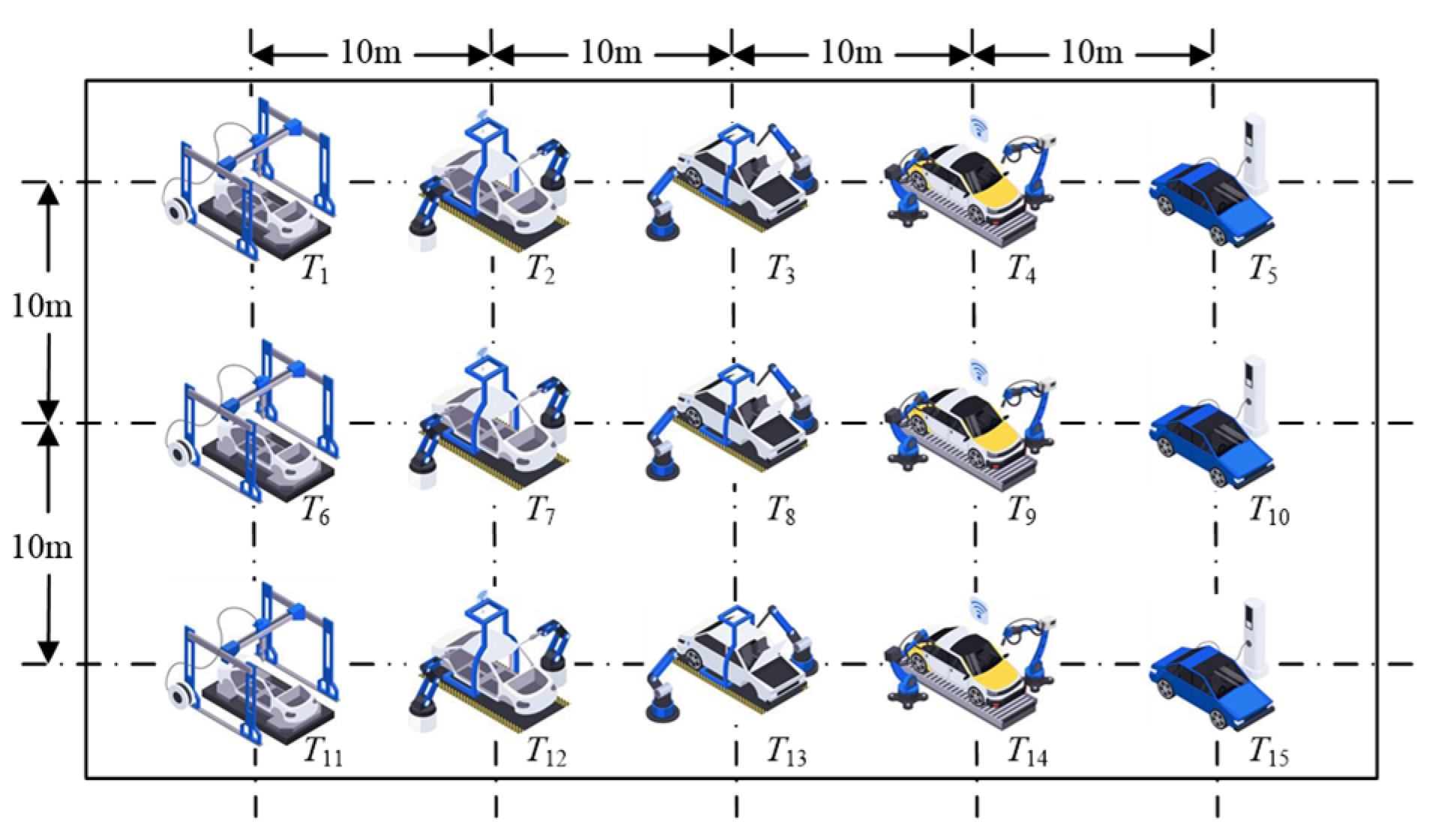

The CMAP can be defined as an undirected assignment graph . In the undirected graph, the set of vertices is a task set , while the set of edges is an assignment set . indicates the task depot, and each edge is associated with a travel time from to . In the aggregation process, different robots gather on the same task to perform different operations, where these different operations occur at different times or locations to avoid collisions when robots aggregate. The set of operations is , and each task has a set of operations . Hence, each task can be divided into several operations and assigned to a set of robots for aggregation and implementation. The robots are initially located at task , and each robot has a load ability , which denotes the amount of demand that the robot can reduce per time unit. Additionally, each robot has a battery capacity for energy consumption in processing and travel.

A collision-free multi-robot aggregation problem contains four elements . For a set of solutions , there is a set of candidate solution , where the robot selection bit 1 if goes from to and 0 otherwise. In CMAP, the position of each task is fixed, and a swarm of robots can aggregate on a task to complete different operations separately. Different robots do not repeat the same operation. During the aggregation process, collisions between robots also need to be prevented.

4.2. Problem Definition

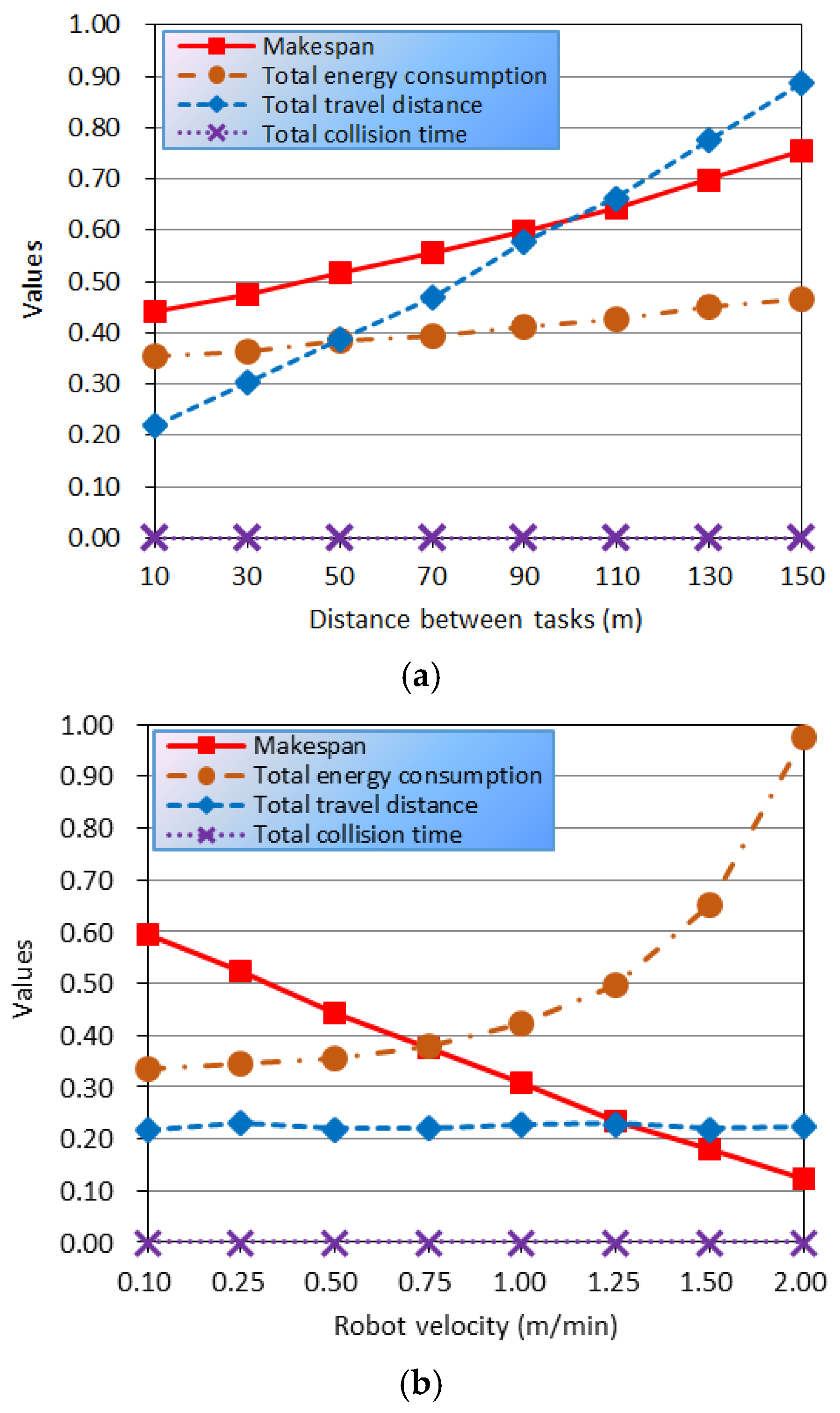

To address the collision-free multi-robot aggregation problem, robots need to be arranged to complete all tasks as soon as possible while, at the same time, ensuring that there is no collision. Therefore, the main objectives include the maximum completion time (makespan) and the collision time of .

The first objective is the maximum completion time (makespan)

of

, which is determined by the difference between the earliest start time

and the latest completion time

of

, where

According to Equations (1) and (2), the maximum completion time (makespan)

of

can be obtained as follows:

The second objective is the collision time

of

, where collision is defined as different robots arriving at the same position at the same time. During the aggregation process, different robots gather on the same task to perform different operations. In order to avoid collisions, different robots handle the same task at different positions or different times. Therefore, the collision time can be calculated based on the time it takes for different aggregation robots to reach and leave the same position when processing the same task, and we have

The third objective is the total energy consumption

of

, including the processing energy consumption

of

and the travel energy consumption

. Considering the processing power

of

, the processing energy consumption

of

can be calculated as follows:

Thus, the processing energy consumption

of

can be obtained as follows:

Then, the processing energy consumption

of

can be described as follows:

Considering the travel power

from

to

, the travel energy consumption

can be calculated as follows:

Then, the travel energy consumption

of

is

According to the processing energy consumption

of

in Equation (7) and the travel energy consumption

of

in Equation (9), the total energy consumption

of

can be calculated as follows:

The fourth objective is the total travel distance

of

, which can be calculated using the travel distance

from

to

; that is,

Then, the collision-free multi-robot aggregation problem can be described as a four-objective function, considering the maximum completion time (makespan)

in Equation (3), the collision time

in Equation (4), the total energy consumption

in Equation (10), and the total travel distance

in Equation (11):

To address the collision-free multi-robot aggregation problem, we need to arrange the aggregation plan of robots to complete all tasks subject to a series of constraints. Whenever a new task is assigned, the robots executing the assigned task form an undirected graph . A complex task can be divided into a series of sub-tasks , enabling each idle robot to aggregate without collision.

As each vertex is a task, it is associated with three factors: the detection/arrival time , the inherent increment rate , and the initial demand . Then, a set of constraints can be obtained.

The first constraint is that a task is unknown by the REI system until it is detected. The emergent demand

of the candidate tasks can be detected by the robotic edge intelligence architecture. The detected demand

of

accumulated at time

can be obtained as follows:

Each edge

is associated with a travel time

from

to

. We have

where

represents the completion time of

.

The second constraint is that a task cannot be executed before it is detected. Therefore,

where

is the start time of

at

.

In particular, the start time

of

at

is determined by the completion time

of

at

and the travel time

from

to

; that is,

where

is a robot selection bit (

1 if

goes from

to

and

0 otherwise). Equation (16) indicates that a robot immediately aggregates to the next task after the completion of the current task.

The third constraint is that a task cannot be executed before the former task is completed; that is,

The fourth constraint is that a task cannot be completed before processing is completed; that is,

Then, the fifth constraint for the robot selection bit can be described as follows:

The sixth constraint is that the number of incoming paths should equal the number of outgoing paths for each robot at each task; that is,

where the binary decision variable

takes a value of 1 if there is a path for

to go from

to

, and 0 otherwise.

The seventh constraint is that each task can be assigned to each robot at most once; that is,

The eighth constraint is that the start time and completion time of all the robots at the depot are 0:

At the final time , all tasks are completed and exit the REI system, and the aggregated robots return to the depot to be reset to an idle state for the next task assignment. It should be noted that all completed tasks should be cleared and all robots should be set as idle again.

The ninth constraint is that the demand for each task must decrease to 0 if it is completed:

Equation (23) indicates the constraint of load ability . When the task is completed, the accumulated demand at equals the total demand fulfilled by the robots executing until .

The tenth constraint is that the inherent increment rate

of

should be limited in the ability

of

; that is,

Equation (24) indicates that, for every task, the inherent increment rate of a task must be lower than the total ability of the available robots executing the task, thus ensuring the completion of the task.

The 11th constraint is that the total energy consumption

of a robot

should not surpass its battery capacity

; that is,

The total energy consumption

of

includes the processing energy consumption

of

and the travel energy consumption

of

. According to the robot selection bit

, which is 1 if

goes from

to

, and 0 otherwise, we have

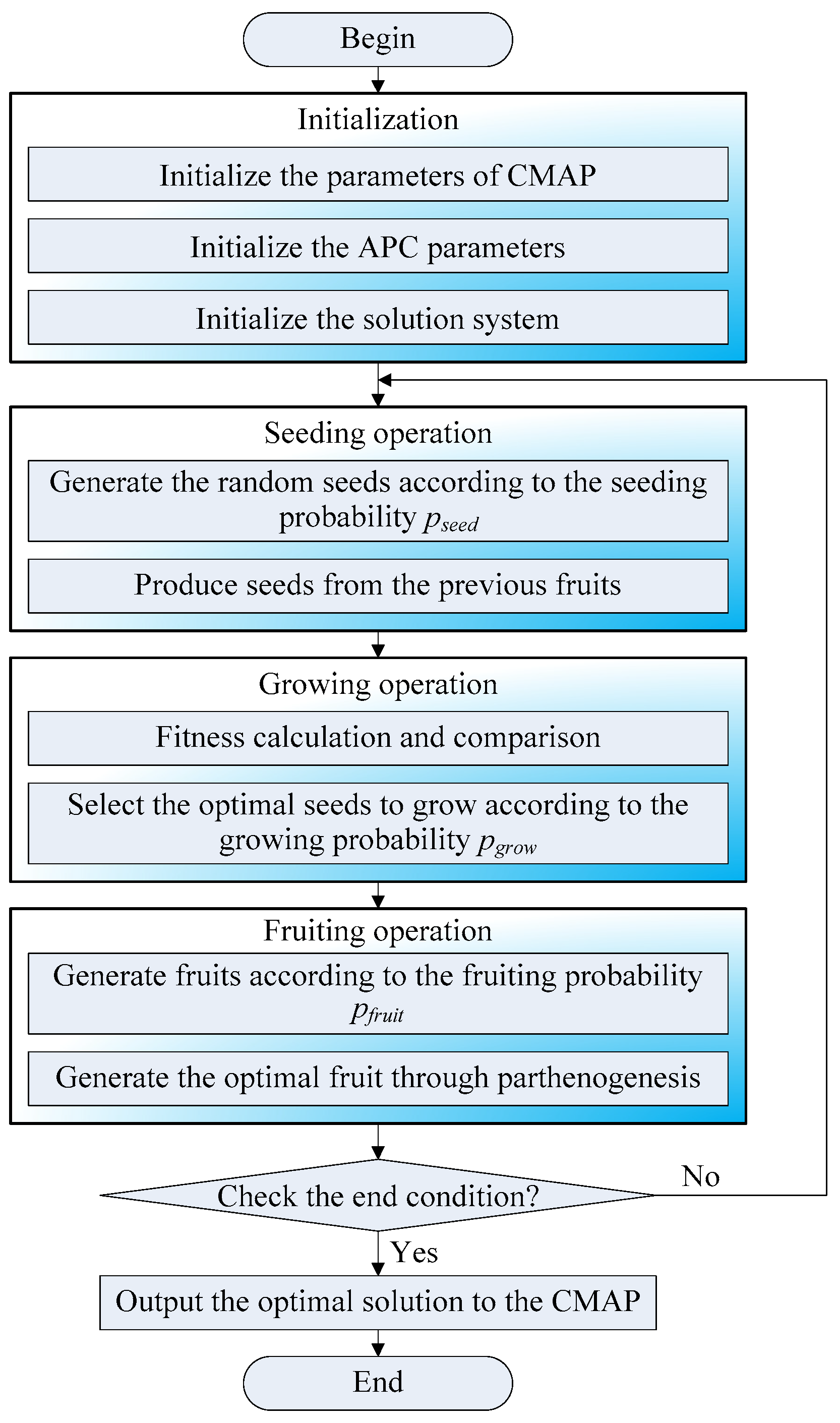

The objective of the proposed CMAP model is to search for the optimal solution to minimize the objective function in Equation (12) on a set of solutions satisfying Equations (13)–(28).

It is challenging to search for all solutions to the CMAP. Given a solution

and its solution

for all of the

values, the makespan can be calculated as follows:

where

and

are calculated from

and

. In the proposed CMAP model, each code

is represented as a binary string of robot selection bits for a solution

.

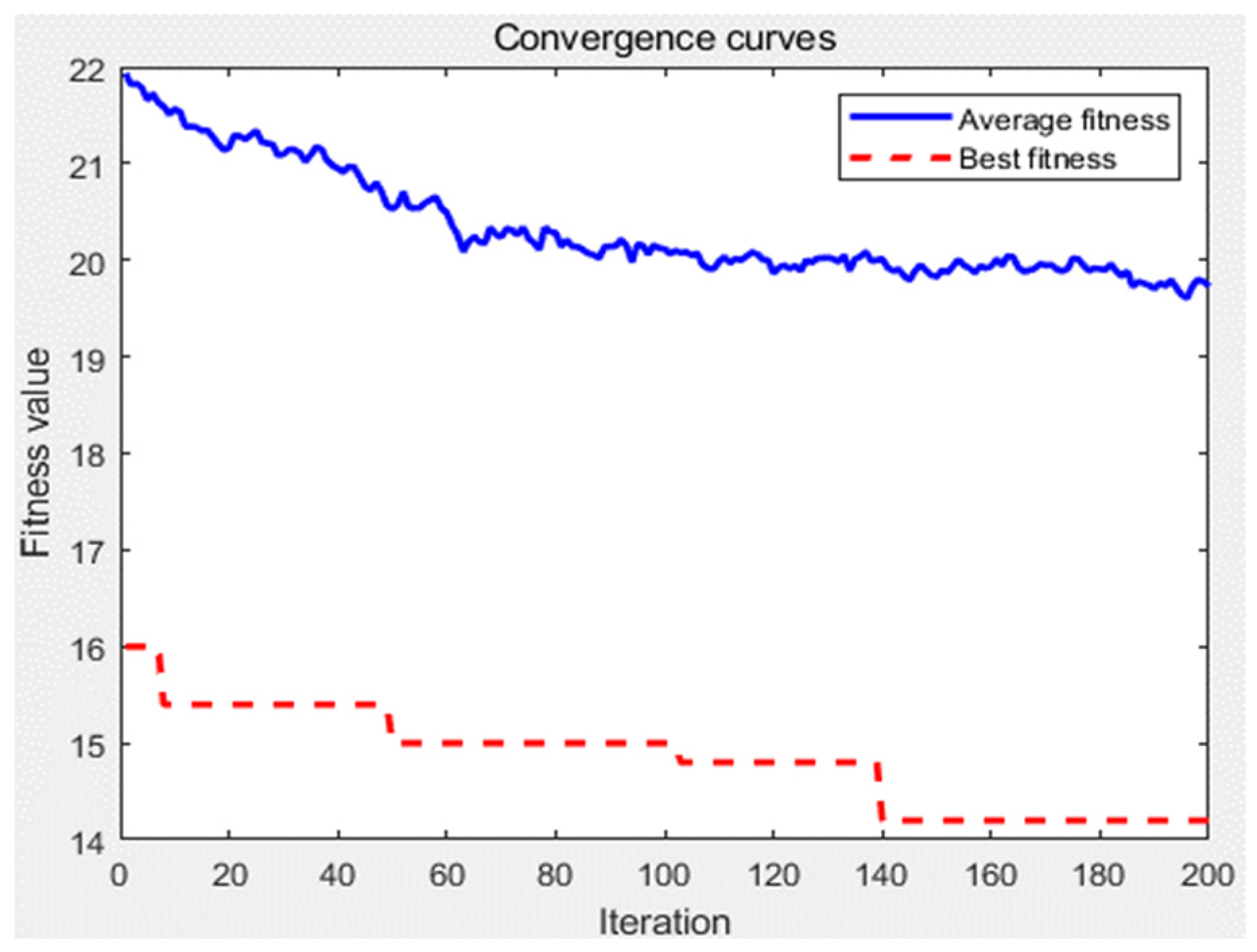

In the aggregation process, the maximum completion time (makespan) and the collision time are evaluated as a value . A task with a shorter processing time, a smaller travel time, and a smaller demand tends to be completed earlier. As the maximum completion time (makespan) and the collision time are often conflicting, and as there are a lot of constraints, it is very difficult to solve the CMAP. In the following section, a novel artificial plant community algorithm is explored in order to help us address the CMAP.