Featured Application

Advanced systems for water purification and ecosystem restoration.

Abstract

In recent years, additive manufacturing technologies have been employed for ecological projects, especially those connected with artificial reefs. This approach brings a lot of advantages, including the design of more complex structures, with surfaces fitted to the needs of water organisms. This technology can effectively support ecological design and engineering, especially in restoration efforts. The main aim of this article is to demonstrate the state of the art and further perspectives for the development of artificial coral reefs. This article is based on a critical analysis of the literature, supported by selected case studies. This article describes current technologies used in the creation of artificial reefs, putting emphasis on additive manufacturing, evaluates currently used materials, and summarizes the influence of this technology on ecosystems through the analysis of selected case studies. It also discusses the challenges and limitations of current technologies used in 3D printing artificial reefs as well as presents current trends and further directions. The most important findings show that the analyzed field is a promising interdisciplinary research area and practical implementations require collaboration between specialists from different branches.

1. Introduction

Artificial reefs are man-made structures that are intentionally submerged to mimic some of the features of natural reefs [1,2]. The first traces of artificial habitats in aquatic environments date back to the Neolithic period (9000–3000 BC), when coastal vegetation and rocks were intentionally submerged to create new fishing grounds off the coast of Africa [3]. Their use was also a common practice in traditional fishing communities, especially in Southeast Asia [4]. The main goal was to increase catches by creating additional structures that provided protection for fish. Research into the role of artificial underwater habitats in attracting, concentrating, and catching fish has been conducted since the 1930s [5,6]. However, the effectiveness of artificial reefs in this regard is controversial. On the one hand, there are studies showing the effectiveness of this method [5,7], but others negate the effectiveness of using artificial reefs for this purpose [8]. Currently, this kind of solution obtains a wider meaning; the main aim of the application of artificial reefs is usually ecosystem restoration, particularly the improvement of biodiversity and support of the reproduction and habitation of underwater life [9,10,11].

3D printing technology brings a lot of benefits, including freedom of design—creating complex shapes without formwork, materials efficiency, and the possibility of working in harsh environments. In this article, the terms additive manufacturing and 3D printing, despite existing differences, are used as synonyms. This review is focused on the practical aspects of this technology. Currently, additive technology finds many applications in different areas, such as medicine, aerospace, automotive, and construction industries, and others [12,13,14,15,16]. Also, in recent years, this technology has been employed for ecological projects, especially those connected with artificial reefs. The usage of additive manufacturing for this purpose gives researchers the possibility to design surfaces with greater complexity and roughness, which is important for the settlement of water organisms, such as corals or mussels and other marine life [17,18]. Some research shows that this technology can effectively support ecological design and engineering, especially in restoration efforts [19,20]. It allows for the matching of artificial reef structures to specific requirements of local ecosystems [21]. Moreover, additive manufacturing can effectively support the shift toward ecological sustainability [19,22]. This technology is also scalable and cost-efficient [23].

The main aim of this article is to demonstrate the state of the art and further perspectives for the development of artificial coral reefs. This article is based on a critical analysis of the literature, supported by selected case studies. This article describes current technologies used in the creation of artificial reefs, putting emphasis on additive manufacturing, evaluates currently used materials, and summarizes the influence of this technology on ecosystems through the analysis of selected case studies. It also discusses the challenges and limitations of current technologies used in 3D printing artificial reefs as well as presents current trends and further directions. The main audience of this work is researchers and practitioners, and the presented knowledge can help them to acquire useful information to develop the research connected with artificial reefs.

2. Research Methodology

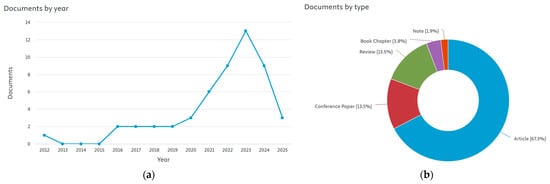

The presented work is based on a critical review. In the beginning, the basic literature for the defined problem was defined by using the Scopus database. The following two main keywords were used: “reef” and “3D printing”. This combination allowed us to obtain 52 results (Figure 1).

Figure 1.

Results of the analysis in the Scopus database, during the period from 2012 (first publication in the topic) to 2025 (March): (a) published documents by year; (b) published documents by type; (c) published documents by country/territory; and (d) published documents by subject area [24].

The first publication in the analyzed area was in 2012 (Figure 1b); however, up to 2020, there was a small number of documents connected with the usage of 3D printing technologies for designing and manufacturing artificial reefs. The development of interest in this topic was connected with the growing importance of the blue economy as well as the development of additive manufacturing technologies, especially for concrete-like materials. According to the structure of the types of publication, it is quite typical for newly developed topics, with about 67% consisting of original articles, 13% consisting of conference papers, and the same number of reviews (Figure 1b). The countries participating in research were taken into consideration. A large number of publications came from the USA and the UK. The great importance of this topic is also visible for developed EU countries, such as France, Portugal, and Spain. Also, some interesting research is visible in Israel and Australia (Figure 1c). These data show that the topic is a priority for developed countries. The characteristic issue is the far position of China or the lack of India in this ranking. Meanwhile, these two countries usually dominate in a large number of scientific topics, because of the significant number of publications. In Figure 1d, it is visible that the topic has a strongly interdisciplinary character, with the main share consisting of environmental sciences and engineering.

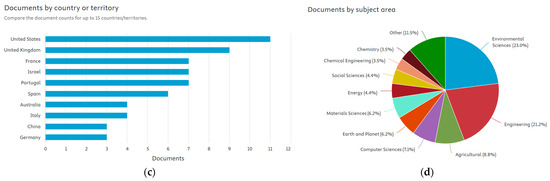

To visualize the obtained results in the Scopus database and receive more information about particular areas, a map of connection keywords was created. The selected limitations for keyword repetition was five, and the VOSviewer version 1.6.20 was applied (Centre for Science and Technology Studies, Leiden University, Leiden, The Netherlands). The visualization is shown in Figure 2.

Figure 2.

Visualization of network connection based on used keywords in analyzed articles.

The visualization shows three main networks (red, blue, and green). The keywords are connected mainly with areas of technology (3D printing, additive manufacturing), environmental issues (environment, climate change), and marine issues (coral, coral reef, cost, marine ecosystem). The graph confirms the interdisciplinary character of the provided investigations. There is a lack of words connected with freshwater, which may be a non-exploited area and suggest a research gap. The current research is focused on research on marine systems due to coral decline, but potential problems with freshwater ecosystems are ignored. This provides a chance for the development of new areas for research specializations. The scheme includes some overall keywords, such as paper and project, that can be suitable for many areas.

3. Technologies Used for Artificial Reef Design and Manufacturing

3.1. Modeling and Design

Modeling artificial reefs can serve several purposes, especially in understanding their impact on coastal processes. It is a crucial element for the design of artificial reefs, especially if 3D printing is involved later in the process. The primary purpose of modeling is to design the artificial reef itself; other processes are connected with the optimization of the model for a particular environment and the simulation of behavior in underwater conditions.

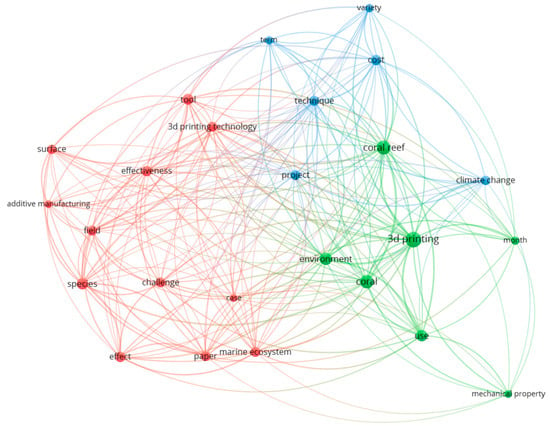

The modeling allows for obtaining the complexity and diversity of shapes used for artificial coral reefs, including the proper surface roughness that is necessary for the further growth of organisms. An exemplary solution, designed using a parametric design tool using Rhino and Grasshopper software (v.7), is presented in Figure 3 [19].

Figure 3.

Samples of the elements used for the artificial reef creation—the trajectory of the printing path [19].

The design tool allowed for the generation using clay deposition trajectories; it was possible to create highly complex microfeatures, which increased the efficiency of colonization by different organisms [19].

In the case of simulation behavior in underwater environments, one primary use is to evaluate the effects of behavior on sediment transport and bed erosion. Numerical models can simulate how artificial reefs influence the movement of sediment and whether they help stabilize the seafloor under different conditions [25]. These models also help to assess how artificial reefs affect morphological changes in coastal areas, such as the formation of sandbars or the trapping of sediment in sheltered areas, which can contribute to beach stabilization [26].

Moreover, numerical modeling can be used to study the hydrodynamic effects of artificial reefs, such as wave attenuation and current modification. These simulations are crucial for understanding how reefs dissipate wave energy and reduce the intensity of currents, which can protect shorelines from erosion [27]. In areas where physical experimentation is challenging, modeling can provide detailed insights into the behavior of artificial reefs in various wave conditions [28], helping to refine designs for coastal protection projects. By simulating different scenarios, models can also predict the long-term impacts of artificial reefs on beach profiles and the surrounding environment, guiding effective coastal management strategies.

Traditionally, the complex morphological features and ocean forces at the field scale have been modeled using two-dimensional wave–current models (2DH) or three-dimensional (3D) wave–current models [29,30,31], with waves and mean currents typically coupled through radiation stresses, as introduced by Longuet-Higgins and Stewart [32]. For spectral wave transformation over realistic reefs, including infragravity waves, the XBEACH phase-averaged surfbeat model and phase-resolving non-hydrostatic models have been used more frequently in recent years [29,33]. At the laboratory scale, Boussinesq-type models, which are computationally efficient and phase-resolving, are the most commonly used. Boussinesq-type models such as FUNWAVE [34,35], COULWAVE [36,37,38], and others have been able to simulate the motion of monochromatic waves, spectral waves (including infragravity waves), and solitary waves over various reef profiles. Another popular group is the non-hydrostatic models, such as XBEACH [39,40] and NHWAVE [41,42], which have been used to model wave transformation over various laboratory reefs. However, both Boussinesq and non-hydrostatic models still face challenges in resolving detailed wave-breaking processes, such as wave overturning and breaking-induced turbulence over reefs. Meanwhile, bottom roughness in the above models is typically addressed using a quadratic friction law or Manning’s friction formula. Recently, some researchers have attempted to improve the friction parameterization by adding an additional drag term in the Boussinesq equations [43] or a porous media model in the non-hydrostatic XBEACH model [44].

The numerical modeling seems to be used only in limited areas. There is a lack of complex works with the prediction of ecosystem growth or correlation between some systems elements, for example, the complex geometry of reefs and the development of desired species. This area can probably be much more explored in the future to better understand the long-term mechanisms and designs for ecosystem development.

3.2. Traditional Manufacturing Technologies vs. Additive Manufacturing Technologies

The first artificial reefs were built with natural materials, such as stones. In the XX century, different components were tested as an artificial reef, including some kind of concrete cubic material, tire waste, materials from wrecks, and others [4]. Different kinds of cheap materials have gained popularity. The construction was rather simple, without necessary complications; mainly, concrete blocks and metal frames were applied [21]. Currently, additive manufacturing and reverse engineering have changed the rules. Technological progress allows for the use of 3D scanning and 3D printing as the background technology for the design of the coral reefs, in the same way as they are used for other applications [21,45,46]. Nowadays, there is a possibility to use scanned geometries of harvested corals to fabricate artificial coral skeletons [21] or design proper shapes dedicated to particular species, including the proper surface topology for settlements [23]. Alternatively, photogrammetric technologies can also be used to obtain 3D models [1]. Also, other advanced techniques are joined with additive manufacturing for customization, including eDNA metabarcoding, and lifecycle-based emergent traits [23]. The combination of these technologies gives the possibility to create biomimetic artificial structures with a high efficiency of restoration in selected ecosystems [23]. Thanks to modern additive technologies, it is possible to produce complicated shapes, potentially even in underwater conditions [47].

Various 3D printing technologies are used for manufacturing artificial coral reefs; the most popular seems to be Fused Deposition Modeling (FDM). However, other technologies are also used, including fused filament fabrication (FFF), binder jetting, and VAT polymerization [48,49]. Albalawi et al. [21], in reaction to coral bleaching, created artificial corals using two different technologies, FDM and stereolithography (SLA), as supplementary processes to build artificial reefs [21]. Jia et al. [49] applied digital light processing (DLP) for coral restoration projects. This technology was selected mainly because of the speed of production and model scalability [49]. In turn, Hitzegrad et al. [50] selected particle bed 3D printing with Selective Cement Activation (SCA) for artificial reef manufacturing [50]. This technology allows for the creation of greatly accurate surrogate surfaces with the desired high roughness [50]. The additional advantages were complex geometry with high porosity and large overhangs, as well as the independence of production time from the model complexity [50]. For the reef projects, various types of devices are used, starting from partly self-modified FDM 3D printers, through concrete laboratory machines, up to large semi-industrial devices. The usage of particular solutions is usually connected with the scale of the project and its budget.

The important aspect of each project is the costs. In comparison to the traditional approach, 3D printing is connected with higher efficiency in restoration, but also with higher costs. Albalawi et al. [21] prepared the cost simulation for coral reef restoration using 3D printing technology [21]. According to his estimation, the cost of a fully functional 3D printing facility was approximately EUR 300,000 in 2021 [21].

4. Materials Used in Construction

4.1. Development of Materials for Artificial Reefs

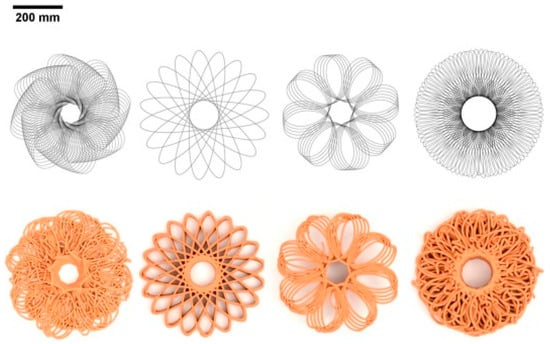

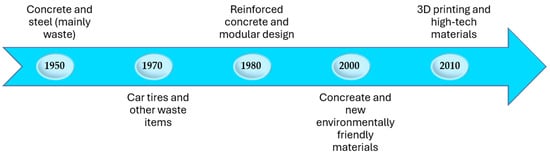

Development of the materials can be divided into several stages, as shown in Figure 4.

Figure 4.

Development of technology and materials used for artificial reefs.

Together with the development of artificial reefs, new materials have been taken into consideration [9]. Traditionally, construction is mainly focused on materials such as wood and stone; next, various waste materials started to be used, including concrete, steel, and rubber [19,48,51]. Currently, together with the development of technologies, the design of materials also becomes important [52,53].

Regardless of the material used, there are important considerations when designing artificial reefs that should be considered in research. One of them is the long-term behavior of the material [9,51,54]. Some research shows the correlation between the artificial reef’s age and its function [9,55]. This mechanism can be also connected with material deterioration as well as other factors [55,56]. As a result, together with material aging, the function of the ecological system can weaken, for instance, by an imbalance in biodiversity or deterioration of habitats [9]. In this case, long-term monitoring has a significant meaning for ensuring proper restoration functions as well as possible effective management, including reaction to changes [9].

4.2. Polymer-Based Solutions

Polymers and their composites are currently the most popular materials for additive manufacturing technology [57], and because of that, they also have a wide application in 3D printing artificial reefs [13,48]. Among the different types of polymers, particular attention was paid to biopolymers, such as celluloses, polylactic acid (PLA), and polyhydroxybutyrate (PHB) [21,58]. The usage of biopolymers improves the formation of coral species and effectively helps to restore marine habitats [21,58]. The efficiency of this system was investigated on oysters [59,60]. The main advantage in this case is the biodegradation of the material, which makes the growth of the organisms easier [61]. However, it could be stressed that biodegradation can potentially be a source of underutilized waste in the water. Also, some potential limitations with the usage of biopolymers in 3D printing artificial reefs are their poor rheological and mechanical properties [23,62]. This kind of material is suitable for the 3D printing process and very often requires modification.

PLA and PHA were employed by Ruhl and Dixson [63] to improve artificial reefs made using 3D printing technology for coral and mussel development [63]. The experiment confirms that the used material is proper for the settlement of reef-building corals, including Porites astreoides, and gives a better effect than limestone tiles made using traditional casting technology [63]. In other research, Temmink et al. [64] confirmed the possibility of using a 3D printing technique for the creation of proper growth conditions for blue mussel settlements [64]. Another research project with 3D-printed biodegradable artificial reefs shows the possibility of using the mineralized cellulose as a proper filament. The investigation was made on coral species (Solenastrea bournoni, Orbicella faveolata, and Porites astreoides) to confirm the proper growth [58] as well as the possibility of using these materials for CO2 adsorption, which enhanced the ecological character of this composition [23].

One of the most interesting ideas is the usage of biopolymers from biomass waste [23]. This material has a lot of advantages, such as low price, possible marine degradability, and a lack of toxicity. However, there is a lack of long-term investigations into the influence of biodegradation products on marine ecosystems, which could potentially influence increasing water eutrophication. Also, some research suggests that several biopolymers, such as PLS and PBH, can be characterized by ecotoxicity to the creation of microplastic waste [65,66]. Currently, two types of biopolymers, depending on their production strategy, can be employed: biomass directly extracted from waste and biomass synthesized from waste with the usage of additional processes, such as microbial fermentation or chemical conversion [23]. Nowadays, only a limited amount of materials from this group have been tested for their potential for the 3D printing of artificial reef creation, such as celluloses, PLA, and PHB [21,58]. However, they are not based on biomass waste. There is a large potential for providing complex research in this direction.

4.3. Cement, Geopolymers, and Similar Compositions

The results of studies conducted in different aquatic environments confirm that ceramic materials can be optimal for creating artificial reefs. The research found that ceramics and concrete were the most colonized by organisms compared with other materials such as metals or plastics, making them the most suitable habitats for a wide range of species, including fauna, flora, and microorganisms [6]. In addition, artificial structures made of ceramic materials are characterized by durability and the ability to form various types of reef structures. The complexity of the structure affects the associated fish communities, and the presence of holes and crevices provides shelter, breeding sites, and protection from predators [67]. The use of new technologies, in particular the use of 3D printing, is also of great importance.

It is not always clear which cementitious material is the best for applications on artificial reefs. Ly et al. [68] compared different cementitious materials, such as geopolymers and cement concrete, assessing their durability and biofouling (colonization of the structure by biological organisms) in seawater [68]. The results indicate that cement is a better material for building an artificial reef using 3D printing, due to its better mechanical properties and lower susceptibility to biofouling [68]. In turn, Yoris-Nobile et al. [69] showed that geopolymers have better biological receptivity compared to cement [69]. This indicates the need for further research on the selection of materials, depending on the purpose of remediation [68,69].

Selecting the right materials is crucial, as some of them can have undesirable effects. The two main problems associated with the use of Portland cement (OPC) or geopolymers are the increase in water alkalinity and the precipitation of calcium carbonate. The high pH value around the surface of the material inhibits the settlement of marine life [70,71]. OPC usually has pH of around 13, far exceeding the seawater pH of 8–9 [69,72]. Such a high value negatively impacts the surrounding environment, including the organism’s settlement [72,73]. The process of neutralization in the natural environment typically takes 3–6 months to lower pH [73], where the colonization of the material is limited [74]. Therefore, during 3D printing, it is necessary to neutralize the print surface to ensure faster adjustment to the marine environment [75]. The second problem is mainly related to the use of OPC; in this case, we are dealing with carbonate formed as a result of the re-precipitation of soluble Ca2+ from alkaline cement. It tends to cover the surface and prevents the growth of marine life, resulting in poor colonization with microalgae [70].

A valuable trend is also the use of waste materials for artificial reef production, including industrial by-products, such as silica fume, which can result in lowering pH [72]. Alternative materials tested in artificial reefs manufacturing also include waste from machine-made sand production [76]. The investigation made by Kuand et al. [77] confirms the feasibility of applying this by-product in concrete for 3D-printed artificial reefs [76]. The replacement of 30% of sand with this waste does not influence the material’s printability and only slightly decreases mechanical properties, while lowering carbon emissions [76]. The influence on the fish behavior was not observed [76]. There are even more possibilities if industrial by-products are used in the geopolymers. Martins et al. [77] investigated the material that was based on industrial waste–biomass of fly ash and red mud [77]. The 3D-printed samples confirm the printability of the created mixture and show that the mechanical properties are sufficient to create an artificial reef [77,78].

4.4. Other Materials

Among the other materials, the most popular are mineral-based, such as calcium carbonate, plasters, sandstone powder, ceramic clay, terracotta, and diatomite sand with magnesium oxide; these materials also show promising results in artificial reef research [13,20,79,80].

Most of them were used in extrusion technology as a paste, but it is not only possible to apply them; for example, calcium carbonate was successfully used as a photoinitiated ink [21]. It was also combined with soybean oil as an environmentally friendly composite, which was used in [49]. The other possibility is plant-based materials. Some of them have been tested using the vat-polymerization technique [48,49]. The investigation confirms the usefulness of these materials for coral restoration [49].

Other investigations show some advantages in using terracotta as a material for artificial reef construction [19]. These materials allow for the creation of highly mimicked natural reef habitats [20,71]. This ceramic material is composed of non-toxic oxides, is highly porous, and has a neutral pH, which is a clear advantage for artificial reef applications [19,71,81,82].

5. Case Studies, Including Impact on the Ecosystem

5.1. Marine Ecosystems

The influence of artificial ecosystems can be analyzed using several platforms, including positive aspects, such as increasing biodiversity, protection against erosion, and changes in the behavior of fish and other organisms, as well as potential challenges, including hazards related to the use of inappropriate materials or technologies.

The use of printing techniques allows for increased structural complexity and biodiversity by precisely adapting the structure to the needs of local ecosystems [68,83]. Artificial reefs created in this way provide additional space for organisms to settle and grow, which contributes to increasing local biodiversity and stimulating ecosystems [68,84]. It also plays an important role with fish populations by offering complex habitat structures [9,85]. 3D printing technology also allows for more effective environmental restoration compared to traditional solutions such as simple-shaped concrete structures [86]. Exemplary research was provided in the framework of the Interreg Atlantic project 3DPARE [87]. The activities in this project were connected with designing and testing different types of 3D-printed concrete reefs. The differences among the particular units were connected by the sizes of holes, tunnels, and overhangs. A total of eight solutions have been tested in the UK, France, Spain, and Portugal. The obtained results show clear differences recorded between the habitat features [87,88]. It confirms the necessity of the “personalization” of solutions, depending on local biodiversity.

Ruhl and Dixson [63] investigated the efficacy of using 3D-printed artificial reefs in comparison to natural coral reefs as habitats for blue-green chromis (Chromis viridis) and larval mustard hill coral (Porites astreoides) [63]. The provided behavior shows that both species did not discriminate or display modified behaviors between 3D-printed and natural coral skeletons. Moreover, larval mustard hill coral displayed a significantly higher settlement when provided with the artificial 3D-printed surfaces; meanwhile, the growth and mortality of the investigated species did not significantly differ [63]. This confirms that this kind of artificial structure can be a valuable ecological tool for ecosystem restoration [63].

The other area of application for additive manufacturing is connected with the restoration of oyster reefs [59]. In this case, the advantage of 3D printing is connected with the possibility of designing irregular and intricate shapes of artificial structures resembling natural oyster reefs [21,69]. This kind of complex shape can ensure optimal substrates for oyster colonization and growth [59]. Another advantage of using additive manufacturing is the possibility to perform tailored structures according to specific environmental conditions, such as water flow and sediment composition in a short time [59,69]. The elements can be optimized for oyster survival and faster growth in a particular local ecosystem [22].

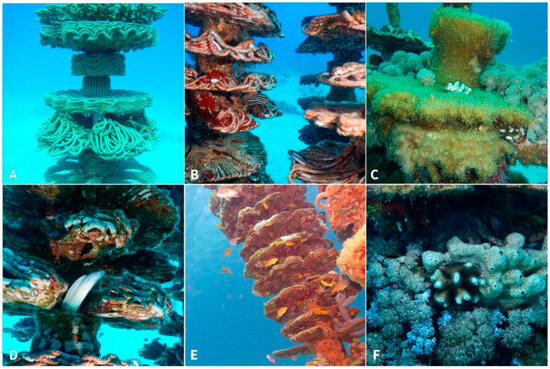

Also, it is important to monitor the efficiency of the artificial reefs and ecological succession [19,89]. The investigation provided by Oren et al. [19] confirms the efficacy of a 3D-printed terracotta artificial reef for the recruitment and settlement of fish, corals, and other marine organisms—Figure 5 [19].

Figure 5.

The ecological process of artificial reef colonization. (A) The first artificial reef structure a week after deployment (4 July 2019). (B) The artificial reef structures 6 months after unification (23 November 2020). (C) The top of the first deployed structure after 3.5 years (1 February 2023), completely covered with Octocorallia Rhytisma fulvum and Xeniidae sp. with two Stylophora pistillata colonies. (D) Gymnothorax griseus inhabiting the artificial reef structure in the inner spaces (23 November 2020). (E) The artificial reefs inhabited by around 60 Pseudanthias squamipinnis, together with various benthic organisms, two years after deployment (21 October 2021). (F) Interspecies interaction Botryllus eilatensis, Stylophora pistillata, and Xeniidae sp. covering the artificial reef (11 August 2022) [19].

The previous research confirms the usefulness of artificial reefs for the restoration of ecosystems; however, is worth noticing that there is a lack of standardization in this kind of research. Nowadays, the efficiency of artificial reefs is assessed mainly using comparisons to traditional methods [64]. Currently, there are no standardized methods for assessing biological invasions or “ecological services” (functioning of artificial reefs). There is a lack of effective methods for comparison and assessment that could take into account different phases of successional ecology [3]. It is necessary to develop such protocols in future studies. Artificial reefs, as a form of ecological engineering created by humans, have the potential to play a positive role in maintaining the stability and diversity of aquatic ecosystems over long time scales [90]. The condition, however, is their proper design, supported by comprehensive research and long-term monitoring. A similar problem is connected with monitoring the succession and biodiversity in artificial reefs, because of a lack of unified standards [9,91]. The most important thing in this area seems to be the long-term monitoring of the ecosystem-carrying capacity, which could potentially lead to unanticipated ecological consequences [9,91].

Artificial reefs can be also connected with some treatments for ecosystems. In the context of artificial reef planning, it is crucial to consider potential ecological threats. One important issue is the phenomenon known as “ocean sprawl”, i.e., the excessive spread of artificial structures along natural environments, which can pose a threat to ecosystems. The increased connectivity of systems caused by the proliferation of artificial reefs has the potential to facilitate biotic homogenization or introduce species outside their native ranges [3]. However, some research confirmed the reverse mechanism as a promotion of the settlement of coralline algae and discouraging invasive species in subtidal zones [17]; the problems connected with potential “ocean sprawl” and the wide spreading of invasive species should be taken into consideration during planning the research.

5.2. Development of Freshwater Systems

Nowadays, artificial reefs are commonly used in warm, salty waters. The benefits of their use include new habitats for organisms, from sessile forms to fish, protection of the shoreline, reduction in the effects of anthropogenic impacts by increasing spatial complexity, and development of tourism [1,8,92]. Artificial reefs mainly act at a local scale, acting as a refuge in the system and increasing spatial heterogeneity in the reservoir [4,8].

In this case, the use of these structures in inland reservoirs becomes particularly important. Despite the high demand, few studies have been conducted on the use of artificial reefs in freshwater lakes [3,93]—Table 1. Among them, there is a lack of additive manufacturing applications for this type of water.

Table 1.

Work to date on artificial reefs dedicated to freshwater.

The analysis of the research conducted to date, presented in Table 1, shows that the currently used solutions for artificial reefs in freshwater reservoirs are characterized by a high degree of primitivism, both in terms of the materials used and the technologies applied. There is a lack of previous research connected with the usage of 3D printing technologies for designing freshwater artificial reefs. Meanwhile, the need to optimize this kind of construction for freshwater ecosystems seems to be even larger than for marine ones.

Previous studies have shown the important role of microhabitats in the lifecycle of lake fauna, with particular emphasis on selected freshwater fish species. The artificial structures in these studies supported freshwater species, helping to reduce the negative impacts of environmental pressures and playing a key role in the successful colonization of these areas by several species. Additionally, these structures promoted the protection of juveniles, reducing the effectiveness of predators as the availability of shelters increased. The studies show that artificial reefs in freshwater can significantly support the maintenance of biodiversity by increasing the spatial complexity of the environment [8].

6. Challenges and Limitations

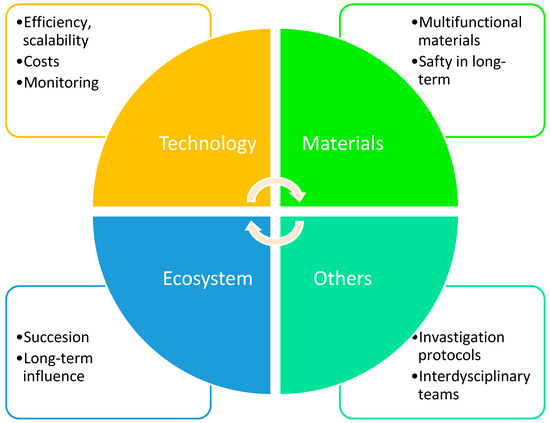

Artificial reefs bring a lot of potential benefits connected with their application, but there are still some challenges that limit their application. Some of the challenges and limitations were presented in previous sections. Here, we would like to summarize the most important among them. The existing challenges have been connected in four main areas, including materials, technologies, the ecosystem, and others. It is worth mentioning that these areas influence each other. The main groups of challenges are presented in Figure 6.

Figure 6.

Selected challenges connected with artificial reefs.

Despite the availability of many materials suitable for this purpose, there is a limited number of studies on the effects of their physical and chemical properties on different species of fauna and flora, especially over long periods [97]. Moreover, in the field research, the ecological impact on the ecosystems is not always easily predictable over a longer perspective [60]. Three-dimensional printing technology seems to be the best option for reef restoration, providing customized and sustainable solutions, but it should be mentioned that there is still a small amount of research that shows the influence of this kind of structure over a longer perspective [23]. Nowadays, the two more popular groups of materials for artificial reef creation using additive manufacturing are plastic-based materials and cement concrete. Both of them could potentially have a negative influence on the environment, such as the release of heavy metals or microplastic particles [23,98,99]. The challenges connected with the materials and technologies for artificial reef manufacturing are in several cases similar to challenges for additive manufacturing development in other areas, especially in terms of designing more environmentally friendly solutions [100,101,102] or optimizing the material parameters [103,104]. Others are very specific, including the application of 3D printing technology in underwater environments [13,47].

An important group of limitations is also connected with current knowledge about different ecosystems and limitations in predicting the changes in the whole complex net of connections between the various organisms. Nowadays, our knowledge in this area is quite limited and we cannot always predict all the consequences of our activities. It can be especially important in the case of new perspectives that are offered by additive manufacturing [17,105].

The current limitations of provided projects are also connected with the scalability of the additive manufacturing technology. Providing research on a large scale is connected with increasing the size of the objects and with significant changes in the required time of production and cost of manufacturing [21]. A lot of publications mention additive manufacturing as a cost-effective approach to restoring coral reefs [21]. However, taking into consideration the huge size of the required scale of implementation, the overall implementation costs will be high. Moreover, the successful implementation requires close cooperation and the development of interdisciplinary teams, which are also challenging tasks [21].

7. Predicted Directions for the Development of Artificial Reefs

Nowadays, in scientific publications, there is a clearly visible trend connected with ensuring the multifunctionality of the reef structure and a more complex approach to investigating the interaction between particular components [88]. Bao et al. [9] predict that future research in the area of artificial coral reefs will be connected with the expansion and renewal of the effect range of these structures, including the influence of climate change [9]. Further research is needed on the impact of artificial reefs on ecosystems [93]. There is an urgent need for further research to better understand the role of artificial habitats, especially in the face of climate change scenarios [3]. This research is essential in the context of properly designing and planning artificial habitats that will support biodiversity conservation efforts in the case of lost or disturbed natural habitats [3].

The other specific problem is associated with decarbonization. The problem of decarbonization in the marine environment has gained its own terminology, most often referred to as “blue carbon ecosystems” or “organic blue carbon sequestration” [106,107]. So far, this issue has been mainly analyzed in the context of living organisms, especially in terms of the carbon dioxide storage capacity of mangrove forest ecosystems and aquatic plants in the coastal zone [108,109,110], and the role of other organisms in this process [111,112]. Only a few studies have been devoted to decarbonization in the context of lake and wetland ecosystems [113,114]. So far, this problem has not been considered in terms of using materials that could bind carbon dioxide underwater, in processes analogous to those occurring on the surface. The opposite situation applies to current solutions in construction, where the issues of carbon dioxide sequestration are implemented, e.g., in geopolymer materials [115,116,117]. However, these solutions have not been applied in underwater environments so far. The introduction of this technology will constitute a research challenge for the future development of artificial reefs. Research in this field should include the prediction of effects, especially considering interactions with other human activities, such as climate change [3].

Another important function of artificial reefs can be support in combating invasive species. Although artificial habitats can lead to an increase in the local abundance and diversity of fauna and flora species, it is necessary to consider the origin of these species (i.e., native or non-native). Previous studies indicate that artificial habitats can be effectively used to reduce the ability of invasive species [95]. Bao et al.’s [9] forecasts also employ molecular ecological regulation to create “active artificial reefs” [9]. This is possible by using specific natural chemicals integrated with reef materials [9]. However, this requires deepening knowledge and adapting the designed structures to specific local conditions and species occurring there. These activities can also be carried out on a micro scale. It is worth emphasizing that an artificial reef can promote the development of desirable microorganisms in a given water body. It can also limit the growth and reproduction of cyanobacteria, while significantly promoting the development of diatoms [93].

Another function of the reef can be connected with water treatment. The experiment in this area was provided by Mendirk et al. with microplastic trapping [118]. This team created mechanisms controlled by hydrodynamics for microplastic catching [118]. This kind of function can also be coupled with the controlled release of particular elements, oxides, or more complex components. Currently, one of the basic requirements for the materials is a lack of significant leaching of the elements from the material, but the controlled leaching of particular nutrients can be positive for the development of desired microorganisms.

Other areas of predictable development are digitalization and integration with smart technologies, including advanced materials. In this area, it is predicted that increasing importance will be given to smart monitoring systems that integrate sensors, self-regulating materials, and energy capture devices [9]. A beneficial idea concerns integrating the artificial reefs into existing and emerging marine infrastructure [9]. This allows for decreasing the investment costs. Concerning the design of new materials, the most promising seems to symbiotic materials and self-healing materials [9,119]. Among the technological trends also worth considering are virtual reality and augmented reality technologies that have immense potential for marine research and conservation, and can help with spreading knowledge in this area [120,121,122].

8. Conclusions

The provided literature review allows us to formulate the following conclusions and identify the following areas for future development:

- Numerical modeling is used mainly for wave simulation. There is a large potential to also use the modeling process for other purposes, such as the prediction of development, particularly of species or ecosystem growth.

- Nowadays, different additive manufacturing technologies are used for designing and manufacturing coral reefs. The most effective seems to be joining several of them in one project, which gives new possibilities for reef restoration.

- Currently, the most reliable seems to be the use of cementitious materials for artificial reef production using additive manufacturing technology; however, the usage of other materials, including biopolymers from biomass waste, seems to be a valuable option for the future.

- A lot of research confirms the benefits connected with artificial reefs for the restoration of ecosystems; however, the problems connected with potential “ocean sprawl” and the wide spreading of invasive species should be taken into consideration during planning the research.

- Still, a lot of challenges exist in the area of artificial reefs, which are connected with materials, additive technology, investigated ecosystems, and other areas. The exemplary challenges are a lack of previous research connected with the usage of 3D printing technologies for designing freshwater artificial reefs and the small number of investigations about the long-term function of artificial reefs.

- There a several areas that seem to be crucial for the further development of artificial reefs, including multifunctionality, digitalization, and the design of advanced materials. This topic seems to have a huge potential in further research, but it also requires joining competences form several scientific disciplines.

Author Contributions

Conceptualization, K.K. and P.D.; methodology, K.K. and A.Ź.; validation, S.G. and W.-T.L.; formal analysis, K.O.; investigation, K.K., S.G. and A.Ź.; resources, K.K.; data curation, W.-T.L. and A.Ź.; writing—original draft preparation, K.K., K.O., P.D. and A.Ź.; writing—review and editing, S.G. and W.-T.L.; visualization, K.O.; supervision, K.K. and P.D.; project administration, K.K.; funding acquisition, K.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the project entitled: “Development of water treatment systems that counteract the eutrophication process of lakes based on zeolites obtained from industrial by-products”, which is financed by the Polish National Center for Research and Development under the M-ERA.NET 3 program, grant number M-ERA.NET3/2023/67/CleanLake/2024.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| DLP | Digital Light Processing |

| FDM | Fused Deposition Modeling |

| FFF | Fused Filament Fabrication |

| PLA | polylactic acid |

| PHB | polyhydroxybutyrate |

| SCA | Selective Cement Activation |

| SLA | Stereolithography |

References

- Yuval, M.; Treibitz, T. Releasing a Dataset of 3D Models of Artificial Reefs from the Northern Red-Sea for 3D Printing and Virtual Reality Applications. Remote Sens. Appl. 2024, 36, 101305. [Google Scholar] [CrossRef]

- Seixas, L.B.; Barreto, N.R.; Santos, L.N.D. Artificial Reefs for Marine and Freshwater Fish Management in Brazil: Researchers Profile and Academic Production over the 1990–2010 Period. Oecol. Austr. 2013, 17, 374–385. [Google Scholar] [CrossRef]

- Frehse, F.D.A.; Derviche, P.; Pereira, F.W.; Hostim-Silva, M.; Vitule, J.R.S. Artificial Aquatic Habitats: A Systematic Literature Review and New Perspectives. Hydrobiologia 2025, 852, 1997–2012. [Google Scholar] [CrossRef]

- Freitas, C.E.C.; Petrere, M. Influence of Artificial Reefs on Fish Assemblage of the Barra Bonita Reservoir (São Paulo, Brazil). Lakes Reserv. 2001, 6, 273–278. [Google Scholar] [CrossRef]

- Santos, L.N.; Araújo, F.G.; Brotto, D.S. Artificial Structures as Tools for Fish Habitat Rehabilitation in a Neotropical Reservoir. Aquat. Conserv. 2008, 18, 896–908. [Google Scholar] [CrossRef]

- Santos, L.N.; García-Berthou, E.; Agostinho, A.A.; Latini, J.D. Fish Colonization of Artificial Reefs in a Large Neotropical Reservoir: Material Type and Successional Changes. Ecol. Appl. 2011, 21, 251–262. [Google Scholar] [CrossRef]

- Creque, S.M.; Raffenberg, M.J.; Brofka, W.A.; Dettmers, J.M. If You Build It, Will They Come? Fish and Angler Use at a Freshwater Artificial Reef. N. Am. J. Fish. Manag. 2006, 26, 702–713. [Google Scholar] [CrossRef]

- Freitas, C.E.C.; Petrere, M.; Barrella, W. Natural and Artificially-induced Habitat Complexity and Freshwater Fish Species Composition. Fish. Manag. Ecol. 2005, 12, 63–67. [Google Scholar] [CrossRef]

- Bao, H.; Nikolaeva, A.; Xia, J.; Ma, F. Evolution Trends and Future Prospects in Artificial Marine Reef Research: A 28-Year Bibliometric Analysis. Sustainability 2024, 17, 184. [Google Scholar] [CrossRef]

- Carr, M.H.; Robinson, S.P.; Wahle, C.; Davis, G.; Kroll, S.; Murray, S.; Schumacker, E.J.; Williams, M. The Central Importance of Ecological Spatial Connectivity to Effective Coastal Marine Protected Areas and to Meeting the Challenges of Climate Change in the Marine Environment. Aquat. Conserv. 2017, 27, 6–29. [Google Scholar] [CrossRef]

- Katiyar, K. Marine Resources: Plethora of Opportunities for Sustainable Future. In Marine Biomass; Thapar Kapoor, R., Rafatullah, M., Ismail, N., Eds.; De Gruyter: Berlin, Germany, 2024; pp. 367–388. ISBN 978-3-11-135395-1. [Google Scholar]

- Korniejenko, K.; Pławecka, K.; Kozub, B. An Overview for Modern Energy-Efficient Solutions for Lunar and Martian Habitats Made Based on Geopolymers Composites and 3D Printing Technology. Energies 2022, 15, 9322. [Google Scholar] [CrossRef]

- Korniejenko, K.; Gądek, S.; Dynowski, P.; Tran, D.H.; Rudziewicz, M.; Pose, S.; Grab, T. Additive Manufacturing in Underwater Applications. Appl. Sci. 2024, 14, 1346. [Google Scholar] [CrossRef]

- Dong, C.; Petrovic, M.; Davies, I.J. Applications of 3D Printing in Medicine: A Review. Ann. 3D Print. Med. 2024, 14, 100149. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.; Abdoli, H.; Diegel, O.; Chan, S.; Iliescu, M.; Ganetsos, T.; Munteanu, I.; Ungureanu, L. Additive Manufacturing for Surgical Planning and Education: A Review. Appl. Sci. 2024, 14, 2550. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- Strain, E.M.A.; Olabarria, C.; Mayer-Pinto, M.; Cumbo, V.; Morris, R.L.; Bugnot, A.B.; Dafforn, K.A.; Heery, E.; Firth, L.B.; Brooks, P.R.; et al. Eco-engineering Urban Infrastructure for Marine and Coastal Biodiversity: Which Interventions Have the Greatest Ecological Benefit? J. Appl. Ecol. 2018, 55, 426–441. [Google Scholar] [CrossRef]

- Sempere-Valverde, J.; Ostalé-Valriberas, E.; Farfán, G.M.; Espinosa, F. Substratum Type Affects Recruitment and Development of Marine Assemblages over Artificial Substrata: A Case Study in the Alboran Sea. Estuar. Coast. Shelf Sci. 2018, 204, 56–65. [Google Scholar] [CrossRef]

- Oren, A.; Berman, O.; Neri, R.; Edery-Lutri, M.; Chernihovsky, N.; Tarazi, E.; Shashar, N. Ecological Succession on 3D Printed Ceramic Artificial Reefs. Sci. Total Environ. 2024, 954, 176371. [Google Scholar] [CrossRef]

- Levy, N.; Berman, O.; Yuval, M.; Loya, Y.; Treibitz, T.; Tarazi, E.; Levy, O. Emerging 3D Technologies for Future Reformation of Coral Reefs: Enhancing Biodiversity Using Biomimetic Structures Based on Designs by Nature. Sci. Total Environ. 2022, 830, 154749. [Google Scholar] [CrossRef]

- Albalawi, H.I.; Khan, Z.N.; Valle-Pérez, A.U.; Kahin, K.M.; Hountondji, M.; Alwazani, H.; Schmidt-Roach, S.; Bilalis, P.; Aranda, M.; Duarte, C.M.; et al. Sustainable and Eco-Friendly Coral Restoration through 3D Printing and Fabrication. ACS Sustain. Chem. Eng. 2021, 9, 12634–12645. [Google Scholar] [CrossRef]

- Berman, O.; Weizman, M.; Oren, A.; Neri, R.; Parnas, H.; Shashar, N.; Tarazi, E. Design and Application of a Novel 3D Printing Method for Bio-Inspired Artificial Reefs. Ecol. Eng. 2023, 188, 106892. [Google Scholar] [CrossRef]

- Talekar, S.; Barrow, C.J.; Nguyen, H.C.; Zolfagharian, A.; Zare, S.; Farjana, S.H.; Macreadie, P.I.; Ashraf, M.; Trevathan-Tackett, S.M. Using Waste Biomass to Produce 3D-Printed Artificial Biodegradable Structures for Coastal Ecosystem Restoration. Sci. Total Environ. 2024, 925, 171728. [Google Scholar] [CrossRef] [PubMed]

- Scopus Analyze Search Results. Available online: https://www.scopus.com/term/analyzer.uri?sort=plf-f&src=s&sid=952515533c296d3c75e56105169cf326&sot=a&sdt=a&sl=52&s=%28TITLE-ABS-KEY%28reef%29+AND+TITLE-ABS-KEY%283D+printing%29%29&origin=resultslist&count=10&analyzeResults=Analyze+results (accessed on 17 March 2025).

- Vieira Da Silva, G.; Hamilton, D.; Strauss, D.; Murray, T.; Tomlinson, R. Sediment Pathways and Morphodynamic Response to a Multi-Purpose Artificial Reef—New Insights. Coast. Eng. 2022, 171, 104027. [Google Scholar] [CrossRef]

- Schuh, E.; Grilli, A.R.; Groetsch, F.; Grilli, S.T.; Crowley, D.; Ginis, I.; Stempel, P. Assessing the Morphodynamic Response of a New England Beach-Barrier System to an Artificial Reef. Coast. Eng. 2023, 184, 104355. [Google Scholar] [CrossRef]

- Kuang, C.; Ma, Y.; Han, X.; Pan, S.; Zhu, L. Experimental Observation on Beach Evolution Process with Presence of Artificial Submerged Sand Bar and Reef. J. Mar. Sci. Eng. 2020, 8, 1019. [Google Scholar] [CrossRef]

- Ma, Y.; Kuang, C.; Han, X.; Niu, H.; Zheng, Y.; Shen, C. Experimental Study on the Influence of an Artificial Reef on Cross-Shore Morphodynamic Processes of a Wave-Dominated Beach. Water 2020, 12, 2947. [Google Scholar] [CrossRef]

- Lowe, R.J.; Falter, J.L.; Monismith, S.G.; Atkinson, M.J. A Numerical Study of Circulation in a Coastal Reef-lagoon System. J. Geophys. Res. 2009, 114, 2008JC005081. [Google Scholar] [CrossRef]

- Lowe, R.J.; Hart, C.; Pattiaratchi, C.B. Morphological Constraints to Wave-driven Circulation in Coastal Reef-lagoon Systems: A Numerical Study. J. Geophys. Res. 2010, 115, 2009JC005753. [Google Scholar] [CrossRef]

- Taebi, S.; Lowe, R.J.; Pattiaratchi, C.B.; Ivey, G.N.; Symonds, G. A Numerical Study of the Dynamics of the Wave-Driven Circulation within a Fringing Reef System. Ocean Dyn. 2012, 62, 585–602. [Google Scholar] [CrossRef]

- Longuet-Higgins, M.S.; Stewart, R.W. Radiation Stresses in Water Waves; a Physical Discussion, with Applications. Deep Sea Res. Oceanogr. Abstr. 1964, 11, 529–562. [Google Scholar] [CrossRef]

- de Ridder, M.P. Non-Hydrostatic Wave Modelling of Coral Reefs with the Addition of a Porous in-Canopy Model. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Su, S.-F.; Ma, G. Modeling Two-Dimensional Infragravity Motions on a Fringing Reef. Ocean Eng. 2018, 153, 256–267. [Google Scholar] [CrossRef]

- Liu, C.; Onat, Y.; Jia, Y.; O’Donnell, J. Modeling Nearshore Dynamics of Extreme Storms in Complex Environments of Connecticut. Coast. Eng. 2021, 168, 103950. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, Z.; Monismith, S.G.; Lo, E.Y.M. 1DH Boussinesq Modeling of Wave Transformation over Fringing Reefs. Ocean Eng. 2012, 47, 30–42. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, Q.; Chen, S.; Tang, Z. Effects of Reef Morphology Variations on Wave Processes over Fringing Reefs. Appl. Ocean Res. 2019, 82, 52–62. [Google Scholar] [CrossRef]

- Yao, Y.; Becker, J.M.; Ford, M.R.; Merrifield, M.A. Modeling Wave Processes over Fringing Reefs with an Excavation Pit. Coast. Eng. 2016, 109, 9–19. [Google Scholar] [CrossRef]

- Buckley, M.; Lowe, R.; Hansen, J. Evaluation of Nearshore Wave Models in Steep Reef Environments. Ocean Dyn. 2014, 64, 847–862. [Google Scholar] [CrossRef]

- Lashley, C.H.; Roelvink, D.; Van Dongeren, A.; Buckley, M.L.; Lowe, R.J. Nonhydrostatic and Surfbeat Model Predictions of Extreme Wave Run-up in Fringing Reef Environments. Coast. Eng. 2018, 137, 11–27. [Google Scholar] [CrossRef]

- Torres-Freyermuth, A.; Brocchini, M.; Corvaro, S.; Pintado-Patiño, J.C. Wave Attenuation over Porous Seabeds: A Numerical Study. Ocean Model. 2017, 117, 28–40. [Google Scholar] [CrossRef]

- Ma, G.; Su, S.-F.; Liu, S.; Chu, J.-C. Numerical Simulation of Infragravity Waves in Fringing Reefs Using a Shock-Capturing Non-Hydrostatic Model. Ocean Eng. 2014, 85, 54–64. [Google Scholar] [CrossRef]

- Yao, Y.; He, F.; Tang, Z.; Liu, Z. A Study of Tsunami-like Solitary Wave Transformation and Run-up over Fringing Reefs. Ocean Eng. 2018, 149, 142–155. [Google Scholar] [CrossRef]

- Wu, Y.-T.; Yeh, C.-L.; Hsiao, S.-C. Three-Dimensional Numerical Simulation on the Interaction of Solitary Waves and Porous Breakwaters. Coast. Eng. 2014, 85, 12–29. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Love, P.E.D. Digital Reproduction of Historical Building Ornamental Components: From 3D Scanning to 3D Printing. Autom. Constr. 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Three-Dimensional Printing and 3D Scanning: Emerging Technologies Exhibiting High Potential in the Field of Cultural Heritage. Appl. Sci. 2023, 13, 4777. [Google Scholar] [CrossRef]

- Becher, A.F.; Zeidler, H.; Gądek, S.; Korniejenko, K. Shaping and Characterization of Additively Manufactured Geopolymer Materials for Underwater Applications. Appl. Sci. 2025, 15, 3449. [Google Scholar] [CrossRef]

- Matus, I.V.; Alves, J.L.; Góis, J.; Vaz-Pires, P.; Barata Da Rocha, A. Artificial Reefs through Additive Manufacturing: A Review of Their Design, Purposes and Fabrication Process for Marine Restoration and Management. Rapid Prototyp. J. 2024, 30, 87–122. [Google Scholar] [CrossRef]

- Jia, Y.; Abdelrahman, S.; Hauser, C.A.E. Developing a Sustainable Resin for 3D Printing in Coral Restoration. Mater. Sci. Addit. Manuf. 2024, 3, 3125. [Google Scholar] [CrossRef]

- Hitzegrad, J.; Brohmann, L.; Herding, F.; Pfennings, K.; Jonischkies, S.; Scharnbeck, E.; Mainka, J.; Mai, I.; Windt, C.; Kloft, H.; et al. Surfaces of Coastal Biogenic Structures: Exploiting Advanced Digital Design and Fabrication Strategies for the Manufacturing of Oyster Reef and Mussel Bed Surrogates. Front. Mar. Sci. 2024, 11, 1395025. [Google Scholar] [CrossRef]

- Tong, F.; Griffiths, T. Hydrodynamics for Subsea Systems. In Encyclopedia of Ocean Engineering; Cui, W., Fu, S., Hu, Z., Eds.; Springer Nature: Singapore, 2022; pp. 751–757. ISBN 978-981-10-6945-1. [Google Scholar]

- Piñeros, V.J.; Reveles-Espinoza, A.M.; Monroy, J.A. From Remote Sensing to Artificial Intelligence in Coral Reef Monitoring. Machines 2024, 12, 693. [Google Scholar] [CrossRef]

- Pondella, D.J.; Claisse, J.T.; Williams, C.M. Theory, Practice, and Design Criteria for Utilizing Artificial Reefs to Increase Production of Marine Fishes. Front. Mar. Sci. 2022, 9, 983253. [Google Scholar] [CrossRef]

- Carral, L.; Lamas, M.I.; Cartelle Barros, J.J.; López, I.; Carballo, R. Proposed Conceptual Framework to Design Artificial Reefs Based on Particular Ecosystem Ecology Traits. Biology 2022, 11, 680. [Google Scholar] [CrossRef]

- Gill, A.B.; Bremner, J.; Vanstaen, K.; Blake, S.; Mynott, F.; Lincoln, S. Limited Evidence Base for Determining Impacts (Or Not) of Offshore Wind Energy Developments on Commercial Fisheries Species. Fish Fish. 2025, 26, 155–170. [Google Scholar] [CrossRef]

- Skinner, C.; Cobain, M.R.D.; Zhu, Y.; Wyatt, A.S.J.; Polunin, N.V.C. Progress and Direction in the Use of Stable Isotopes to Understand Complex Coral Reef Ecosystems: A Review. In Oceanography and Marine Biology: An Annual Review, Volume 60; CRC Press: Boca Raton, FL, USA, 2022; pp. 373–432. ISBN 978-1-003-28860-2. [Google Scholar]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- Reyes, G.; Vega-Coloma, M.; Antonova, A.; Ajdary, R.; Jonveaux, S.; Flanigan, C.; Lautenbacher, N.; Rojas, O.J. Direct CO2 Capture by Alkali-Dissolved Cellulose and Sequestration in Building Materials and Artificial Reef Structures. Adv. Mater. 2023, 35, 2209327. [Google Scholar] [CrossRef] [PubMed]

- Jamil, A.; Ahmad, A.; Zhao, Y.; Zhao, Y.; Yang, C.; Li, Y.; Tu, J.; Niu, F.; Kong, W.; Liu, X. Advances in Global Oyster Reef Restoration: Innovations and Sustainable Ecological Approaches. Sustainability 2024, 16, 9795. [Google Scholar] [CrossRef]

- Dela Cruz, D.W.; Rinkevich, B.; Gomez, E.D.; Yap, H.T. Assessing an Abridged Nursery Phase for Slow Growing Corals Used in Coral Restoration. Ecol. Eng. 2015, 84, 408–415. [Google Scholar] [CrossRef]

- Temmink, R.J.M.; Angelini, C.; Fivash, G.S.; Swart, L.; Nouta, R.; Teunis, M.; Lengkeek, W.; Didderen, K.; Lamers, L.P.M.; Bouma, T.J.; et al. Life Cycle Informed Restoration: Engineering Settlement Substrate Material Characteristics and Structural Complexity for Reef Formation. J. Appl. Ecol. 2021, 58, 2158–2170. [Google Scholar] [CrossRef]

- Patti, A. Challenges to Improve Extrusion-Based Additive Manufacturing Process of Thermoplastics toward Sustainable Development. Macromol. Rapid Commun. 2024, 45, 2400249. [Google Scholar] [CrossRef]

- Ruhl, E.J.; Dixson, D.L. 3D Printed Objects Do Not Impact the Behavior of a Coral-Associated Damselfish or Survival of a Settling Stony Coral. PLoS ONE 2019, 14, e0221157. [Google Scholar] [CrossRef]

- Temmink, R.J.M.; Fivash, G.S.; Govers, L.L.; Nauta, J.; Marin-Diaz, B.; Cruijsen, P.M.J.M.; Didderen, K.; Penning, E.; Olff, H.; Heusinkveld, J.H.T.; et al. Initiating and Upscaling Mussel Reef Establishment with Life Cycle Informed Restoration: Successes and Future Challenges. Ecol. Eng. 2022, 175, 106496. [Google Scholar] [CrossRef]

- Green, D.S. Effects of Microplastics on European Flat Oysters, Ostrea Edulis and Their Associated Benthic Communities. Environ. Pollut. 2016, 216, 95–103. [Google Scholar] [CrossRef]

- Magara, G.; Khan, F.R.; Pinti, M.; Syberg, K.; Inzirillo, A.; Elia, A.C. Effects of Combined Exposures of Fluoranthene and Polyethylene or Polyhydroxybutyrate Microplastics on Oxidative Stress Biomarkers in the Blue Mussel (Mytilus edulis). J. Toxicol. Environ. Health Part A 2019, 82, 616–625. [Google Scholar] [CrossRef] [PubMed]

- Gatts, P.; Franco, M.; Dos Santos, L.; Rocha, D.; De Sá, F.; Netto, E.; Machado, P.; Masi, B.; Zalmon, I. Impact of Artificial Patchy Reef Design on the Ichthyofauna Community of Seasonally Influenced Shores at Southeastern Brazil. Aquat. Ecol. 2015, 49, 343–355. [Google Scholar] [CrossRef]

- Ly, O.; Yoris-Nobile, A.I.; Sebaibi, N.; Blanco-Fernandez, E.; Boutouil, M.; Castro-Fresno, D.; Hall, A.E.; Herbert, R.J.H.; Deboucha, W.; Reis, B.; et al. Optimisation of 3D Printed Concrete for Artificial Reefs: Biofouling and Mechanical Analysis. Constr. Build. Mater. 2021, 272, 121649. [Google Scholar] [CrossRef]

- Yoris-Nobile, A.I.; Slebi-Acevedo, C.J.; Lizasoain-Arteaga, E.; Indacoechea-Vega, I.; Blanco-Fernandez, E.; Castro-Fresno, D.; Alonso-Estebanez, A.; Alonso-Cañon, S.; Real-Gutierrez, C.; Boukhelf, F.; et al. Artificial Reefs Built by 3D Printing: Systematisation in the Design, Material Selection and Fabrication. Constr. Build. Mater. 2023, 362, 129766. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Yang, Z.; Ye, Y. Preliminary Investigation of Artificial Reef Concrete with Sulphoaluminate Cement, Marine Sand and Sea Water. Constr. Build. Mater. 2019, 211, 837–846. [Google Scholar] [CrossRef]

- O’Reilly, L.M.; Willerth, S.M. Evaluating the Biocompatibility of Ceramic Materials for Constructing Artificial Reefs. Front. Mar. Sci. 2024, 10, 1292584. [Google Scholar] [CrossRef]

- Srinivas, D.; Panda, B.; Suraneni, P.; Sitharam, T.G. Influence of Mixture Composition and Carbonation Curing on Properties of Sustainable 3D Printable Mortars. J. Clean. Prod. 2025, 492, 144894. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Peng, L.; Wang, N.; Meng, T.; Zhao, Y.; Gong, F. Preliminary Investigation and Life Cycle Assessment of Artificial Reefs with Recycled Brick-Concrete Aggregates. Constr. Build. Mater. 2024, 432, 136618. [Google Scholar] [CrossRef]

- Bone, J.R.; Stafford, R.; Hall, A.E.; Herbert, R.J.H. The Intrinsic Primary Bioreceptivity of Concrete in the Coastal Environment—A Review. Dev. Built Environ. 2022, 10, 100078. [Google Scholar] [CrossRef]

- Ido, S.; Shimrit, P.-F. Blue Is the New Green—Ecological Enhancement of Concrete Based Coastal and Marine Infrastructure. Ecol. Eng. 2015, 84, 260–272. [Google Scholar] [CrossRef]

- Kuang, W.; Pavlenko, P.; Guo, H.; Tian, K.; Liu, H.; Zhou, Z.; Duan, Y.; Shi, X. Utilization of Machine-Made Sand Waste in 3D-Printed Ecological Concrete for Artificial Reefs. Case Stud. Constr. Mater. 2025, 22, e04494. [Google Scholar] [CrossRef]

- Martins, J.R.; Novais, R.M.; Hotza, D.; Labrincha, J.A.; Senff, L. Waste-Derived Geopolymers for Artificial Coral Development by 3D Printing. J. Sustain. Metall. 2025, 11, 114–125. [Google Scholar] [CrossRef]

- Madirisha, M.M.; Dada, O.R.; Ikotun, B.D. Chemical Fundamentals of Geopolymers in Sustainable Construction. Mater. Today Sustain. 2024, 27, 100842. [Google Scholar] [CrossRef]

- Mohammed, J.S. Applications of 3D Printing Technologies in Oceanography. Methods Oceanogr. 2016, 17, 97–117. [Google Scholar] [CrossRef]

- Krishna, R.S.; Rehman, A.U.; Mishra, J.; Saha, S.; Korniejenko, K.; Rehman, R.U.; Salamci, M.U.; Sglavo, V.M.; Shaikh, F.U.A.; Qureshi, T.S. Additive Manufacturing of Geopolymer Composites for Sustainable Construction: Critical Factors, Advancements, Challenges, and Future Directions. Prog. Addit. Manuf. 2024, 10, 1003–1061. [Google Scholar] [CrossRef]

- Kalam, M.A.; Mieno, T.; Casareto, B.E. Development of Artificial Reefs Using Environmentally Safe Ceramic Material. J. Ecosyst. Ecogr. 2018, 8, 253. [Google Scholar] [CrossRef]

- Ponti, M.; Fava, F.; Perlini, R.A.; Giovanardi, O.; Abbiati, M. Benthic Assemblages on Artificial Reefs in the Northwestern Adriatic Sea: Does Structure Type and Age Matter? Mar. Environ. Res. 2015, 104, 10–19. [Google Scholar] [CrossRef]

- Levy, N.; Simon-Blecher, N.; Ben-Ezra, S.; Yuval, M.; Doniger, T.; Leray, M.; Karako-Lampert, S.; Tarazi, E.; Levy, O. Evaluating Biodiversity for Coral Reef Reformation and Monitoring on Complex 3D Structures Using Environmental DNA (eDNA) Metabarcoding. Sci. Total Environ. 2023, 856, 159051. [Google Scholar] [CrossRef]

- Berman, O.; Levy, N.; Parnas, H.; Levy, O.; Tarazi, E. Exploring New Frontiers in Coral Nurseries: Leveraging 3D Printing Technology to Benefit Coral Growth and Survival. J. Mar. Sci. Eng. 2023, 11, 1695. [Google Scholar] [CrossRef]

- Parker, T.A.; Gallegos, J.A.; Beaver, J.; Brick, M.; Brown, J.K.; Cichy, K.; Debouck, D.G.; Delgado-Salinas, A.; Dohle, S.; Ernest, E.; et al. Genetic Resources and Breeding Priorities in Phaseolus Beans: Vulnerability, Resilience, and Future Challenges. In Plant Breeding Reviews; Goldman, I., Ed.; Wiley: Hoboken, NJ, USA, 2022; pp. 289–420. ISBN 978-1-119-87412-6. [Google Scholar]

- Riera, E.; Hubas, C.; Ungermann, M.; Rigot, G.; Pey, A.; Francour, P.; Rossi, F. Artificial Reef Effectiveness Changes among Types as Revealed by Underwater Hyperspectral Imagery. Restor. Ecol. 2023, 31, e13978. [Google Scholar] [CrossRef]

- 3DPARE Artificial Reef 3D Printing for Atlantic Area. Available online: https://www.giteco.unican.es/proyectos/3dpare/index.html (accessed on 17 March 2025).

- Hall, A.E.; Herbert, R.J.H.; Stafford, R.; Jones, G.; Greenhill, S.; Pinto, I.S.; Reis, B.; Van Der Linden, P.; Boutouil, M.; Sebaibi, N.; et al. 3D Printed Habitat Enhancement Units: Key Features to Incorporate within Multifunctional Infrastructure. In Coasts, Marine Structures and Breakwaters 2023: Resilience and Adaptability in a Changing Climate; Emerald Publishing Limited: Portsmouth, UK, 2024; pp. 969–984. [Google Scholar]

- Ahirwal, J.; Maiti, S.K. Ecological Restoration of Abandoned Mine Land: Theory to Practice. In Handbook of Ecological and Ecosystem Engineering; Prasad, M.N.V., Ed.; Wiley: Hoboken, NJ, USA, 2021; pp. 231–246. ISBN 978-1-119-67853-3. [Google Scholar]

- Wan, Y.; Kong, Q.; Du, H.; Yang, W.; Zha, W.; Li, W. Effectiveness of Artificial Reefs in Enhancing Phytoplankton Community Dynamics: A Meta-Analysis. Sci. Total Environ. 2024, 947, 174593. [Google Scholar] [CrossRef] [PubMed]

- Matthiopoulos, J.; Fieberg, J.; Aarts, G. Species-Habitat Associations: Spatial Data, Predictive Models, and Ecological Insights, 2nd ed.; University of Minnesota Libraries Publishing: Minneapolis, MN, USA, 2023; ISBN 978-1-946135-93-3. [Google Scholar]

- Kalita, T.L.; Mingaleova, O.N.; Khatuntsov, D.S.; Zhavnerov, A.N. Freshwater Artificial Reefs as a Way to Increase of the Productivity; European Publisher: London, UK, 2022; pp. 68–74. [Google Scholar]

- Zhu, H.; Liu, X.; Cheng, S.; Wang, J. Effects of Artificial Reefs on Phytoplankton Community Structure in Baiyangdian Lake, China. Water 2021, 13, 1802. [Google Scholar] [CrossRef]

- Guilbeau, B.P.; Harry, F.P.; Gambrell, R.P.; Knopf, F.C.; Dooley, K.M. Algae Attachment on Carbonated Cements in Fresh and Brackish Waters—Preliminary Results. Ecol. Eng. 2003, 20, 309–319. [Google Scholar] [CrossRef]

- Frehse, F.D.A.; Weyl, O.L.F.; Vitule, J.R.S. Differential Use of Artificial Habitats by Native and Non-Native Fish Species in Neotropical Reservoirs. Hydrobiologia 2021, 848, 2355–2367. [Google Scholar] [CrossRef]

- Raeini, L.I.; Negarestan, H.; Khoee, A.J. An Ecological Investigation on Colonization of Fresh Water Artificial Reefs. J. Environ. Hydrol. 2007, 15, 1–9. [Google Scholar]

- Leonard, C.; Hédouin, L.; Lacorne, M.C.; Dalle, J.; Lapinski, M.; Blanc, P.; Nugues, M.M. Performance of Innovative Materials as Recruitment Substrates for Coral Restoration. Restor. Ecol. 2022, 30, e13625. [Google Scholar] [CrossRef]

- Accardo, S.; Schiavo, S.; Parrella, L.; Montereali, M.R.; Lama, G.; Verdolotti, L.; Manzo, S. Do New Cement-Based Mortars Pose a Significant Threat to the Aquatic Environment? Chemosphere 2023, 332, 138818. [Google Scholar] [CrossRef]

- Ma, H.; Pu, S.; Liu, S.; Bai, Y.; Mandal, S.; Xing, B. Microplastics in Aquatic Environments: Toxicity to Trigger Ecological Consequences. Environ. Pollut. 2020, 261, 114089. [Google Scholar] [CrossRef]

- Zuo, X.; Zhou, Y.; Hao, K.; Liu, C.; Yu, R.; Huang, A.; Wu, C.; Yang, Y. 3D Printed All-Natural Hydrogels: Flame-Retardant Materials Toward Attaining Green Sustainability. Adv. Sci. 2024, 11, 2306360. [Google Scholar] [CrossRef]

- Ding, C.; Li, C.; Xiong, Z.; Li, Z. Computer Big Data Technology in Additive Manufacturing and Product Design in Sustainable Manufacturing. Int. J. Adv. Manuf. Technol. 2024, 135, 4855–4863. [Google Scholar] [CrossRef]

- Hassan, A.; Alomayri, T.; Noaman, M.F.; Zhang, C. 3D Printed Concrete for Sustainable Construction: A Review of Mechanical Properties and Environmental Impact. Arch. Comput. Methods Eng. 2025. [Google Scholar] [CrossRef]

- Peng, X.; Chen, K.; Jia, W.; Li, K.; Huang, C.; Liu, X. Stacking Sequence Optimization of Variable Thickness Composite Laminated Plate Based on Multi-Peak Stacking Sequence Table. Compos. Struct. 2025, 356, 118886. [Google Scholar] [CrossRef]

- Chen, S.; Khan, S.B.; Li, N.; Xiao, C. In-Depth Analysis of Sintering, Exposure Time, and Layer Height (Um) in LRS 3D Printed Devices with DLP. J. Manuf. Process. 2025, 133, 576–591. [Google Scholar] [CrossRef]

- Lee, H. Engineering In Vitro Models: Bioprinting of Organoids with Artificial Intelligence. Cyborg Bionic Syst. 2023, 4, 0018. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W.; Lu, J.; Tanveer, M.; Qi, Z.; Fu, C.; Xie, H.; Zhuang, L.; Hu, Z. Current Research Hotspots and Frontier Trends on Carbon Budget of Coastal Wetlands: A Bibliometric Analysis. Water Sci. Technol. 2024, 89, 3104–3121. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, H.; Lin, Q.; Zhang, C.; He, C.; Zheng, H. Exploring the International Research Landscape of Blue Carbon: Based on Scientometrics Analysis. Ocean Coast. Manag. 2024, 252, 107106. [Google Scholar] [CrossRef]

- Tasneem, S.; Ahsan, M.N. A Bibliometric Analysis on Mangrove Ecosystem Services: Past Trends and Emerging Interests. Ocean Coast. Manag. 2024, 256, 107276. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, C.; Li, X.; Wang, Y.; Sun, P.; Xu, X.; Wang, H.; Chen, Y.; Lin, J.; Huang, G.; et al. International Mangrove Carbon Sink Research Analysis. Reg. Stud. Mar. Sci. 2024, 77, 103681. [Google Scholar] [CrossRef]

- Hao, Q.; Song, Z.; Zhang, X.; He, D.; Guo, L.; Van Zwieten, L.; Yu, C.; Wang, Y.; Wang, W.; Fang, Y.; et al. Organic Blue Carbon Sequestration in Vegetated Coastal Wetlands: Processes and Influencing Factors. Earth-Sci. Rev. 2024, 255, 104853. [Google Scholar] [CrossRef]

- Derviche, P.; Menegotto, A.; Lana, P. Carbon Budget Trends in Octocorals: A Literature Review with Data Reassessment and a Conceptual Framework to Understand Their Resilience to Environmental Changes. Mar. Biol. 2022, 169, 159. [Google Scholar] [CrossRef]

- Coppari, M.; Zanella, C.; Rossi, S. The Importance of Coastal Gorgonians in the Blue Carbon Budget. Sci. Rep. 2019, 9, 13550. [Google Scholar] [CrossRef]

- Rowland, P.I.; Lovelock, C.E. Global Impacts of Introduced Ungulates on Wetland Carbon and Biodiversity: A Review. Biol. Conserv. 2024, 290, 110432. [Google Scholar] [CrossRef]

- Gao, K.; Beardall, J. Using Macroalgae to Address UN Sustainable Development Goals through CO2 Remediation and Improvement of the Aquaculture Environment. Appl. Phycol. 2022, 3, 360–367. [Google Scholar] [CrossRef]

- Nasvi, M.C.M.; Ranjith, P.G.; Sanjayan, J. Effect of Different Mix Compositions on Apparent Carbon Dioxide (CO2) Permeability of Geopolymer: Suitability as Well Cement for CO2 Sequestration Wells. Appl. Energy 2014, 114, 939–948. [Google Scholar] [CrossRef]

- Freire, A.L.; José, H.J.; Moreira, R.D.F.P.M. Potential Applications for Geopolymers in Carbon Capture and Storage. Int. J. Greenh. Gas Control 2022, 118, 103687. [Google Scholar] [CrossRef]

- Minelli, M.; Medri, V.; Papa, E.; Miccio, F.; Landi, E.; Doghieri, F. Geopolymers as Solid Adsorbent for CO2 Capture. Chem. Eng. Sci. 2016, 148, 267–274. [Google Scholar] [CrossRef]

- Mendrik, F.; Houseago, R.C.; Hackney, C.R.; Parsons, D.R. Microplastic Trapping Efficiency and Hydrodynamics in Model Coral Reefs: A Physical Experimental Investigation. Environ. Pollut. 2024, 342, 123094. [Google Scholar] [CrossRef]

- Wei, J.; Wan, F.; Zhang, P.; Zeng, Z.; Ping, H.; Xie, J.; Zou, Z.; Wang, W.; Xie, H.; Shen, Z.; et al. Bioprocess-Inspired Synthesis of Printable, Self-Healing Mineral Hydrogels for Rapidly Responsive, Wearable Ionic Skin. Chem. Eng. J. 2021, 424, 130549. [Google Scholar] [CrossRef]

- Vidal, M.; Mills, S.C.; Gairin, E.; Bertucci, F.; Lecchini, D. Validation of a Novel Immersive Virtual Reality Set-up with Responses of Wild-Caught Freely Moving Coral Reef Fish. Anim. Behav. 2023, 206, 99–123. [Google Scholar] [CrossRef]

- Korniejenko, K.; Kontny, B. The Usage of Virtual and Augmented Reality in Underwater Archeology. Appl. Sci. 2024, 14, 8188. [Google Scholar] [CrossRef]

- Vijayan, M.; Mustapha, S.; Aljibori, H.S.S.; Al-Tamimi, A.; Mohammed, M.N.; Alfiras, M. The Development of the MSU MyCoral Virtual Reality Application: An Innovative Approach to Educating Students on the Imperative of Coral Reef Rehabilitation. In Proceedings of the 2023 IEEE 8th International Conference on Engineering Technologies and Applied Sciences (ICETAS), Bahrain, 25 October 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).