Utilisation of Mining Waste for Production of Ceramic Tiles

Abstract

1. Introduction

- Evaluate the potential for the simultaneous utilisation of post-flotation sludge and mining clay waste in ceramic tile production.

- Determine the optimal waste ratios and processing conditions to meet the PN-EN 14411:2016 standard [37].

- Assess the technical and environmental benefits of this waste utilisation approach.

- Establish a foundation for sustainable waste management practices that could be applied even if lignite mining decreases due to CO2 emission policies [38].

2. Materials and Methods

2.1. Characterisation of Raw Materials

2.1.1. Characteristics of Post-Flotation Waste

2.1.2. TG3 Clay Characteristics

2.2. Compositions of Sets Intended for Testing

2.3. Research Methodology

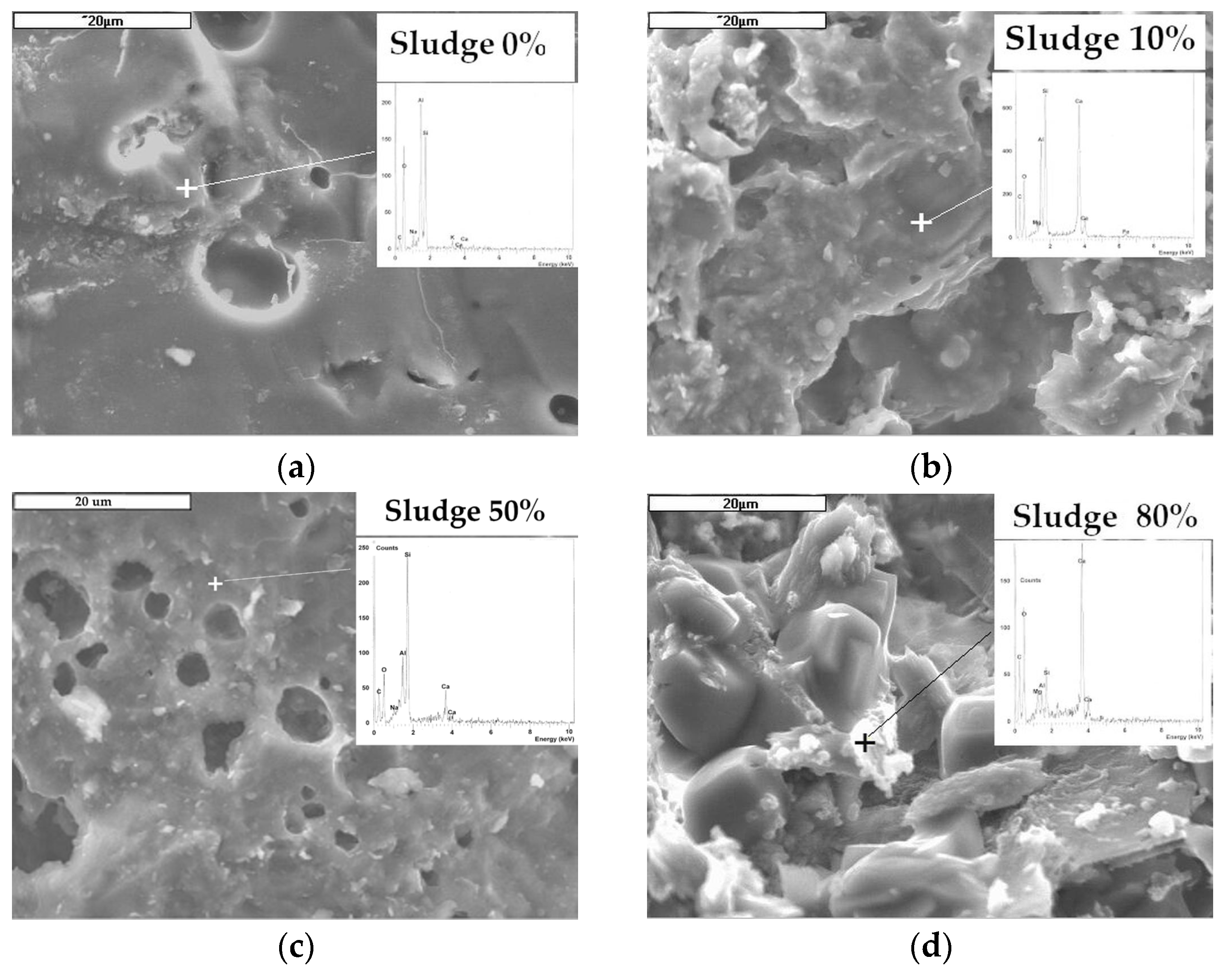

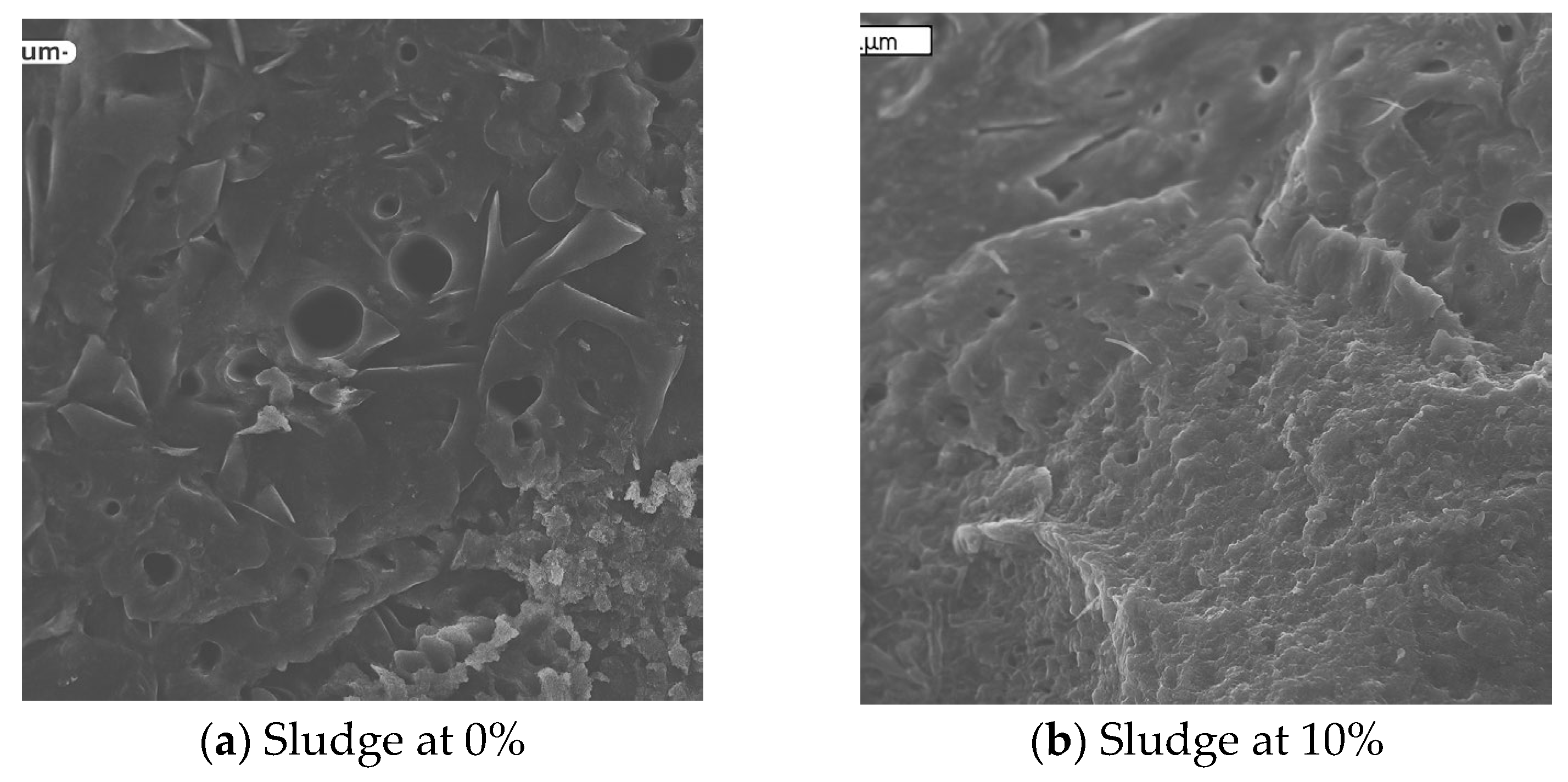

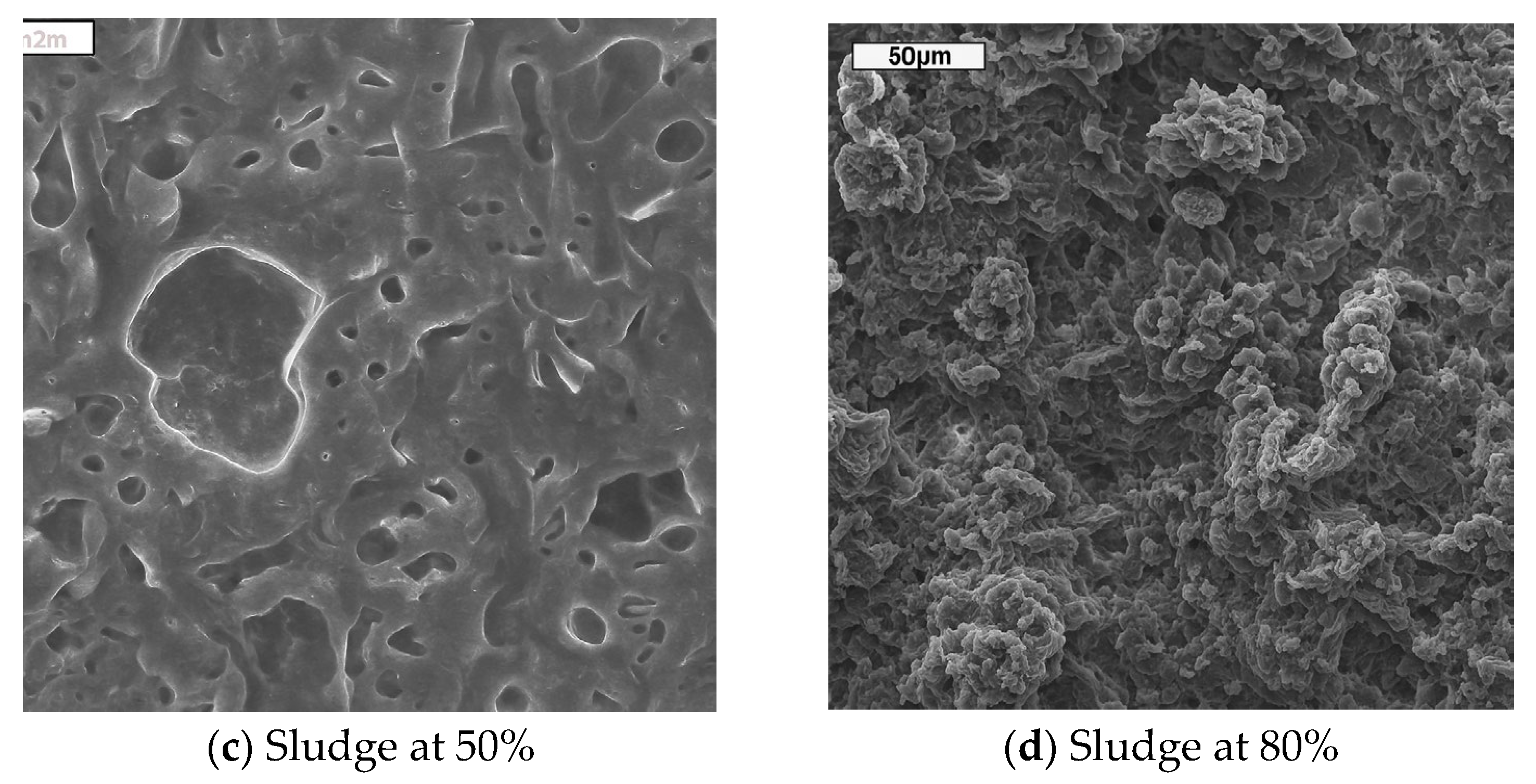

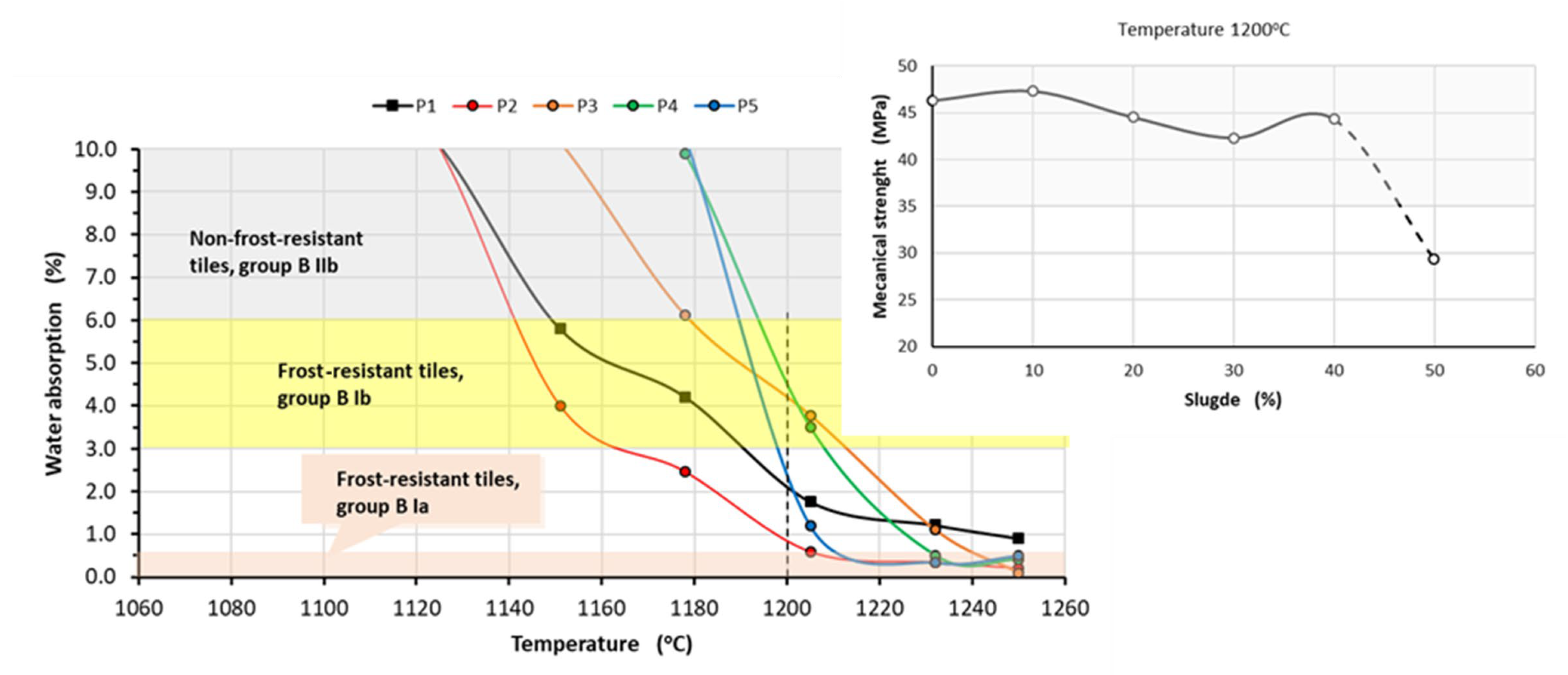

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaźmierczak, U.; Blachowski, J.; Górniak-Zimroz, J.; Wirth, H. Quantitative and qualitative research on the waste from the mining of rock raw materials in Lower Silesia. Minerals 2018, 8, 375. [Google Scholar] [CrossRef]

- Blachowski, J.; Buczyńska, A. Spatial and multicriteria analysis of dimension stones and crushed rocks quarrying in the context of sustainable regional development: Case study of Lower Silesia (Poland). Sustainability 2020, 12, 3022. [Google Scholar] [CrossRef]

- Blachowski, J.; Buczyńska, A. Analysis of rock raw materials transport and its implications for regional development and planning. Case study of Lower Silesia (Poland). Sustainability 2020, 12, 3165. [Google Scholar] [CrossRef]

- Lewińska-Preis, L.; Szram, E.; Fabiańska, M.J.; Nádudvari, Á.; Misz-Kennan, M.; Abramowicz, A.K.; Kruszewski, Ł.; Kita, A. Selected ions and major and trace elements as contaminants in coal-waste dump water from the Lower and Upper Silesian Coal Basins (Poland). Int. J. Coal Sci. Technol. 2021, 4, 790–814. [Google Scholar] [CrossRef]

- Lasocki, S.; Antoniuk, J.; Moscicki, J. Environmental protection problems in the vicinity of the Zelazny most flotation wastes depository in Poland. J. Environ. Sci. Health Part A Tox. Hazard Subst. Environ. Eng. 2003, 38, 1435–1443. [Google Scholar] [CrossRef] [PubMed]

- Czaban, S. Klasyfikacja jakości wód powierzchniowych w Polsce. Infrastrukt. I Ekol. Teren. Wiej. Nr 2008, 5, 9. [Google Scholar]

- Bogda, A.; Chodak, T. Niektóre właściwości fizyczne i skład mineralogiczny osadów poflotacyjnych ze zbiornika „Gilow”. Zesz. Probl. Postępów Nauk. Rol. 1995, 418, 415–420. [Google Scholar]

- Czaban, S. Wybrane aspekty starych składowisk odpadów mineralnych. Zesz. Pol. Akad. Nauk 2008, 7, 45–55. [Google Scholar]

- Krztoń, K. Skład i Właściwości Chemiczne Osadów Poflotacyjnych Zbiornika nr 3 w Iwinach; Maszynopis; Instytut Gleboznawstwa i Ochrony Środowiska Rolniczego AR we Wrocławiu: Wrocław, Poland, 2001. [Google Scholar]

- Uzarowicz, Ł.; Kwasowski, W.; Śpiewak, O.; Świtoniak, M. Studies of technogenic soils in Poland: Past, present, and future perspectives. Soil Sci. Annu. 2020, 71, 281–299. [Google Scholar] [CrossRef]

- Baran, A.; Śliwka, M.; Lis, M. Wybrane właściwości odpadów poflotacyjnych zdeponowanych w zbiornikach Gilów i Żelazny Most w aspekcie możliwości ich zagospodarowania przyrodniczego. Arch. Min. Sci. 2013, 58, 969–978. [Google Scholar]

- Rybak, B.; Gediga, K.; Stefanek, P.; Bożęcki, P.; Jabłoński, M. Fitotoksyczność Odpadów Poflotacyjnych w Rejonie Iwin; PW-R1403903 MNiSW; Instytut Ochrony Środowiska: Warsaw, Poland, 2020; pp. 343–348. [Google Scholar]

- Kotarska, I. Odpady wydobywcze z górnictwa miedzi w Polsce—Bilans, stan zagospodarowania i aspekty środowiskowe. Cuprum 2012, 4, 45–62. [Google Scholar]

- Janiec, R.; Nowak, J. Odpady z przeróbki rud i ich mieszaniny z piaskiem jako materiał podsadzkowy. Rudy I Met. Nieżelazne 1973, 18, 428–432. [Google Scholar]

- Duczmal-Czernikiewicz, A.; Diatta, J.B.; Rachwał, L. Mineralogia odpadów po flotacji rud miedzi oraz możliwość ich rolniczego zastosowania. Biul. Państw. Inst. Geol. 2012, 448, 371–380. [Google Scholar]

- Kudełko, J.; Nitek, D. Wykorzystanie odpadów z działalności górniczej jako substytutów surowców mineralnych. Cuprum 2011, 60, 51–64. [Google Scholar]

- Lin, D.F.; Chang, W.C.; Yuan, C.; Luo, H.L. Production and characterization of glazed tiles containing incinerated sewage sludge. Waste Manag. 2008, 28, 502–508. [Google Scholar]

- Łuszczkiewicz, A. Koncepcje wykorzystania odpadów flotacyjnych z przeróbki rud miedzi w okręgu legnicko-głogowskim. Inżynieria Min. 2000, 25–35. Available online: http://potopk.com.pl/Full_text/2000_full/2000_1_03.pdf (accessed on 30 March 2025).

- Izak, P.; Delikhovskyi, Y.; Olszyna, A. Use of Post-Flotation Solidified Tailings from Copper Production for Ceramic Tile Production. Materials 2023, 16, 132. [Google Scholar] [CrossRef]

- Zou, D.H.S. An innovative technology for tailings treatment. In Proceedings of the Tailings and Mine Waste ’97, Fort Collins, CO, USA, 13–17 January 1997; pp. 633–642. [Google Scholar]

- Haxel, G.B.; Hedrick, J.B.; Orris, G.J. Rare Earth Elements—Critical Resources for High Technology; Fact Sheet 087-02; U.S. Geological Survey: Reston, VA, USA, 2002. [Google Scholar]

- Lewicka, E. Rational use of selected mining by-products in the ceramic industry in Poland Gospodarka surowcami mineralnymi. Miner. Resour. Manag. 2020, 36, 59–76. [Google Scholar]

- Gawor, Ł. Potential conflicts connected with the recovery of secondary materials from post mining waste dump. Environ. Socio-Econ. Stud. 2017, 5, 82–86. [Google Scholar] [CrossRef][Green Version]

- Nadłonek, W.; Cabała, J. Potentially toxic elements in soils and plants on a reclaimed coal-waste dump in southern Poland: Preliminary study. Acta Geodyn. Geomater. 2016, 13, 271–279. [Google Scholar] [CrossRef]

- Castilhos, Z.C.; Cesar, R.G.; Egler, S.G.; Alamino, R.; Magalhães, D.d.P.; Pinheiro, B.A.; Vezzone, M.; Serrano, A.F.; Lourenço, R.S.; Schneider, C.L. Chemical and ecotoxicological indicators for evaluating the treatment of coal mining wastes. Environ. Sci. Pollut. Res. 2023, 30, 85721–85732. [Google Scholar] [CrossRef]

- Yap, C.K.; Khor, W.C.; Peng, S.N.; Peng, S.X.; Leong, S.Y.; Fong, F.T. Heavy Metals in Environment: Toxicity, Sources, and Control. In Heavy Metal Contamination Prevention; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Lavrinenko, A.A.; Svechnikova, N.Y.; Konovnitsyna, N.S.; Igumensheva, E.A.; Kuklina, O.V.; Khasanzyanova, A.I. Utilization of Bituminous Coal Flotation Wastes in the Manufacture of Ceramic Brick. Solid Fuel Chem. 2018, 52, 406–410. [Google Scholar] [CrossRef]

- Rebelo, W.B.; Zaccaron, A.; Saviatto, E.; Olivo, E.F.; Acordi, J.; Raupp-Pereira, F.; Ribeiro, M.J. Valorization of the Residual Fraction of Coal Tailings: A Mineral Circularity Strategy for the Clay Ceramic Industry in the Carboniferous Region of Santa Catarina, Southern Brazil. Materials 2024, 17, 2131. [Google Scholar] [CrossRef]

- Rakhimova, G.; Stolboushkin, A.; Vyshar, O.; Stanevich, V.; Rakhimov, M.; Kozlov, P. Strong Structure Formation of Ceramic Composites Based on Coal Mining Overburden Rocks. J. Compos. Sci. 2023, 7, 209. [Google Scholar] [CrossRef]

- Gawor, Ł.; Dolnicki, P.; Warcholik, W. Możliwości eksploatacji złóż wtórnych (zwałowisk pogórniczych) jako przykład zmian w sektorze przemysłu wydobywczego. Pr. Kom. Geogr. Przemysłu Pol. Tow. Geogr. 2014, 27, 256–266. [Google Scholar]

- Gawor, Ł. Coal mining waste dumps as secondary deposits—Examples from the Upper Silesian Coal Basin and the Lublin Coal Basin. Geol. Geophys. Environ. 2014, 40, 285–289. [Google Scholar] [CrossRef]

- KGHM Polska Miedź S.A. Report on Sustainable Development 2022. pp. 232–235. Available online: https://kghm.com/en/investors/results-center/integrated-reports (accessed on 10 March 2025).

- Kowalczyk, W. Mining Waste. Raport of Raw Materials from Anthropogenic Fields, Urząd Marszałkowski, Wrocław 2017. Available online: https://projects2014-2020.interregeurope.eu/fileadmin/user_upload/tx_tevprojects/library/file_1580812753.pdf (accessed on 10 March 2025).

- Kucha, H.; Pawlikowski, M. Genetic investigations of copper Zechstein deposits. Pol. Geol. 2010, 36, 513–538. [Google Scholar]

- Bakalarz, A. An Analysis of Copper Concentrate from a Kupferschiefer-type Ore from Legnica-Glogow Copper Basin (SW Poland). Miner. Process. Extr. Metall. Rev. 2021, 42, 552–564. [Google Scholar] [CrossRef]

- Ratajczak, T.; Hycnar, E. Kopaliny Towarzyszące w Złożach Węgla Brunatnego; Instytut Gospodarki Surowcami Mineralnymi i Energią Polskiej Akademii Nauk: Kraków, Poland, 2017. [Google Scholar]

- PN-EN 14411:2016; Ceramic Tiles—Definition, Classification, Characteristics, Assessment and Verification of Constancy of Performance and Marking. Polish Committee for Standardization: Warsaw, Poland, 2017.

- Uberman, R. Procedures leading to acquirement of mineral raw materials from antropogenic deposits. Miner. Resour. Manag. 2021, 37, 101–110. [Google Scholar]

- EN ISO 10545-4:2019; Ceramic Tiles—Part 4: Determination of Modulus of Rupture and Breaking Strength. ISO: Geneva, Switzerland, 2019.

- Zadeh, A.J.; Sarrafi, A.; Izadpanah, M.R.; Aminian, F.; Ghotbi, E. Production of ceramic tiles from the waste materials of copper extraction process. In Proceedings of the 12th Conference of the European Ceramic Society, Stockholm, Sweden, 19–23 June 2011. [Google Scholar]

- Jordán, M.M.; Boix, A.; Sanfeliu, T.; de la Fuente, C. Firing transformations of cretaceous clays used in the manufacturing of ceramic tiles. Appl. Clay Sci. 1999, 14, 225–234. [Google Scholar] [CrossRef]

- Romero, M.; Andrés, A.; Alonso, R.; Viguri, J.; Rincón, J.M. Sintering behaviour of ceramic bodies from contaminated marine sediments. Ceram. Int. 2008, 34, 1917–1924. [Google Scholar] [CrossRef]

- Xu, L.; Liu, Y.; Chen, M.; Wang, N.; Chen, H.; Liu, L. Production of green, low-cost and high-performance anorthite-based ceramics from reduced copper slag. Constr. Build. Mater. 2023, 375, 130982. [Google Scholar]

- Dondi, M.; Cappelletti, P.; D’amore, M.; de Gennaro, R.; Graziano, S.; Langella, A.; Raimondo, M.; Zanelli, C. Lightweight aggregates from waste materials: Reappraisal of expansion behavior and prediction schemes for bloating. Constr. Build. Mater. 2016, 127, 394–409. [Google Scholar] [CrossRef]

- Cheng, X.; Ke, S.; Wang, Q.; Wang, H.; Shui, A.; Liu, P. Fabrication and characterization of anorthite-based ceramic using mineral raw materials. Ceram. Int. 2012, 38, 3227–3235. [Google Scholar] [CrossRef]

- Ozturk, Z.B.; Gultekin, E.E. Preparation of ceramic wall tiling derived from blast furnace slag. Ceram. Int. 2015, 41, 12020–12026. [Google Scholar] [CrossRef]

- Andreola, F.; Barbieri, L.; Lancellotti, I.; Leonelli, C.; Manfredini, T. Recycling of industrial wastes in ceramic manufacturing: State of art and glass case studies. Ceram. Int. 2016, 42, 13333–13338. [Google Scholar] [CrossRef]

- Zanelli, C.; Conte, S.; Molinari, C.; Soldati, R.; Dondi, M. Waste recycling in ceramic tiles: A technological outlook. Resour. Conserv. Recycl. 2020, 168, 105289. [Google Scholar] [CrossRef]

- Zanoletti, A.; Federici, S.; Borgese, L.; Bergese, P.; Ferroni, M.; Depero, L.E.; Bontempi, E. Embodied energy as key parameter for sustainable materials selection: The case of reusing coal fly ash for removing anionic surfactants. Chem. Eng. Trans. 2018, 70, 859–864. [Google Scholar] [CrossRef]

- Marghussian, V.K.; Maghsoodipoor, A. Fabrication of unglazed floor tiles containing Iranian copper slags. Ceram. Int. 1999, 25, 617–622. [Google Scholar] [CrossRef]

- Dondi, M.; Raimondo, M.; Zanelli, C. Clays and bodies for ceramic tiles: Reappraisal and technological classification. Appl. Clay Sci. 2014, 96, 91–109. [Google Scholar] [CrossRef]

- Dondi, M. Mechanical and tribological properties of ceramic tiles: A reappraisal. In Proceedings of the 4th SERES ’07, Eskişehir, Turkey, 26 September 2007. [Google Scholar]

- Ayati, B.; Ferrándiz-Mas, V.; Newport, D.; Cheeseman, C. Use of clay in the manufacture of lightweight aggregate. Constr. Build. Mater. 2018, 162, 124–131. [Google Scholar] [CrossRef]

- Gorai, B.; Jana, R.K.; Premchand. Characteristics and utilisation of copper slag—A review. Resour. Conserv. Recycl. 2003, 39, 299–313. [Google Scholar]

- Cuttaree, V.; Olievschi, V.; Oh, J.E.; Strand, J.P.; Marquez, P.; Shrestha, A.; Czapski, R.; Giemza, J.; Podolske, R.; Mircheva, B. Poland Transport Policy Note: Toward a Sustainable Land Transport Sector; Report No. 59715-PL; World Bank, Europe and Central Asia Region: Washington, DC, USA, 2011. [Google Scholar]

- Wang, Y.; Liu, Y.; Cui, S.; Sun, B.; Gong, X.; Gao, F.; Wang, Z. Comparative life cycle assessment of different fuel scenarios and milling technologies for ceramic tile production: A case study in China. J. Clean. Prod. 2020, 273, 122846. [Google Scholar] [CrossRef]

- Romero, M.; Padilla, I.; Contreras, M.; López-Delgado, A. Mullite-Based Ceramics from Mining Waste: A Review. Minerals 2021, 11, 332. [Google Scholar] [CrossRef]

- Ye, L.; Hong, J.; Ma, X.; Qi, C.; Yang, D. Life cycle environmental and economic assessment of ceramic tile production: A case study in China. J. Clean. Prod. 2018, 189, 432–441. [Google Scholar] [CrossRef]

- Gabaldón-Estevan, D.; Criado, E.; Monfort, E. The green factor in European manufacturing: A case study of the Spanish ceramic tile industry. J. Clean. Prod. 2014, 70, 242–250. [Google Scholar] [CrossRef]

- Vieira, A.W.; Rosso, L.S.; Demarch, A.; Pasini, D.; Ruzza, S.P.; Arcaro, S.; Ribeiro, M.J.; Angioletto, E. Life cycle assessment in the ceramic tile industry: A review. J. Mater. Res. Technol. 2023, 23, 3904–3915. [Google Scholar] [CrossRef]

| Grain Size | |

|---|---|

| Class [mm] | Content [%] |

| >0.2 | 2.0 |

| 0.2–0.1 | 4.6 |

| 0.1–0.06 | 2.3 |

| <0.06 | 89.9 |

| Component | Content [%wt] |

|---|---|

| SiO2 | 60.0–63.0 |

| Al2O3 | 3.9–4.9 |

| CaO | 14.4–17.2 |

| MgO | 5.1–6.9 |

| K2O | 1.1–1.5 |

| Na2O | 0.29–0.31 |

| Fe2O3 | 0.55–0.65 |

| LOI | 10.0–11.0 |

| Cu | (0.92–0.93)10−6 |

| Ag | (14.6–14.7) 10−6 |

| Co | (23.0–24.1) 10−6 |

| Physicochemical Features | “Clean” | “Grey” | Test Temperature |

|---|---|---|---|

| Al2O3 [%] | 15.0–22.0 | 19.1–20.3 | |

| Fe2O3 [%] | 0.7–2.0 | 1.1–1.3 | |

| SiO2 [%] | 55.0–69.0 | 57.7–62.9 | |

| TiO2 [%] | 0.1–0.8 | 0.7–0.8 | |

| CaO [%] | 0.1-0.3 | 0.9–0.92 | |

| MgO [%] | 0.1–0.5 | 0.1–0.3 | |

| Na2O [%] | 0.1–0.2 | 0.1–0.2 | |

| K2O [%] | 2.3–4.5 | 2.9–3.1 | |

| Mechanical strength in raw condition [MPa] | 6.5–12.0 | 2.5–4.5 | 25 °C |

| Water absorption [%] | 10.0–11.0 8.3–8.8 6.0–6.5 | 10.0–11.0 7.0–8.0 2.1–4.0 | 1120 °C 1180 °C 1240 °C |

| Drying shrinkage [%] | 3.9–4.1 | 5.5–6.5 | |

| Contractility [%] | 9.5–11.0 11.0–12.0 12.2–14.8 | 8.2–8.3 10.0–10.9 11.6–11.7 | 1120 °C 1180 °C 1240 °C |

| Whiteness after firing [%] | 57–69 51–62 45–75 | 48–49 43–46 39–42 | 1120 °C 1140 °C 1240 °C |

| Loss of ignition [%] | 13.1 | 13.8 | |

| Kaolinite [%] | 22–28 | 67–69 | |

| Illite [%] | 17–27 | 0.1–0.9 | |

| Quartz | 57–62 | 57.6–63.0 | |

| Residue 0.06 mm [%] | 40–42 | 4.6–5.0 | |

| 0–2 µm [%] | 80 | 55 | |

| 0–5 µm [%] | 90 | 75 | |

| Mixing water [%] | 33.1 | 33.9 |

| Oxides | TG3clay [%] | Tailing Sludge [%] |

|---|---|---|

| SiO2 | 60.3 | 61.0 |

| Al2O3 | 19.7 | 4.4 |

| CaO | 0.9 | 15.9 |

| MgO | 0.2 | 6.0 |

| K2O | 3.0 | 1.3 |

| Na2O | 0.1 | 0.3 |

| Fe2O3 | 1.2 | 0.6 |

| LOI | 13.8 | 10.5 |

| Ʃ | 100.0 | 100.0 |

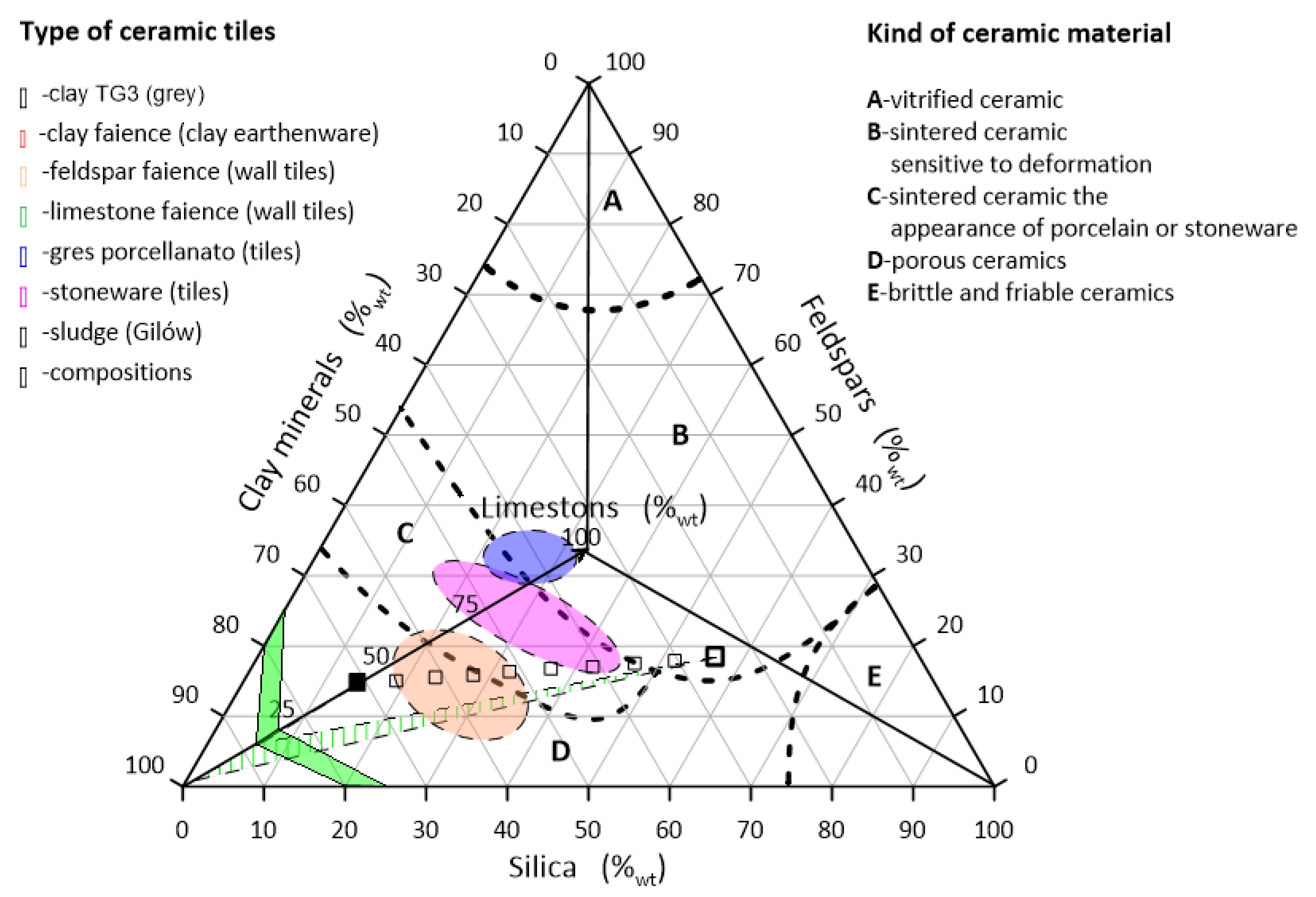

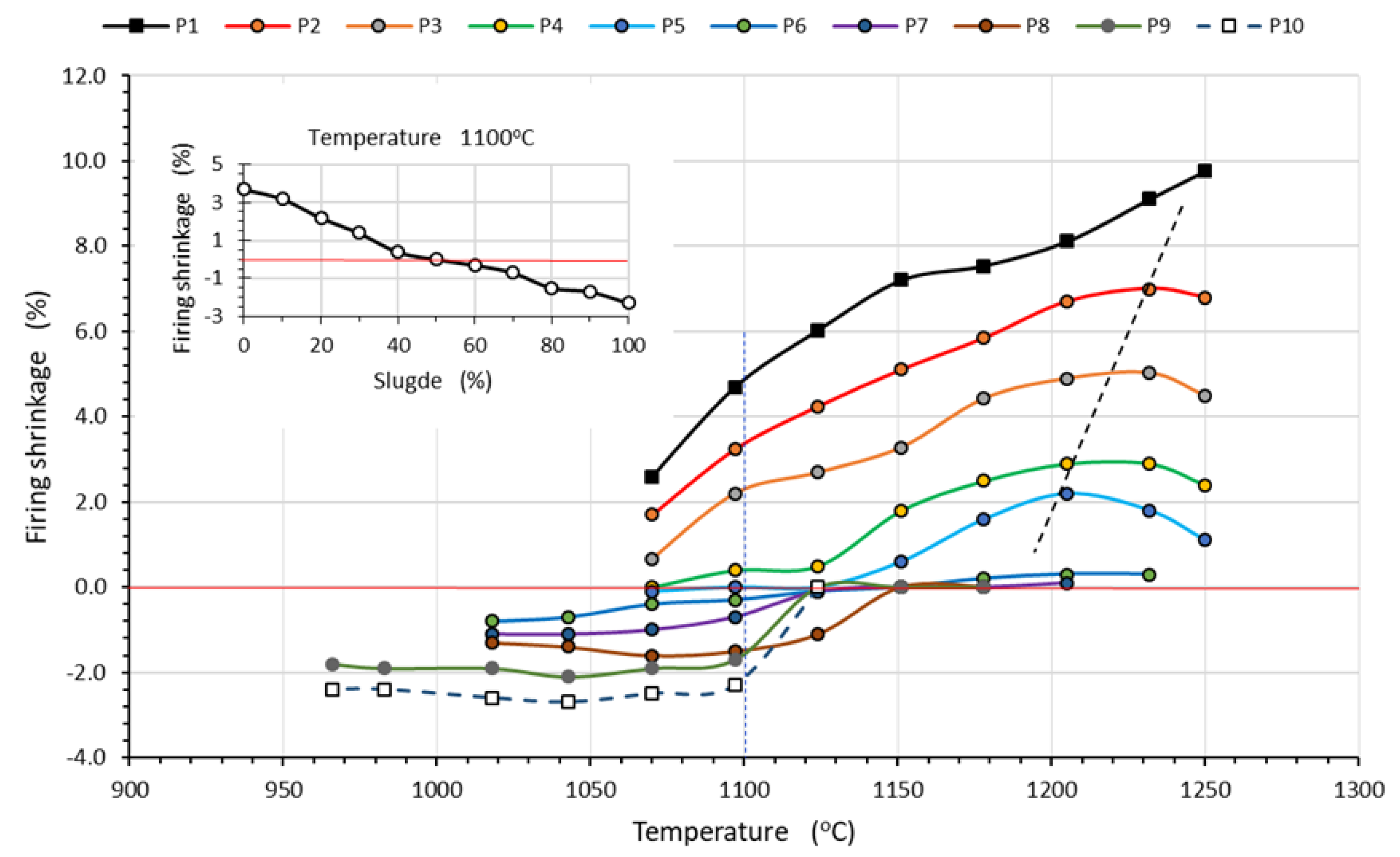

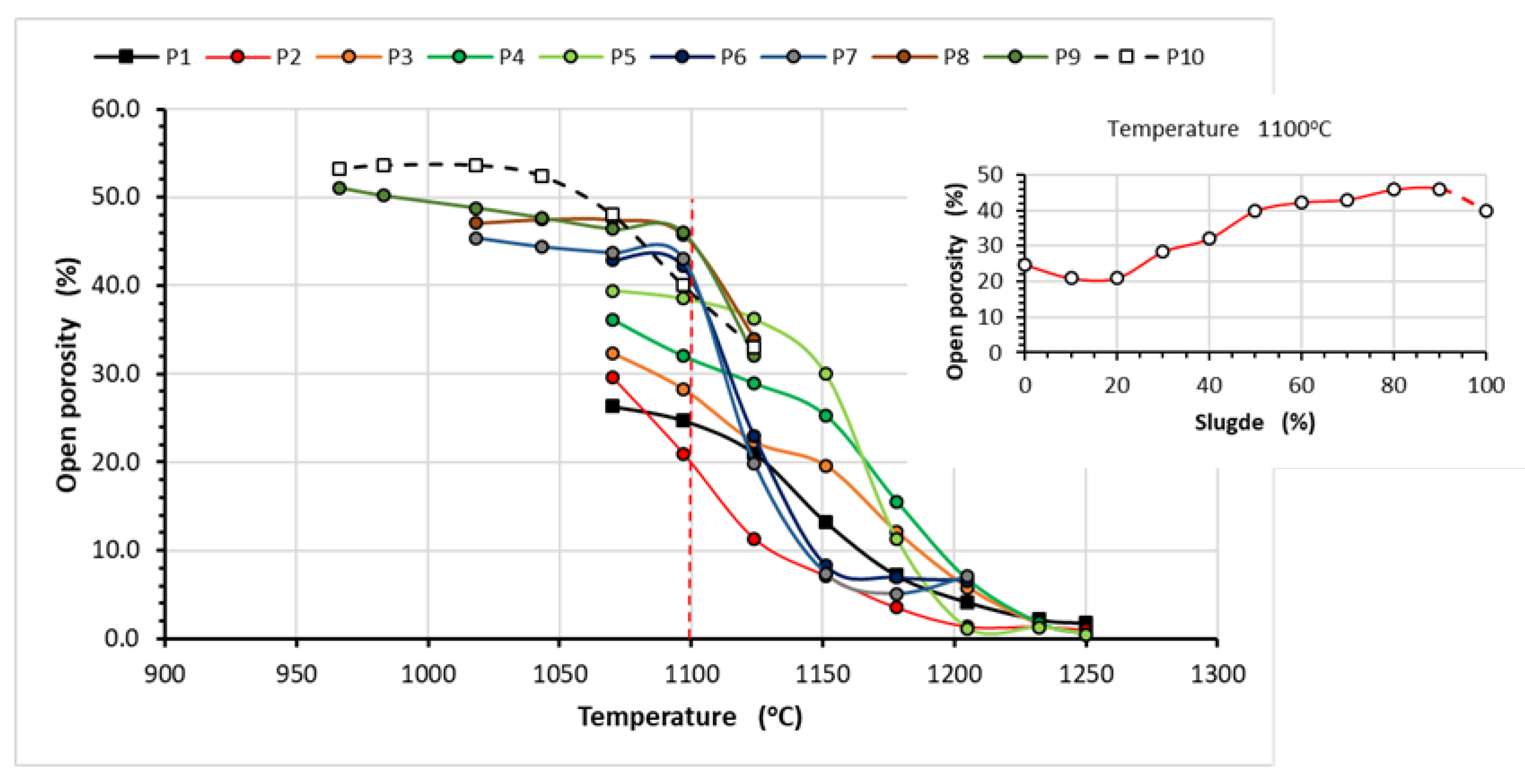

| Mass Symbol | TG3 [%] | Sludge [%] | Clay Minerals [%] | Quartz [%] | Feldspar [%] | Carbonates [%] |

|---|---|---|---|---|---|---|

| P0 | 100 | 0 | 66 | 14 | 19 | 1 |

| P1 | 90 | 10 | 60 | 19 | 19 | 2 |

| P2 | 80 | 20 | 54 | 25 | 17 | 4 |

| P3 | 70 | 30 | 48 | 30 | 17 | 5 |

| P4 | 60 | 40 | 43 | 35 | 16 | 6 |

| P5 | 50 | 50 | 36 | 40 | 16 | 8 |

| P6 | 40 | 60 | 30 | 46 | 15 | 9 |

| P7 | 30 | 70 | 25 | 51 | 14 | 10 |

| P8 | 20 | 80 | 19 | 56 | 14 | 11 |

| P9 | 10 | 90 | 13 | 61 | 13 | 13 |

| P10 | 0 | 100 | 9 | 64 | 13 | 14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Izak, P.; Delihowski, J.; Mastalska-Popławska, J.; Stempkowska, A. Utilisation of Mining Waste for Production of Ceramic Tiles. Appl. Sci. 2025, 15, 3957. https://doi.org/10.3390/app15073957

Izak P, Delihowski J, Mastalska-Popławska J, Stempkowska A. Utilisation of Mining Waste for Production of Ceramic Tiles. Applied Sciences. 2025; 15(7):3957. https://doi.org/10.3390/app15073957

Chicago/Turabian StyleIzak, Piotr, Jurij Delihowski, Joanna Mastalska-Popławska, and Agata Stempkowska. 2025. "Utilisation of Mining Waste for Production of Ceramic Tiles" Applied Sciences 15, no. 7: 3957. https://doi.org/10.3390/app15073957

APA StyleIzak, P., Delihowski, J., Mastalska-Popławska, J., & Stempkowska, A. (2025). Utilisation of Mining Waste for Production of Ceramic Tiles. Applied Sciences, 15(7), 3957. https://doi.org/10.3390/app15073957