Estimation of Welding Current with Adaptive Neuro Fuzzy Inference System (ANFIS): Utilization of Arc Light Signal Emitted in the Arc Welding Process

Abstract

1. Introduction

2. Materials and Methods

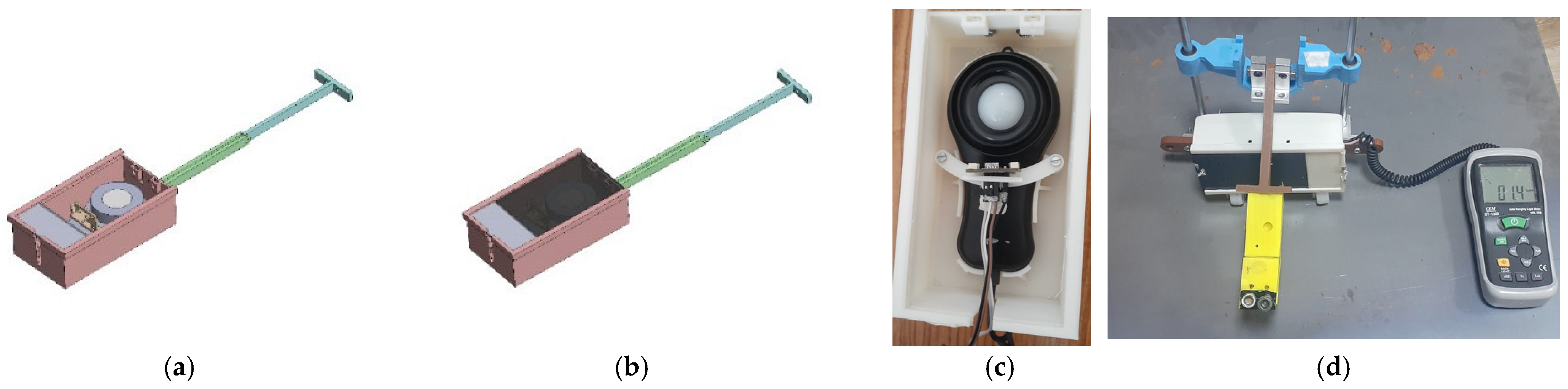

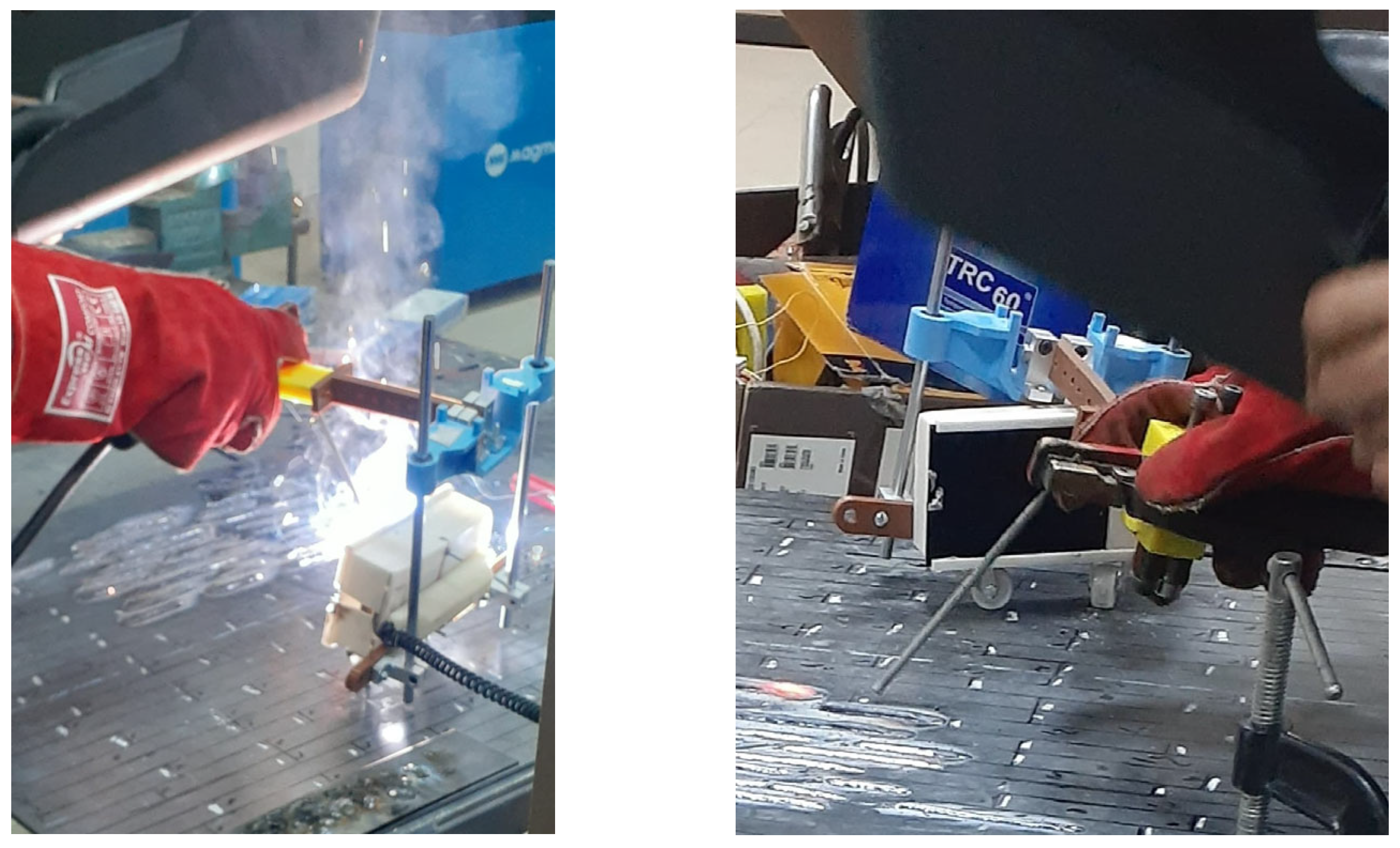

2.1. Data Acquisition

2.2. Data Preprocessing

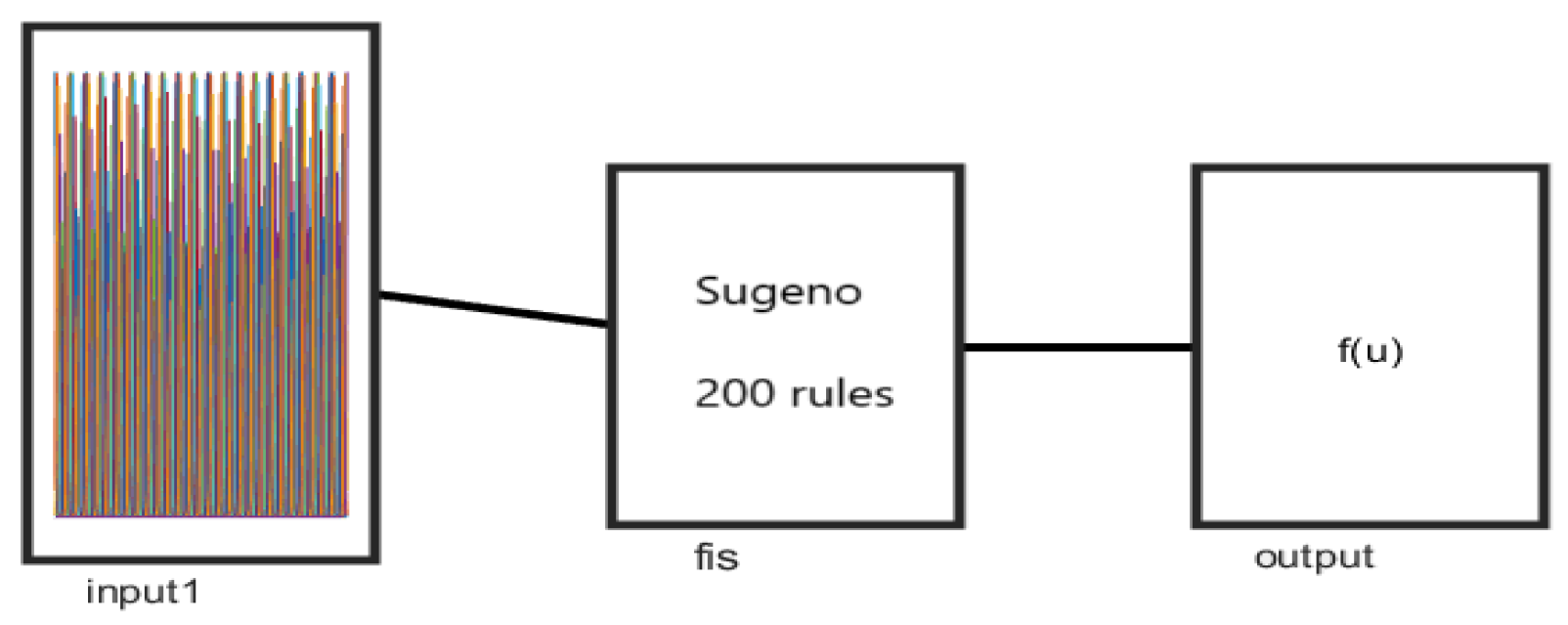

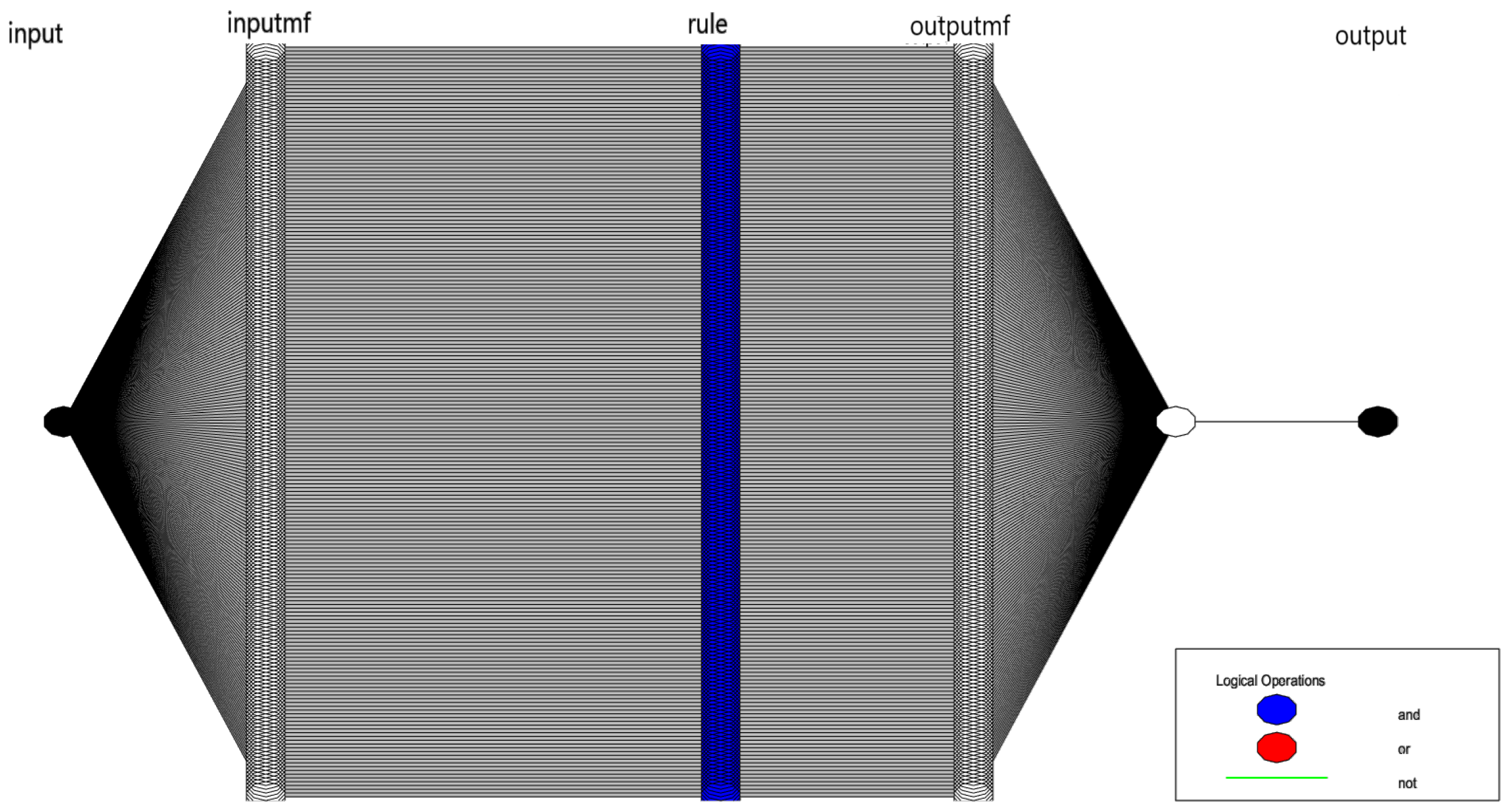

2.3. Adaptive Neuro Fuzzy Inference System (ANFIS)

2.4. Artificial Neural Network (ANN)

2.5. Statistical Metrics

3. Results

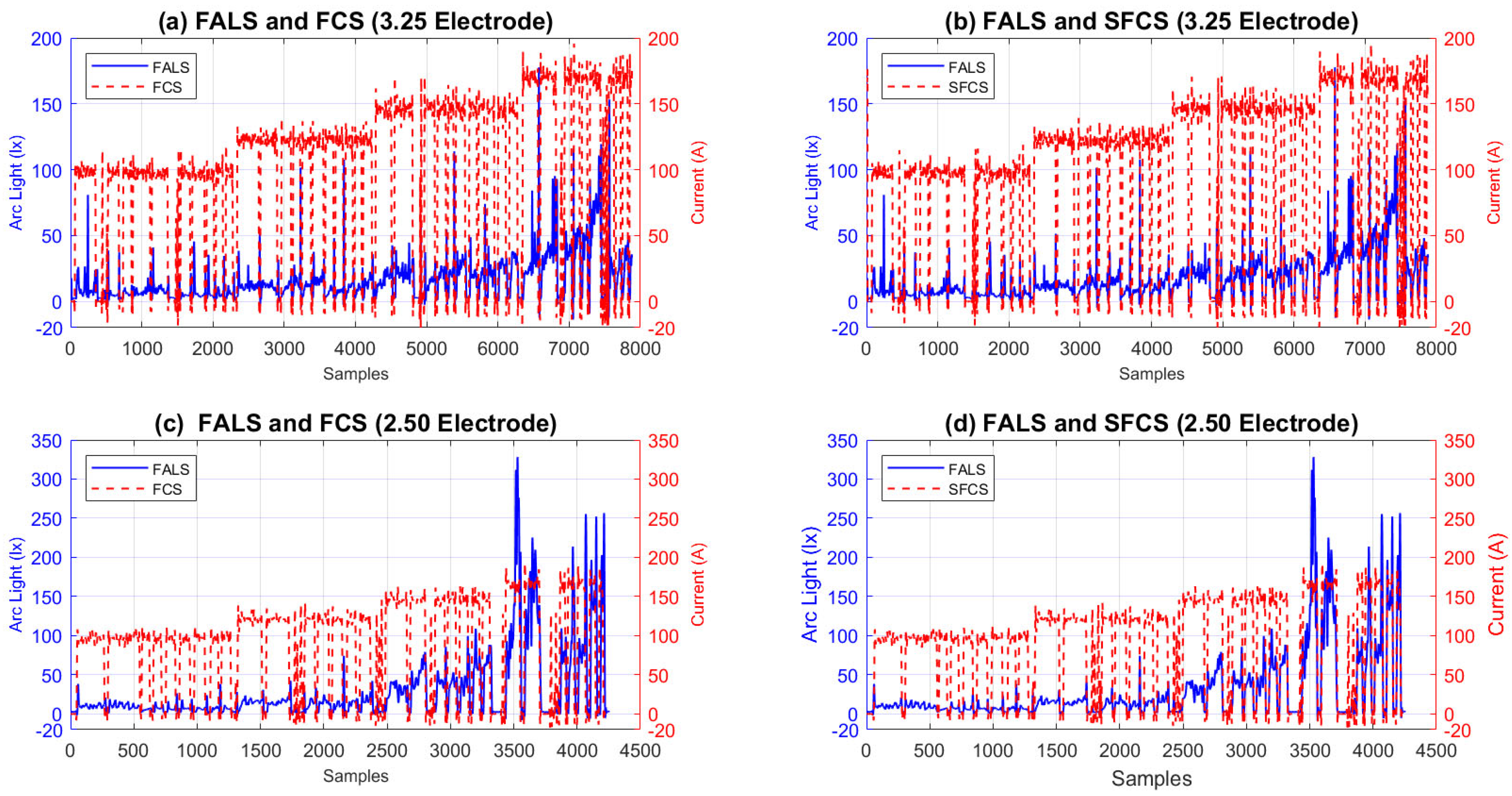

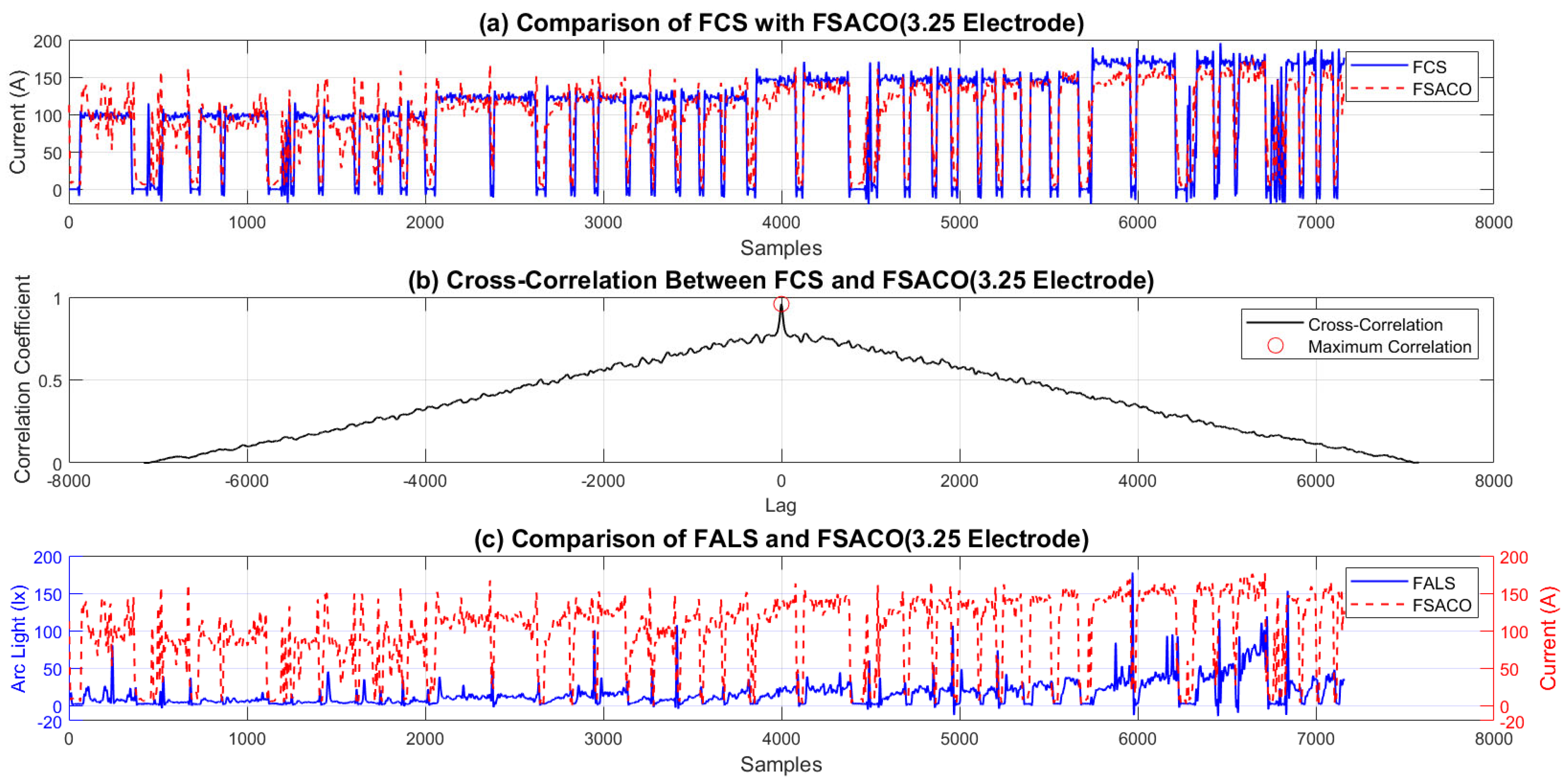

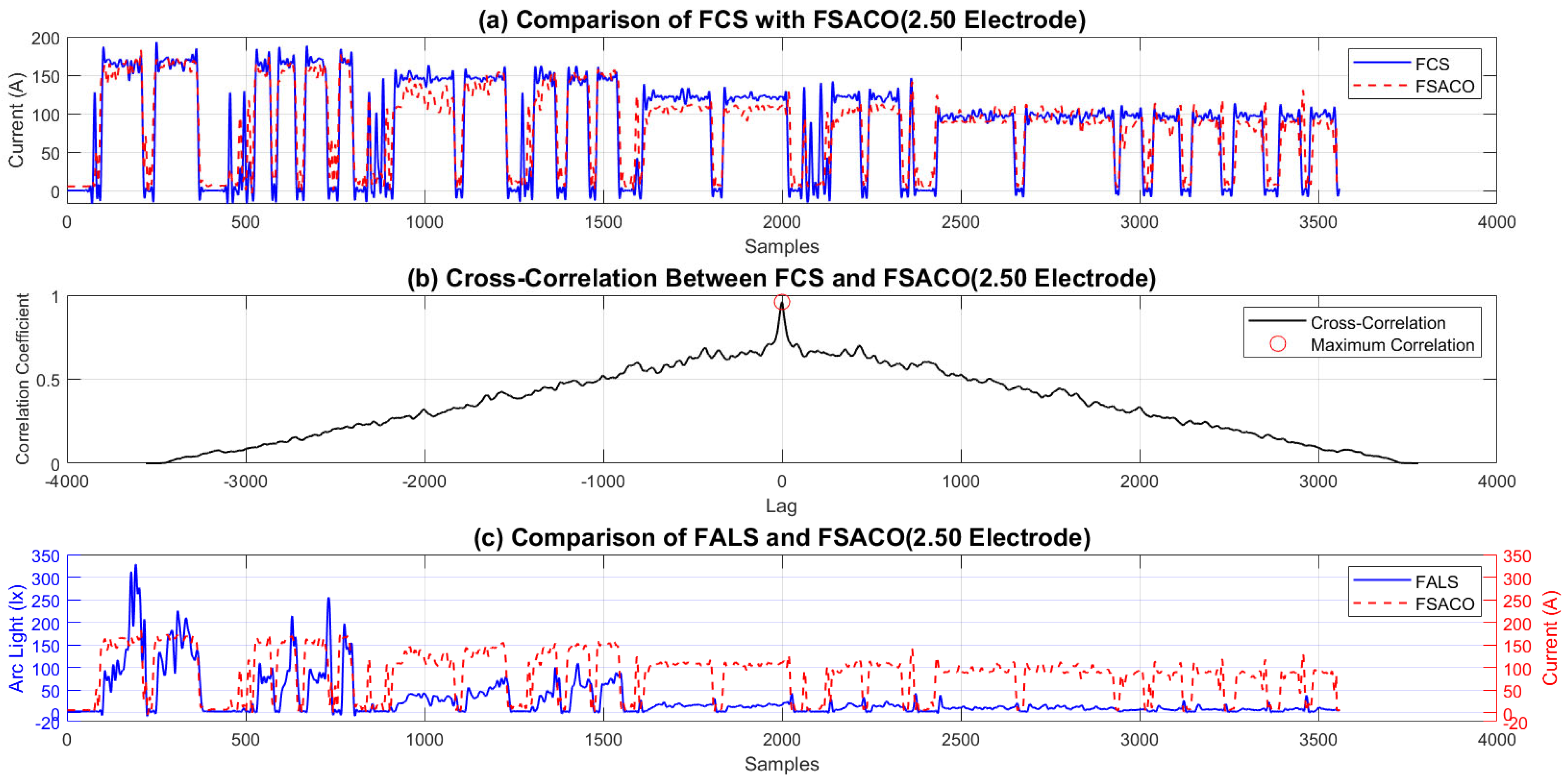

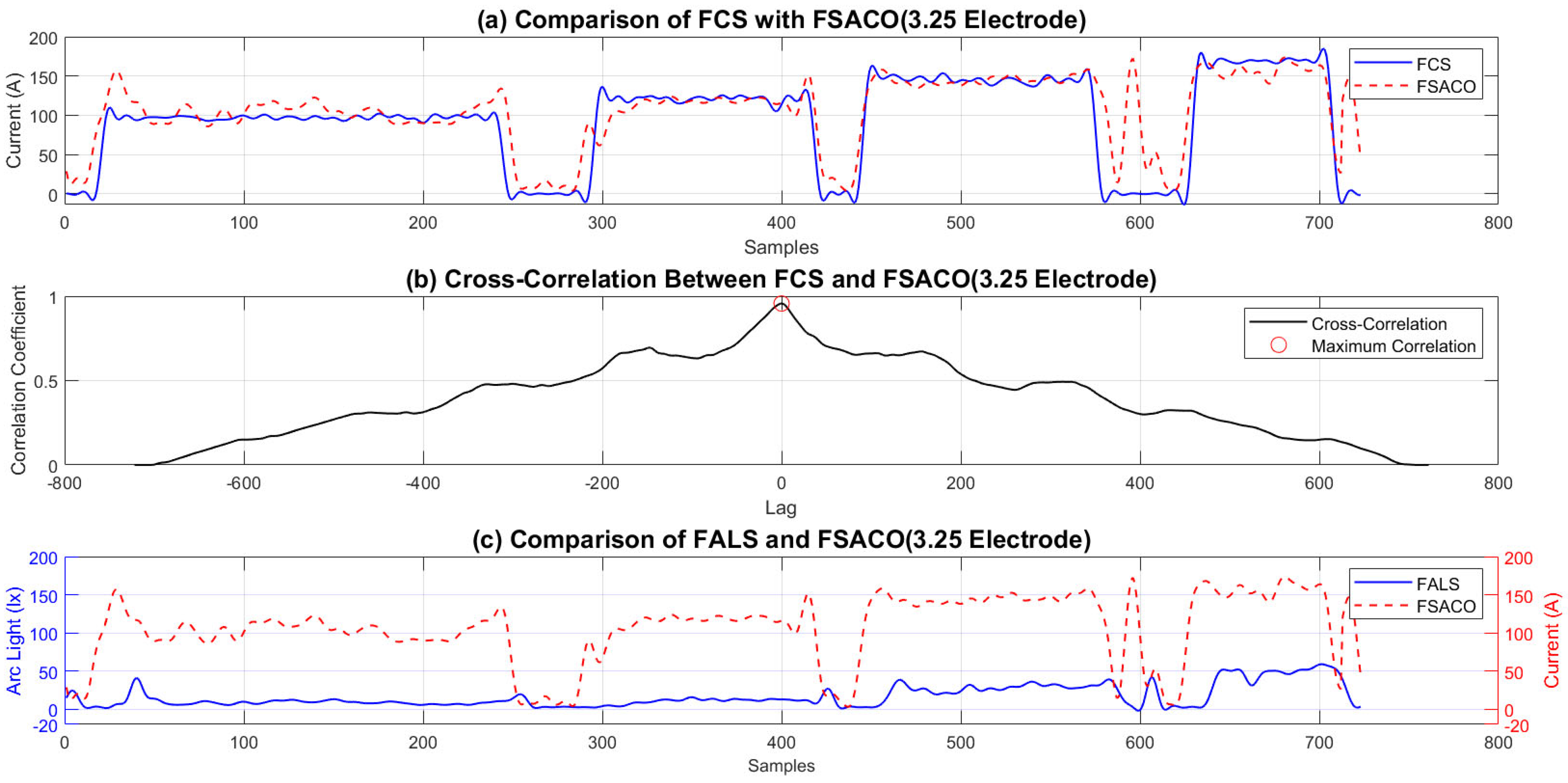

3.1. Data Analysis

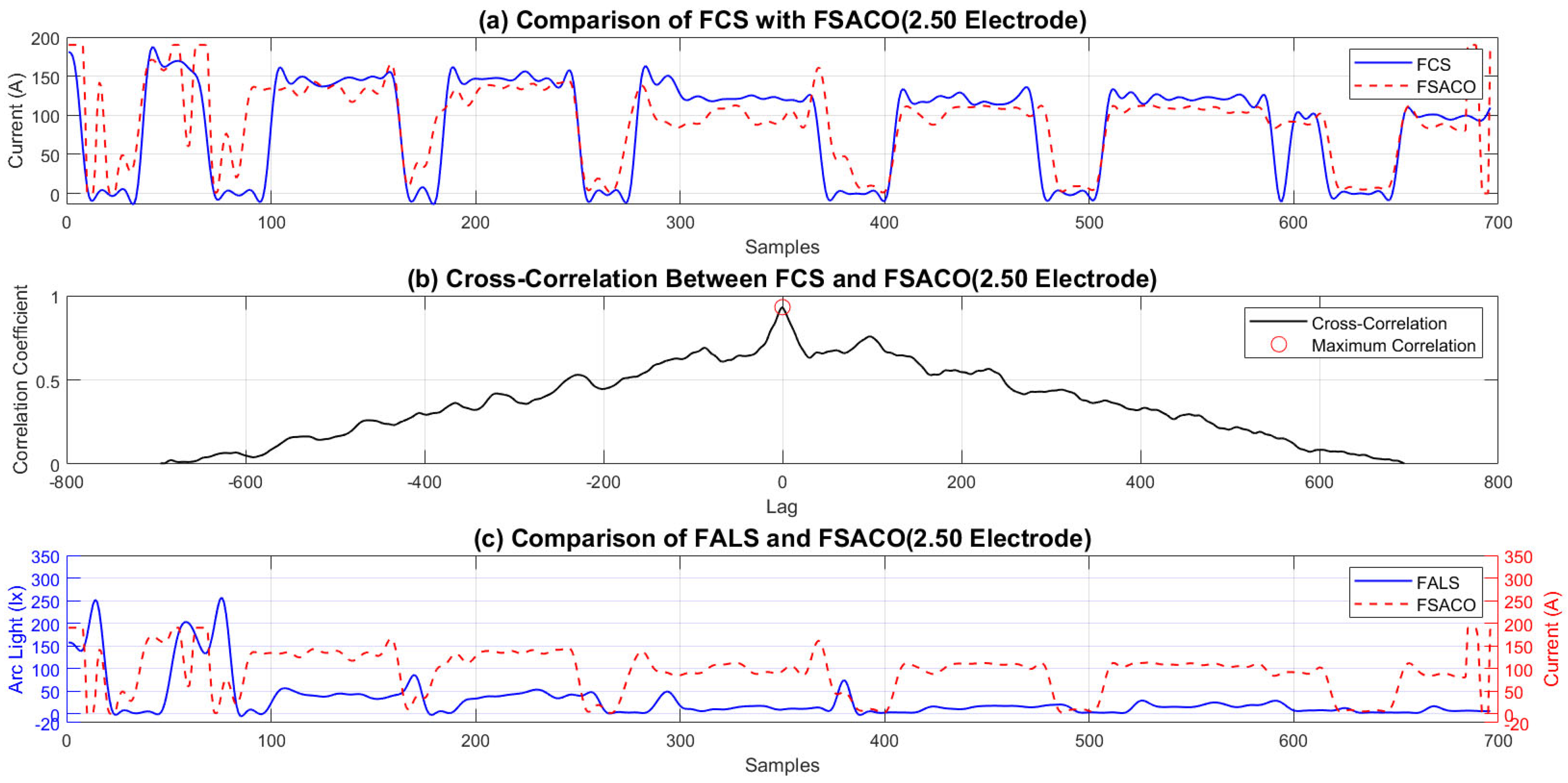

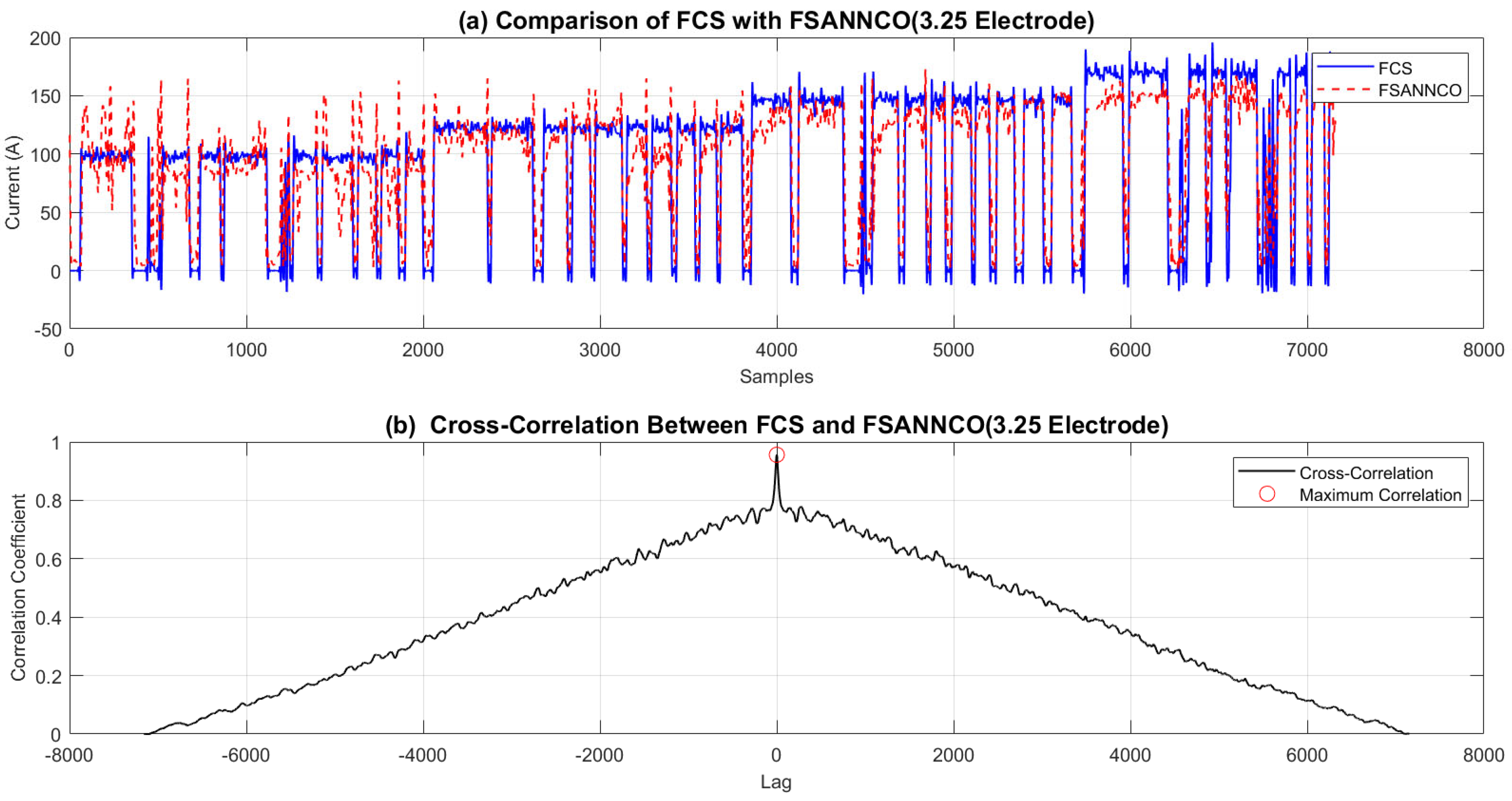

3.2. Data Preprocessing Results

3.3. ANFIS Performance Results

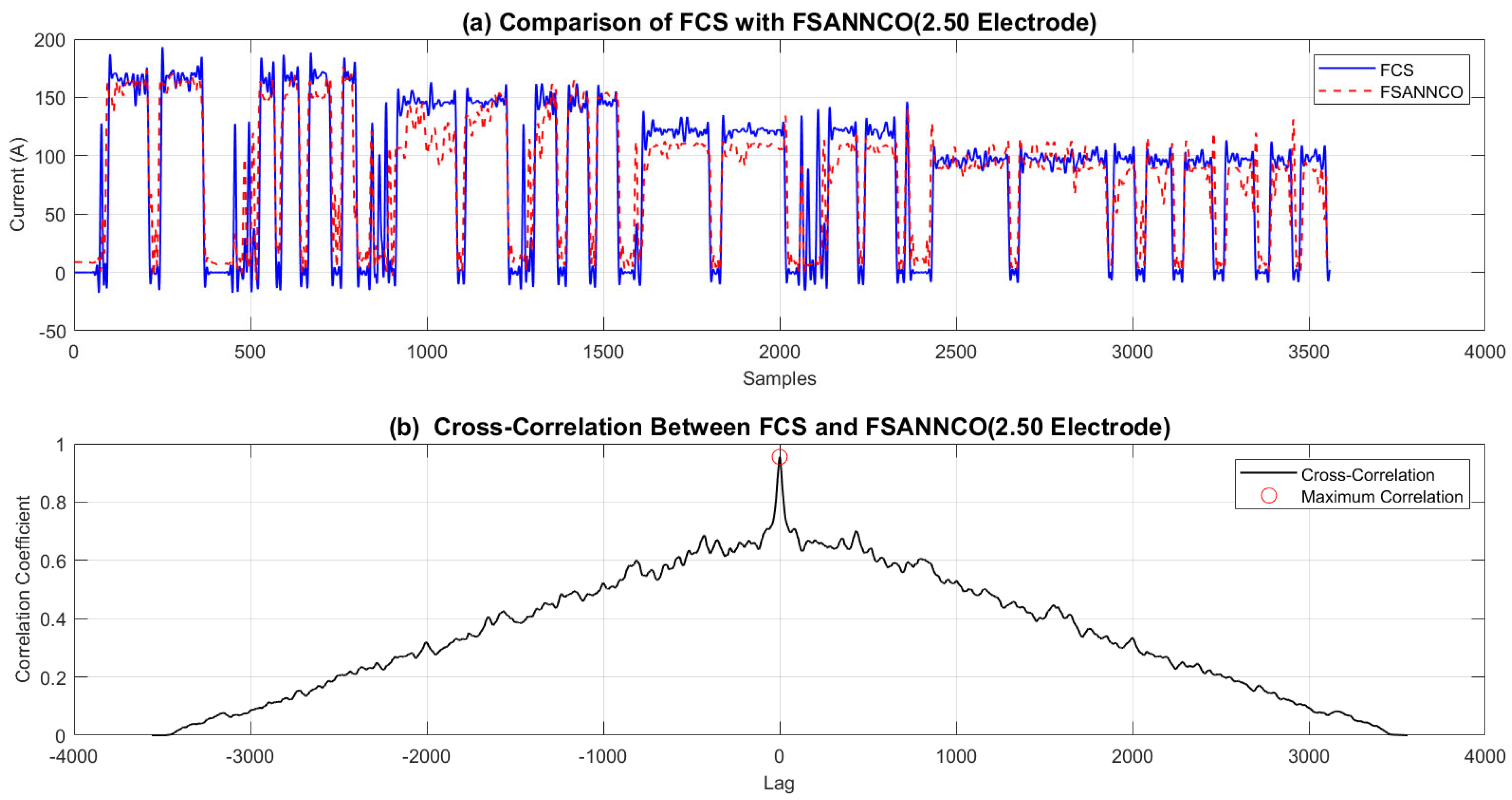

3.4. ANN Performance Results

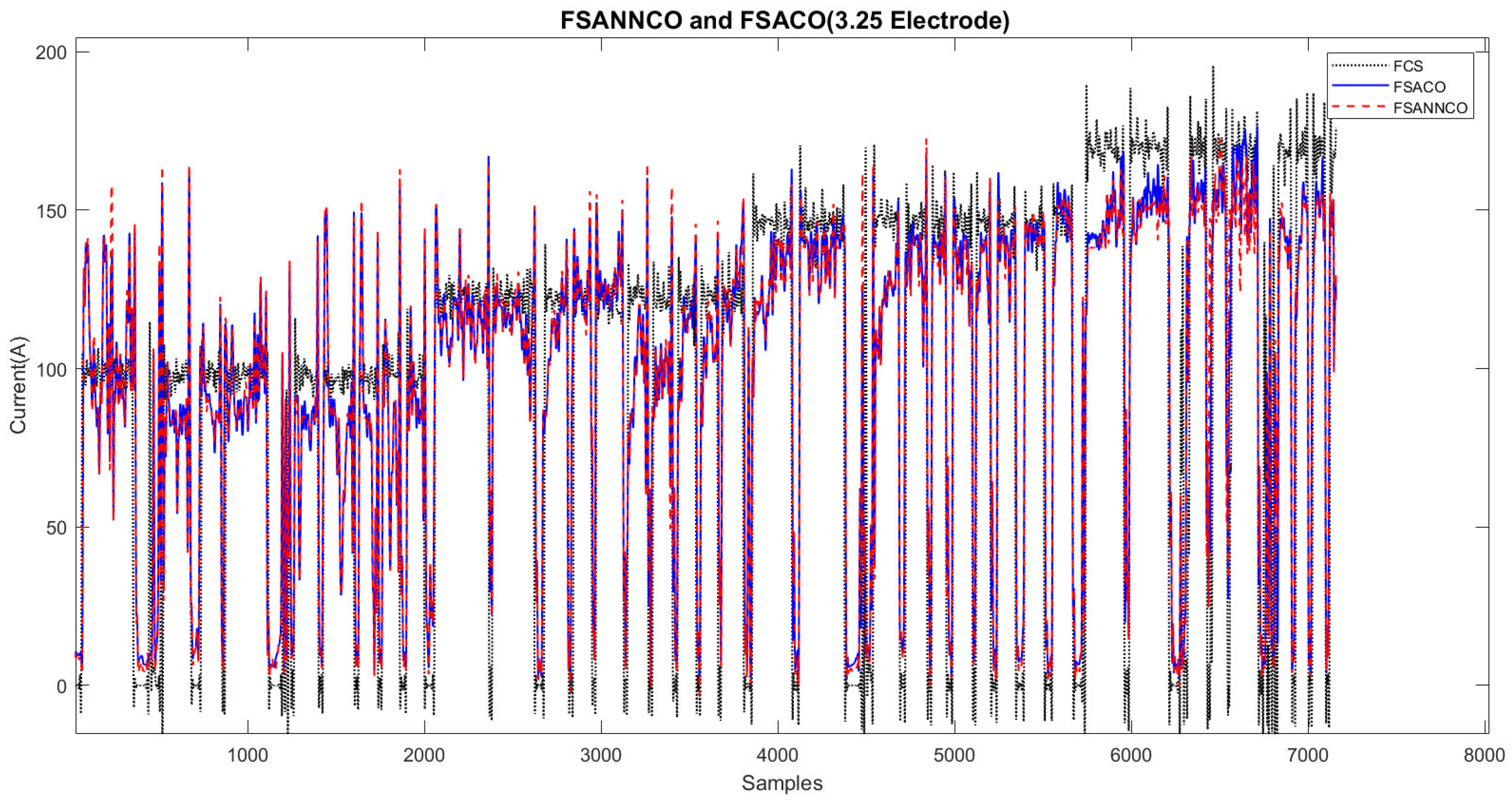

3.5. Comparison of ANFIS and ANN Performance Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Weglowski, M.S. Investigation on the electric arc light emission in TIG welding. Int. J. Comput. Mater. Sci. Surf. Eng. 2007, 1, 734. [Google Scholar] [CrossRef]

- Węglowski, M.S. Measurement of arc light spectrum in the MAG welding method. Metrol. Meas. Syst. 2009, 16, 143–159. [Google Scholar]

- Stanisaw, M. Monitoring of Arc Welding Process Based on Arc Light Emission; InTech eBooks: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.-M. Robust sensing of arc length. IEEE Trans. Instrum. Meas. 2001, 50, 697–704. [Google Scholar] [CrossRef]

- Chernyak, V.; Korzhyk, V.; Gao, S.; Khaskin, V.; Voitenko, O.; Illiashenko, Y.; Wang, X.; Grynyuk, A.; Konoreva, O.; Sviridova, I. Investigation of Spectral Parameters of Constricted arc Plasma for Controlling Welding Processes and Related Technologies. Adv. Sci. Technol. Res. J. 2024, 18, 250–263. [Google Scholar] [CrossRef]

- Li, L.; Lin, T.; Chen, S. Light intensity analysis of a passive visual sensing system in GTAW. Int. J. Adv. Manuf. Technol. 2005, 27, 106–111. [Google Scholar] [CrossRef]

- Guo, Q.; Yang, Z.; Xu, J.; Jiang, Y.; Wang, W.; Liu, Z.; Zhao, W.; Sun, Y. Progress, challenges and trends on vision sensing technologies in automatic/intelligent robotic welding: State-of-the-art review. Robot. Comput.-Integr. Manuf. 2024, 89, 102767. [Google Scholar] [CrossRef]

- Yu, S.; Hu, J.; Hong, J.; Zhang, H.; Guan, Y.; Zhang, T. Optimal Imaging Band Selection for Laser-vision System Based on Welding Arc Spectrum Analysis. IEEE Sens. J. 2024, 25, 2534–2546. [Google Scholar] [CrossRef]

- Yu, R.; Zhang, T.; Huang, Y.; Wang, K. Monitoring of gas metal arc welding process using optical temperature measurement and neural network modelling. Measurement 2025, 248, 116934. [Google Scholar]

- Yang, L.; Liu, Y.; Peng, J. Advances techniques of the structured light sensing in intelligent welding robots: A review. Int. J. Adv. Manuf. Technol. 2020, 110, 1027–1046. [Google Scholar] [CrossRef]

- Eren, B.; Demir, M.H.; Mistikoglu, S. Recent developments in computer vision and artificial intelligence aided intelligent robotic welding applications. Int. J. Adv. Manuf. Technol. 2023, 126, 4763–4809. [Google Scholar] [CrossRef]

- Mao, Z.; Feng, W.; Han, X.; Ma, H.; Hao, C.; Liu, C.; Liu, Z. Development of a melt pool characteristics detection platform based on multi-information fusion of temperature fields and photodiode signals in plasma arc welding. J. Intell. Manuf. 2024, 36, 2017–2037. [Google Scholar] [CrossRef]

- Bestard, G.A.; Alfaro, S.C.A. Measurement and estimation of the weld bead geometry in arc welding processes: The last 50 years of development. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 444. [Google Scholar] [CrossRef]

- Cai, W.; Wang, J.; Jiang, P.; Cao, L.; Mi, G.; Zhou, Q. Application of sensing techniques and artificial intelligence-based methods to laser welding real-time monitoring: A critical review of recent literature. J. Manuf. Syst. 2020, 57, 1–18. [Google Scholar] [CrossRef]

- Xu, F.; Xu, Y.; Zhang, H.; Chen, S. Application of sensing technology in intelligent robotic arc welding: A review. J. Manuf. Process. 2022, 79, 854–880. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Xu, P. Visual Sensing and Depth Perception for Welding Robots and Their Industrial Applications. Sensors 2023, 23, 9700. [Google Scholar] [CrossRef]

- Čudina, M.; Prezelj, J. Evaluation of the sound signal based on the welding current in the gas—Metal arc welding process. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 483–494. [Google Scholar] [CrossRef]

- Cullen, M.; Ji, J.C. Online defect detection and penetration estimation system for gas metal arc welding. Int. J. Adv. Manuf. Technol. 2025, 136, 2143–2164. [Google Scholar] [CrossRef]

- Alfaro, S.C.A.; Cayo, E.H. Sensoring Fusion Data from the Optic and Acoustic Emissions of Electric Arcs in the GMAW-S Process for Welding Quality Assessment. Sensors 2012, 12, 6953–6966. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, S. Real-time seam penetration identification in arc welding based on fusion of sound, voltage and spectrum signals. J. Intell. Manuf. 2017, 28, 207–218. [Google Scholar] [CrossRef]

- Yoo, C.D.; Yoo, Y.S.; Sunwoo, H. Investigation on arc light intensity in gas metal arc welding. Part 1: Relationship between arc light intensity and arc length. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1997, 211, 345–353. [Google Scholar] [CrossRef]

- da Silva, N.N.; Ribeiro, P.H.; Moreno, A.M.; Arias, A.R.; Bracarense, A.Q. Study on the electric arc of GTAW process. J. Phys. Conf. Ser. 2018, 1126, 012013. [Google Scholar] [CrossRef]

- Wei, E.; Farson, D.; Richardson, R.; Ludewig, H. Detection of weld surface porosity by statistical analysis of arc current in gas metal arc welding. J. Manuf. Process. 2001, 3, 50–59. [Google Scholar] [CrossRef]

- Lin, J.; Jia, A.; Huang, W.; Wen, Z.; Hong, B.; Hong, Y. Weld seam tracking method of root pass welding with variable gap based on magnetically controlled arc sensor. Int. J. Adv. Manuf. Technol. 2023, 126, 5227–5243. [Google Scholar] [CrossRef]

- Madigan, R.B.; Quinn, T.P.; Siewert, T.A. Control of Gas-Metal-Arc Welding Using Arc-Light Sensing; Report QC 100.U56 NO. 5037; Materials Science and Engineering Laboratory, National Institute of Standards and Technology, U.S. Department of Commerce, NIST Manufacturing Engineering Laboratory: Boulder, CO, USA, 1995. [Google Scholar]

- Kim, J.W.; Na, S.J. A Study on Prediction of Welding Current in Gas Metal arc Welding Part 2: Experimental Modelling of Relationship Between Welding Current and Tip-to-Workpiece Distance and its Application to Weld Seam Tracking System. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1991, 205, 64–69. [Google Scholar] [CrossRef]

- Mahadevan, R.; Jagan, A.; Pavithran, L.; Shrivastava, A.; Selvaraj, S.K. Intelligent welding by using machine learning techniques. Mater. Today Proc. 2021, 46, 7402–7410. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Zhang, Y. Dynamic neuro-fuzzy estimation of the weld penetration in GTAW process. In Proceedings of the 2013 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Minneapolis, MN, USA, 6–9 May 2013; Volume 91, pp. 1380–1385. [Google Scholar] [CrossRef]

- Jang, J.-S.R. ANFIS: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Shehabeldeen, T.A.; Zhou, J.; Shen, X.; Yin, Y.; Ji, X. Comparison of RSM with ANFIS in predicting tensile strength of dissimilar friction stir welded AA2024-AA5083 aluminium alloys. Procedia Manuf. 2019, 37, 555–562. [Google Scholar] [CrossRef]

- Yang, L.; Li, E.; Fan, J.; Long, T.; Liang, Z. Automatic extraction and identification of narrow butt joint based on ANFIS before GMAW. Int. J. Adv. Manuf. Technol. 2018, 100, 609–622. [Google Scholar] [CrossRef]

- Shahabi, H.; Kolahan, F. A novel approach for monitoring and improving the quality of welded joint in gas metal arc welding process using adaptive neuro-fuzzy systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 230, 1489–1501. [Google Scholar] [CrossRef]

- Hassan, A.K.; Jasim, R.; Ashoor, Y. Estimation of Submerged Arc Plates Weldment Properties Using ANFIS and Regression Techniques. Basrah J. Eng. Sci. 2020, 20, 27–33. [Google Scholar] [CrossRef]

- Podder, S.; Roy, U. ANFIS Based Weld Metal Deposition Prediction System in MAG Welding using Hybrid Learning Algorithm. Int. J. Fuzzy Log. Syst. 2013, 3, 33–46. [Google Scholar] [CrossRef]

- Dhas, J.E.R.; Somasundaram, K. ANFIS for prediction of weld bead width in a submerged arc welding process. J. Sci. Ind. Res. 2007, 66, 335–338. [Google Scholar]

- Liu, Y.; Zhang, Y. Iterative Local ANFIS-Based Human Welder Intelligence Modeling and Control in Pipe GTAW Process: A Data-Driven Approach. IEEE/ASME Trans. Mechatron. 2014, 20, 1079–1088. [Google Scholar] [CrossRef]

- Liu, Y.K.; Zhang, Y.M. Model-Based Predictive Control of Weld Penetration in Gas Tungsten Arc Welding. IEEE Trans. Control Syst. Technol. 2013, 22, 955–966. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Zhang, Y. Dynamic Neuro-Fuzzy-Based Human Intelligence Modeling and Control in GTAW. IEEE Trans. Autom. Sci. Eng. 2013, 12, 324–335. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Zhang, Y. ANFIS Modeling of Human Welder’s Response to Three-Dimensional Weld Pool Surface in GTAW. J. Manuf. Sci. Eng. 2013, 135, 021010. [Google Scholar] [CrossRef]

- Eguchi, K.; Yamane, S.; Sugi, H.; Kubota, T.; Oshima, K. Application of neural network to arc sensor. Sci. Technol. Weld. Join. 1999, 4, 327–334. [Google Scholar] [CrossRef]

- Akinci, T.Ç.; Noğay, H.S.; Gökmen, G. Determination of optimum operation cases in electric arc welding machine using neural network. J. Mech. Sci. Technol. 2011, 25, 1003–1010. [Google Scholar] [CrossRef]

- Thekkuden, D.T.; Mourad, A.-H.I. Investigation of feed-forward back propagation ANN using voltage signals for the early prediction of the welding defect. SN Appl. Sci. 2019, 1, 1615. [Google Scholar] [CrossRef]

- Pryymak, B.; Zhelinskyi, M.; Ostroverkhov, M.; Khalimovskyy, O. Neural Network Based Estimator of the Electrode Deviation in Robotic Welding with Arc Oscillations. In Proceedings of the 3rd International Workshop on Information Technologies: Theoretical and Applied Problems, Opole, Poland, 22–24 November 2023. [Google Scholar]

- Chokkalingham, S.; Chandrasekhar, N.; Vasudevan, M. Artificial Neural Network Modeling for Estimating the Depth of Penetration and Weld Bead Width from the Infra Red Thermal Image of the Weld Pool During A-TIG Welding. In Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2010; pp. 270–278. [Google Scholar] [CrossRef]

- Ghanty, P.; Vasudevan, M.; Mukherjee, D.P.; Pal, N.R.; Chandrasekhar, N.; Maduraimuthu, V.; Bhaduri, A.K.; Barat, P.; Raj, B. Artificial neural network approach for estimating weld bead width and depth of penetration from infrared thermal image of weld pool. Sci. Technol. Weld. Join. 2008, 13, 395–401. [Google Scholar] [CrossRef]

- Khalid, M.N.; Naranje, V.; Gaidhane, V.H. Prediction of Best Weld Quality Using Artificial Neural Network. In Proceedings of the 2019 Amity International Conference on Artificial Intelligence (AICAI), Dubai, United Arab Emirates, 4–6 February 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Gokmen, G.; Akinci, T.C.; Kocyigit, G.; Kiyak, I.; Akbas, M.I. Estimating Average Power of Welding Process with Emitted Noises based on Adaptive Neuro Fuzzy Inference System. IEEE Access 2023, 11, 39154–39164. [Google Scholar] [CrossRef]

- Chandrasekhar, N.; Vasudevan, M.; Bhaduri, A.K.; Jayakumar, T. Intelligent modeling for estimating weld bead width and depth of penetration from infra-red thermal images of the weld pool. J. Intell. Manuf. 2013, 26, 59–71. [Google Scholar] [CrossRef]

- Subashini, L.; Vasudevan, M. Adaptive Neuro-Fuzzy Inference System (ANFIS)-Based Models for Predicting the Weld Bead Width and Depth of Penetration from the Infrared Thermal Image of the Weld Pool. Metall. Mater. Trans. B 2011, 43, 145–154. [Google Scholar] [CrossRef]

- Devaraj, J.; Ziout, A.; Qudeiri, J.E.A. Grey-Based Taguchi Multiobjective Optimization and Artificial Intelligence-Based Prediction of Dissimilar Gas Metal Arc Welding Process Performance. Metals 2021, 11, 1858. [Google Scholar] [CrossRef]

- Chatterjee, S.; Mahapatra, S.S.; Lamberti, L.; Pruncu, C.I. Prediction of welding responses using AI approach: Adaptive neuro-fuzzy inference system and genetic programming. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 53. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks and Learning Machines, 3rd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2009; p. 2. [Google Scholar]

- De La Selle, T.; Weiss, J.; Deschanel, S. Acoustic multiplets detection based on DBSCAN and cross-correlation. Mech. Syst. Signal Process. 2024, 211, 111149. [Google Scholar] [CrossRef]

- Cui, X.; Gao, Y.; Han, X. On the mixed acoustic and vibration sensors for the cross-correlation analysis of pipe leakage signals. Appl. Acoust. 2023, 216, 109798. [Google Scholar] [CrossRef]

- Westfall, P.H.; Arias, A.L. Understanding Regression Analysis; Taylor & Francis: London, UK, 2020; pp. 152–290. [Google Scholar] [CrossRef]

- Tasneem, S.; Ageeli, A.A.; Alamier, W.M.; Hasan, N.; Safaei, M.R. Organic catalysts for hydrogen production from noodle wastewater: Machine learning and deep learning-based analysis. Int. J. Hydrogen Energy 2023, 52, 599–616. [Google Scholar] [CrossRef]

| Current and Arc Light Data | Electrode (mm) | 80 A | 100 A | 120 A | 140 A |

|---|---|---|---|---|---|

| Raw data (arc light and current) | 3.25 | 2320 × 1 | 1948 × 1 | 2014 × 1 | 1600 × 1 |

| 2.50 | 1276 × 1 | 1116 × 1 | 945 × 1 | 919 × 1 | |

| Train data (arc light and current) | 3.25 | 2041 × 1 | 1802 × 1 | 1835 × 1 | 1481 × 1 |

| 2.50 | 1177 × 1 | 817 × 1 | 746 × 1 | 820 × 1 | |

| Test data (arc light and current) | 3.25 | 279 × 1 | 146 × 1 | 179 × 1 | 119 × 1 |

| 2.50 | 99 × 1 | 299 × 1 | 199 × 1 | 99 × 1 |

| Model | Phase | R-Squared | Cross-Correlation | RMSE (A) |

|---|---|---|---|---|

| ANFIS 3.25 | Train | 0.7033 | 0.9587 | 32.6174 |

| ANFIS 3.25 | Test | 0.6449 | 0.9565 | 33.5493 |

| ANFIS 2.50 | Train | 0.7640 | 0.9598 | 29.4357 |

| ANFIS 2.50 | Test | 0.5853 | 0.9323 | 38.9470 |

| ANN 3.25 | Train | 0.6842 | 0.9559 | 33.6504 |

| ANN 3.25 | Test | 0.6417 | 0.9554 | 33.7037 |

| ANN 2.50 | Train | 0.7364 | 0.9550 | 31.1072 |

| ANN 2.50 | Test | 0.5412 | 0.9349 | 40.9669 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kanat, Y.; Birbir, Y.; Büyüktaş, G. Estimation of Welding Current with Adaptive Neuro Fuzzy Inference System (ANFIS): Utilization of Arc Light Signal Emitted in the Arc Welding Process. Appl. Sci. 2025, 15, 3824. https://doi.org/10.3390/app15073824

Kanat Y, Birbir Y, Büyüktaş G. Estimation of Welding Current with Adaptive Neuro Fuzzy Inference System (ANFIS): Utilization of Arc Light Signal Emitted in the Arc Welding Process. Applied Sciences. 2025; 15(7):3824. https://doi.org/10.3390/app15073824

Chicago/Turabian StyleKanat, Yalçın, Yaşar Birbir, and Gazi Büyüktaş. 2025. "Estimation of Welding Current with Adaptive Neuro Fuzzy Inference System (ANFIS): Utilization of Arc Light Signal Emitted in the Arc Welding Process" Applied Sciences 15, no. 7: 3824. https://doi.org/10.3390/app15073824

APA StyleKanat, Y., Birbir, Y., & Büyüktaş, G. (2025). Estimation of Welding Current with Adaptive Neuro Fuzzy Inference System (ANFIS): Utilization of Arc Light Signal Emitted in the Arc Welding Process. Applied Sciences, 15(7), 3824. https://doi.org/10.3390/app15073824