Research on the Settlement Patterns of Tunnel-Surrounding Rock Under Groundwater Conditions

Abstract

1. Introduction

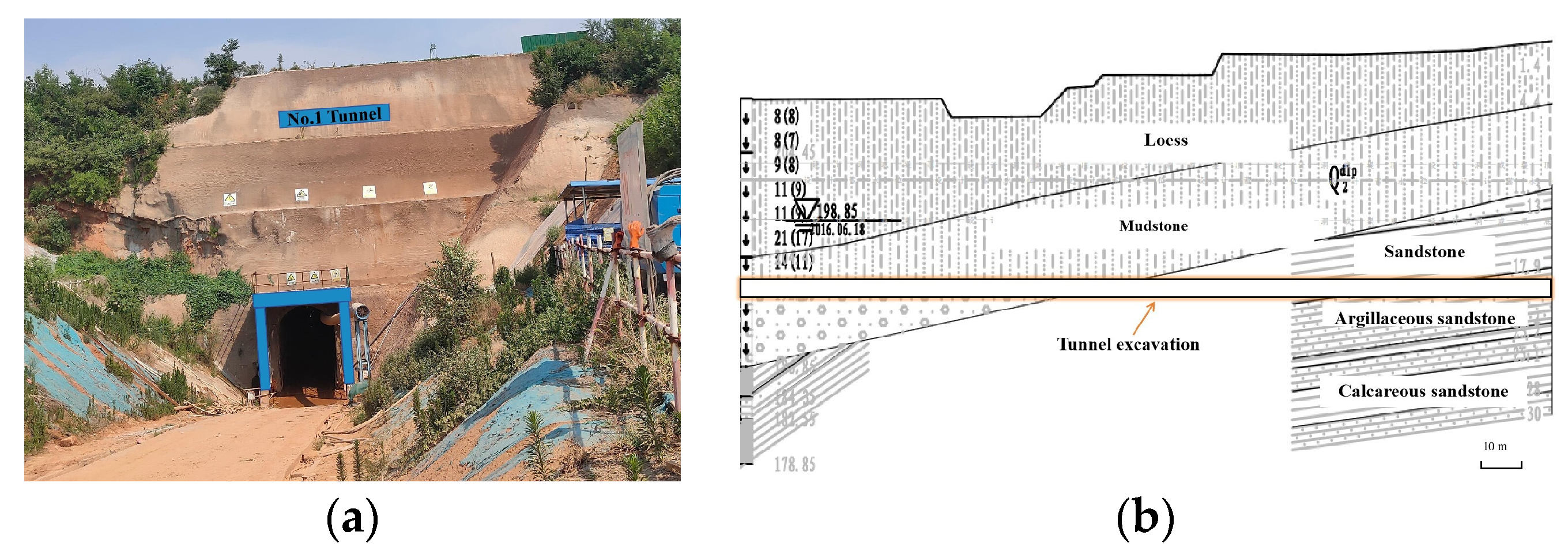

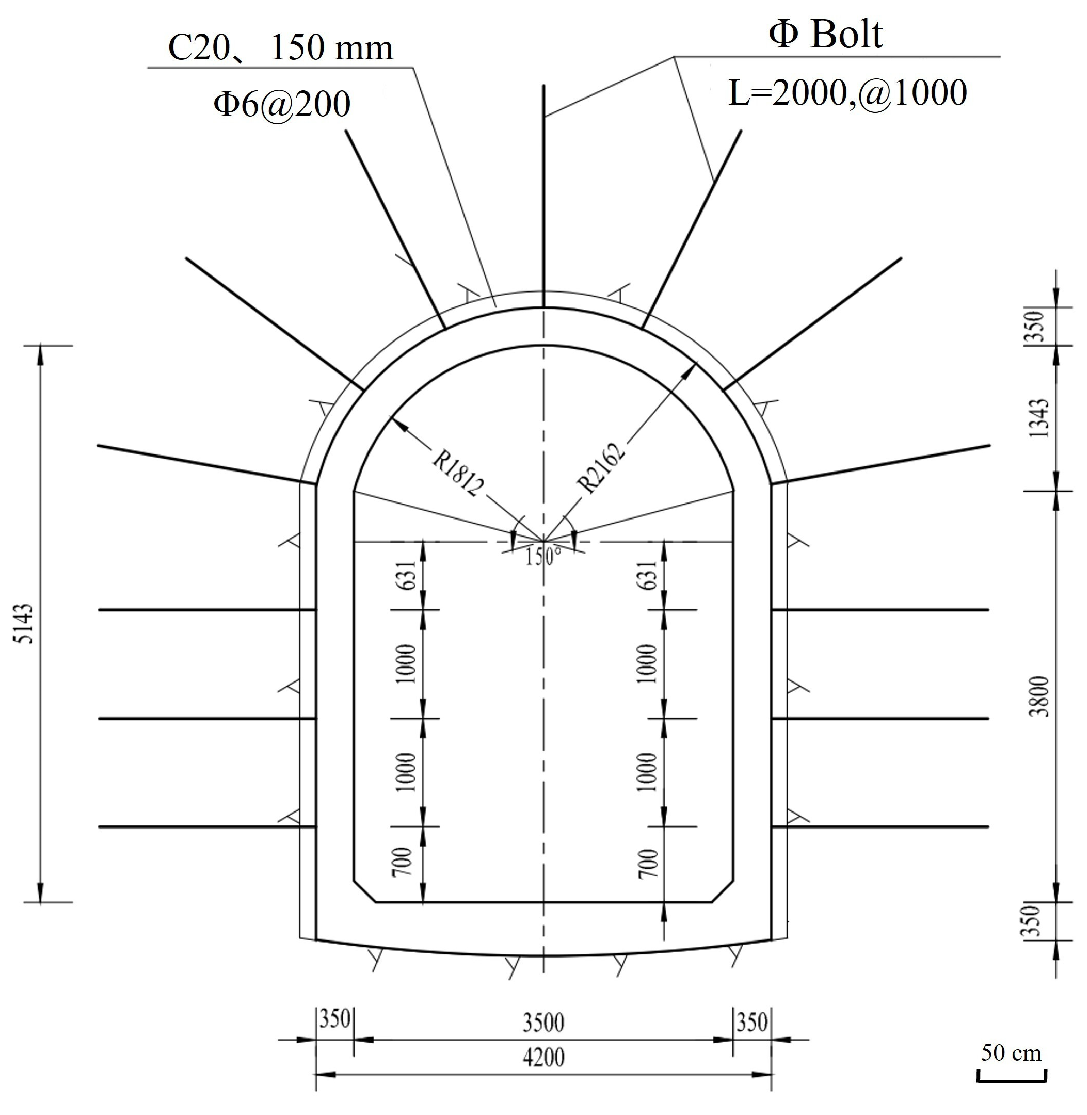

2. Engineering Background

3. Research Methods

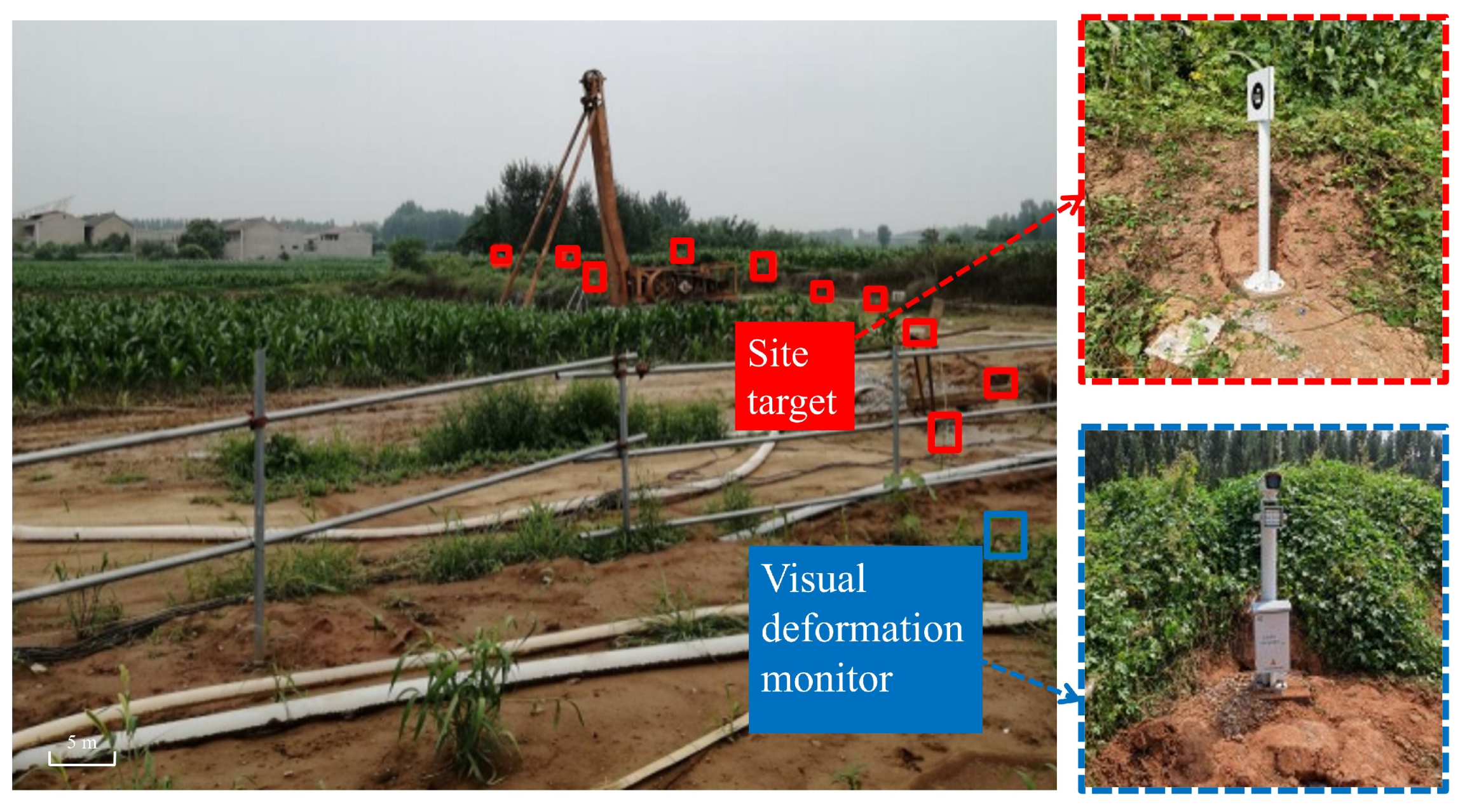

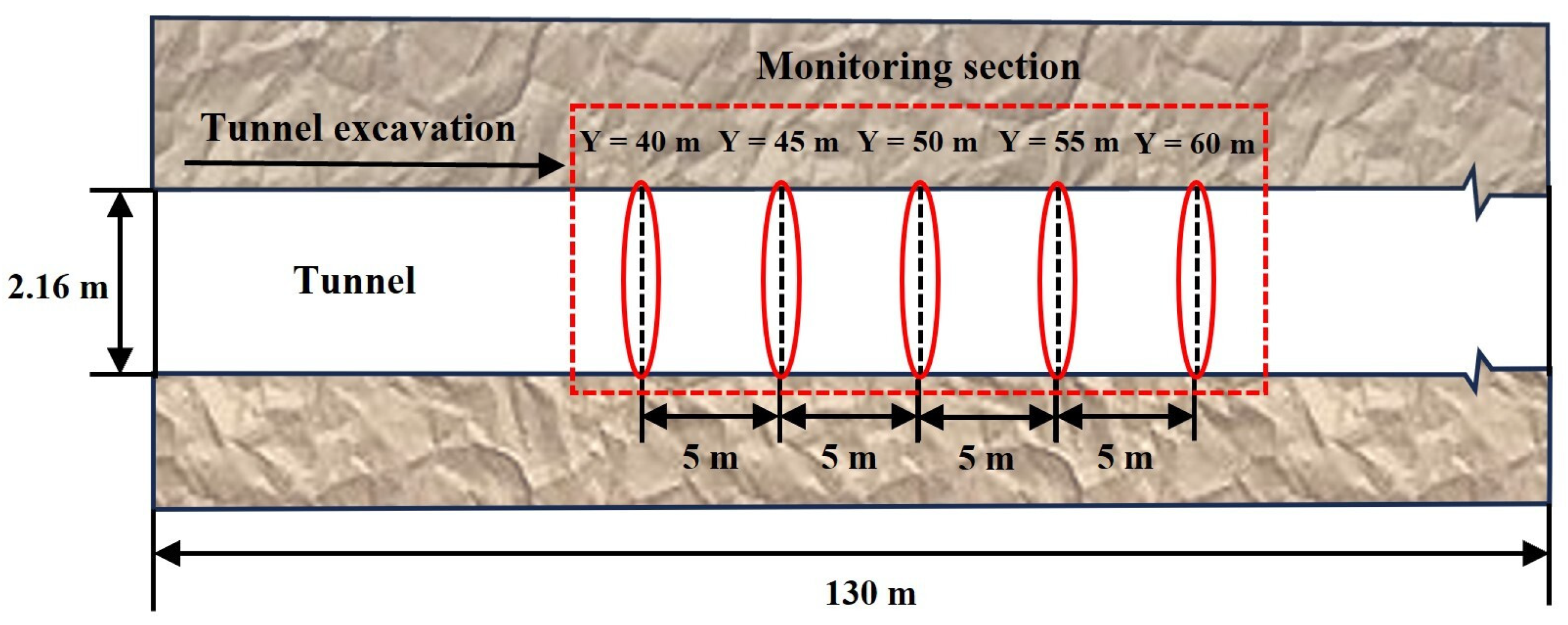

3.1. Monitoring Scheme

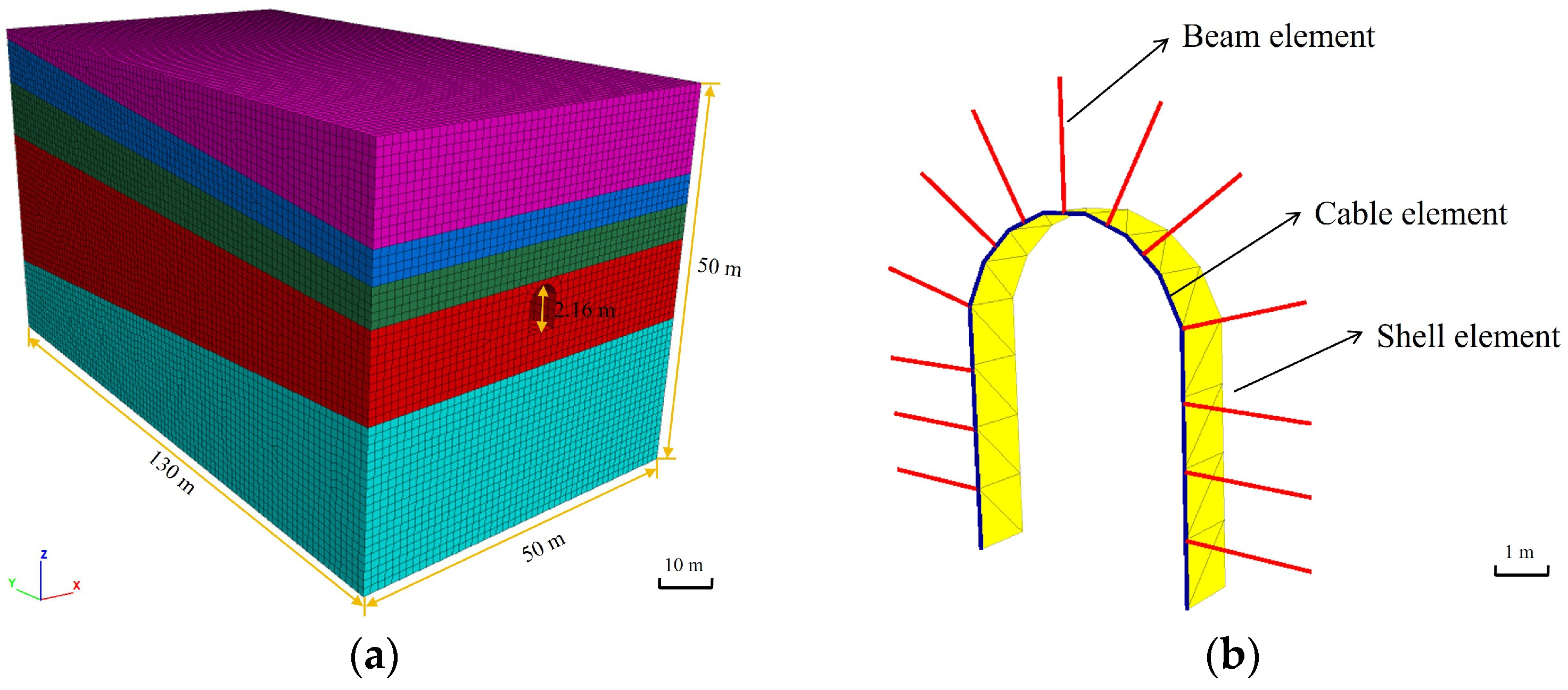

3.2. Model and Parameters

3.3. Model Verification

4. Results and Discussion

4.1. Settlement Monitoring Analysis

4.2. Settlement Simulation Analysis

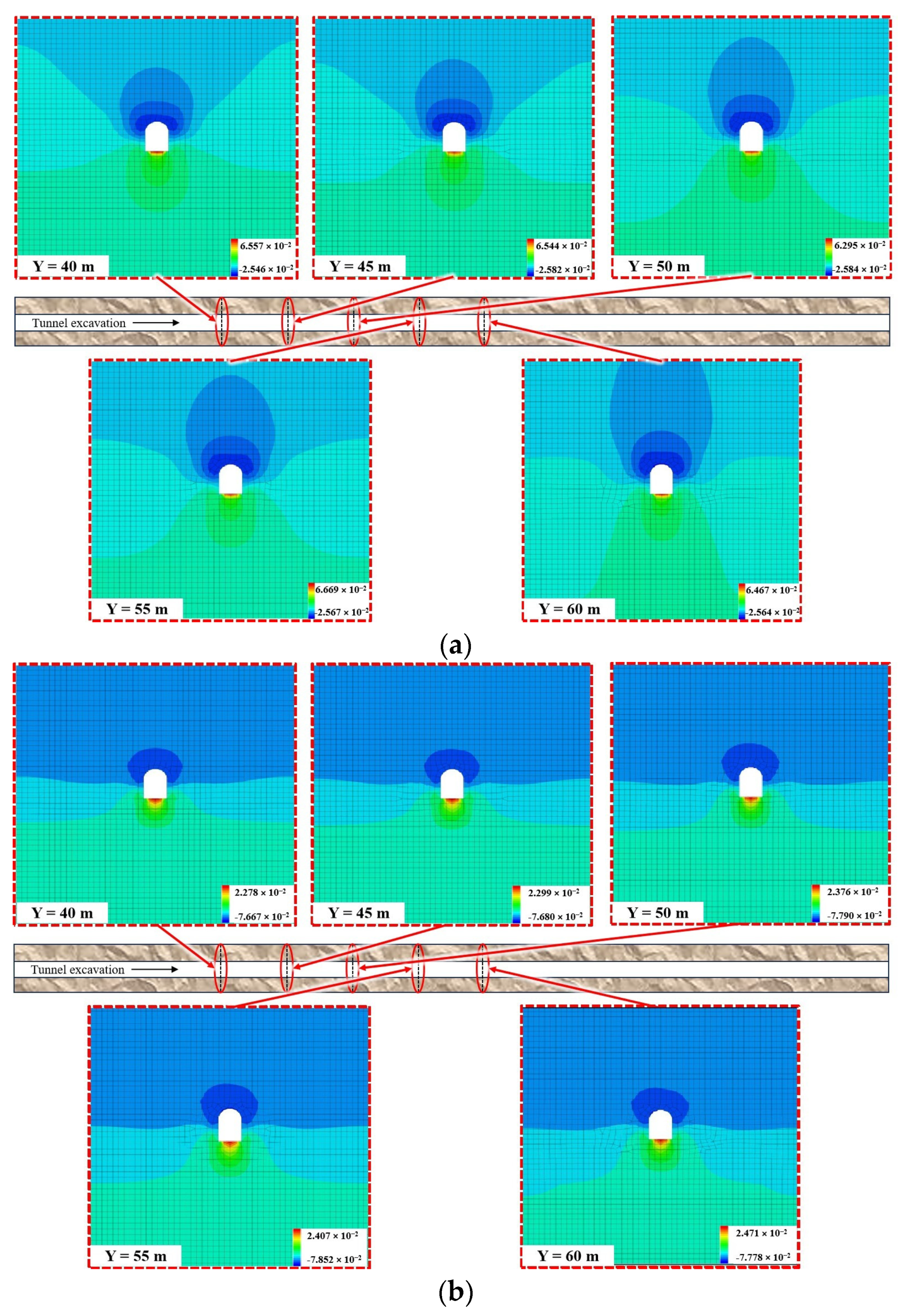

4.2.1. Displacement Cloud Images Analysis

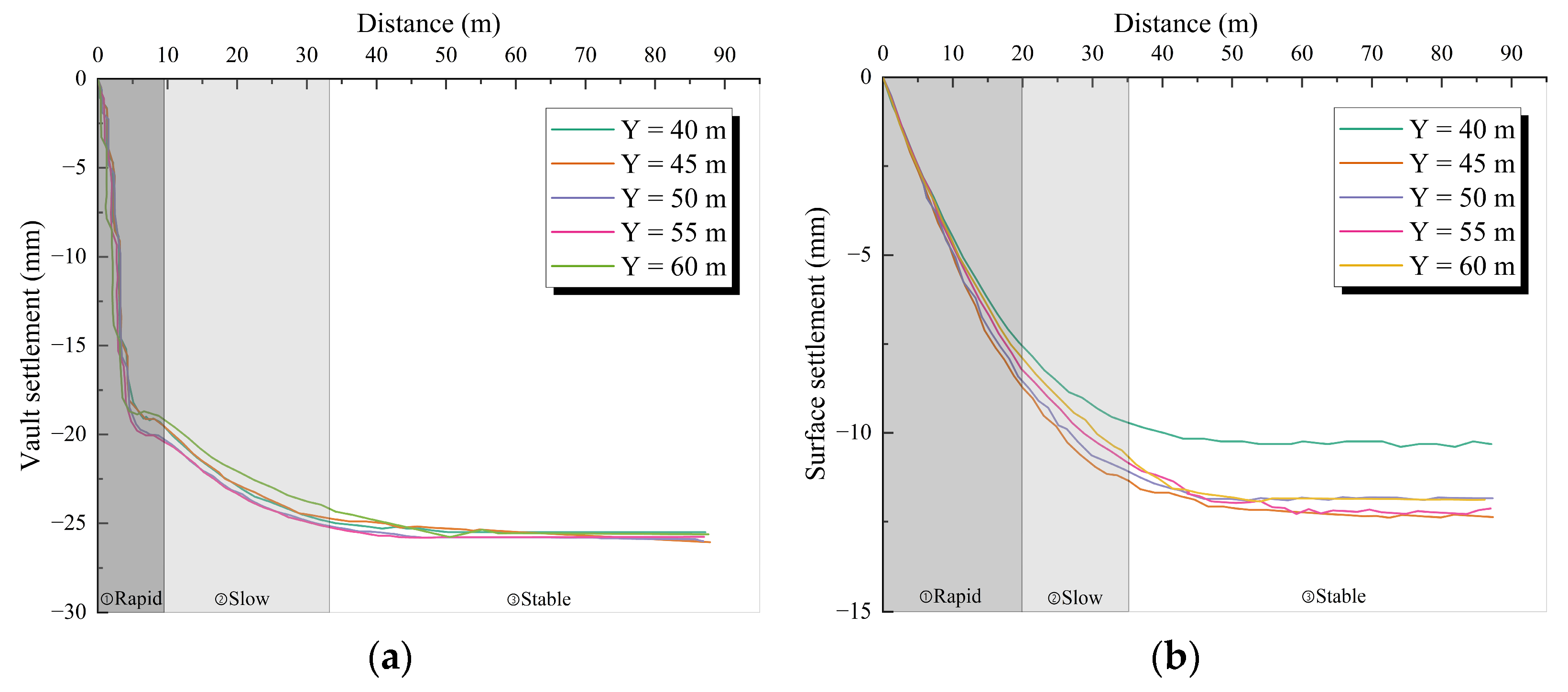

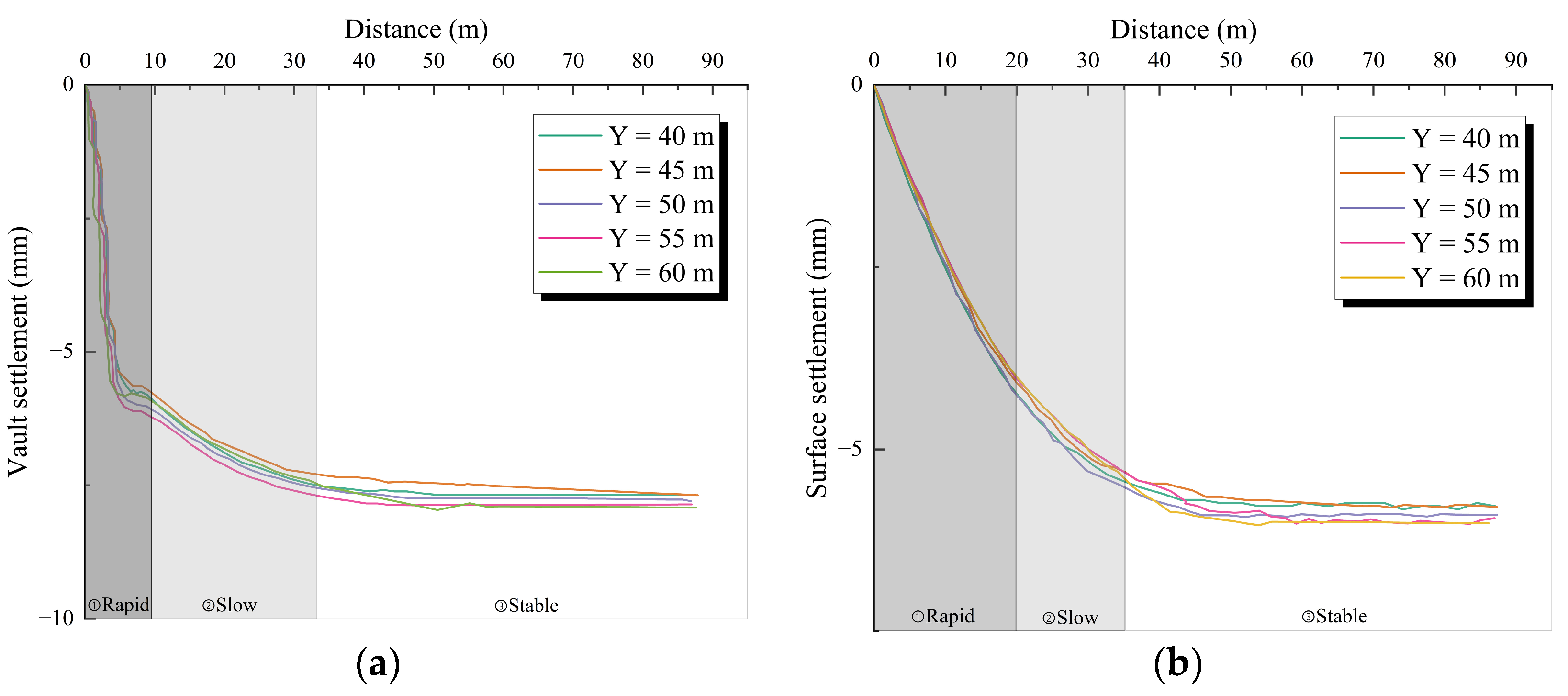

4.2.2. Displacement Curves Analysis

4.3. Groundwater Action Mechanism Analysis

5. Conclusions

- (1)

- The settlement rates after tunnel excavation demonstrate a clear “steep decline—gradual decline—stable” evolution trend, stabilizing around 35 m once excavation reaches the monitoring cross-sections. Rising groundwater levels reduce the effective stress in the soil, accelerating plastic deformation and resulting in an earlier stabilization point. Conversely, falling groundwater levels strengthen the soil skeleton, delaying plastic deformation development and resulting in a later stabilization point.

- (2)

- The numerical simulation settlement curves closely align with the field monitoring curves, both exhibiting a three-phase trend of “steep, gradual, stable”. The error rates for vault settlements range from 0.35% to 2.86%, and those for ground surface settlements range from 3.47% to 5.48%. Both error rates fall below 20%, indicating the simulation’s reliability and its good correlation with the monitoring results.

- (3)

- Groundwater significantly influences the deformation patterns of tunnel-surrounding rock, particularly in strata such as loess and mudstone, which soften upon contact with water. Deformation quantities in these strata are significantly greater under groundwater influence than in conditions without groundwater. Under groundwater influence, the maximum vault settlement displacement is 3.28 times greater than that without groundwater influence, and the maximum ground surface settlement displacement is 1.8 times greater. This indicates that groundwater significantly amplifies rock deformation, warranting special attention in similar engineering projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Zhu, L.; Liang, X.; He, J.; Suo, G.; Wu, H.; Wang, Z. Sustainable application of waste gangue mortar in coal mine tunnel support. Sci. Rep. 2025, 15, 2682. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, Y.; Easa, S.; Yan, X. Risk factors influencing tunnel construction safety: Structural equation model approach. Heliyon 2023, 9, e12924. [Google Scholar] [CrossRef]

- Ye, Z.; Ye, Y.; Zhang, C.; Zhang, Z.; Li, W.; Wang, X.; Wang, L.; Wang, L. A digital twin approach for tunnel construction safety early warning and management. Comput. Ind. 2023, 144, 103783. [Google Scholar]

- Bao, H.; Liu, C.; Liang, N.; Lan, H.; Yan, C.; Xu, X. Analysis of large deformation of deep-buried brittle rock tunnel in strong tectonic active area based on macro and microcrack evolution. Eng. Fail. Anal. 2022, 138, 106351. [Google Scholar] [CrossRef]

- Shi, C.; Cao, C.; Lei, M.; Yang, W. Face stability analysis of shallow underwater tunnels in fractured zones. Arab. J. Geosci. 2016, 9, 24. [Google Scholar] [CrossRef]

- Liu, C.; Bao, H.; Lan, H.; Li, L.; Chen, W.; Lv, H.; Liu, S. Bedding effect on progressive crack propagation in layered sandstone grotto roof. Tunn. Undergr. Space Technol. 2024, 152, 105914. [Google Scholar]

- Huang, M.; Zhan, J. Face stability assessment for underwater tunneling across a fault zone. J. Perform. Constr. Facil. 2019, 33, 04019034. [Google Scholar]

- Bao, H.; Liu, C.; Lan, H.; Yan, C.; Li, L.; Zheng, H.; Dong, Z. Time-dependency deterioration of polypropylene fiber reinforced soil and guar gum mixed soil in loess cut-slope protecting. Eng. Geol. 2022, 311, 106895. [Google Scholar] [CrossRef]

- Tarifard, A.; Görög, P.; Török, Á. Long-term assessment of creep and water effects on tunnel lining loads in weak rocks using displacement-based direct back analysis: An example from northwest of Iran. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 31. [Google Scholar] [CrossRef]

- Yan, Q.; Zhong, H.; Zhang, C.; Zhao, Z.; Wen, Y.; Wang, P. Novel numerical model to simulate water seepage through segmental gasketed joints of underwater shield tunnels considering the superimposed seepage squeezing effect. Undergr. Space 2023, 13, 104–120. [Google Scholar]

- Fu, Y.; Zeng, D.; Xiong, H.; Li, X.; Chen, Y. Seepage effect on failure mechanisms of the underwater tunnel face via CFD–DEM coupling. Comput. Geotech. 2022, 146, 104591. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, H.; Han, L.; Zhao, Z. Study of water–sand inrush through a vertical karst conduit uncovered through tunnel excavation. Water 2023, 15, 2010. [Google Scholar] [CrossRef]

- Gong, C.; Ding, W.; Xie, D. Parametric investigation on the sealant behavior of tunnel segmental joints under water pressurization. Tunn. Undergr. Space Technol. 2020, 97, 103231. [Google Scholar] [CrossRef]

- Elgamal, A.; Elfaris, N. Stability of Shield-Bored Tunnel for the Challenge of Nile Crossing. Infrastructures 2021, 6, 147. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, Q.; Jiang, Y.; Li, Z.; Wang, Y. Analysis of Structure Stability of Underwater Shield Tunnel under Different Temperatures Based on Finite Element Method. Water 2023, 15, 2577. [Google Scholar] [CrossRef]

- Liu, W.; Albers, B.; Zhao, Y.; Tang, X.W. Upper bound analysis for estimation of the influence of seepage on tunnel face stability in layered soils. J. Zhejiang Univ.-Sci. A 2016, 17, 886–902. [Google Scholar] [CrossRef]

- Chen, L.; Xi, B.; Dong, Y.; He, S.; Shi, Y.; Gao, Q.; Liu, K.; Zhao, N. Study on the Stability and Seepage Characteristics of Underwater Shield Tunnels under High Water Pressure Seepage. Sustainability 2023, 15, 15581. [Google Scholar] [CrossRef]

- Cheng, X.; Zhang, S.; Zhou, X.; Xia, P. Parameter analysis of excavation face stability of shield tunnel under high water pressure seepage. Phys. Chem. Earth 2022, 128, 103218. [Google Scholar] [CrossRef]

- Zareifard, M.R.; Shekari, M.R. Comprehensive solutions for underwater tunnels in rock masses with different GSI values considering blast-induced damage zone and seepage forces. Appl. Math. Model. 2021, 96, 236–268. [Google Scholar] [CrossRef]

- Frenelus, W.; Peng, H.; Zhang, J. Seepage Actions and Their Consequences on the Support Scheme of Deep-Buried Tunnels Constructed in Soft Rock Strata. Infrastructures 2024, 9, 13. [Google Scholar] [CrossRef]

- Huang, F.; Qin, C.B.; Li, S.C. Determination of minimum cover depth for shallow tunnel subjected to water pressure. J. Cent. South Univ. 2013, 20, 2307–2313. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, Z.; Xu, W. Research progress and prospects on pier-type submerged floating tunnels. Ocean Eng. 2024, 308, 118187. [Google Scholar]

- Shen, Y.; Zhang, T.; Liu, H.; Zhu, J.; Yang, P.; Wang, Y. Research on Leakage Mechanism of Underwater Shield Tunnels with Different Soil Layers during Operation Period. Sustainability 2022, 14, 14276. [Google Scholar] [CrossRef]

- Wang, S.; Li, L.P.; Cheng, S.; Hu, H.J.; Zhang, M.G.; Wen, T. Risk assessment of water inrush in tunnels based on attribute interval recognition theory. J. Cent. South Univ. 2020, 27, 517–530. [Google Scholar] [CrossRef]

- Hao, X.; Yuan, L.; Sun, Z.; Zhao, Y.; Ren, B.; Zhao, D.; Xue, J.; Zhang, X.; Yu, G.; Zhang, Q. An integrated study of physical and numerical modelling on the stability of underground tunnel influenced by unloading rate. Tunn. Undergr. Space Technol. 2022, 129, 104602. [Google Scholar]

- Liu, Y.; Wu, H.; Gao, Y.; Wang, W.; Wang, Z. Influence of macadamia nutshell particles on the apparent density and mechanical behavior of cement-based mortars. Constr. Build. Mater. 2024, 411, 134600. [Google Scholar] [CrossRef]

- Bao, H.; Rao, Z.; Lan, H.; Yan, C.; Liu, C.; Liu, S. Discrete element modeling method for anisotropic mechanical behavior of biotite quartz schist based on mineral identification technology. Bull. Eng. Geol. Environ. 2025, 84, 28. [Google Scholar]

- Huang, Y.; Yu, Z.; Zhou, Z. Simulating Groundwater Inflow in the Underground Tunnel with a Coupled Fracture-Matrix Model. J. Hydrol. Eng. 2013, 18, 1557–1561. [Google Scholar]

- Qiu, J.L.; Lu, Y.Q.; Lai, J.X.; Zhang, Y.W.; Yang, T.; Wang, K. Experimental study on the effect of water gushing on loess metro tunnel. Environ. Earth Sci. 2020, 79, 261. [Google Scholar] [CrossRef]

- Gao, C.; Li, L.; Zhou, Z.; Li, Z.; Cheng, S.; Wang, L.; Zhang, D. Peridynamics Simulation of Water Inrush Channels Evolution Process Due to Rock Mass Progressive Failure in Karst Tunnels. Int. J. Geomech. 2021, 21, 04021028. [Google Scholar]

- Wang, T.; Liu, H.; Kang, M.; Zhao, B.; Shen, J.; Li, Y.; Yang, Y. Study on the Synergistic Effect of Primary Support and Surrounding Rock of Large Buried Depth Tunnel in Soft and Fractured Strata. Appl. Sci. 2024, 14, 2028. [Google Scholar] [CrossRef]

- Tan, X.; Chen, W.; Wu, G.; Wang, L.; Yang, J. A structural health monitoring system for data analysis of segment joint opening in an underwater shield tunnel. Struct. Health Monit. 2020, 19, 1032–1050. [Google Scholar]

- Hou, T.; Yang, X.; Xing, H.; Huang, K.; Zhou, J. Forecasting and prevention of water inrush during the excavation process of a diversion tunnel at the Jinping II Hydropower Station, China. SpringerPlus 2016, 5, 700. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Wang, M.; Feng, D.; Wang, J. Water Inflow Amount Prediction for Karst Tunnel with Steady Seepage Conditions. Sustainability 2023, 15, 10638. [Google Scholar] [CrossRef]

- Yang, F.; Zhou, H.; Zhang, C.; Lu, J.; Lu, X.; Geng, Y. An analysis method for evaluating the safety of pressure water conveyance tunnel in argillaceous sandstone under water-weakening conditions. Tunn. Undergr. Space Technol. 2020, 97, 103264. [Google Scholar]

- Liu, Y.; He, J.; Liang, J.; Wang, W.; Wang, Z. A new improved particle swarm algorithm for optimization of anchor lattice beam support structures. Nat. Hazards 2024, 121, 225–243. [Google Scholar]

- Li, W.T.; Yang, N.; Li, T.C.; Zhang, Y.H.; Wang, G. A new approach to simulate the supporting arch in a tunnel based on improvement of the beam element in FLAC3D. J. Zhejiang Univ. Sci. A 2017, 18, 179–193. [Google Scholar] [CrossRef]

- Qu, T.; Wang, S.; Fu, J.; Hu, Q.; Zhang, X. Numerical Examination of EPB Shield Tunneling–Induced Responses at Various Discharge Ratios. J. Perform. Constr. Facil. 2019, 33, 04019035. [Google Scholar]

- Cai, P.L. Analysis on ground settlement caused by Qingdao subway tunnel excavation based on FLAC3D. Master’s thesis, JiLin University, Changchun, China, 2015.

- Yang, C.; Ma, W.; Peng, H.; Cai, X.; Cheng, L.; Liu, J.; Huo, Z. Research on the Settlement Control of Existing Shield Tunnels Affected by Construction of Underneath Dual Shield Tunnels. J. Railw. Eng. Soc. 2018, 35, 91–98. [Google Scholar]

- Huang, D.; Li, S.; Shi, Y. Experimental Study on the Effect of Groundwater Level Variation on Settlement of Subway Tunnel in Sandy Stratum. China Railw. Sci. 2024, 45, 122–130. [Google Scholar]

- Cheng, P.; Zhao, L.H.; Li, L.; Zou, J.F.; Luo, W. Limiting drainage criterion for groundwater of mountain tunnel. J. Cent. South Univ. 2014, 21, 4660–4668. [Google Scholar]

- Sui, W.; Liu, Z.; Zhang, G.; Mao, D.; Li, R.; Liang, J. Experimental investigation on grout propagation in poured aggregates for controlling water inrush in tunnels with flowing water. Geoenvironmental Disasters 2023, 10, 15. [Google Scholar] [CrossRef]

- Shrestha, P.K.; Panthi, K.K. Groundwater effect on faulted rock mass: An evaluation of Modi Khola pressure tunnel in the Nepal Himalaya. Rock Mech. Rock Eng. 2014, 47, 1021–1035. [Google Scholar]

- Bobet, A. Deep tunnel in transversely anisotropic rock with groundwater flow. Rock Mech. Rock Eng. 2016, 49, 4817–4832. [Google Scholar]

- Joo, E.J.; Shin, J.H. Relationship between water pressure and inflow rate in underwater tunnels and buried pipes. Géotechnique 2014, 64, 226–231. [Google Scholar]

- Chen, G.; Shi, Y.; Ji, F.; Li, T.; Wang, J.; Wang, Z. Corrosion investigation of groundwater for underground tunnel. Disaster Adv. 2013, 6, 228–235. [Google Scholar]

- Bayat, N.; Sadeghi, E.; Nassery, H.R. Evaluating the characteristics of geological structures in karst groundwater inflow, Nowsud Tunnel. J. Mt. Sci. 2024, 21, 3434–3452. [Google Scholar]

| Density (g/cm3) | Elastic Modulus (Pa) | Poisson | Cohesion (Pa) | Friction (°) | ||

|---|---|---|---|---|---|---|

| Loess | Saturated | 1.86 | 2.79 × 107 | 0.2 | 1.36 × 104 | 21 |

| Unsaturated | 1.86 | 8.43 × 106 | 0.2 | 7.48 × 103 | 23 | |

| Shale | Saturated | 2.37 | 5.75 × 107 | 0.26 | 1.39 × 105 | 29 |

| Unsaturated | 2.37 | 1.74 × 107 | 0.26 | 7.65 × 104 | 31 | |

| Sandstone | Saturated | 2.46 | 6.93 × 108 | 0.27 | 6.62 × 105 | 37 |

| Unsaturated | 2.46 | 2.09 × 108 | 0.27 | 3.64 × 105 | 39 | |

| Argillaceous Sandstone | Saturated | 2.18 | 1.94 × 108 | 0.26 | 4.82 × 105 | 35 |

| Unsaturated | 2.18 | 5.87 × 107 | 0.26 | 2.65 × 105 | 37 | |

| Calcareous Sandstone | Saturated | 2.51 | 1.33 × 109 | 0.27 | 7.08 × 105 | 38 |

| Unsaturated | 2.51 | 4.02 × 108 | 0.27 | 3.9 × 105 | 40 | |

| Cross-Section Position | Vault Settlement (mm) | Surface Settlement (mm) | ||||

|---|---|---|---|---|---|---|

| Monitored | Simulated | Error Rate | Monitored | Simulated | Error Rate | |

| Y = 40 m (Target 1) | 25.24 | 25.5 | 1.03% | 9.23 | 9.73 | 5.42% |

| Y = 45 m (Target 2) | 25.71 | 25.8 | 0.35% | 10.38 | 10.87 | 4.72% |

| Y = 50 m (Target 3) | 25.73 | 25.83 | 0.39% | 11.54 | 11.94 | 3.47% |

| Y = 55 m (Target 4) | 25.19 | 25.91 | 2.86% | 12.23 | 12.9 | 5.48% |

| Y = 60 m (Target 5) | 25.66 | 25.96 | 1.17% | 13.24 | 13.8 | 4.23% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Wang, T.; Ma, W.; Kang, M.; Fu, Y.; Yan, T. Research on the Settlement Patterns of Tunnel-Surrounding Rock Under Groundwater Conditions. Appl. Sci. 2025, 15, 3796. https://doi.org/10.3390/app15073796

Liu H, Wang T, Ma W, Kang M, Fu Y, Yan T. Research on the Settlement Patterns of Tunnel-Surrounding Rock Under Groundwater Conditions. Applied Sciences. 2025; 15(7):3796. https://doi.org/10.3390/app15073796

Chicago/Turabian StyleLiu, Haining, Tianyi Wang, Wenjia Ma, Minglei Kang, Yunyou Fu, and Tingsong Yan. 2025. "Research on the Settlement Patterns of Tunnel-Surrounding Rock Under Groundwater Conditions" Applied Sciences 15, no. 7: 3796. https://doi.org/10.3390/app15073796

APA StyleLiu, H., Wang, T., Ma, W., Kang, M., Fu, Y., & Yan, T. (2025). Research on the Settlement Patterns of Tunnel-Surrounding Rock Under Groundwater Conditions. Applied Sciences, 15(7), 3796. https://doi.org/10.3390/app15073796