1. Introduction

Industry 4.0 has become a driving force in both the research and improvement of manufacturing processes within industrial environments. However, this term serves as an umbrella under which different technologies converge with a common goal: enhancing industrial conditions in terms of productivity, reliability, ecological impact, and worker’s safety [1]. Within this umbrella is the integration of various advanced technologies, such as robotics, digitalization, the Internet of Things (IoT), extended reality (XR), 3D printing, artificial intelligence (AI), and digital twin (DT) technology [2]. Each of these advancements plays a distinct yet complementary role in the evolution of industrial automation. For example, robotics and 3D printing increase the automation of manufacturing processes, while others, such as IoT and AI, provide tools to manage and extract valuable insights from large volumes of data [3]. Additionally, some technologies focus directly on workers’ safety and training, such as extended reality [4]. Although these technologies may seem disconnected at first glance, all of them play a major and complementary role in the common goal of industry automatization and advancement. For instance, the inclusion of biosensors in XR simulators to improve workers skills and their productivity will require the use of IoT to extract real data from their performance and AI tools to adapt the XR simulators in real time to the worker’s emotional state and cognitive workload [5]. Digital twins (DTs) replicate physical assets in near-real-time, integrating real-world sensor data with advanced modeling for enhanced analysis. In fault prognostics, they aid by simulating expected operational behavior or potentially destructive cases, enabling early diagnostics and risk assessment. AI further benefits from the resulting data augmentation, improving predictive accuracy and decision-making [6].

To maximize industrial process reliability, the detection and diagnosis of faults is essential. Early fault detection in machinery will avoid damage in both critical machine components and workpieces. Additionally, in terms of industrial safety, this would facilitate safer operations, reducing the risk to plant workers. Therefore, the early detection and correct diagnosis of faults will facilitate decision-making that allows corrective actions to be taken to repair damaged components. In recent years, fault detection techniques, combining artificial intelligence and signal processing, have emerged to achieve this goal for different industrial processes, such as energy generation [7], machining [8], or chemical processes [9]. However, the topic continues to generate new trends [10] in methodologies related to multiple fault detection, novelty detection, data mining, hardware development, etc. Continuous advancements in this domain have led to the integration of more sophisticated methodologies that leverage domain-specific knowledge to enhance multi-fault classification and predictive maintenance capabilities. These developments highlight the increasing role of feature engineering and specialized knowledge in refining AI-driven fault detection strategies, contributing to more accurate and computationally efficient solutions [11].

This Special Issue aims to compile novel research findings merging artificial intelligence and signal processing techniques to boost fault diagnosis. The selected works consider not only the development of new techniques but also their industrial implementation, with real-world industrial requirements in mind.

2. An Overview of Published Articles

This Special Issue compiles 15 research works and one review focusing on artificial intelligence and signal processing techniques applied to fault diagnosis in different industrial problems and environments.

In these works, different signals are acquired and processed. Signals extracted from most of the most widely used sensors are considered: linear strain gauges, temperature sensors, vibration and acoustic sensors, among others. These signals address a variety of real-world problems, such as data imbalance, management of missing data and outliers, data augmentation, pseudo-anomaly sample generation, and the creation of benchmark datasets.

In addition, different signal processing techniques and artificial intelligence techniques have been proposed as the most suitable solutions for modeling and extracting information from signals of different natures. Most systems combine time-series data analysis methods for preprocessing with supervised or unsupervised learning methods for system prediction. Some examples of the time-series data analysis methods for preprocessing proposed in these works are cluster-based segmentation or Mel-frequency cepstral coefficients, discrete wavelet transform, and hybridization of principal component analysis and kernel regression methods based on mutual information. The learning methods for system prediction proposed in these works are cutting-edge solutions, such as convolutional neural networks, extreme learning machine classifiers, the YOLOv8 deep neural network, deep support vector data description models, and one-dimensional convolutional neural networks.

Finally, this combination of artificial intelligence and signal processing techniques has been applied to different fault diagnosis cases. Some of these cases are related to high-end industries, such as the fault detection of next-generation chemical reaction devices, temperature-based warnings in high-speed trains, or defect detection in the manufacturing of laminated composites or printed circuit boards. Some others are focused on well-spread moving devices with a high impact on our society, such as real-time monitoring of conveyor belt damage, engine fault detection of traditional vehicles, fault detection of gears in machinery systems, or positional accuracy degradation in industrial robots. Lastly, others are focused on mechanically fixed structures, such as superficial defect detection for concrete bridges or submerged structure–foundation systems. In this way, this Special Issue covers a wide range of highly demanding applications.

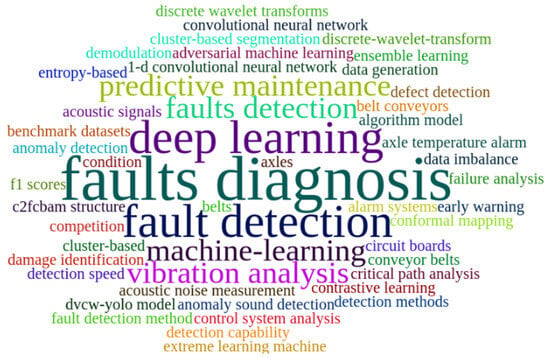

To support this descriptive analysis, a bibliometric analysis was conducted on the 16 manuscripts included in this Special Issue. Figure 1 shows a cloud graph of the words included in the keywords of these works. Firstly, this figure outlines the orientation of all works with the Special Issue topic, being the words machine learning and those words related to fault diagnosis (predictive maintenance, faults diagnosis, and detection) the most relevant. Secondly, it includes words related to the most promising machine learning techniques for these purposes, such as deep learning, convolutional neural networks, or adversarial learning. Thirdly, it includes words about the main signals to be taken into consideration in this field, such as temperature, vibration, or acoustic. Fourthly, it includes words that highlight the main challenges of machine learning in this field of application, such as data imbalance, benchmark datasets, or cluster detection. Finally, it includes words related to the final application of these techniques to this research field, such as belt conveyors, circuit boards, or failure analysis. In summary, Figure 1 shows the convergence of published keywords in the works included in the Special Issue, by means of using different machine learning techniques and sensors’ signals in different industrial problems but facing the same challenges and finding generalizable solutions.

Figure 1.

Cloud graph of most repeated keywords in the works included in this Special Issue.

3. Conclusions

Artificial intelligence techniques play a major role in fault diagnosis and signal processing of complex systems. These techniques help overcome intrinsic limitations in fault diagnosis, such as dataset imbalance, the scarcity of rare fault instances, signal deviations caused by component wear over time, and the lack of labeling processes due to time and cost constraints [12]. Addressing these challenges effectively and implementing these techniques in industrial settings will aid in the broader adoption of Industry 4.0 paradigms, ensuring a more sustainable future of manufacturing, energy generation, and goods and people transport [13]. This Special Issue includes 15 works that try to give some light to this exciting future.

Author Contributions

Conceptualization, A.B.; methodology, A.B.; formal analysis, A.B.; writing—original draft preparation, A.B.; writing—review and editing, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Spanish Centro para el Desarrollo Tecnológico y la Innovación (CDTI), grant number MIG-20221059 (Project MHAYA).

Acknowledgments

This Special Section was firstly defined and promoted by Roque A. Osornio-Ríos, who passed away during this Special Issue period. We dedicate the memory of this Special Issue to him. Those of us who had the pleasure of knowing him saw a person who was approachable, optimistic, and full of energy—always finding common ground between cultures, ideas, and interests. He was warm and personable, with a ready smile and a sharp sense of humor that could captivate you and inspire you to embark on new scientific and personal journeys.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Mahdiraji, H.A.; Iranmanesh, M.; Jafari-Sadeghi, V. From Industry 4.0 Digital Manufacturing to Industry 5.0 Digital Society: A Roadmap Toward Human-Centric, Sustainable, and Resilient Production. Inf. Syst. Front. 2024, 1–33. [Google Scholar] [CrossRef]

- Ukwaththa, J.; Herath, S.; Meddage, D.P.P. A Review of Machine Learning (ML) and Explainable Artificial Intelligence (XAI) Methods in Additive Manufacturing (3D Printing). Mater. Today Commun. 2024, 41, 110294. [Google Scholar] [CrossRef]

- Adriana Cárdenas-Robledo, L.; Hernández-Uribe, Ó.; Reta, C.; Antonio Cantoral-Ceballos, J. Extended Reality Applications in Industry 4.0.—A Systematic Literature Review. Telemat. Inform. 2022, 73, 101863. [Google Scholar] [CrossRef]

- Guillen-Sanz, H.; Checa, D.; Miguel-Alonso, I.; Bustillo, A. A Systematic Review of Wearable Biosensor Usage in Immersive Virtual Reality Experiences. Virtual Real. 2024, 28, 74. [Google Scholar] [CrossRef]

- Jeremiah, S.R.; El Azzaoui, A.; Xiong, N.N.; Park, J.H. A Comprehensive Survey of Digital Twins: Applications, Technologies and Security Challenges. J. Syst. Archit. 2024, 151, 103120. [Google Scholar] [CrossRef]

- Balachandran, G.B.; Devisridhivyadharshini, M.; Ramachandran, M.E.; Santhiya, R. Comparative Investigation of Imaging Techniques, Pre-Processing and Visual Fault Diagnosis Using Artificial Intelligence Models for Solar Photovoltaic System—A Comprehensive Review. Measurement 2024, 232, 114683. [Google Scholar] [CrossRef]

- Kounta, C.A.K.A.; Arnaud, L.; Kamsu-Foguem, B.; Tangara, F. Review of AI-Based Methods for Chatter Detection in Machining Based on Bibliometric Analysis. Int. J. Adv. Manuf. Technol. 2022, 122, 2161–2186. [Google Scholar] [CrossRef]

- Mowbray, M.; Vallerio, M.; Perez-Galvan, C.; Zhang, D.; Del Rio Chanona, A.; Navarro-Brull, F.J. Industrial Data Science—A Review of Machine Learning Applications for Chemical and Process Industries. React. Chem. Eng. 2022, 7, 1471–1509. [Google Scholar] [CrossRef]

- Abid, A.; Khan, M.T.; Iqbal, J. A Review on Fault Detection and Diagnosis Techniques: Basics and Beyond. Artif. Intell. Rev. 2021, 54, 3639–3664. [Google Scholar] [CrossRef]

- Soori, M.; Jough, F.K.G.; Dastres, R.; Arezoo, B. AI-Based Decision Support Systems in Industry 4.0, A Review. J. Econ. Technol. 2024. [Google Scholar] [CrossRef]

- Ramírez-Sanz, J.M.; Maestro-Prieto, J.-A.; Arnaiz-González, Á.; Bustillo, A. Semi-Supervised Learning for Industrial Fault Detection and Diagnosis: A Systemic Review. ISA Trans. 2023, 143, 255–270. [Google Scholar] [CrossRef]

- Jayashree, S.; Reza, M.N.H.; Mohiuddin, M. Impact of Cleaner Production and Environmental Management Systems on Sustainability: The Moderating Role of Industry 4.0. IOP Conf. Ser. Earth Environ. Sci. 2021, 795, 012013. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).