A Review of Additive Manufacturing Techniques in Artificial Reef Construction: Materials, Processes, and Ecological Impact

Abstract

Featured Application

Abstract

1. Introduction

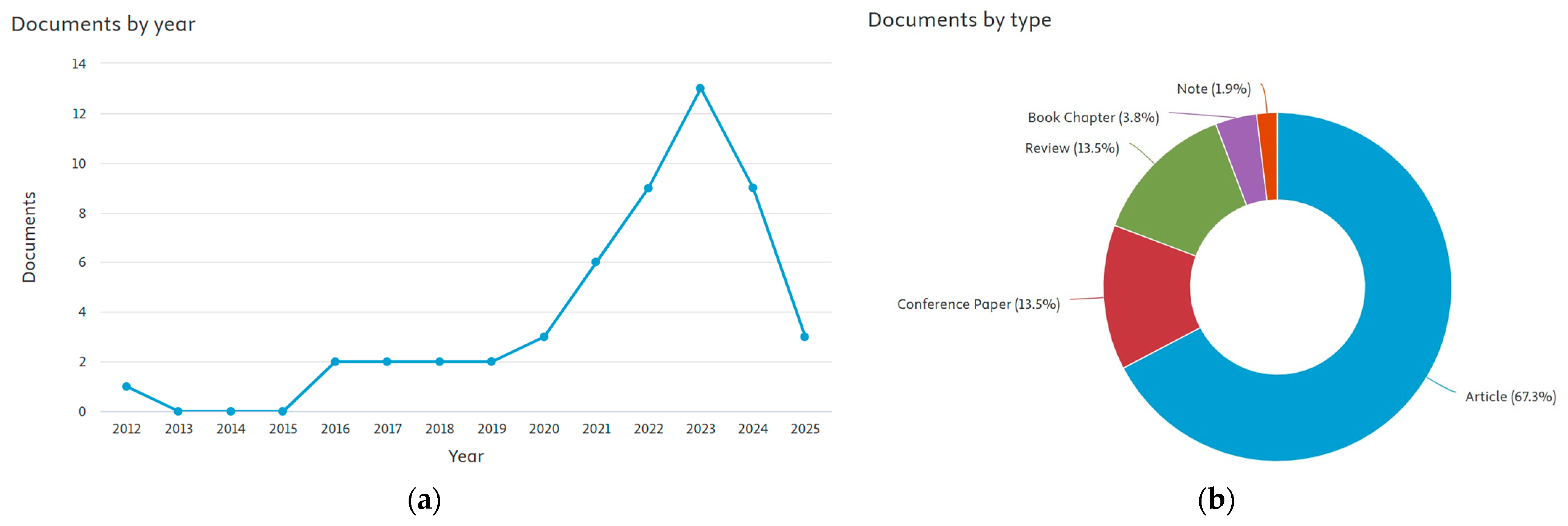

2. Research Methodology

3. Technologies Used for Artificial Reef Design and Manufacturing

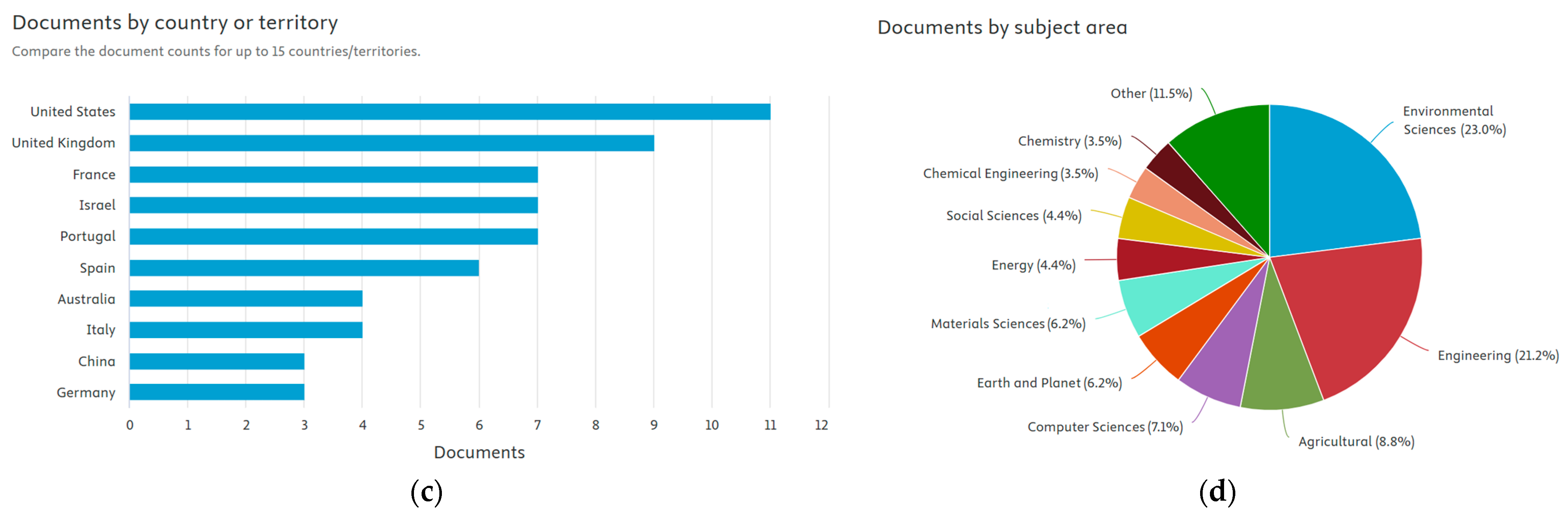

3.1. Modeling and Design

3.2. Traditional Manufacturing Technologies vs. Additive Manufacturing Technologies

4. Materials Used in Construction

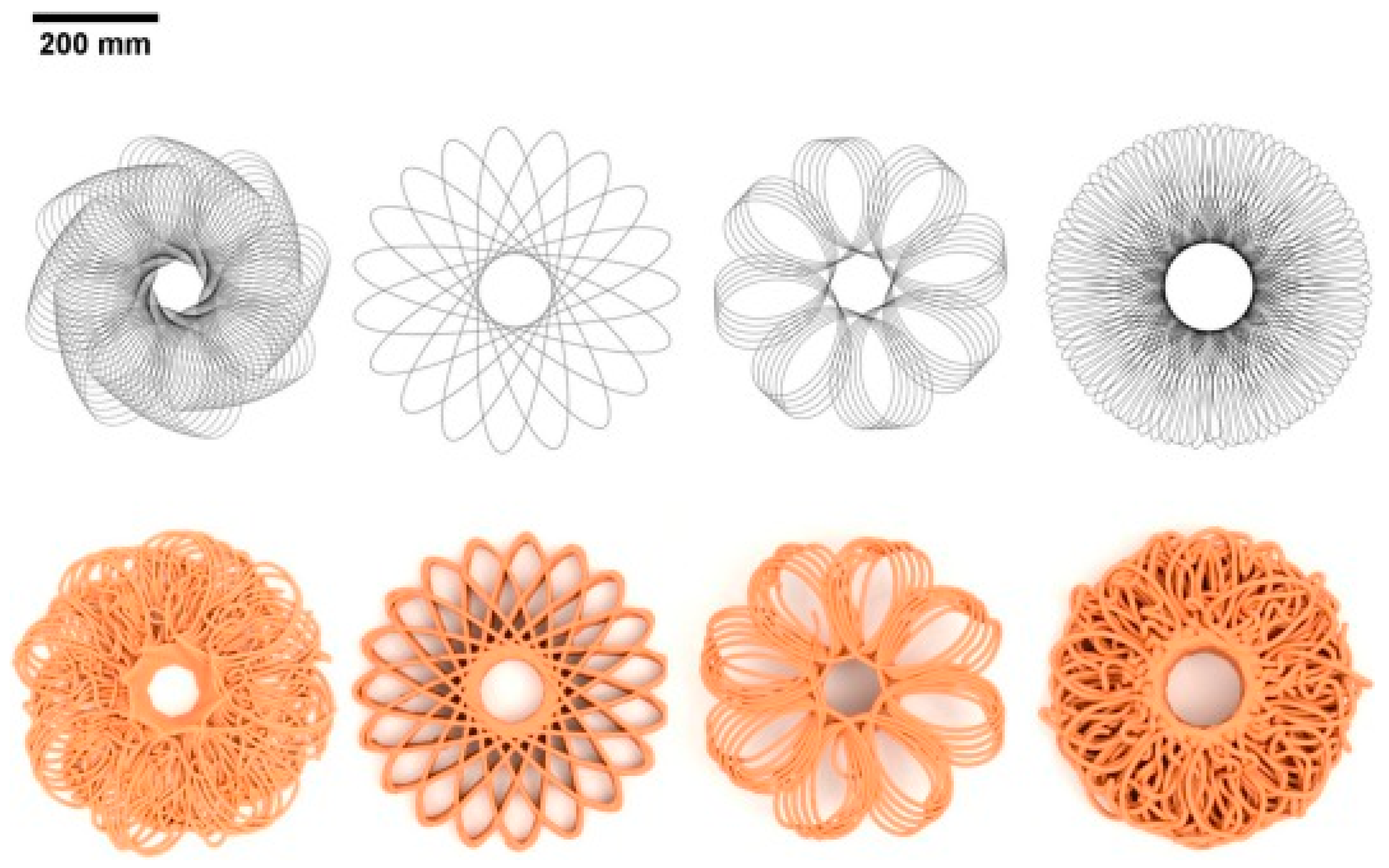

4.1. Development of Materials for Artificial Reefs

4.2. Polymer-Based Solutions

4.3. Cement, Geopolymers, and Similar Compositions

4.4. Other Materials

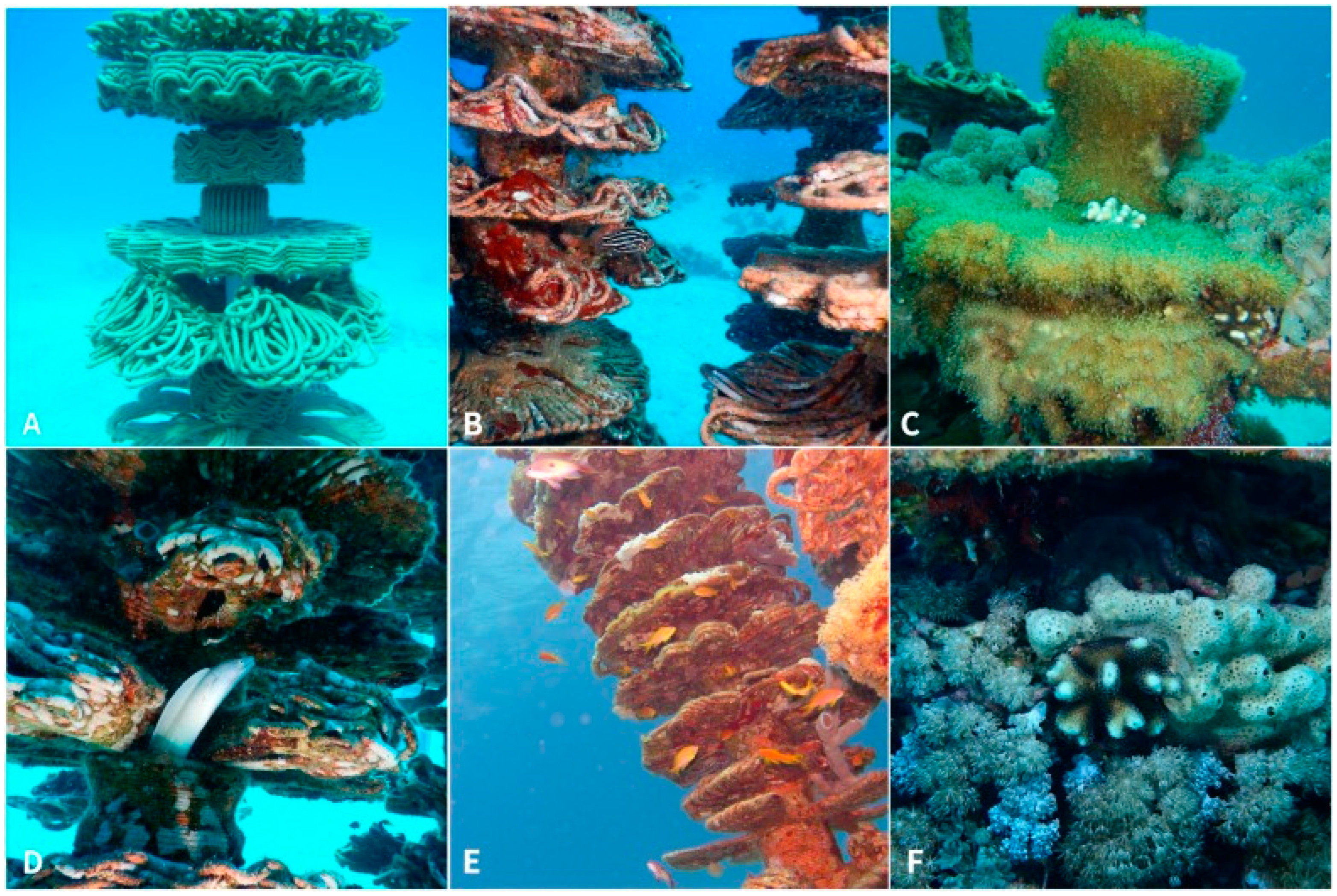

5. Case Studies, Including Impact on the Ecosystem

5.1. Marine Ecosystems

5.2. Development of Freshwater Systems

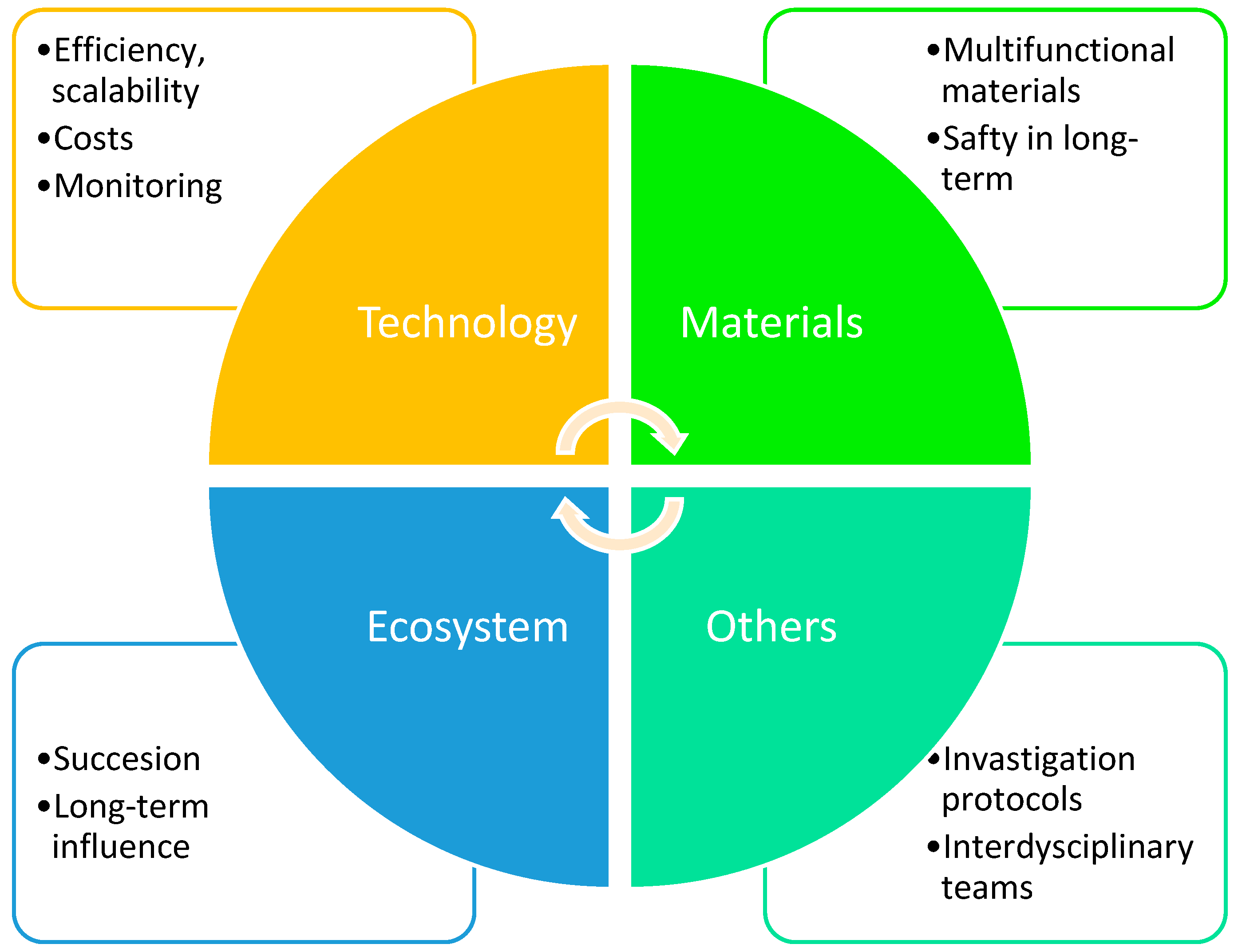

6. Challenges and Limitations

7. Predicted Directions for the Development of Artificial Reefs

8. Conclusions

- Numerical modeling is used mainly for wave simulation. There is a large potential to also use the modeling process for other purposes, such as the prediction of development, particularly of species or ecosystem growth.

- Nowadays, different additive manufacturing technologies are used for designing and manufacturing coral reefs. The most effective seems to be joining several of them in one project, which gives new possibilities for reef restoration.

- Currently, the most reliable seems to be the use of cementitious materials for artificial reef production using additive manufacturing technology; however, the usage of other materials, including biopolymers from biomass waste, seems to be a valuable option for the future.

- A lot of research confirms the benefits connected with artificial reefs for the restoration of ecosystems; however, the problems connected with potential “ocean sprawl” and the wide spreading of invasive species should be taken into consideration during planning the research.

- Still, a lot of challenges exist in the area of artificial reefs, which are connected with materials, additive technology, investigated ecosystems, and other areas. The exemplary challenges are a lack of previous research connected with the usage of 3D printing technologies for designing freshwater artificial reefs and the small number of investigations about the long-term function of artificial reefs.

- There a several areas that seem to be crucial for the further development of artificial reefs, including multifunctionality, digitalization, and the design of advanced materials. This topic seems to have a huge potential in further research, but it also requires joining competences form several scientific disciplines.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DLP | Digital Light Processing |

| FDM | Fused Deposition Modeling |

| FFF | Fused Filament Fabrication |

| PLA | polylactic acid |

| PHB | polyhydroxybutyrate |

| SCA | Selective Cement Activation |

| SLA | Stereolithography |

References

- Yuval, M.; Treibitz, T. Releasing a Dataset of 3D Models of Artificial Reefs from the Northern Red-Sea for 3D Printing and Virtual Reality Applications. Remote Sens. Appl. 2024, 36, 101305. [Google Scholar] [CrossRef]

- Seixas, L.B.; Barreto, N.R.; Santos, L.N.D. Artificial Reefs for Marine and Freshwater Fish Management in Brazil: Researchers Profile and Academic Production over the 1990–2010 Period. Oecol. Austr. 2013, 17, 374–385. [Google Scholar] [CrossRef]

- Frehse, F.D.A.; Derviche, P.; Pereira, F.W.; Hostim-Silva, M.; Vitule, J.R.S. Artificial Aquatic Habitats: A Systematic Literature Review and New Perspectives. Hydrobiologia 2025, 852, 1997–2012. [Google Scholar] [CrossRef]

- Freitas, C.E.C.; Petrere, M. Influence of Artificial Reefs on Fish Assemblage of the Barra Bonita Reservoir (São Paulo, Brazil). Lakes Reserv. 2001, 6, 273–278. [Google Scholar] [CrossRef]

- Santos, L.N.; Araújo, F.G.; Brotto, D.S. Artificial Structures as Tools for Fish Habitat Rehabilitation in a Neotropical Reservoir. Aquat. Conserv. 2008, 18, 896–908. [Google Scholar] [CrossRef]

- Santos, L.N.; García-Berthou, E.; Agostinho, A.A.; Latini, J.D. Fish Colonization of Artificial Reefs in a Large Neotropical Reservoir: Material Type and Successional Changes. Ecol. Appl. 2011, 21, 251–262. [Google Scholar] [CrossRef]

- Creque, S.M.; Raffenberg, M.J.; Brofka, W.A.; Dettmers, J.M. If You Build It, Will They Come? Fish and Angler Use at a Freshwater Artificial Reef. N. Am. J. Fish. Manag. 2006, 26, 702–713. [Google Scholar] [CrossRef]

- Freitas, C.E.C.; Petrere, M.; Barrella, W. Natural and Artificially-induced Habitat Complexity and Freshwater Fish Species Composition. Fish. Manag. Ecol. 2005, 12, 63–67. [Google Scholar] [CrossRef]

- Bao, H.; Nikolaeva, A.; Xia, J.; Ma, F. Evolution Trends and Future Prospects in Artificial Marine Reef Research: A 28-Year Bibliometric Analysis. Sustainability 2024, 17, 184. [Google Scholar] [CrossRef]

- Carr, M.H.; Robinson, S.P.; Wahle, C.; Davis, G.; Kroll, S.; Murray, S.; Schumacker, E.J.; Williams, M. The Central Importance of Ecological Spatial Connectivity to Effective Coastal Marine Protected Areas and to Meeting the Challenges of Climate Change in the Marine Environment. Aquat. Conserv. 2017, 27, 6–29. [Google Scholar] [CrossRef]

- Katiyar, K. Marine Resources: Plethora of Opportunities for Sustainable Future. In Marine Biomass; Thapar Kapoor, R., Rafatullah, M., Ismail, N., Eds.; De Gruyter: Berlin, Germany, 2024; pp. 367–388. ISBN 978-3-11-135395-1. [Google Scholar]

- Korniejenko, K.; Pławecka, K.; Kozub, B. An Overview for Modern Energy-Efficient Solutions for Lunar and Martian Habitats Made Based on Geopolymers Composites and 3D Printing Technology. Energies 2022, 15, 9322. [Google Scholar] [CrossRef]

- Korniejenko, K.; Gądek, S.; Dynowski, P.; Tran, D.H.; Rudziewicz, M.; Pose, S.; Grab, T. Additive Manufacturing in Underwater Applications. Appl. Sci. 2024, 14, 1346. [Google Scholar] [CrossRef]

- Dong, C.; Petrovic, M.; Davies, I.J. Applications of 3D Printing in Medicine: A Review. Ann. 3D Print. Med. 2024, 14, 100149. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.; Abdoli, H.; Diegel, O.; Chan, S.; Iliescu, M.; Ganetsos, T.; Munteanu, I.; Ungureanu, L. Additive Manufacturing for Surgical Planning and Education: A Review. Appl. Sci. 2024, 14, 2550. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- Strain, E.M.A.; Olabarria, C.; Mayer-Pinto, M.; Cumbo, V.; Morris, R.L.; Bugnot, A.B.; Dafforn, K.A.; Heery, E.; Firth, L.B.; Brooks, P.R.; et al. Eco-engineering Urban Infrastructure for Marine and Coastal Biodiversity: Which Interventions Have the Greatest Ecological Benefit? J. Appl. Ecol. 2018, 55, 426–441. [Google Scholar] [CrossRef]

- Sempere-Valverde, J.; Ostalé-Valriberas, E.; Farfán, G.M.; Espinosa, F. Substratum Type Affects Recruitment and Development of Marine Assemblages over Artificial Substrata: A Case Study in the Alboran Sea. Estuar. Coast. Shelf Sci. 2018, 204, 56–65. [Google Scholar] [CrossRef]

- Oren, A.; Berman, O.; Neri, R.; Edery-Lutri, M.; Chernihovsky, N.; Tarazi, E.; Shashar, N. Ecological Succession on 3D Printed Ceramic Artificial Reefs. Sci. Total Environ. 2024, 954, 176371. [Google Scholar] [CrossRef]

- Levy, N.; Berman, O.; Yuval, M.; Loya, Y.; Treibitz, T.; Tarazi, E.; Levy, O. Emerging 3D Technologies for Future Reformation of Coral Reefs: Enhancing Biodiversity Using Biomimetic Structures Based on Designs by Nature. Sci. Total Environ. 2022, 830, 154749. [Google Scholar] [CrossRef]

- Albalawi, H.I.; Khan, Z.N.; Valle-Pérez, A.U.; Kahin, K.M.; Hountondji, M.; Alwazani, H.; Schmidt-Roach, S.; Bilalis, P.; Aranda, M.; Duarte, C.M.; et al. Sustainable and Eco-Friendly Coral Restoration through 3D Printing and Fabrication. ACS Sustain. Chem. Eng. 2021, 9, 12634–12645. [Google Scholar] [CrossRef]

- Berman, O.; Weizman, M.; Oren, A.; Neri, R.; Parnas, H.; Shashar, N.; Tarazi, E. Design and Application of a Novel 3D Printing Method for Bio-Inspired Artificial Reefs. Ecol. Eng. 2023, 188, 106892. [Google Scholar] [CrossRef]

- Talekar, S.; Barrow, C.J.; Nguyen, H.C.; Zolfagharian, A.; Zare, S.; Farjana, S.H.; Macreadie, P.I.; Ashraf, M.; Trevathan-Tackett, S.M. Using Waste Biomass to Produce 3D-Printed Artificial Biodegradable Structures for Coastal Ecosystem Restoration. Sci. Total Environ. 2024, 925, 171728. [Google Scholar] [CrossRef] [PubMed]

- Scopus Analyze Search Results. Available online: https://www.scopus.com/term/analyzer.uri?sort=plf-f&src=s&sid=952515533c296d3c75e56105169cf326&sot=a&sdt=a&sl=52&s=%28TITLE-ABS-KEY%28reef%29+AND+TITLE-ABS-KEY%283D+printing%29%29&origin=resultslist&count=10&analyzeResults=Analyze+results (accessed on 17 March 2025).

- Vieira Da Silva, G.; Hamilton, D.; Strauss, D.; Murray, T.; Tomlinson, R. Sediment Pathways and Morphodynamic Response to a Multi-Purpose Artificial Reef—New Insights. Coast. Eng. 2022, 171, 104027. [Google Scholar] [CrossRef]

- Schuh, E.; Grilli, A.R.; Groetsch, F.; Grilli, S.T.; Crowley, D.; Ginis, I.; Stempel, P. Assessing the Morphodynamic Response of a New England Beach-Barrier System to an Artificial Reef. Coast. Eng. 2023, 184, 104355. [Google Scholar] [CrossRef]

- Kuang, C.; Ma, Y.; Han, X.; Pan, S.; Zhu, L. Experimental Observation on Beach Evolution Process with Presence of Artificial Submerged Sand Bar and Reef. J. Mar. Sci. Eng. 2020, 8, 1019. [Google Scholar] [CrossRef]

- Ma, Y.; Kuang, C.; Han, X.; Niu, H.; Zheng, Y.; Shen, C. Experimental Study on the Influence of an Artificial Reef on Cross-Shore Morphodynamic Processes of a Wave-Dominated Beach. Water 2020, 12, 2947. [Google Scholar] [CrossRef]

- Lowe, R.J.; Falter, J.L.; Monismith, S.G.; Atkinson, M.J. A Numerical Study of Circulation in a Coastal Reef-lagoon System. J. Geophys. Res. 2009, 114, 2008JC005081. [Google Scholar] [CrossRef]

- Lowe, R.J.; Hart, C.; Pattiaratchi, C.B. Morphological Constraints to Wave-driven Circulation in Coastal Reef-lagoon Systems: A Numerical Study. J. Geophys. Res. 2010, 115, 2009JC005753. [Google Scholar] [CrossRef]

- Taebi, S.; Lowe, R.J.; Pattiaratchi, C.B.; Ivey, G.N.; Symonds, G. A Numerical Study of the Dynamics of the Wave-Driven Circulation within a Fringing Reef System. Ocean Dyn. 2012, 62, 585–602. [Google Scholar] [CrossRef]

- Longuet-Higgins, M.S.; Stewart, R.W. Radiation Stresses in Water Waves; a Physical Discussion, with Applications. Deep Sea Res. Oceanogr. Abstr. 1964, 11, 529–562. [Google Scholar] [CrossRef]

- de Ridder, M.P. Non-Hydrostatic Wave Modelling of Coral Reefs with the Addition of a Porous in-Canopy Model. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Su, S.-F.; Ma, G. Modeling Two-Dimensional Infragravity Motions on a Fringing Reef. Ocean Eng. 2018, 153, 256–267. [Google Scholar] [CrossRef]

- Liu, C.; Onat, Y.; Jia, Y.; O’Donnell, J. Modeling Nearshore Dynamics of Extreme Storms in Complex Environments of Connecticut. Coast. Eng. 2021, 168, 103950. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, Z.; Monismith, S.G.; Lo, E.Y.M. 1DH Boussinesq Modeling of Wave Transformation over Fringing Reefs. Ocean Eng. 2012, 47, 30–42. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, Q.; Chen, S.; Tang, Z. Effects of Reef Morphology Variations on Wave Processes over Fringing Reefs. Appl. Ocean Res. 2019, 82, 52–62. [Google Scholar] [CrossRef]

- Yao, Y.; Becker, J.M.; Ford, M.R.; Merrifield, M.A. Modeling Wave Processes over Fringing Reefs with an Excavation Pit. Coast. Eng. 2016, 109, 9–19. [Google Scholar] [CrossRef]

- Buckley, M.; Lowe, R.; Hansen, J. Evaluation of Nearshore Wave Models in Steep Reef Environments. Ocean Dyn. 2014, 64, 847–862. [Google Scholar] [CrossRef]

- Lashley, C.H.; Roelvink, D.; Van Dongeren, A.; Buckley, M.L.; Lowe, R.J. Nonhydrostatic and Surfbeat Model Predictions of Extreme Wave Run-up in Fringing Reef Environments. Coast. Eng. 2018, 137, 11–27. [Google Scholar] [CrossRef]

- Torres-Freyermuth, A.; Brocchini, M.; Corvaro, S.; Pintado-Patiño, J.C. Wave Attenuation over Porous Seabeds: A Numerical Study. Ocean Model. 2017, 117, 28–40. [Google Scholar] [CrossRef]

- Ma, G.; Su, S.-F.; Liu, S.; Chu, J.-C. Numerical Simulation of Infragravity Waves in Fringing Reefs Using a Shock-Capturing Non-Hydrostatic Model. Ocean Eng. 2014, 85, 54–64. [Google Scholar] [CrossRef]

- Yao, Y.; He, F.; Tang, Z.; Liu, Z. A Study of Tsunami-like Solitary Wave Transformation and Run-up over Fringing Reefs. Ocean Eng. 2018, 149, 142–155. [Google Scholar] [CrossRef]

- Wu, Y.-T.; Yeh, C.-L.; Hsiao, S.-C. Three-Dimensional Numerical Simulation on the Interaction of Solitary Waves and Porous Breakwaters. Coast. Eng. 2014, 85, 12–29. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Love, P.E.D. Digital Reproduction of Historical Building Ornamental Components: From 3D Scanning to 3D Printing. Autom. Constr. 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Three-Dimensional Printing and 3D Scanning: Emerging Technologies Exhibiting High Potential in the Field of Cultural Heritage. Appl. Sci. 2023, 13, 4777. [Google Scholar] [CrossRef]

- Becher, A.F.; Zeidler, H.; Gądek, S.; Korniejenko, K. Shaping and Characterization of Additively Manufactured Geopolymer Materials for Underwater Applications. Appl. Sci. 2025, 15, 3449. [Google Scholar] [CrossRef]

- Matus, I.V.; Alves, J.L.; Góis, J.; Vaz-Pires, P.; Barata Da Rocha, A. Artificial Reefs through Additive Manufacturing: A Review of Their Design, Purposes and Fabrication Process for Marine Restoration and Management. Rapid Prototyp. J. 2024, 30, 87–122. [Google Scholar] [CrossRef]

- Jia, Y.; Abdelrahman, S.; Hauser, C.A.E. Developing a Sustainable Resin for 3D Printing in Coral Restoration. Mater. Sci. Addit. Manuf. 2024, 3, 3125. [Google Scholar] [CrossRef]

- Hitzegrad, J.; Brohmann, L.; Herding, F.; Pfennings, K.; Jonischkies, S.; Scharnbeck, E.; Mainka, J.; Mai, I.; Windt, C.; Kloft, H.; et al. Surfaces of Coastal Biogenic Structures: Exploiting Advanced Digital Design and Fabrication Strategies for the Manufacturing of Oyster Reef and Mussel Bed Surrogates. Front. Mar. Sci. 2024, 11, 1395025. [Google Scholar] [CrossRef]

- Tong, F.; Griffiths, T. Hydrodynamics for Subsea Systems. In Encyclopedia of Ocean Engineering; Cui, W., Fu, S., Hu, Z., Eds.; Springer Nature: Singapore, 2022; pp. 751–757. ISBN 978-981-10-6945-1. [Google Scholar]

- Piñeros, V.J.; Reveles-Espinoza, A.M.; Monroy, J.A. From Remote Sensing to Artificial Intelligence in Coral Reef Monitoring. Machines 2024, 12, 693. [Google Scholar] [CrossRef]

- Pondella, D.J.; Claisse, J.T.; Williams, C.M. Theory, Practice, and Design Criteria for Utilizing Artificial Reefs to Increase Production of Marine Fishes. Front. Mar. Sci. 2022, 9, 983253. [Google Scholar] [CrossRef]

- Carral, L.; Lamas, M.I.; Cartelle Barros, J.J.; López, I.; Carballo, R. Proposed Conceptual Framework to Design Artificial Reefs Based on Particular Ecosystem Ecology Traits. Biology 2022, 11, 680. [Google Scholar] [CrossRef]

- Gill, A.B.; Bremner, J.; Vanstaen, K.; Blake, S.; Mynott, F.; Lincoln, S. Limited Evidence Base for Determining Impacts (Or Not) of Offshore Wind Energy Developments on Commercial Fisheries Species. Fish Fish. 2025, 26, 155–170. [Google Scholar] [CrossRef]

- Skinner, C.; Cobain, M.R.D.; Zhu, Y.; Wyatt, A.S.J.; Polunin, N.V.C. Progress and Direction in the Use of Stable Isotopes to Understand Complex Coral Reef Ecosystems: A Review. In Oceanography and Marine Biology: An Annual Review, Volume 60; CRC Press: Boca Raton, FL, USA, 2022; pp. 373–432. ISBN 978-1-003-28860-2. [Google Scholar]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- Reyes, G.; Vega-Coloma, M.; Antonova, A.; Ajdary, R.; Jonveaux, S.; Flanigan, C.; Lautenbacher, N.; Rojas, O.J. Direct CO2 Capture by Alkali-Dissolved Cellulose and Sequestration in Building Materials and Artificial Reef Structures. Adv. Mater. 2023, 35, 2209327. [Google Scholar] [CrossRef] [PubMed]

- Jamil, A.; Ahmad, A.; Zhao, Y.; Zhao, Y.; Yang, C.; Li, Y.; Tu, J.; Niu, F.; Kong, W.; Liu, X. Advances in Global Oyster Reef Restoration: Innovations and Sustainable Ecological Approaches. Sustainability 2024, 16, 9795. [Google Scholar] [CrossRef]

- Dela Cruz, D.W.; Rinkevich, B.; Gomez, E.D.; Yap, H.T. Assessing an Abridged Nursery Phase for Slow Growing Corals Used in Coral Restoration. Ecol. Eng. 2015, 84, 408–415. [Google Scholar] [CrossRef]

- Temmink, R.J.M.; Angelini, C.; Fivash, G.S.; Swart, L.; Nouta, R.; Teunis, M.; Lengkeek, W.; Didderen, K.; Lamers, L.P.M.; Bouma, T.J.; et al. Life Cycle Informed Restoration: Engineering Settlement Substrate Material Characteristics and Structural Complexity for Reef Formation. J. Appl. Ecol. 2021, 58, 2158–2170. [Google Scholar] [CrossRef]

- Patti, A. Challenges to Improve Extrusion-Based Additive Manufacturing Process of Thermoplastics toward Sustainable Development. Macromol. Rapid Commun. 2024, 45, 2400249. [Google Scholar] [CrossRef]

- Ruhl, E.J.; Dixson, D.L. 3D Printed Objects Do Not Impact the Behavior of a Coral-Associated Damselfish or Survival of a Settling Stony Coral. PLoS ONE 2019, 14, e0221157. [Google Scholar] [CrossRef]

- Temmink, R.J.M.; Fivash, G.S.; Govers, L.L.; Nauta, J.; Marin-Diaz, B.; Cruijsen, P.M.J.M.; Didderen, K.; Penning, E.; Olff, H.; Heusinkveld, J.H.T.; et al. Initiating and Upscaling Mussel Reef Establishment with Life Cycle Informed Restoration: Successes and Future Challenges. Ecol. Eng. 2022, 175, 106496. [Google Scholar] [CrossRef]

- Green, D.S. Effects of Microplastics on European Flat Oysters, Ostrea Edulis and Their Associated Benthic Communities. Environ. Pollut. 2016, 216, 95–103. [Google Scholar] [CrossRef]

- Magara, G.; Khan, F.R.; Pinti, M.; Syberg, K.; Inzirillo, A.; Elia, A.C. Effects of Combined Exposures of Fluoranthene and Polyethylene or Polyhydroxybutyrate Microplastics on Oxidative Stress Biomarkers in the Blue Mussel (Mytilus edulis). J. Toxicol. Environ. Health Part A 2019, 82, 616–625. [Google Scholar] [CrossRef] [PubMed]

- Gatts, P.; Franco, M.; Dos Santos, L.; Rocha, D.; De Sá, F.; Netto, E.; Machado, P.; Masi, B.; Zalmon, I. Impact of Artificial Patchy Reef Design on the Ichthyofauna Community of Seasonally Influenced Shores at Southeastern Brazil. Aquat. Ecol. 2015, 49, 343–355. [Google Scholar] [CrossRef]

- Ly, O.; Yoris-Nobile, A.I.; Sebaibi, N.; Blanco-Fernandez, E.; Boutouil, M.; Castro-Fresno, D.; Hall, A.E.; Herbert, R.J.H.; Deboucha, W.; Reis, B.; et al. Optimisation of 3D Printed Concrete for Artificial Reefs: Biofouling and Mechanical Analysis. Constr. Build. Mater. 2021, 272, 121649. [Google Scholar] [CrossRef]

- Yoris-Nobile, A.I.; Slebi-Acevedo, C.J.; Lizasoain-Arteaga, E.; Indacoechea-Vega, I.; Blanco-Fernandez, E.; Castro-Fresno, D.; Alonso-Estebanez, A.; Alonso-Cañon, S.; Real-Gutierrez, C.; Boukhelf, F.; et al. Artificial Reefs Built by 3D Printing: Systematisation in the Design, Material Selection and Fabrication. Constr. Build. Mater. 2023, 362, 129766. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Yang, Z.; Ye, Y. Preliminary Investigation of Artificial Reef Concrete with Sulphoaluminate Cement, Marine Sand and Sea Water. Constr. Build. Mater. 2019, 211, 837–846. [Google Scholar] [CrossRef]

- O’Reilly, L.M.; Willerth, S.M. Evaluating the Biocompatibility of Ceramic Materials for Constructing Artificial Reefs. Front. Mar. Sci. 2024, 10, 1292584. [Google Scholar] [CrossRef]

- Srinivas, D.; Panda, B.; Suraneni, P.; Sitharam, T.G. Influence of Mixture Composition and Carbonation Curing on Properties of Sustainable 3D Printable Mortars. J. Clean. Prod. 2025, 492, 144894. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Peng, L.; Wang, N.; Meng, T.; Zhao, Y.; Gong, F. Preliminary Investigation and Life Cycle Assessment of Artificial Reefs with Recycled Brick-Concrete Aggregates. Constr. Build. Mater. 2024, 432, 136618. [Google Scholar] [CrossRef]

- Bone, J.R.; Stafford, R.; Hall, A.E.; Herbert, R.J.H. The Intrinsic Primary Bioreceptivity of Concrete in the Coastal Environment—A Review. Dev. Built Environ. 2022, 10, 100078. [Google Scholar] [CrossRef]

- Ido, S.; Shimrit, P.-F. Blue Is the New Green—Ecological Enhancement of Concrete Based Coastal and Marine Infrastructure. Ecol. Eng. 2015, 84, 260–272. [Google Scholar] [CrossRef]

- Kuang, W.; Pavlenko, P.; Guo, H.; Tian, K.; Liu, H.; Zhou, Z.; Duan, Y.; Shi, X. Utilization of Machine-Made Sand Waste in 3D-Printed Ecological Concrete for Artificial Reefs. Case Stud. Constr. Mater. 2025, 22, e04494. [Google Scholar] [CrossRef]

- Martins, J.R.; Novais, R.M.; Hotza, D.; Labrincha, J.A.; Senff, L. Waste-Derived Geopolymers for Artificial Coral Development by 3D Printing. J. Sustain. Metall. 2025, 11, 114–125. [Google Scholar] [CrossRef]

- Madirisha, M.M.; Dada, O.R.; Ikotun, B.D. Chemical Fundamentals of Geopolymers in Sustainable Construction. Mater. Today Sustain. 2024, 27, 100842. [Google Scholar] [CrossRef]

- Mohammed, J.S. Applications of 3D Printing Technologies in Oceanography. Methods Oceanogr. 2016, 17, 97–117. [Google Scholar] [CrossRef]

- Krishna, R.S.; Rehman, A.U.; Mishra, J.; Saha, S.; Korniejenko, K.; Rehman, R.U.; Salamci, M.U.; Sglavo, V.M.; Shaikh, F.U.A.; Qureshi, T.S. Additive Manufacturing of Geopolymer Composites for Sustainable Construction: Critical Factors, Advancements, Challenges, and Future Directions. Prog. Addit. Manuf. 2024, 10, 1003–1061. [Google Scholar] [CrossRef]

- Kalam, M.A.; Mieno, T.; Casareto, B.E. Development of Artificial Reefs Using Environmentally Safe Ceramic Material. J. Ecosyst. Ecogr. 2018, 8, 253. [Google Scholar] [CrossRef]

- Ponti, M.; Fava, F.; Perlini, R.A.; Giovanardi, O.; Abbiati, M. Benthic Assemblages on Artificial Reefs in the Northwestern Adriatic Sea: Does Structure Type and Age Matter? Mar. Environ. Res. 2015, 104, 10–19. [Google Scholar] [CrossRef]

- Levy, N.; Simon-Blecher, N.; Ben-Ezra, S.; Yuval, M.; Doniger, T.; Leray, M.; Karako-Lampert, S.; Tarazi, E.; Levy, O. Evaluating Biodiversity for Coral Reef Reformation and Monitoring on Complex 3D Structures Using Environmental DNA (eDNA) Metabarcoding. Sci. Total Environ. 2023, 856, 159051. [Google Scholar] [CrossRef]

- Berman, O.; Levy, N.; Parnas, H.; Levy, O.; Tarazi, E. Exploring New Frontiers in Coral Nurseries: Leveraging 3D Printing Technology to Benefit Coral Growth and Survival. J. Mar. Sci. Eng. 2023, 11, 1695. [Google Scholar] [CrossRef]

- Parker, T.A.; Gallegos, J.A.; Beaver, J.; Brick, M.; Brown, J.K.; Cichy, K.; Debouck, D.G.; Delgado-Salinas, A.; Dohle, S.; Ernest, E.; et al. Genetic Resources and Breeding Priorities in Phaseolus Beans: Vulnerability, Resilience, and Future Challenges. In Plant Breeding Reviews; Goldman, I., Ed.; Wiley: Hoboken, NJ, USA, 2022; pp. 289–420. ISBN 978-1-119-87412-6. [Google Scholar]

- Riera, E.; Hubas, C.; Ungermann, M.; Rigot, G.; Pey, A.; Francour, P.; Rossi, F. Artificial Reef Effectiveness Changes among Types as Revealed by Underwater Hyperspectral Imagery. Restor. Ecol. 2023, 31, e13978. [Google Scholar] [CrossRef]

- 3DPARE Artificial Reef 3D Printing for Atlantic Area. Available online: https://www.giteco.unican.es/proyectos/3dpare/index.html (accessed on 17 March 2025).

- Hall, A.E.; Herbert, R.J.H.; Stafford, R.; Jones, G.; Greenhill, S.; Pinto, I.S.; Reis, B.; Van Der Linden, P.; Boutouil, M.; Sebaibi, N.; et al. 3D Printed Habitat Enhancement Units: Key Features to Incorporate within Multifunctional Infrastructure. In Coasts, Marine Structures and Breakwaters 2023: Resilience and Adaptability in a Changing Climate; Emerald Publishing Limited: Portsmouth, UK, 2024; pp. 969–984. [Google Scholar]

- Ahirwal, J.; Maiti, S.K. Ecological Restoration of Abandoned Mine Land: Theory to Practice. In Handbook of Ecological and Ecosystem Engineering; Prasad, M.N.V., Ed.; Wiley: Hoboken, NJ, USA, 2021; pp. 231–246. ISBN 978-1-119-67853-3. [Google Scholar]

- Wan, Y.; Kong, Q.; Du, H.; Yang, W.; Zha, W.; Li, W. Effectiveness of Artificial Reefs in Enhancing Phytoplankton Community Dynamics: A Meta-Analysis. Sci. Total Environ. 2024, 947, 174593. [Google Scholar] [CrossRef] [PubMed]

- Matthiopoulos, J.; Fieberg, J.; Aarts, G. Species-Habitat Associations: Spatial Data, Predictive Models, and Ecological Insights, 2nd ed.; University of Minnesota Libraries Publishing: Minneapolis, MN, USA, 2023; ISBN 978-1-946135-93-3. [Google Scholar]

- Kalita, T.L.; Mingaleova, O.N.; Khatuntsov, D.S.; Zhavnerov, A.N. Freshwater Artificial Reefs as a Way to Increase of the Productivity; European Publisher: London, UK, 2022; pp. 68–74. [Google Scholar]

- Zhu, H.; Liu, X.; Cheng, S.; Wang, J. Effects of Artificial Reefs on Phytoplankton Community Structure in Baiyangdian Lake, China. Water 2021, 13, 1802. [Google Scholar] [CrossRef]

- Guilbeau, B.P.; Harry, F.P.; Gambrell, R.P.; Knopf, F.C.; Dooley, K.M. Algae Attachment on Carbonated Cements in Fresh and Brackish Waters—Preliminary Results. Ecol. Eng. 2003, 20, 309–319. [Google Scholar] [CrossRef]

- Frehse, F.D.A.; Weyl, O.L.F.; Vitule, J.R.S. Differential Use of Artificial Habitats by Native and Non-Native Fish Species in Neotropical Reservoirs. Hydrobiologia 2021, 848, 2355–2367. [Google Scholar] [CrossRef]

- Raeini, L.I.; Negarestan, H.; Khoee, A.J. An Ecological Investigation on Colonization of Fresh Water Artificial Reefs. J. Environ. Hydrol. 2007, 15, 1–9. [Google Scholar]

- Leonard, C.; Hédouin, L.; Lacorne, M.C.; Dalle, J.; Lapinski, M.; Blanc, P.; Nugues, M.M. Performance of Innovative Materials as Recruitment Substrates for Coral Restoration. Restor. Ecol. 2022, 30, e13625. [Google Scholar] [CrossRef]

- Accardo, S.; Schiavo, S.; Parrella, L.; Montereali, M.R.; Lama, G.; Verdolotti, L.; Manzo, S. Do New Cement-Based Mortars Pose a Significant Threat to the Aquatic Environment? Chemosphere 2023, 332, 138818. [Google Scholar] [CrossRef]

- Ma, H.; Pu, S.; Liu, S.; Bai, Y.; Mandal, S.; Xing, B. Microplastics in Aquatic Environments: Toxicity to Trigger Ecological Consequences. Environ. Pollut. 2020, 261, 114089. [Google Scholar] [CrossRef]

- Zuo, X.; Zhou, Y.; Hao, K.; Liu, C.; Yu, R.; Huang, A.; Wu, C.; Yang, Y. 3D Printed All-Natural Hydrogels: Flame-Retardant Materials Toward Attaining Green Sustainability. Adv. Sci. 2024, 11, 2306360. [Google Scholar] [CrossRef]

- Ding, C.; Li, C.; Xiong, Z.; Li, Z. Computer Big Data Technology in Additive Manufacturing and Product Design in Sustainable Manufacturing. Int. J. Adv. Manuf. Technol. 2024, 135, 4855–4863. [Google Scholar] [CrossRef]

- Hassan, A.; Alomayri, T.; Noaman, M.F.; Zhang, C. 3D Printed Concrete for Sustainable Construction: A Review of Mechanical Properties and Environmental Impact. Arch. Comput. Methods Eng. 2025. [Google Scholar] [CrossRef]

- Peng, X.; Chen, K.; Jia, W.; Li, K.; Huang, C.; Liu, X. Stacking Sequence Optimization of Variable Thickness Composite Laminated Plate Based on Multi-Peak Stacking Sequence Table. Compos. Struct. 2025, 356, 118886. [Google Scholar] [CrossRef]

- Chen, S.; Khan, S.B.; Li, N.; Xiao, C. In-Depth Analysis of Sintering, Exposure Time, and Layer Height (Um) in LRS 3D Printed Devices with DLP. J. Manuf. Process. 2025, 133, 576–591. [Google Scholar] [CrossRef]

- Lee, H. Engineering In Vitro Models: Bioprinting of Organoids with Artificial Intelligence. Cyborg Bionic Syst. 2023, 4, 0018. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W.; Lu, J.; Tanveer, M.; Qi, Z.; Fu, C.; Xie, H.; Zhuang, L.; Hu, Z. Current Research Hotspots and Frontier Trends on Carbon Budget of Coastal Wetlands: A Bibliometric Analysis. Water Sci. Technol. 2024, 89, 3104–3121. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, H.; Lin, Q.; Zhang, C.; He, C.; Zheng, H. Exploring the International Research Landscape of Blue Carbon: Based on Scientometrics Analysis. Ocean Coast. Manag. 2024, 252, 107106. [Google Scholar] [CrossRef]

- Tasneem, S.; Ahsan, M.N. A Bibliometric Analysis on Mangrove Ecosystem Services: Past Trends and Emerging Interests. Ocean Coast. Manag. 2024, 256, 107276. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, C.; Li, X.; Wang, Y.; Sun, P.; Xu, X.; Wang, H.; Chen, Y.; Lin, J.; Huang, G.; et al. International Mangrove Carbon Sink Research Analysis. Reg. Stud. Mar. Sci. 2024, 77, 103681. [Google Scholar] [CrossRef]

- Hao, Q.; Song, Z.; Zhang, X.; He, D.; Guo, L.; Van Zwieten, L.; Yu, C.; Wang, Y.; Wang, W.; Fang, Y.; et al. Organic Blue Carbon Sequestration in Vegetated Coastal Wetlands: Processes and Influencing Factors. Earth-Sci. Rev. 2024, 255, 104853. [Google Scholar] [CrossRef]

- Derviche, P.; Menegotto, A.; Lana, P. Carbon Budget Trends in Octocorals: A Literature Review with Data Reassessment and a Conceptual Framework to Understand Their Resilience to Environmental Changes. Mar. Biol. 2022, 169, 159. [Google Scholar] [CrossRef]

- Coppari, M.; Zanella, C.; Rossi, S. The Importance of Coastal Gorgonians in the Blue Carbon Budget. Sci. Rep. 2019, 9, 13550. [Google Scholar] [CrossRef]

- Rowland, P.I.; Lovelock, C.E. Global Impacts of Introduced Ungulates on Wetland Carbon and Biodiversity: A Review. Biol. Conserv. 2024, 290, 110432. [Google Scholar] [CrossRef]

- Gao, K.; Beardall, J. Using Macroalgae to Address UN Sustainable Development Goals through CO2 Remediation and Improvement of the Aquaculture Environment. Appl. Phycol. 2022, 3, 360–367. [Google Scholar] [CrossRef]

- Nasvi, M.C.M.; Ranjith, P.G.; Sanjayan, J. Effect of Different Mix Compositions on Apparent Carbon Dioxide (CO2) Permeability of Geopolymer: Suitability as Well Cement for CO2 Sequestration Wells. Appl. Energy 2014, 114, 939–948. [Google Scholar] [CrossRef]

- Freire, A.L.; José, H.J.; Moreira, R.D.F.P.M. Potential Applications for Geopolymers in Carbon Capture and Storage. Int. J. Greenh. Gas Control 2022, 118, 103687. [Google Scholar] [CrossRef]

- Minelli, M.; Medri, V.; Papa, E.; Miccio, F.; Landi, E.; Doghieri, F. Geopolymers as Solid Adsorbent for CO2 Capture. Chem. Eng. Sci. 2016, 148, 267–274. [Google Scholar] [CrossRef]

- Mendrik, F.; Houseago, R.C.; Hackney, C.R.; Parsons, D.R. Microplastic Trapping Efficiency and Hydrodynamics in Model Coral Reefs: A Physical Experimental Investigation. Environ. Pollut. 2024, 342, 123094. [Google Scholar] [CrossRef]

- Wei, J.; Wan, F.; Zhang, P.; Zeng, Z.; Ping, H.; Xie, J.; Zou, Z.; Wang, W.; Xie, H.; Shen, Z.; et al. Bioprocess-Inspired Synthesis of Printable, Self-Healing Mineral Hydrogels for Rapidly Responsive, Wearable Ionic Skin. Chem. Eng. J. 2021, 424, 130549. [Google Scholar] [CrossRef]

- Vidal, M.; Mills, S.C.; Gairin, E.; Bertucci, F.; Lecchini, D. Validation of a Novel Immersive Virtual Reality Set-up with Responses of Wild-Caught Freely Moving Coral Reef Fish. Anim. Behav. 2023, 206, 99–123. [Google Scholar] [CrossRef]

- Korniejenko, K.; Kontny, B. The Usage of Virtual and Augmented Reality in Underwater Archeology. Appl. Sci. 2024, 14, 8188. [Google Scholar] [CrossRef]

- Vijayan, M.; Mustapha, S.; Aljibori, H.S.S.; Al-Tamimi, A.; Mohammed, M.N.; Alfiras, M. The Development of the MSU MyCoral Virtual Reality Application: An Innovative Approach to Educating Students on the Imperative of Coral Reef Rehabilitation. In Proceedings of the 2023 IEEE 8th International Conference on Engineering Technologies and Applied Sciences (ICETAS), Bahrain, 25 October 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

| No | Solution | Research Area | Source |

|---|---|---|---|

| 1 | Building a reef from piles of car tires placed on a wooden support—dimensions 2.45 m × 1.05 m × 1.25 m | A river in Brazil where the impact of introducing artificial reefs on fish communities in a tropical hypereutrophic reservoir was assessed | [4] |

| 2 | Reefs made of piles of car tires placed on a wooden support—dimensions 2.45 m × 1.05 m × 1.25 m | The impact of habitat complexity induced by artificial reef construction on fish communities in a reservoir in Brazil | [8] |

| 3 | Structure consisting of cement discs (weight: 25 g, diameter 39 mm, thickness: 13 mm). Cements enriched with silica (pozzolanic), blast furnace slag, and fly ash were used for the construction | Assessment of the suitability of different cements as substrates for the construction of artificial reefs based on the occurrence of microalgae populations on the structures in the USA | [94] |

| 4 | An artificial reef built of granite rubble | Impact on the number of different fish species in the USA | [7] |

| 5 | A round frame made of 19 mm diameter polyvinyl chloride (PVC) pipe with standard dimensions (diameter 1.8 m and surface area 2.5 m2). Polyethylene ropes were attached radially to the rope to tie bunches of plants | Effects on the number of different fish species in the oligotrophic reservoir in Brazil | [5] |

| 6 | The artificial reefs were constructed from ceramics, concrete, and polyvinyl chloride (PVC) by arranging pipes of the individual materials with a length of 1.0 m and a diameter of 0.3 m in a pyramidal frame (10 pipes in a 4:3:2:1 arrangement from the base to the top) | Influence of reef material (ceramics, concrete, and PVC) on its colonization by fish in Itaipu Reservoir in Brazil | [6] |

| 7 | Two artificial structures: pipes and trees and two semi-natural rocks. The pipe structure was built from ceramic pipes 0.8 m long and 0.25 m in diameter. The structure is in the shape of a pyramid made of 10 pipes. The wooden structure was composed of four pine trees | Experimental verification of the use of artificial habitats by fish in two neotropical reservoirs (2 water reservoirs in Brazil). Determination of the relationship between the type of habitat and the impact on selected species | [95] |

| 8 | Artificial reef consisting of biomass modules, each measuring 900 mm × 900 mm × 120 mm. Raw materials were mainly derived from by-products of biomass energy production from crops and forest residues | Research on the structure of phytoplankton communities around an artificial reef and its adjacent waters in China | [93] |

| 9 | Four types of artificial reefs (cemented rope, brick, wood, and ceramic) were tested over a period of six months | Benthic species were studied. Colonization was faster and denser on bricks and ceramics. The study was conducted in a freshwater pond filled with water from a river in Iran | [96] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korniejenko, K.; Oliwa, K.; Gądek, S.; Dynowski, P.; Źróbek, A.; Lin, W.-T. A Review of Additive Manufacturing Techniques in Artificial Reef Construction: Materials, Processes, and Ecological Impact. Appl. Sci. 2025, 15, 4216. https://doi.org/10.3390/app15084216

Korniejenko K, Oliwa K, Gądek S, Dynowski P, Źróbek A, Lin W-T. A Review of Additive Manufacturing Techniques in Artificial Reef Construction: Materials, Processes, and Ecological Impact. Applied Sciences. 2025; 15(8):4216. https://doi.org/10.3390/app15084216

Chicago/Turabian StyleKorniejenko, Kinga, Kacper Oliwa, Szymon Gądek, Piotr Dynowski, Anna Źróbek, and Wei-Ting Lin. 2025. "A Review of Additive Manufacturing Techniques in Artificial Reef Construction: Materials, Processes, and Ecological Impact" Applied Sciences 15, no. 8: 4216. https://doi.org/10.3390/app15084216

APA StyleKorniejenko, K., Oliwa, K., Gądek, S., Dynowski, P., Źróbek, A., & Lin, W.-T. (2025). A Review of Additive Manufacturing Techniques in Artificial Reef Construction: Materials, Processes, and Ecological Impact. Applied Sciences, 15(8), 4216. https://doi.org/10.3390/app15084216