Analysis of Tribological Properties of Expanded Graphite—Alloy Steel Pair Under High Loads in Dry and Humid Conditions

Abstract

1. Introduction

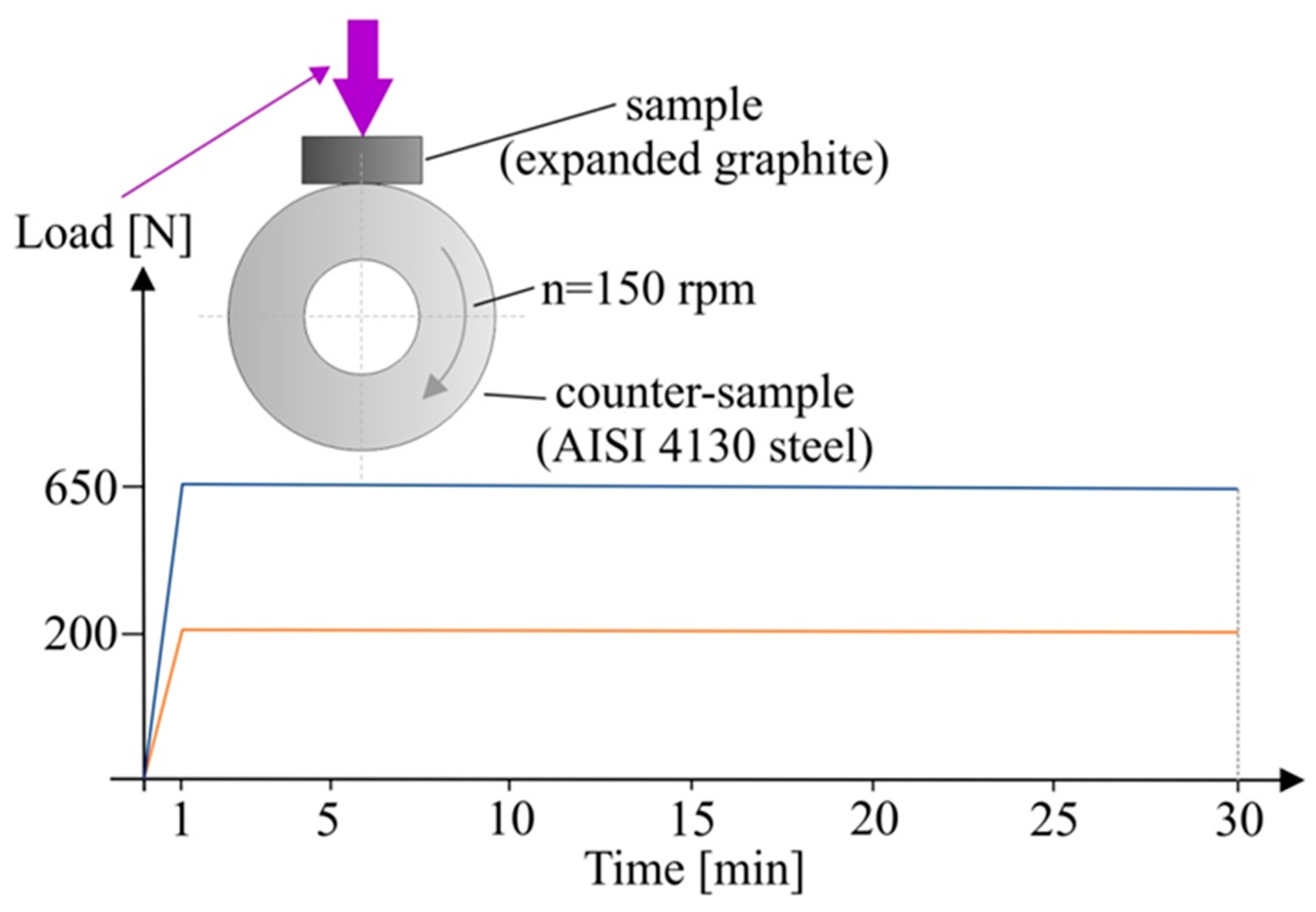

2. Materials and Methods

3. Results

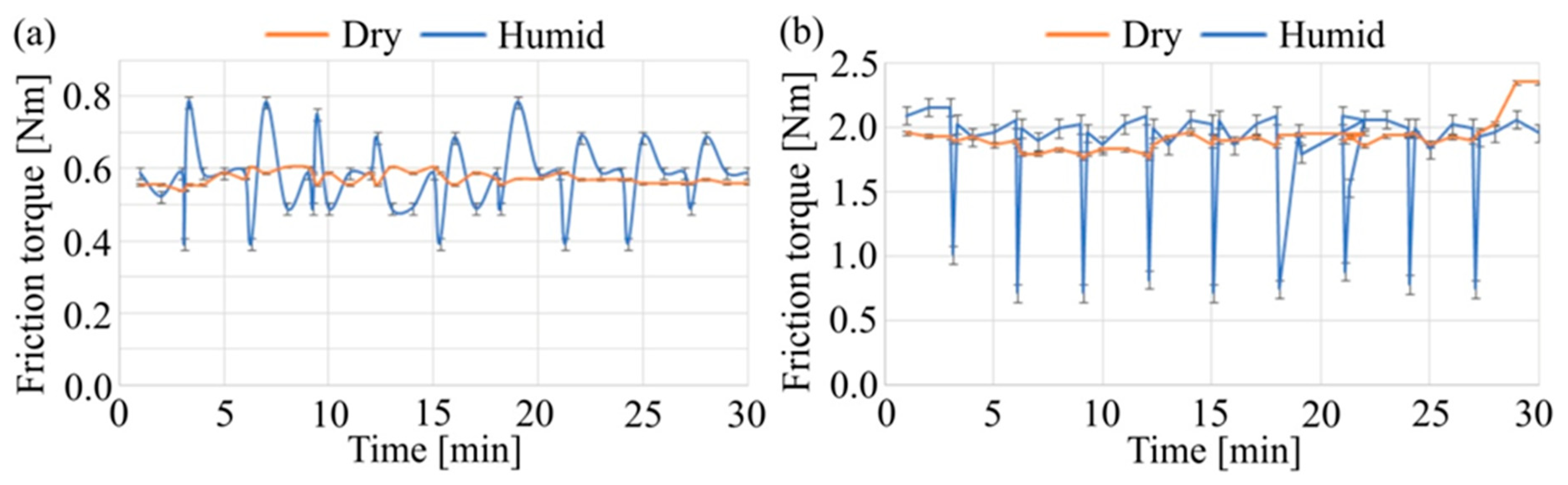

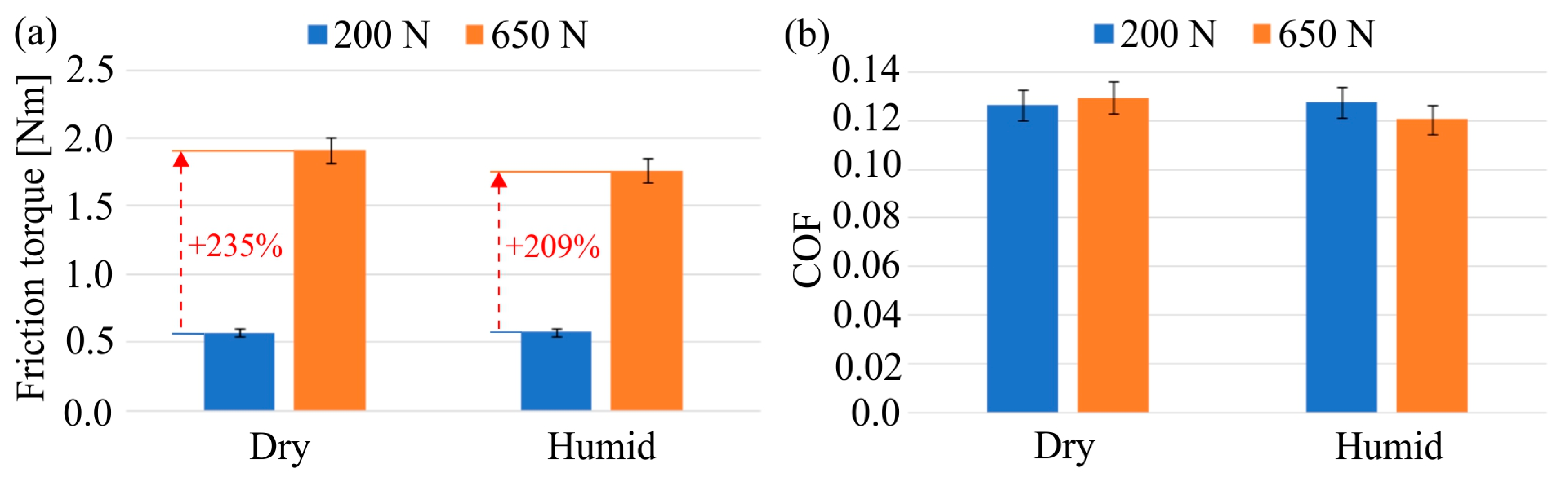

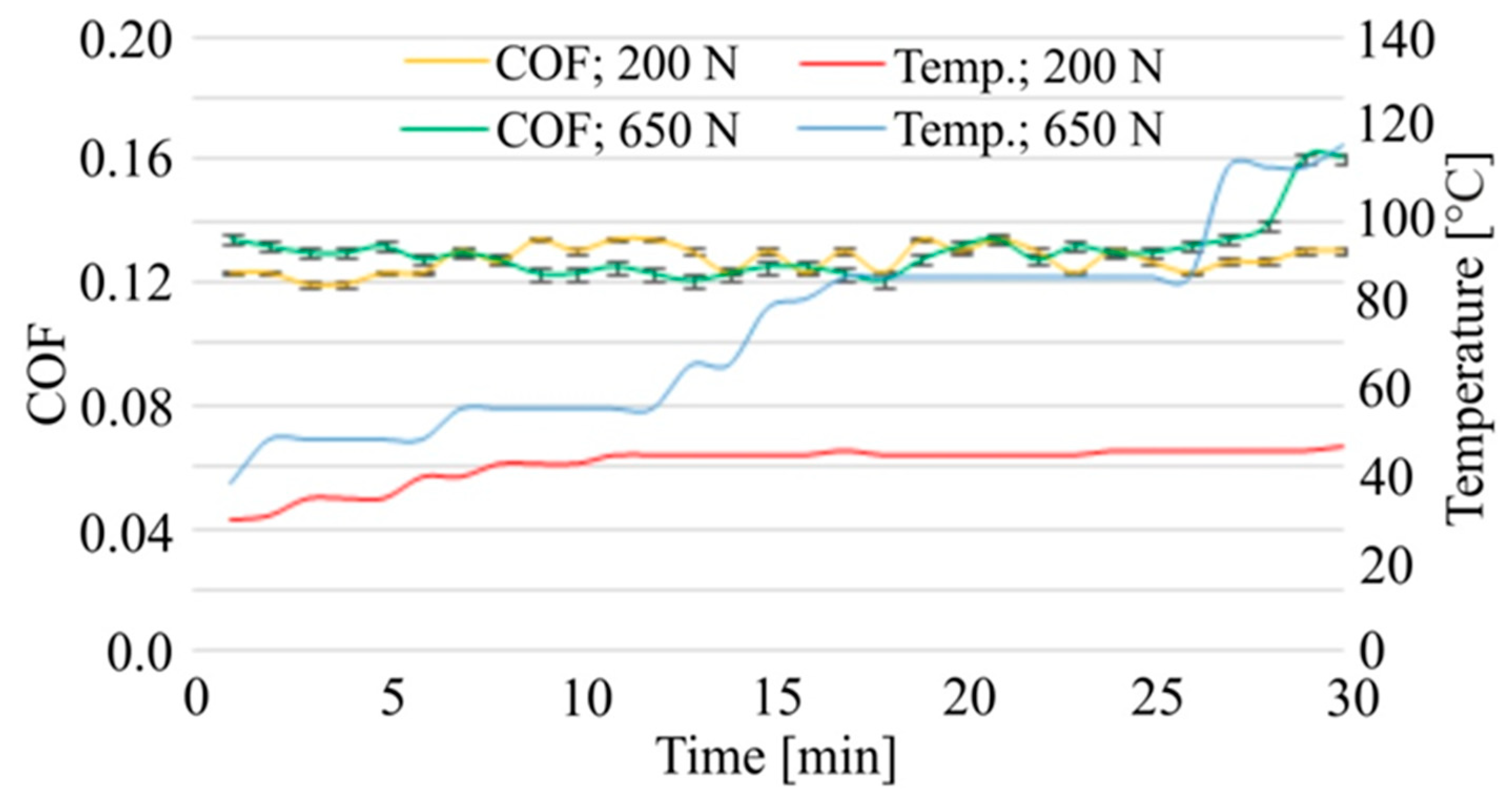

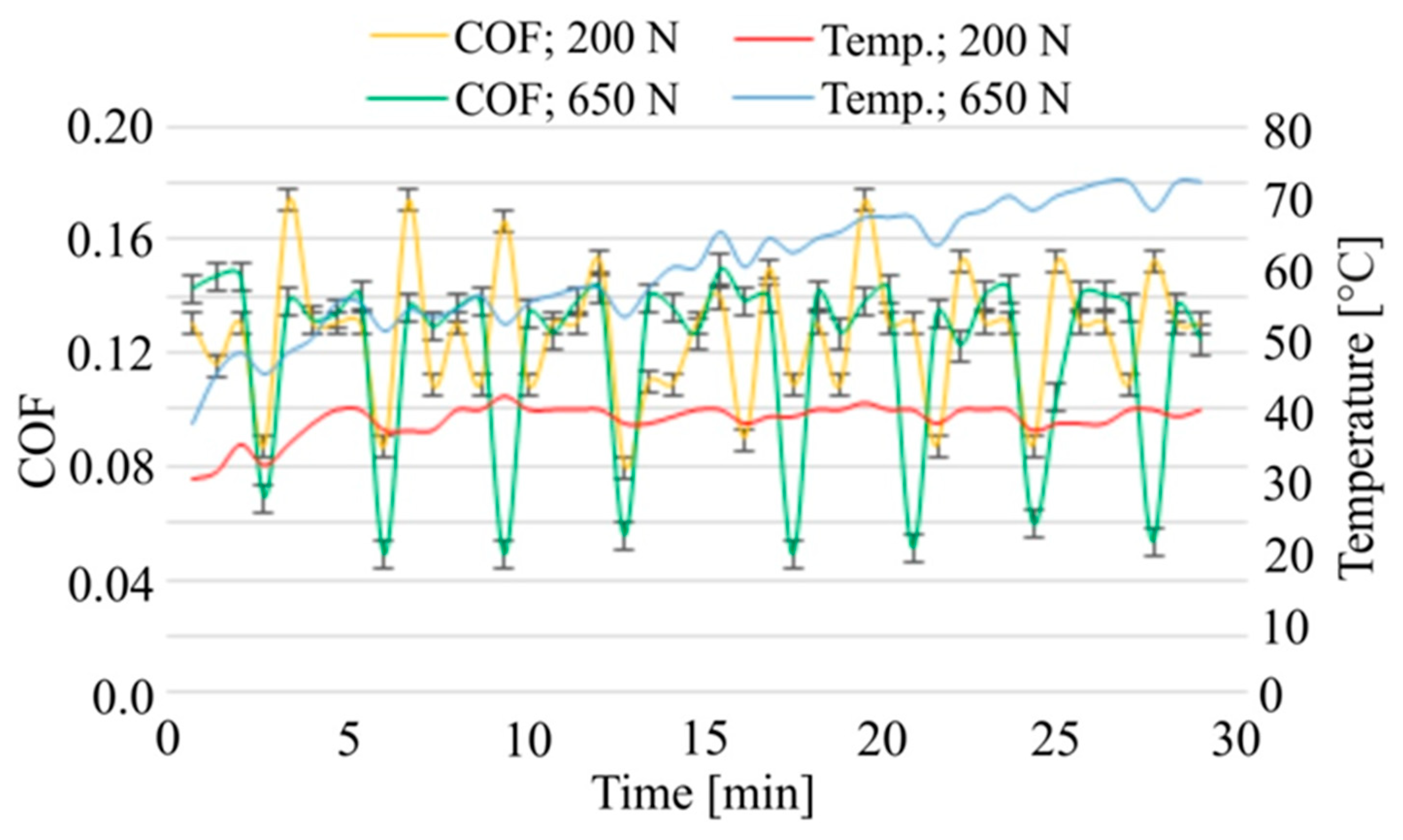

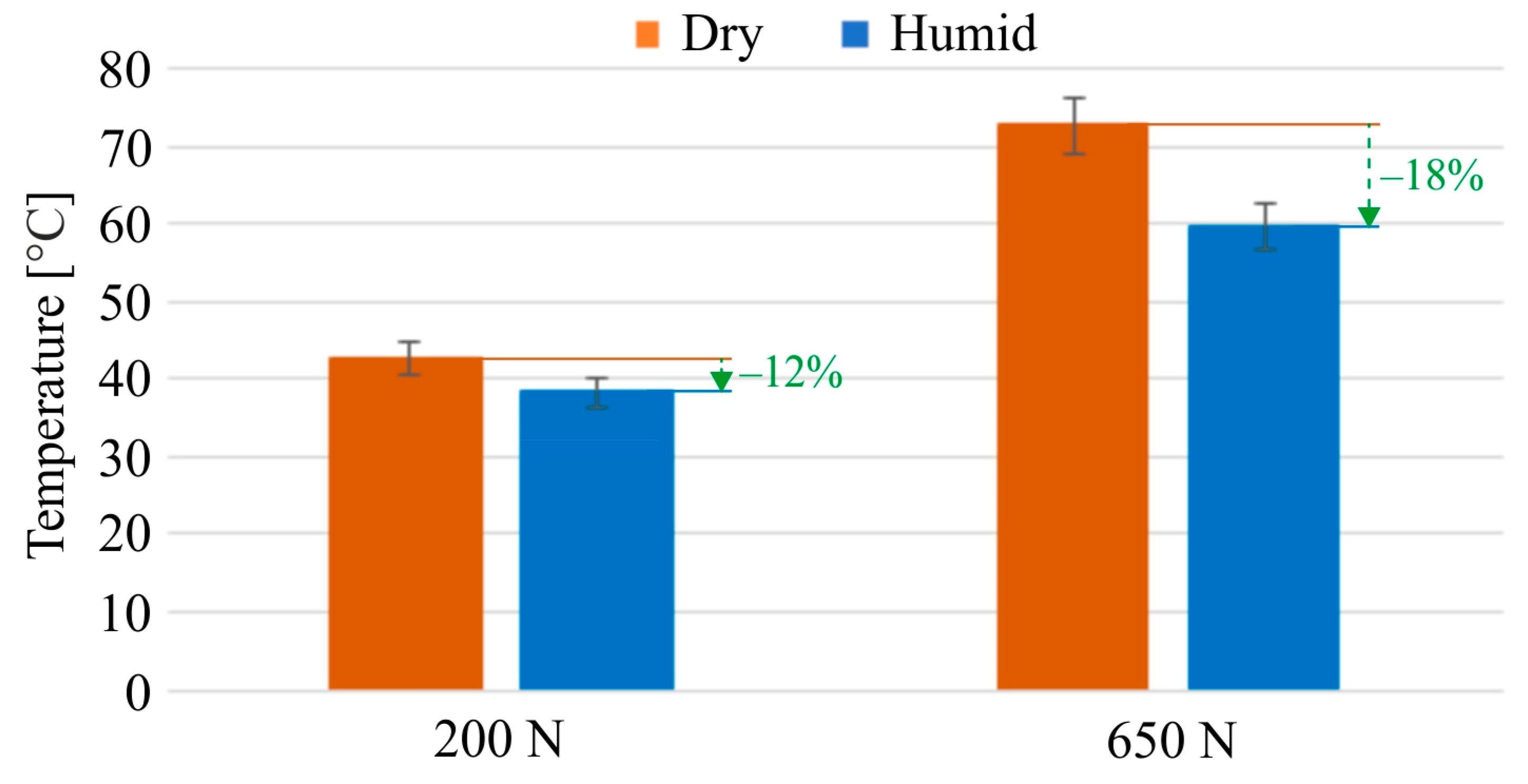

3.1. Analysis of the Friction and Temperature Indices of Expanded Graphite–Alloy Steel Pairs

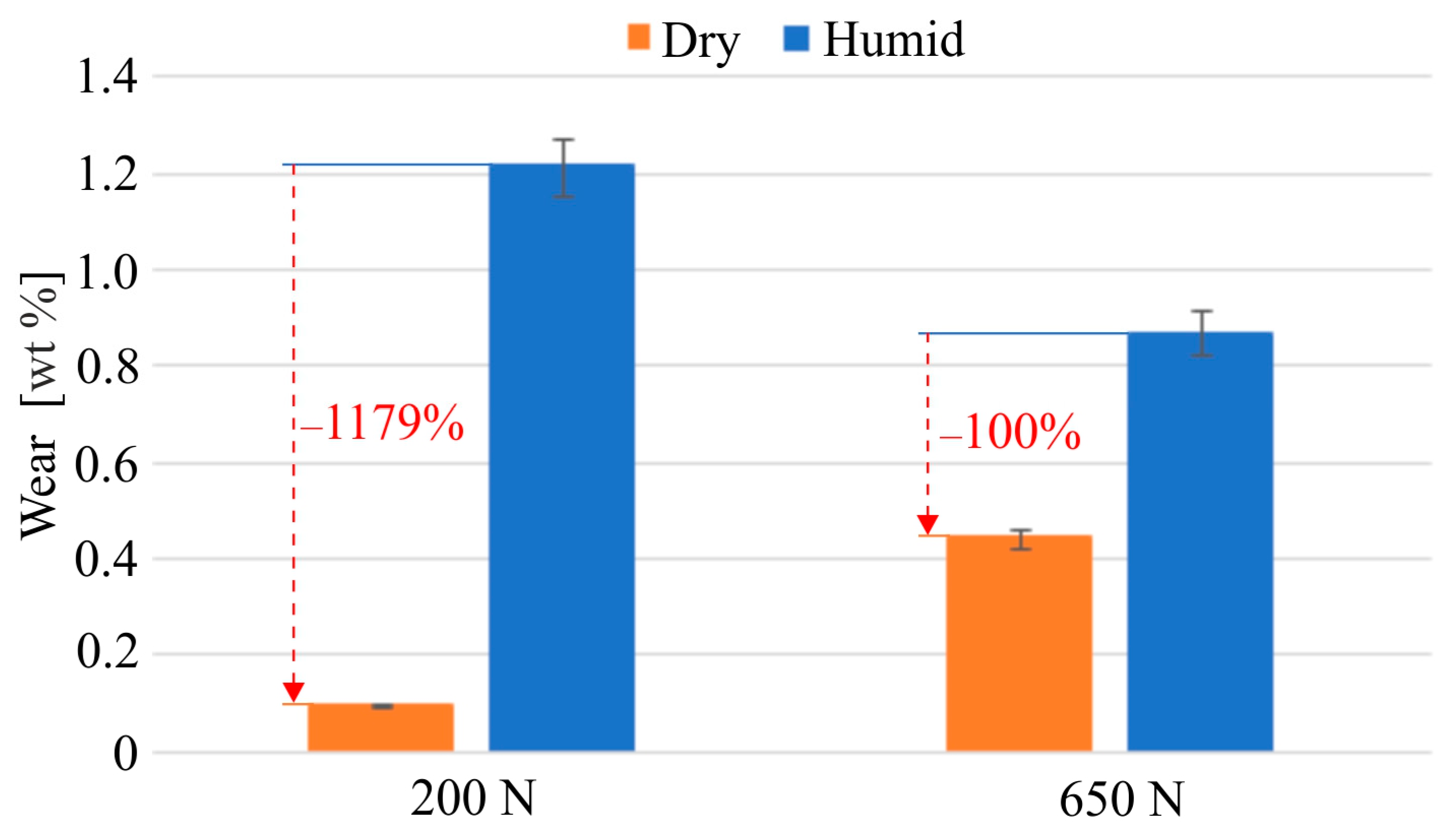

3.2. Evaluation of Graphite Mass Loss and Its Transfer to the Steel Surface After the Friction Cycle

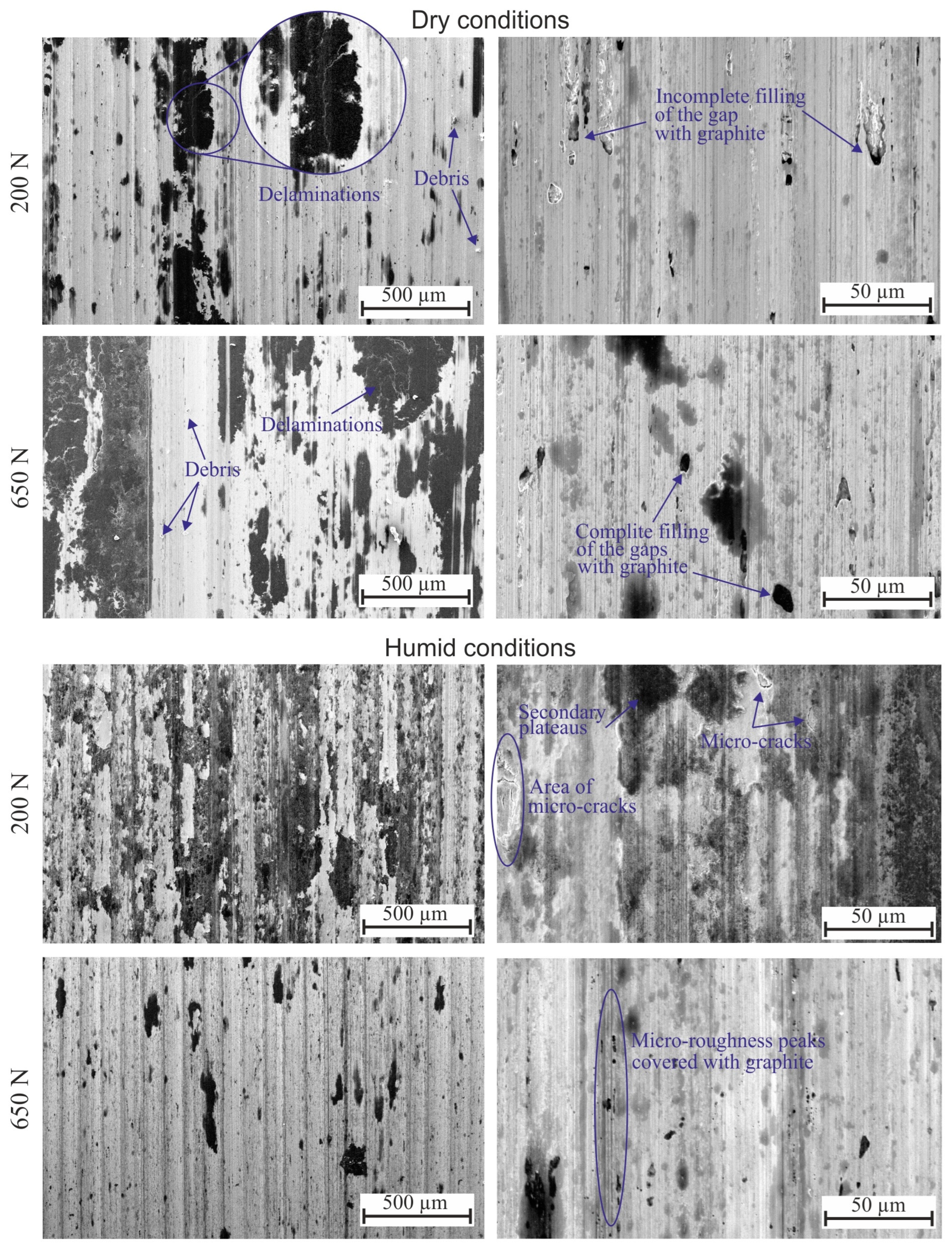

3.3. Scanning Evaluation of Alloy Steel Surface After Friction Cycle

4. Discussion

5. Conclusion

- For the tested loads and operating conditions in dry conditions, the friction torque remained stable, whereas in humid conditions, cyclic variations were observed due to the application of water to the friction zone. Similar trends of change and behavior after the application of water are observed for COF. Under dry conditions, an increase in load from 200 to 650 N results in an increase in average friction torque of about 235%, and under humid conditions, by about 209%. In contrast, no clear average COF changes were observed for the operating and load conditions tested.

- Compared to dry running conditions, humid conditions contribute to a decrease in friction node temperature of about 12% for a 200 N load and about 18% for a 650 N load.

- Regardless of the load, compared to dry operating conditions, humid conditions contribute to significantly higher wear on the graphite surface. Water acts as a lubricant, reducing direct contact between surfaces while weakening the cohesive bonds of the graphite. For a load of 200 N, an increase in wear of about 1179% was recorded, and for 650 N, an increase of about 100%.

- Compared to dry conditions, under humid conditions at a 200 N load, the mass applied to the steel surface increased by about 114%, while at 650 N it decreased by about 250%, indicating a dependence on the amount of deposited graphite on load and operating conditions.

- After a dry friction cycle with loads of 200 and 650 N, an unevenly deposited graphite layer, traces of its delamination, and isolated wear products were observed on the steel surface. After a humid friction cycle at a load of 200 N, large areas of graphite are observed on the steel surface. The graphite takes on a characteristic layered structure, and local secondary plateaus and areas of microcracks in the graphite layers can also be seen. At a load of 650 N, only sparse and small areas of graphite are observed on the steel surface.

- The research results obtained may be helpful for engineers looking for possibilities to increase the durability and efficiency of technical seals operating in demanding conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| COF | Coefficient of Friction |

References

- Shah, R.; Chen, R.; Woydt, M. The Effects of Energy Efficiency and Resource Consumption on Environmental Sustainability. Lubricants 2021, 9, 117. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Kayode, J.F.; Afolalu, S.A.; Emetere, M.E.; Monye, S.I.; Sunday, L.; Lawa, S.L. Application and impact of tribology in energy-an overview. E3S Web Conf. 2023, 391, 01081. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, J.; Wang, S.; Wang, Y.; Li, Y. Effects of carbon nanotubes functionalization on mechanical and tribological properties of nitrile rubber nanocomposites: Molecular dynamics simulations. Comput. Mater. Sci. 2021, 196, 110556. [Google Scholar] [CrossRef]

- Alajmi, M.; Alrashdan, K.R.; Alsaeed, T.; Shalwan, A. Tribological characteristics of graphite epoxy composites using adhesive wear experiments. J. Mater. Res. Technol. 2020, 9, 13671–13681. [Google Scholar] [CrossRef]

- Xu, F.; Wang, Y.; Feng, Y.; Chen, F.-F.; Zhu, Y.-J.; Yu, Y. Graphene oxide/polyethyleneimine/hydroxyapatite nanowire composite paper: Unexpected mechanical robustness after fire attacking and fire alarm application. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107061. [Google Scholar] [CrossRef]

- Dong, Z.; Yang, K.; Zhang, F. Investigations on the mechanics and tribology of multilayer graphene nanosheet in TiAl aviation composites. Adv. Mech. Eng. 2021, 13, 16878140211040714. [Google Scholar] [CrossRef]

- Zhai, M.; Zhang, F.; Chen, X.; Lin, Y.; Zhu, M.; Tang, H. Preparation and characterization of nanodiamond reinforced aluminum matrix composites by hot-press sintering. Diam. Relat. Mater. 2021, 120, 108664. [Google Scholar] [CrossRef]

- Hajdukiewicz, G.; Komarov, A.I.; Orda, D.V.; Panasiuk, K. Analysis of the Impact of Graphite Addition on the Tribological Properties of Composites with Polyester–Glass Recyclate. Materials 2025, 18, 376. [Google Scholar] [CrossRef]

- Yang, C.; Sheng, L.; Zhao, C.; Chen, P.; Ouyang, W.; Xu, D.; Zheng, Y.; Chu, P.K. Improved lubricating and corrosion resistance of MAO coatings on ZK61 Mg alloy by co-doping with graphite and nano-zirconia. J. Mater. Res. Technol. 2024, 33, 2275–2291. [Google Scholar] [CrossRef]

- Shukla, D.K.; Mukherjee, B.; Islam, A.; Keshri, A.K. Peculiar high temperature tribological behaviour of plasma sprayed graphene nanoplatelets reinforced cerium oxide coatings. Ceram. Int. 2021, 47, 17809–17812. [Google Scholar]

- Musharavati, F.; Jaber, F.; Nasor, M.; Sarraf, M.; Nezhad, E.Z.; Uzun, K. Micromechanical properties of hydroxyapatite nanocomposites reinforced with CNTs and ZrO2. Ceram. Int. 2023, 49, 7466–7475. [Google Scholar] [CrossRef]

- Puchý, V.; Hvizdoš, P.; Hrubovčáková, M.; Falat, L.; Mrázek, J.; Vojtko, M.; Milkovič, O.; Podobová, M. Tribological behaviour of spark plasma sintered and laser ablated SiC-graphene nanoplatelets composite. Ceram. Int. 2023, 49, 24332–24338. [Google Scholar]

- Chriaa, M.; Karkri, A.; Trigui, I.; Jedidi, E. The performances of expanded graphite on the phase change materials composites for thermal energy storage. Polymer 2021, 212, 123128. [Google Scholar] [CrossRef]

- Wu, F.; Li, X.; Jiao, Y.; Pan, C.; Fan, G.; Long, Y.; Yang, H. Multifunctional flexible composite membrane based on nanocellulose-modified expanded graphite/electrostatically spun fiber network structure for solar thermal energy conversion. Energy Rep. 2024, 11, 4564–4571. [Google Scholar]

- Bai, L.; Ge, Y.; Zhu, L.; Chen, Y.; Yi, M. Preparation and properties of copper-plated expanded graphite/copper composites. Tribol. Int. 2021, 161, 107094. [Google Scholar]

- Jin, H.; Zhou, K.; Ji, Z.; Tian, X.; Chen, Y.; Lu, L.; Ren, Y.; Xu, C.; Duan, S.; Li, J.; et al. Comparative tribological behavior of friction composites containing natural graphite and expanded graphite. Friction 2020, 8, 684–694. [Google Scholar]

- Sun, Z.; Zhao, Z.-K.; Zhang, Y.-Y.; Li, Y.-Q.; Fu, Y.-Q.; Sun, B.-G.; Shi, F.-Q.; Huang, P.; Hu, N.; Fu, S.-Y. Mechanical, tribological and thermal properties of injection molded short carbon fiber/expanded graphite/polyetherimide composites. Compos. Sci. Technol. 2021, 201, 108498. [Google Scholar]

- Vande Ryse, R.; Van Osta, M.; Gruyaert, M.; Oosterlinck, M.; Kalácska, Á.; Edeleva, M.; Pille, F.; D’hooge, D.R.; Cardon, L.; De Baets, P. Playing with Low Amounts of Expanded Graphite for Melt-Processed Polyamide and Copolyester Nanocomposites to Achieve Control of Mechanical, Tribological, Thermal and Dielectric Properties. Nanomaterials 2024, 14, 606. [Google Scholar] [CrossRef]

- Manoharan, S.; Vijay, R.; Lenin, D.; Singaravelu, P.; Kchaou, M. Experimental Investigation on the Tribo-Thermal Properties of Brake Friction Materials Containing Various Forms of Graphite: A Comparative Study. Arab. J. Sci. Eng. 2019, 44, 1459–1473. [Google Scholar]

- Tang, X.; Tong, J.; Wang, L.; Hu, W.; Liu, D.; Yu, C.; Yuan, S.; Ma, Y.; Zhuang, J. Study on the mechanism of expanded graphite to improve the fading resistance of the non-asbestos organic composite braking materials. Tribol. Int. 2023, 180, 108278. [Google Scholar] [CrossRef]

- Xue, Y.; Yan, S.; Chen, Y. Thermomechanical and tribological properties of polyimide and polyethersulfone blends reinforced with expanded graphite particles at various elevated temperatures. J. Appl. Polym. Sci. 2022, 139, e52512. [Google Scholar]

- Jia, Z.; Hao, C.; Yan, Y.; Yang, Y. Effects of nanoscale expanded graphite on the wear and frictional behaviors of polyimide-based composites. Wear 2015, 338–339, 282–287. [Google Scholar]

- Struchkova, T.S.; Okhlopkova, A.A.; Sleptsova, S.A. Triboengineering properties of polytetrafluoroethylene modified by thermally expanded graphite. J. Frict. Wear 2008, 29, 381–385. [Google Scholar]

- Wang, L.; Zhang, L.; Tian, M. Effect of expanded graphite (EG) dispersion on the mechanical and tribological properties of nitrile rubber/EG composites. Wear 2012, 276–277, 85–93. [Google Scholar]

- Somberg, J.; Gonçalves, G.; Emami, N. Graphene oxide versus graphite and chemically expanded graphite as solid lubricant in ultrahigh molecular weight polyethylene composites. Tribol. Int. 2023, 187, 108643. [Google Scholar]

- Japić, D.; Kulovec, S.; Kalin, M.; Slapnik, J.; Nardin, B.; Huskić, M. Effect of Expanded Graphite on Mechanical and TribologicalProperties of Polyamide 6/Glass Fibre Composites. Adv. Polym. 2022, 2022, 9974889. [Google Scholar]

- Li, J.; Zhang, W.; Tang, Z.; Hu, T.; Li, X.; Wu, W.; Zhang, C. Facile fabrication and tribological properties of self-lubricating polyurethane based on expanded graphite/paraffin for water lubricated bearings. J. Mater. Res. Technol. 2024, 33, 9791–9801. [Google Scholar]

- Feng, W.; Liang, B.; Chen, J.; Gao, X.; Yao, D.; Lu, C.; Pang, X. Tribological performance of epoxy composites reinforced by 3D expanded graphite skeleton containing oil microcapsules. Tribol. Int. 2024, 197, 109814. [Google Scholar] [CrossRef]

- Feng, W.; Liang, B.; Li, H.; Chen, J.; Gao, X.; Yao, D.; Lu, C.; Pang, X. Interconnected expanded graphite/stearic acid networks for self-lubricating PA6 composites with excellent heat dissipation performance. Polym. Compos. 2024, 1–13. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, G.; Wang, J.; Wang, H.; Zhao, W.; Zeng, Q. Tribological properties of low-temperature time-dependent pretreated graphite for mechanical seal pairs in high-speed turbopump. Friction 2024, 12, 305–318. [Google Scholar]

- Zhao, J.; Liu, Y.; Liu, D.; Gu, Y.; Zheng, R.; Ma, R.; Li, S.; Wang, Y.; Shi, Y. The Tribological Performance of Metal-/Resin-Impregnated Graphite under Harsh Condition. Lubricants 2022, 10, 2. [Google Scholar] [CrossRef]

- Litwin, W. Marine propeller shaft bearings under low-speed conditions: Water vs. oil lubrication. Tribology 2019, 62, 839–841. [Google Scholar]

- Li, Q.; Xie, O.; Du, P.; Fei, D.; Li, X.; Li, B.; Liu, Z. Experimental study on scale-down pads for nuclear main pump thrust bearing. Ann. Nucl. Energy 2024, 198, 110297. [Google Scholar] [CrossRef]

- Staf, M.; Šnajdárek, L.; Hlinčík, T. A gasket design suitable for helium circuits of generation IV Gas-Cooled reactors. Ann. Nucl. Energy 2024, 200, 110383. [Google Scholar]

- Płaza, S.; Margielewski, L.; Celichowski, G. Introduction to Tribology and Tribochemistry; WUŁ: Łódź, Poland, 2005. [Google Scholar]

- Jia, J.H.; Chen, J.M.; Zhou, H.D.; Wang, J.B.; Zhou, H. Friction and wear properties of bronze graphite composite under water lubrication. Tribol. Int. 2004, 37, 423–429. [Google Scholar]

- Hirani, H.; Goilkar, S.S. Formation of transfer layer and its effect on friction and wear of carbon–graphite face seal under dry, water and steam environments. Wear 2009, 266, 1141–1154. [Google Scholar]

- Restuccia, P.; Ferrario, M.; Righi, M.C. Monitoring water and oxygen splitting at graphene edges and folds: Insights into the lubricity of graphitic materials. Carbon 2020, 156, 93–103. [Google Scholar]

- Venturi, F. Carbon-based films: A review on mechanical and tribology properties. Mater. Chem. Phys. 2024, 325, 129716. [Google Scholar]

- Wang, D.Y.; Chang, C.L.; Ho, W.Y. Oxidation behavior of diamond-like carbon films. Surf. Coat. Technol. 1999, 120–121, 138–144. [Google Scholar]

- Scharf, T.; Prasad, S. Solid lubricants: A review. J. Mater. Sci. 2012, 48, 511–531. [Google Scholar]

- Tahir, N.A.M.; Liza, S.; Fukuda, K.; Yaakob, Y.; Zulkifli, N.A.; Rawian, N.A.M.; Ghazazi, N.A.M. Influence of humidity on the tribological performance of graphite reinforced aluminium anodic oxide coating. Tribol. Int. 2024, 197, 109752. [Google Scholar]

- Bhowmick, S.; Banerji, A.; Alpas, A.T. Role of humidity in reducing sliding friction of multilayered graphene. Carbon 2015, 87, 374–384. [Google Scholar]

- Li, Z.; Yang, W.; Wu, Y.; Wu, S.; Cai, Z. Role of humidity in reducing the friction of graphene layers on textured surfaces. Appl. Surf. Sci. 2017, 403, 362–370. [Google Scholar]

- Chen, Z.; Hui, H.; Jin, K.; Cheng, J.; Zhu, S.; Zhang, B.; Yang, J. Microstructure and high temperature tribological properties of copper-based graphite composite coatings reinforced with in-situ Fe3C. Tribol. Int. 2025, 204, 110452. [Google Scholar]

- Chen, Z.; He, X.; Xiao, C.; Kim, S.H. Effect of Humidity on Friction and Wear—A Critical Review. Lubricants 2018, 6, 74. [Google Scholar] [CrossRef]

- Bregliozzi, G.; Di Schino, A.; Kenny, J.M.; Haefke, H. The influence of atmospheric humidity and grain size on the friction and wear of AISI 304 austenitic stainless steel. Mater. Lett. 2003, 57, 4505–4508. [Google Scholar] [CrossRef]

- Baets, P.; Kalacska, G.; Strijckmans, K.; Van de Velde, F.; Van Peteghem, A.P. Experimental study by means of thin layer activation of the humidity influence on the fretting wear of steel surfaces. Wear 1998, 216, 131–137. [Google Scholar] [CrossRef]

- Ma, W.; Lu, J. Effect of surface texture on transfer layer formation and tribological behaviour of copper–graphite composite. Wear 2011, 270, 218–229. [Google Scholar] [CrossRef]

| Material | Expanded Graphite | Alloy Steel (AISI 4130) |

|---|---|---|

| Chemical composition [%] | C-98, O-0.5-1, S-0.01-0.1, Si,Al,Fe,Ca,Mg-0.5-2 | Fe-96, C-0.28-0.33, Cr-0.8-1.1, Mn-0.4-0.6, P-0.035, Si-0.15-0.35, S-0.035 |

| Sample | Counter-Sample | |

| Properties | expanded graphite | alloy steel (AISI 4130) |

| Density [g/cm3] | 1.6 | 7.85 |

| Roughness Ra [μm] | - | 0.5 |

| Hardness [HB] | - | 217 |

| Expansion [mL/h] | 200 ÷ 300 | - |

| Tensile strength [MPa] | 1–10 | 560 |

| Yield strength [MPa] | - | 460 |

| Thermal conductivity (W/mK) | 25–470 | 42.7 |

| Conditions | dry | humid | ||

| Humidity in the test room [%] | 41 | |||

| Test duration [min] | 30 | |||

| Rotational speed [rpm] | 150 | |||

| Load [N] | 200 | 650 | 200 | 650 |

| Load [N] | Conditions | No. | Element At. [%] | |||||

|---|---|---|---|---|---|---|---|---|

| C | Fe | O | Si | S | P | |||

| 200 | dry | 1 | 9.88 | 84.27 | 4.31 | 0.54 | 0.19 | 0.08 |

| humid | 2 | 83.97 | 4.19 | 11.27 | 0.15 | 0.09 | 0.16 | |

| 650 | dry | 3 | 18.57 | 75.48 | 4.29 | 0.5 | 0.23 | 0.17 |

| humid | 4 | 27.63 | 58.26 | 11.0 | 0.88 | 0.23 | 1.02 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rewolińska, A.; Leksycki, K.; Wojciechowski, Ł.; Perz, K. Analysis of Tribological Properties of Expanded Graphite—Alloy Steel Pair Under High Loads in Dry and Humid Conditions. Appl. Sci. 2025, 15, 4022. https://doi.org/10.3390/app15074022

Rewolińska A, Leksycki K, Wojciechowski Ł, Perz K. Analysis of Tribological Properties of Expanded Graphite—Alloy Steel Pair Under High Loads in Dry and Humid Conditions. Applied Sciences. 2025; 15(7):4022. https://doi.org/10.3390/app15074022

Chicago/Turabian StyleRewolińska, Aleksandra, Kamil Leksycki, Łukasz Wojciechowski, and Karolina Perz. 2025. "Analysis of Tribological Properties of Expanded Graphite—Alloy Steel Pair Under High Loads in Dry and Humid Conditions" Applied Sciences 15, no. 7: 4022. https://doi.org/10.3390/app15074022

APA StyleRewolińska, A., Leksycki, K., Wojciechowski, Ł., & Perz, K. (2025). Analysis of Tribological Properties of Expanded Graphite—Alloy Steel Pair Under High Loads in Dry and Humid Conditions. Applied Sciences, 15(7), 4022. https://doi.org/10.3390/app15074022