Smart Infrastructure and Additive Manufacturing: Synergies, Advantages, and Limitations

Abstract

1. Introduction

2. 3D Printing in Smart Infrastructure: An Overview

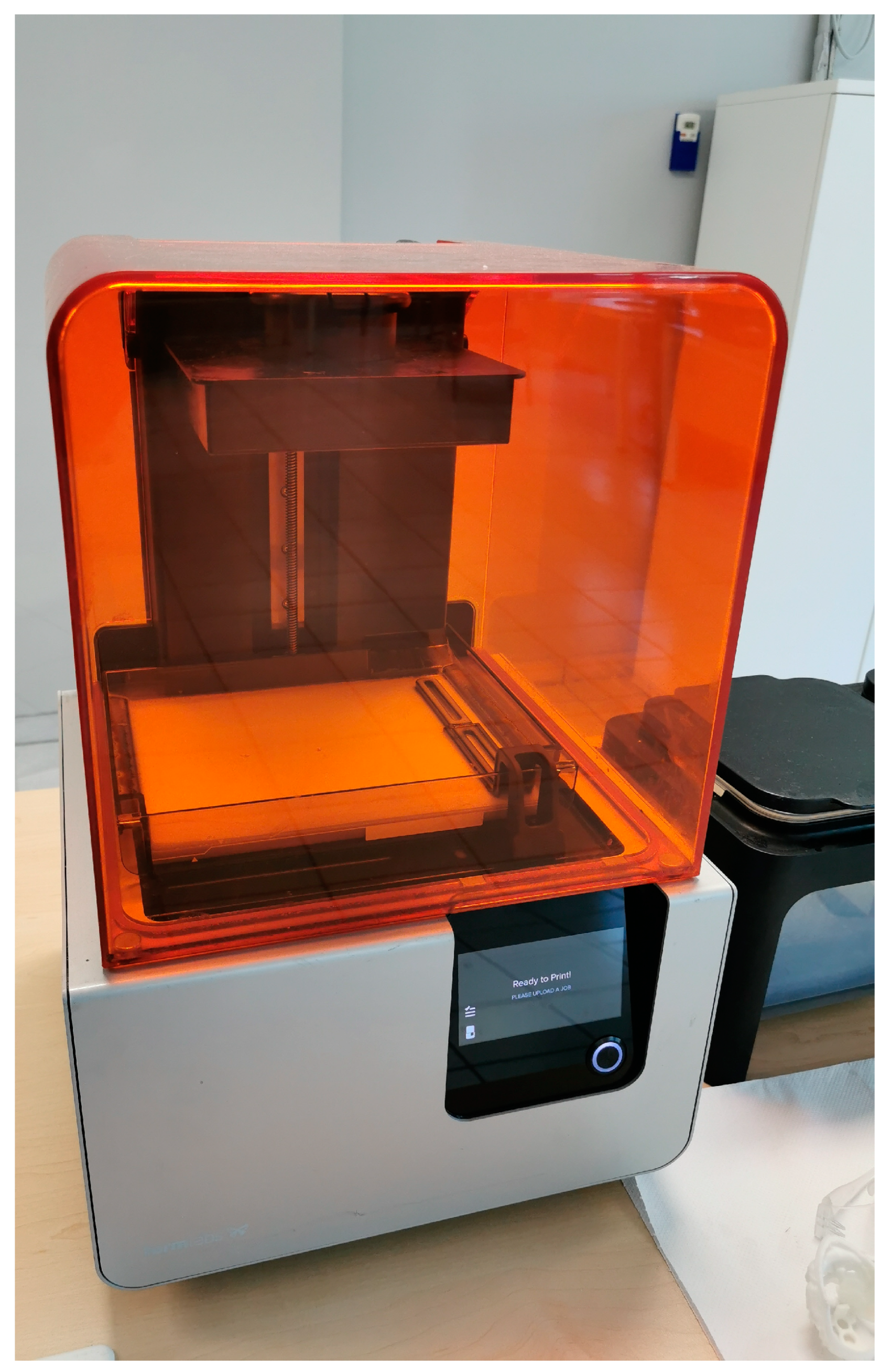

2.1. Types of 3D Printing Technologies Relevant to Smart Infrastructure

2.2. Examples of 3D-Printed Infrastructure Components

3. Key Applications of 3D Printing in Smart Infrastructure

3.1. 3D-Printed Sensors and IoT Devices

3.2. Modular and Prefabricated Components

3.3. Sustainable and Self-Healing Materials

4. Benefits of Integrating 3D Printing with Smart Infrastructure

4.1. Tailored Components for Specific Applications

4.2. Sustainability and Optimization of Performance and Durability

5. Challenges and Limitations

6. Future Perspectives and Research Directions

6.1. Advancements in Multi-Material 3D Printing for Smart Infrastructure

Standards, Material Properties, and Reinforcement in 3D-Printed Structures

6.2. The Role of AI and Machine Learning in Optimizing 3D Printing for Smart Cities

6.3. Emerging Trends in Self-Sustaining, Autonomous 3D-Printed Systems

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| AM | Additive Manufacturing |

| CAD | Computer-Aided Design |

| DED | Directed Energy Deposition |

| FDM | Fused Deposition Modeling |

| IoT | Internet of Things |

| SLA | Stereolithography |

| SLS | Selective Laser Sintering |

| UV | Ultraviolet |

| VR | Virtual Reality |

References

- Kangana, N.; Kankanamge, N.; De Silva, C.; Goonetilleke, A.; Mahamood, R.; Ranasinghe, D. Bridging Community En-gagement and Technological Innovation for Creating Smart and Resilient Cities: A Systematic Literature Review. Smart Cities 2024, 7, 3823–3852. [Google Scholar] [CrossRef]

- Talari, S.; Shafie-khah, M.; Siano, P.; Loia, V.; Tommasetti, A.; Catalão, J. A Review of Smart Cities Based on the Internet of Things Concept. Energies 2017, 10, 421. [Google Scholar] [CrossRef]

- Gracias, J.S.; Parnell, G.S.; Specking, E.; Pohl, E.A.; Buchanan, R. Smart Cities—A Structured Literature Review. Smart Cities 2023, 6, 1719–1743. [Google Scholar] [CrossRef]

- Radu, L.-D. Disruptive Technologies in Smart Cities: A Survey on Current Trends and Challenges. Smart Cities 2020, 3, 1022–1038. [Google Scholar] [CrossRef]

- Lazaroiu, A.C.; Roscia, M.; Lazaroiu, G.C.; Siano, P. Review of Energy Communities: Definitions, Regulations, Topologies, and Technologies. Smart Cities 2025, 8, 8. [Google Scholar] [CrossRef]

- Zeng, F.; Pang, C.; Tang, H. Sensors on Internet of Things Systems for the Sustainable Development of Smart Cities: A Systematic Literature Review. Sensors 2024, 24, 2074. [Google Scholar] [CrossRef]

- Zikria, Y.B.; Ali, R.; Afzal, M.K.; Kim, S.W. Next-Generation Internet of Things (IoT): Opportunities, Challenges, and So-lutions. Sensors 2021, 21, 1174. [Google Scholar] [CrossRef]

- Konstantopoulou, D.; Zacharia, P.; Papoutsidakis, M.; Leligou, H.C.; Patrikakis, C. GAGAN: Enhancing Image Generation through Hybrid Optimization of Genetic Algorithms and Deep Convolutional Generative Adversarial Networks. Algorithms 2024, 17, 584. [Google Scholar] [CrossRef]

- Shulajkovska, M.; Smerkol, M.; Noveski, G.; Gams, M. Enhancing Urban Sustainability: Developing an Open-Source AI Framework for Smart Cities. Smart Cities 2024, 7, 2670–2701. [Google Scholar] [CrossRef]

- Al-Rimawi, T.; Nadler, M. Leveraging Smart City Technologies for Enhanced Real Estate Development: An Integrative Review. Smart Cities 2025, 8, 10. [Google Scholar] [CrossRef]

- Khan, J.; Elfakharany, R.; Saleem, H.; Pathan, M.; Shahzad, E.; Dhou, S.; Aloul, F. Can Machine Learning Enhance Intrusion Detection to Safeguard Smart City Networks from Multi-Step Cyberattacks? Smart Cities 2025, 8, 13. [Google Scholar] [CrossRef]

- Yahia, O.; Chohan, A.H.; Arar, M.; Awad, J. Toward Sustainable Urban Mobility: A Systematic Review of Transit-Oriented Development for the Appraisal of Dubai Metro Stations. Smart Cities 2025, 8, 21. [Google Scholar] [CrossRef]

- Ulpiani, G.; Pisoni, E.; Bastos, J.; Monforti-Ferrario, F.; Vetters, N. Are Cities Ready to Synergise Climate Neutrality and Air Quality Efforts? Sustain. Cities Soc. 2025, 118, 106059. [Google Scholar] [CrossRef]

- Ali, S.; Niaz, H.; Ahmad, S.; Khan, S. Investigating How Rapid Urbanization Contributes to Climate Change and the Social Challenges Cities Face in Mitigating Its Effects. Rev. Appl. Manag. Soc. Sci. 2024, 8, 1–16. [Google Scholar] [CrossRef]

- Gavaldà-Torrellas, O.; Monsalvete, P.; Ranjbar, S.; Eicker, U. The Urban Building Energy Retrofitting Tool: An Open-Source Framework to Help Foster Building Retrofitting Using a Life Cycle Costing Perspective—First Results for Montréal. Smart Cities 2025, 8, 17. [Google Scholar] [CrossRef]

- Garcia-Cantón, S.; Ruiz de Mendoza, C.; Cervelló-Pastor, C.; Sallent, S. Multi-Agent Reinforcement Learning-Based Routing and Scheduling Models in Time-Sensitive Networking for Internet of Vehicles Communications between Transportation Field Cabinets. Appl. Sci. 2025, 15, 1122. [Google Scholar] [CrossRef]

- Tariq, U.; Ahanger, T.A. Enhancing Intelligent Transport Systems through Decentralized Security Frameworks in Vehi-cle-to-Everything Networks. World Electr. Veh. J. 2025, 16, 24. [Google Scholar] [CrossRef]

- Jokar, H.; Niknam, T.; Dehghani, M.; Siano, P.; Ouahada, K.; Aly, M. Integrated Energy Management in Small-Scale Smart Grids Considering the Emergency Load Conditions: A Combined Battery Energy Storage, Solar PV, and Pow-er-to-Hydrogen System. Smart Cities 2024, 7, 3764–3797. [Google Scholar] [CrossRef]

- Shaik, M.A.; Sneha, P. Revolutionizing Infrastructure Resilience: AI-Driven Predictive Maintenance and Structural Health Monitoring. Preprints 2025. [Google Scholar] [CrossRef]

- Gunderia, A.; Agarwal, P.; Nikam, V.B.; Bambole, A.N. AI Approaches for Predictive Maintenance in Road Bridge Infra-structure. In Proceedings of the 2024 International Conference on Smart Applications, Communications and Networking (SmartNets), Washington DC, USA, 28–30 May 2024; IEEE: New York, NY, USA, 2024; pp. 1–6. [Google Scholar]

- Apeiranthitis, S.; Zacharia, P.; Chatzopoulos, A.; Papoutsidakis, M. Predictive Maintenance of Machinery with Rotating Parts Using Convolutional Neural Networks. Electronics 2024, 13, 460. [Google Scholar] [CrossRef]

- Liu, F.; Feng, J.; Zhai, G.; Razzaq, A. Influence of Fiscal Decentralization and Renewable Energy Investment on Ecological Sustainability in EU: What Is the Moderating Role of Institutional Governance? Renew. Energy 2022, 200, 1265–1274. [Google Scholar] [CrossRef]

- Garlík, B. Energy Sustainability of a Cluster of Buildings with the Application of Smart Grids and the Decentralization of Renewable Energy Sources. Energies 2022, 15, 1649. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 3D and 4D Printing as Integrated Manufacturing Methods of Industry 4.0. Am. J. Eng. Appl. Sci. 2023, 16, 12–22. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Ganetsos, T.; Petrescu, F.I.T. Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes 2023, 11, 1385. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- He, Q.; Tang, T.; Zeng, Y.; Iradukunda, N.; Bethers, B.; Li, X.; Yang, Y. Review on 3D Printing of Bioinspired Structures for Surface/Interface Applications. Adv. Funct. Mater. 2024, 34, 2309323. [Google Scholar] [CrossRef]

- Barcena, A.J.R.; Ravi, P.; Kundu, S.; Tappa, K. Emerging Biomedical and Clinical Applications of 3D-Printed Poly(Lactic Acid)-Based Devices and Delivery Systems. Bioengineering 2024, 11, 705. [Google Scholar] [CrossRef]

- Mazeeva, A.; Masaylo, D.; Konov, G.; Popovich, A. Multi-Metal Additive Manufacturing by Extrusion-Based 3D Printing for Structural Applications: A Review. Metals 2024, 14, 1296. [Google Scholar] [CrossRef]

- Bănică, C.-F.; Sover, A.; Anghel, D.-C. Printing the Future Layer by Layer: A Comprehensive Exploration of Additive Manufacturing in the Era of Industry 4.0. Appl. Sci. 2024, 14, 9919. [Google Scholar] [CrossRef]

- Wawryniuk, Z.; Brancewicz-Steinmetz, E.; Sawicki, J. Revolutionizing Transportation: An Overview of 3D Printing in Aviation, Automotive, and Space Industries. Int. J. Adv. Manuf. Technol. 2024, 134, 3083–3105. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.; Abdoli, H.; Diegel, O.; Chan, S.; Iliescu, M.; Ganetsos, T.; Munteanu, I.; Ungureanu, L. Additive Manufacturing for Surgical Planning and Education: A Review. Appl. Sci. 2024, 14, 2550. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T. Transforming Object Design and Creation: Biomaterials and Contemporary Manufacturing Leading the Way. Biomimetics 2024, 9, 48. [Google Scholar] [CrossRef] [PubMed]

- Hassan, H.; Rodriguez-Ubinas, E.; Al Tamimi, A.; Trepci, E.; Mansouri, A.; Almehairbi, K. Towards Innovative and Sus-tainable Buildings: A Comprehensive Review of 3D Printing in Construction. Autom. Constr. 2024, 163, 105417. [Google Scholar] [CrossRef]

- Afshar, S.; Pazouki, S.; Haghifam, M.-R.; Disfani, V.; Siano, P. Optimal Planning of Residential Energy Hubs Considering Customer Desire Function. Electr. Power Compon. Syst. 2022, 50, 1113–1129. [Google Scholar] [CrossRef]

- Góra, M.; Bańkosz, M.; Tyliszczak, B. Use of Innovative Methods to Produce Highly Insulating Walls Using 3D-Printing Technology. Materials 2024, 17, 3990. [Google Scholar] [CrossRef]

- Ma, J.; Samarasinghe, D.A.S.; Rotimi, J.O.B.; Zuo, K. Supply Chain Landscape of 3D Printed Buildings: A Stakeholder De-cision Support Framework. Buildings 2024, 14, 1811. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Z.; Hou, J.; Ge, M. Research Progress and Trend Analysis of Concrete 3D Printing Technology Based on CiteSpace. Buildings 2024, 14, 989. [Google Scholar] [CrossRef]

- Tsaramirsis, G.; Kantaros, A.; Al-Darraji, I.; Piromalis, D.; Apostolopoulos, C.; Pavlopoulou, A.; Alrammal, M.; Ismail, Z.; Buhari, S.M.; Stojmenovic, M.; et al. A Modern Approach towards an Industry 4.0 Model: From Driving Technologies to Management. J. Sens. 2022, 2022, 5023011. [Google Scholar] [CrossRef]

- Symeonaki, E.; Leligou, H.C.; Tseles, D.; Ganetsos, T.; Drosos, C. Integrating IoT into Agricultural Operations towards the Industry 4.0 and Sustainability. JAPMED 2023, 12, 88–89. [Google Scholar]

- Mastrantonas, A.; Kokkas, P.; Chatzopoulos, A.; Papoutsidakis, M.; Stergiou, C.; Vairis, A.; Kanetaki, Z. Identifying the Effects of Industry 4.0 in the Pharmaceutical Sector: Achieving the Sustainable Development Goals. Discov. Sustain. 2024, 5, 460. [Google Scholar] [CrossRef]

- Szechyńska-Hebda, M.; Hebda, M.; Doğan-Sağlamtimur, N.; Lin, W.-T. Let’s Print an Ecology in 3D (and 4D). Materials 2024, 17, 2194. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 4D Printing: Technology Overview and Smart Materials Utilized. J. Mechatron. Robot. 2023, 7, 1–14. [Google Scholar] [CrossRef]

- Kantaros, A. Intellectual Property Challenges in the Age of 3D Printing: Navigating the Digital Copycat Dilemma. Appl. Sci. 2024, 14, 11448. [Google Scholar] [CrossRef]

- Ganetsos, T.; Kantaros, A.; Gioldasis, N.; Brachos, K. Applications of 3D Printing and Illustration in Industry. In Proceedings of the 2023 17th International Conference on Engineering of Modern Electric Systems (EMES), Oradea, Romania, 9–10 June 2023; IEEE: New York, NY, USA, 2023; pp. 1–4. [Google Scholar]

- Mantalas, E.-M.; Sagias, V.D.; Zacharia, P.; Stergiou, C.I. Neuro-Fuzzy Model Evaluation for Enhanced Prediction of Me-chanical Properties in AM Specimens. Appl. Sci. 2024, 15, 7. [Google Scholar] [CrossRef]

- Sagias, V.D.; Zacharia, P.; Tempeloudis, A.; Stergiou, C. Adaptive Neuro-Fuzzy Inference System-Based Predictive Mod-eling of Mechanical Properties in Additive Manufacturing. Machines 2024, 12, 523. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Macko, M.; Szczepański, Z.; Dostatni, E. Optimization of Extrusion-Based 3D Printing Process Using Neural Networks for Sustainable Development. Materials 2021, 14, 2737. [Google Scholar] [CrossRef]

- Maraveas, C.; Kyrtopoulos, I.V.; Arvanitis, K.G. Evaluation of the Viability of 3D Printing in Recycling Polymers. Polymers 2024, 16, 1104. [Google Scholar] [CrossRef] [PubMed]

- Kantaros, A.; Ganetsos, T. From Static to Dynamic: Smart Materials Pioneering Additive Manufacturing in Regenerative Medicine. Int. J. Mol. Sci. 2023, 24, 15748. [Google Scholar] [CrossRef]

- Huo, S.; Sheng, L.; Su, B.; Xue, W.; Wang, L.; Xu, H.; He, X. 3D Printing Manufacturing of Lithium Batteries: Prospects and Challenges toward Practical Applications. Adv. Mater. 2024, 36, 2310396. [Google Scholar] [CrossRef]

- Yang, J.; Li, B.; Liu, J.; Tu, Z.; Wu, X. Application of Additive Manufacturing in the Automobile Industry: A Mini Review. Processes 2024, 12, 1101. [Google Scholar] [CrossRef]

- Di Somma, M.; Dolatabadi, M.; Burgio, A.; Siano, P.; Cimmino, D.; Bianco, N. Optimizing Virtual Energy Sharing in Re-newable Energy Communities of Residential Users for Incentives Maximization. Sustain. Energy Grids Netw. 2024, 39, 101492. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D Printing: Making an Innovative Technology Widely Accessible through Makerspaces and Outsourced Services. Mater. Today 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Karimi, A.; Rahmatabadi, D.; Baghani, M. Various FDM Mechanisms Used in the Fabrication of Continuous-Fiber Rein-forced Composites: A Review. Polymers 2024, 16, 831. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah; Arifin, Z. A Review on the Fused Deposition Modeling (FDM) 3D Printing: Filament Processing, Materials, and Printing Parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. FBG Based in Situ Characterization of Residual Strains in FDM Process. In Conference Proceedings of the Society for Experimental Mechanics Series; Springer International Publishing: Cham, Switzerland, 2014; pp. 333–337. ISBN 9783319008752. [Google Scholar]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Mod-elling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Gueche, Y.A.; Sanchez-Ballester, N.M.; Cailleaux, S.; Bataille, B.; Soulairol, I. Selective Laser Sintering (SLS), a New Chapter in the Production of Solid Oral Forms (SOFs) by 3D Printing. Pharmaceutics 2021, 13, 1212. [Google Scholar] [CrossRef]

- Hozdić, E. Characterization and Comparative Analysis of Mechanical Parameters of FDM- and SLA-Printed ABS Materials. Appl. Sci. 2024, 14, 649. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process Phenomena and Material Properties in Selective Laser Sintering of Polymers: A Review. Materials 2021, 15, 183. [Google Scholar] [CrossRef] [PubMed]

- Piscopo, G.; Atzeni, E.; Saboori, A.; Salmi, A. An Overview of the Process Mechanisms in the Laser Powder Directed Energy Deposition. Appl. Sci. 2022, 13, 117. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Ayoub, M.; Aljaghoub, H.; Alasad, S.; Abdelkareem, M.A. 3D Concrete Printing: Recent Progress, Applications, Challenges, and Role in Achieving Sustainable Development Goals. Buildings 2023, 13, 924. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.-H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Micro-structural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef] [PubMed]

- Rudziewicz, M.; Maroszek, M.; Góra, M.; Dziura, P.; Mróz, K.; Hager, I.; Hebda, M. Feasibility Review of Aerated Materials Application in 3D Concrete Printing. Materials 2023, 16, 6032. [Google Scholar] [CrossRef]

- Guamán-Rivera, R.; Martínez-Rocamora, A.; García-Alvarado, R.; Muñoz-Sanguinetti, C.; González-Böhme, L.F.; Auat-Cheein, F. Recent Developments and Challenges of 3D-Printed Construction: A Review of Research Fronts. Buildings 2022, 12, 229. [Google Scholar] [CrossRef]

- World’s First 3D-Printed Bridge. Available online: https://www.witteveenbos.com/projects/worlds-first-3d-printed-bridge (accessed on 11 February 2025).

- The Story Behind the World’s Longest 3D Printed Bridge-Sci-Tech News-EnglishChannel. Available online: https://www.stdaily.com/web/English/2021-08/05/content_1858900.html (accessed on 11 February 2025).

- Asensio, J.; Josa, I.; Monserrat, A.; de la Fuente, A. 3D-printed Concrete Footbridges: An Approach to Assess the Sustain-ability Performance. Struct. Concr. 2023, 24, 7705–7725. [Google Scholar] [CrossRef]

- Žujović, M.; Obradović, R.; Rakonjac, I.; Milošević, J. 3D Printing Technologies in Architectural Design and Construction: A Systematic Literature Review. Buildings 2022, 12, 1319. [Google Scholar] [CrossRef]

- Bici, A.; Yunitsyna, A. Analysis of 3D Printing Techniques for Building Construction: A Review. Constr. Robot. 2023, 7, 107–123. [Google Scholar] [CrossRef]

- Jung, C.; Al Qassimi, N.; Sherzad, M. The Comparative Analysis of 3D Printing Technology Development for Building Construction. Int. J. Adv. Res. Technol. Innov. 2023, 4, 56–67. [Google Scholar] [CrossRef]

- Blue Cycle. Available online: https://bluecycle.com/en/ (accessed on 11 February 2025).

- Ramírez-Moreno, M.A.; Keshtkar, S.; Padilla-Reyes, D.A.; Ramos-López, E.; García-Martínez, M.; Hernández-Luna, M.C.; Mogro, A.E.; Mahlknecht, J.; Huertas, J.I.; Peimbert-García, R.E.; et al. Sensors for Sustainable Smart Cities: A Review. Appl. Sci. 2021, 11, 8198. [Google Scholar] [CrossRef]

- Al-Obaidi, K.M.; Hossain, M.; Alduais, N.A.M.; Al-Duais, H.S.; Omrany, H.; Ghaffarianhoseini, A. A Review of Using IoT for Energy Efficient Buildings and Cities: A Built Environment Perspective. Energies 2022, 15, 5991. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, X.; Guo, X.; Kong, B.; Zhang, M.; Qian, X.; Mi, S.; Sun, W. The Boom in 3D-Printed Sensor Technology. Sensors 2017, 17, 1166. [Google Scholar] [CrossRef]

- Ni, Y.; Ji, R.; Long, K.; Bu, T.; Chen, K.; Zhuang, S. A Review of 3D-Printed Sensors. Appl. Spectrosc. Rev. 2017, 52, 623–652. [Google Scholar] [CrossRef]

- Jiang, Y.; Islam, M.N.; He, R.; Huang, X.; Cao, P.-F.; Advincula, R.C.; Dahotre, N.; Dong, P.; Wu, H.F.; Choi, W. Recent Advances in 3D Printed Sensors: Materials, Design, and Manufacturing. Adv. Mater. Technol. 2023, 8, 2200492. [Google Scholar] [CrossRef]

- Hassan, M.S.; Zaman, S.; Dantzler, J.Z.R.; Leyva, D.H.; Mahmud, M.S.; Ramirez, J.M.; Gomez, S.G.; Lin, Y. 3D Printed In-tegrated Sensors: From Fabrication to Applications—A Review. Nanomaterials 2023, 13, 3148. [Google Scholar] [CrossRef]

- Maurizi, M.; Slavič, J.; Cianetti, F.; Jerman, M.; Valentinčič, J.; Lebar, A.; Boltežar, M. Dynamic Measurements Using FDM 3D-Printed Embedded Strain Sensors. Sensors 2019, 19, 2661. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Kundu, S.; Nag, A.; Xu, Y. 3D Printed Sensors for Biomedical Applications: A Review. Sensors 2019, 19, 1706. [Google Scholar] [CrossRef]

- Cândido, T.C.d.O.; da Silva, D.N.; Borges, M.M.C.; Barbosa, T.G.; Trindade, S.O.D.d.; Pereira, A.C. 3D-Printed Electro-chemical Sensors: A Comprehensive Review of Clinical Analysis Applications. Analytica 2024, 5, 552–575. [Google Scholar] [CrossRef]

- Nicolay, P.; Schlögl, S.; Thaler, S.M.; Humbert, C.; Filipitsch, B. Smart Materials for Green(Er) Cities, a Short Review. Appl. Sci. 2023, 13, 9289. [Google Scholar] [CrossRef]

- Zhao, J.; Zhou, B.; Butler, J.P.; Bock, R.G.; Portelli, J.P.; Bilén, S.G. IoT-Based Sanitizer Station Network: A Facilities Man-agement Case Study on Monitoring Hand Sanitizer Dispenser Usage. Smart Cities 2021, 4, 979–994. [Google Scholar] [CrossRef]

- Salamone, F.; Belussi, L.; Danza, L.; Ghellere, M.; Meroni, I. Design and Development of nEMoS, an All-in-One, Low-Cost, Web-Connected and 3D-Printed Device for Environmental Analysis. Sensors 2015, 15, 13012–13027. [Google Scholar] [CrossRef]

- Ferreira, J.; Costa, D. Enhancing Cycling Safety in Smart Cities: A Data-Driven Embedded Risk Alert System. Smart Cities 2024, 7, 1992–2014. [Google Scholar] [CrossRef]

- Cui, Y.; Jung, E.M.; Adeyeye, A.; Lynch, C.; He, X.; Tentzeris, M. Additively Manufactured RF Devices for 5G, IoT, RFID, WSN, and Smart City Applications. Int. J. High Speed Electron. Syst. 2020, 29, 2040016. [Google Scholar] [CrossRef]

- Wong, Y.J.; Nakayama, R.; Shimizu, Y.; Kamiya, A.; Shen, S.; Muhammad Rashid, I.Z.; Nik Sulaiman, N.M. Toward In-dustrial Revolution 4.0: Development, Validation, and Application of 3D-Printed IoT-Based Water Quality Monitoring System. J. Clean. Prod. 2021, 324, 129230. [Google Scholar] [CrossRef]

- Rojas, D.; Torricelli, D.; Cuartero, M.; Crespo, G.A. 3D-Printed Transducers for Solid Contact Potentiometric Ion Sensors: Improving Reproducibility by Fabrication Automation. Anal. Chem. 2024, 96, 15572–15580. [Google Scholar] [CrossRef] [PubMed]

- Rayhana, R.; Xiao, G.G.; Liu, Z. Printed Sensor Technologies for Monitoring Applications in Smart Farming: A Review. IEEE Trans. Instrum. Meas. 2021, 70, 9513419. [Google Scholar] [CrossRef]

- Padhiary, M.; Barbhuiya, J.A.; Roy, D.; Roy, P. 3D Printing Applications in Smart Farming and Food Processing. Smart Agric. Technol. 2024, 9, 100553. [Google Scholar] [CrossRef]

- Syrový, T.; Vik, R.; Pretl, S.; Syrová, L.; Čengery, J.; Hamáček, A.; Kubáč, L.; Menšík, L. Fully Printed Disposable IoT Soil Moisture Sensors for Precision Agriculture. Chemosensors 2020, 8, 125. [Google Scholar] [CrossRef]

- Stark, B.; Stevenson, B.; Stow-Parker, K.; Chen, Y. Embedded Sensors for the Health Monitoring of 3D Printed Unmanned Aerial Systems. In Proceedings of the 2014 International Conference on Unmanned Aircraft Systems (ICUAS), Orlando, FL, USA, 27–30 May 2014; IEEE: New York, NY, USA, 2014; pp. 175–180. [Google Scholar]

- Bird, D.T.; Ravindra, N.M. Additive Manufacturing of Sensors for Military Monitoring Applications. Polymers 2021, 13, 1455. [Google Scholar] [CrossRef]

- Maurya, D.; Khaleghian, S.; Sriramdas, R.; Kumar, P.; Kishore, R.A.; Kang, M.G.; Kumar, V.; Song, H.-C.; Lee, S.-Y.; Yan, Y.; et al. 3D Printed Graphene-Based Self-Powered Strain Sensors for Smart Tires in Autonomous Vehicles. Nat. Commun. 2020, 11, 5392. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. 3D-Printed Sensors: Current Progress and Future Challenges. Sens. Actuators A Phys. 2020, 305, 111916. [Google Scholar] [CrossRef]

- Dijkshoorn, A.; Werkman, P.; Welleweerd, M.; Wolterink, G.; Eijking, B.; Delamare, J.; Sanders, R.; Krijnen, G.J.M. Em-bedded Sensing: Integrating Sensors in 3-D Printed Structures. J. Sens. Sens. Syst. 2018, 7, 169–181. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, X.; Meves, J.; Billings, C.; Liu, Y. 3D Printed and Embedded Strain Sensors in Structural Composites for Loading Monitoring and Damage Diagnostics. J. Compos. Sci. 2023, 7, 437. [Google Scholar] [CrossRef]

- Iso/Astm 52900:2021. Available online: https://www.iso.org/standard/74514.html (accessed on 20 February 2025).

- Pradela Filho, L.A.; Araújo, D.A.G.; Ataide, V.N.; Meloni, G.N.; Paixão, T.R.L.C. Challenges Faced with 3D-Printed Elec-trochemical Sensors in Analytical Applications. Anal. Bioanal. Chem. 2024, 416, 4679–4690. [Google Scholar] [CrossRef] [PubMed]

- Yaakoubi, I.; Mejri, A.; Elfil, H.; Mars, A. Current Progress in 3D-Printed Sensors: Design, Application, and Future Chal-lenges. In Handbook of Nanosensors; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 1–32. ISBN 9783031163388. [Google Scholar]

- Parupelli, S.K.; Desai, S. The 3D Printing of Nanocomposites for Wearable Biosensors: Recent Advances, Challenges, and Prospects. Bioengineering 2023, 11, 32. [Google Scholar] [CrossRef]

- File:3D Printed Concrete Bicycle Bridge in Gemert (NL).Jpg. Available online: https://commons.wikimedia.org/wiki/File:3D_printed_concrete_bicycle_bridge_in_Gemert_%28NL%29.jpg (accessed on 20 February 2025).

- Category:Tecla House. Available online: https://commons.wikimedia.org/wiki/Category:Tecla_house#/media/File:Eco-sustainable_3D_printed_house_%22Tecla%22.jpg/2 (accessed on 20 February 2025).

- ICON Vulcan II 3D Concrete Printer. Available online: https://www.m3design.com/case-study/3d-concrete-printer-design/ (accessed on 20 February 2025).

- Pessoa, S.; Guimarães, A.S.; Lucas, S.S.; Simões, N. 3D Printing in the Construction Industry—A Systematic Review of the Thermal Performance in Buildings. Renew. Sustain. Energy Rev. 2021, 141, 110794. [Google Scholar] [CrossRef]

- Freire, T.; Brun, F.; Mateus, A.; Gaspar, F. 3D Printing Technology in the Construction Industry. In Advances in Science, Technology & Innovation; Springer International Publishing: Cham, Switzerland, 2021; pp. 157–167. ISBN 9783030355326. [Google Scholar]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Man-agement in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- Available online: https://www.reuters.com/technology/chile-team-builds-regions-first-3d-printed-seed-home-2024-10-22/ (accessed on 20 February 2025).

- House of DUS 3D Print Canal House. Available online: https://houseofdus.com/project/3d-print-canal-house/ (accessed on 20 February 2025).

- van Baarsen, S.B.; Schönwälder, J.; Houtman, R.; van der Veen, A.C.; Vermeulen, H.; Haan, S.d. The 3D Printed Canal House. Proc. IASS Annu. Symp. 2015, 2015, 1–7. [Google Scholar]

- Available online: https://3dprintcanalhouse.com/presskit/0f6604e09cb825c58826f5245fa19da7.pdf (accessed on 20 February 2025).

- Konior, J.; Rejment, M. Correlation between Defects and Technical Wear of Materials Used in Traditional Construction. Materials 2021, 14, 2482. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E. Shape Memory Alloys for Aerospace, Recent Developments, and New Applications: A Short Re-view. Materials 2020, 13, 1856. [Google Scholar] [CrossRef]

- Huang, Y.; Kormakov, S.; He, X.; Gao, X.; Zheng, X.; Liu, Y.; Sun, J.; Wu, D. Conductive Polymer Composites from Re-newable Resources: An Overview of Preparation, Properties, and Applications. Polymers 2019, 11, 187. [Google Scholar] [CrossRef]

- Amran, M.; Onaizi, A.M.; Fediuk, R.; Vatin, N.I.; Muhammad Rashid, R.S.; Abdelgader, H.; Ozbakkaloglu, T. Self-Healing Concrete as a Prospective Construction Material: A Review. Materials 2022, 15, 3214. [Google Scholar] [CrossRef]

- Alzard, M.H.; El-Hassan, H.; El-Maaddawy, T.; Alsalami, M.; Abdulrahman, F.; Hassan, A.A. A Bibliometric Analysis of the Studies on Self-Healing Concrete Published between 1974 and 2021. Sustainability 2022, 14, 11646. [Google Scholar] [CrossRef]

- Hermawan, H.; Minne, P.; Serna, P.; Gruyaert, E. Understanding the Impacts of Healing Agents on the Properties of Fresh and Hardened Self-Healing Concrete: A Review. Processes 2021, 9, 2206. [Google Scholar] [CrossRef]

- Panza Uguzzoni, A.M.; Fregonara, E.; Ferrando, D.G.; Anglani, G.; Antonaci, P.; Tulliani, J.-M. Concrete Self-Healing for Sustainable Buildings: A Focus on the Economic Evaluation from a Life-Cycle Perspective. Sustainability 2023, 15, 13637. [Google Scholar] [CrossRef]

- Han, H.R. Hybrid Fiber Materials According to the Manufacturing Technology Methods and IOT Materials: A Systematic Review. Materials 2023, 16, 1351. [Google Scholar] [CrossRef]

- Kubášová, K.; Drátovská, V.; Losertová, M.; Salvetr, P.; Kopelent, M.; Kořínek, F.; Havlas, V.; Džugan, J.; Daniel, M. A Review on Additive Manufacturing Methods for NiTi Shape Memory Alloy Production. Materials 2024, 17, 1248. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Cerrato, M.; Fraile, I.; Gómez-Cortés, J.F.; Urionabarrenetxea, E.; Ruiz-Larrea, I.; González, I.; Nó, M.L.; Burgos, N.; San Juan, J.M. Designing for Shape Memory in Additive Manufacturing of Cu–Al–Ni Shape Memory Alloy Processed by Laser Powder Bed Fusion. Materials 2022, 15, 6284. [Google Scholar] [CrossRef]

- Cersoli, T.; Cresanto, A.; Herberger, C.; MacDonald, E.; Cortes, P. 3D Printed Shape Memory Polymers Produced via Direct Pellet Extrusion. Micromachines 2021, 12, 87. [Google Scholar] [CrossRef]

- Singh, R.; Gehlot, A.; Akram, S.V.; Gupta, L.R.; Jena, M.K.; Prakash, C.; Singh, S.; Kumar, R. Cloud Manufacturing, Internet of Things-Assisted Manufacturing and 3D Printing Technology: Reliable Tools for Sustainable Construction. Sustainability 2021, 13, 7327. [Google Scholar] [CrossRef]

- Kantaros, A.; Laskaris, N.; Piromalis, D.; Ganetsos, T. Manufacturing Zero-Waste COVID-19 Personal Protection Equip-ment: A Case Study of Utilizing 3D Printing While Employing Waste Material Recycling. Circ. Econ. Sustain. 2021, 1, 851–869. [Google Scholar] [CrossRef]

- Ben-Ner, A.; Siemsen, E. Decentralization and Localization of Production: The Organizational and Economic Consequences of Additive Manufacturing (3D Printing). Calif. Manage. Rev. 2017, 59, 5–23. [Google Scholar] [CrossRef]

- Yu, H.; Hong, H.; Cao, S.; Ahmad, R. Topology Optimization for Multipatch Fused Deposition Modeling 3D Printing. Appl. Sci. 2020, 10, 943. [Google Scholar] [CrossRef]

- Malbašić, S.; Đorđević, A.; Živković, S.; Džunić, D.; Sokolović, V. Topology Optimization, Part Orientation, and Symmetry Operations as Elements of a Framework for Design and Production Planning Process in Additive Manufacturing L-PBF Technology. Symmetry 2024, 16, 1616. [Google Scholar] [CrossRef]

- Abdalla, H.; Fattah, K.P.; Abdallah, M.; Tamimi, A.K. Environmental Footprint and Economics of a Full-Scale 3D-Printed House. Sustainability 2021, 13, 11978. [Google Scholar] [CrossRef]

- Nguyen, N.D.; Ashraf, I.; Kim, W. Compact Model for 3D Printer Energy Estimation and Practical Energy-Saving Strategy. Electronics 2021, 10, 483. [Google Scholar] [CrossRef]

- El youbi El idrissi, M.A.; Laaouina, L.; Jeghal, A.; Tairi, H.; Zaki, M. Energy Consumption Prediction for Fused Deposition Modelling 3D Printing Using Machine Learning. Appl. Syst. Innov. 2022, 5, 86. [Google Scholar] [CrossRef]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef]

- Salandin, A.; Quintana-Gallardo, A.; Gómez-Lozano, V.; Guillén-Guillamón, I. The First 3D-Printed Building in Spain: A Study on Its Acoustic, Thermal and Environmental Performance. Sustainability 2022, 14, 13204. [Google Scholar] [CrossRef]

- Rigatos, G.; Abbaszadeh, M.; Hamida, M.; Siano, P. Intelligent Control for Electric Power Systems and Electric Vehicles; CRC Press: Boca Raton, FL, USA, 2024; ISBN 9781040134672. [Google Scholar]

- Banks, J. Adding Value in Additive Manufacturing: Researchers in the United Kingdom and Europe Look to 3D Printing for Customization. IEEE Pulse 2013, 4, 22–26. [Google Scholar] [CrossRef]

- Živković, M.; Žujović, M.; Milošević, J. Architectural 3D-Printed Structures Created Using Artificial Intelligence: A Review of Techniques and Applications. Appl. Sci. 2023, 13, 10671. [Google Scholar] [CrossRef]

- Charaan, R.M.D.; Mallad, A.; Maram, B.; Mamodiya, U.; Nidhya, M.S. 3D Modelling and Printing in Smart Transportation System. In Lecture Notes in Intelligent Transportation and Infrastructure; Springer Nature Switzerland: Cham, Switzerland, 2025; pp. 411–422. ISBN 9783031726163. [Google Scholar]

- Boon, W.; van Wee, B. Influence of 3D Printing on Transport: A Theory and Experts Judgment Based Conceptual Model. Transp. Rev. 2018, 38, 556–575. [Google Scholar] [CrossRef]

- Bazli, M.; Ashrafi, H.; Rajabipour, A.; Kutay, C. 3D Printing for Remote Housing: Benefits and Challenges. Autom. Constr. 2023, 148, 104772. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- García-Alvarado, R.; Moroni-Orellana, G.; Banda, P. Development of Variable Residential Buildings with 3D-Printed Walls. Buildings 2022, 12, 1796. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Pomares, J. Impact of 3D Printing on the Overall Project Success of Residential Construction Projects Using Structural Equation Modelling. Int. J. Environ. Res. Public Health 2023, 20, 3800. [Google Scholar] [CrossRef] [PubMed]

- García-Alvarado, R.; Moroni-Orellana, G.; Banda-Pérez, P. Architectural Evaluation of 3D-Printed Buildings. Buildings 2021, 11, 254. [Google Scholar] [CrossRef]

- de Souza, E.A.; Borges, P.H.R.; Stengel, T.; Nematollahi, B.; Bos, F.P. 3D Printed Sustainable Low-Cost Materials for Con-struction of Affordable Social Housing in Brazil: Potential, Challenges, and Research Needs. J. Build. Eng. 2024, 87, 108985. [Google Scholar] [CrossRef]

- Barbosa, L.L. Chaos and Innovation in Design for Disaster Resilience. In Springer Series in Design and Innovation; Springer International Publishing: Cham, Switzerland, 2021; pp. 507–518. ISBN 9783030556990. [Google Scholar]

- Xu, W.; Huang, S.; Han, D.; Zhang, Z.; Gao, Y.; Feng, P.; Zhang, D. Toward Automated Construction: The Design-to-Printing Workflow for a Robotic in-Situ 3D Printed House. Case Stud. Constr. Mater. 2022, 17, e01442. [Google Scholar] [CrossRef]

- Smith, D. Printed Buildings: An International Race for the Ultimate in Automation. Constr. Res. Innov. 2012, 3, 26–31. [Google Scholar] [CrossRef]

- Mahadevan, M.; Francis, A.; Thomas, A. A Simulation-Based Investigation of Sustainability Aspects of 3D Printed Structures. J. Build. Eng. 2020, 32, 101735. [Google Scholar] [CrossRef]

- Wilson, T.T.; Mativenga, P.T.; Marnewick, A.L. Sustainability of 3D Printing in Infrastructure Development. Procedia CIRP 2023, 120, 195–200. [Google Scholar] [CrossRef]

- Lacava, H.; Cherrington, N.; Corrado, A.; Bigdellou, S.; Chen, Q. A Preliminary Study of 3D Printing Home Designs for Improving Efficiency and Sustainability of Indigenous Housing in Canada. Sustainability 2024, 16, 5781. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building Envelope Prefabricated with 3D Printing Technology. Sustainability 2021, 13, 8923. [Google Scholar] [CrossRef]

- Al Masri, A.; Haddad, A.N.; Najjar, M.K. Comparative Analysis of Energy Efficiency in Conventional, Modular, and 3D-Printing Construction Using Building Information Modeling and Multi-Criteria Decision-Making. Computation 2024, 12, 247. [Google Scholar] [CrossRef]

- Moghayedi, A.; Mahachi, J.; Lediga, R.; Mosiea, T.; Phalafala, E. Revolutionizing Affordable Housing in Africa: A Com-prehensive Technical and Sustainability Study of 3D-Printing Technology. Sustain. Cities Soc. 2024, 105, 105329. [Google Scholar] [CrossRef]

- Ahmed, G.H. A Review of “3D Concrete Printing”: Materials and Process Characterization, Economic Considerations and Environmental Sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Wong, L.S. Durability Performance of Geopolymer Concrete: A Review. Polymers 2022, 14, 868. [Google Scholar] [CrossRef]

- Muñoz-Bonilla, A.; Echeverria, C.; Sonseca, Á.; Arrieta, M.P.; Fernández-García, M. Bio-Based Polymers with Antimicrobial Properties towards Sustainable Development. Materials 2019, 12, 641. [Google Scholar] [CrossRef]

- Chin, W.; Lee, Y.; Amran, M.; Fediuk, R.; Vatin, N.; Kueh, A.; Lee, Y. A Sustainable Reuse of Agro-Industrial Wastes into Green Cement Bricks. Materials 2022, 15, 1713. [Google Scholar] [CrossRef]

- Keskin, T.; Yilmaz, E.; Kasap, T.; Sari, M.; Cao, S. Toward Viable Industrial Solid Residual Waste Recycling: A Review of Its Innovative Applications and Future Perspectives. Minerals 2024, 14, 943. [Google Scholar] [CrossRef]

- Ihl, C.; Piller, F. 3D Printing as Driver of Localized Manufacturing: Expected Benefits from Producer and Consumer Per-spectives. In Progress in IS; Springer International Publishing: Cham, Switzerland, 2016; pp. 179–204. ISBN 9783319316840. [Google Scholar]

- Rayna, T.; Striukova, L. Assessing the Effect of 3D Printing Technologies on Entrepreneurship: An Exploratory Study. Technol. Forecast. Soc. Change 2021, 164, 120483. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A Critical Review of 3D Printing in Construction: Benefits, Challenges, and Risks. Arch. Civ. Mech. Eng. 2020, 20. [Google Scholar] [CrossRef]

- Griño, A.A., Jr.; Daly, M.K.M.; Ongpeng, J.M.C. Bio-Influenced Self-Healing Mechanism in Concrete and Its Testing: A Review. Appl. Sci. 2020, 10, 5161. [Google Scholar] [CrossRef]

- Huang, F.; Zhou, S. A Review of Lightweight Self-Healing Concrete. Materials 2022, 15, 7572. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Shilov, A.A.; Chernil’nik, A.; El’shaeva, D.; Chistyakov, V.A. Analysis of the Current State of Research on Bio-Healing Concrete (Bioconcrete). Materials 2024, 17, 4508. [Google Scholar] [CrossRef] [PubMed]

- Albuhairi, D.; Di Sarno, L. Low-Carbon Self-Healing Concrete: State-of-the-Art, Challenges and Opportunities. Buildings 2022, 12, 1196. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, Y.; Li, Y. Resilience and Life-Cycle Performance of Smart Bridges with Shape Memory Alloy (SMA)-Cable-Based Bearings. Constr. Build. Mater. 2018, 158, 389–400. [Google Scholar] [CrossRef]

- Qiang, X.; Wu, Y.; Wang, Y.; Jiang, X. Research Progress and Applications of Fe-Mn-Si-Based Shape Memory Alloys on Reinforcing Steel and Concrete Bridges. Appl. Sci. 2023, 13, 3404. [Google Scholar] [CrossRef]

- Qiang, X.; Chen, L.; Jiang, X. Achievements and Perspectives on Fe-Based Shape Memory Alloys for Rehabilitation of Reinforced Concrete Bridges: An Overview. Materials 2022, 15, 8089. [Google Scholar] [CrossRef]

- Tamošaitienė, J.; Parham, S.; Sarvari, H.; Chan, D.W.M.; Edwards, D.J. A Review of the Application of Synthetic and Natural Polymers as Construction and Building Materials for Achieving Sustainable Construction. Buildings 2024, 14, 2569. [Google Scholar] [CrossRef]

- Li, M.; Zhong, J.; Li, G.; Zhang, Q.; Cen, F.; Gao, P. Study on the Performance of Polymer-Modified Conductive Ce-ment-Based Materials. Buildings 2023, 13, 2961. [Google Scholar] [CrossRef]

- Pang, H.; Xu, L.; Yan, D.-X.; Li, Z.-M. Conductive Polymer Composites with Segregated Structures. Prog. Polym. Sci. 2014, 39, 1908–1933. [Google Scholar] [CrossRef]

- Hu, X.; Guo, C.; Huang, Y.; Xu, Z.; Shi, Z.; Zhou, F.; Li, G.; Zhou, Y.; Li, Y.; Li, Z.; et al. Liquid-Induced Healing of Cracks in Nickel-Based Superalloy Fabricated by Laser Powder Bed Fusion. Acta Mater. 2024, 267, 119731. [Google Scholar] [CrossRef]

- Griffiths, S.; Ghasemi Tabasi, H.; Ivas, T.; Maeder, X.; De Luca, A.; Zweiacker, K.; Wróbel, R.; Jhabvala, J.; Logé, R.E.; Leinenbach, C. Combining Alloy and Process Modification for Micro-Crack Mitigation in an Additively Manufactured Ni-Base Superalloy. Addit. Manuf. 2020, 36, 101443. [Google Scholar] [CrossRef]

- Nodehi, M.; Aguayo, F.; Nodehi, S.E.; Gholampour, A.; Ozbakkaloglu, T.; Gencel, O. Durability Properties of 3D Printed Concrete (3DPC). Autom. Constr. 2022, 142, 104479. [Google Scholar] [CrossRef]

- Gebhard, L.; Mata-Falcón, J.; Anton, A.; Dillenburger, B.; Kaufmann, W. Structural Behaviour of 3D Printed Concrete Beams with Various Reinforcement Strategies. Eng. Struct. 2021, 240, 112380. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. Mechanical Characterization of 3D Printable Concrete. Constr. Build. Mater. 2019, 227, 116710. [Google Scholar] [CrossRef]

- Sapata, A.; Šinka, M.; Šahmenko, G.; Korat Bensa, L.; Hanžič, L.; Šter, K.; Ručevskis, S.; Bajāre, D.; Bos, F.P. Establishing Benchmark Properties for 3D-Printed Concrete: A Study of Printability, Strength, and Durability. J. Compos. Sci. 2025, 9, 74. [Google Scholar] [CrossRef]

- Meurer, M.; Classen, M. Mechanical Properties of Hardened 3D Printed Concretes and Mortars—Development of a Con-sistent Experimental Characterization Strategy. Materials 2021, 14, 752. [Google Scholar] [CrossRef]

- Chua, C.K.; Wong, C.H.; Yeong, W.Y. Standards, Quality Control, and Measurement Sciences in 3D Printing and Additive Manufacturing; Academic Press: San Diego, CA, USA, 2017; ISBN 9780128134900. [Google Scholar]

- Phillips, C.; Kortschot, M.; Azhari, F. Towards Standardizing the Preparation of Test Specimens Made with Material Ex-trusion: Review of Current Techniques for Tensile Testing. Addit. Manuf. 2022, 58, 103050. [Google Scholar] [CrossRef]

- Wu, P.; Zhao, X.; Baller, J.H.; Wang, X. Developing a Conceptual Framework to Improve the Implementation of 3D Printing Technology in the Construction Industry. Archit. Sci. Rev. 2018, 61, 133–142. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D Printing Trends in Building and Con-struction Industry: A Review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Perkins, I.; Skitmore, M. Three-Dimensional Printing in the Construction Industry: A Review. Int. J. Constr. Manag. 2015, 15, 1–9. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D Printing of Buildings and Building Components as the Future of Sustainable Construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef]

- Kidwell, J. Best Practices and Applications of 3D Printing in the Construction Industry. 2017. Available online: https://digitalcommons.calpoly.edu/cmsp/79 (accessed on 12 February 2025).

- Nazir, A.; Gokcekaya, O.; Md Masum Billah, K.; Ertugrul, O.; Jiang, J.; Sun, J.; Hussain, S. Multi-Material Additive Manu-facturing: A Systematic Review of Design, Properties, Applications, Challenges, and 3D Printing of Materials and Cellular Metamaterials. Mater. Des. 2023, 226, 111661. [Google Scholar] [CrossRef]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on Ad-ditive Manufacturing of Multi-Material Parts: Progress and Challenges. J. Manuf. Mater. Process. 2021, 6, 4. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-material 3D and 4D Printing: A Survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Goh, G.L.; Zhang, H.; Chong, T.H.; Yeong, W.Y. 3D Printing of Multilayered and Multimaterial Electronics: A Review. Adv. Electron. Mater. 2021, 7, 2100445. [Google Scholar] [CrossRef]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef]

- Stender, B.; Mantei, W.; Houbertz, R. From Lab to Fab—High-Precision 3D Printing: Towards High Throughputs and Industrial Scalability. Laser Tech. J. 2017, 14, 20–23. [Google Scholar] [CrossRef][Green Version]

- Rastegarpanah, M.; Asif, M.E.; Butt, J.; Voos, H.; Rastegarpanah, A. Mobile Robotics and 3D Printing: Addressing Challenges in Path Planning and Scalability. Virtual Phys. Prototyp. 2024, 19, e2433588. [Google Scholar] [CrossRef]

- Lopes, L.R.; Silva, A.F.; Carneiro, O.S. Multi-Material 3D Printing: The Relevance of Materials Affinity on the Boundary Interface Performance. Addit. Manuf. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Shaukat, U.; Rossegger, E.; Schlögl, S. A Review of Multi-Material 3D Printing of Functional Materials via Vat Photo-polymerization. Polymers 2022, 14, 2449. [Google Scholar] [CrossRef] [PubMed]

- Verma, A.; Kapil, A.; Klobčar, D.; Sharma, A. A Review on Multiplicity in Multi-Material Additive Manufacturing: Process, Capability, Scale, and Structure. Materials 2023, 16, 5246. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Zhang, W.; Baca Lopez, D.M.; Ahmad, R. Scientometric Analysis and Systematic Review of Multi-Material Ad-ditive Manufacturing of Polymers. Polymers 2021, 13, 1957. [Google Scholar] [CrossRef]

- Ferro, P.; Fabrizi, A.; Elsayed, H.; Savio, G. Multi-Material Additive Manufacturing: Creating IN718-AISI 316L Bimetallic Parts by 3D Printing, Debinding, and Sintering. Sustainability 2023, 15, 11911. [Google Scholar] [CrossRef]

- Hager, I.; Maroszek, M.; Mróz, K.; Kęsek, R.; Hebda, M.; Dvorkin, L.; Marchuk, V. Interlayer Bond Strength Testing in 3D-Printed Mineral Materials for Construction Applications. Materials 2022, 15, 4112. [Google Scholar] [CrossRef] [PubMed]

- Kaščak, J.; Kočiško, M.; Vodilka, A.; Török, J.; Coranič, T. Adhesion Testing Device for 3D Printed Objects on Diverse Printing Bed Materials: Design and Evaluation. Appl. Sci. 2024, 14, 945. [Google Scholar] [CrossRef]

- Ritzen, L.; Montano, V.; Garcia, S.J. 3D Printing of a Self-Healing Thermoplastic Polyurethane through FDM: From Polymer Slab to Mechanical Assessment. Polymers 2021, 13, 305. [Google Scholar] [CrossRef]

- Choi, S.-J.; Kim, J.-H.; Jeong, H.; Lee, J.-S.; Lim, T.-U.; Ko, H.M.; Kim, S.H.; Jung, W. Simulated and Experimental Investi-gation of the Mechanical Properties and Solubility of 3D-Printed Capsules for Self-Healing Cement Composites. Materials 2021, 14, 4578. [Google Scholar] [CrossRef]

- Sitthi-Amorn, P.; Ramos, J.E.; Wangy, Y.; Kwan, J.; Lan, J.; Wang, W.; Matusik, W. MultiFab: A Machine Vision Assisted Platform for Multi-Material 3D Printing. ACM Trans. Graph. 2015, 34, 1–11. [Google Scholar] [CrossRef]

- Emon, M.O.F.; Alkadi, F.; Philip, D.G.; Kim, D.-H.; Lee, K.-C.; Choi, J.-W. Multi-Material 3D Printing of a Soft Pressure Sensor. Addit. Manuf. 2019, 28, 629–638. [Google Scholar] [CrossRef]

- An, J.; Leong, K.F. Multi-Material and Multi-Dimensional 3D Printing for Biomedical Materials and Devices. Biomed. Mater. Devices 2023, 1, 38–48. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, X.; Chen, S. Multi-Material 3D Printing and Computational Design in Pharmaceutical Tablet Manufacturing. J. Comput. Sci. Artif. Intell. 2024, 1, 34–38. [Google Scholar] [CrossRef]

- Ali, M.H.; Mir-Nasiri, N.; Ko, W.L. Multi-Nozzle Extrusion System for 3D Printer and Its Control Mechanism. Int. J. Adv. Manuf. Technol. 2016, 86, 999–1010. [Google Scholar] [CrossRef]

- Tiryaki, M.E.; Zhang, X.; Pham, Q.-C. Printing-While-Moving: A New Paradigm for Large-Scale Robotic 3D Printing. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; IEEE: New York, NY, USA, 2019; pp. 2286–2291. [Google Scholar] [CrossRef]

- ACI CODE-318-19(22): Building Code Requirements for Structural Concrete and Commentary (Reapproved 2022). Available online: https://www.concrete.org/store/productdetail.aspx?ItemID=318U19&Language=English&Units=US_Units (accessed on 20 March 2025).

- ACI CODE-562-21: Assessment, Repair, and Rehabilitation of Existing Concrete Structures—Code and Commentary. Available online: https://www.concrete.org/store/productdetail.aspx?ItemID=562U21&Language=English&Units=US_Units (accessed on 20 March 2025).

- Iso/Astm Dis 52929. Available online: https://www.iso.org/standard/84733.html (accessed on 20 March 2025).

- Capêto, A.P.; Jesus, M.; Uribe, B.E.B.; Guimarães, A.S.; Oliveira, A.L.S. Building a Greener Future: Advancing Concrete Production Sustainability and the Thermal Properties of 3D-Printed Mortars. Buildings 2024, 14, 1323. [Google Scholar] [CrossRef]

- Bolina, F.L.; Fachinelli, E.G.; Pachla, E.C.; Centeno, F.R. A Critical Analysis of the Influence of Architecture on the Tem-perature Field of RC Structures Subjected to Fire Using CFD and FEA Models. Appl. Therm. Eng. 2024, 247, 123086. [Google Scholar] [CrossRef]

- Shi, J.; Ju, K.; Chen, H.; Mirabolghasemi, A.; Akhtar, S.; Sasmito, A.; Akbarzadeh, A. 3D printed architected shell-based ferroelectric metamaterials with programmable piezoelectric and pyroelectric properties. Nano Energy 2024, 123, 109385. [Google Scholar] [CrossRef]

- Prasittisopin, L. How 3D Printing Technology Makes Cities Smarter: A Review, Thematic Analysis, and Perspectives. Smart Cities 2024, 7, 3458–3488. [Google Scholar] [CrossRef]

- Rojek, I.; Marciniak, T.; Mikołajewski, D. Digital Twins in 3D Printing Processes Using Artificial Intelligence. Electronics 2024, 13, 3550. [Google Scholar] [CrossRef]

- Mohammed, N.S.; Fadiel, A.A.M.; Rahman, A.B.A.; Ali, E.A.B.; Abu-Lebdeh, T.; Kantaros, A.; Petrescu, F.I.T. Spirally Confined Reinforcing Bar for Flexural Behavior of Glass Fiber-Reinforced Concrete Beam. J. Compos. Sci. 2025, 9, 149. [Google Scholar] [CrossRef]

- Tuloup, C.; Harizi, W.; Aboura, Z.; Meyer, Y. Integration of piezoelectric transducers (PZT and PVDF) within poly-mer-matrix composites for structural health monitoring applications: New success and challenges. Int. J. Smart Nano Mater. 2020, 11, 343–369. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Bassey, D.E.; Olukanni, D.O.; Ngene, B.U.; Adegoke, D.; Odetoyan, A.O.; Kareem, M.A.; Enabulele, D.O. Waste materials in highway applications: An overview on generation and utilization implications on sustainability. J. Clean. Prod. 2021, 283, 124581. [Google Scholar] [CrossRef]

- Dixon, T.; Eames, M. Sustainable urban development to 2050: Complex transitions in the built environment of cities. In Urban Retrofitting for Sustainability; Routledge: London, UK, 2014; pp. 19–47. [Google Scholar]

- Sun, J.; Xiao, J.; Li, Z.; Feng, X. Experimental study on the thermal performance of a 3D printed concrete prototype building. Energy Build. 2021, 241, 110965. [Google Scholar] [CrossRef]

- Sachs, J.D.; Lafortune, G.; Fuller, G.; Drumm, E. Sustainable Development Report 2023: Implementing the SDG Stimulus; Dublin University Press: Dublin, Ireland, 2023. [Google Scholar] [CrossRef]

- Patti, A. Process–Property Correlation in Sustainable Printing Extrusion of Bio-Based Filaments. J. Compos. Sci. 2024, 8, 305. [Google Scholar] [CrossRef]

- Faleschini, F.; Trento, D.; Masoomi, M.; Pellegrino, C.; Zanini, M.A. Sustainable mixes for 3D printing of earth-based constructions. Constr. Build. Mater. 2023, 398, 132496. [Google Scholar] [CrossRef]

- Mu, H.; He, F.; Yuan, L.; Hatamian, H.; Commins, P.; Pan, Z. Online distortion simulation using generative machine learning models: A step toward digital twin of metallic additive manufacturing. J. Ind. Inf. Integr. 2024, 38, 100563. [Google Scholar] [CrossRef]

- Pecunia, V.; Occhipinti, L.G.; Hoye, R.L. Emerging indoor photovoltaic technologies for sustainable internet of things. Adv. Energy Mater. 2021, 11, 2100698. [Google Scholar] [CrossRef]

- Chen, G.; Wang, K.; Yang, J.; Huang, J. Printable thermochromic hydrogel-based smart window for all-weather building temperature regulation in diverse climates. Adv. Mater. 2023, 35, 2211716. [Google Scholar] [CrossRef]

- Kim, T.-H.; Moeinnia, H.; Kim, W.S. 3D printed vorticella-kirigami inspired sensors for structural health monitoring in internet-of-things. Mater. Des. 2023, 234, 112332. [Google Scholar] [CrossRef]

- Sadeghi, A.; Del Dottore, E.; Mondini, A. Passive morphological adaptation for obstacle avoidance in a self-growing robot produced by additive manufacturing. Soft Robot. 2020, 7, 85–94. [Google Scholar] [CrossRef]

- Treutler, K.; Wesling, V. The current state of research of wire arc additive manufacturing (WAAM): A review. Appl. Sci. 2021, 11, 8619. [Google Scholar] [CrossRef]

| Benefit | Description |

|---|---|

| Customization and Design Optimization | Enables precise customization of components for specific applications, such as aerodynamic bridges, acoustically optimized structures, and bio-inspired facades. Facilitates generative design and AI-driven optimization for lightweight yet strong structures. |

| Speed and Efficiency | Significantly reduces construction time by using automated layer-by-layer fabrication. Capable of rapidly deploying essential infrastructure, such as housing for disaster relief, within hours. Eliminates the need for formworks, scaffolds, and extensive manual labor. |

| Cost Reduction * | Minimizes material waste by using only the required amount of resources, reducing raw material costs by 30–60%. Lowers labor expenses due to automation and reduces transportation costs by enabling on-site manufacturing. |

| Sustainability and Environmental Impact | Uses sustainable and recycled materials (e.g., geopolymer concrete, bio-based polymers, and repurposed industrial waste). Reduces energy consumption by eliminating excessive transportation and energy-intensive manufacturing steps. Lowers carbon emissions by streamlining construction processes. |

| Enhanced Durability and Longevity | Incorporates self-healing materials, such as microcapsule-filled concrete that repairs cracks, extending infrastructure lifespan. Utilizes adaptive materials like shape-memory alloys and conductive polymers to enhance resilience against environmental stressors. Enables real-time structural monitoring for predictive maintenance, reducing long-term repair costs. |

| Challenge | Description |

|---|---|

| Material Limitations | Three-dimensional-printed materials, such as concrete and polymer composites, require further optimization to match the strength, durability, and environmental resistance of traditional materials like steel and reinforced concrete. Exposure to UV light, temperature fluctuations, and chemical degradation affects long-term performance. |

| Regulatory and Standardization Issues | The absence of universally accepted standards and regulatory frameworks creates uncertainty regarding the safety, reliability, and sustainability of 3D-printed infrastructure. The lack of certification processes for new materials and techniques hinders large-scale implementation, especially in publicly funded projects. |

| Integration with Existing Systems | Compatibility issues arise when integrating 3D-printed components with legacy infrastructure, such as utility grids, transportation networks, and drainage systems. Material mismatches, structural behavior disparities, and different construction tolerances limit seamless incorporation into traditional urban planning. |

| Technical Barriers in Multi-Material Printing | Current 3D printing technologies struggle to integrate multiple materials in a single process, limiting the fabrication of multifunctional infrastructure elements, such as self-sensing bridges, energy-harvesting pavements, and bio-inspired facades with dynamic thermal properties. |

| Scalability Constraints | The majority of existing 3D printing equipment lacks the capability to efficiently produce large-scale structures. Gantry-based and robotic arm systems still face speed, cost, and raw material limitations compared to traditional large-scale construction methods. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Zacharia, P.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. Smart Infrastructure and Additive Manufacturing: Synergies, Advantages, and Limitations. Appl. Sci. 2025, 15, 3719. https://doi.org/10.3390/app15073719

Kantaros A, Zacharia P, Drosos C, Papoutsidakis M, Pallis E, Ganetsos T. Smart Infrastructure and Additive Manufacturing: Synergies, Advantages, and Limitations. Applied Sciences. 2025; 15(7):3719. https://doi.org/10.3390/app15073719

Chicago/Turabian StyleKantaros, Antreas, Paraskevi Zacharia, Christos Drosos, Michail Papoutsidakis, Evangelos Pallis, and Theodore Ganetsos. 2025. "Smart Infrastructure and Additive Manufacturing: Synergies, Advantages, and Limitations" Applied Sciences 15, no. 7: 3719. https://doi.org/10.3390/app15073719

APA StyleKantaros, A., Zacharia, P., Drosos, C., Papoutsidakis, M., Pallis, E., & Ganetsos, T. (2025). Smart Infrastructure and Additive Manufacturing: Synergies, Advantages, and Limitations. Applied Sciences, 15(7), 3719. https://doi.org/10.3390/app15073719