Optimization of Processing Parameters of Powder Metallurgy for Preparing AZ31/GNP Nanocomposites Using Taguchi Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Matrix and Reinforcement Material

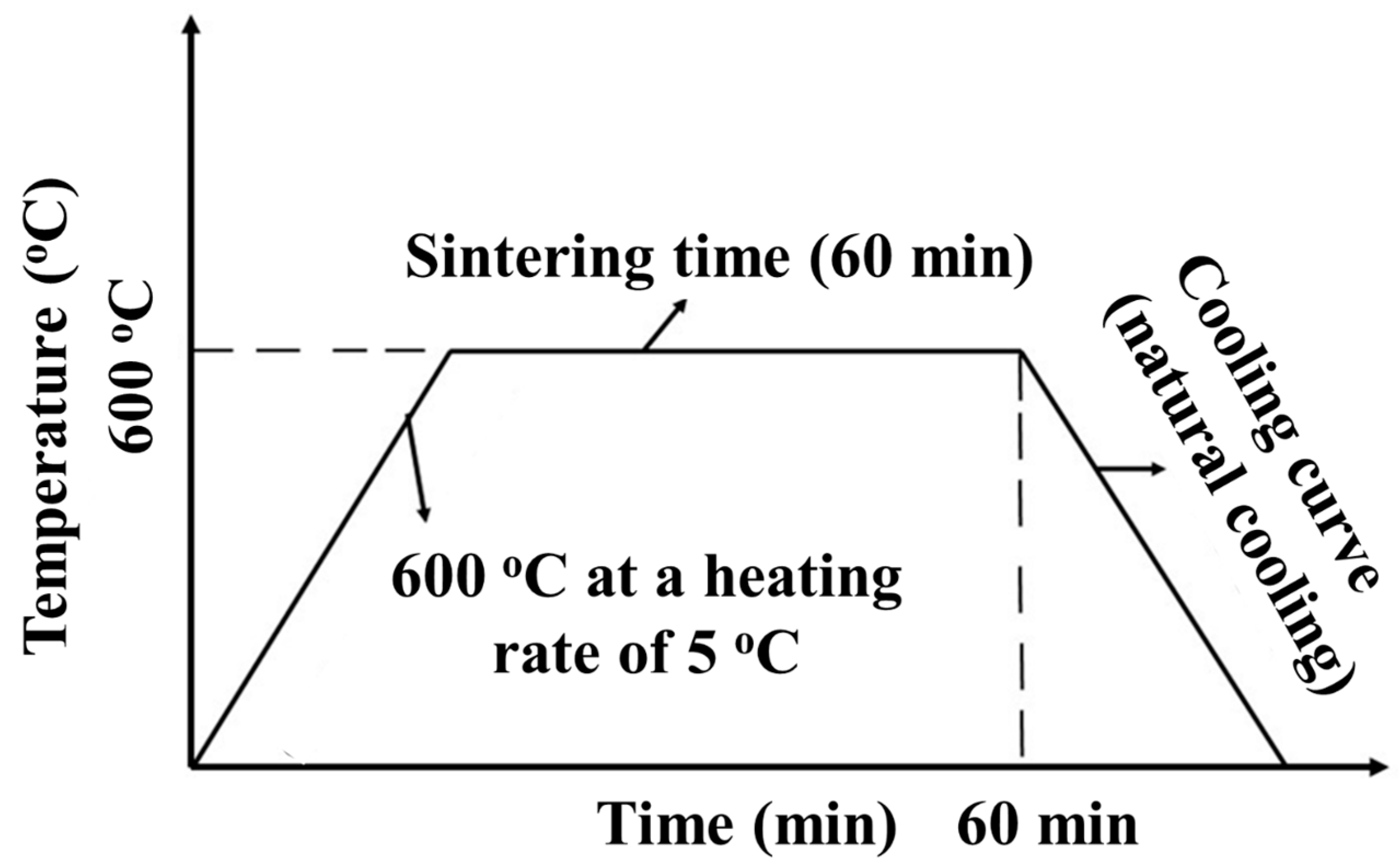

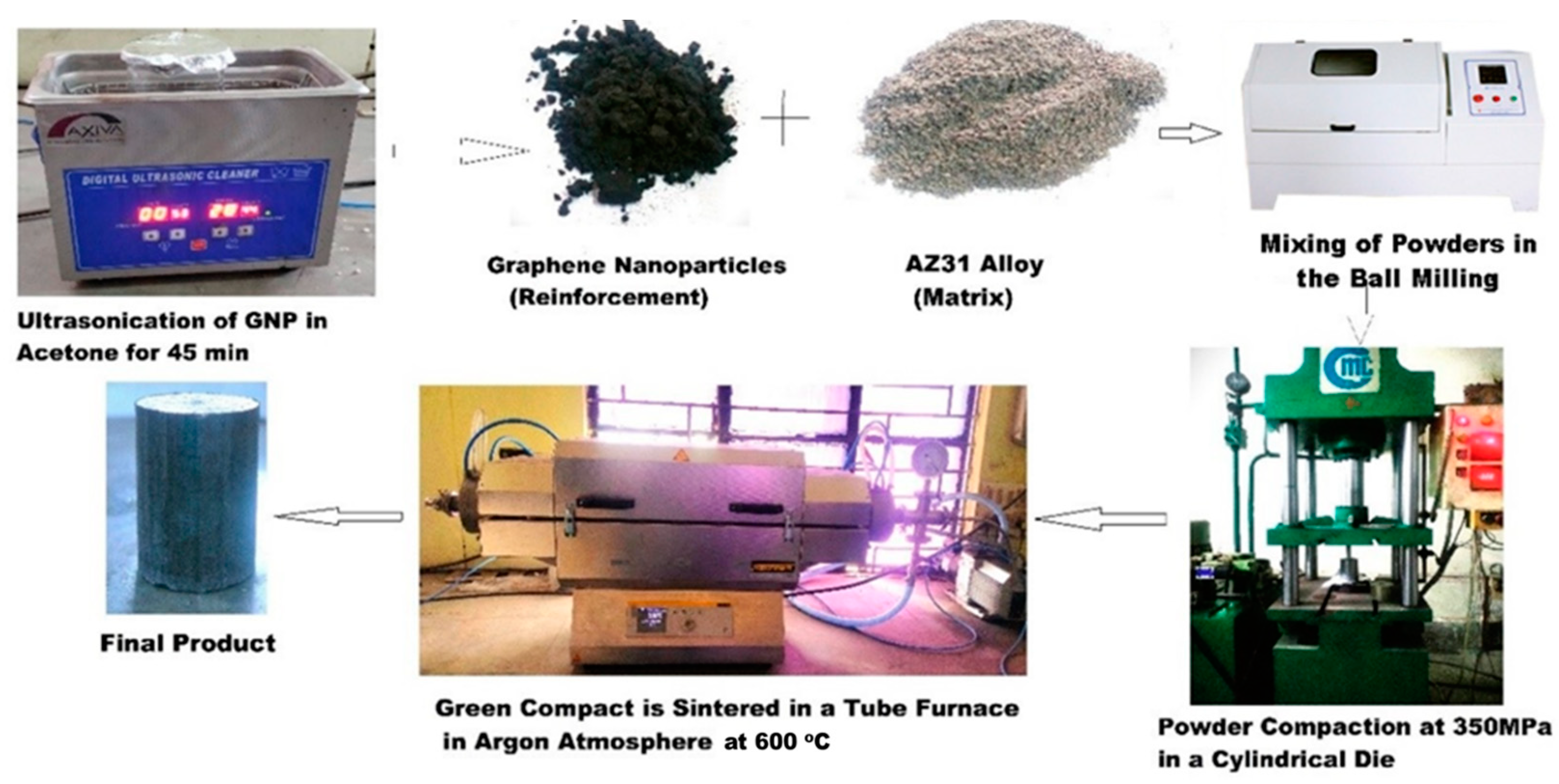

2.2. Methodology

2.3. Characterization, Testing, and Experimentation

Optimization Technique: Taguchi Method

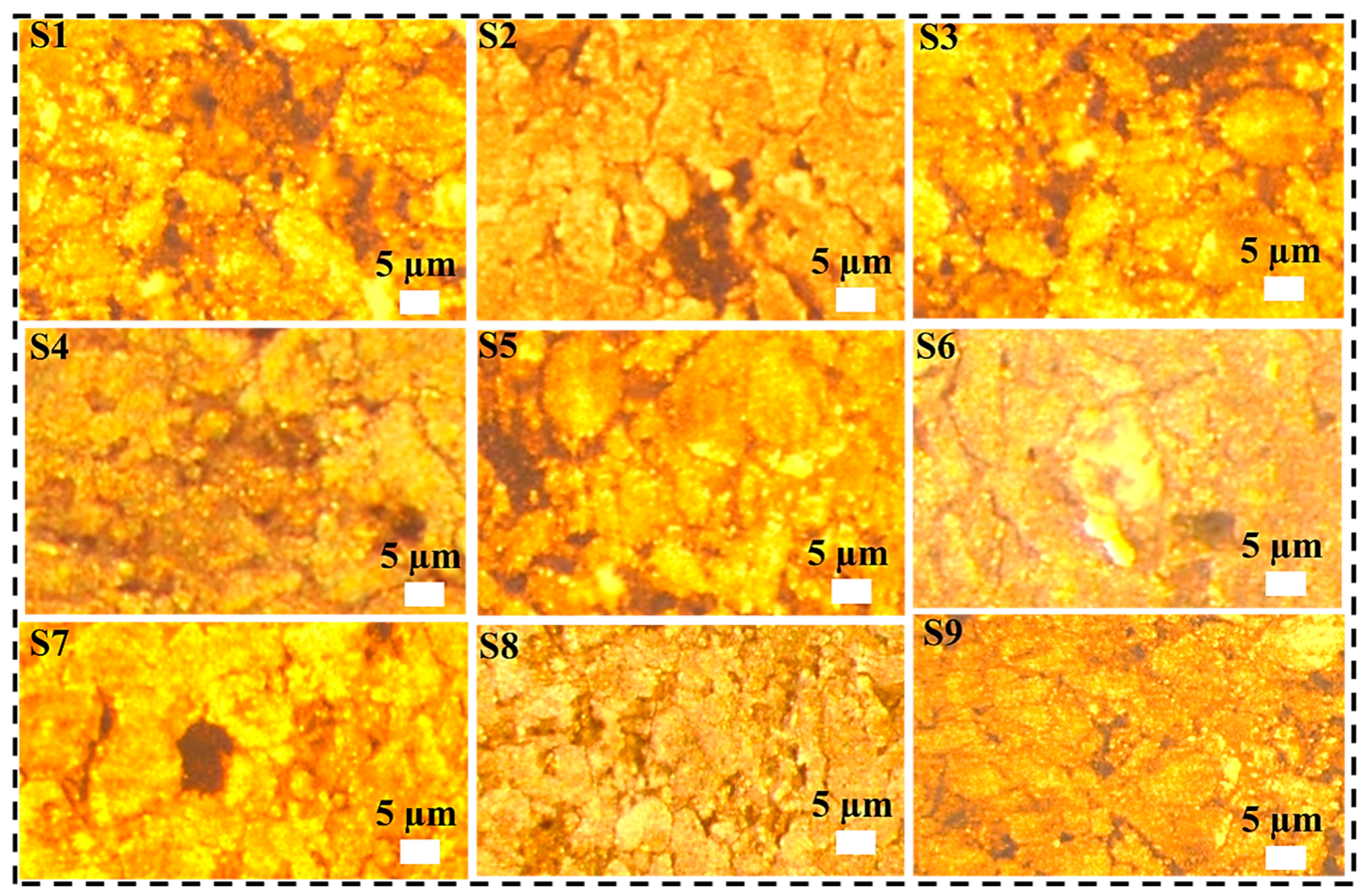

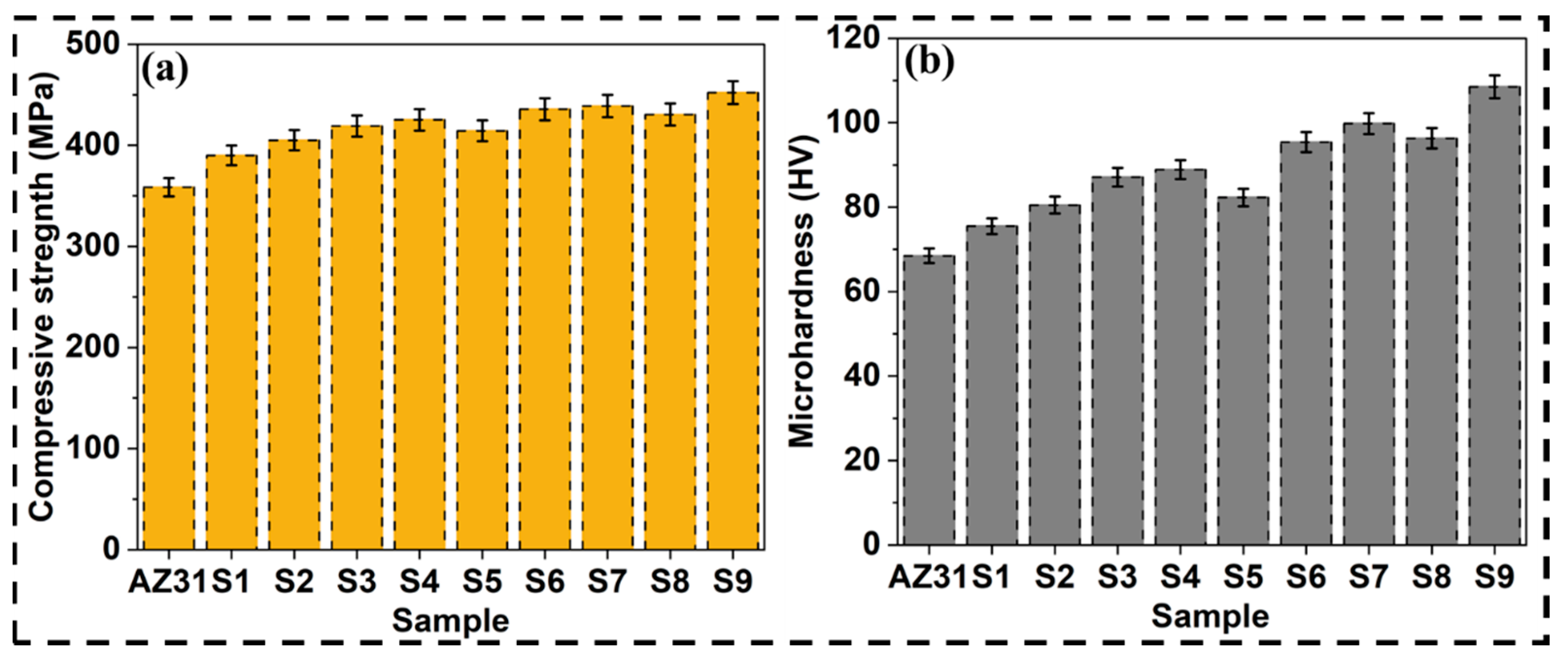

3. Results and Discussion

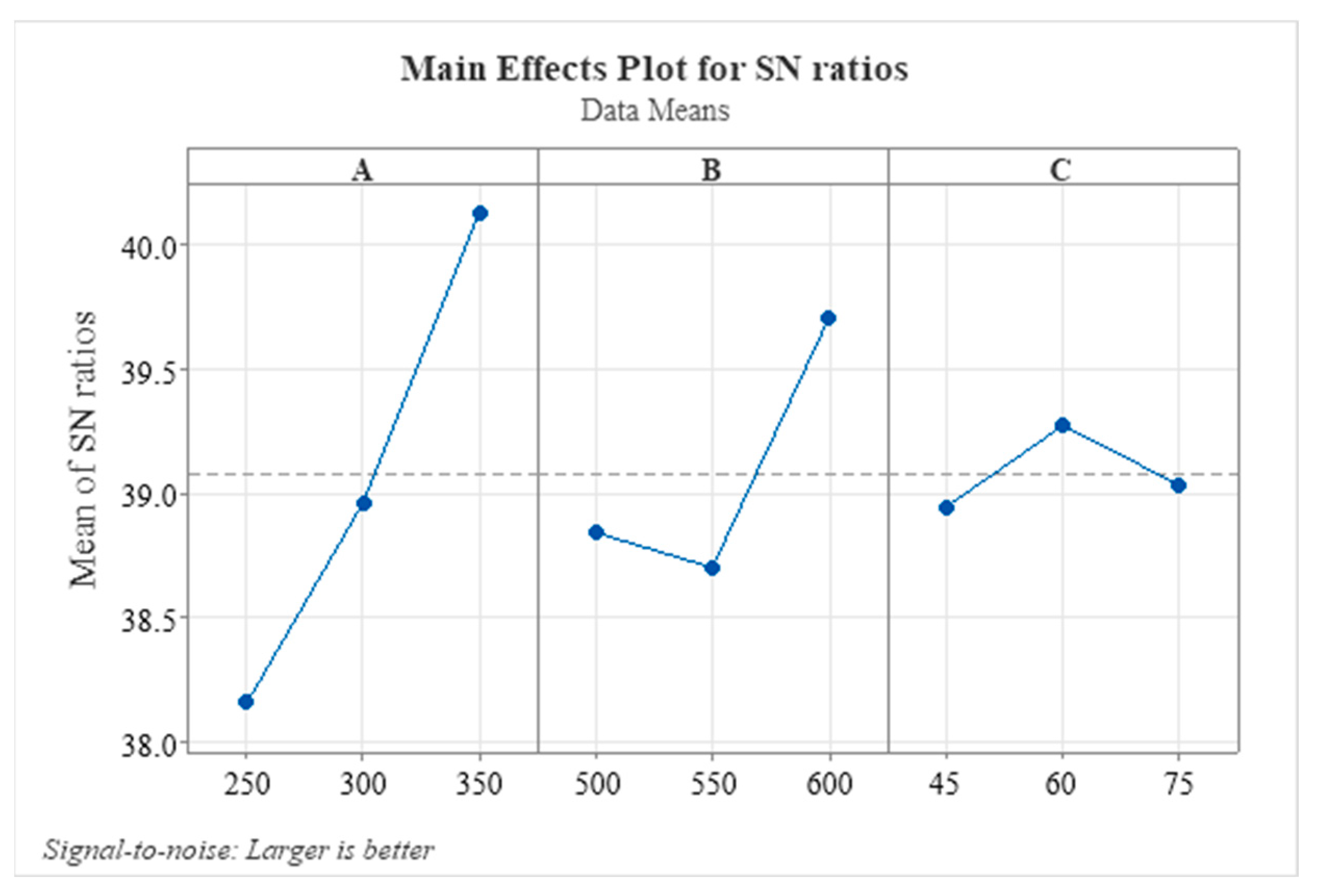

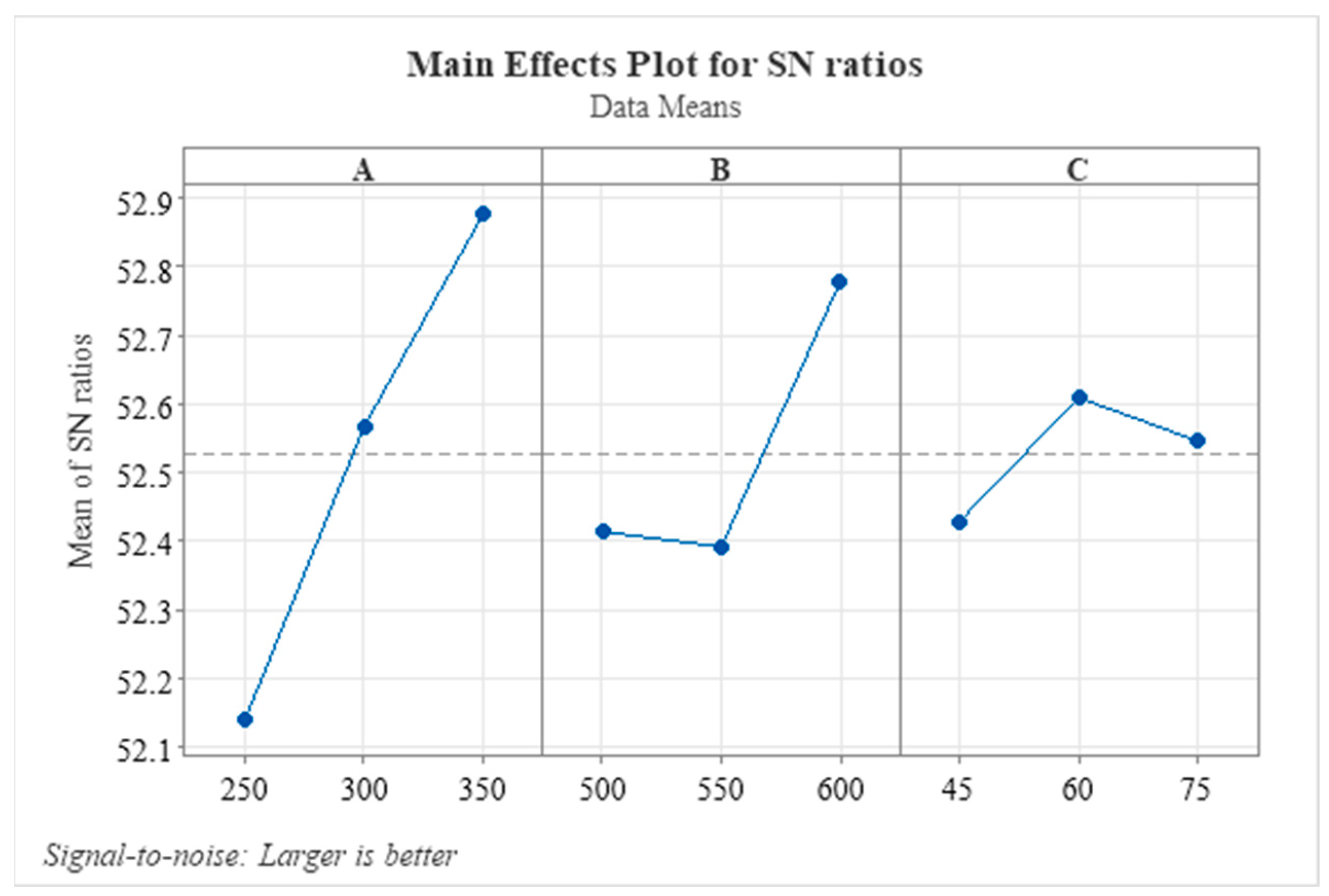

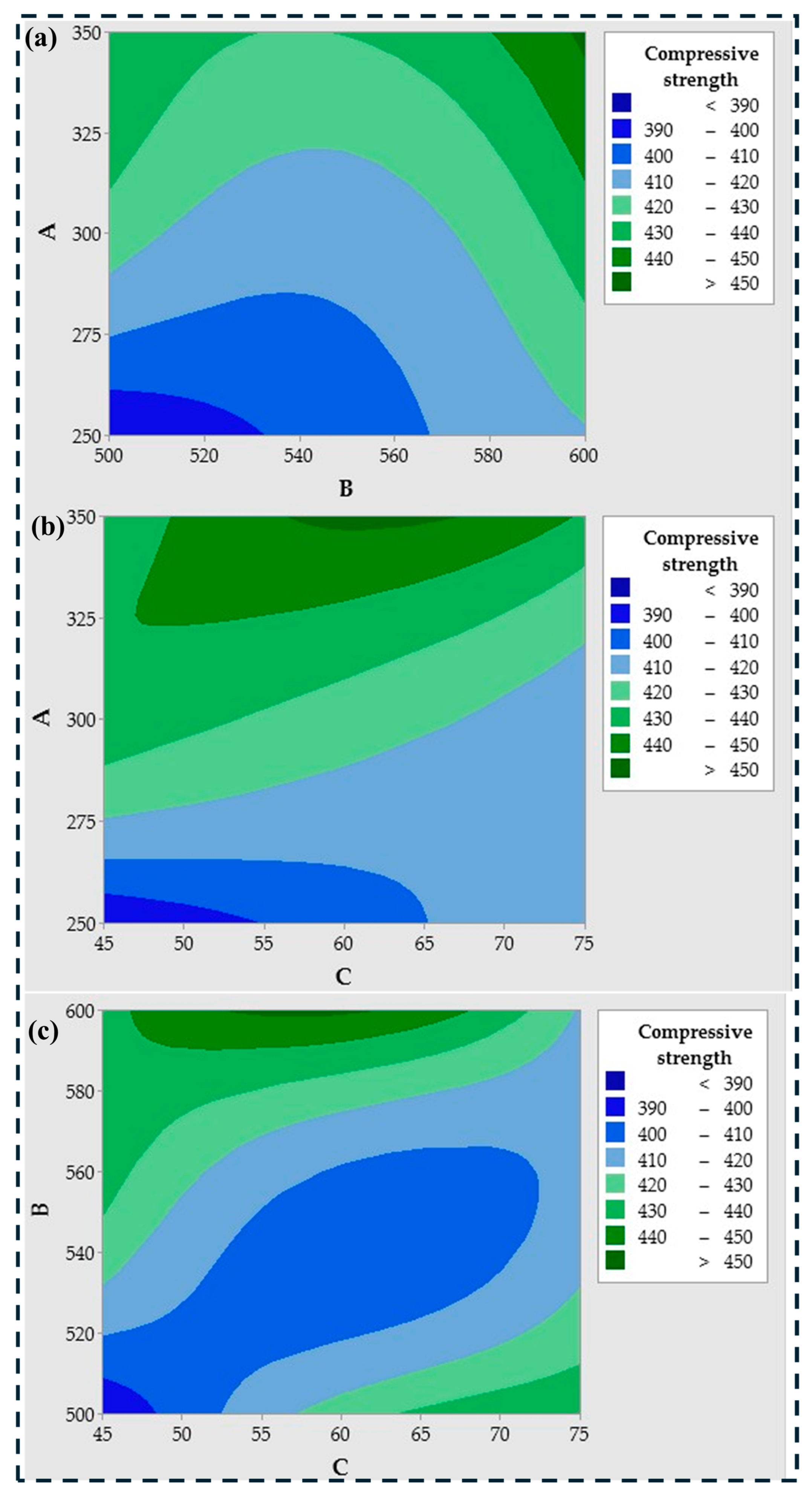

3.1. Statistical Analysis

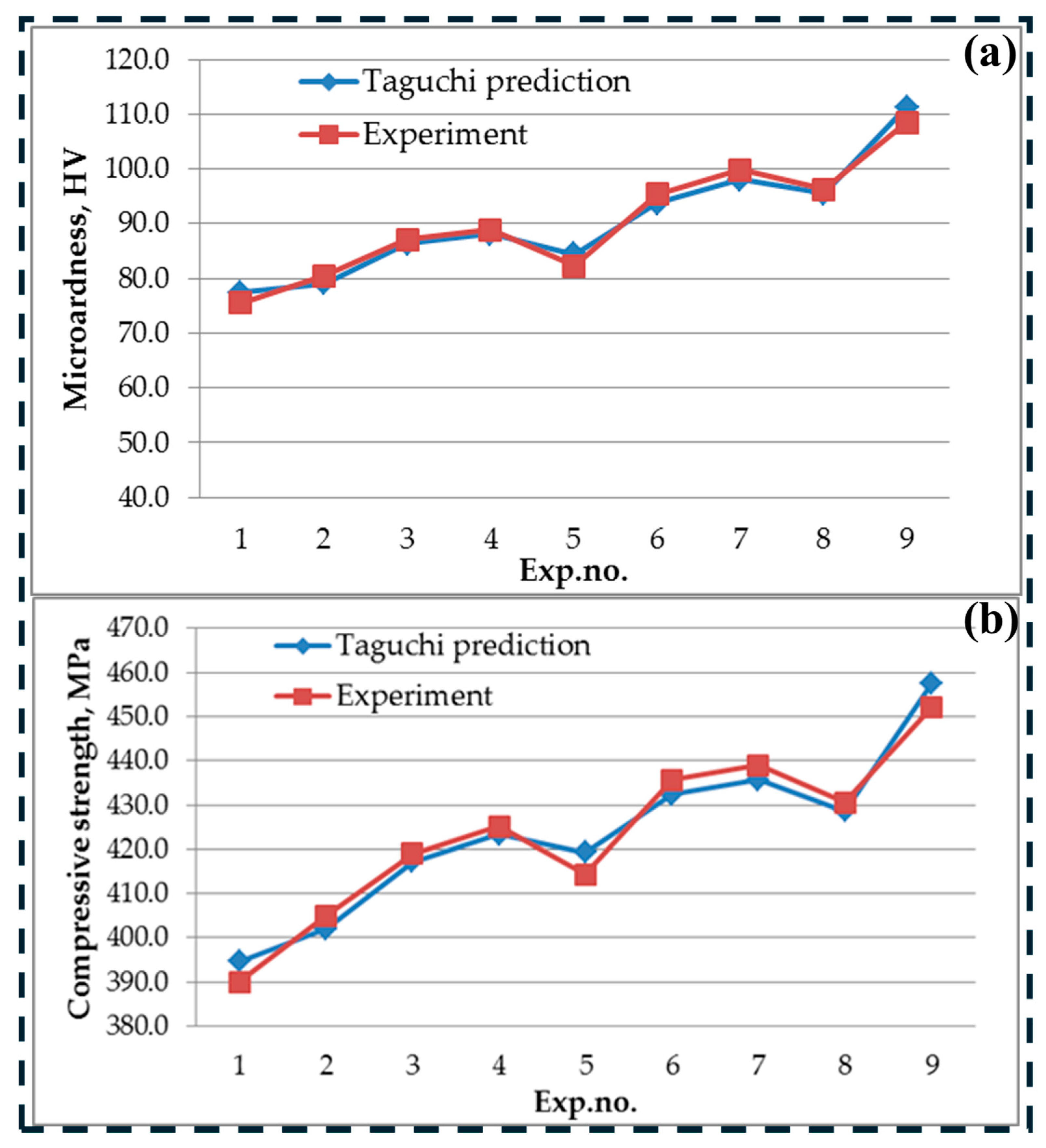

3.2. Validation of Results

4. Conclusions

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anbuchezhiyan, G.; Mubarak, N.M.; Karri, R.R.; Khalid, M. A synergistic effect on enriching the Mg–Al–Zn alloy-based hybrid composite properties. Sci. Rep. 2022, 12, 20053. [Google Scholar] [CrossRef] [PubMed]

- Bahmani, A.; Lotfpour, M.; Taghizadeh, M.; Kim, W.J. Corrosion behavior of severely plastically deformed Mg and Mg alloys. J. Magnes. Alloys 2022, 10, 2607–2648. [Google Scholar] [CrossRef]

- Abazari, S.; Shamsipur, A.; Bakhsheshi-Rad, H.R.; Ismail, A.F.; Sharif, S.; Razzaghi, M.; Ramakrishna, S.; Berto, F. Carbon nanotubes (CNTs)-reinforced magnesium-based matrix composites: A comprehensive review. Materials 2020, 13, 4421. [Google Scholar] [CrossRef]

- Bhoi, N.K.; Singh, H.; Pratap, S. Developments in the aluminum metal matrix composites reinforced by micro/nano particles–A review. J. Compos. Mater. 2020, 54, 813–833. [Google Scholar] [CrossRef]

- Krstic, J.; Jovanovic, J.; Gajevic, S.; Miladinovic, S.; Vaxevanidis, N.; Kiss, I.; Stojanovic, B. Application of Metal Matrix Nanocomposites in Engineering. Adv. Eng. Lett. 2024, 3, 180–190. [Google Scholar] [CrossRef]

- Meher, A.; Mahapatra, M.M.; Samal, P.; Vundavilli, P.R. A review on manufacturability of magnesium matrix composites: Processing, tribology, joining, and machining. CIRP J. Manuf. Sci. Technol. 2022, 39, 134–158. [Google Scholar] [CrossRef]

- Eacherath, S.; Murugesan, S. Synthesis and characterization of magnesium-based hybrid composites—A review. Int. J. Mater. Res. 2018, 109, 661–672. [Google Scholar] [CrossRef]

- Sharma, S.K.; Saxena, K.K.; Salem, K.H.; Mohammed, K.A.; Singh, R.; Prakash, C. Effects of various fabrication techniques on the mechanical characteristics of metal matrix composites: A review. Adv. Mater. Process. Technol. 2024, 10, 277–294. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Paramore, J.D.; Sun, P.; Chandran, K.R.; Zhang, Y.; Xia, Y.; Cao, F.; Koopman, M.; Free, M. Powder metallurgy of titanium–past, present, and future. Int. Mater. Rev. 2018, 63, 407–459. [Google Scholar] [CrossRef]

- Attia, U.M. Cold-isostatic pressing of metal powders: A review of the technology and recent developments. Crit. Rev. Solid State Mater. Sci. 2021, 46, 587–610. [Google Scholar] [CrossRef]

- Wu, L.; Wu, R.; Hou, L.; Zhang, J.; Sun, J.; Zhang, M. Microstructure and mechanical properties of CNT-reinforced AZ31 matrix composites prepared using hot-press sintering. J. Mater. Eng. Perform. 2017, 26, 5495–5500. [Google Scholar] [CrossRef]

- Kavimani, V.; Soorya Prakash, K.; Thankachan, T. Investigation of graphene-reinforced magnesium metal matrix composites processed through a solvent-based powder metallurgy route. Bull. Mater. Sci. 2019, 42, 1–9. [Google Scholar] [CrossRef]

- Raja, K.S.; Srikanth, S.; Arif, S.; ArunKumar, T.; Hemanandh, J.; Ganesan, S.; Kumar, J.S. Mechanical and Micro-structural behaviour of graphene coated with magnesium alloy. Mater. Today Proc. 2021, 44, 3589–3594. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Asif, M.; Li, L. Enhanced ductility of Mg–3Al–1Zn alloy reinforced with short length multi-walled carbon nanotubes using a powder metallurgy method. Prog. Nat. Sci. Mater. Int. 2015, 25, 276–281. [Google Scholar] [CrossRef]

- Jayakumar, J.; Raghunath, B.K.; Rao, T.H. Investigation on fracture mechanisms in Mg alloy AZ31 nano composites reinforced with multi wall carbon nano tubes. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 4753–4758. [Google Scholar]

- Zhou, M.; Qu, X.; Ren, L.; Fan, L.; Zhang, Y.; Guo, Y.; Quan, G.; Tang, Q.; Liu, B.; Sun, H. The effects of carbon nanotubes on the mechanical and wear properties of AZ31 alloy. Materials 2017, 10, 1385. [Google Scholar] [CrossRef]

- Zhang, B.T.; Zheng, X.; Li, H.F.; Lin, J.M. Application of carbon-based nanomaterials in sample preparation: A review. Anal. Chim. Acta 2013, 784, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi, B.; Shamanian, M.; Cavaliere, P.; Ashrafizadeh, F. Effect of processing parameters on the microstructural and mechanical properties of aluminum–carbon nanotube composites produced by spark plasma sintering. Int. J. Mater. Res. 2018, 109, 900–909. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Wang, H. Densification and grain growth during sintering of nanosized particles. Int. Mater. Rev. 2008, 53, 326–352. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.A.; Sánchez-Sánchez, X.; Zapata-Hidalgo, D.; Mullo, J.L.; Puma-Araujo, S.D. Influence of the processing parameters on the microstructure and mechanical properties of 316L stainless steel fabricated by laser powder bed fusion. J. Manuf. Mater. Process. 2024, 8, 35. [Google Scholar] [CrossRef]

- Kumar, N.; Soren, S.; Prasad, R.; Singh, Y.; Nautiyal, H.; Sharma, A.; Tiang, S.S.; Lim, W.H. Optimization of sintering process parameters by taguchi method for developing Al-CNT-Reinforced powder composites. Crystals 2023, 13, 1352. [Google Scholar] [CrossRef]

- Sahoo, S.; Jha, B.B.; Mantry, S. Optimization of process parameters of hot consolidated steel matrix composites by taguchi method. JOM 2024, 76, 818–828. [Google Scholar] [CrossRef]

- Calaph, Y.C.; Shanawaz, A.M.; SankarGanesh, P.S.P.; Kavitha, S.; Gnanakumar, N.; Arunprasath, K. Optimization study of hybrid aluminium metal matrix composite using proposed Taguchi method. Interactions 2024, 245, 95. [Google Scholar] [CrossRef]

- Tahir, N.A.M.; Abdollah, M.F.B.; Tamaldin, N.; Amiruddin, H.; Mohamad Zin, M.R.B. A brief review on the wear mechanisms and interfaces of carbon based materials. Compos. Interfaces 2018, 25, 491–513. [Google Scholar] [CrossRef]

- Wei, L.K.; Abd Rahim, S.Z.; Al Bakri Abdullah, M.M.; Yin, A.T.M.; Ghazali, M.F.; Omar, M.F.; Nemeș, O.; Sandu, A.V.; Vizureanu, P.; Abdellah, A.E.H. Producing metal powder from machining chips using ball milling process: A review. Materials 2023, 16, 4635. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Chen, T.; Xu, H.; Ma, J. Achieving a heterogeneous lamella-structured aluminum alloy with excellent synergy of strength and ductility by powder thixoforming. Mater. Sci. Eng. A 2022, 838, 142781. [Google Scholar] [CrossRef]

- ASTM E9-09; Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM E384-08; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2010.

- Mokhtari, S.; Eftekhari Yekta, B.; Marghussian, V.; Ahmadi, P.T. Synthesis and characterization of biodegradable AZ31/calcium phosphate glass composites for orthopedic applications. Adv. Compos. Hybrid Mater. 2020, 3, 390–401. [Google Scholar] [CrossRef]

- Veličković, S.; Stojanović, B.; Babić, M.; Vencl, A.; Bobić, I.; Vadaszne Bognar, G.; Vučetić, F. Parametric optimization of the aluminium nanocomposites wear rate. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 19. [Google Scholar] [CrossRef]

- Gajević, S.; Miladinović, S.; Güler, O.; Özkaya, S.; Stojanović, B. Optimization of dry sliding wear in hot-pressed Al/B4C metal matrix composites using Taguchi method and ANN. Materials 2024, 17, 4056. [Google Scholar] [CrossRef]

| Elements | Mg | Al | Zn | Mn | Si | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|---|

| Distribution (%) | 95.09 | 2.80 | 1.75 | 0.20 | 0.10 | 0.05 | 0.005 | 0.005 |

| S. No | Properties | AZ31 Alloy |

|---|---|---|

| 1. | Tensile strength | 260 MPa |

| 2. | Yield strength | 200 MPa |

| 3. | Purity | 99% |

| 4. | Density | 1.77 g/cc |

| 5. | Elongation | 15% |

| 6. | Brinell hardness | 49 BHN |

| S. No | Properties | Graphene Nanoparticles |

|---|---|---|

| 1. | Purity | >99% |

| 2. | Tensile modulus | >1000 GPa |

| 3. | Length | 5–10 microns |

| 4. | Thickness | 5–10 nm |

| 5. | Density | 2.5 g/cc |

| 6. | Thermal conductivity | 2000 watt/m-k |

| 7. | Surface area | 200–240 m2/g |

| 8. | Number of layers | Layers |

| Symbol Notation | Control Factor | Unit | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|

| A | Compaction pressure | MPa | 250 | 300 | 350 |

| B | Sintering temperature | °C | 500 | 550 | 600 |

| C | Sintering time | min | 45 | 60 | 75 |

| Sample | A | B | C |

|---|---|---|---|

| S1 | 250 | 500 | 45 |

| S2 | 250 | 550 | 60 |

| S3 | 250 | 600 | 75 |

| S4 | 300 | 500 | 60 |

| S5 | 300 | 550 | 75 |

| S6 | 300 | 600 | 45 |

| S7 | 350 | 500 | 75 |

| S8 | 350 | 550 | 45 |

| S9 | 350 | 600 | 60 |

| Sample | Microhardness (Hv) | Compressive Strength (MPa) | S/N for Microhardness (dB) | S/N for Compressive Strength (dB) | Prediction for Microhardness (dB) | Prediction for Compressive Strength (dB) |

|---|---|---|---|---|---|---|

| S1 | 75.5 | 390 | 37.5589 | 51.8213 | 37.7800 | 51.9243 |

| S2 | 80.5 | 405 | 38.1159 | 52.1491 | 37.9656 | 52.0835 |

| S3 | 87.1 | 419 | 38.8004 | 52.4443 | 38.7296 | 52.4069 |

| S4 | 88.9 | 425.2 | 38.9780 | 52.5719 | 38.9073 | 52.5344 |

| S5 | 82.3 | 414.3 | 38.3080 | 52.3463 | 38.5290 | 52.4493 |

| S6 | 95.4 | 435.7 | 39.5910 | 52.7838 | 39.4407 | 52.7181 |

| S7 | 99.8 | 438.9 | 39.9826 | 52.8473 | 39.8323 | 52.7817 |

| S8 | 96.3 | 430.5 | 39.6725 | 52.6795 | 39.6018 | 52.6420 |

| S9 | 108.5 | 452.2 | 40.7086 | 53.1066 | 40.9296 | 53.2097 |

| Microhardness | Compressive Strength | |||||

|---|---|---|---|---|---|---|

| Level | A | B | C | A | B | C |

| 1 | 38.16 | 38.84 | 38.94 | 52.14 | 52.41 | 52.43 |

| 2 | 38.96 | 38.70 | 39.27 | 52.57 | 52.39 | 52.61 |

| 3 | 40.12 | 39.70 | 39.03 | 52.88 | 52.78 | 52.55 |

| Delta | 1.96 | 1.00 | 0.33 | 0.74 | 0.39 | 0.18 |

| Rank | 1 | 2 | 3 | 1 | 2 | 3 |

| Microhardness | |||||||

|---|---|---|---|---|---|---|---|

| Source | DF | Seq SS | Adj SS | Adj MS | F | p | % |

| A | 2 | 5.8445 | 5.8445 | 2.92225 | 25.48 | 0.038 | 72.99 |

| B | 2 | 1.7620 | 1.7620 | 0.88101 | 7.68 | 0.115 | 22.01 |

| C | 2 | 0.1710 | 0.1710 | 0.08550 | 0.75 | 0.573 | 2.14 |

| Residual Error | 2 | 0.2293 | 0.2293 | 0.11467 | 2.86 | ||

| Total | 8 | 8.0069 | 100.00 | ||||

| R-Sq (97.14%), R-Sq(adj) (88.54%) | |||||||

| Compressive Strength | |||||||

| Source | DF | Seq SS | Adj SS | Adj MS | F | p | % |

| A | 2 | 0.82748 | 0.82748 | 0.41374 | 16.90 | 0.056 | 68.38 |

| B | 2 | 0.28296 | 0.28296 | 0.14148 | 5.78 | 0.148 | 23.38 |

| C | 2 | 0.05064 | 0.05064 | 0.02532 | 1.03 | 0.492 | 4.18 |

| Residual Error | 2 | 0.04897 | 0.04897 | 0.02448 | 4.05 | ||

| Total | 8 | 1.21005 | 100.00 | ||||

| R-Sq (95.95%), R-Sq(adj) 83.81% | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, S.K.; Ivanović, L.; Gajević, S.; Sharma, L.K.; Sharma, Y.; Miladinović, S.; Stojanović, B. Optimization of Processing Parameters of Powder Metallurgy for Preparing AZ31/GNP Nanocomposites Using Taguchi Method. Appl. Sci. 2025, 15, 4181. https://doi.org/10.3390/app15084181

Sharma SK, Ivanović L, Gajević S, Sharma LK, Sharma Y, Miladinović S, Stojanović B. Optimization of Processing Parameters of Powder Metallurgy for Preparing AZ31/GNP Nanocomposites Using Taguchi Method. Applied Sciences. 2025; 15(8):4181. https://doi.org/10.3390/app15084181

Chicago/Turabian StyleSharma, Sachin Kumar, Lozica Ivanović, Sandra Gajević, Lokesh Kumar Sharma, Yogesh Sharma, Slavica Miladinović, and Blaža Stojanović. 2025. "Optimization of Processing Parameters of Powder Metallurgy for Preparing AZ31/GNP Nanocomposites Using Taguchi Method" Applied Sciences 15, no. 8: 4181. https://doi.org/10.3390/app15084181

APA StyleSharma, S. K., Ivanović, L., Gajević, S., Sharma, L. K., Sharma, Y., Miladinović, S., & Stojanović, B. (2025). Optimization of Processing Parameters of Powder Metallurgy for Preparing AZ31/GNP Nanocomposites Using Taguchi Method. Applied Sciences, 15(8), 4181. https://doi.org/10.3390/app15084181