Optimization Methodologies for Analyzing the Impact of Operational Parameters on a Light-Duty Methane/Diesel Reactivity-Controlled Compression Ignition (RCCI) Engine

Abstract

1. Introduction

2. Numerical Methodology

2.1. Governing Equations

2.2. CFD Models

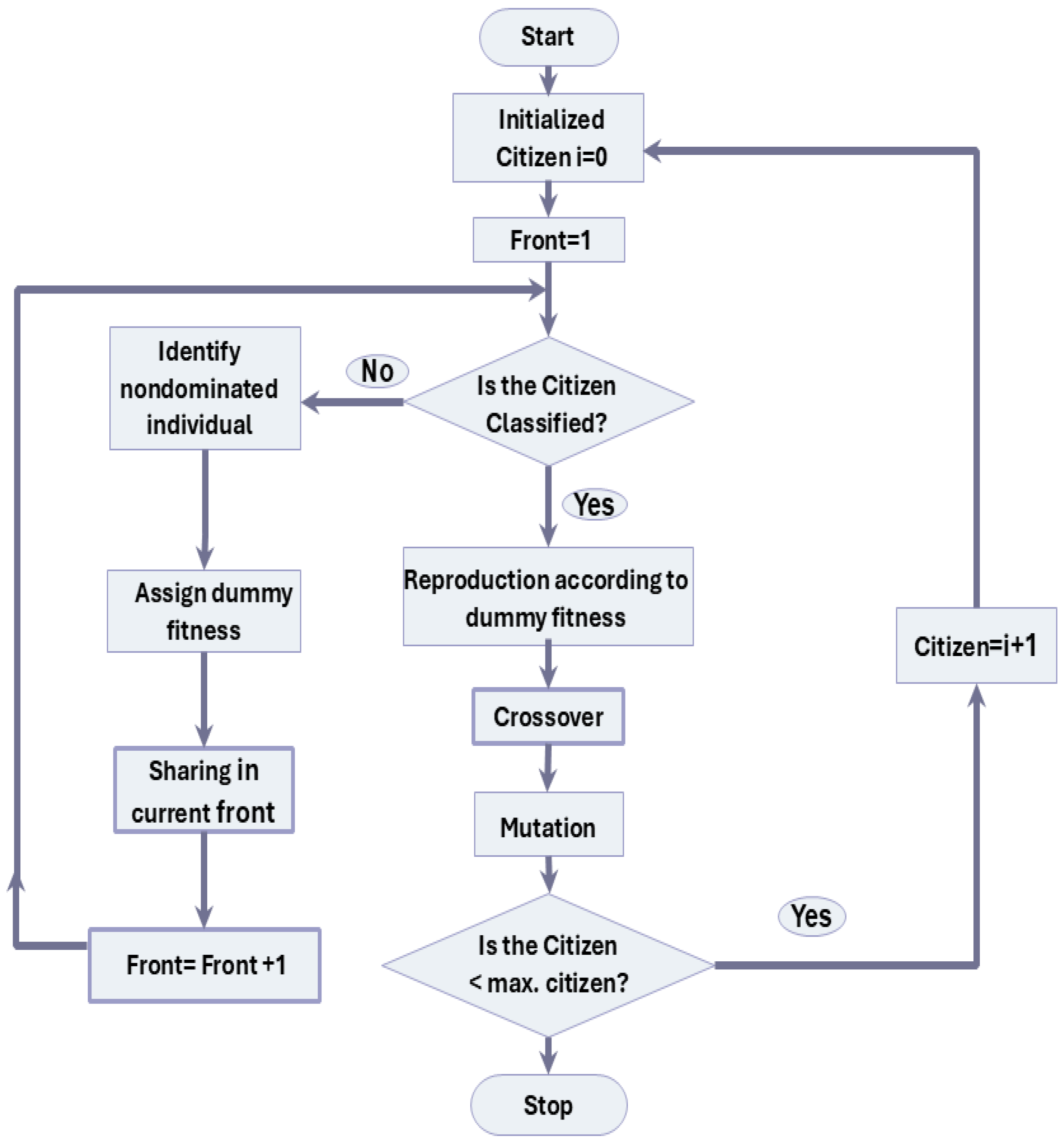

2.3. Optimization Approach

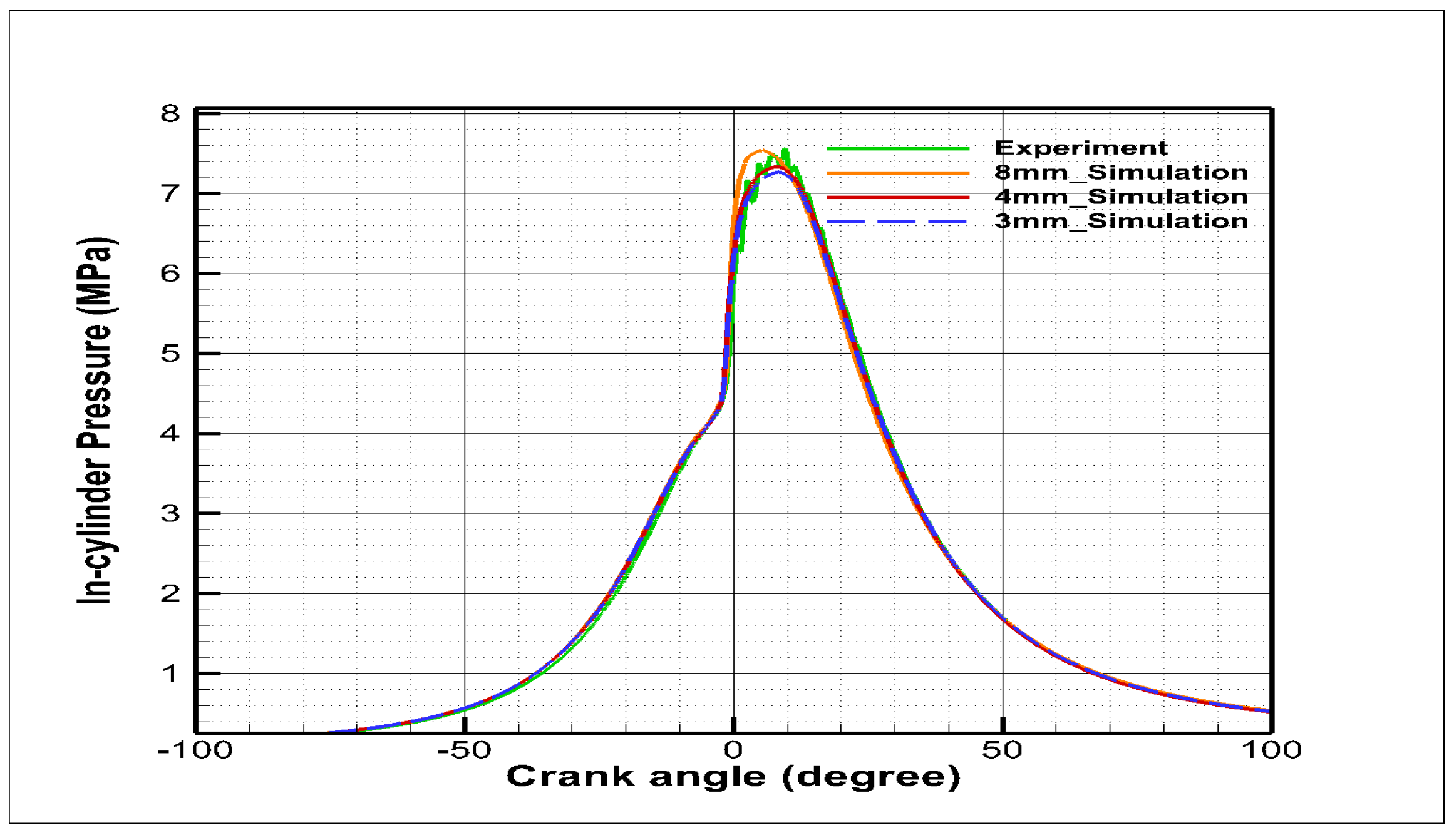

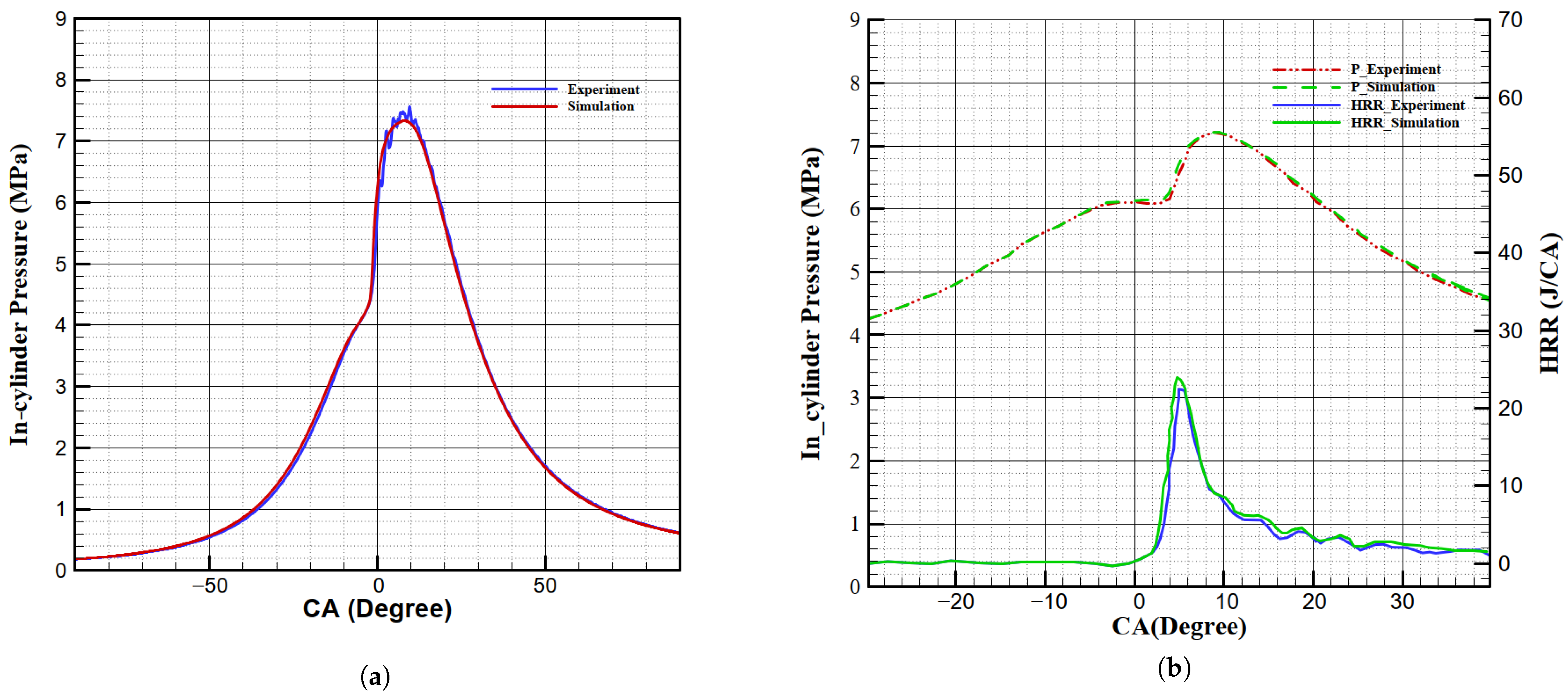

2.4. Validation Study

3. Results

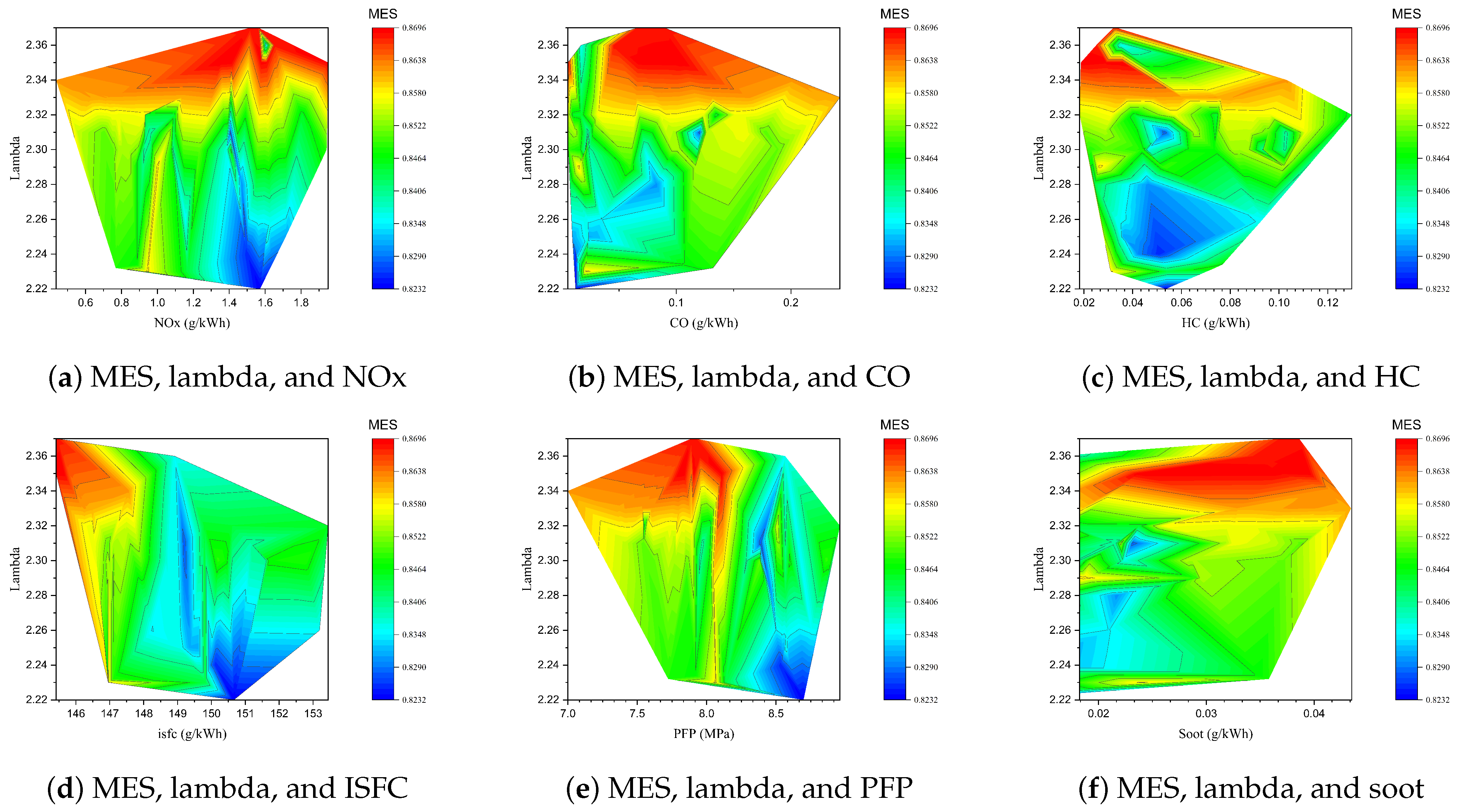

3.1. Lambda and MES Impacts

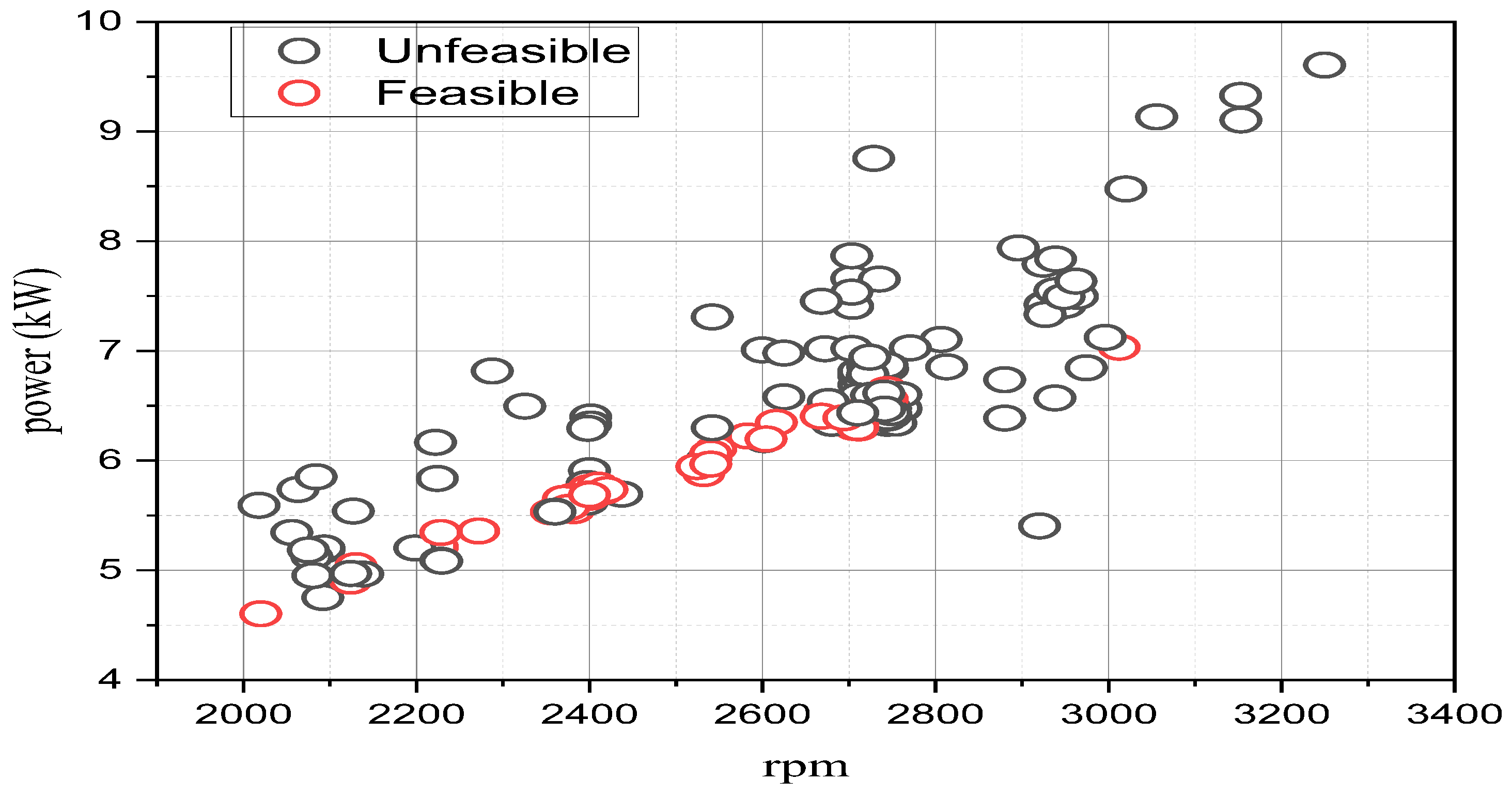

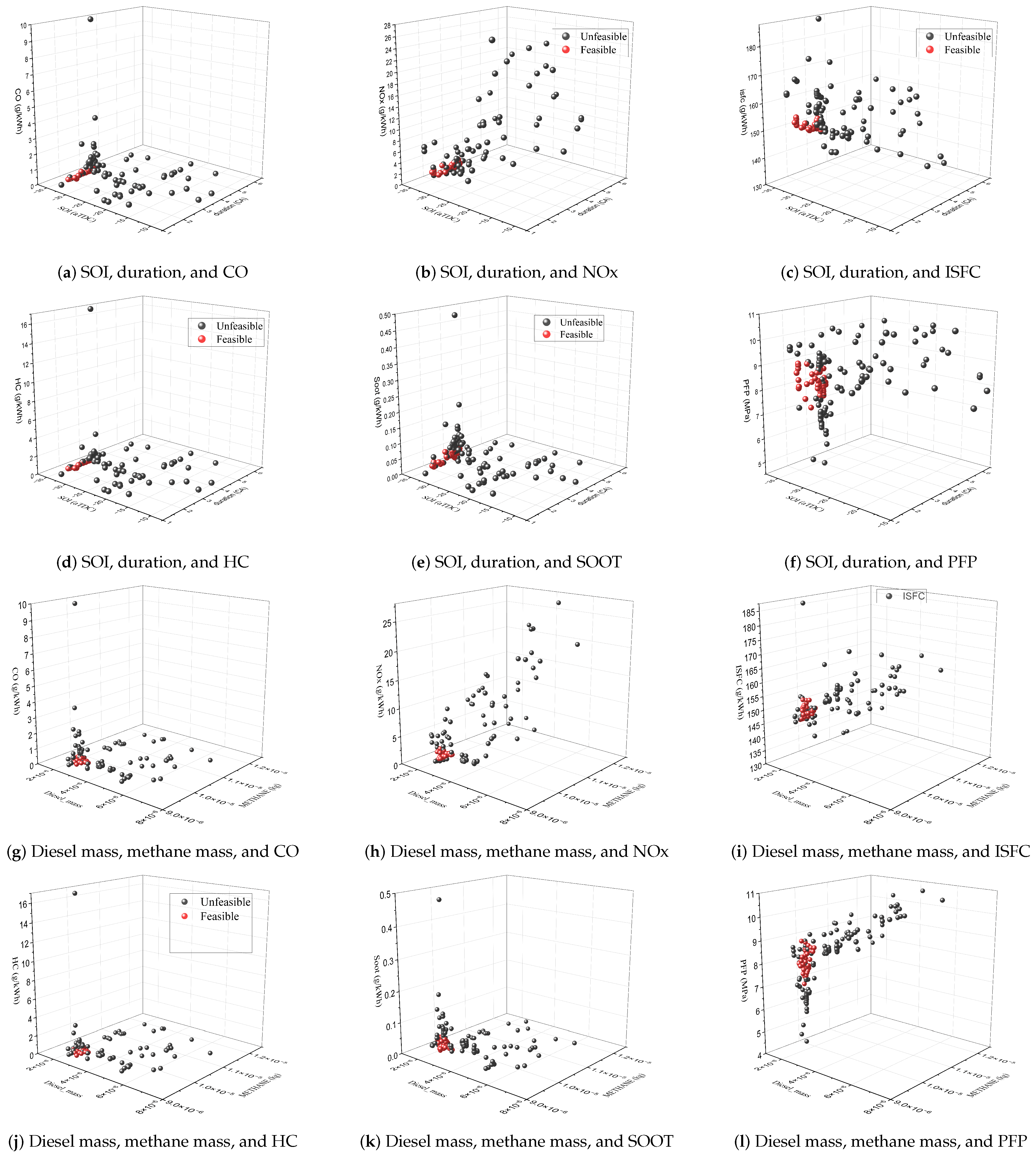

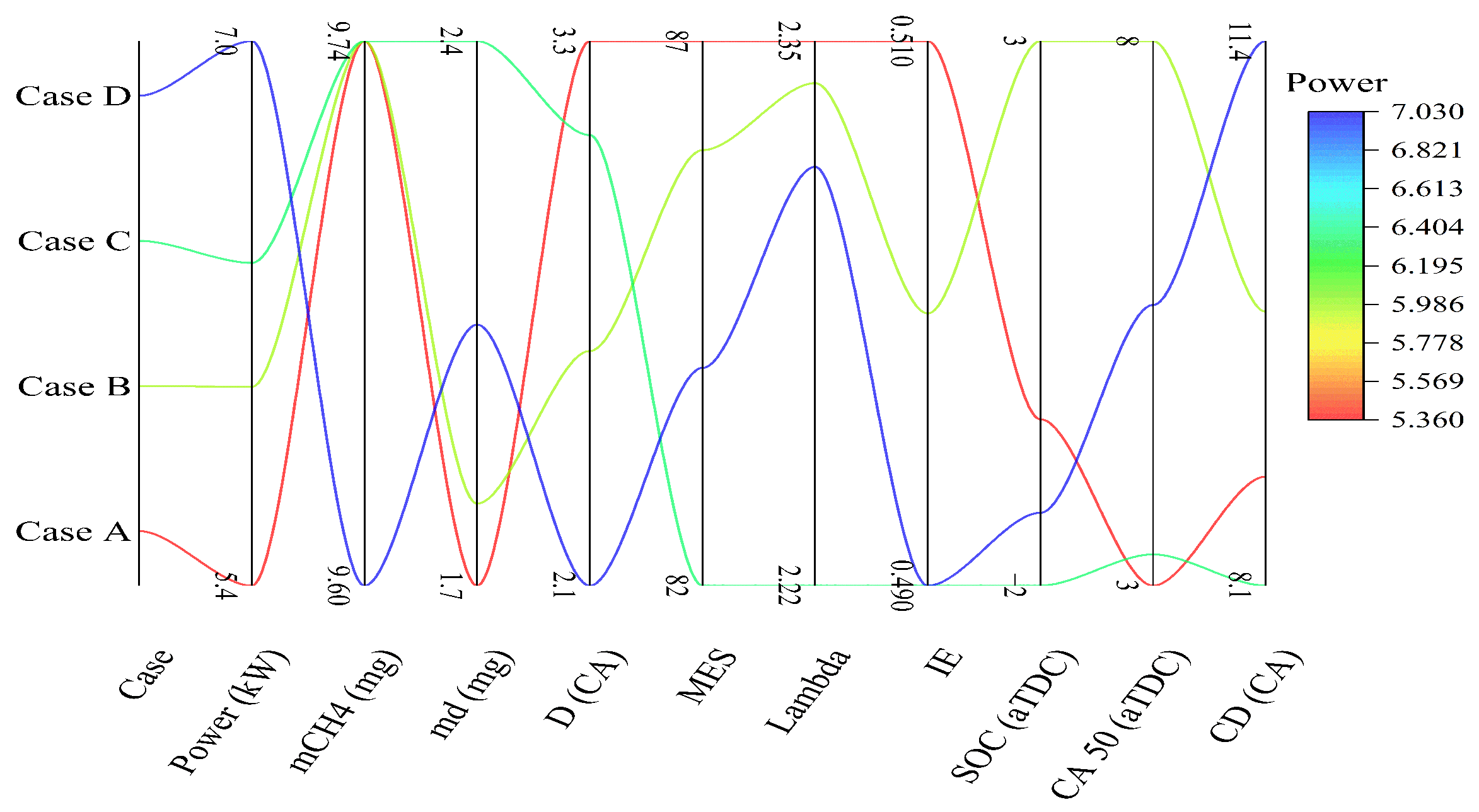

3.2. Operational Parameters Impact

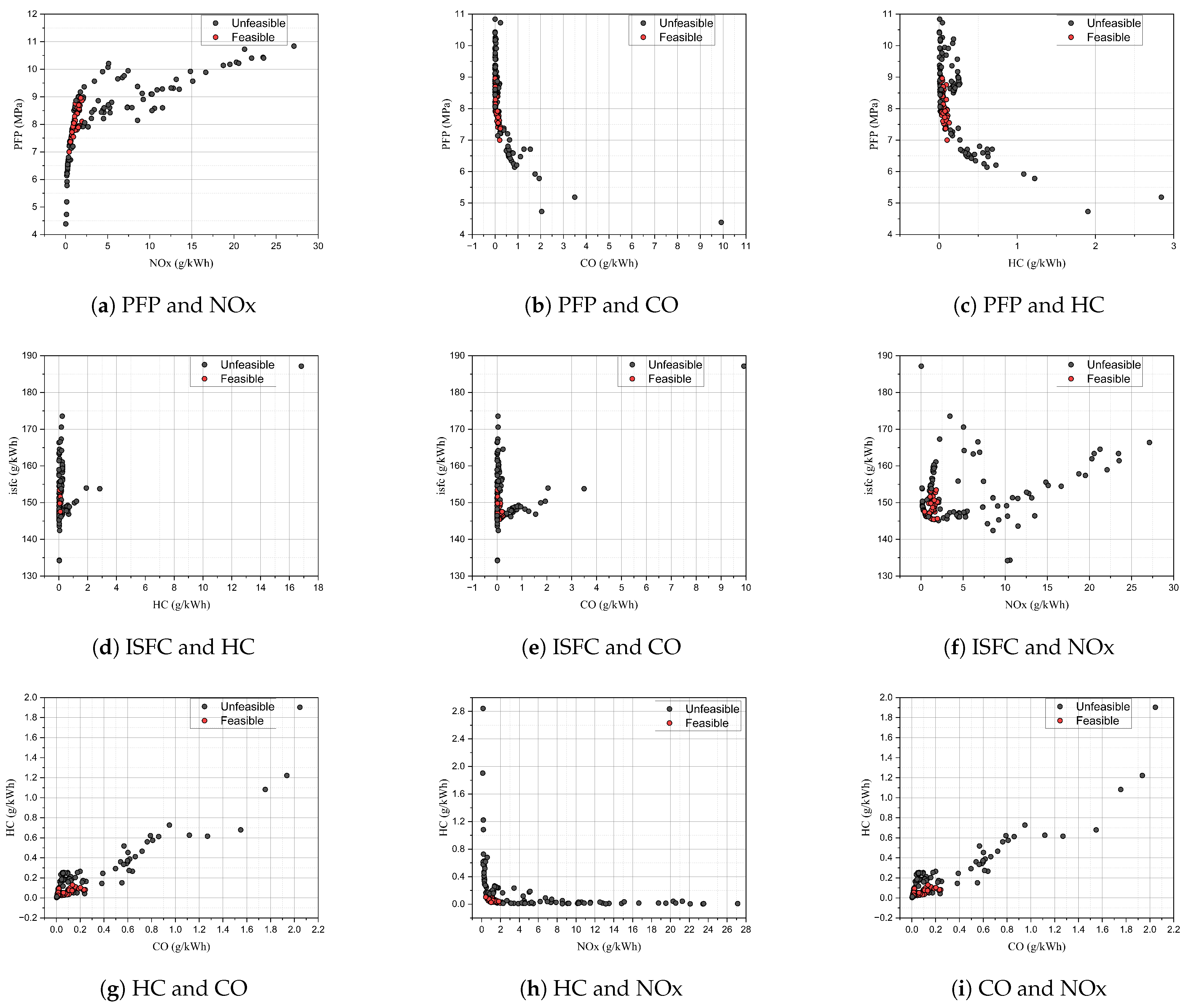

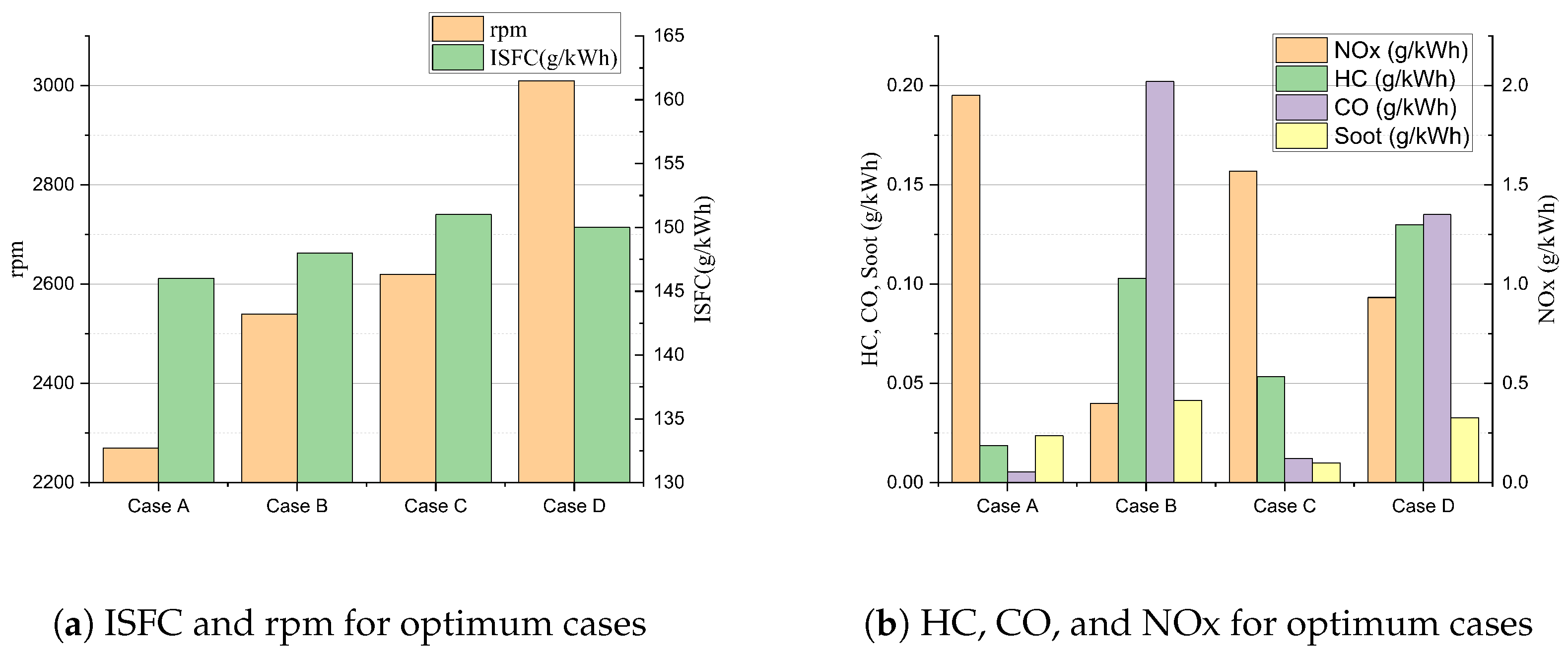

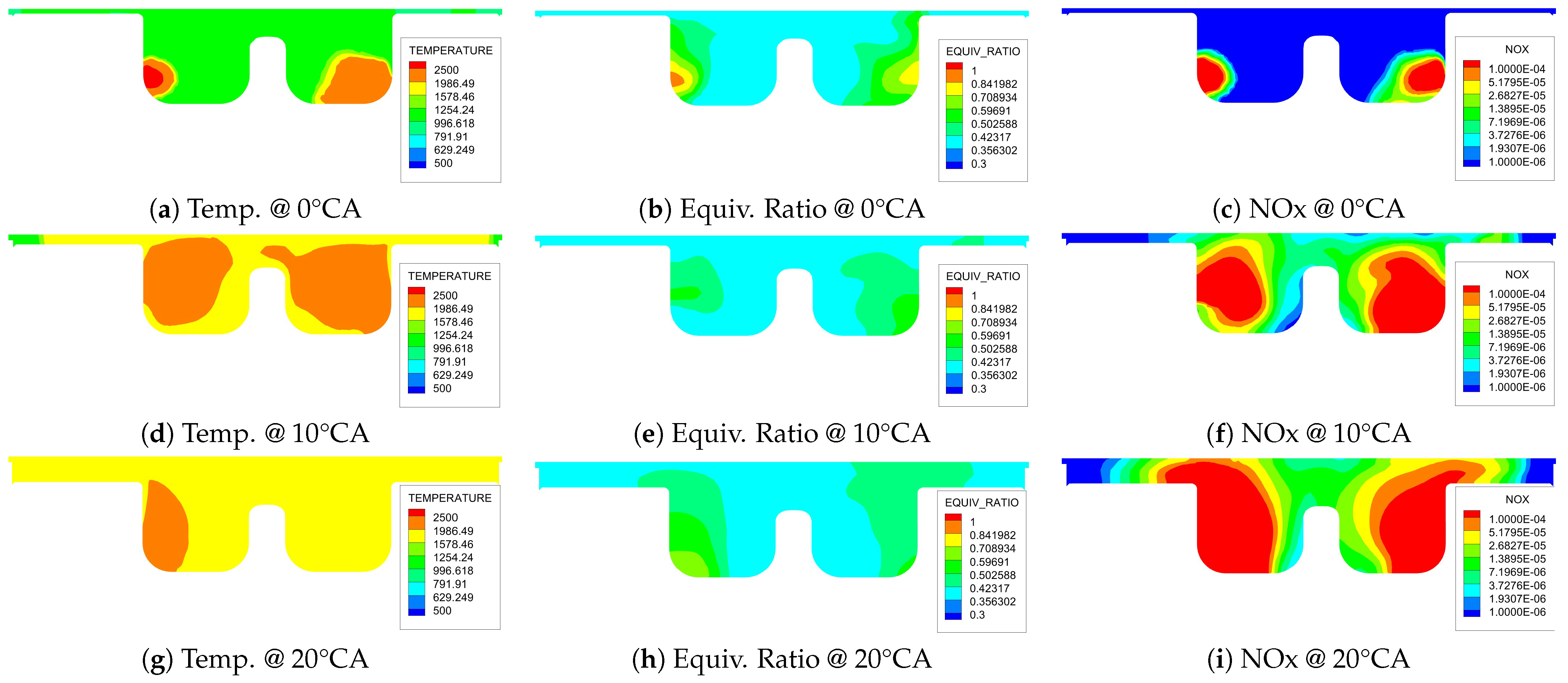

3.3. Emissions Results

4. Conclusions

- A well-justified selection of parameters, meshing strategies, and numerical methods ensures that simulations are both computationally feasible and practically useful.

- The highest indicative thermal efficiency of the methane/diesel RCCI engine was 51%, with an efficiency enhancement of 10% compared with the diesel engine.

- High power was achieved by RCCI engines, but with a tradeoff of high NOx emissions, which were out of standards, so the highest power achieved with an acceptable range of emissions and without being used after treatment was 7.03 kW, which is in the range of 0.89 from the maximum allowable load of CDE.

- All feasible results were in the range of the access air ratio of 2.22 to 2.37, MES in the range of 0.82 to 0.87, methane mass of 9.45 to 9.87 mg, diesel mass range of 1.71 to 2.44 mg, duration of 1.99 to 3.36 CA, SOI of −34 to 35 aTDC, and rotational speed range of 2020 to 3010 rpm.

- The minimum outcomes of (CO, HC) emissions and ISFC achieved were (0.00543, 0.0187) g/kWh and 146 g/kWh, respectively, which are lower than the CDE emissions by 99%, 72%, and 28.7%, respectively.

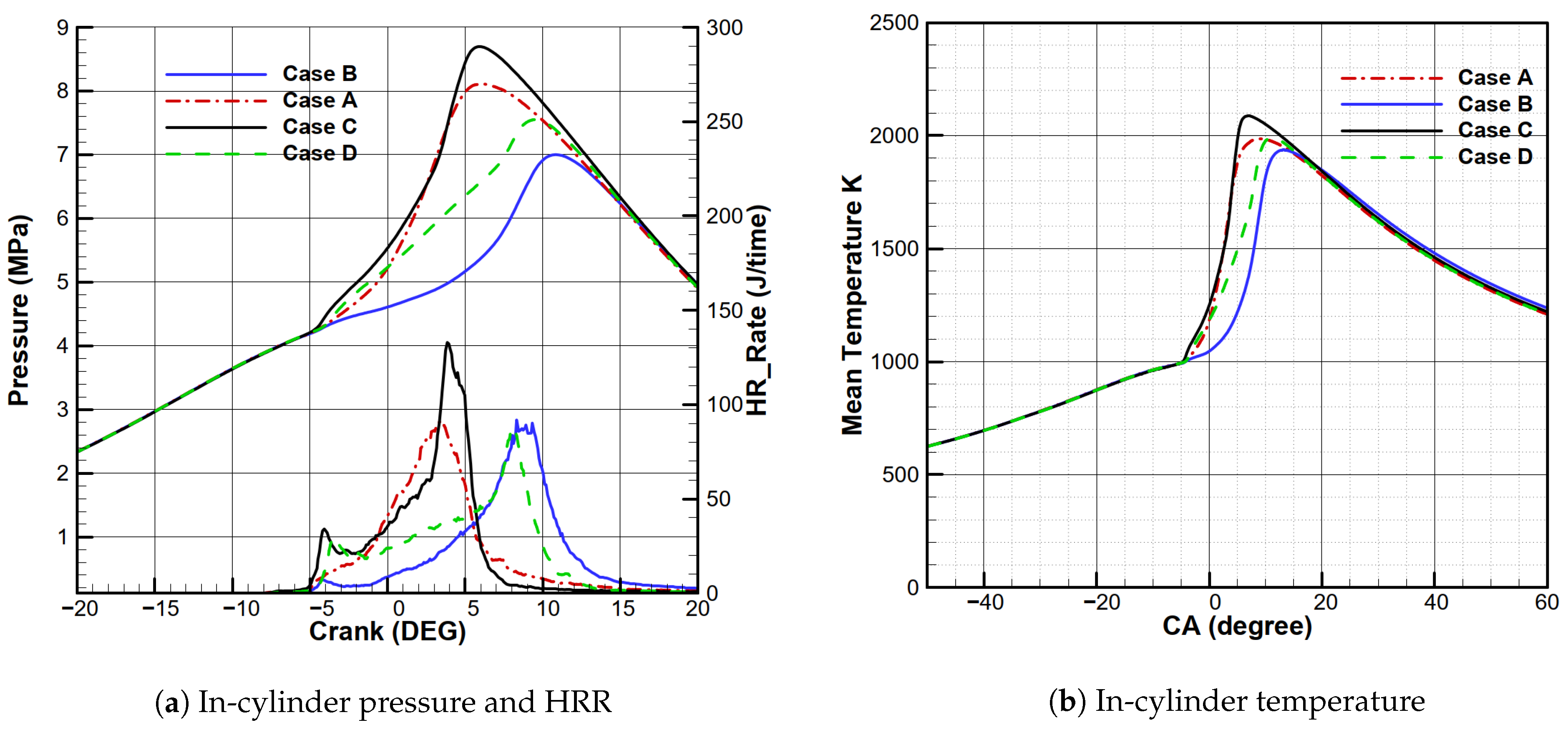

- Minimum NOx emissions were gained when the high range of cylinder temperature was the lowest and stayed for a short period. This was within the EURO IV standards of 0.4 g/kWh with a reduction of 97.5% compared with CDE.

- Minimum soot emissions were obtained when the SOC advanced and the in-cylinder temperature in the high range was higher than in other selected optimum cases.

- The improvement in IFSC along with reduced emissions suggests that utilizing methane-diesel in internal combustion engines is a cost-effective and promising approach.

Future Studies

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AMR | Adaptive Mesh Refinement |

| ANN | Artificial Neural Network |

| aTDC | After Top Dead Center |

| BMEP | Brake Mean Effective Pressure |

| CA10 | Crank Angle at 10% Mass Fraction Burned |

| CA50 | Crank Angle at 50% Mass Fraction Burned |

| CA90 | Crank Angle at 90% Mass Fraction Burned |

| CD | Duration of Combustion |

| CDE | Conventional Diesel Engine |

| CFD | Computational Fluid Dynamics |

| CO | Carbon Monoxide |

| CR | Compression Ratio |

| DOE | Experimental Design |

| EGR | Exhaust Gas Recirculation |

| EVO | Exhaust Valve Opening |

| HCCI | Homogeneous-Charge Compression Ignition |

| IMEP | Indicated Mean Effective Pressure |

| ISFC | Indicated Specific Fuel Consumption |

| IVC | Intake Valve Closure |

| LIVC | Late Intake Valve Closure |

| LTC | Low-Temperature Combustion |

| MES | Methane Energy Share |

| MN | Methane Number |

| NOx | Nitrogen Oxides |

| NSGA-II | Nondominated Sorting Genetic Algorithm-II |

| PFP | Peak Firing Pressure |

| PPCI | Partially Premixed Compression Ignition |

| RANS | Reynolds-Averaged Navier–Stokes Equations |

| RCCI | Reactivity-Controlled Compression Ignition |

| RI | Ringing Intensity |

| SCR | Selective Catalytic Reduction |

| SOC | Start of Combustion |

| SOI | Start of Injection |

| TDC | Top Dead Center |

| UHC | Unburned Hydrocarbons |

References

- Raimi, D.; Zhu, Y.; Newell, R.G.; Prest, B.C.; Bergman, A. Global energy outlook 2023: Sowing the seeds of an energy transition. Resour. Future 2023, 1, 1–44. [Google Scholar]

- Yapıcı, E.Ö.; Al-Attwani, A.H.S. Thermodynamic Analysis And Simulation of Steam Turbine Power Plant Hybrid With Parabolic Trough Collectors; A Study in Iraq. Mugla J. Sci. Technol. 2019, 5, 1–12. [Google Scholar]

- European Environment Agency. Transport and Environment Report 2022—Digitalisation in the Mobility System: Challenges and Opportunities; (Issue 07); European Environment Agency: Copenhagen, Denmark, 2022. [Google Scholar] [CrossRef]

- Milojević, S.; Savić, S.; Marić, D.; Stopka, O.; Krstić, B.; Stojanović, B. Correlation between emission and combustion characteristics with the compression ratio and fuel injection timing in tribologically optimized diesel engine. Teh. Vjesn. 2022, 29, 1210–1219. [Google Scholar]

- Milojević, S.; Glišović, J.; Savić, S.; Bošković, G.; Bukvić, M.; Stojanović, B. Particulate matter emission and air pollution reduction by applying variable systems in tribologically optimized diesel engines for vehicles in road traffic. Atmosphere 2024, 15, 184. [Google Scholar] [CrossRef]

- Kokjohn, S.L.; Hanson, R.M.; Splitter, D.A.; Reitz, R.D. Experiments and modeling of dual-fuel HCCI and PCCI combustion using in-cylinder fuel blending. SAE Int. J. Engines 2010, 2, 24–39. [Google Scholar]

- SivaPrasad, K.; Rao, S.S.; Raju, V.R.K. Enhancement of mixture homogeneity for DI-CI engine to achieve Homogeneous Charge Compression Ignition (HCCI) combustion characteristics: A numerical approach. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 4318–4333. [Google Scholar]

- Pandey, S.; Diwan, P.; Sahoo, P.K.; Thipse, S.S. A review of combustion control strategies in diesel HCCI engines. Biofuels 2018, 9, 61–74. [Google Scholar]

- Noehre, C.; Andersson, M.; Johansson, B.; Hultqvist, A. Characterization of Partially Premixed Combustion; SAE Technical Paper No. 2006-01-3412; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Manente, V.; Johansson, B.; Tunestal, P. Partially Premixed Combustion at High Load Using Gasoline and Ethanol, a Comparison with Diesel; SAE Technical Paper No. 2009-01-0944; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Hanson, R.M.; Kokjohn, S.L.; Splitter, D.A.; Reitz, R.D. An experimental investigation of fuel reactivity controlled PCCI combustion in a heavy-duty engine. SAE Int. J. Engines 2010, 3, 700–716. [Google Scholar]

- Dempsey, A.B.; Walker, N.R.; Reitz, R. Effect of piston bowl geometry on dual fuel reactivity controlled compression ignition (RCCI) in a light-duty engine operated with gasoline/diesel and methanol/diesel. SAE Int. J. Engines 2013, 6, 78–100. [Google Scholar]

- Curran, S.J.; Cho, K.; Briggs, T.E.; Wagner, R.M. Drive cycle efficiency and emissions estimates for reactivity controlled compression ignition in a multi-cylinder light-duty diesel engine. In Proceedings of the Internal Combustion Engine Division Fall Technical Conference, Morgantown, WV, USA, 2–5 October 2011; Volume 44427. [Google Scholar]

- Splitter, D.; Hanson, R.; Kokjohn, S.; Reitz, R.D. Reactivity Controlled Compression Ignition (RCCI) Heavy-Duty Engine Operation at Mid-and High-Loads with Conventional and Alternative Fuels; SAE Technical Paper No. 2011-01-0363; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Curran, S.; Hanson, R.; Wagner, R. Effect of E85 on RCCI Performance and Emissions on a Multi-Cylinder Light-Duty Diesel Engine; SAE Technical Paper No. 2012-01-0376; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Hanson, R.; Curran, S.; Wagner, R.; Reitz, R. Effects of biofuel blends on RCCI combustion in a light-duty, multi-cylinder diesel engine. SAE Int. J. Engines 2013, 6, 488–503. [Google Scholar]

- Reitz, R.D. Directions in internal combustion engine research. Combust. Flame 2013, 160, 1–8. [Google Scholar]

- Tripathi, G.; Dhar, A. Performance, emissions, and combustion characteristics of methane-diesel dual-fuel engines: A review. Front. Therm. Eng. 2022, 2, 870077. [Google Scholar]

- Yoon, M.; Choi, M.; Kang, K.; Oh, C.; Park, Y.; Choi, G. Effects of n-Heptane/Methane Blended Fuel on Ignition Delay Time in Pre-Mixed Compressed Combustion. Energies 2022, 15, 4081. [Google Scholar]

- Jia, Z. Dual-Fuel Combustion in a Heavy-Duty Engine. Ph.D. Thesis, Chalmers Tekniska Hogskola, Gothenburg, Sweden, 2018. [Google Scholar]

- Doosje, E.; Willems, F.; Baert, R. Experimental Demonstration of RCCI in Heavy-Duty Engines Using Diesel and Natural Gas; SAE Technical Paper No. 2014-01-1318; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Ryan Walker, N.; Wissink, M.L.; DelVescovo, D.A.; Reitz, R.D. Natural gas for high load dual-fuel reactivity controlled compression ignition in heavy-duty engines. J. Energy Resour. Technol. 2015, 137, 042202. [Google Scholar]

- Pedrozo, V.B.; Wang, X.; Guan, W.; Zhao, H. The effects of natural gas composition on conventional dual-fuel and reactivity-controlled compression ignition combustion in a heavy-duty diesel engine. Int. J. Engine Res. 2022, 23, 397–415. [Google Scholar]

- Paykani, A.; Kakaee, A.H.; Rahnama, P.; Reitz, R.D. Effects of diesel injection strategy on natural gas/diesel reactivity controlled compression ignition combustion. Energy 2015, 90, 814–826. [Google Scholar]

- Wu, Z.; Rutl, C.J.; Han, Z. Numerical evaluation of the effect of methane number on natural gas and diesel dual-fuel combustion. Int. J. Engine Res. 2019, 20, 405–423. [Google Scholar]

- Nieman, D.E.; Dempsey, A.B.; Reitz, R.D. Heavy-duty RCCI operation using natural gas and diesel. SAE Int. J. Engines 2012, 5, 270–285. [Google Scholar]

- Ansari, E.; Shahbakhti, M.; Naber, J. Optimization of performance and operational cost for a dual mode diesel-natural gas RCCI and diesel combustion engine. Appl. Energy 2018, 231, 549–561. [Google Scholar]

- Ebrahimi, M.; Najafi, M.; Jazayeri, S.A. Artificial neural network to identify RCCI combustion mathematical model for a heavy-duty diesel engine fueled with natural gas and diesel oil. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 407. [Google Scholar]

- Kakaee, A.H.; Nasiri-Toosi, A.; Partovi, B.; Paykani, A. Effects of piston bowl geometry on combustion and emissions characteristics of a natural gas/diesel RCCI engine. Appl. Therm. Eng. 2016, 102, 1462–1472. [Google Scholar]

- Wang, B.; Li, T.; Ge, L.; Ogawa, H. Optimization of combustion chamber geometry for natural gas engines with diesel micro-pilot-induced ignition. Energy Convers. Manag. 2016, 122, 552–563. [Google Scholar] [CrossRef]

- Liu, J.; Ma, B.; Zhao, H. Combustion parameters optimization of a diesel/natural gas dual fuel engine using genetic algorithm. Fuel 2020, 260, 116365. [Google Scholar]

- Shirvani, S.; Shirvani, S.; Jazayeri, S.A.; Reitz, R. Optimization of the exergy efficiency, exergy destruction, and engine noise index in an engine with two direct injectors using NSGA-II and artificial neural network. Int. J. Engine Res. 2023, 24, 579–594. [Google Scholar]

- Moradi, J.; Gharehghani, A.; Aghahasani, M. Application of machine learning to optimize the combustion characteristics of RCCI engine over wide load range. Fuel 2022, 324, 124494. [Google Scholar]

- Richards, K.J.; Senecal, P.K.; Pomraning, E. CONVERGE Manual 3.0; CONVERGE: Manila, Philippines, 2020. [Google Scholar]

- Han, Z.; Reitz, R.D. Turbulence modeling of internal combustion engines using RNG κ-ε models. Combust. Sci. Technol. 1995, 106, 267–295. [Google Scholar]

- Wang, B.L.; Miles, P.C.; Reitz, R.D.; Han, Z.; Petersen, B. Assessment of RNG Turbulence Modeling and the Development of a Generalized RNG Closure Model; SAE Technical Paper No. 2011-01-0829; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Issa, R.I. Solution of the implicitly discretised fluid flow equations by operator-splitting. J. Comput. Phys. 1986, 62, 40–65. [Google Scholar]

- Beale, J.C.; Reitz, R.D. Modeling spray atomization with the Kelvin-Helmholtz/Rayleigh-Taylor hybrid model. At. Sprays 1999, 9, 623–650. [Google Scholar]

- Reitz, R. Modeling atomization processes in high-pressure vaporizing sprays. At. Spray Technol. 1987, 3, 309–337. [Google Scholar]

- Frassoldati, A.; D’Errico, G.; Lucchini, T.; Stagni, A.; Cuoci, A.; Faravelli, T.; Onorati, A.; Ranzi, E. Reduced kinetic mechanisms of diesel fuel surrogate for engine CFD simulations. Combust. Flame 2015, 162, 3991–4007. [Google Scholar]

- Yousefi, A.; Guo, H.; Birouk, M. An experimental and numerical study on diesel injection split of a natural gas/diesel dual-fuel engine at a low engine load. Fuel 2018, 212, 332–346. [Google Scholar]

- Senecal, P.K.; Pomraning, E.; Richards, K.J.; Briggs, T.E.; Choi, C.Y.; McDavid, R.M.; Patterson, M.A. Multi-dimensional modeling of direct-injection diesel spray liquid length and flame lift-off length using CFD and parallel detailed chemistry. Sae Trans. 2003, 112, 1331–1351. [Google Scholar]

- Rahimi, A.; Fatehifar, E.; Saray, R.K. Development of an optimized chemical kinetic mechanism for homogeneous charge compression ignition combustion of a fuel blend of n-heptane and natural gas using a genetic algorithm. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2010, 224, 1141–1159, Erratum in Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2011, 225, 1098. [Google Scholar]

- Frössling, N. Evaporation, Heat Transfer, and Velocity Distribution in Two-Dimensional and Rotationally Symmetrical Laminar Boundary-Layer Flow; Fysiografiska Saellskapets Handlingar 51.NACA-TM-1432; NASA: Washington, DC, USA, 1958. [Google Scholar]

- Post, S.L.; Abraham, J. Modeling the outcome of drop–drop collisions in Diesel sprays. Int. J. Multiph. Flow 2002, 28, 997–1019. [Google Scholar]

- Schmidt, D.P.; Rutl, C.J. A new droplet collision algorithm. J. Comput. Phys. 2000, 164, 62–80. [Google Scholar]

- Gonzalez, D.; Manuel, A.; Lian, Z.W.; Reitz, R.D. Modeling diesel engine spray vaporization and combustion. SAE Trans. 1992, 101, 1064–1076. [Google Scholar]

- Heywood, J. Internal Combustion Engine Fundamentals; McGraw Hill: New York, NY, USA, 2018. [Google Scholar]

- Hiroyasu, H.; Kadota, T. Models for combustion and formation of nitric oxide and soot in direct injection diesel engines. SAE Trans. 1976, 85, 513–526. [Google Scholar]

- Yousefi, A.; Guo, H.; Birouk, M.; Liko, B. On greenhouse gas emissions and thermal efficiency of natural gas/diesel dual-fuel engine at low load conditions: Coupled effect of injector rail pressure and split injection. Appl. Energy 2019, 242, 216–231. [Google Scholar]

- Sener, R.; Yangaz, M.U.; Gul, M.Z. Effects of injection strategy and combustion chamber modification on a single-cylinder diesel engine. Fuel 2020, 266, 117122. [Google Scholar]

- Şener, R.; Gül, M.Z. Optimization of the combustion chamber geometry and injection parameters on a light-duty diesel engine for emission minimization using multi-objective genetic algorithm. Fuel 2021, 304, 121379. [Google Scholar]

- Master Engineering Complexity and Speed Up Product Development. Available online: https://engineering.esteco.com/modefrontier/ (accessed on 1 March 2025).

- Yang, X.S. Nature-Inspired Optimization Algorithms; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Srinivas, N.; Deb, K. Muiltiobjective optimization using nondominated sorting in genetic algorithms. Evol. Comput. 1994, 2, 221–248. [Google Scholar]

- Halis, S. An experimental study of operating range, combustion and emission characteristics in an RCCI engine fueled with iso-propanol/n-heptane. Sustainability 2023, 15, 10897. [Google Scholar] [CrossRef]

- Dempsey, A.B.; Reitz, R.D. Computational optimization of reactivity controlled compression ignition in a heavy-duty engine with ultra low compression ratio. SAE Int. J. Engines 2011, 4, 2222–2239. [Google Scholar]

| Properties | n-Heptane | Methane |

|---|---|---|

| Chemical formula | C7H16 | CH4 |

| Density at 15 °C (g/m3) | 0.688 | 0.664 |

| Lower heating value (MJ/kg) | 44.24 | 49.94 |

| Auto-ignition temperature (K) | 558 | 810 |

| Molecular weight | 100.21 | 16.042 |

| Cetane number | 56 | - |

| Octane number | - | 130 |

| Boiling point (K) | 372 | 111.55 |

| Specification | Value |

|---|---|

| Cylinder volume (cc) | 510 |

| Compression ratio (CR) | 17.5:1 |

| Bore diameter/stroke (mm) | 85/90 |

| Number of valves | 2 |

| RPM | 3000 |

| IVO/IVC (°CA) | 339/592 |

| EVO/EVC (°CA) | 135/388 |

| Torque at rated speed (Nm) | 25 |

| Power (kW) | 7.88 |

| Injector hole diameter (mm) | 0.29 |

| Number of injector holes | 4 |

| Process | Model |

|---|---|

| Turbulence | RANS and RNG k- |

| Combustion | SAGE |

| Drop collision | NTC method |

| Break-up process of diesel spray | Kelvin–Helmholtz and Rayleigh–Taylor (KH-RT) |

| Evaporation of droplets | Frossling model |

| Droplet coalescence | Post-collision outcome model |

| Spray droplet interaction with solid surfaces | Rebound/slide model |

| Formation of NOx | Zeldovich mechanism |

| Soot oxidation rate | Hiroyasu–NSC empirical soot model |

| Operational Parameter | Range | Objective | Constraint | Range |

|---|---|---|---|---|

| Rotational velocity (rpm) | 2000–3250 | Minimize PFP (MPa) | HC | <0.13 g/kWh |

| Premixed CH4 fraction | 0.02–0.026 | Minimize ISFC | NOx | <2 g/kWh |

| Diesel mass (mg) | 1.4–7 | - | CO | <1.5 g/kWh |

| SOI (°CA) | −35 to −10 | - | - | - |

| Diesel injection duration (°CA) | 1.5–6 | - | - | - |

| Parameter | Value |

|---|---|

| Swirl ratio | 2.57 |

| Turbulent kinetic energy (m2/s2) | 61.2 |

| Energy dissipation (m2/s3) | 43,512.2 |

| Pressure (Pa) | 116,545.7 |

| Temperature (K) | 400.8 |

| Start of injection SOI (CA aTDC) | −23 |

| Diesel mass (mg) | 1.5 |

| Diesel injected pressure (bar) | 180 |

| Methane mass (mg) | 9.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alattwani, A.H.S.; Gul, M.Z.; Yilmaz, M. Optimization Methodologies for Analyzing the Impact of Operational Parameters on a Light-Duty Methane/Diesel Reactivity-Controlled Compression Ignition (RCCI) Engine. Appl. Sci. 2025, 15, 3849. https://doi.org/10.3390/app15073849

Alattwani AHS, Gul MZ, Yilmaz M. Optimization Methodologies for Analyzing the Impact of Operational Parameters on a Light-Duty Methane/Diesel Reactivity-Controlled Compression Ignition (RCCI) Engine. Applied Sciences. 2025; 15(7):3849. https://doi.org/10.3390/app15073849

Chicago/Turabian StyleAlattwani, Anwer Hamed Salih, Mehmet Zafer Gul, and Mustafa Yilmaz. 2025. "Optimization Methodologies for Analyzing the Impact of Operational Parameters on a Light-Duty Methane/Diesel Reactivity-Controlled Compression Ignition (RCCI) Engine" Applied Sciences 15, no. 7: 3849. https://doi.org/10.3390/app15073849

APA StyleAlattwani, A. H. S., Gul, M. Z., & Yilmaz, M. (2025). Optimization Methodologies for Analyzing the Impact of Operational Parameters on a Light-Duty Methane/Diesel Reactivity-Controlled Compression Ignition (RCCI) Engine. Applied Sciences, 15(7), 3849. https://doi.org/10.3390/app15073849