Durability of Mortars with Partial Cement Replacement by Recycled Brick Powder

Abstract

1. Introduction

2. Experimental Plan

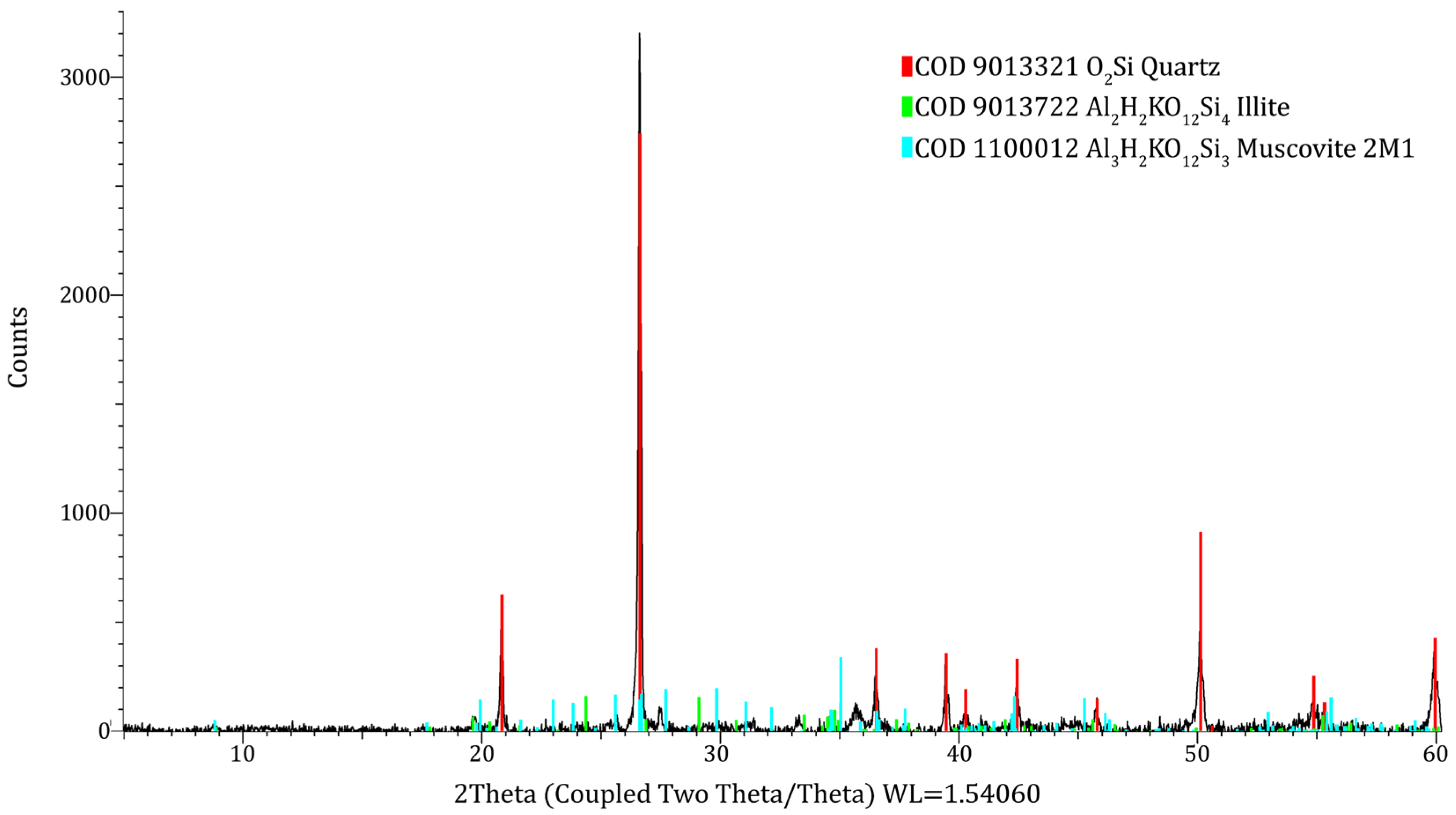

2.1. Materials

2.2. Methods

- Water-accessible porosity

- Carbonation resistance

- Chloride diffusion resistance

- Electrical resistivity

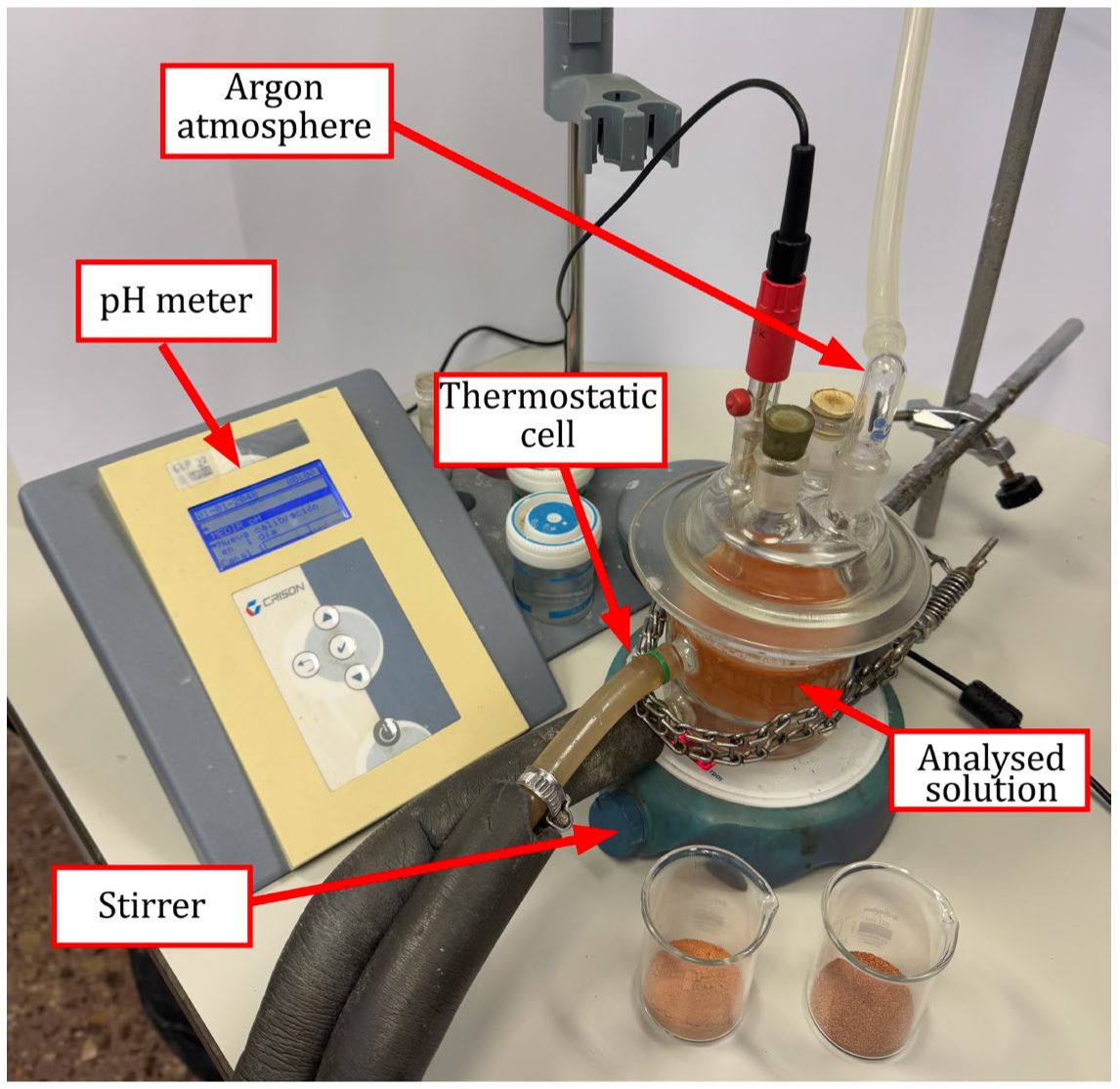

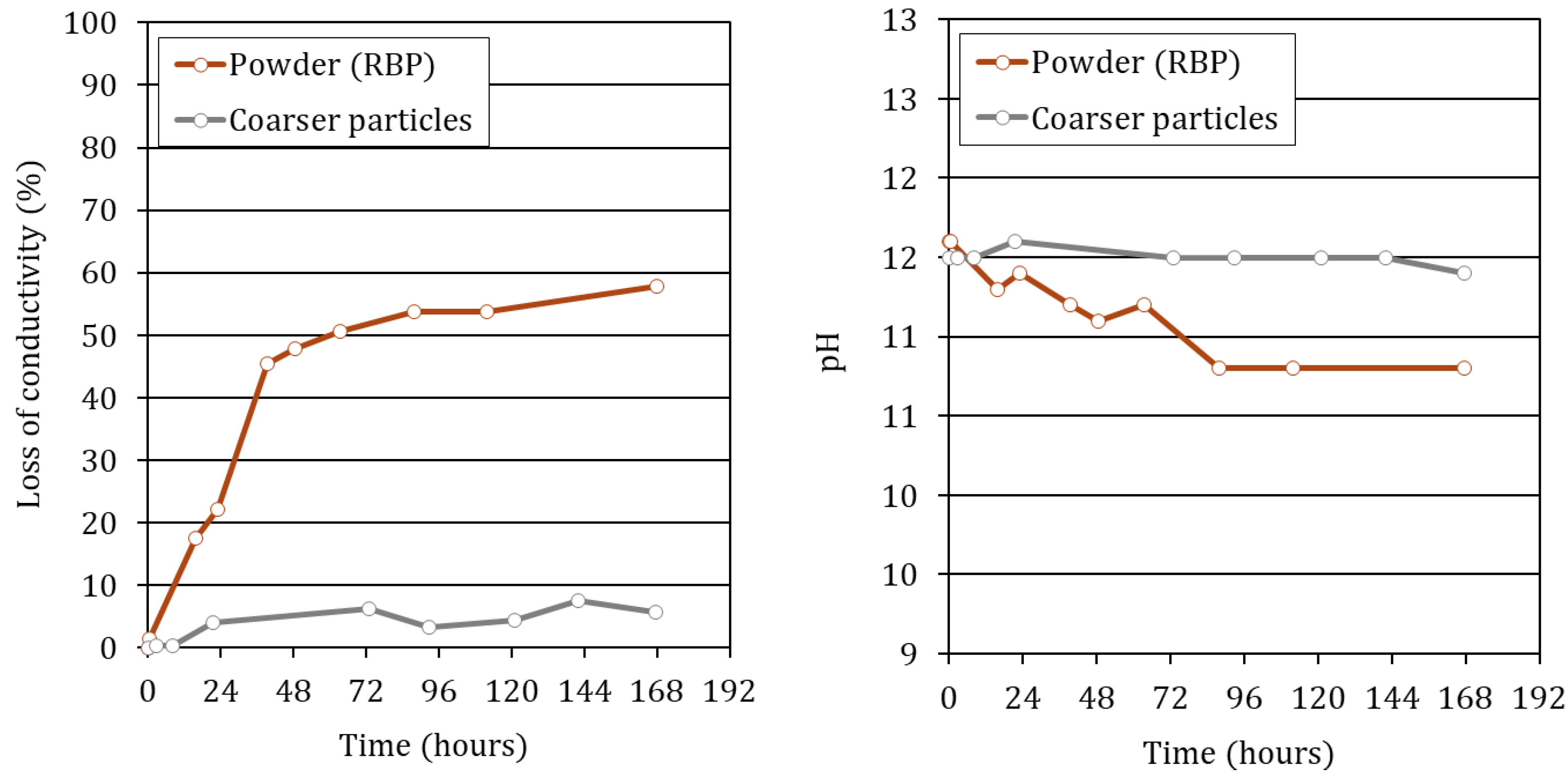

- Electrical conductivity and pH

3. Results

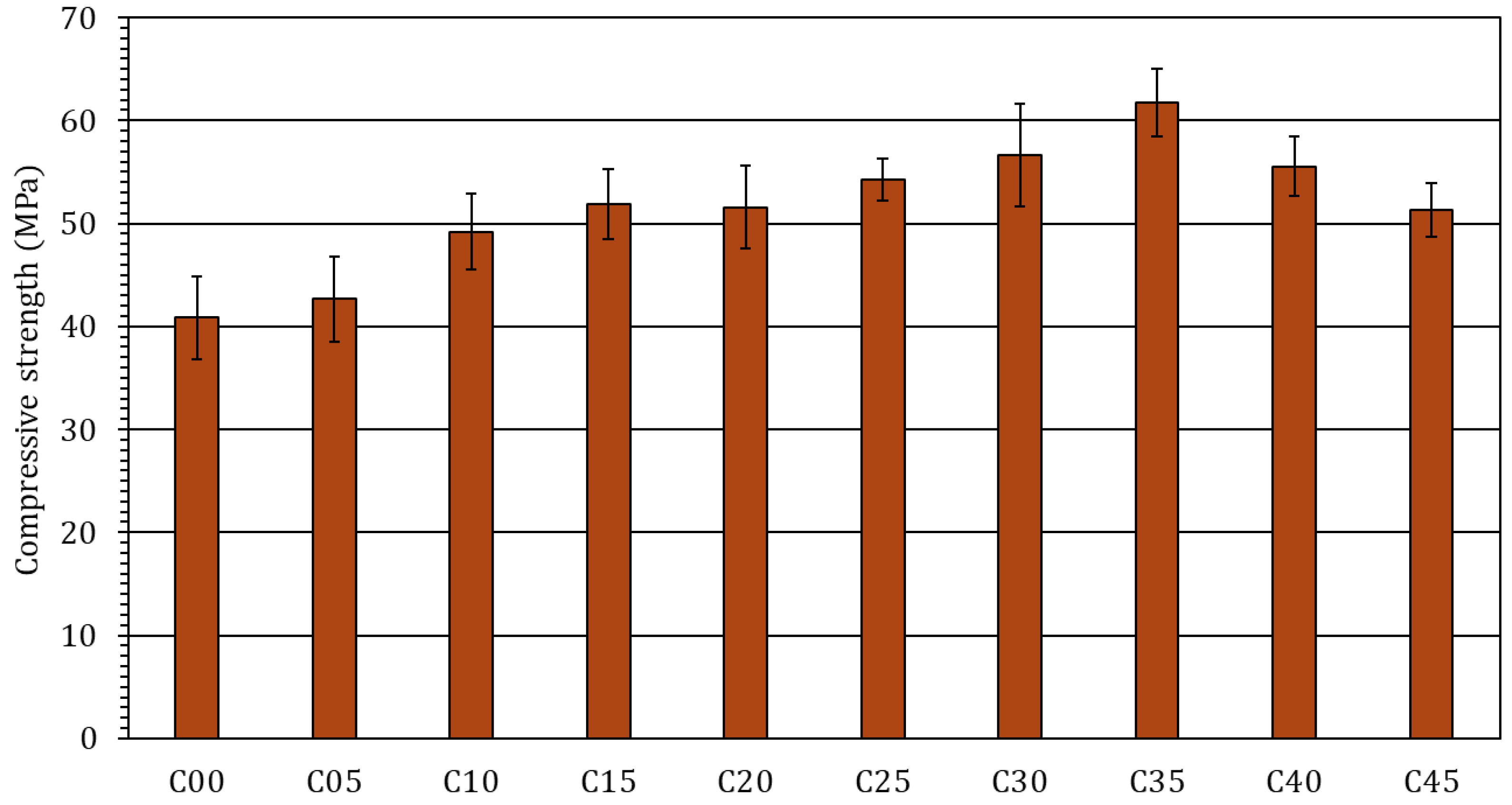

3.1. Compressive Strength

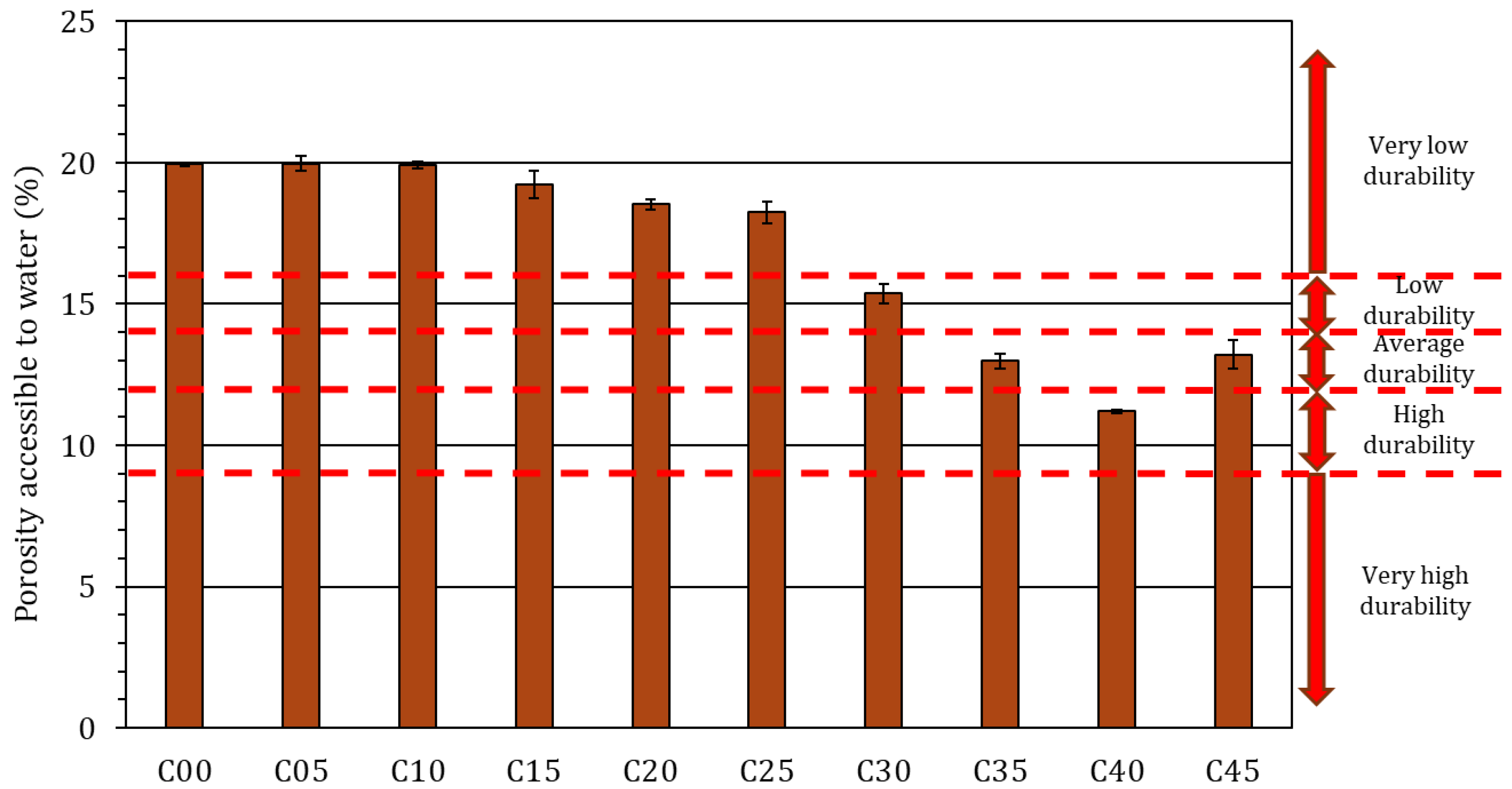

3.2. Porosity Accessible to Water (Water Absorption)

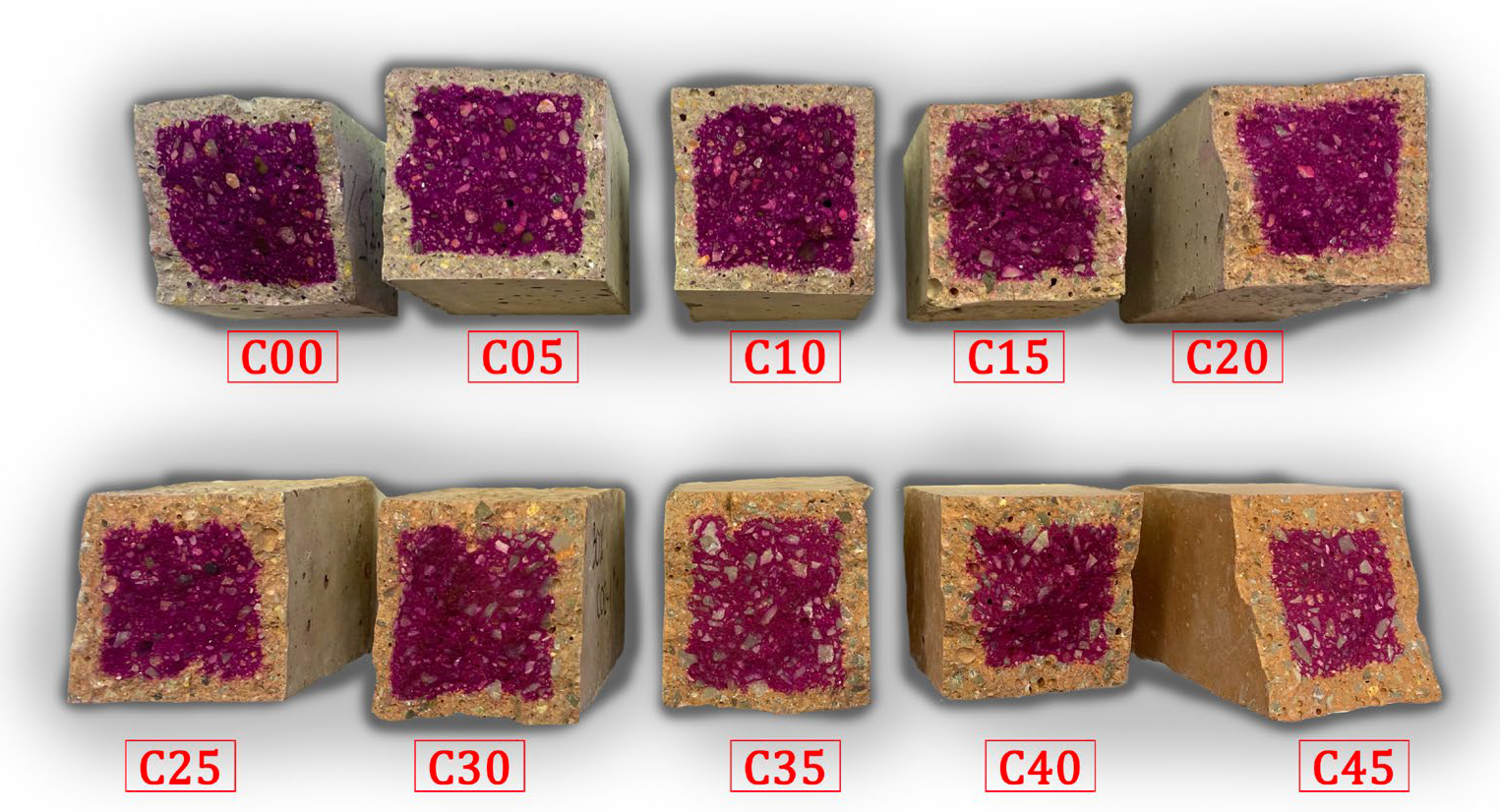

3.3. Carbonation Resistance

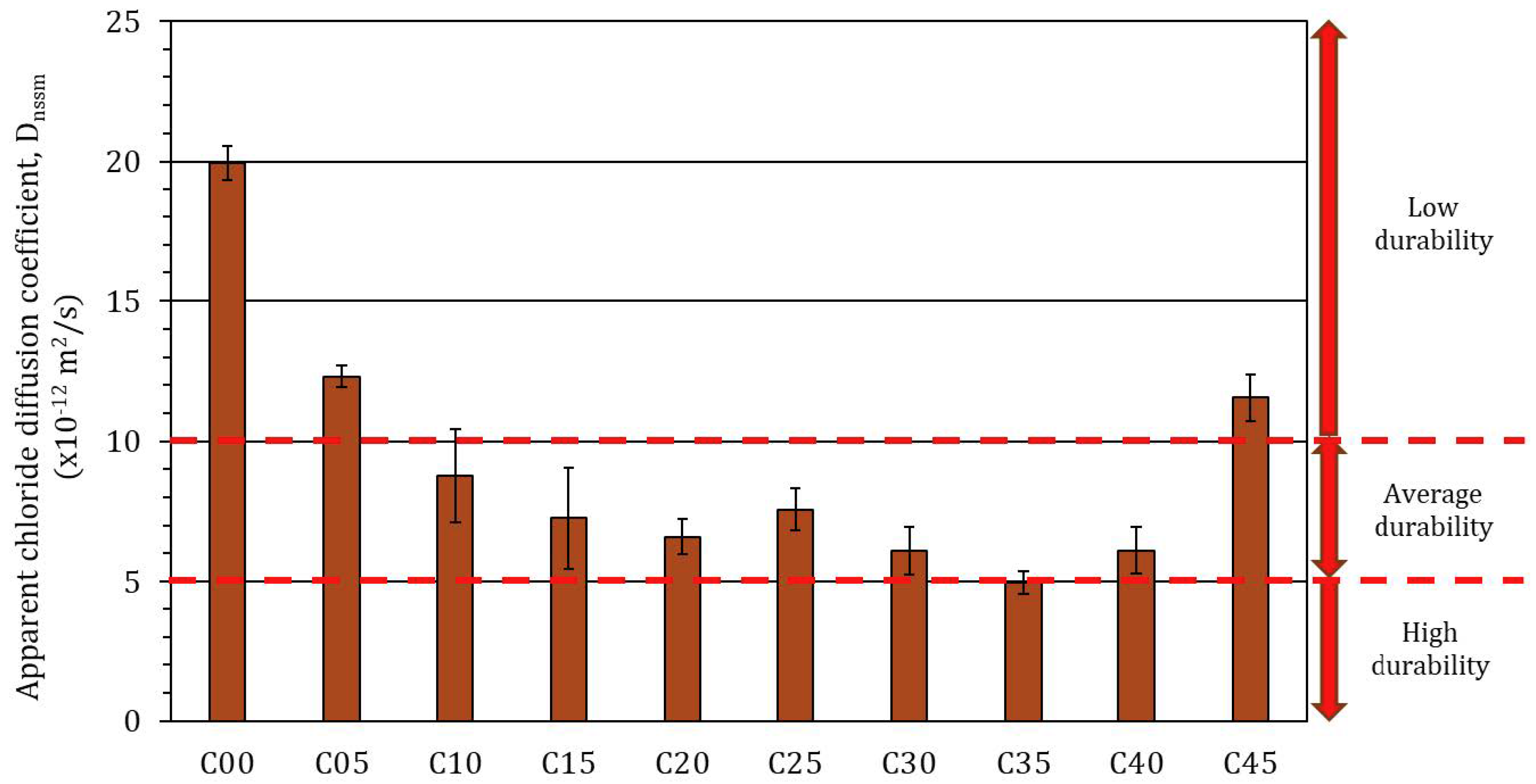

3.4. Chloride Diffusion Resistance

3.5. Electrical Resistivity

4. Conclusions

- (1)

- RBP was identified as an effective supplementary cementitious material due to its pozzolanic reactivity, which was evaluated by measuring the electrical conductivity and pH of aqueous calcium hydroxide/RBP suspensions. When RBP partially replaces Ordinary Portland Cement (OPC), it reacts with the calcium hydroxide (Ca(OH)2) released during cement hydration, leading to the formation of C-S-H gels. This secondary reaction produces additional solid phases that obstruct the capillary pore network, resulting in pore refinement and a more tortuous microstructure.

- (2)

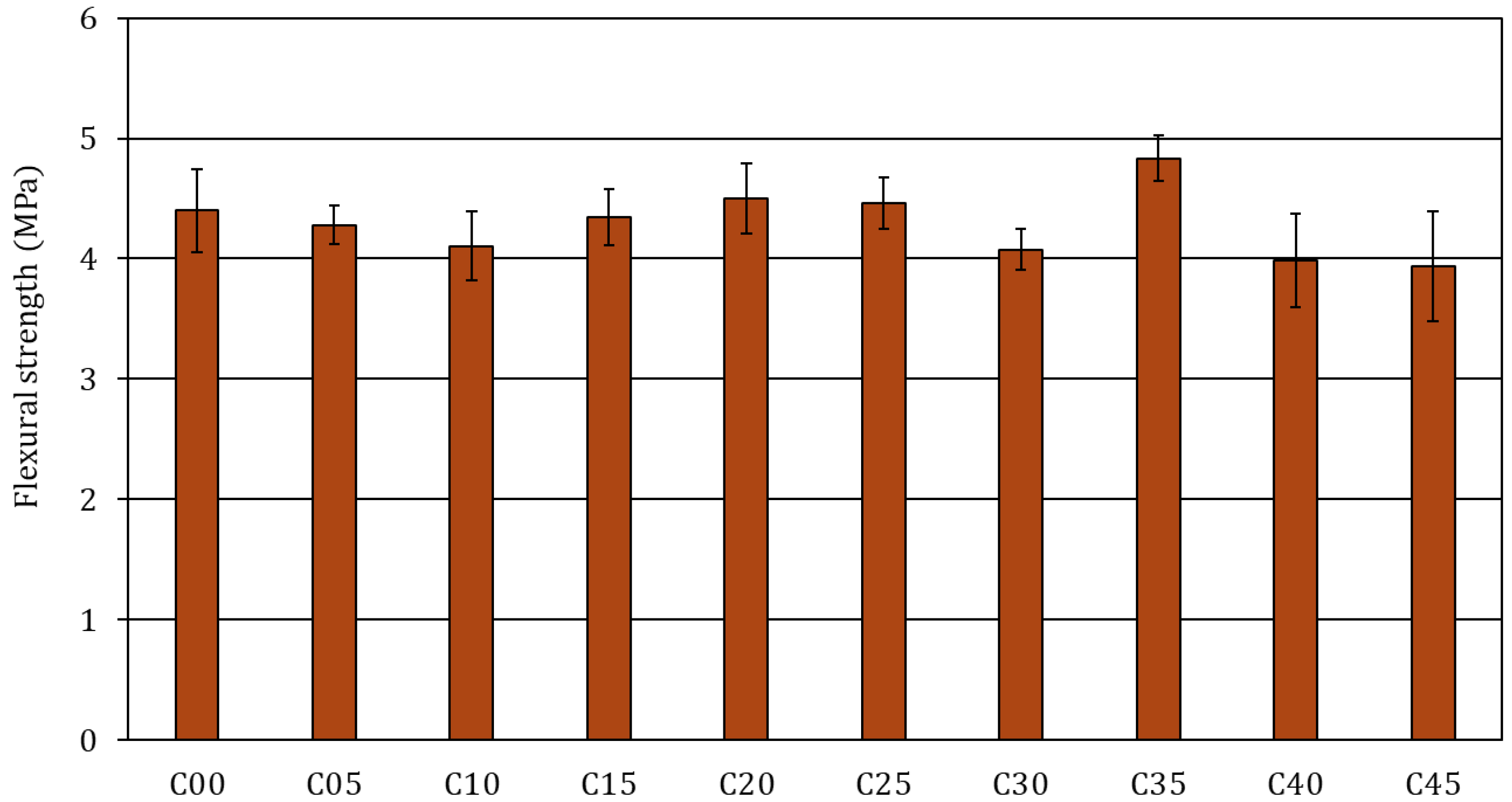

- The formation of additional C-S-H gels resulted in an increase in compressive strength when OPC was partially replaced with RBP. In mixtures where the substitution level was 35%, compressive strength increased by more than 50%. However, no significant effect on flexural strength was observed.

- (3)

- The partial replacement of OPC with RBP resulted in a reduction in water-accessible porosity, with a decrease of up to 43% observed at a substitution level of 40%.

- (4)

- Carbonation resistance remained virtually unaffected by the introduction of RBP at replacement levels of 35% or lower. However, at higher replacement levels, carbonation resistance decreased by 30% to 60%.

- (5)

- Chloride diffusion resistance improved with the partial replacement of OPC by RBP. In this case, at a substitution level of 35%, the chloride diffusion values were four times lower than those of the reference specimens.

- (6)

- The partial replacement of OPC with RBP also influenced the electrical resistivity of the material, increasing as the substitution level rose. At substitution levels of 40% and 45%, electrical resistivity increased by a factor of eight to nine, while at levels of 30% and 35%, the increase ranged from four to five times compared to the reference mixture (without RBP).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zandifaez, P.; Nezhad, A.A.; Zhou, H.; Dias-da-Costa, D. A systematic review on energy-efficient concrete: Indicators, performance metrics, strategies, and future trends. Renew. Sustain. Energy Rev. 2024, 194, 114306. [Google Scholar] [CrossRef]

- EL Afandi, M.; Yehia, S.; Landolsi, T.; Qaddoumi, N.; Elchalakani, M. Concrete-to-concrete bond Strength: A review. Constr. Build. Mater. 2023, 363, 129820. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Gursel, A.P.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Kanagaraj, B.; Anand, N.; Raj, R.S.; Lubloy, E. Techno-socio-economic aspects of Portland cement, Geopolymer, and Limestone Calcined Clay Cement (LC3) composite systems: A-State-of-Art-Review. Constr. Build. Mater. 2023, 398, 132484. [Google Scholar] [CrossRef]

- Sinkhonde, D. Generating response surface models for optimisation of CO2 emission and properties of concrete modified with waste materials. Clean. Mater. 2022, 6, 100146. [Google Scholar] [CrossRef]

- Van Den Heede, P.; De Belie, N. Environmental impact; life cycle assessment (LCA) of traditional and “green” concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Menke, C.; Price, L. The CO2 abatement cost curve for the Thailand cement industry. J. Clean. Prod. 2010, 18, 1509–1518. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Kääntee, U.; Zevenhoven, R.; Backman, R.; Hupa, M. Cement manufacturing using alternative fuels and the advantages of process modelling. Fuel Process. Technol. 2004, 85, 293–301. [Google Scholar] [CrossRef]

- Aïtcin, P.C. Cements of yesterday and today—Concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- The European Cement Association (CEMBUREAU). The European Cement Association: Activity Report, Brussels, Belgium, 2023. Available online: https://www.cembureau.eu/media/dnbf4xzc/activity-report-2023-for-web.pdf (accessed on 12 December 2024).

- Shen, W.; Cao, L.; Li, Q.; Zhang, W.; Wang, G.; Li, C. Quantifying CO2 emissions from China’s cement industry. Renew. Sustain. Energy Rev. 2015, 50, 1004–1012. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production-present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Rodrigues, F.A.; Joekes, I. Cement industry: Sustainability, challenges and perspectives. Environ. Chem. Lett. 2011, 9, 151–166. [Google Scholar] [CrossRef]

- Onyenokporo, N. Supplementary Cementitious Materials as Sustainable Partial Replacement for Cement in the Building Industry. Int. J. Archit. Environ. Eng. 2021, 15, 407–417. [Google Scholar]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Khedr, S.A.; Abou-Zeid, M.N. Characteristics of Silica-Fume Concrete. J. Mater. Civ. Eng. 1995, 6, 357–375. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Shekarchi, M.; Rafiee, A.; Layssi, H. Long-term chloride diffusion in silica fume concrete in harsh marine climates. Cem. Concr. Compos. 2009, 31, 769–775. [Google Scholar] [CrossRef]

- Song, H.W.; Pack, S.W.; Nam, S.H.; Jang, J.C.; Saraswathy, V. Estimation of the permeability of silica fume cement concrete. Constr. Build. Mater. 2010, 24, 315–321. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Beycioglu, A.; Aruntaş, H.Y. Workability and mechanical properties of self-compacting concretes containing LLFA, GBFS and MC. Constr. Build. Mater. 2014, 73, 626–635. [Google Scholar] [CrossRef]

- Yang, X.; Wu, S.; Xu, S.; Chen, B.; Chen, D.; Wang, F.; Jiang, J.; Fan, L.; Tu, L. Effects of GBFS content and curing methods on the working performance and microstructure of ternary geopolymers based on high-content steel slag. Constr. Build. Mater. 2024, 410, 134128. [Google Scholar] [CrossRef]

- Oner, A.; Akyuz, S. An experimental study on optimum usage of GGBS for the compressive strength of concrete. Cem. Concr. Compos. 2007, 29, 505–514. [Google Scholar] [CrossRef]

- Saranya, P.; Nagarajan, P.; Shashikala, A.P. Eco-friendly GGBS Concrete: A State-of-The-Art Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012057. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Kahla, N.B.; Isleem, H.F.; Qaidi, S.M.A. A Comprehensive Review on the Ground Granulated Blast Furnace Slag (GGBS) in Concrete Production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Gesoǧlu, M.; Güneyisi, E.; Özbay, E. Properties of self-compacting concretes made with binary, ternary, and quaternary cementitious blends of fly ash, blast furnace slag, and silica fume. Constr. Build. Mater. 2009, 23, 1847–1854. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; Van Breugel, K.; Fraaij, A.L.A.; Bui, D.D. The study of using rice husk ash to produce ultra high performance concrete. Constr. Build. Mater. 2011, 25, 2030–2035. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Comparative sustainability assessment of binary blended concretes using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar] [CrossRef]

- Saraswathy, V.; Song, H.W. Corrosion performance of rice husk ash blended concrete. Constr. Build. Mater. 2007, 21, 1779–1784. [Google Scholar] [CrossRef]

- Chao-Lung, H.; Le Anh-Tuan, B.; Chun-Tsun, C. Effect of rice husk ash on the strength and durability characteristics of concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Bahurudeen, A.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M.; Nazar, S.; Jittin, V.; Ashish, D.K. Sugarcane bagasse ash as supplementary cementitious material in concrete—A review. Mater. Today Sustain. 2021, 15, 100086. [Google Scholar] [CrossRef]

- Neto, J.d.S.A.; de França, M.J.S.; de Amorim Júnior, N.S.; Ribeiro, D.V. Effects of adding sugarcane bagasse ash on the properties and durability of concrete. Constr. Build. Mater. 2021, 266, 120959. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.C.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mishra, M.; Suganya, O. The incorporation of wood waste ash as a partial cement replacement material for making structural grade concrete: An overview. Ain Shams Eng. J. 2015, 6, 429–437. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular economy on construction and demolition waste. Materials 2020, 13, 2970. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Khalaf, F.M. Using Crushed Clay Brick as Coarse Aggregate in Concrete. J. Mater. Civ. Eng. 2006, 18, 518–526. [Google Scholar] [CrossRef]

- Xu, L.; Su, W.; Su, T. Influence of recycled clay brick aggregate on the mechanical properties of concrete. Rev. Adv. Mater. Sci. 2022, 61, 372–380. [Google Scholar] [CrossRef]

- Zhang, S.; He, P.; Niu, L. Mechanical properties and permeability of fiber-reinforced concrete with recycled aggregate made from waste clay brick. J. Clean. Prod. 2020, 268, 121690. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Zheng, C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Arif, R.; Khitab, A.; Kırgız, M.S.; Khan, R.B.N.; Tayyab, S.; Khan, R.A.; Anwar, W.; Arshad, M.T. Experimental analysis on partial replacement of cement with brick powder in concrete. Case Stud. Constr. Mater. 2021, 15, e00749. [Google Scholar] [CrossRef]

- Naceri, A.; Hamina, M.C. Use of waste brick as a partial replacement of cement in mortar. Waste Manag. 2009, 29, 2378–2384. [Google Scholar] [CrossRef]

- Mansoor, S.S.; Hama, S.M.; Hamdullah, D.N. Effectiveness of replacing cement partially with waste brick powder in mortar. J. King Saud Univ. Eng. Sci. 2022, 36, 524–532. [Google Scholar] [CrossRef]

- Khan, M.N.A.; Liaqat, N.; Ahmed, I.; Basit, A.; Umar, M.; Khan, M.A. Effect of Brick Dust on Strength and Workability of Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 414, 012005. [Google Scholar] [CrossRef]

- Letelier, V.; Ortega, J.M.; Muñoz, P.; Tarela, E.; Moriconi, G. Influence of Waste brick powder in the mechanical properties of recycled aggregate concrete. Sustainability 2018, 10, 1037. [Google Scholar] [CrossRef]

- Kirgiz, M.S. Strength gain mechanisms of blended-cements containing marble powder and brick powder. KSCE J. Civ. Eng. 2015, 19, 165–172. [Google Scholar] [CrossRef]

- Shao, J.; Gao, J.; Zhao, Y.; Chen, X. Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr. Build. Mater. 2019, 213, 209–215. [Google Scholar] [CrossRef]

- Pitarch, A.M.; Reig, L.; Tomás, A.E.; Forcada, G.; Soriano, L.; Borrachero, M.V.; Payá, J.; Monzó, J.M. Pozzolanic activity of tiles, bricks and ceramic sanitary-ware in eco-friendly Portland blended cements. J. Clean. Prod. 2021, 279, 123713. [Google Scholar] [CrossRef]

- Wu, J.D.; Guo, L.P.; Qin, Y.Y. Preparation and characterization of ultra-high-strength and ultra-high-ductility cementitious composites incorporating waste clay brick powder. J. Clean. Prod. 2021, 312, 127813. [Google Scholar] [CrossRef]

- Ge, Z.; Gao, Z.; Sun, R.; Zheng, L. Mix design of concrete with recycled clay-brick-powder using the orthogonal design method. Constr. Build. Mater. 2012, 31, 289–293. [Google Scholar] [CrossRef]

- Amakye, S.Y.; Abbey, S.J.; Olubanwo, A.O. Consistency and mechanical properties of sustainable concrete blended with brick dust waste cementitious materials. SN Appl. Sci. 2021, 3, 420. [Google Scholar] [CrossRef]

- Wu, H.; Xiao, J.; Liang, C.; Ma, Z. Properties of cementitious materials with recycled aggregate and powder both from clay brick waste. Buildings 2021, 11, 119. [Google Scholar] [CrossRef]

- Horsakulthai, V. Effect of recycled concrete powder on strength, electrical resistivity, and water absorption of self-compacting mortars. Case Stud. Constr. Mater. 2021, 15, e00725. [Google Scholar] [CrossRef]

- Sun, C.; Chen, L.; Xiao, J.; Singh, A.; Zeng, J. Compound utilization of construction and industrial waste as cementitious recycled powder in mortar. Resour. Conserv. Recycl. 2021, 170, 105561. [Google Scholar] [CrossRef]

- Tremiño, R.M.; Real-Herraiz, T.; Letelier, V.; Ortega, J.M. Four-years influence of waste brick powder addition in the pore structure and several durability-related parameters of cement-based mortars. Constr. Build. Mater. 2021, 306, 124839. [Google Scholar] [CrossRef]

- Schackow, A.; Stringari, D.; Senff, L.; Correia, S.L.; Segadães, A.M. Influence of fired clay brick waste additions on the durability of mortars. Cem. Concr. Compos. 2015, 62, 82–89. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Liu, C.; Chen, X.; Xu, Z. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement. J. Clean. Prod. 2020, 242, 118521. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, D.; Cheng, S.; Xu, X.; Zhao, C.; Wang, X.; Wu, Q.; Bai, X. Sustainable reuse of ceramic waste powder as a supplementary cementitious material in recycled aggregate concrete: Mechanical properties, durability and microstructure assessment. J. Build. Eng. 2022, 52, 104418. [Google Scholar] [CrossRef]

- Gonçalves, J.P.; Tavares, L.M.; Filho, R.D.T.; Fairbairn, E.M.R. Performance evaluation of cement mortars modified with metakaolin or ground brick. Constr. Build. Mater. 2009, 23, 1971–1979. [Google Scholar] [CrossRef]

- Filho, R.D.T.; Gonçalves, J.P.; Americano, B.B.; Fairbairn, E.M.R. Potential for use of crushed waste calcined-clay brick as a supplementary cementitious material in Brazil. Cem. Concr. Res. 2007, 37, 1357–1365. [Google Scholar] [CrossRef]

- Liu, Q.; Tong, T.; Liu, S.; Yang, D.; Yu, Q. Investigation of using hybrid recycled powder from demolished concrete solids and clay bricks as a pozzolanic supplement for cement. Constr. Build. Mater. 2014, 73, 754–763. [Google Scholar] [CrossRef]

- Liu, Q.; Li, B.; Xiao, J.; Singh, A. Utilization potential of aerated concrete block powder and clay brick powder from C&D waste. Constr. Build. Mater. 2020, 238, 117721. [Google Scholar] [CrossRef]

- Rao, M.C. Influence of brick dust, stone dust, and recycled fine aggregate on properties of natural and recycled aggregate concrete. Struct. Concr. 2021, 22, E105–E120. [Google Scholar] [CrossRef]

- Duan, Z.; Hou, S.; Xiao, J.; Li, B. Study on the essential properties of recycled powders from construction and demolition waste. J. Clean. Prod. 2020, 253, 119865. [Google Scholar] [CrossRef]

- Liu, X.; Liu, E.; Fu, Y. Reduction in Drying Shrinkage and Efflorescence of Recycled Brick and Concrete Fine Powder–Slag-Based Geopolymer. Appl. Sci. 2023, 13, 2997. [Google Scholar] [CrossRef]

- Yuan, C.; Fu, W.; Raza, A.; Li, H. Study on Mechanical Properties and Mechanism of Recycled Brick Powder UHPC. Buildings 2022, 12, 1622. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, R. Application of the supplementary cementitious material and aggregates made from waste clay bricks in the preparation of plastering mortar. Constr. Build. Mater. 2024, 450, 138705. [Google Scholar] [CrossRef]

- Letelier, V.; Tarela, E.; Moriconi, G. Mechanical Properties of Concretes with Recycled Aggregates and Waste Brick Powder as Cement Replacement. Procedia Eng. 2017, 171, 627–632. [Google Scholar] [CrossRef]

- UNE-EN:2018; Métodos de Ensayo de Cementos. Parte 1. Determinación de Resistencias. AENOR: Madrid, Spain, 2018; pp. 1–4.

- UNE-EN 1015-3:2000; Métodos de Ensayo de Los Morteros Para Albañilería. Parte 3. Determinación de la Consistencia del Mortero Fresco (Por la Mesa de Sacudidas). AENOR: Madrid, Spain, 2000.

- UNE 83980:2014; Durabilidad del Hormigón. Métodos de Ensayo. Determinación de la Absorción de Agua, la Densidad y la Porosidad Accesible al Agua del Hormigón. AENOR: Madrid, Spain, 2024.

- UNE 83993-2:2013; Durabilidad del Hormigón. Métodos de Ensayo. Determinación de la Velocidad de Penetración de la Carbonatación en el Hormigón Endurecido. Parte 2. Método Acelerado. AENOR: Madrid, Spain, 2024.

- UNE-EN 12390-18:2021; Ensayos de Hormigón Endurecido. Parte 18. Determinación del Coeficiente de Migración de Cloruros. AENOR: Madrid, Spain, 2021.

- Lliso-Ferrando, J.R.; Gasch, I.; Martínez-Ibernón, A.; Valcuende, M. Macrocell Corrosion Currents in Simulated Concrete Pore Solution and Reinforced Concrete. Int. J. Concr. Struct. Mater. 2023, 17, 15. [Google Scholar] [CrossRef]

- UNE-EN 12390-19:2023; Ensayos de Hormigón Endurecido. Parte 19. Determinación de la Resistividad Eléctrica. AENOR: Madrid, Spain, 2024.

- Tashima, M.M.; Soriano, L.; Monzó, J.; Borrachero, M.V.; Akasaki, J.L.; Payá, J. New method to assess the pozzolanic reactivity of mineral admixtures by means of pH and electrical conductivity measurements in lime: Pozzolan suspensions. Mater. Constr. 2014, 64, 316. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, C.; He, B.; Yi, S.; Tang, L. Recycling fine powder collected from construction and demolition wastes as partial alternatives to cement: A comprehensive analysis on effects, mechanism, cost and CO2 emission. J. Build. Eng. 2023, 71, 106507. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Zhao, Y.; Xu, Z.; Luo, X.; Liu, C.; Gao, J. Investigation on the reactivity of recycled brick powder. Cem. Concr. Compos. 2023, 139, 105042. [Google Scholar] [CrossRef]

- Wang, W.; Liu, J.; Agostini, F.; Davy, C.A.; Skoczylas, F.; Corvez, D. Durability of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) under progressive aging. Cem. Concr. Res. 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V. Conception des Bétons Pour une Durée de vie Donnée des Ouvrages—Maîtrise de la Durabilité vis-à-vis de la Corrosion des Armatures et de L’alcali-Réaction—Etat de L’art et Guide Pour la Mise en Oeuvre d’une Approche Performantielle et Prédictive sur la Bas, Bagneux, France, 2004. Available online: http://eprints.uanl.mx/5481/1/1020149995.PDF (accessed on 10 December 2024).

- Vernet, C. Mécanismes Chimiques d’Interactions Ciment-Adjuvants; Centre Technique Groupe, Spa: Guerville, France, 1995. [Google Scholar]

- Zou, Z.; Provoost, S.; Gruyaert, E. Utilization of Waste Brick Powder as a Partial Replacement of Portland Cement in Mortars. Sustainability 2024, 16, 624. [Google Scholar] [CrossRef]

- Chen, G.; Li, S.; Zhao, Y.; Xu, Z.; Luo, X.; Gao, J. Hydration and microstructure evolution of a novel low-carbon concrete containing recycled clay brick powder and ground granulated blast furnace slag. Constr. Build. Mater. 2023, 386, 131596. [Google Scholar] [CrossRef]

- Chinchón-Payá, S.; Andrade, C.; Chinchón, S. Indicator of carbonation front in concrete as substitute to phenolphthalein. Cem. Concr. Res. 2016, 82, 87–91. [Google Scholar] [CrossRef]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.Á.; Sánchez, I. Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef]

- Sengul, O. Use of electrical resistivity as an indicator for durability. Constr. Build. Mater. 2014, 73, 434–441. [Google Scholar] [CrossRef]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Redaelli, E.; Polder, R.B. Corrosion of Stell in Concrete: Prevention, Diagnosis and Repair; Wiley-VCH: Weinheim, Germany, 2013. [Google Scholar]

- Likes, L.; Markandeya, A.; Haider, M.M.; Bollinger, D.; McCloy, J.S.; Nassiri, S. Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. J. Clean. Prod. 2022, 364, 132651. [Google Scholar] [CrossRef]

- Rios, R.T.; Lolli, F.; Xie, L.; Xie, Y.; Kurtis, K.E. Screening candidate supplementary cementitious materials under standard and accelerated curing through time-series surface resistivity measurements and change-point detection. Cem. Concr. Res. 2021, 148, 106538. [Google Scholar] [CrossRef]

- Polder, R.B.; Peelen, W.H.A. Characterisation of chloride transport and reinforcement corrosion in concrete under cyclic wetting and drying by electrical resistivity. Cem. Concr. Compos. 2002, 24, 427–435. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | SO3 | MgO | K2O | Na2O | LOI * |

|---|---|---|---|---|---|---|---|---|

| 61.05 | 17.04 | 6.92 | 5.56 | 0.88 | 1.86 | 2.49 | 1.05 | 0.29 |

| Ref. | % RBP as Cement Substitute | CEM | RBP | Water | Sand | SP 1 | Flowability (mm) |

|---|---|---|---|---|---|---|---|

| C00 | 0 | 450.00 | 0.00 | 225.00 | 1350.00 | 3.375 | 126 |

| C05 | 5 | 427.50 | 22.50 | 225.00 | 1350.00 | 4.050 | 149 |

| C10 | 10 | 405.00 | 45.00 | 225.00 | 1350.00 | 4.700 | 120 |

| C15 | 15 | 382.50 | 67.50 | 225.00 | 1350.00 | 5.550 | 154 |

| C20 | 20 | 360.00 | 90.00 | 225.00 | 1350.00 | 6.250 | 138 |

| C25 | 25 | 337.50 | 112.50 | 225.00 | 1350.00 | 6.900 | 131 |

| C30 | 30 | 315.00 | 135.00 | 225.00 | 1350.00 | 7.750 | 148 |

| C35 | 35 | 292.50 | 157.50 | 225.00 | 1350.00 | 8.400 | 153 |

| C40 | 40 | 270.00 | 180.00 | 225.00 | 1350.00 | 9.050 | 144 |

| C45 | 45 | 247.50 | 202.50 | 225.00 | 1350.00 | 9.650 | 138 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lliso-Ferrando, J.R.; Arenós-Barrachina, A.; Monzón-Bello, P.; Valcuende, M. Durability of Mortars with Partial Cement Replacement by Recycled Brick Powder. Appl. Sci. 2025, 15, 4133. https://doi.org/10.3390/app15084133

Lliso-Ferrando JR, Arenós-Barrachina A, Monzón-Bello P, Valcuende M. Durability of Mortars with Partial Cement Replacement by Recycled Brick Powder. Applied Sciences. 2025; 15(8):4133. https://doi.org/10.3390/app15084133

Chicago/Turabian StyleLliso-Ferrando, Josep Ramon, Alba Arenós-Barrachina, Pablo Monzón-Bello, and Manuel Valcuende. 2025. "Durability of Mortars with Partial Cement Replacement by Recycled Brick Powder" Applied Sciences 15, no. 8: 4133. https://doi.org/10.3390/app15084133

APA StyleLliso-Ferrando, J. R., Arenós-Barrachina, A., Monzón-Bello, P., & Valcuende, M. (2025). Durability of Mortars with Partial Cement Replacement by Recycled Brick Powder. Applied Sciences, 15(8), 4133. https://doi.org/10.3390/app15084133