High-Performance NiO/PANI/ZnNb2O6 Composites for EMI Shielding: Structural Insights and Microwave Shielding Effectiveness in the Sub-8 GHz Range

Abstract

1. Introduction

2. Experimental

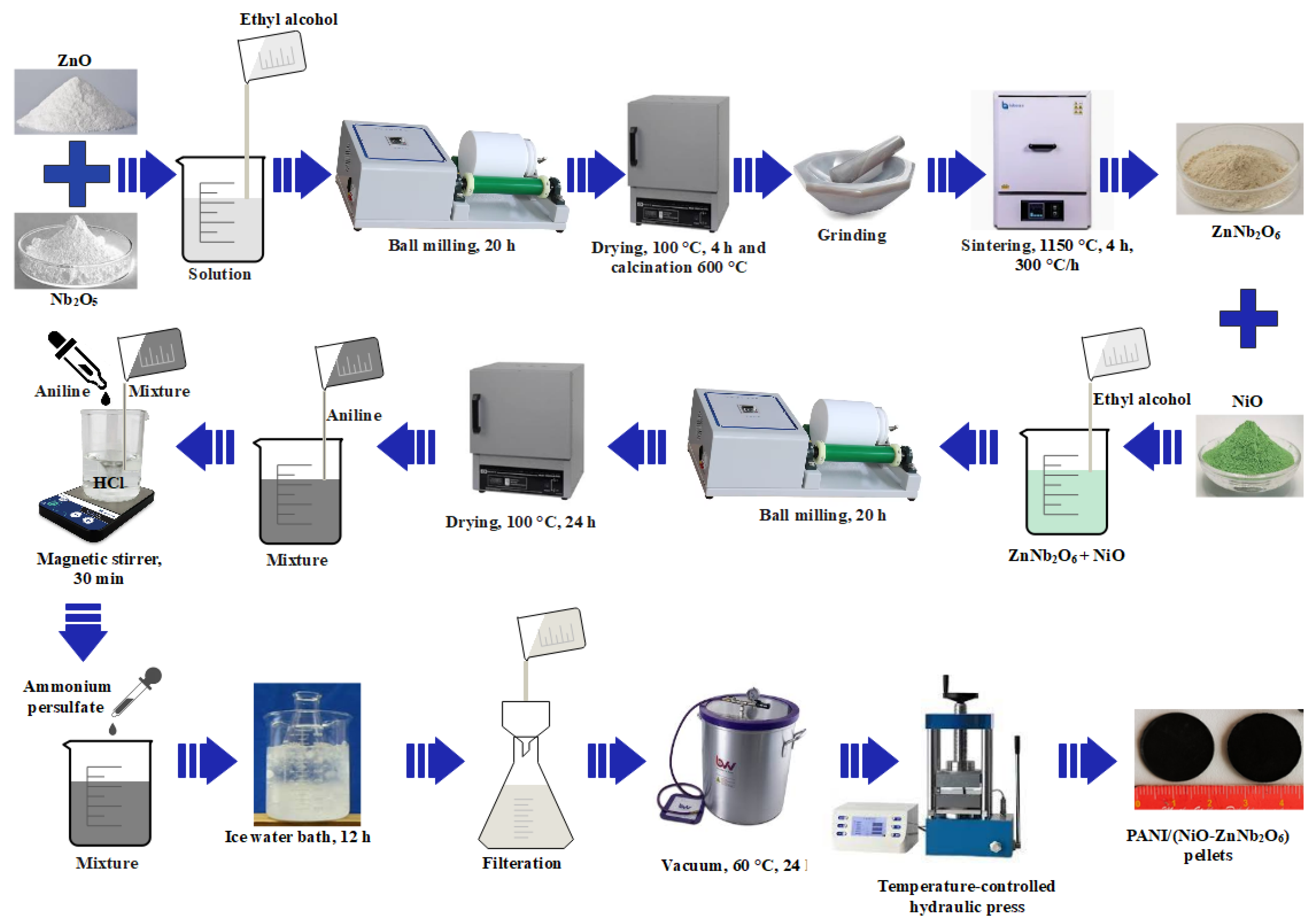

2.1. Preparation of NiO/ZnNb2O6

2.2. Production of Polyaniline/(NiO-ZnNb2O6) Composites

2.3. Preparation of Epoxy-(PANI Based NiO-ZnNb2O6) Composites

3. Results and Discussion

3.1. XRD Investigations of NiO-ZnNb2O6

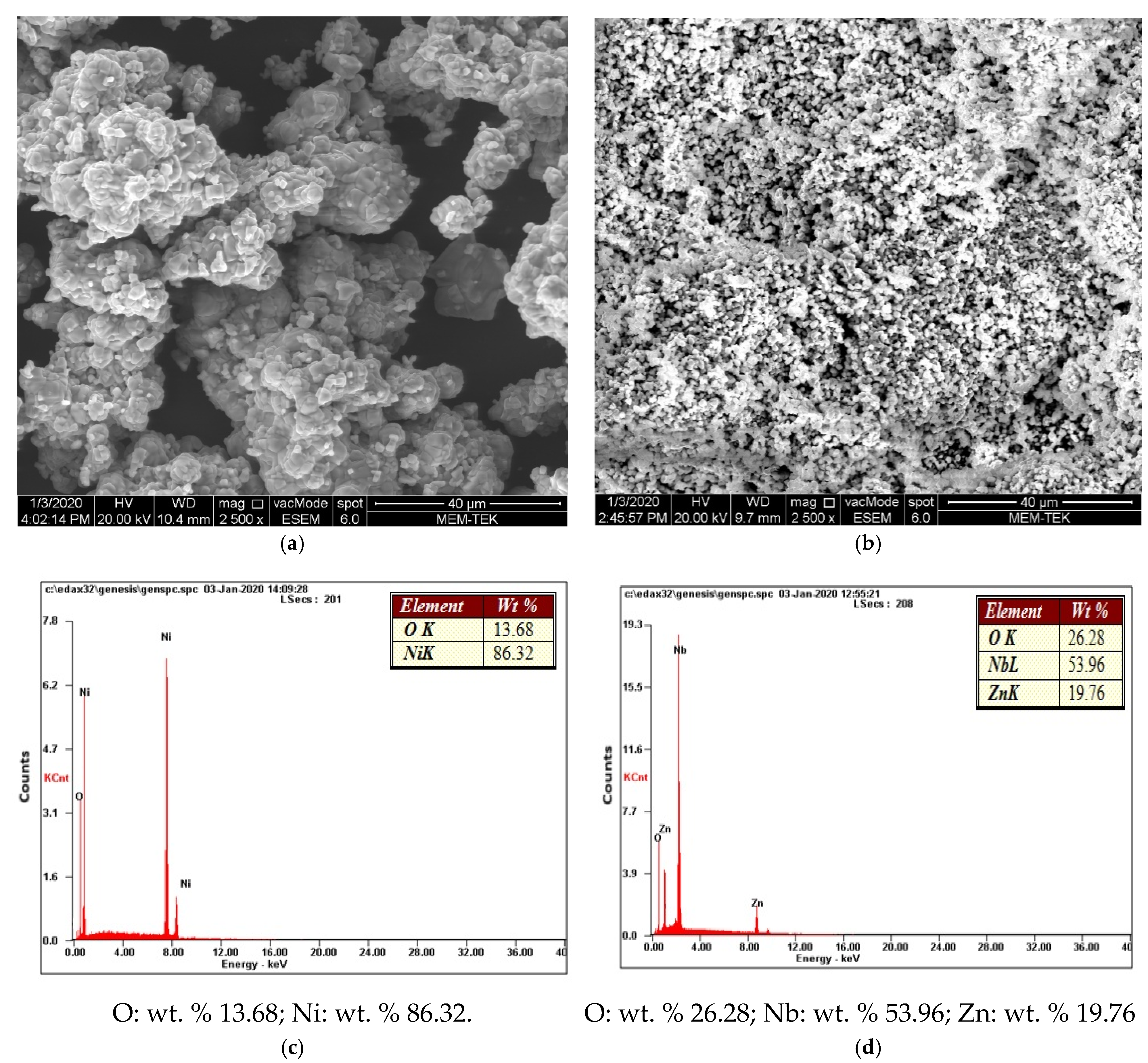

3.2. SEM Analysis of NiO and ZnNb2O6

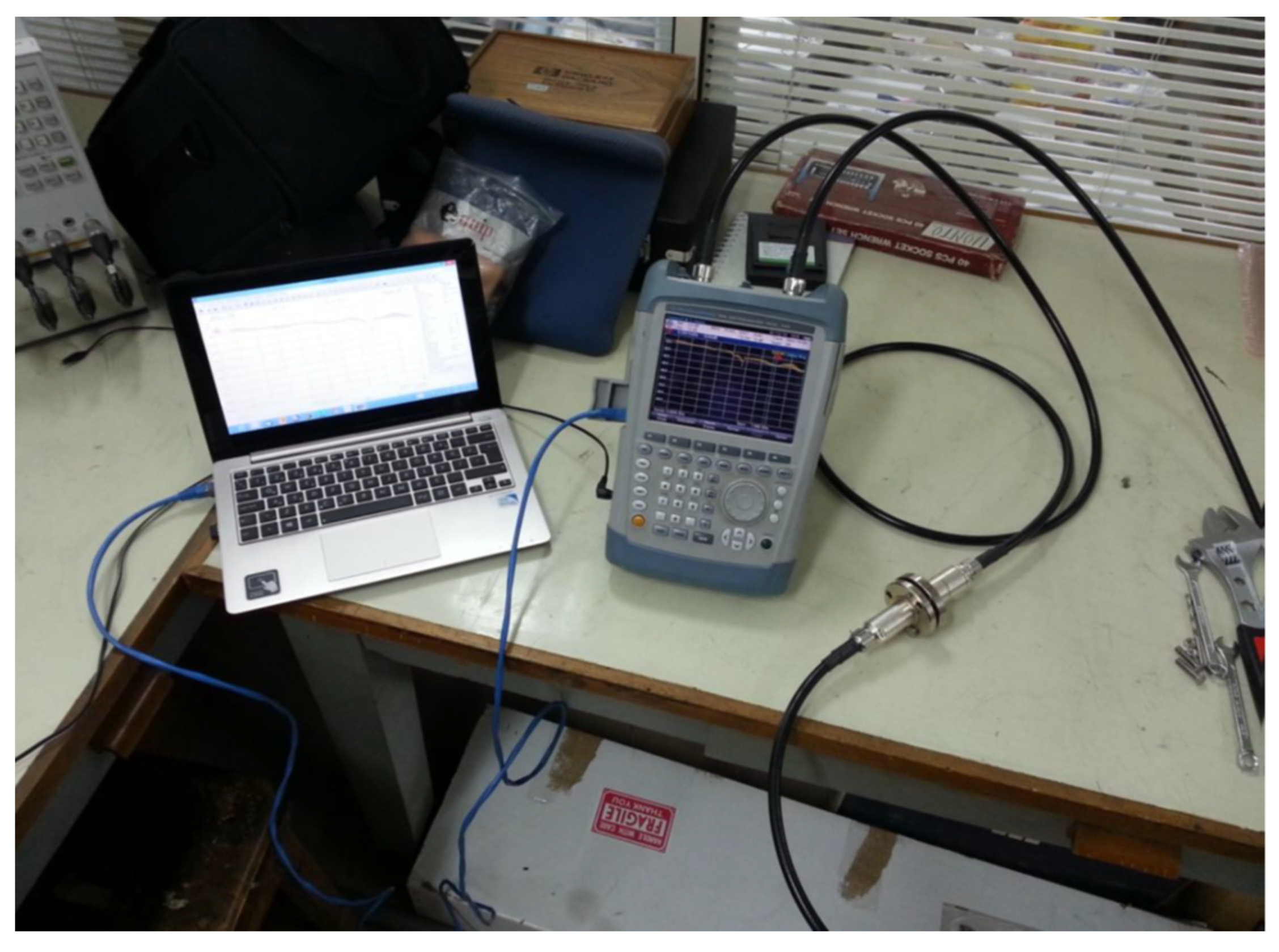

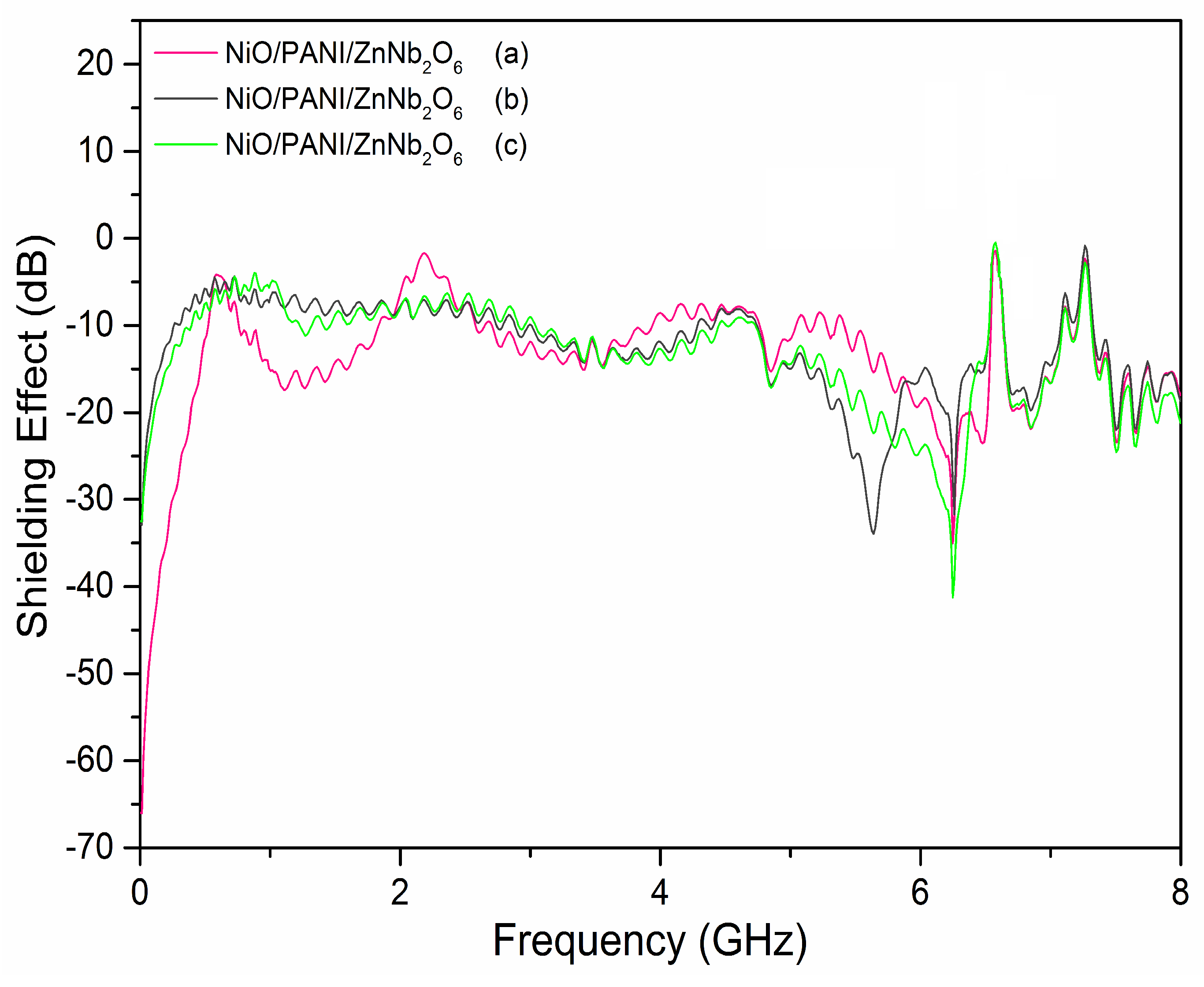

3.3. Measurements of NiO/PANI/ZnNb2O6 Composite’s EMI Shielding Effect

Microstructural Influence on Shielding Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Şahin, E.İ. Electromagnetic shielding effectiveness of Ba(Zn1/3Nb2/3)O3:Chopped strands composites for wide frequency applications. J. Ceram. Process. Res. 2023, 24, 190–196. [Google Scholar]

- Şahin, E.İ.; Emek, M.; Ibrahim, J.E.F.M. Instrumental Measurements Laboratory, 1st ed.; Iksad Publishing House: Ankara, Turkey, 2023. [Google Scholar]

- Kumar, S.; Ohlan, A.; Kumar, P.; Verma, V. Improved electromagnetic interference shielding response of polyaniline containing magnetic nano-ferrites. J. Supercond. Nov. Magn. 2019, 33, 1187–1198. [Google Scholar] [CrossRef]

- He, Y.; Wang, Y.; Ren, L.; He, Q.; Wu, D.; Deng, S.; Wu, G. Construction of heterointerfaces and honeycomb-like structure for ultrabroad microwave absorption. J. Colloid Interface Sci. 2022, 627, 102–112. [Google Scholar] [PubMed]

- Zaroushani, V.; Khavanin, A.; Mortazavi, S.; Jnonidi, A.; Moieni, M.; Javadzadeh, M. The role of a new electromagnetic shielding in reducing the microwave radiation for the X-band frequencies. Iran Occup. Health 2015, 12, 83–99. [Google Scholar]

- Ganguly, S.; Bhawal, P.; Ravindren, R.; Das, N.C. Polymer nanocomposite for electromagnetic interference shielding: A review. J. Nanosci. Nanotechnol. 2018, 18, 7641–7669. [Google Scholar] [CrossRef]

- Panagopoulos, D.J.; Margaritis, L.H. The effect of exposure duration on the biological activity of mobile telephony radiation. Mutat. Res. Genet. Toxicol. Environ. Mutagen. 2010, 699, 17–22. [Google Scholar] [CrossRef]

- Jie, H.; Zhao, Z.; Zeng, Y.; Chang, Y.; Fan, F.; Wang, C.; See, K.Y. A review of intentional electromagnetic interference in power electronics: Conducted and radiated susceptibility. IET Power Electron. 2024, 17, 1487–1506. [Google Scholar]

- Emek, M.; Şahin, E.İ.; Ibrahim, J.E.F. Production and Shielding Effectiveness Features of Chopped Strands Backed-GdMnO3 Composites for 6.5–17.5 GHz Applications. Materials 2025, 18, 863. [Google Scholar] [CrossRef]

- Liu, L.; Bian, X.-M.; Hou, Z.-L.; Wang, C.-Y.; Li, Z.S.; Hu, H.D.; Qi, X.; Zhang, X. Electromagnetic response of magnetic graphene hybrid fillers and their evolutionary behaviors. J. Mater. Sci. Mater. Electron. 2016, 27, 2760–2772. [Google Scholar] [CrossRef]

- Luo, X.; Chung DD, L. Electromagnetic interference shielding using continuous carbon-fiber carbon-matrix and polymer-matrix composites. Compos. Part B 1999, 30, 227–231. [Google Scholar] [CrossRef]

- Shukla, V. Role of spin disorder in magnetic and EMI shielding properties of Fe3O4/C/PPy core/shell composites. J. Mater. Sci. 2020, 55, 2826–2835. [Google Scholar]

- Şahin, E.İ. Katkılı NiFe2O4 Polimer Tabanlı Mikrodalga Yutucuların Frekans Seçici Malzeme Tasarımı. Ph.D. Thesis, İstanbul Teknik Üniversitesi, Bilişim Enstitüsü, Istanbul, Turkey, 2019. [Google Scholar]

- Schnitzler, D.C.; Meruvia, M.S.; Hümmelgen, I.; Aldo, J.; Zarbin, G. Preparation and characterization of novel hybrid materials formed from (Ti,Sn)O2. Nanopart. Polyaniline Chem. Mater. 2003, 15, 4658–4665. [Google Scholar]

- Şahin, E.İ. Microwave electromagnetic shielding effectiveness of ZnNb2O6-chopped strands composites for radar and wideband (6.5-18 GHz) applications. Lith. J. Phys. 2022, 62, 127–136. [Google Scholar]

- Kim, D.W.; Ko, K.H.; Hong, K.S. Influence of copper (II) oxide additions to zinc niobate microwave ceramics on sintering temperature and dielectric properties. J. Am. Ceram. Soc. 2001, 84, 1286–1290. [Google Scholar]

- Wee, S.H.; Kim, D.W.; Yoo, S.I. Microwave dielectric properties of low-fired ZnNb2O6 ceramics with BiVO4 addition. J. Am. Ceram. Soc. 2004, 87, 871–874. [Google Scholar]

- Giannakou, P.; Slade, R.C.T.; Shkunov, M. Cylic voltammetry studies of inkjet-printed NiO supercapacitors: Effect of substrates, printing and materials. Electrochim. Acta 2020, 353, 136539. [Google Scholar] [CrossRef]

- Srinivasan, V.; Weidner, J.W. An electrochemical route for making porous nickel oxide electrochemical capacitors. J. Electrochem. Soc. 1997, 144, L210–L213. [Google Scholar]

- Wilhelm, S.M. Photoelectrochemical characterization of the passive films on iron and nickel. J. Electrochem. Soc. 1981, 128, 1668–1674. [Google Scholar]

- Bonomo, M.; Naponiella, G.; Dini, D. Oxidative dissolution of NiO in aqueous electrolyte: An impedance study. J. Electroanal. Chem. 2018, 816, 205–214. [Google Scholar]

- Tariq, F.; Shifa, M.; Tariq, M.; Hasan, S.K.; Baloch, R.A. Hybrid Nanocomposite Material for EMI Shielding in Spacecrafts. Adv. Mater. Res. 2015, 1101, 46–50. [Google Scholar]

- Chung, D.D.L. Materials for Electromagnetic Interference Shielding. J. Mater. Eng. Perform. 2000, 9, 350–354. [Google Scholar]

- Ting, T.H.; Yu, R.P.; Jau, Y.N. Synthesis and Microwave Absorption Characteristics of Polyaniline/NiZn Ferrite Composites in 2–40 GHz. Mater. Chem. Phys. 2011, 126, 364–368. [Google Scholar]

- Şahin, E.İ. Production of Frequency Selective NiO/PANI/ZnNb2O-Composites for 0–8 GHz Applications; Pulatov, X., Tavaldıeva, G., Jalilov, S., Eds.; 2st-International Congress on Modern Sciences December 16–17, 2022 Proceedings Book; Iksad Publishing House: Tashkent, Uzbekistan, 2022; pp. 1218–1229. [Google Scholar]

- Tamil Selvan, S.; Mani, A.; Athinarayanasamy, K.; Phani, K.; Pitchumani, S. Synthesis of crystalline polyaniline. Mater. Res. Bull. 1995, 30, 699–705. [Google Scholar]

- Martin, K.; McCarthy, G. ICDD Grant-in-Aid. In Elements of Optical Mineralogy; Winchell, Ed.; North Dakota State University: Fargo, ND, USA, 1991; p. 58. [Google Scholar]

| Sample | a (Å) | b (Å) | c (Å) | Volume (Å3) | SYS |

|---|---|---|---|---|---|

| NiO | 4.177 | 4.177 | 4.177 | 72.88 | Cubic |

| ZnNb2O6 | 5.726 | 14.208 | 5.04 | 410.03 | Orthorhombic |

| PANI | 7.65 | 10.22 | 5.75 | 449.55 | Orthorhombic |

| Samples | Shielding Effectiveness Value | Frequency | Reference |

|---|---|---|---|

| NiFe1.7Cu0.3O3.85/Aniline: 1/3 | −29.74 dB | 6.82 GHz | [2] |

| % 25 MWCNT | −39 dB | 1.6 GHz | [22] |

| Chopped strands/Ba(Zn1/3Nb2/3)O3 (at 20–80 wt. %) | −24.96 dB | 6.22 GHz | [1] |

| Epoxy-(NiO/PANI/ZnNb2O6) | −41.16 dB | 6.24 GHz | This work |

| Sample | SE (dB) | Frequency (GHz) |

|---|---|---|

| NiO:ZnNb2O6 (wt. % 25–75)/Anilin: 1/1 | −35.3 | 6.24 |

| −20 | 6.11–6.32 | |

| −10 | 0–0.51, 0.78–1.81, 2.69–3.8, 5.56–6.51, 6.65–7.1, 7.34–8 | |

| NiO:ZnNb2O6 (wt. % 50–50)/Anilin: 1/1 | −33.94 | 5.64 |

| −20 | 5.43–5.79 | |

| −10 | 0–0.29, 4.74–6.52, 6.64–7.06, 7.34–8 | |

| NiO:ZnNb2O6 (wt. % 25–75)/Anilin: 1/1 | −41.16 | 6.24 |

| −20 | 5.71–6.34 | |

| −10 | 0–0.36, 3.16–4.43, 4.74–6.52, 7.31–8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emek, M.; Şahin, E.İ.; Ibrahim, J.-E.F.M. High-Performance NiO/PANI/ZnNb2O6 Composites for EMI Shielding: Structural Insights and Microwave Shielding Effectiveness in the Sub-8 GHz Range. Appl. Sci. 2025, 15, 3689. https://doi.org/10.3390/app15073689

Emek M, Şahin Eİ, Ibrahim J-EFM. High-Performance NiO/PANI/ZnNb2O6 Composites for EMI Shielding: Structural Insights and Microwave Shielding Effectiveness in the Sub-8 GHz Range. Applied Sciences. 2025; 15(7):3689. https://doi.org/10.3390/app15073689

Chicago/Turabian StyleEmek, Mehriban, Ethem İlhan Şahin, and Jamal-Eldin F. M. Ibrahim. 2025. "High-Performance NiO/PANI/ZnNb2O6 Composites for EMI Shielding: Structural Insights and Microwave Shielding Effectiveness in the Sub-8 GHz Range" Applied Sciences 15, no. 7: 3689. https://doi.org/10.3390/app15073689

APA StyleEmek, M., Şahin, E. İ., & Ibrahim, J.-E. F. M. (2025). High-Performance NiO/PANI/ZnNb2O6 Composites for EMI Shielding: Structural Insights and Microwave Shielding Effectiveness in the Sub-8 GHz Range. Applied Sciences, 15(7), 3689. https://doi.org/10.3390/app15073689