Tooth Movement Patterns Based on Traction Methods for Mandibular Canine Retraction Using Skeletal Anchorage: A Finite Element Analysis

Abstract

1. Introduction

2. Materials and Methods

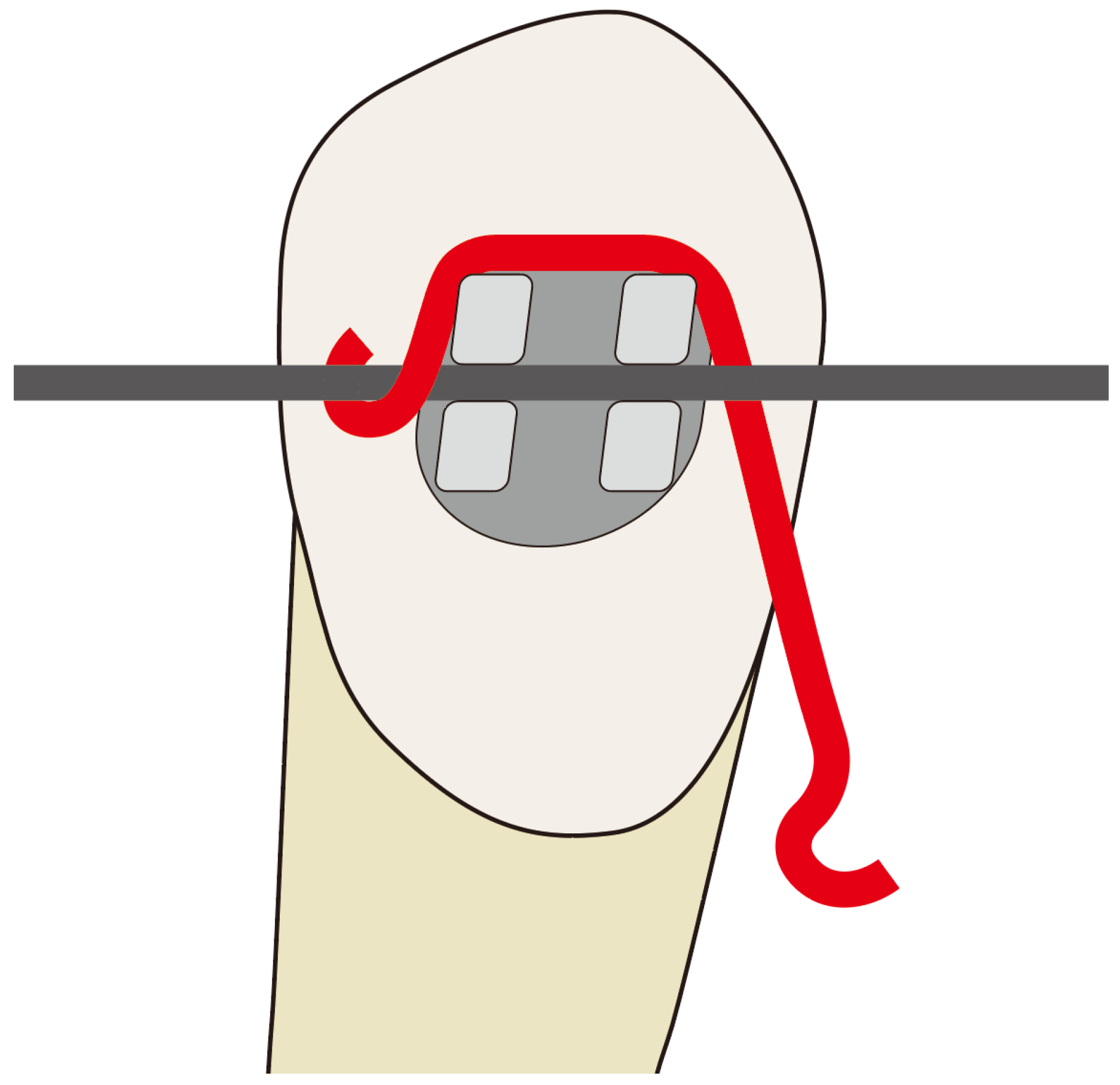

2.1. Fabrication of the Lever Jig

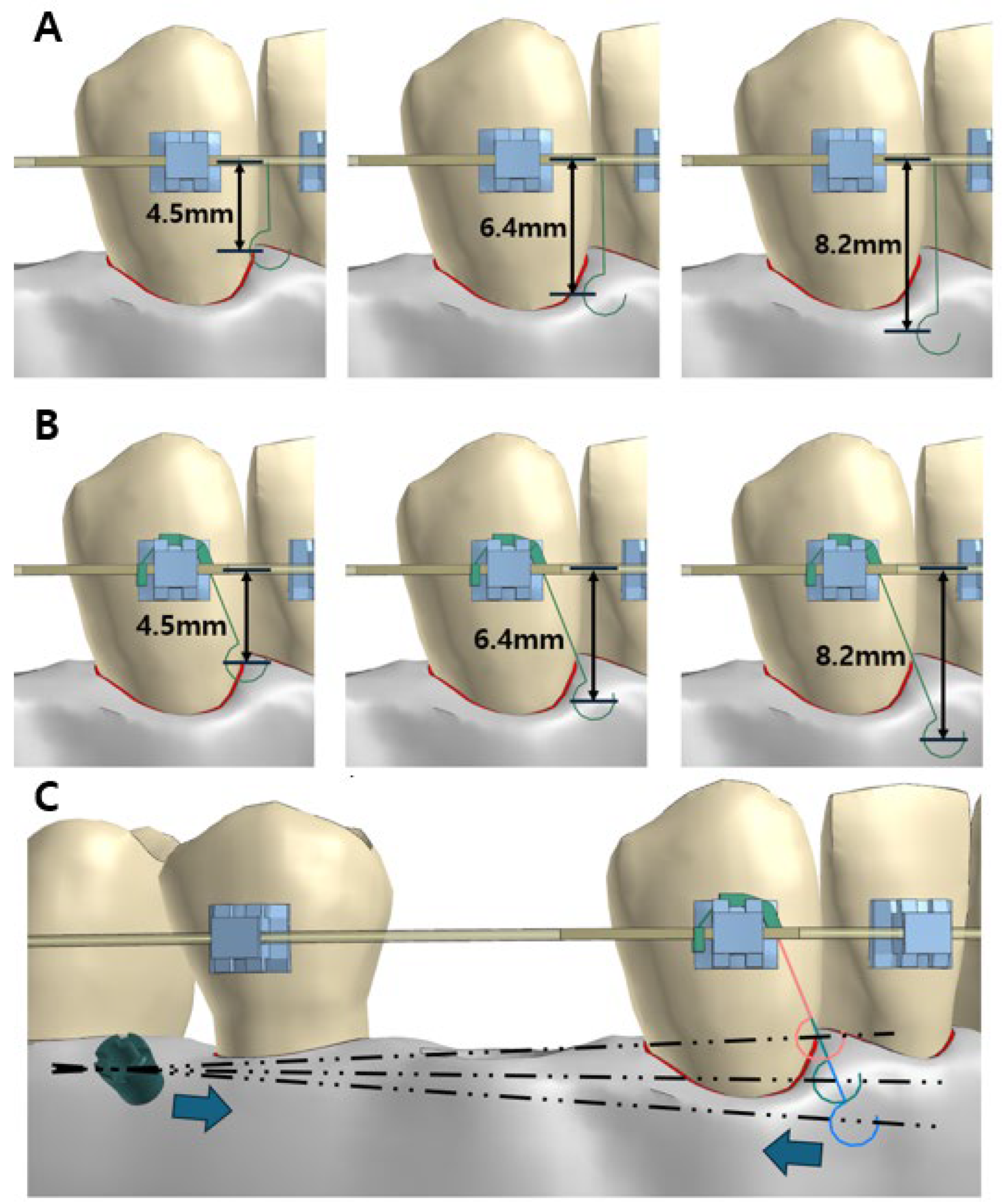

2.2. Experimental Design

- A model utilizing a power arm positioned between the lateral incisor and the canine on the main archwire;

- A model incorporating a lever jig.

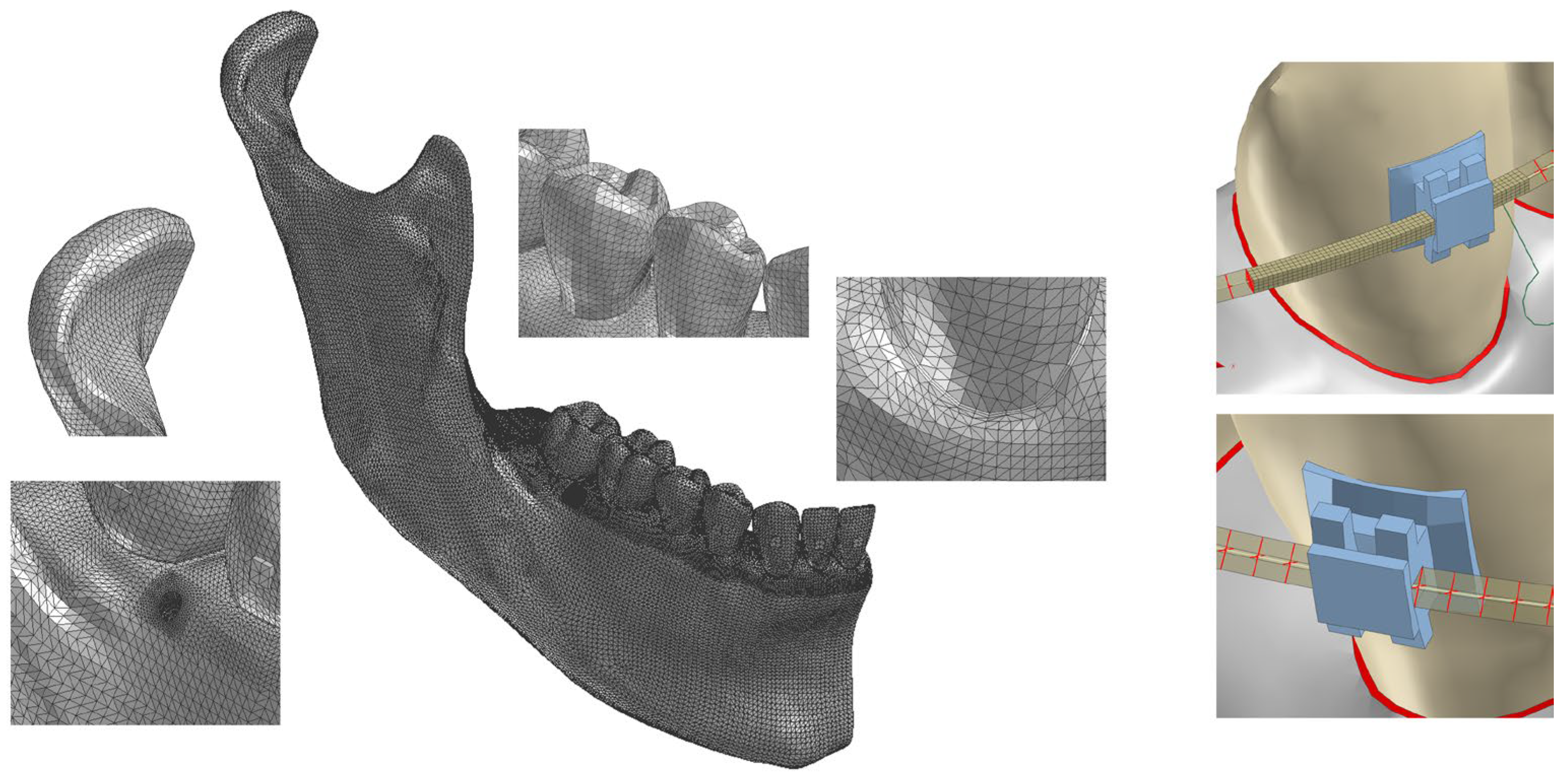

2.3. Finite Element Analysis (FEA) Modeling

2.4. Material Properties

2.5. Loading and Boundary Conditions

2.6. Coordinate System

- Positive X-axis: Mesial direction;

- Positive Y-axis: Lingual direction;

- Positive Z-axis: Coronal direction.

2.7. Dynamic Simulation of Initial Tooth Movement Process

- The load transmitted to the bracket;

- The displacement of the mandibular canine;

- The distribution of tensile and compressive stress in the PDL.

3. Results

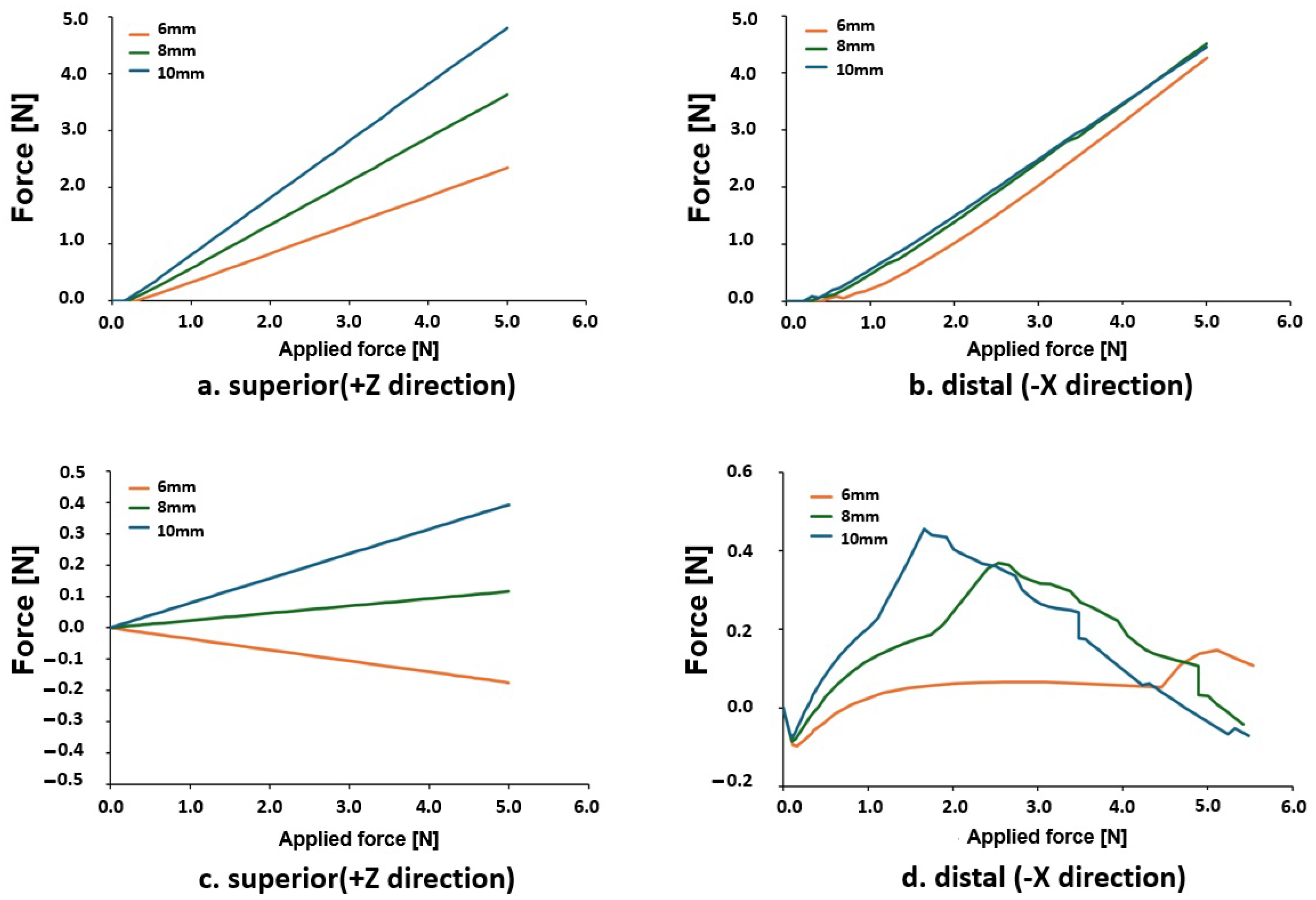

3.1. Load Transmission to the Bracket

3.2. Initial Displacement Pattern of the Canine

3.3. Tensile Stress Distribution in the PDL

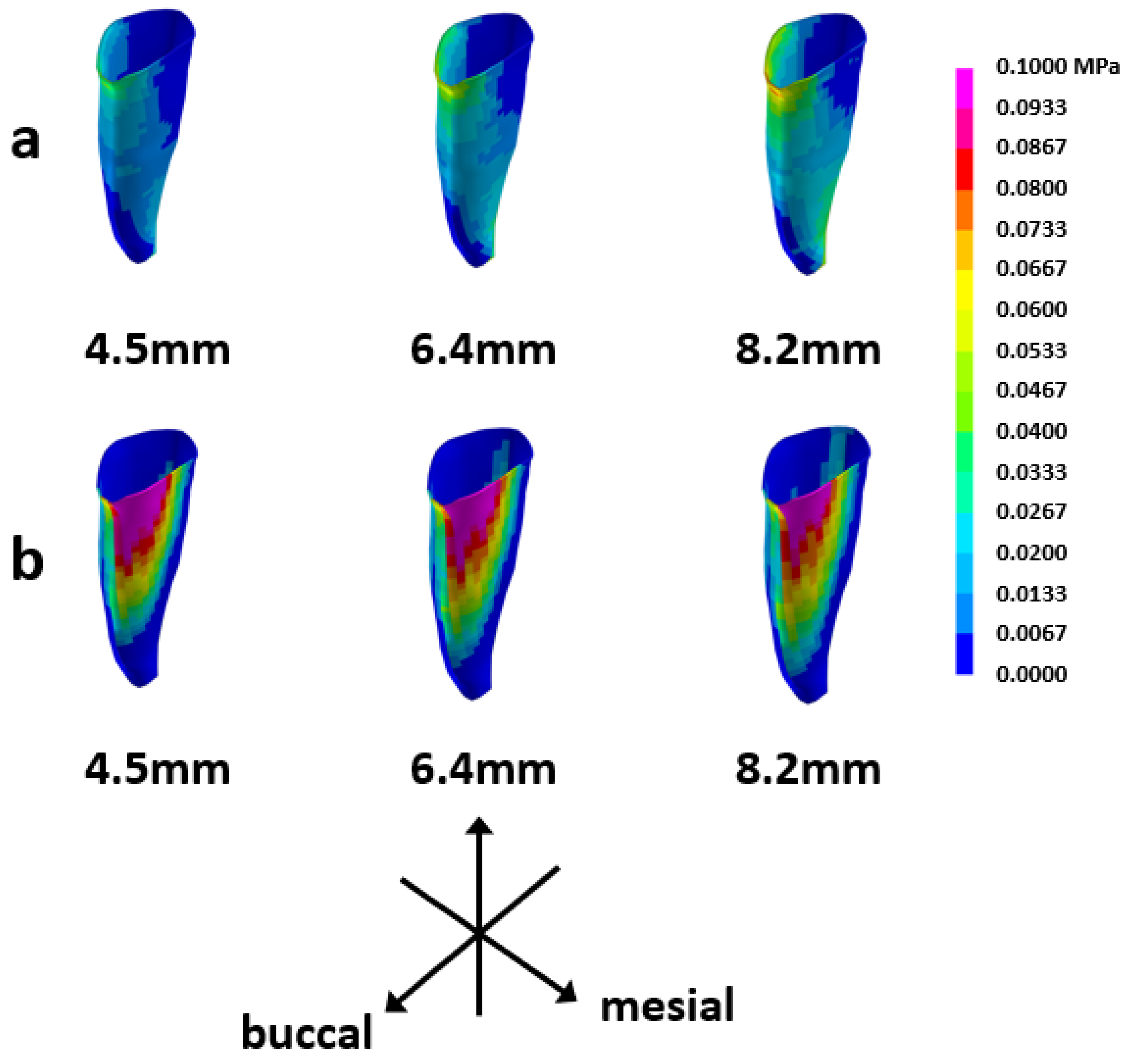

3.4. Compressive Stress Distribution in the PDL

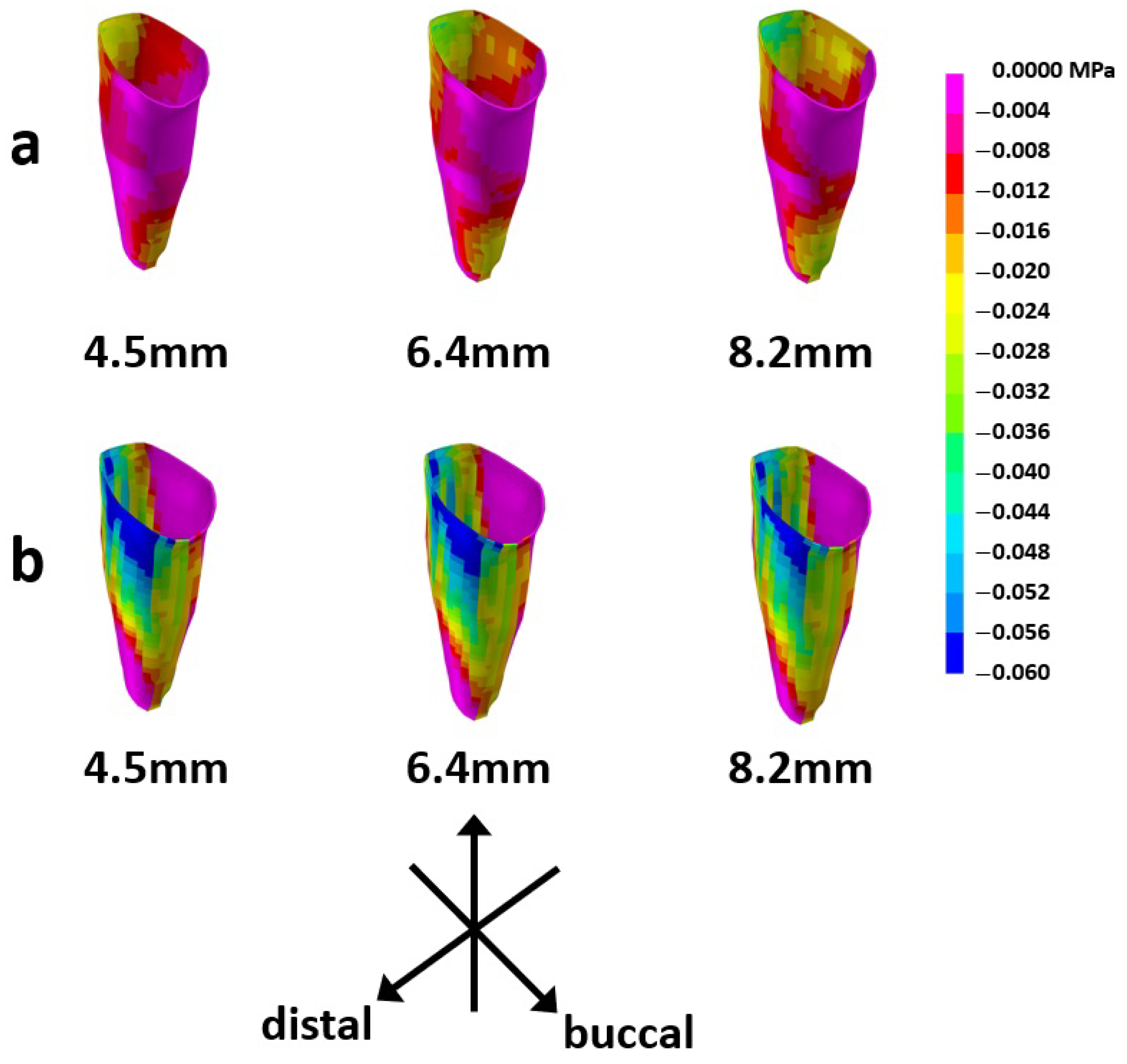

4. Discussion

5. Conclusions

- It redirects force more efficiently, reducing unnecessary vertical displacement.

- It minimizes tipping and maintains a better moment-to-force ratio for controlled translation.

- It generates a more balanced stress field in the PDL, reducing excessive concentration in limited areas.

- Since the lever jig naturally minimizes tipping and extrusion, additional mechanics, such as torquing auxiliaries, may be less necessary.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kuruthukulam, R.M.; Patil, A.S. The center of resistance of a tooth: A review of the literature. Biophys. Rev. 2023, 15, 35–41. [Google Scholar] [CrossRef] [PubMed]

- Kawamura, J.; Park, J.H.; Kojima, Y.; Tamaya, N.; Kook, Y.A.; Kyung, H.M.; Chae, J.M. Biomechanical analysis for total distalization of the maxillary dentition: A finite element study. Am. J. Orthod. Dentofac. Orthop. 2021, 160, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Chae, J.M.; Park, J.H.; Kojima, Y.; Tai, K.; Kook, Y.A.; Kyung, H.M. Biomechanical analysis for total distalization of the mandibular dentition: A finite element study. Am. J. Orthod. Dentofac. Orthop. 2019, 155, 388–397. [Google Scholar] [CrossRef] [PubMed]

- Sung, E.H.; Kim, S.J.; Chun, Y.S.; Park, Y.C.; Yu, H.S.; Lee, K.J. Distalization pattern of whole maxillary dentition according to force application points. Korean J. Orthod. 2015, 45, 20–28. [Google Scholar] [CrossRef]

- He, X.; Zhuang, W.-H.; Zhang, D.-L. A three-dimensional finite element analysis: Maxillary dentition distalization with the aid of microimplant in lingual orthodontics. Int. J. Gen. Med. 2021, 14, 8455–8461. [Google Scholar] [CrossRef]

- Lee, J.Y.; Park, J.H.; Lee, N.K.; Kim, J.; Chae, J.M.; Kook, Y.A. Biomechanical analysis for total arch distalization according to location of force application and types of temporary skeletal anchorage devices. Clin. J. Korean Assoc. Orthod. 2021, 11, 89–101. [Google Scholar] [CrossRef]

- Goh, M.S.; Choi, S.K. Orthodontic Treatment of a Stage IV Periodontitis Patient Exhibiting Severe Attachment Loss and Pathological Tooth Migration. Clin. J. Korean Assoc. Orthod. 2024, 14, 227–236. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, D.; Zhao, M.; Cheng, Z.; Pan, Y.; Liu, X. Three-dimensional finite element analysis of the optimal mechanical design for maximum inward movement of the anterior teeth with clear aligners. Sci. Rep. 2024, 14, 13203. [Google Scholar] [CrossRef]

- Guo, R.; Li, L.; Lam, X.Y.; Qin, Q.; Zheng, Y.; Huang, Y.; Lin, Y.; Li, W. Tooth movement analysis of maxillary dentition distalization using clear aligners with buccal and palatal mini-screw anchorages: A finite element study. Orthod. Craniofac. Res. 2024, 27, 868–876. [Google Scholar] [CrossRef]

- Wu, J.L.; Liu, Y.F.; Peng, W.; Dong, H.Y.; Zhang, J.X. A biomechanical case study on the optimal orthodontic force on the maxillary canine tooth based on finite element analysis. J. Zhejiang Univ. Sci. B 2018, 19, 535. [Google Scholar] [CrossRef]

- Zhao, W.; Lou, Y.; Yan, W. Evaluation of stress and displacement of maxillary canine during the single canine retraction in the maxillary first premolar extraction cases-A finite element study. Clin. Oral Investig. 2024, 28, 206. [Google Scholar] [CrossRef] [PubMed]

- Schwertner, A.; de Almeida-Pedrin, R.R.; Poleti, T.M.F.F.; Oltramari, P.; de Castro Conti, A.C.F.; Cotrim-Ferreira, F.A.; de Almeida, M.R. Biomechanical analysis of total arch maxillary distalization using infrazygomatic crest miniscrews: A finite element analysis study. Prog. Orthod. 2024, 25, 10. [Google Scholar] [CrossRef] [PubMed]

- Kojima, Y.; Fukui, H. Numerical simulation of canine retraction by sliding mechanics. Am. J. Orthod. Dentofac. Orthop. 2005, 127, 542–551. [Google Scholar] [CrossRef] [PubMed]

- Jain, A.; Prasantha, G.S.; Mathew, S.; Sabrish, S. Analysis of stress in periodontium associated with orthodontic tooth movement: A three-dimensional finite element analysis. Comput. Methods Biomech. Biomed. Eng. 2021, 24, 1841–1853. [Google Scholar] [CrossRef]

- Atif, M.; Tewari, N.; Reshikesh, M.; Chanda, A.; Mathur, V.P.; Morankar, R. Methods and applications of finite element analysis in dental trauma research: A scoping review. Dent. Traumatol. 2024, 40, 366–388. [Google Scholar] [CrossRef]

- Hsu, M.L.; Chang, C.L. Application of finite element analysis in dentistry. Finite Elem. Anal. 2010, 5, 43–46. [Google Scholar]

- Cattaneo, P.M.; Dalstra, M.; Melsen, B. Strains in periodontal ligament and alveolar bone associated with orthodontic tooth movement analyzed by finite element. Orthod. Craniofac. Res. 2009, 12, 120–128. [Google Scholar] [CrossRef]

- Moga, R.-A.; Olteanu, C.D.; Delean, A.G. The importance of boundary conditions and failure criterion in finite element analysis accuracy—A comparative assessment of periodontal ligament biomechanical behavior. Appl. Sci. 2024, 14, 3370. [Google Scholar] [CrossRef]

- McGuinness, N.J.; Wilson, A.N.; Jones, M.L.; Middleton, J. A stress analysis of the periodontal ligament under various orthodontic loadings. Eur. J. Orthod. 1991, 13, 231–242. [Google Scholar] [CrossRef]

- Cobo, J.; Sicilia, A.; Argüelles, J.; Suárez, D.; Vijande, M. Initial stress induced in periodontal tissue with diverse degrees of bone loss by an orthodontic force: Tridimensional analysis by means of the finite element method. Am. J. Orthod. Dentofac. Orthop. 1993, 104, 448–454. [Google Scholar] [CrossRef]

- Provatidis, C.G. A comparative FEM-study of tooth mobility using isotropic and anisotropic models of the periodontal ligament. Med. Eng. Phys. 2000, 22, 359–370. [Google Scholar] [CrossRef] [PubMed]

- Provatidis, C.; Kanarachos, A. Boundary-type hydrodynamic analysis of tooth movement. Eng. Anal. Bound. Elem. 2000, 24, 661–669. [Google Scholar] [CrossRef]

- Papageorgiou, S.N.; Konstantinidis, I.; Papadopoulou, K.; Jäger, A.; Bourauel, C. Clinical effects of pre-adjusted edgewise orthodontic brackets: A systematic review and meta-analysis. Eur. J. Orthod. 2014, 36, 350–363. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Kapur Wadhwa, R.; Kwon, H.K.; Close, J.M. Frictional resistances of different bracket-wire combinations. Aust. Orthod. J. 2004, 20, 25–30. [Google Scholar] [PubMed]

| Component | Young’s Modulus | Poisson’s Ratio |

|---|---|---|

| PDL | 18 Mpa | 0.45 |

| Cortical bone | 14 Gpa | 0.30 |

| Trabecular bone Stainless steel wire | 1.4 Gpa 200 Gpa | 0.30 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.-H.; Chae, J.-M.; Park, J.H.; Chang, N.-Y.; Kang, K.-H.; Choi, S.-K. Tooth Movement Patterns Based on Traction Methods for Mandibular Canine Retraction Using Skeletal Anchorage: A Finite Element Analysis. Appl. Sci. 2025, 15, 4109. https://doi.org/10.3390/app15084109

Lee D-H, Chae J-M, Park JH, Chang N-Y, Kang K-H, Choi S-K. Tooth Movement Patterns Based on Traction Methods for Mandibular Canine Retraction Using Skeletal Anchorage: A Finite Element Analysis. Applied Sciences. 2025; 15(8):4109. https://doi.org/10.3390/app15084109

Chicago/Turabian StyleLee, Dong-Hwan, Jong-Moon Chae, Jae Hyun Park, Na-Young Chang, Kyung-Hwa Kang, and Sung-Kwon Choi. 2025. "Tooth Movement Patterns Based on Traction Methods for Mandibular Canine Retraction Using Skeletal Anchorage: A Finite Element Analysis" Applied Sciences 15, no. 8: 4109. https://doi.org/10.3390/app15084109

APA StyleLee, D.-H., Chae, J.-M., Park, J. H., Chang, N.-Y., Kang, K.-H., & Choi, S.-K. (2025). Tooth Movement Patterns Based on Traction Methods for Mandibular Canine Retraction Using Skeletal Anchorage: A Finite Element Analysis. Applied Sciences, 15(8), 4109. https://doi.org/10.3390/app15084109