Genetic Algorithm-Based Model Updating in a Real-Time Digital Twin for Steel Bridge Monitoring

Abstract

1. Introduction

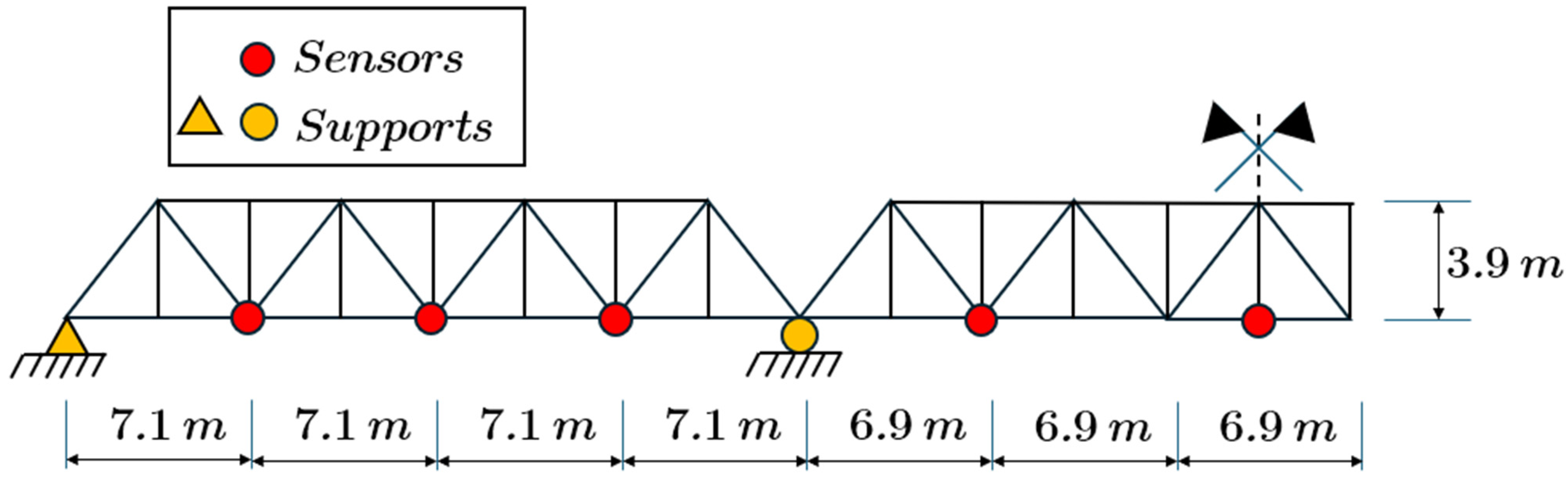

2. Case Study

3. Real Bridge: Dynamic Identification

3.1. Extraction of Free Vibrations

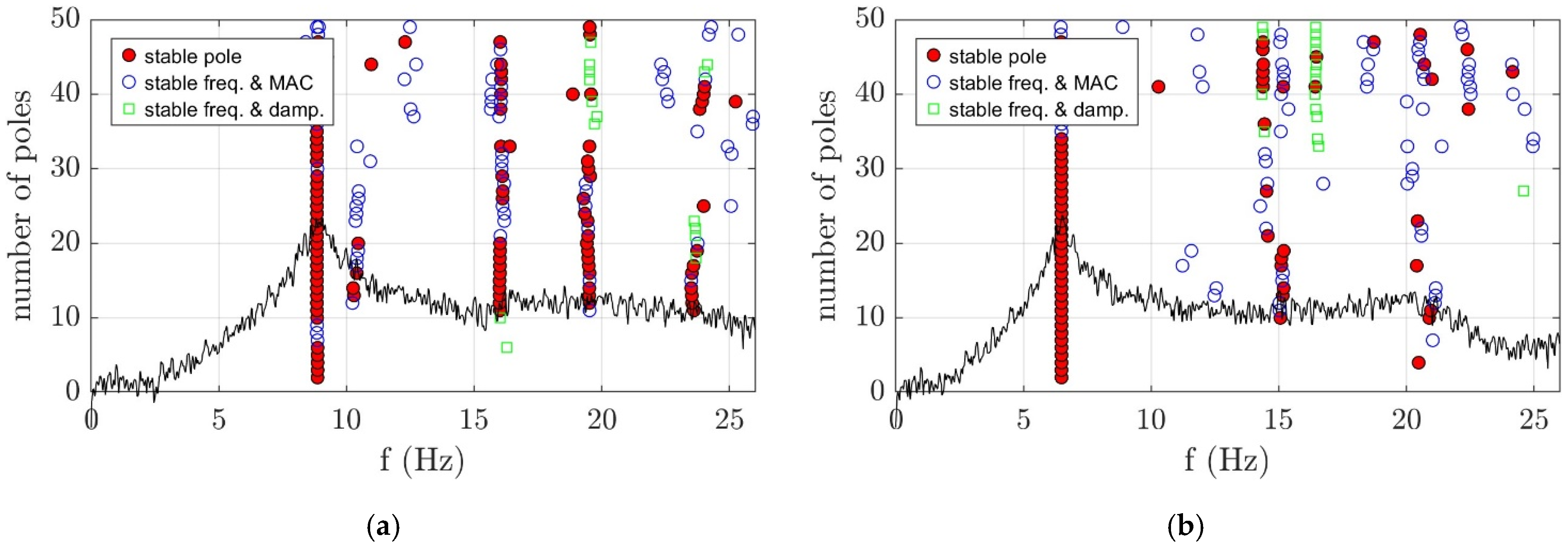

3.2. Operational Modal Analysis Using SSI

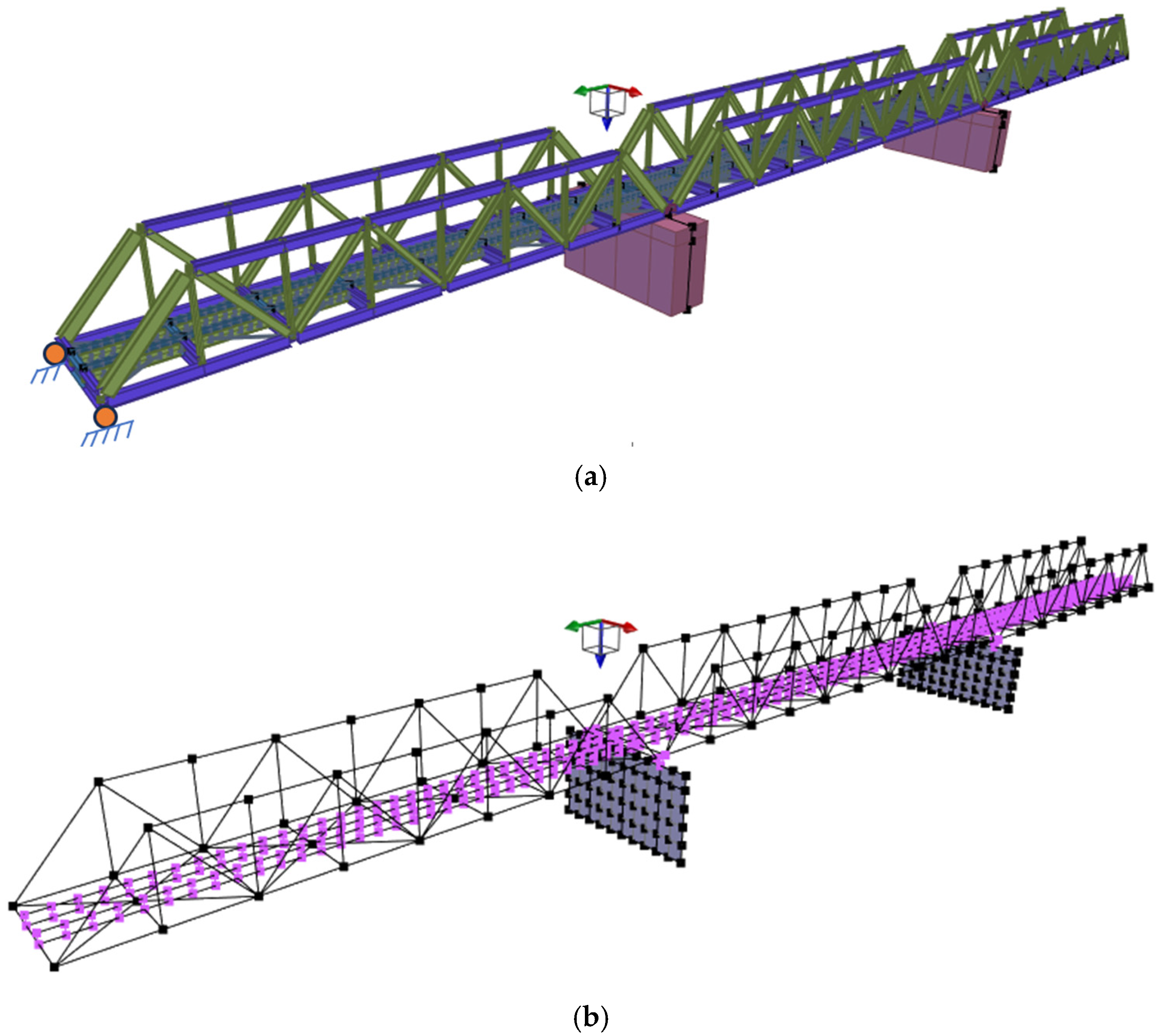

4. FE Modeling

- (1)

- Braces: Modeled using T-profile truss elements to capture their axial load-bearing behavior.

- (2)

- Piers: Represented using 4-node shell elements (ASDShellQ4) to simulate their bending and shear resistance.

- (3)

- Ballast: Modeled as a series of springs to account for its elastic support and damping effects on the bridge structure.

- (4)

- Track Support Beams: Simulated using IPE beam elements to replicate their flexural and torsional stiffness.

- (5)

- Top and Bottom Chords: Modeled with double-T beam elements to accurately reflect their combined axial and bending capacities.

- (6)

- Verticals: Represented using IPE300 beam elements to capture their structural role in transferring loads between the chords and the diagonals.

- (7)

- Diagonals: Modeled using double-C beam elements to simulate their ability to withstand both tension and compression forces.

- (8)

- Boundary Conditions: The boundary conditions of the model were carefully defined to reflect real-world constraints: (1) the piers were fixed at their base to simulate their rigid connection to the foundation; (2) one abutment was constrained to block linear displacements along the x-, y-, and z-axes, as well as rotations about the x-axis, to represent a fixed support condition; (3) the other abutment was constrained to block linear displacements along the y and z axes, allowing for potential thermal expansion along the x-axis; (4) the spans were connected to the piers using rigidLink elements in OpenSees, ensuring a rigid connection that transfers forces and moments effectively.

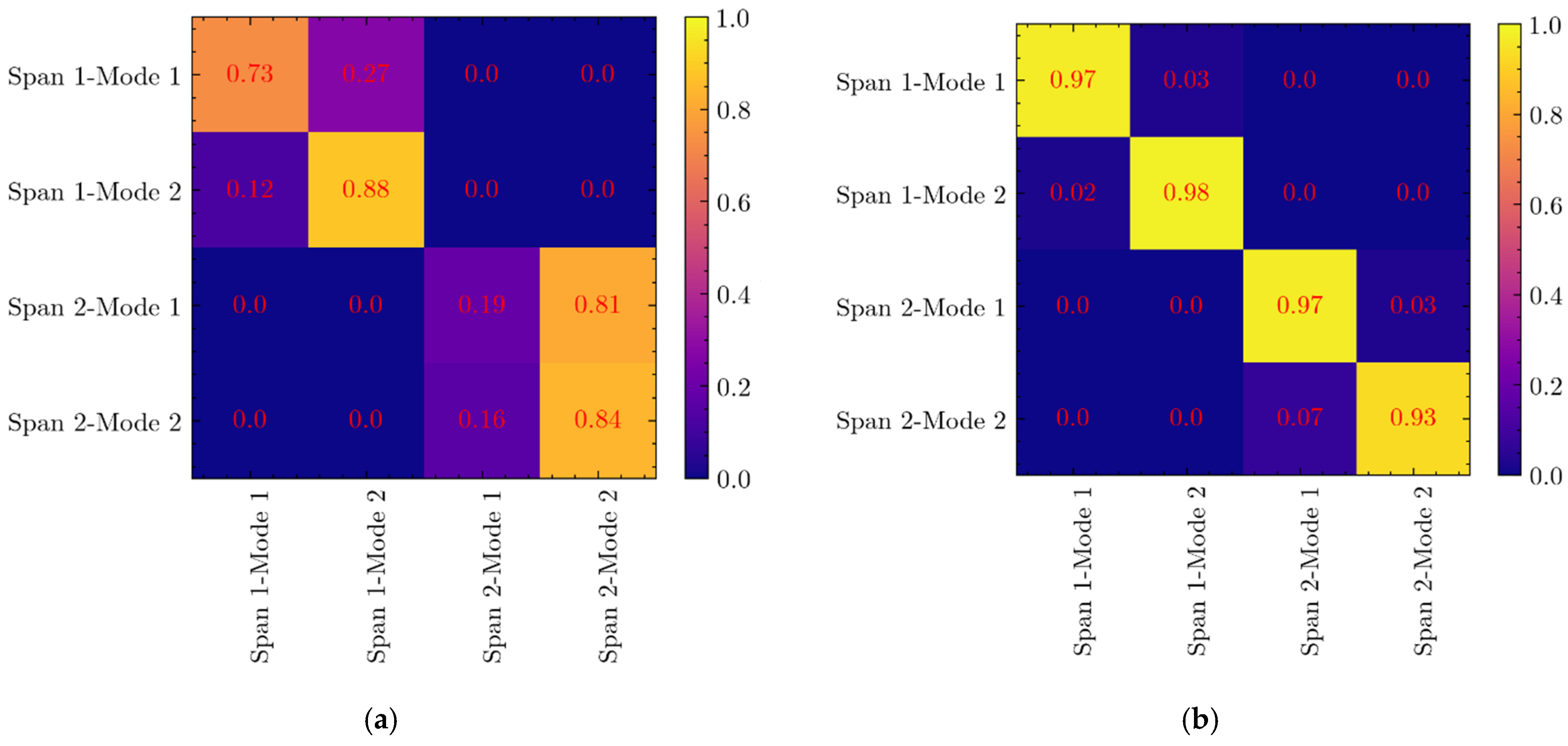

5. Model Updating and Results

- (1)

- Natural Frequency Error: The relative difference between the first natural frequencies () obtained from OMA using accelerometer data and the corresponding FEM-derived frequencies ():

- (2)

- Modal Shape Correlation: The modal assurance criterion (MAC) is employed to evaluate the consistency between real and numerical mode shapes ():

6. Conclusions

- (1)

- Accurate modal parameter identification: the SSI method effectively extracted the bridge’s natural frequencies and mode shapes from free vibration responses, demonstrating its reliability for real-world structural monitoring.

- (2)

- High-fidelity digital twin calibration: by optimizing the elastic modulus of steel components, the model updating process reduced frequency errors to below 5% and significantly improved modal assurance criterion (MAC) values (>0.93), ensuring strong alignment between numerical predictions and experimental data.

- (3)

- Scalable and practical digital twin framework: the integration of OpenSeesPy for FE modeling and PyGAD for optimization proves to be an efficient approach for real-time SHM applications, making this methodology adaptable to other bridge structures and critical infrastructure systems.

- (4)

- Enhanced predictive maintenance and damage detection: the validated digital twin provides a reliable baseline for monitoring structural changes over time, enabling early damage detection and data-driven maintenance decisions to improve bridge safety and service life.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zapico, J.L.; González, M.P.; Friswell, M.I.; Taylor, C.A.; Crewe, A.J. Finite Element Model Updating of a Small Scale Bridge. J. Sound Vib. 2003, 268, 993–1012. [Google Scholar] [CrossRef]

- Chung, W.; Sotelino, E.D. Three-Dimensional Finite Element Modeling of Composite Girder Bridges. Eng. Struct. 2006, 28, 63–71. [Google Scholar] [CrossRef]

- Kwasniewski, L.; Li, H.; Wekezer, J.; Malachowski, J. Finite Element Analysis of Vehicle–Bridge Interaction. Finite Elem. Anal. Des. 2006, 42, 950–959. [Google Scholar] [CrossRef]

- Lopez, S.; D’amato, M.; Ramos, L.; Laterza, M.; Lourenço, P.B. Simplified Formulations for Estimating the Main Frequencies of Ancient Masonry Churches. Front. Built Environ. 2019, 5, 442789. [Google Scholar] [CrossRef]

- Chen, Y.L.; Tong, J.Z.; Li, Q.H.; Zhang, E.Y.; Gao, W.; Xu, S.L. Local Instability and Interactive Mechanism Analysis of UHTCC-Encased Rectangular Steel Tubular Columns. J. Constr. Steel Res. 2025, 228, 109444. [Google Scholar] [CrossRef]

- Tong, J.Z.; Chen, Y.L.; Li, Q.H.; Dai, J.B.; Wang, G.Z.; Shen, J.J.; Gao, W.; Xu, S.L. Flexural Performance and Crack Width Prediction of Steel-UHTCC Composite Bridge Decks with Wet Joints. Eng. Struct. 2025, 323, 119264. [Google Scholar] [CrossRef]

- Chen, Y.L.; Tong, J.Z.; Li, Q.H.; Xu, S.L.; Gao, W.; Liu, X. Flexural Behavior of Novel Profiled Steel-UHTCC Assembled Composite Bridge Decks. J. Constr. Steel Res. 2024, 212, 108258. [Google Scholar] [CrossRef]

- Cabboi, A.; Gentile, C.; Saisi, A. From Continuous Vibration Monitoring to FEM-Based Damage Assessment: Application on a Stone-Masonry Tower. Constr. Build. Mater. 2017, 156, 252–265. [Google Scholar] [CrossRef]

- Bartoli, G.; Betti, M.; Galano, L.; Zini, G. Numerical Insights on the Seismic Risk of Confined Masonry Towers. Eng. Struct. 2019, 180, 713–727. [Google Scholar] [CrossRef]

- Rabi, R.R.; Vailati, M.; Monti, G. Effectiveness of Vibration-Based Techniques for Damage Localization and Lifetime Prediction in Structural Health Monitoring of Bridges: A Comprehensive Review. Buildings 2024, 14, 1183. [Google Scholar] [CrossRef]

- Beck, J.L.; Katafygiotis, L.S. Updating Models and Their Uncertainties. I: Bayesian Statistical Framework. J. Eng. Mech. 1998, 124, 455–461. [Google Scholar] [CrossRef]

- Standoli, G.; Salachoris, G.P.; Masciotta, M.G.; Clementi, F. Modal-Based FE Model Updating via Genetic Algorithms: Exploiting Artificial Intelligence to Build Realistic Numerical Models of Historical Structures. Constr. Build. Mater. 2021, 303, 124393. [Google Scholar] [CrossRef]

- Grieves, M.W. Digital Twins: Past, Present, and Future. Digit. Twin 2023, 1, 97–121. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.K.; Huang, H.; Xu, X. Digital Twin-Driven Smart Manufacturing: Connotation, Reference Model, Applications and Research Issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Tran, M.Q.; Sousa, H.S.; Matos, J.; Fernandes, S.; Nguyen, Q.T.; Dang, S.N. Finite Element Model Updating for Composite Plate Structures Using Particle Swarm Optimization Algorithm. Appl. Sci. 2023, 13, 7719. [Google Scholar] [CrossRef]

- Qin, S.; Zhou, Y.L.; Cao, H.; Wahab, M.A. Model Updating in Complex Bridge Structures Using Kriging Model Ensemble with Genetic Algorithm. KSCE J. Civil Eng. 2018, 22, 3567–3578. [Google Scholar] [CrossRef]

- Alkayem, N.F.; Cao, M.; Zhang, Y.; Bayat, M.; Su, Z. Structural Damage Detection Using Finite Element Model Updating with Evolutionary Algorithms: A Survey. Neural Comput. Appl. 2018, 30, 389–411. [Google Scholar] [CrossRef]

- Qin, S.; Yuan, Y.; Gan, Y.; Wang, Q. Improved Metaheuristic Algorithm Based Finite Element Model Updating of a Hybrid Girder Cable-Stayed Railway Bridge. Buildings 2022, 12, 958. [Google Scholar] [CrossRef]

- Peeters, B.; De Roeck, G. Reference-Based Stochastic Subspace Identification for Output-Only Modal Analysis. Mech. Syst. Signal Process. 1999, 13, 855–878. [Google Scholar] [CrossRef]

- Reynders, E.; Maes, K.; Lombaert, G.; De Roeck, G. Uncertainty Quantification in Operational Modal Analysis with Stochastic Subspace Identification: Validation and Applications. Mech. Syst. Signal Process. 2016, 66–67, 13–30. [Google Scholar] [CrossRef]

- Bianconi, F.; Salachoris, G.P.; Clementi, F.; Lenci, S. A Genetic Algorithm Procedure for the Automatic Updating of FEM Based on Ambient Vibration Tests. Sensors 2020, 20, 3315. [Google Scholar] [CrossRef] [PubMed]

- Friswell, M.; Mottershead, J.E. Finite Element Model Updating in Structural Dynamics; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1995. [Google Scholar]

- Barros, B.; Conde, B.; Cabaleiro, M.; Riveiro, B. Deterministic and Probabilistic-Based Model Updating of Aging Steel Bridges. Structures 2023, 54, 89–105. [Google Scholar] [CrossRef]

- Park, G.; Hong, K.N.; Yoon, H. Vision-Based Structural FE Model Updating Using Genetic Algorithm. Appl. Sci. 2021, 11, 1622. [Google Scholar] [CrossRef]

- Mustafa, S.; Debnath, N.; Dutta, A. Bayesian Probabilistic Approach for Model Updating and Damage Detection for a Large Truss Bridge. Int. J. Steel Struct. 2015, 15, 473–485. [Google Scholar] [CrossRef]

- Zhu, M.; McKenna, F.; Scott, M.H. OpenSeesPy: Python Library for the OpenSees Finite Element Framework. SoftwareX 2018, 7, 6–11. [Google Scholar] [CrossRef]

- Gad, A.F. PyGAD: An Intuitive Genetic Algorithm Python Library. Multimed. Tools Appl. 2024, 83, 58029–58042. [Google Scholar] [CrossRef]

- Petracca, M.; Candeloro, F.; Camata, G. STKO User Manual; ASDEA Software Technology: Pescara, Italy, 2017. [Google Scholar]

| Element | Profile |

|---|---|

| Braces | T 100 × 10 mm |

| Tracks | I 200 × 150 × 20 mm |

| Top chords | T 400 × 10 mm |

| Bottom chords | T 400 × 32 mm |

| Verticals | IPE300 |

| Rail support beam | IPE500 |

| Mode | ) | |||

|---|---|---|---|---|

| Span 1 | 1 | 8.85 | 10.86 | 18.51 |

| 2 | 16.03 | 19.50 | 17.79 | |

| Span 2 | 1 | 6.48 | 7.48 | 13.37 |

| 2 | 14.38 | 17.98 | 20.02 |

| Number of generations | 1000 |

| Population size | 20 |

| Number of genes | 6 |

| Parent selection type | Tournament |

| K tournament | 3 |

| Cross over type | Two points |

| Mutation type | Random |

| Mutation probability | 0.1 |

| Stop criteria | “Saturate 50” or “reach 1000” |

| Initial | Calibrated ) | |

|---|---|---|

| Braces | 200 | 186 |

| Tracks | 205 | |

| Top and bottom chords | 178 | |

| Verticals | 191 |

| Mode | Real Bridge | Initial FE Model | Updated FE Model | |||||

|---|---|---|---|---|---|---|---|---|

| Span 1 | 1 | 8.85 | 10.86 | 18.51 | 0.73 | 8.85 | 0.00 | 0.97 |

| 2 | 16.03 | 19.50 | 17.79 | 0.88 | 16.50 | 2.85 | 0.98 | |

| Span 2 | 1 | 6.48 | 7.48 | 13.37 | 0.19 | 6.49 | 0.15 | 0.97 |

| 2 | 14.38 | 17.98 | 20.02 | 0.84 | 14.88 | 3.36 | 0.93 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahmat Rabi, R.; Monti, G. Genetic Algorithm-Based Model Updating in a Real-Time Digital Twin for Steel Bridge Monitoring. Appl. Sci. 2025, 15, 4074. https://doi.org/10.3390/app15084074

Rahmat Rabi R, Monti G. Genetic Algorithm-Based Model Updating in a Real-Time Digital Twin for Steel Bridge Monitoring. Applied Sciences. 2025; 15(8):4074. https://doi.org/10.3390/app15084074

Chicago/Turabian StyleRahmat Rabi, Raihan, and Giorgio Monti. 2025. "Genetic Algorithm-Based Model Updating in a Real-Time Digital Twin for Steel Bridge Monitoring" Applied Sciences 15, no. 8: 4074. https://doi.org/10.3390/app15084074

APA StyleRahmat Rabi, R., & Monti, G. (2025). Genetic Algorithm-Based Model Updating in a Real-Time Digital Twin for Steel Bridge Monitoring. Applied Sciences, 15(8), 4074. https://doi.org/10.3390/app15084074