A Review and Future Directions on the Deterioration Evaluation of Concrete Utility Poles

Abstract

1. Introduction

2. Existing Standards of Japanese Concrete Utility Poles

3. The Current Status and Issues of Concrete Utility Pole

3.1. Deterioration Factors

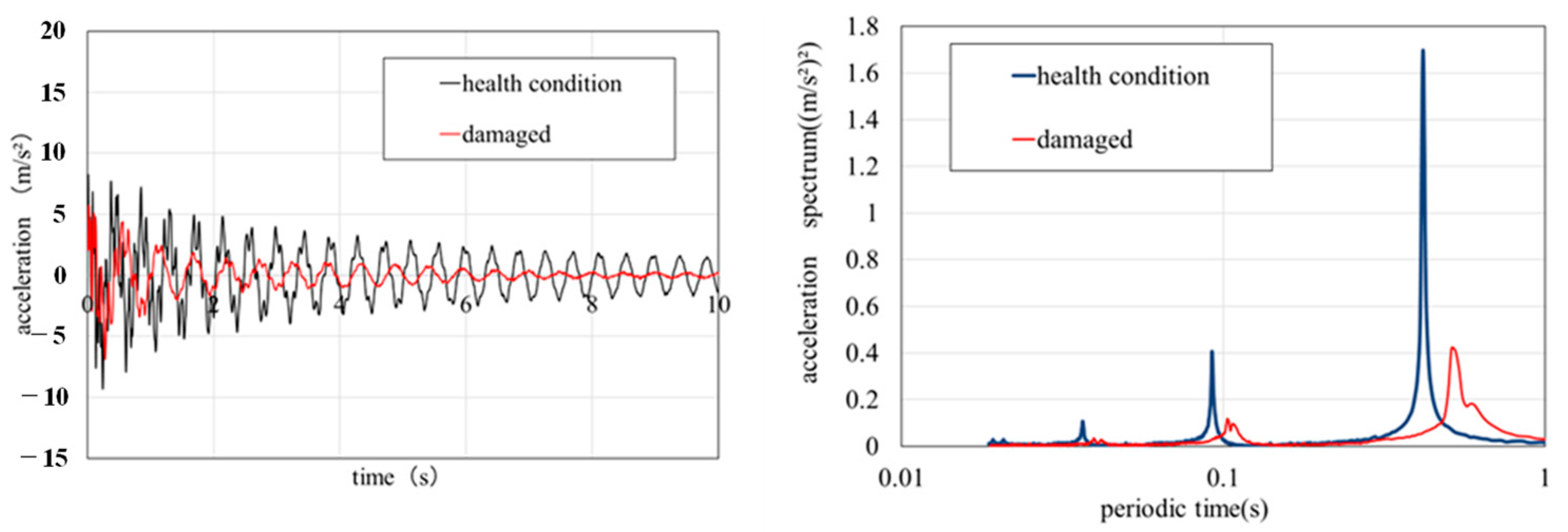

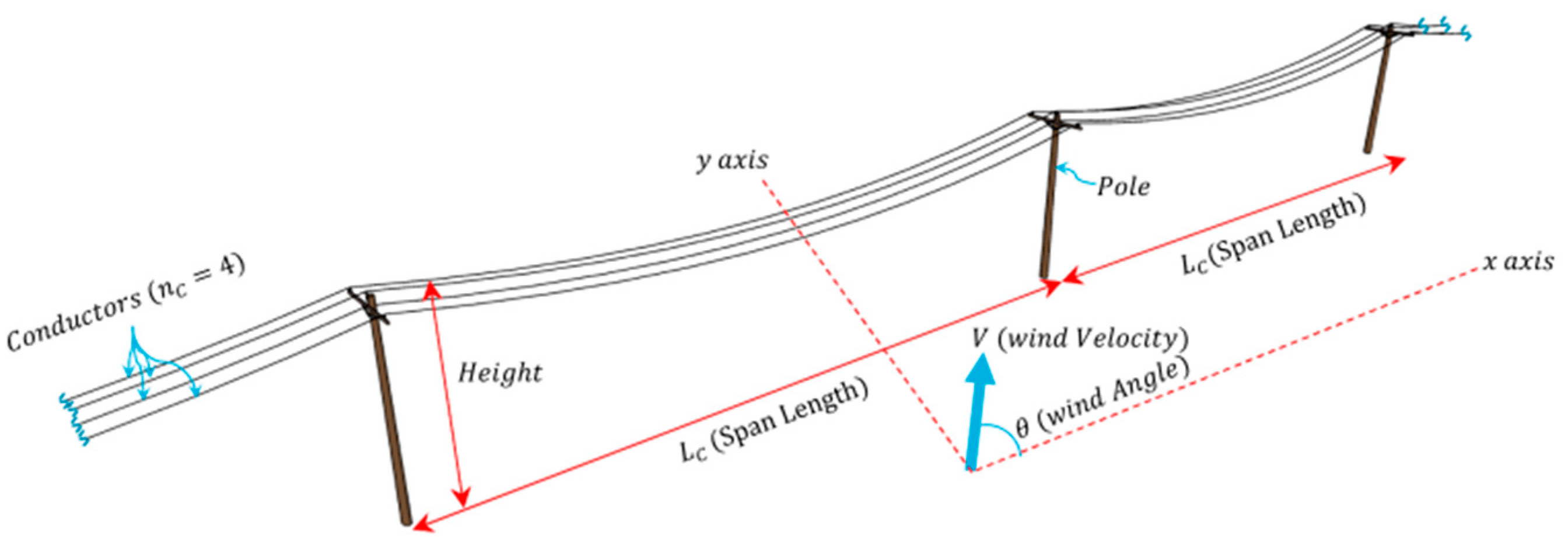

3.2. Dynamic Characteristics and Load-Bearing Behavior

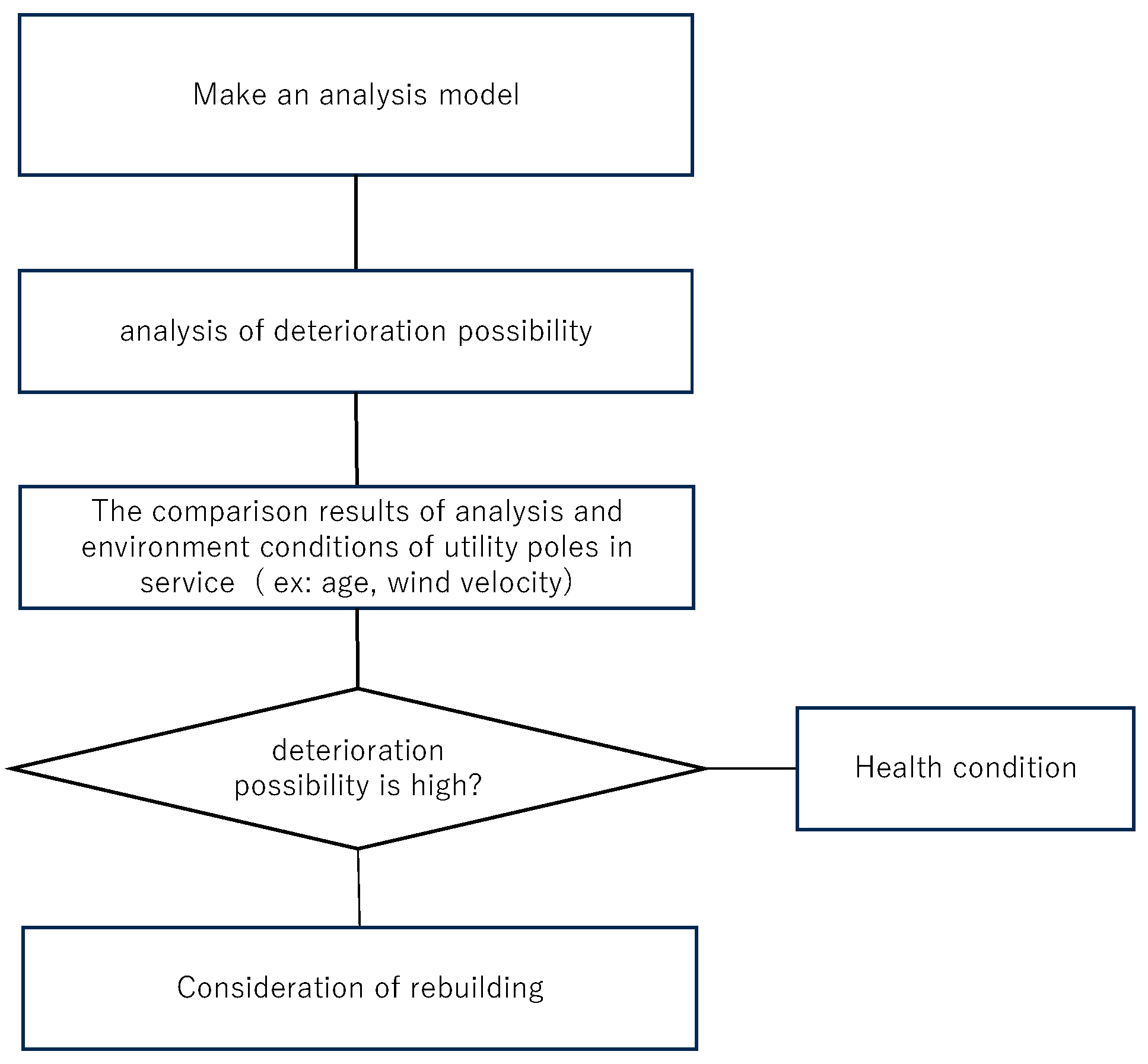

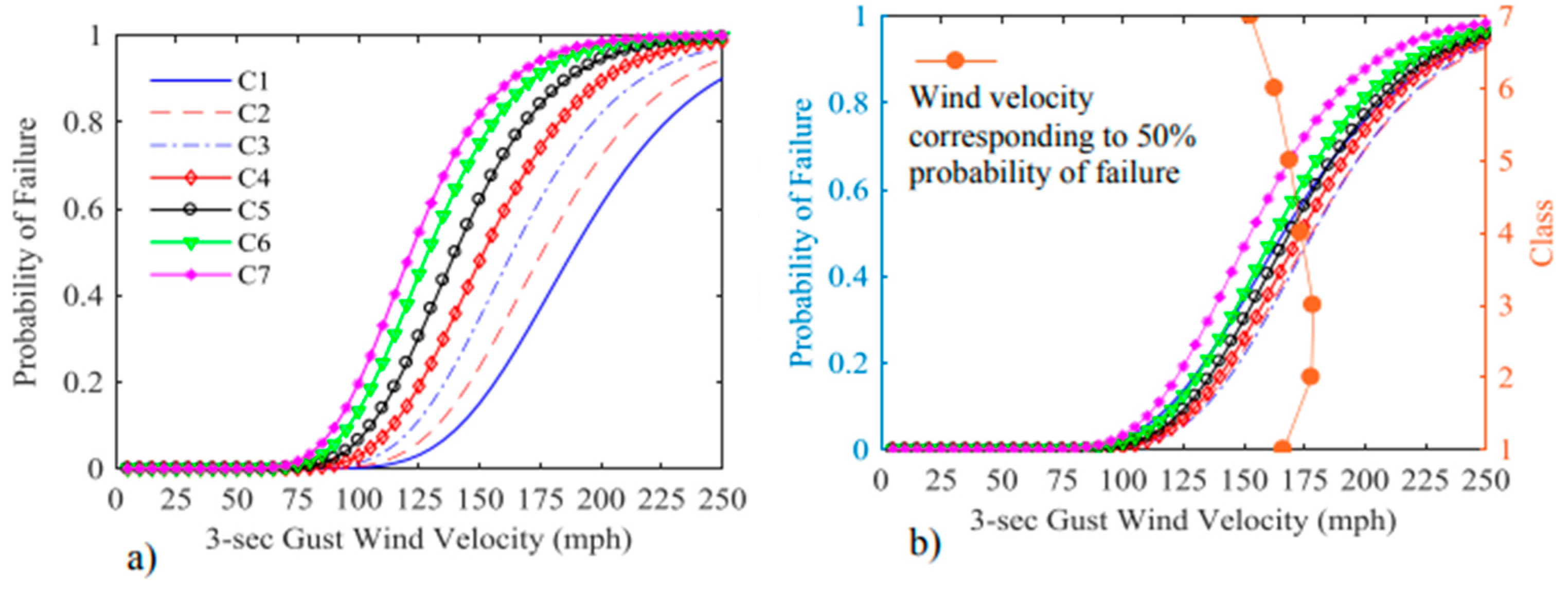

3.3. Deterioration Evaluation

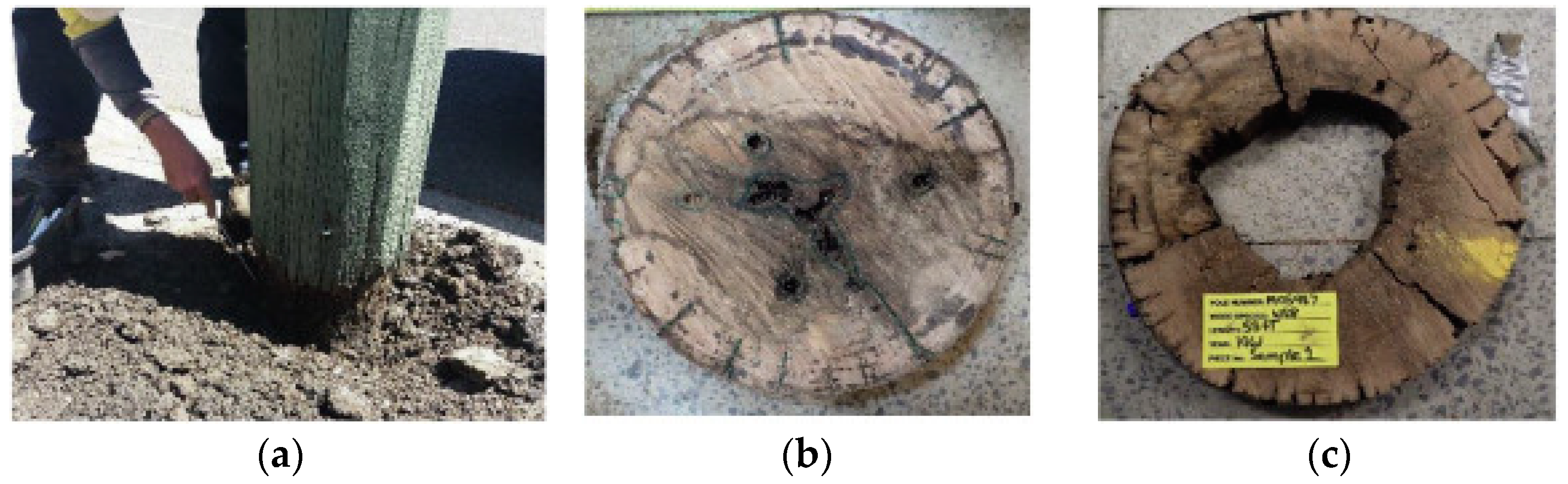

4. The Current Studies of Wood Utility Pole

4.1. Deterioration Factors and Dynamic Performance

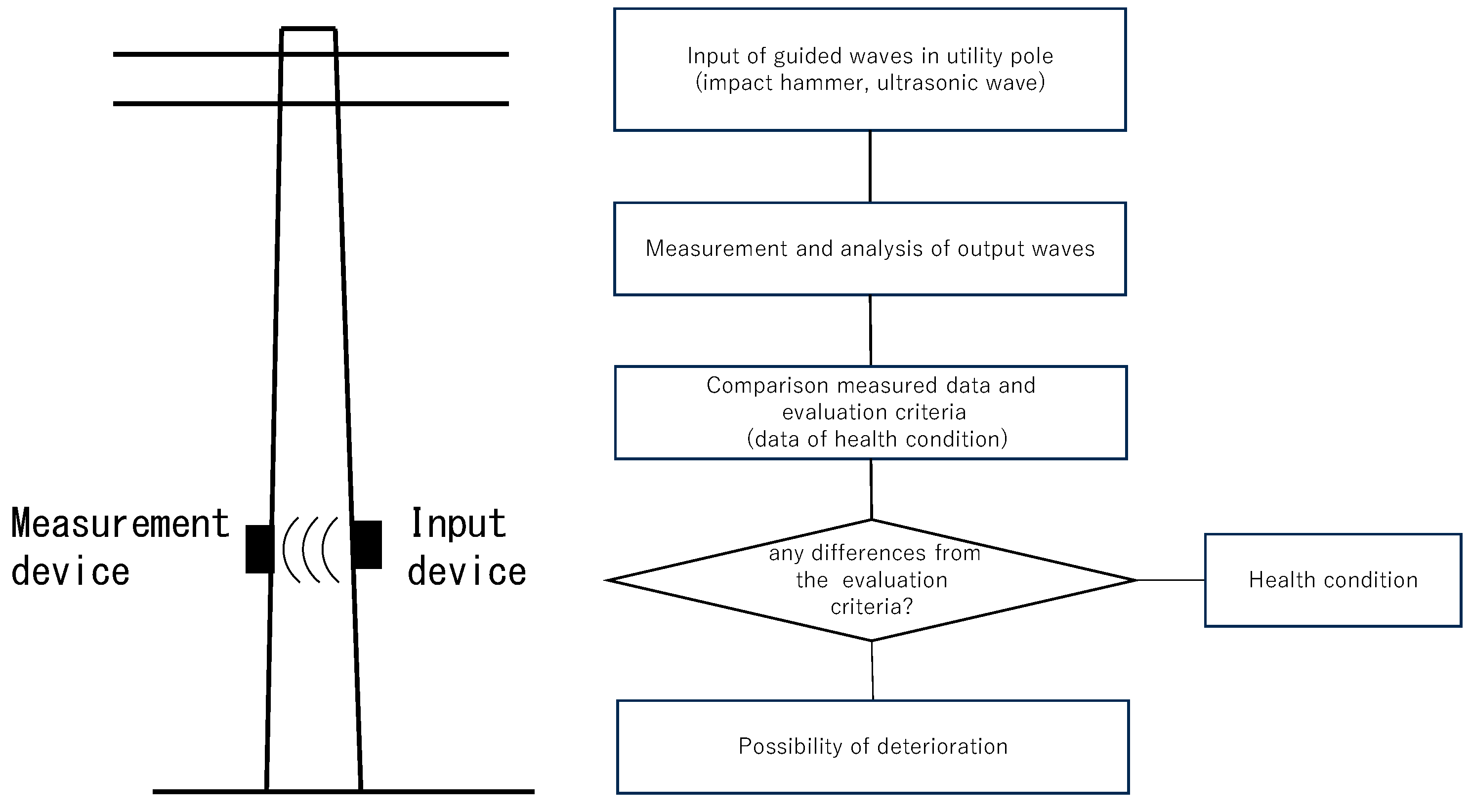

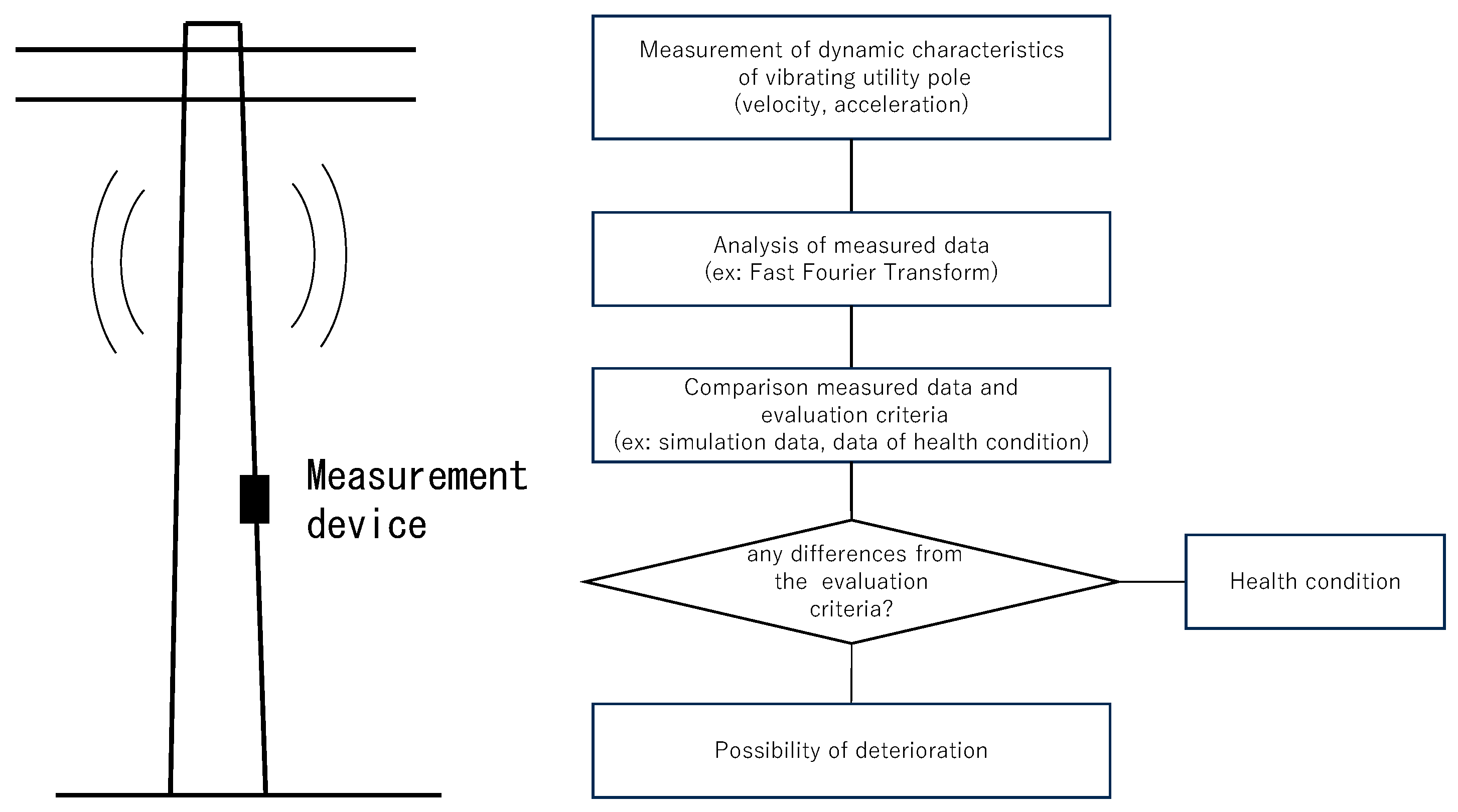

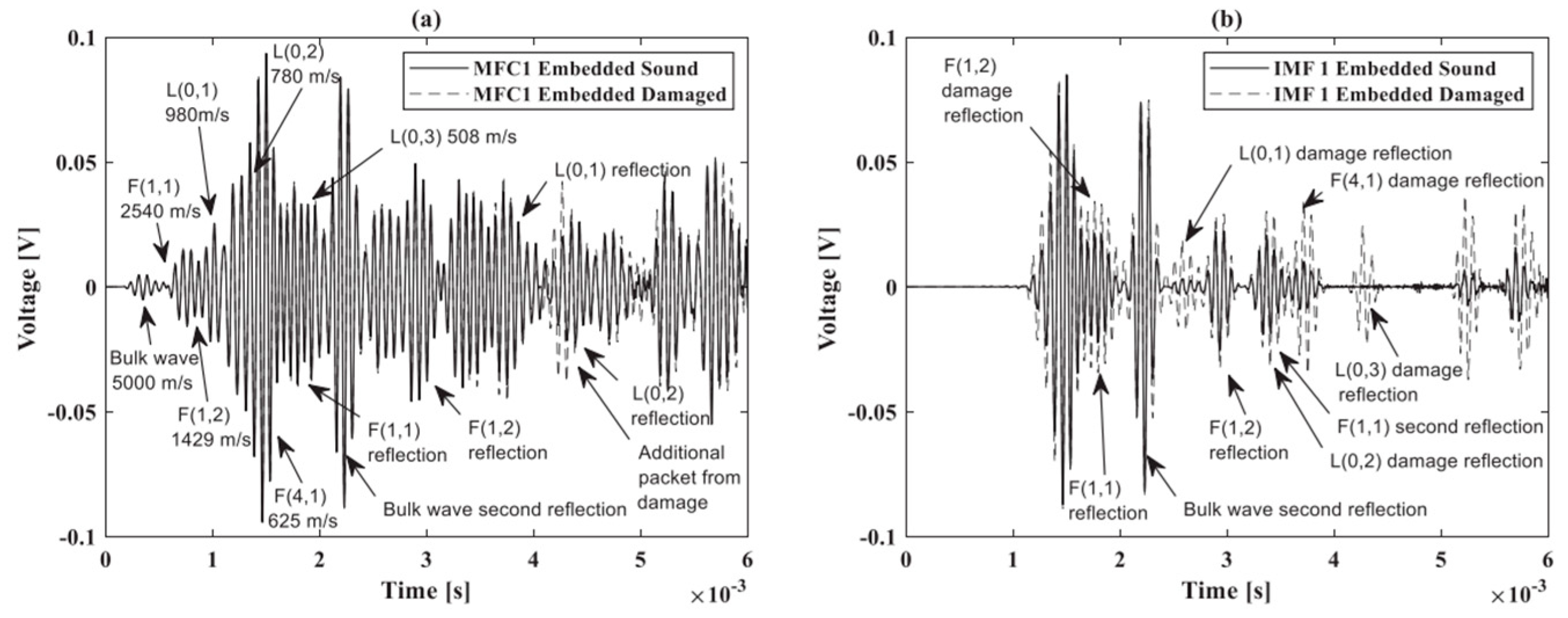

4.2. Deterioration Evaluation of Wood Utility Pole

5. Issues for Concrete Utility Pole Maintenance

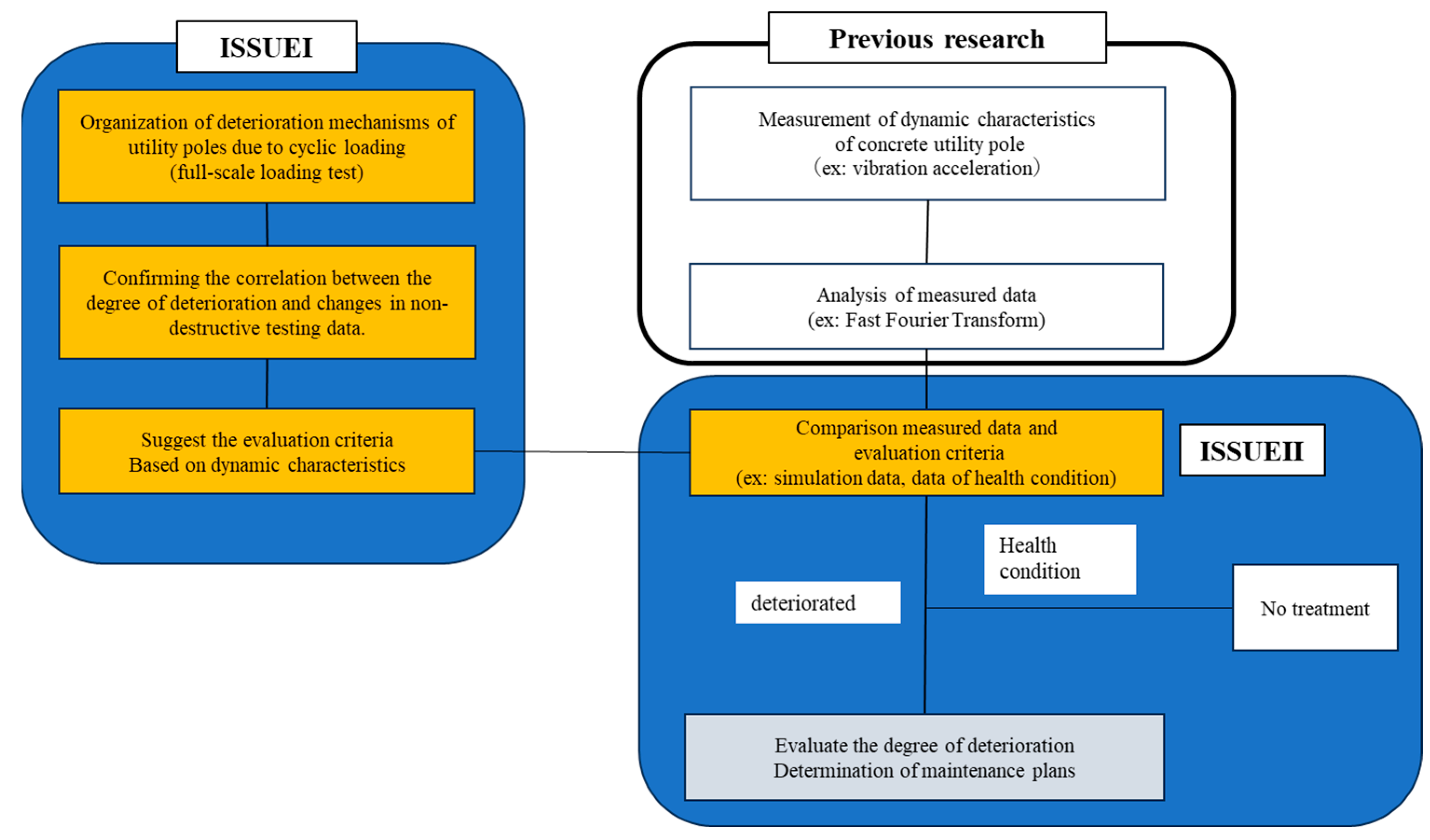

5.1. Issues for the Deterioration Evaluation of Concrete Utility Poles

5.2. Issues for Applying Non-Destructive Testing Methods to Concrete Utility Poles

6. Summary

- Regarding deterioration evaluation methods for concrete utility poles, there are few case studies due to the global prevalence of wooden utility poles. However, some findings from wooden utility poles can be applied.

- In existing studies, it is important to understand the mechanisms of deterioration in concrete utility poles in service and identify the threshold of accumulated mechanical damage requiring replacement. However, existing research on concrete utility poles has not addressed these aspects. Future studies on the deterioration evaluation of concrete utility poles should focus on analyzing the mechanisms of mechanical damage and failure progression in service poles and defining the ultimate state and damage conditions that necessitate replacement.

- Non-destructive inspection methods for concrete utility poles, such as vibration-based evaluation methods and advanced visual inspection using drones, which have also been explored for wooden utility poles, are deemed appropriate. While the application of failure probability analysis, which requires the construction of analytical models, may take time, it is worth considering due to its compatibility with economic impact assessments in existing studies. An important challenge for the future is the need to establish the correlation between damage states and data obtained through non-destructive testing, as current methods only allow for identifying the presence or absence of damage. This step is crucial for efficiently maintaining both concrete and wooden utility poles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Polyzois, D.; Ibrahim, S.; Burachynsky, V.; Hassan, S.K. Glass fiber-reinforced plastic poles for transmission and distribution lines: An Experimental Investigation. In Proceedings of the 12th International Conference on Composite Materials (ICCM-12), Paris, France, 5–9 July 1999. [Google Scholar]

- Ministry of Land, Infrastructure, Transport, and Tourism, Status of Development of Pole-Free Systems (National and International). Available online: https://www.mlit.go.jp/road/road/traffic/chicyuka/chi_13_01.html (accessed on 25 September 2024). (In Japanese).

- Takahashi, T.; Iwata, K.; Matsuda, Y. Considerations for the Promotion of no Utility Poles in Japan in Comparison with Overseas Countries Field Survey of Three Asian Countries—Civil Engineering Research Institute for Cold Region Index. Available online: https://thesis.ceri.go.jp/db/documents/public_detail/64252/ (accessed on 25 September 2024). (In Japanese).

- Haruyama, H.; Member, Y.S.; Member, Y.O.; Member, T.S. Investigation and technical trends to deal with aging management of distribution equipment. IEEJ Trans. Power Energy 2019, 139, 1–4. (In Japanese) [Google Scholar] [CrossRef]

- Organization for Cross-Regional Coordination of Transmission Operators Guidelines for the Renewal of Highly Aged Equipment. Available online: https://www.occto.or.jp/kouikikeitou/guidelines/index.html (accessed on 25 September 2024). (In Japanese).

- JIS A 5373; Precast Prestressed Concrete Products. Japanese Standards Association: Tokyo, Japan, 2016. (In Japanese)

- AS/NZS 4676:2000; Structural Design Requirements for Utility Service Poles. CE-019 (Utility Service Poles): Sydney, Australia, 2000.

- Japan International Cooperation Agency Comparison of Electric Power Technical Standards and Policy Making for Technical Cooperation. JICA. Available online: https://libopac.jica.go.jp/images/report/P0000168100.html (accessed on 25 September 2024).

- Ministry of Economy, Trade and Industry Interpretation of Technical Standards for Electrical Installations. Available online: https://www.meti.go.jp/policy/safety_security/industrial_safety/law/denjikokuji.html (accessed on 25 September 2024). (In Japanese).

- Morrell, J.J. Estimated Service Life of Wood Poles; North American Wood Pole Council Technical Bulletin: Vancouver, WA, USA, 2016. [Google Scholar]

- Richard, W.L. Wood Pole Design Considerations. North American Wood Pole Council. Available online: https://woodpoles.org/wp-content/uploads/TB_Design.pdf (accessed on 25 September 2024).

- Vidor, F.L.R.; Pires, M.; Dedavid, B.A.; Montani, P.D.B.; Gabiatti, A. Inspection of wooden poles in electrical power distribution networks in southern Brazil. IEEE Trans. Power Deliv. 2010, 25, 479–484. [Google Scholar] [CrossRef]

- Association of Concrete Pole Diagnosticians. Concrete Pole Diagnostician Textbook; Concrete Pole Consulting Association: Tokyo, Japan, 2018. (In Japanese) [Google Scholar]

- Hashimoto, T.; Hosoda, A.; Yoshida, H.; Eguchi, M. Investigation into the mechanisms of chloride attack deterioration of concrete poles and basic study of methods for extending the service life. Proc. Jpn. Concr. Inst. 2014, 36, 982–987. Available online: https://data.jci-net.or.jp/data_html/36/036-01-1157.html (accessed on 25 September 2024). (In Japanese).

- Funamoto, N.; Iwata, N.; Shimojo, T.; Hara, Y. Study on the effect of environmental conditions on the ageing of prestressed concrete poles. Proc. Jpn. Concr. Inst. 2014, 36, 1381–1386. Available online: https://data.jci-net.or.jp/data_html/36/036-01-2231.html (accessed on 25 September 2024). (In Japanese).

- Hashimoto, T.; Kanai, S.; Hirono, S.; Torii, K. A consideration on improvement in durability aspects of concrete poles. Cem. Sci. Concr. Technol. 2015, 69, 550–557. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Fujimoto, N. Study on Hydrogen Absorption and Hydrogen Embrittlement of High-Strength Steel in a Simulated Concrete Environment. Tokyo Tech Research Repository. Available online: https://t2r2.star.titech.ac.jp/cgi-bin/publicationinfo.cgi?q_publication_content_number=CTT100759695 (accessed on 25 September 2024). (In Japanese).

- Kamisho, T.; Ishii, R.; Tsuda, M. Technology for Predicting Hydrogen Embrittlement in Reinforcing Bars of Concrete Poles. NTT Tech. J. 2021, 19, 66–70. Available online: https://ntt-review.jp/archive/ntttechnical.php?contents=ntr202106fa10.html (accessed on 25 September 2024). (In Japanese) [CrossRef]

- Sasaki, T.; Nozawa, S.; Tsukishima, D.; Kaneko, A. Earthquake damage to concrete utility poles for Shinkansen and remedial measures. Concr. J. 2015, 53, 622–628. (In Japanese) [Google Scholar] [CrossRef]

- Oba, T.; Inoue, T. Damage of utility poles caused by 15th Typhoon of 2019 and its impact on the social acceptance of undergrounding and utility pole removal projects. J. City Plan. Inst. Jpn. 2021, 56, 224–233. (In Japanese) [Google Scholar] [CrossRef]

- Ito, Y.; Kobayashi, H. Development of seismic reinforcement method using steel for PC poles supported by civil engineering structures. Proc. Jpn. Concr. Inst. 2018, 40, 991–996. Available online: https://data.jci-net.or.jp/data_html/40/040-01-2166.html (accessed on 25 September 2024). (In Japanese).

- Baghmisheh, A.G.; Mahsuli, M. Seismic performance and fragility analysis of power distribution concrete poles. Soil Dyn. Earthq. Eng. 2021, 150, 106909. [Google Scholar] [CrossRef]

- Tsunemoto, M.; Shimizu, M.; Kondo, Y.; Kudo, T.; Ueda, H.; Iijima, T. Replacement criteria for concrete catenary poles. Q. Rep. RTRI 2017, 58, 270–276. [Google Scholar] [CrossRef]

- Vivek, B.; Sharma, S.; Raychowdhury, P.; Ray-Chaudhri, S. A study on failure mechanism of self-supported electric poles through full-scale field testing. Eng. Fail. Anal. 2017, 77, 102–117. [Google Scholar] [CrossRef]

- Zeynalian, M.; Khorasgani, M.Z. Structural performance of concrete poles used in electric power distribution network. Arch. Civ. Mech. Eng. 2018, 18, 863–876. [Google Scholar] [CrossRef]

- Kuwahara, H.; Shimizu, H.; Hatakeyama, A. Earthquake resistance of various electric poles subjected to ground motion of 200 gals in peak acceleration. Doboku Gakkai Ronbunshu 1992, 1992, 59–68. (In Japanese) [Google Scholar] [CrossRef]

- Kliukas, R.; Daniunas, A.; Gribniak, V.; Lukoseviciene, O.; Vanagas, E.; Patapavicius, A. Half a century of reinforced concrete electric poles maintenance: Inspection, field-testing, and performance assessment. Struct. Infrastruct. Eng. 2018, 14, 1221–1232. [Google Scholar] [CrossRef]

- Manos, G.C.; Mpoufidis, D.; Melidis, L.; Katakalos, K. Testing of concrete or metal hollow poles employing pseudo-dynamic or fatigue loads. In Proceedings of the 9th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, Athens, Greece, 12–14 June 2023; COMPDYN Proceedings: Athens, Greece, 2023. [Google Scholar] [CrossRef]

- Zekavati, A.; Jafari, M.A.; Rahnavard, A.; Yavartalab, A.; Samadi, M. Development of seismic capacity curve (S.C.C.) for power distribution concrete poles. In Proceedings of the 22nd International Conference and Exhibition on Electricity Distribution (CIRED 2013), Stockholm, Sweden, 10–13 June 2013. [Google Scholar] [CrossRef]

- Iwatsuki, E.; Koduka, T.; Honda, Y.; Hikida, T.; Sato, M. Investigation of the Inspection of Concrete Poles Using Ultrasonic Waves, AIT Associated Repository of Academic Resources. 2019. Available online: http://repository.aitech.ac.jp/dspace/handle/11133/3610 (accessed on 25 September 2024). (In Japanese).

- Matsuo, R.; Furukawa, K.; Mizugaki, Y. Non-destructive inspection for inner fault of concrete pole by elastic impulse waves method. Jpn. Soc. Mech. Eng. Kyushu Branch Proc. 2001, 54, 33–34. (In Japanese) [Google Scholar] [CrossRef]

- Ullah, S.; Jeong, M.; Lee, W. Nondestructive inspection of reinforced concrete utility poles with ISOMAP and random forest. Sensors 2018, 18, 3463. [Google Scholar] [CrossRef]

- AZhou, J.; Qiu, K.; Deng, B.; Zhang, Z.; Ye, G. A NDT method for location and buried depth measurement of rebars in concrete pole. IEEE Trans. Instrum. Meas. 2022, 71, 1–10. [Google Scholar] [CrossRef]

- Sheyi, R.; Wei, R.; Qiaozhi, W.; Yuanyuan, S. Non-destructive testing of reinforced concrete utility poles based on electromagnetic induction. In Proceedings of the 2023 8th International Conference on Power and Renewable Energy, ICPRE, Shanghai, China, 22–25 September 2023. [Google Scholar] [CrossRef]

- Li, L.; Wang, H.; Wen, Z.; Dou, Y. Nondestructive testing method for internal surface cracks in underground section of concrete transmission pole. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering, MACE2010, Wuhan, China, 26–28 June 2010. [Google Scholar] [CrossRef]

- Hengbo, X.; Fengjun, L.; Xuan, D. Condition evaluation of in-service concrete electric poles based on improved multi-granularity cascading forest. Eng. Res. Express 2023, 5, 015010. [Google Scholar] [CrossRef]

- Rahman, A.; Chattopadhyay, G.; Hossain, M.J. Maintenance decisions for inground decay of power-supply timber poles. IEEE Trans. Power Deliv. 2016, 31, 1106–1111. [Google Scholar] [CrossRef]

- Harness, R.E.; Walters, E.L. Woodpeckers and utility pole damage. IEEE Ind. Appl. Mag. 2004, 11, 68–73. [Google Scholar] [CrossRef]

- Bandara, S.; Rajeev, P.; Gad, E.; Sriskantharajah, B.; Flatley, I. Damage detection of in service timber poles using Hilbert-Huang transform. NDT E Int. 2019, 107, 102141. [Google Scholar] [CrossRef]

- Dai, K.; Chen, S.E.; Luo, M.; Loflin, G. A framework for holistic designs of power line systems based on lessons learned from Super Typhoon Haiyan. Sustain. Cities Soc. 2017, 35, 350–364. [Google Scholar] [CrossRef]

- Bjarnadottir, S.; Li, Y.; Stewart, M.G. Risk-based economic assessment of mitigation strategies for power distribution poles subjected to hurricanes. Struct. Infrastruct. Eng. 2014, 10, 740–752. [Google Scholar] [CrossRef]

- Bjarnadottir, S.; Li, Y.; Stewart, M.G. Hurricane risk assessment of power distribution poles considering impacts of a changing climate. J. Infrastruct. Syst. 2013, 19, 12–24. [Google Scholar] [CrossRef]

- Mensah, A.F.; Dueñas-Osorio, L. Efficient resilience assessment framework for electric power systems affected by hurricane events. J. Struct. Eng. 2016, 142, C4015013. [Google Scholar] [CrossRef]

- Shafieezadeh, A.; Onyewuchi, U.P.; Begovic, M.M.; Desroches, R. Age-dependent fragility models of utility wood poles in power distribution networks against extreme wind hazards. IEEE Trans. Power Deliv. 2014, 29, 131–139. [Google Scholar] [CrossRef]

- Teodorescu, I.; Ţǎpuşi, D.; Erbaşu, R.; Bastidas-Arteaga, E.; Aoues, Y. Influence of the climatic changes on Wood Structures Behaviour. Energy Procedia 2017, 112, 450–459. [Google Scholar] [CrossRef]

- Merschman, E.; Salman, A.M.; Bastidas-Arteaga, E.; Li, Y. Assessment of the effectiveness of wood pole repair using FRP considering the impact of climate change on decay and hurricane risk. Adv. Clim. Change Res. 2020, 11, 332–348. [Google Scholar] [CrossRef]

- Nguyen, M.; Foliente, G.; Wang, X. State-of-the-practice & challenges in non-destructive evaluation of utility poles in service. Key Eng. Mater. 2004, 270–273, 1521–1528. [Google Scholar] [CrossRef]

- El Najjar, J.; Mustapha, S. Condition assessment of timber utility poles using ultrasonic guided waves. Constr. Build. Mater. 2021, 272, 121902. [Google Scholar] [CrossRef]

- Dackermann, U.; Skinner, B.; Li, J. Guided wave-based condition assessment of in situ timber utility poles using machine learning algorithms. Struct. Health Monit. 2014, 13, 374–388. [Google Scholar] [CrossRef]

- Yu, Y.; Dackermann, U.; Li, J.; Yan, N. Guided-wave-based damage detection of timber poles using a hierarchical data fusion algorithm. In Proceedings of the Australasian Conference on the Mechanics of Structures and Materials, East Lisbon, Australia, 9–12 December 2014; Available online: https://opus.lib.uts.edu.au/handle/10453/33150 (accessed on 25 September 2024).

- Yan, N. Numerical Modelling and Condition Assessment of Timber Utility Poles Using Stress Wave Techniques. Ph.D. Thesis, University of Technology Sydney, Sydney, Australia, 2015. Available online: https://opus.lib.uts.edu.au/handle/10453/36983 (accessed on 25 September 2024).

- Subhani, M.; Li, J.; Samali, B. A comparative study of guided wave propagation in timber poles with isotropic and transversely isotropic material models. J. Civ. Struct. Health Monit. 2013, 3, 65–79. [Google Scholar] [CrossRef]

- Tomikawa, Y.; Iwase, Y.; Arita, K.; Yamada, H. Nondestructive inspection of a wooden pole using ultrasonic computed tomography. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1986, 33, 354–358. [Google Scholar] [CrossRef]

- Subhani, M.M. A Study on the Behavior of Guided Wave Propagation in Utility Timber Poles. Ph.D. Thesis, University of Technology Sydney, Sydney, Australia, 2014. Available online: https://opus.lib.uts.edu.au/handle/10453/30350 (accessed on 25 September 2024).

- Tallavo, F.J.; Pandey, M.D.; Cascante, G.; Lara, C.A. Ultrasonic and acoustic pulse velocity methods for nondestructive detection of early decay in wood poles. Can. J. Civ. Eng. 2022, 49, 1059–1068. [Google Scholar] [CrossRef]

- Lee, Y.; Franca FJ, N.; Seale, R.D.; Winandy, J.E.; Senalik, C.A. Correlation analysis of ultrasonic stress wave characteristics and the destructive strength measurements in cylindrical wooden structure. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2022, 69, 350–358. [Google Scholar] [CrossRef]

- Tsang, K.M.; Chan, W.L. Non-destructive stiffness detection of utility wooden poles using wireless MEMS sensor. Meas. J. Int. Meas. Confed. 2011, 44, 1201–1207. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Zhu, W.; Li, G. A non-destructive health evaluation method for wooden utility poles with frequency-modulated empirical mode decomposition and laplace wavelet correlation filtering. Sensors 2022, 22, 4007. [Google Scholar] [CrossRef]

- Mohammad, H.J. Development of a Vibration-Based Non-Destructive Testing Method for In-Service Utility Poles. Ph.D. Thesis, Memorial University of Newfoundland, St. John’s, NL, Canada, 2021. [Google Scholar] [CrossRef]

- Samali, B.; Li, J.; Dackermann, U.; Choi, F.C. Vibration-based damage detection for timber structures in Australia. In Structural Health Monitoring in Australia; Nova: New York, NY, USA, 2014. [Google Scholar]

- Martins, C.E.J.; Dias, A.M.P.G.; Marques, A.F.S.; Dias, A.M.A. Non-destructive methodologies for assessment of the mechanical properties of new utility poles. BioResources 2017, 12, 2269–2283. [Google Scholar] [CrossRef]

- Dackermann, U.; Yu, Y.; Niederleithinger, E.; Li, J.; Wiggenhauser, H. Condition assessment of foundation piles and utility poles based on guided wave propagation using a network of tactile transducers and support vector machines. Sensors 2017, 17, 2938. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.H.; Leicester, R.H.; Nguyen, M. Probabilistic procedure for design of untreated timber poles in-ground under attack of decay fungi. Reliab. Eng. Syst. Saf. 2008, 93, 476–481. [Google Scholar] [CrossRef]

- Nguyen, M.N.; Leicester, R.H.; Wang, C.H.; Cookson, L.J. Probabilistic procedure for design of untreated timber piles under marine borer attack. Reliab. Eng. Syst. Saf. 2008, 93, 482–488. [Google Scholar] [CrossRef]

- Ryan, P.C.; Stewart, M.G.; Spencer, N.; Li, Y. Reliability assessment of power pole infrastructure incorporating deterioration and network maintenance. Reliab. Eng. Syst. Saf. 2014, 132, 261–273. [Google Scholar] [CrossRef]

- Stillman, R.H.; Mackisack, M.S.; Griffin, M. Modelling the reliability of distribution line structures. Electr. Power Syst. Res. 1997, 41, 85–90. [Google Scholar] [CrossRef]

- Datla, S.V.; Pandey, M.D. Estimation of life expectancy of wood poles in electrical distribution networks. Struct. Saf. 2006, 28, 304–319. [Google Scholar] [CrossRef]

- Pierson, K.; Blanc, T. The operational determinants of utility pole decay and optimal replacement in the pacific northwest. IEEE Trans. Power Deliv. 2016, 31, 2223–2230. [Google Scholar] [CrossRef]

- Ouyang, M.; Dueñas-Osorio, L. Multi-dimensional hurricane resilience assessment of electric power systems. Struct. Saf. 2014, 48, 15–24. [Google Scholar] [CrossRef]

- Mohammadi Darestani, Y.; Shafieezadeh, A. Multi-dimensional wind fragility functions for wood utility poles. Eng. Struct. 2019, 183, 937–948. [Google Scholar] [CrossRef]

- Mohammadi Darestani, Y.; Shafieezadeh, A.; DesRoches, R. An equivalent boundary model for effects of adjacent spans on wind reliability of wood utility poles in overhead distribution lines. Eng. Struct. 2016, 128, 441–452. [Google Scholar] [CrossRef]

- Gustavsen, B.; Rolfseng, L. Asset management of wood pole utility structures. Int. J. Electr. Power Energy Syst. 2005, 27, 641–646. [Google Scholar] [CrossRef]

- Darestani, Y.M.; Shafieezadeh, A.; DesRoches, R. Hurricane performance assessment of power distribution lines using multi-scale matrix-based system reliability analysis method. In Proceedings of the Americas Conference on Wind Engineering, ACWE, Gainesville, FL, USA, 21–24 May 2017. [Google Scholar]

- Darestani, Y.M.; Shafieezadeh, A. Modeling the impact of adjacent spans in overhead distribution lines on the wind response of utility poles. In Proceedings of the Joint Geotechnical and Structural Engineering Congress, Phoenix, AZ, USA, 14–17 February 2016. [Google Scholar] [CrossRef]

- Lee, S.; Ham, Y. Probabilistic analysis of structural reliability of leaning poles in power distribution infrastructure systems under extreme wind loads. In Proceedings of the Construction Research Congress 2020: Infrastructure Systems and Sustainability—Selected Papers from the Construction Research Congress 2020, Tempe, AZ, USA, 8–10 March 2020. [Google Scholar] [CrossRef]

- Lee, S.; Ham, Y. Probabilistic framework for assessing the vulnerability of power distribution infrastructures under extreme wind conditions. Sustain. Cities Soc. 2021, 65, 102587. [Google Scholar] [CrossRef]

- Sousa, H.S.; Sørensen, J.D.; Kirkegaard, P.H.; Branco, J.M.; Lourenço, P.B. On the use of NDT data for reliability-based assessment of existing timber structures. Eng. Struct. 2013, 56, 298–311. [Google Scholar] [CrossRef]

- Kim, J.; Ham, Y. Vision-based analysis of utility poles using drones and digital twin modeling in the context of power distribution infrastructure systems. In Proceedings of the Construction Research Congress 2020: Computer Applications—Selected Papers from the Construction Research Congress 2020, Tempe, AZ, USA, 8–10 March 2020. [Google Scholar] [CrossRef]

- Alam, M.M.; Eren Tokgoz, B.; Hwang, S. Framework for measuring the resilience of utility poles of an electric power distribution network. Int. J. Disaster Risk Sci. 2019, 10, 270–281. [Google Scholar] [CrossRef]

- Alam, M.M.; Zhu, Z.; Eren Tokgoz, B.; Zhang, J.; Hwang, S. Automatic assessment and prediction of the resilience of utility poles using unmanned aerial vehicles and computer vision techniques. Int. J. Disaster Risk Sci. 2020, 11, 119–132. [Google Scholar] [CrossRef]

- Matikainen, L.; Lehtomäki, M.; Ahokas, E.; Hyyppä, J.; Karjalainen, M.; Jaakkola, A.; Kukko, A.; Heinonen, T. Remote sensing methods for power line corridor surveys. ISPRS J. Photogramm. Remote Sens. 2016, 119, 10–31. [Google Scholar] [CrossRef]

- Nguyen, V.N.; Jenssen, R.; Roverso, D. Automatic autonomous vision-based power line inspection: A review of current status and the potential role of deep learning. Int. J. Electr. Power Energy Syst. 2018, 99, 107–120. [Google Scholar] [CrossRef]

- Benoit, Y.L.; Sandoz, J.L. Wood Poles Non-Destructive Inspections. Available online: https://www.semanticscholar.org/paper/WOOD-POLES-NON-DESTRUCTIVE-INSPECTIONS-Benoit-Sandoz/8b136ac90a58d3fc2f6d870dea65cde5f6ac65e3#extracted (accessed on 25 September 2024).

- Moczko, A.; Moczko, M. Modern NDT systems for structural integrity examination of concrete bridge structures. Procedia Eng. 2014, 91, 418–423. [Google Scholar] [CrossRef][Green Version]

- Dey, A.; Miyani, G.; Debroy, S.; Sil, A. In-situ NDT investigation to estimate degraded quality of concrete on existing structure considering time-variant uncertainties. J. Build. Eng. 2020, 27, 101001. [Google Scholar] [CrossRef]

- Kilic, G. Integrated health assessment strategy using NDT for reinforced concrete bridges. NDT E Int. 2014, 61, 80–94. [Google Scholar] [CrossRef]

- Amini, K.; Jalalpour, M.; Delatte, N. Advancing concrete strength prediction using non-destructive testing: Development and verification of a generalizable model. Constr. Build. Mater. 2016, 102, 762–768. [Google Scholar] [CrossRef]

- Rao, S.S. Probabilistic design of prestressed concrete poles. Build. Environ. 1980, 15, 49–56. [Google Scholar] [CrossRef]

- Petr, S.; Ivana, L.; Petr, S. Probability-based design and life cycle assessment of a spun concrete pole. In Proceedings of the 2015 International Conference on Structural, Mechanical and Material Engineering, Dalian, China, 6–8 November 2015. [Google Scholar] [CrossRef]

| City | Undergrounding Rate (%) | Inspection Year |

|---|---|---|

| Tokyo | 7 | 2015 |

| Osaka | 5 | 2015 |

| London | 100 | 2015 |

| Paris | 100 | 2015 |

| Washington D.C. | 65 | 2012 |

| New York | 85 | 2016 |

| Taipei | 85 | 2015 |

| Country | Total Electric Line Length (km) | Undergrounding Rate (%) |

|---|---|---|

| Japan | 1,765,457 | 0.3 |

| Germany | 1,152,138 | 87.5 |

| Italy | 762,616 | 33.1 |

| France | 685,413 | 38.9 |

| United Kingdom | 408,875 | 82.6 |

| Spain | 383,202 | 36.9 |

| Sweden | 306,019 | 77.2 |

| Finland | 237,966 | 37.5 |

| Greece | 121,409 | 11.2 |

| Belgium | 120,643 | 56.8 |

| Denmark | 96,093 | 95.9 |

| Ireland | 69,200 | 17.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ueno, T.; Tamai, H.; Yasukawa, K.; Haruguchi, M. A Review and Future Directions on the Deterioration Evaluation of Concrete Utility Poles. Appl. Sci. 2025, 15, 3527. https://doi.org/10.3390/app15073527

Ueno T, Tamai H, Yasukawa K, Haruguchi M. A Review and Future Directions on the Deterioration Evaluation of Concrete Utility Poles. Applied Sciences. 2025; 15(7):3527. https://doi.org/10.3390/app15073527

Chicago/Turabian StyleUeno, Takayuki, Hiroki Tamai, Kanoko Yasukawa, and Masahiro Haruguchi. 2025. "A Review and Future Directions on the Deterioration Evaluation of Concrete Utility Poles" Applied Sciences 15, no. 7: 3527. https://doi.org/10.3390/app15073527

APA StyleUeno, T., Tamai, H., Yasukawa, K., & Haruguchi, M. (2025). A Review and Future Directions on the Deterioration Evaluation of Concrete Utility Poles. Applied Sciences, 15(7), 3527. https://doi.org/10.3390/app15073527